Preparation and Characterization of Chitosan/TiO2 Composite Membranes as Adsorbent Materials for Water Purification

Abstract

:1. Introduction

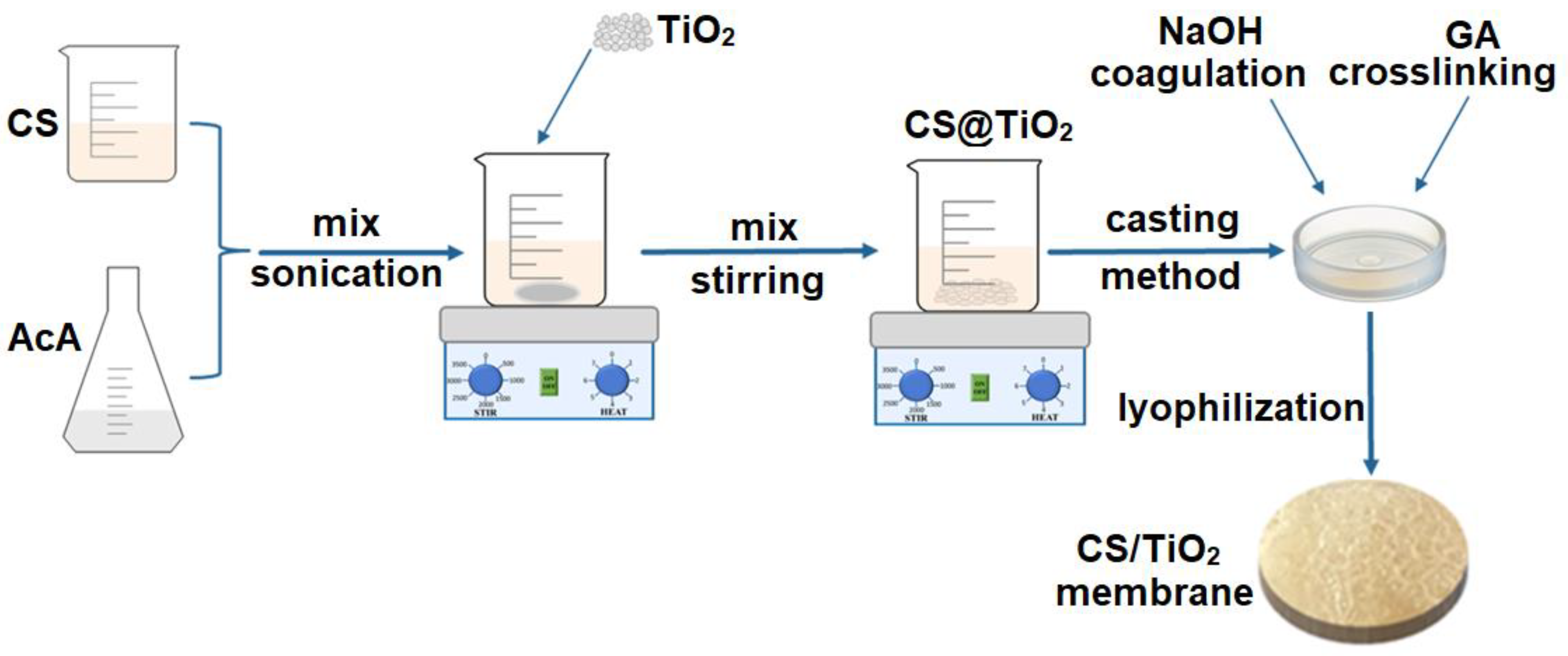

2. Materials and Methods

2.1. Experimental

2.2. Characterization

3. Results and Discussion

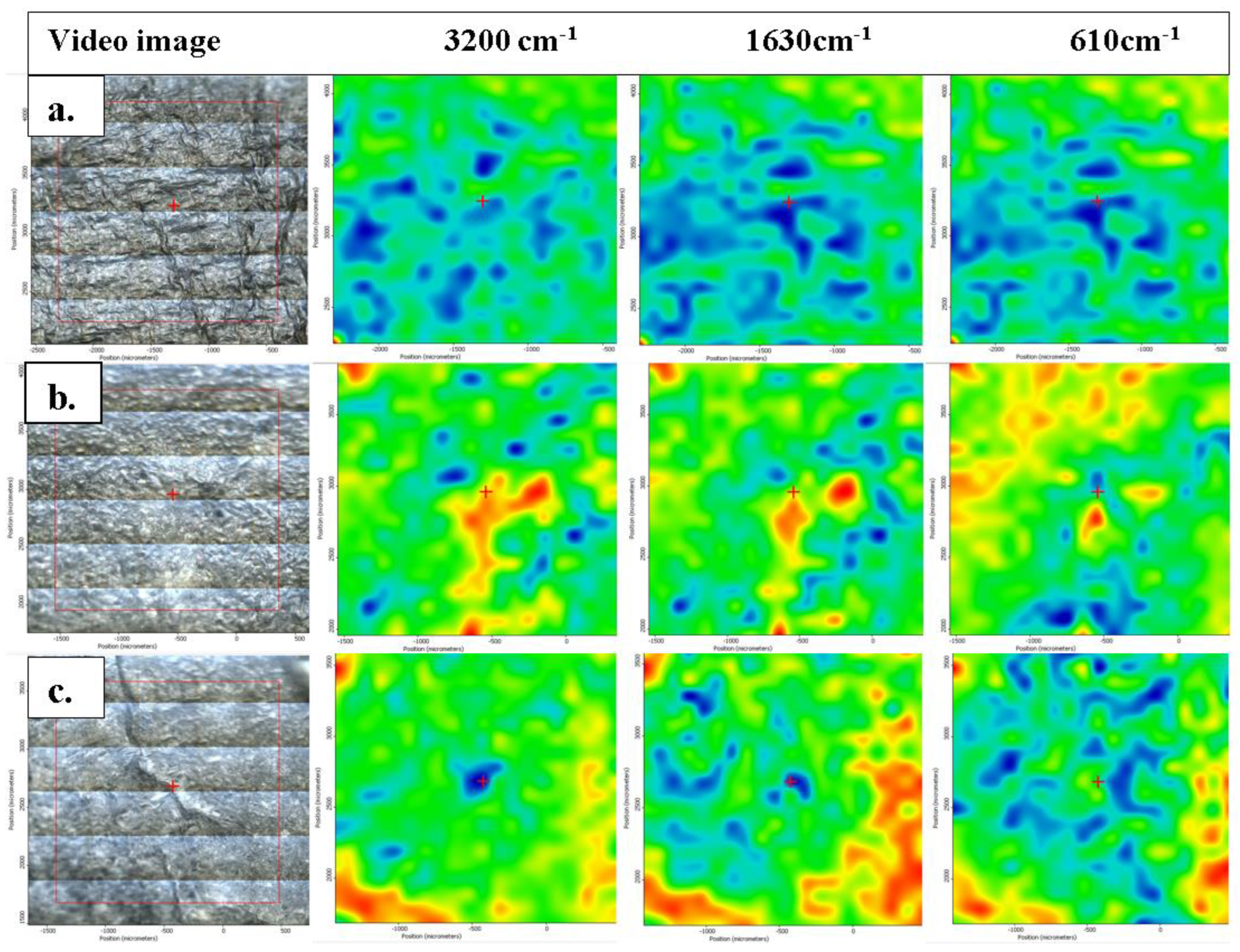

3.1. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

3.2. X-ray Diffraction (XRD) Analysis

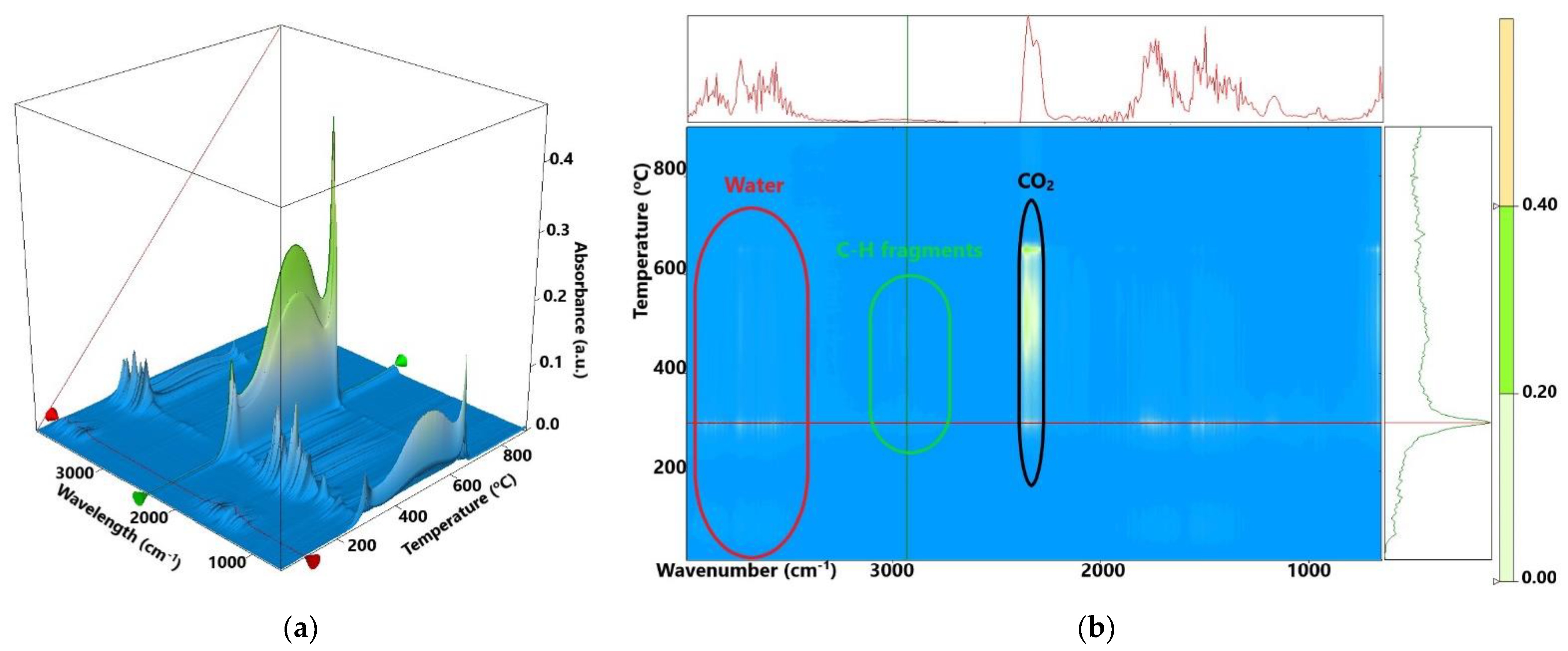

3.3. Thermal (TG-DSC) Analysis

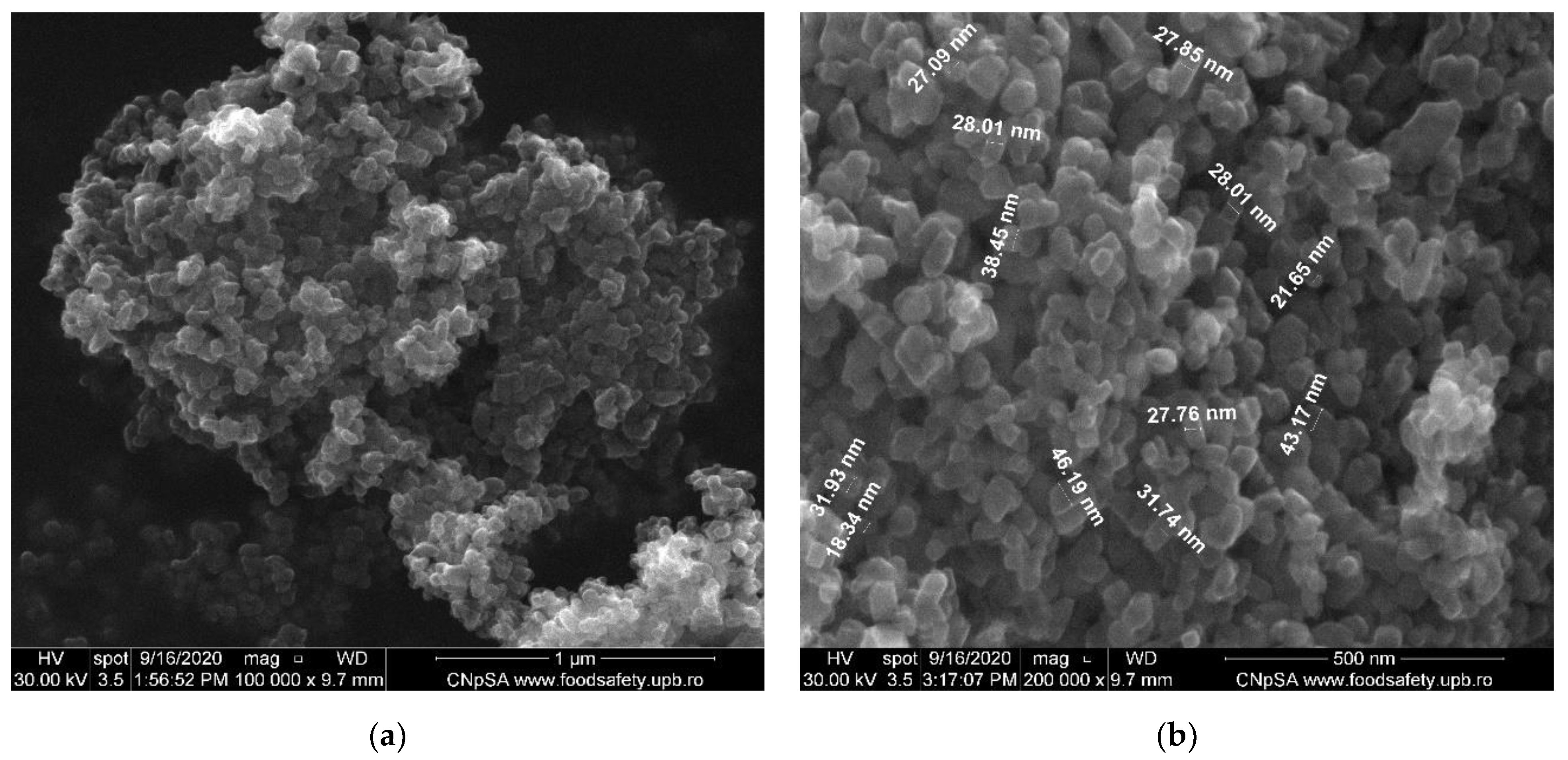

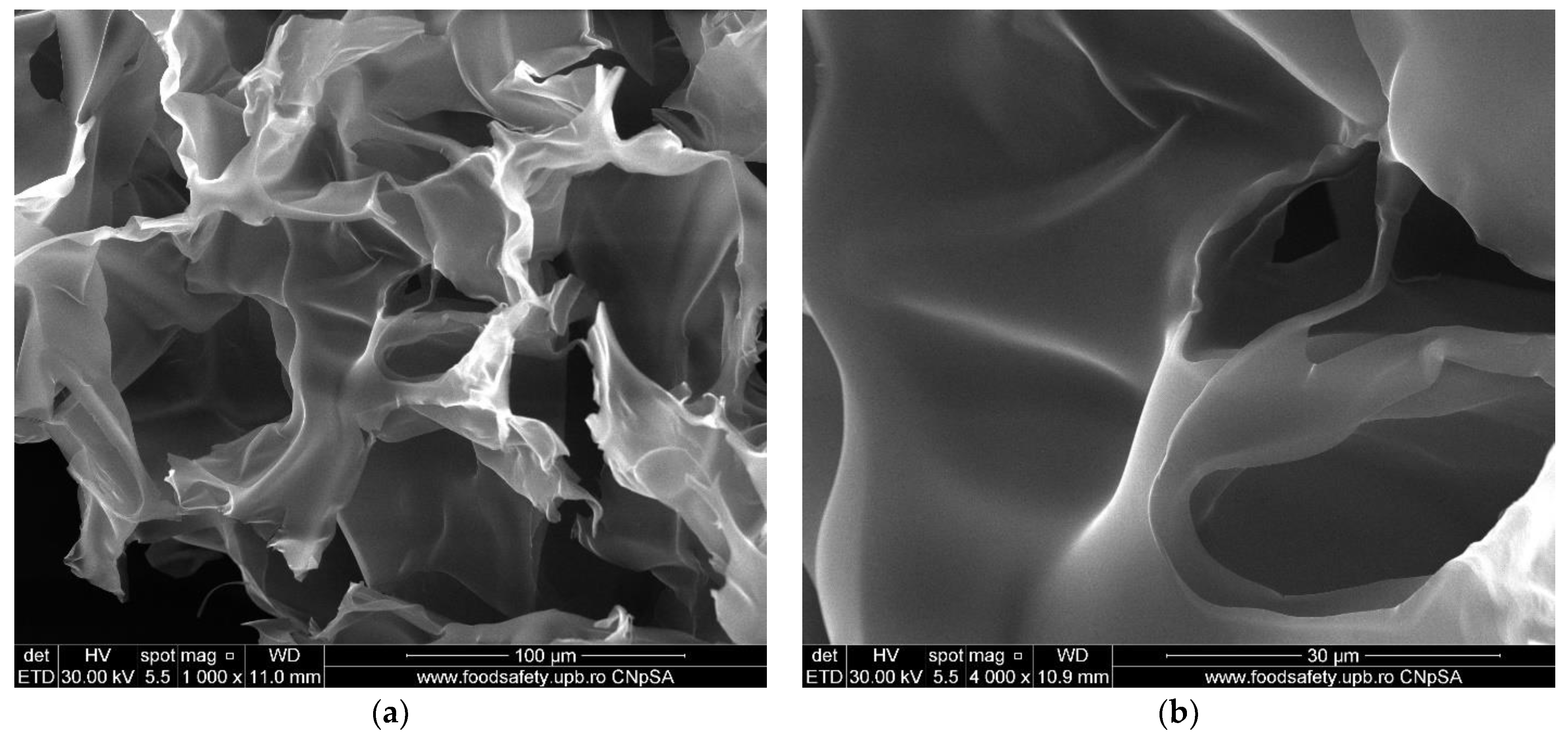

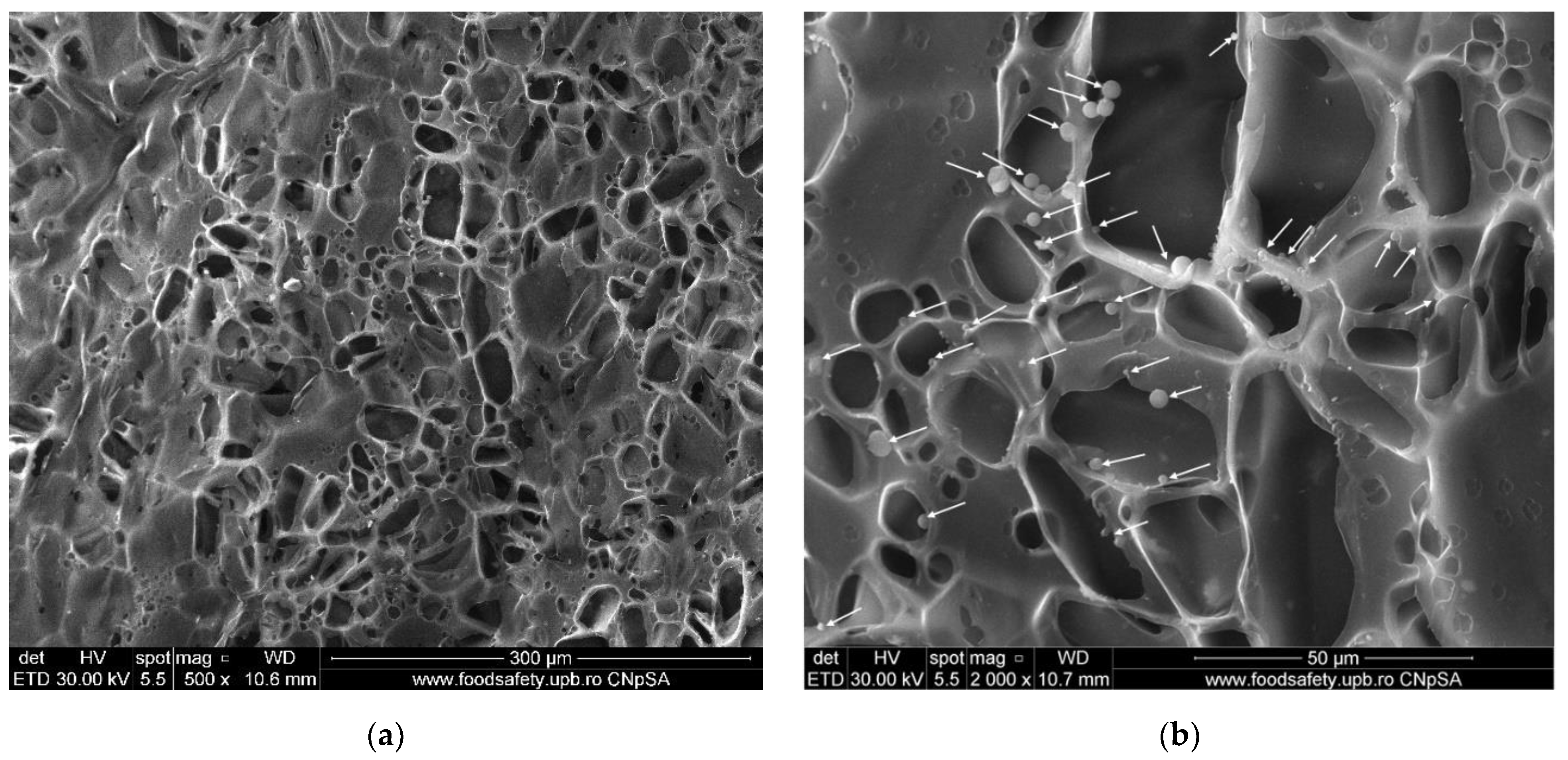

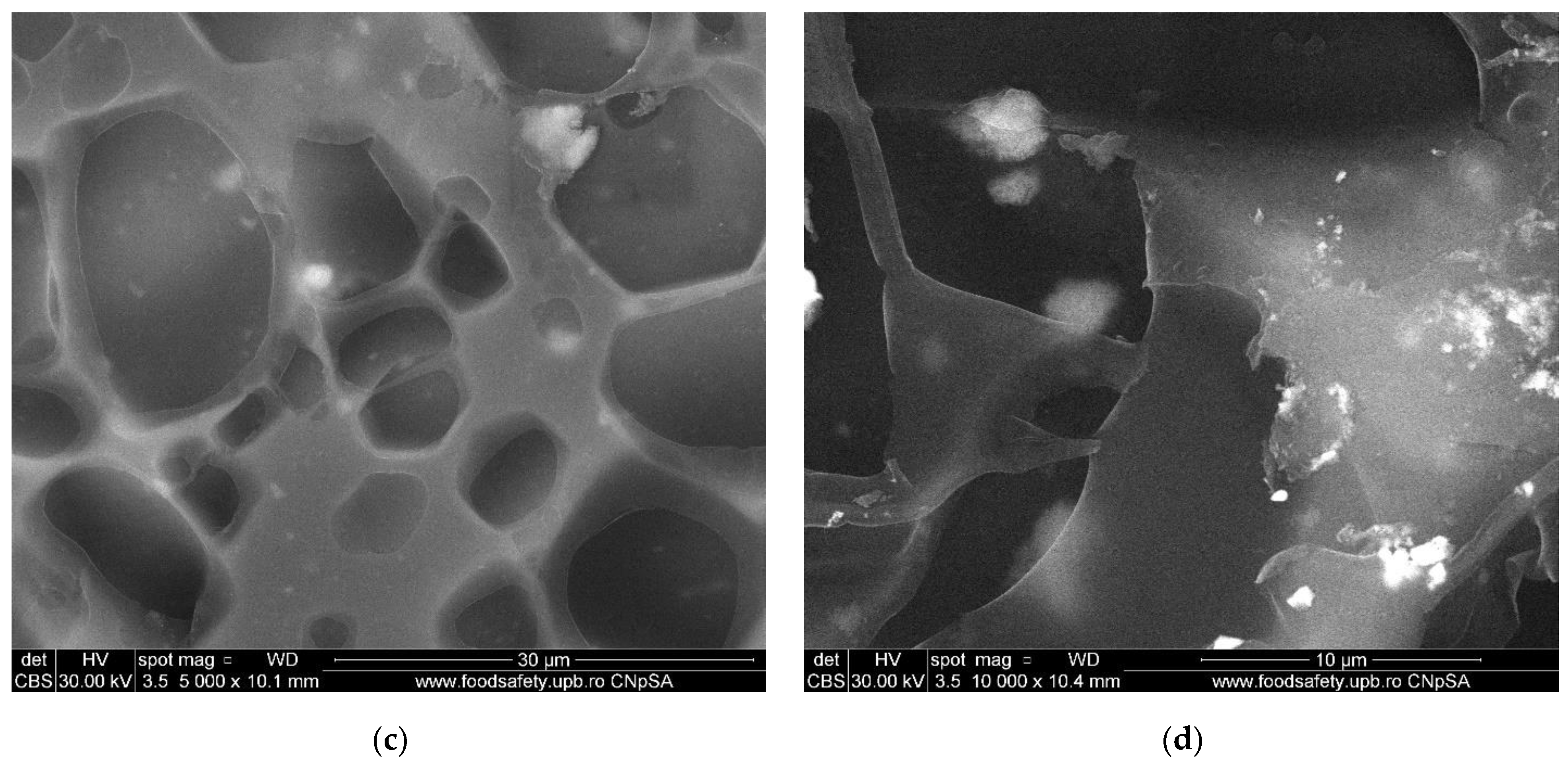

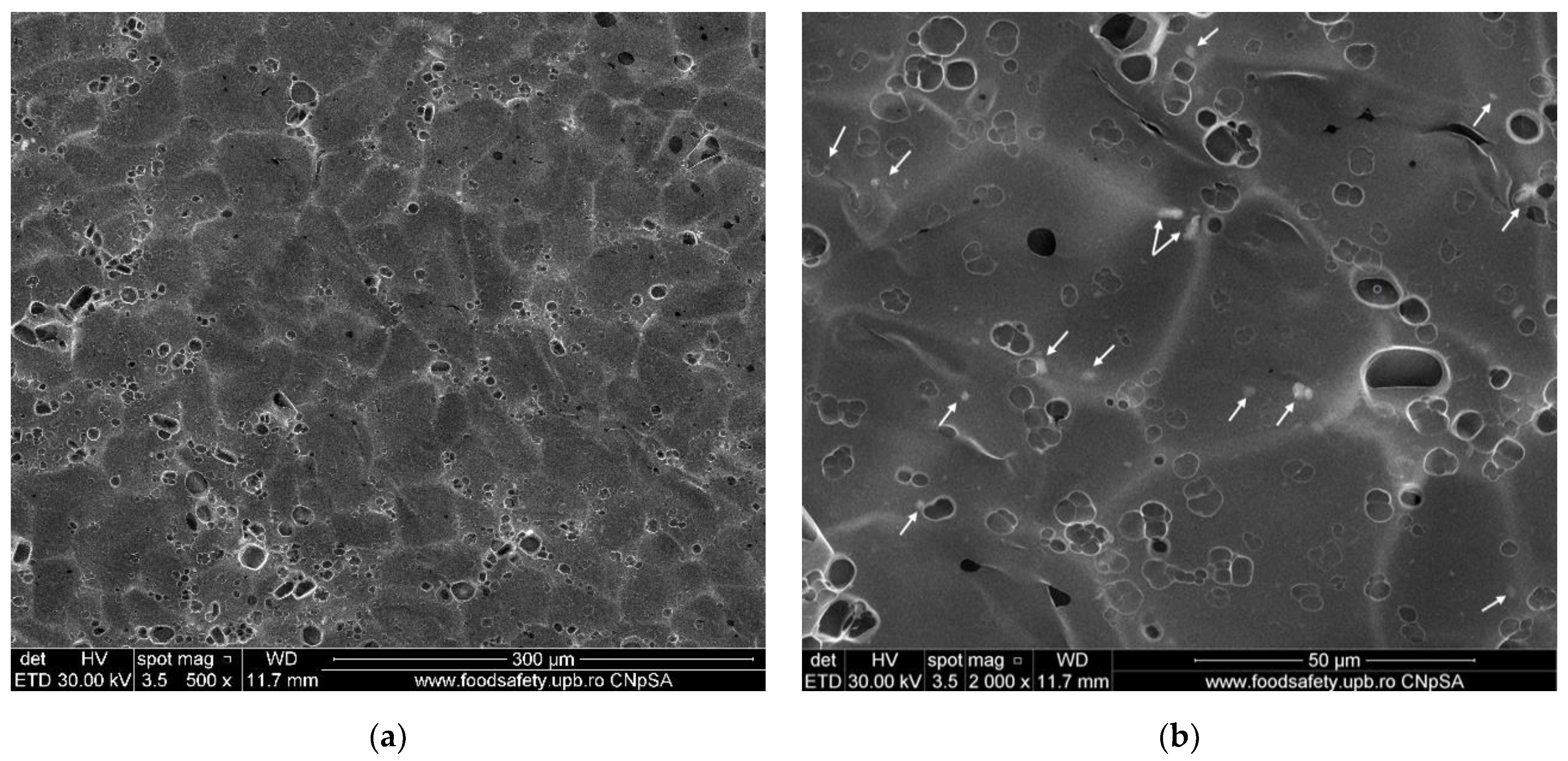

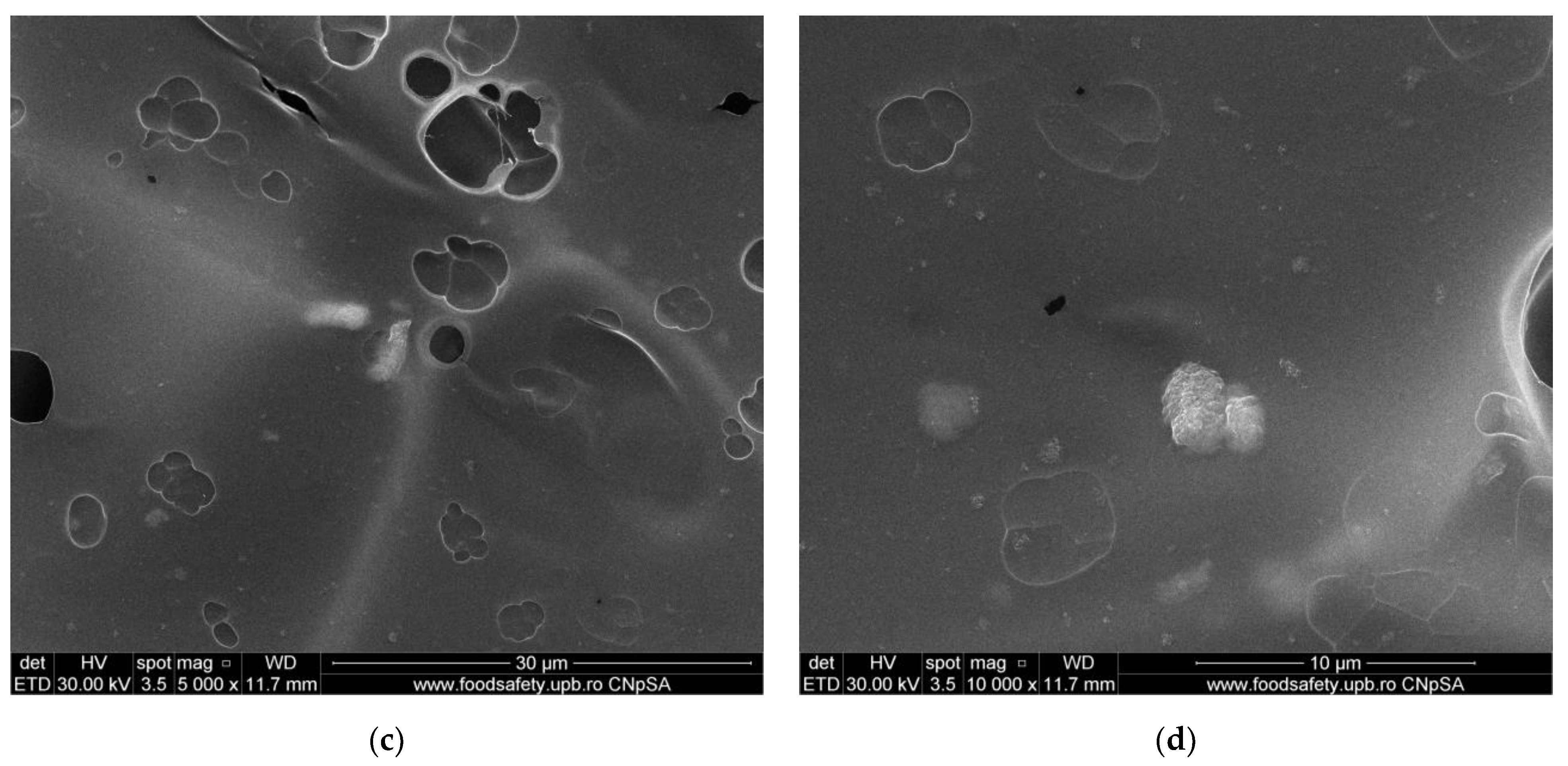

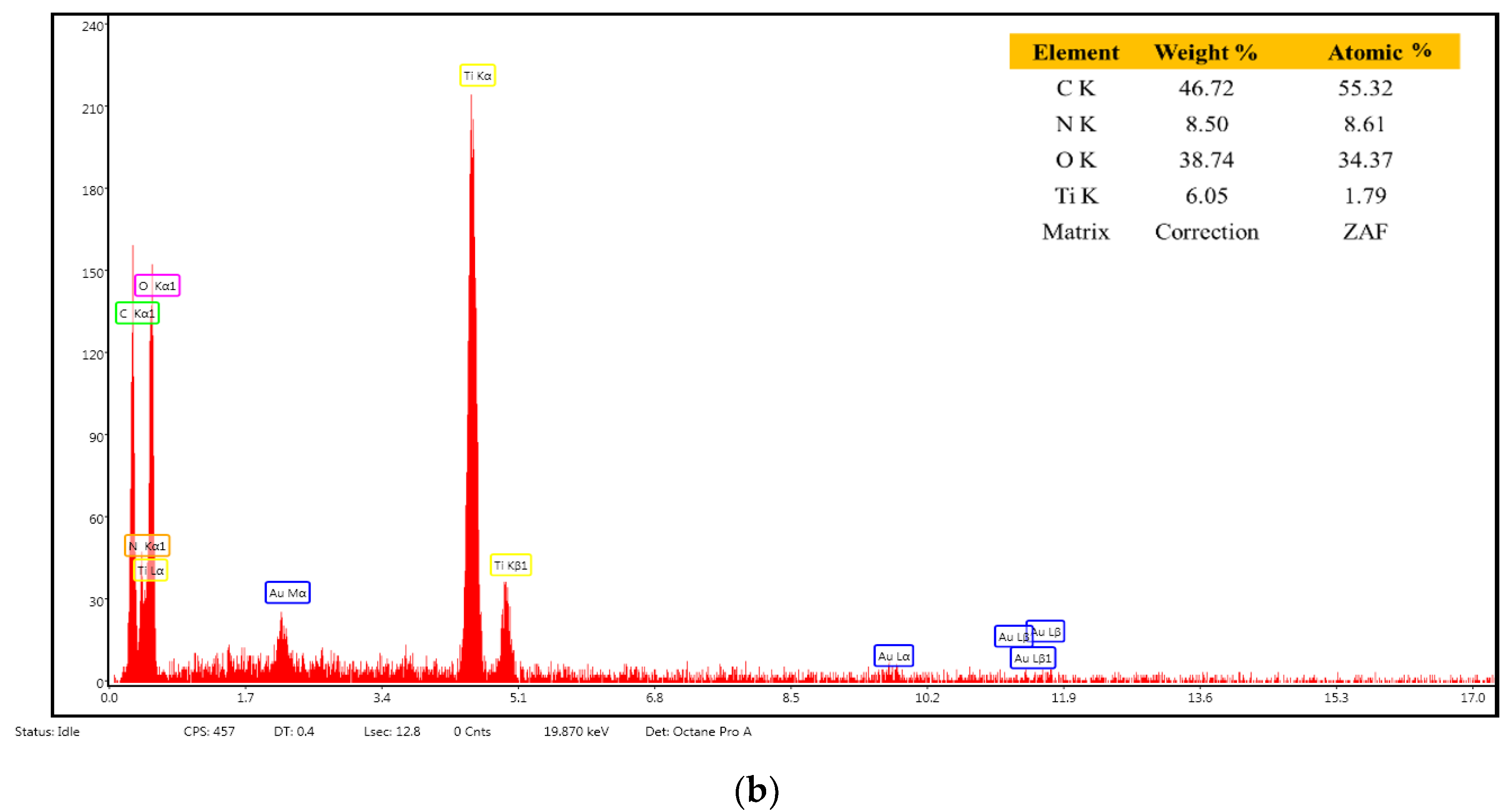

3.4. Scanning Electron Microscopy (SEM) Characterization

3.5. Adsorption of Heavy Metal Ions (Cd and Pb)

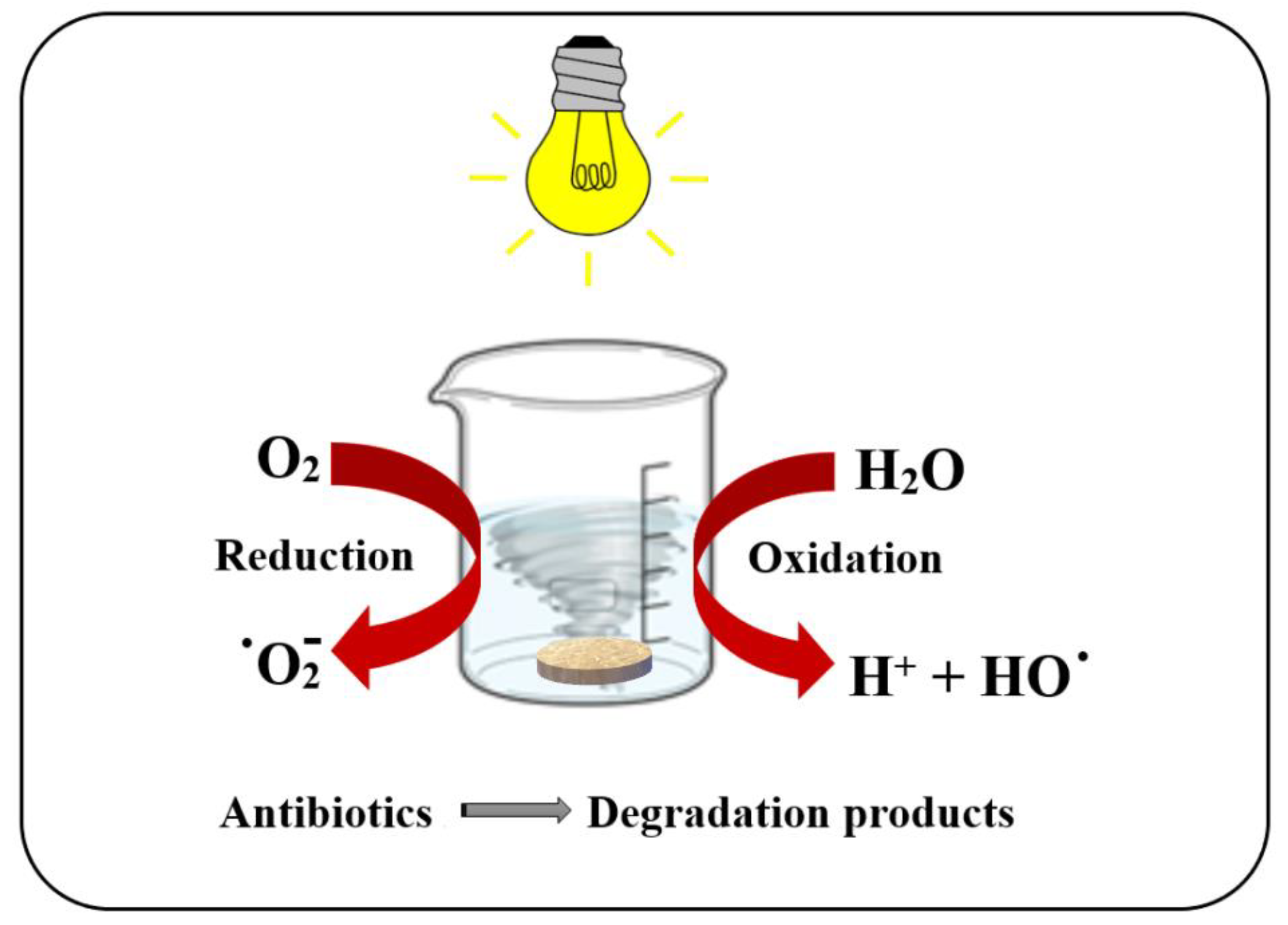

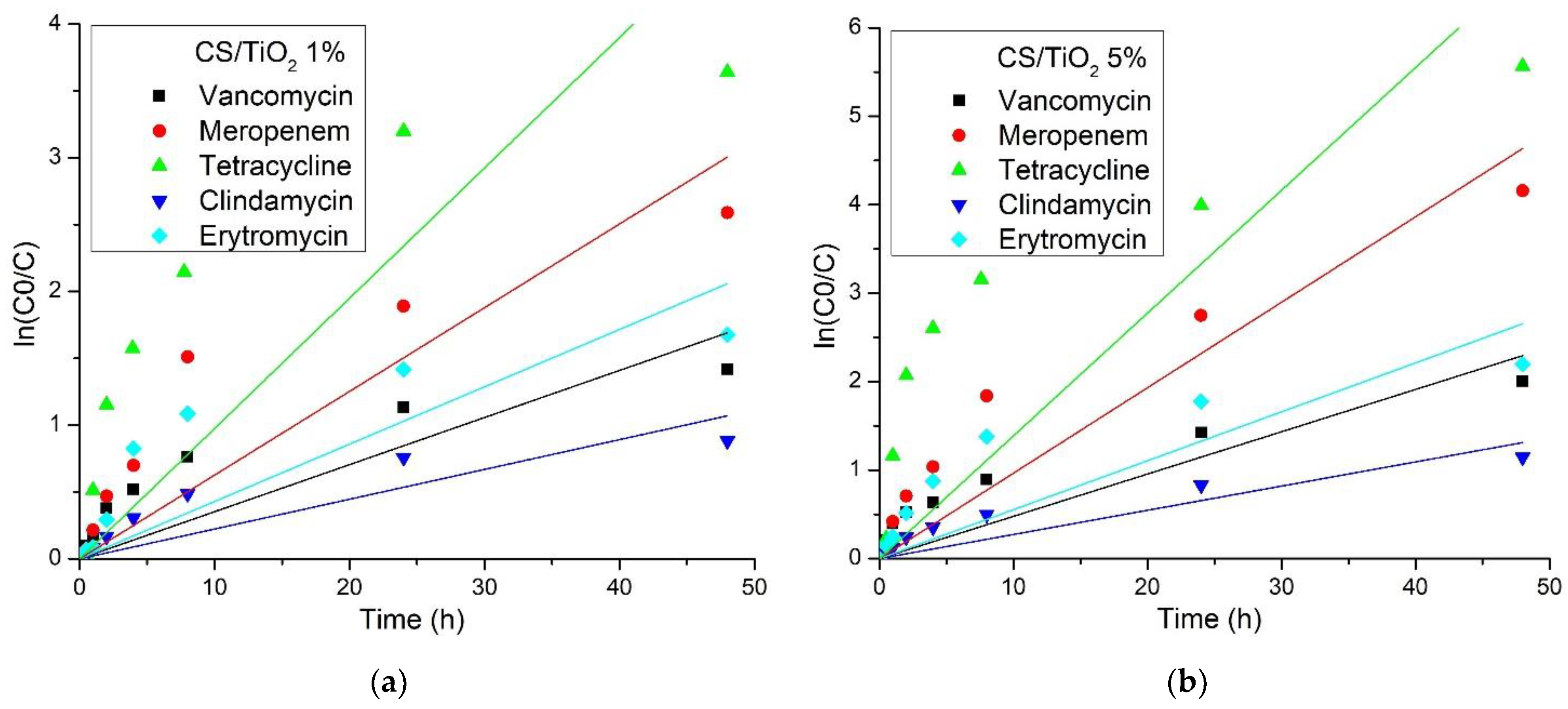

3.6. Photocatalytic Activity Determination

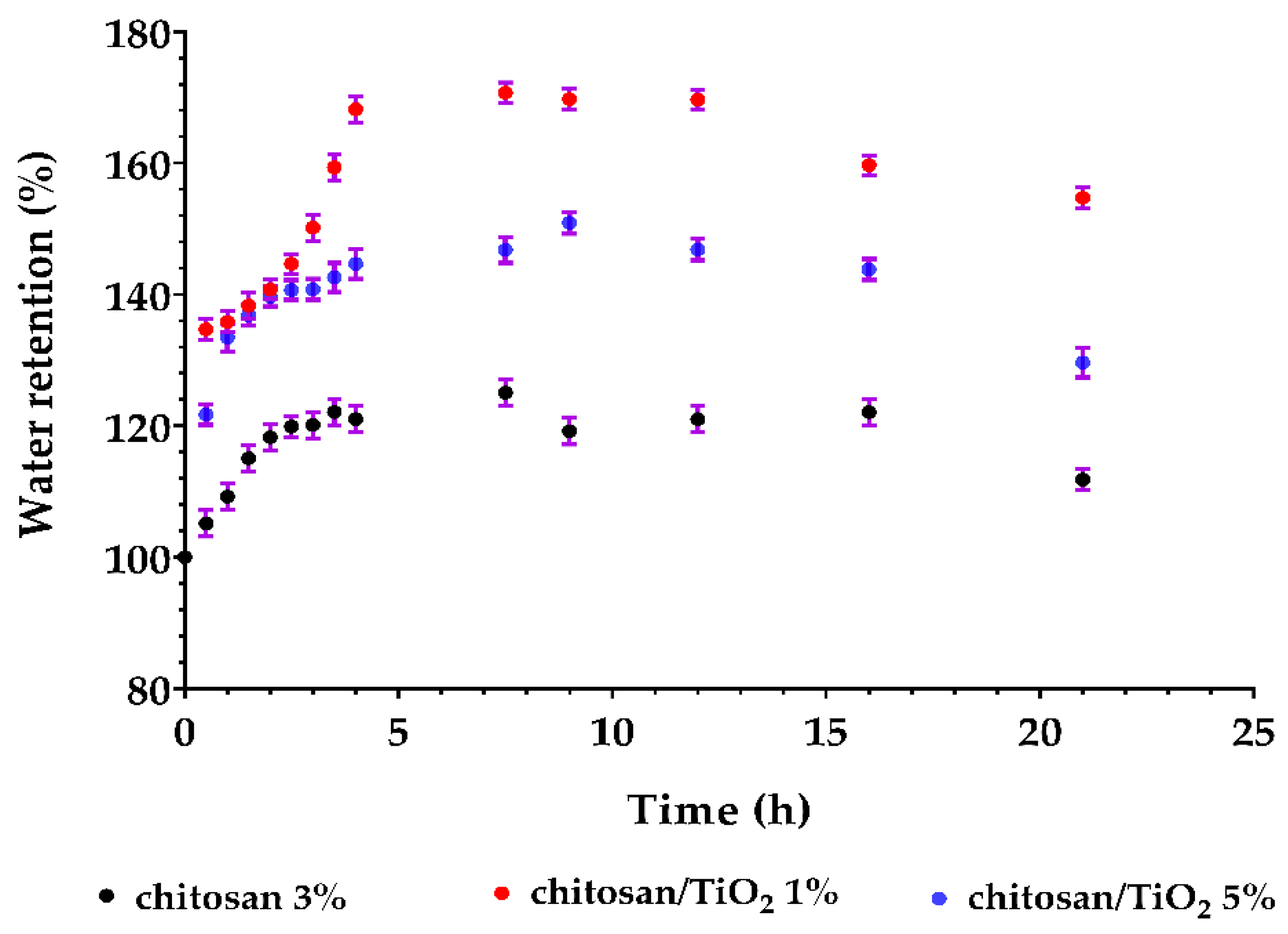

3.7. Swelling Study

3.8. The Antibacterial Assessments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mihaly, M.; Comanescu, A.F.; Rogozea, E.A.; Meghea, A. Nonionic microemulsion extraction of Ni (II) from wastewater. Mol. Cryst. Liq. Cryst. 2010, 523, 63–72. [Google Scholar] [CrossRef]

- Spoială, A.; Ilie, C.-I.; Dolete, G.; Trușcă, R.-D.; Motelică, L.; Oprea, O.-C.; Ficai, D.; Ficai, A.; Andronescu, E.; Dițu, L.-M. The development of antimicrobial chitosan/ ZnO nanocomposite membranes for water purification. Rev. Română Mater. Rom. J. Mater. 2022, 52, 17–25. [Google Scholar]

- Voicu, G.; Oprea, O.; Vasile, B.S.; Andronescu, E. Antibacterial activity of zinc oxide—Gentamicin hybrid material. Dig. J. Nanomater. Biostructures 2013, 8, 1191–1203. [Google Scholar]

- Enache, D.F.; Vasile, E.; Simonescu, C.M.; Razvan, A.; Nicolescu, A.; Nechifor, A.C.; Oprea, O.; Patescu, R.E.; Onose, C.; Dumitru, F. Cysteine-functionalized silica-coated magnetite nanoparticles as potential nano adsorbents. J. Solid State Chem. 2017, 253, 318–328. [Google Scholar] [CrossRef]

- Enache, D.F.; Vasile, E.; Simonescu, C.M.; Culita, D.; Vasile, E.; Oprea, O.; Pandele, A.M.; Razvan, A.; Dumitru, F.; Nechifor, G. Schiff base-functionalized mesoporous silicas (MCM-41, HMS) as Pb(II) adsorbents. RSC Adv. 2018, 8, 176–189. [Google Scholar] [CrossRef] [Green Version]

- Motelica, L.; Marinof, L.; Holban, A.; Vasile, B.S.; Ficai, A. Optical, photocatalytic and antibacterial properties of zinc oxide nanoparticles obtained by a solvothermal method. UPB Sci. Bull. Ser. B 2020, 82, 59–70. [Google Scholar]

- Chaudhary, M.; Maiti, A. Fe-Al-Mn@chitosan based metal oxides blended cellulose acetate mixed matrix membrane for fluoride decontamination from water: Removal mechanisms and antibacterial behavior. J. Membr. Sci. 2020, 611, 118372. [Google Scholar] [CrossRef]

- Modi, A.; Bellare, J. Efficient removal of 2,4-dichlorophenol from contaminated water and alleviation of membrane fouling by high flux polysulfone-iron oxide/graphene oxide composite hollow fiber membranes. J. Water Process Eng. 2020, 33, 101113. [Google Scholar]

- Mihaly, M.; Lacatusu, I.; Enesca, I.A.; Meghea, A. Hybride nanomaterials based on silica coated C-60 clusters obtained by microemulsion technique. Mol. Cryst. Liq. Cryst. 2008, 483, 205–215. [Google Scholar] [CrossRef]

- Mihaly, M.; Lacatusu, I.; Meghea, A. Sulphonephtalein chromophore as molecular probe in micelle systems. Rev. Chim.-Buchar. 2007, 58, 929–932. [Google Scholar]

- Wang, J.; Zhuang, S. Removal of various pollutants from water and wastewater by modified chitosan adsorbents. Crit. Rev. Environ. Sci. Technol. 2018, 47, 2331–2386. [Google Scholar] [CrossRef]

- Modi, A.; Jiang, Z.Y.; Kasher, R. Hydrostable ZIF-8 layer on polyacrylonitrile membrane for efficient treatment of oilfield produced water. Chem. Eng. J. 2022, 434, 133513. [Google Scholar] [CrossRef]

- Croitoru, A.M.; Ficai, A.; Ficai, D.; Trusca, R.; Dolete, G.; Andronescu, E.; Turculet, S.C. Chitosan/graphene oxide nanocomposite membranes as adsorbents with applications in water purification. Materials 2020, 13, 1687. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jamshaid, M.; Arshad Khan, A.; Ahmed, K.; Saleem, M. Heavy metal in drinking water its effect on human health and its treatment techniques-a review. Int. J. Biosci. 2018, 12, 223–240. [Google Scholar]

- Qa, M.; Ms, K. Effect on human health due to drinking water contaminated with heavy metals. J. Pollut. Eff. Control. 2016, 5. [Google Scholar] [CrossRef] [Green Version]

- Culita, D.C.; Simonescu, C.M.; Patescu, R.E.; Preda, S.; Stanica, N.; Munteanu, C.; Oprea, O. Polyamine functionalized magnetite nanoparticles as novel adsorbents for Cu(II) removal from aqueous solutions. J. Inorg. Organomet. Polym. Mater. 2017, 27, 490–502. [Google Scholar] [CrossRef]

- Motelica, L.; Ficai, D.; Oprea, O.C.; Ficai, A.; Ene, V.L.; Vasile, B.S.; Andronescu, E.; Holban, A.M. Antibacterial biodegradable films based on alginate with silver nanoparticles and lemongrass essential oil-innovative packaging for cheese. Nanomaterials 2021, 11, 2377. [Google Scholar] [CrossRef]

- Motelica, L.; Ficai, D.; Oprea, O.; Ficai, A.; Trusca, R.D.; Andronescu, E.; Holban, A.M. Biodegradable alginate films with ZnO nanoparticles and citronella essential oil-a novel antimicrobial structure. Pharmaceutics 2021, 13, 1020. [Google Scholar] [CrossRef]

- Spoiala, A.; Ilie, C.I.; Trusca, R.D.; Oprea, O.C.; Surdu, V.A.; Vasile, B.S.; Ficai, A.; Ficai, D.; Andronescu, E.; Ditu, L.M. Zinc oxide nanoparticles for water purification. Materials 2021, 14, 4747. [Google Scholar] [CrossRef]

- Ly, Q.V.; Matindi, C.N.; Kuvarega, A.T.; Le, Q.V.; Tran, V.S.; Hu, Y.X.; Li, J.X. Organic fouling assessment of novel PES/SPSf/double layered hydroxide mixed matrix membrane for water treatment application. J. Water Process Eng. 2020, 37, 101526. [Google Scholar] [CrossRef]

- Modi, A.; Bellare, J. Efficient separation of biological macromolecular proteins by polyethersulfone hollow fiber ultrafiltration membranes modified with Fe3O4 nanoparticles-decorated carboxylated graphene oxide nanosheets. Int. J. Biol. Macromol. 2019, 135, 798–807. [Google Scholar] [CrossRef] [PubMed]

- Verma, S.K.; Modi, A.; Singh, A.K.; Teotia, R.; Kadam, S.; Bellare, J. Functionally coated polyethersulfone hollow fiber membranes: A substrate for enhanced HepG2/C3A functions. Colloids Surf. B 2018, 164, 358–369. [Google Scholar] [CrossRef] [PubMed]

- Spoială, A.; Ilie, C.I.; Ficai, D.; Ficai, A.; Andronescu, E. Chitosan-based nanocomposite polymeric membranes for water purification-a review. Materials 2021, 14, 2091. [Google Scholar] [CrossRef]

- Crini, G.; Badot, P.-M. Application of chitosan, a natural aminopolysaccharide, for dye removal from aqueous solutions by adsorption processes using batch studies: A review of recent literature. Prog. Polym. Sci. 2008, 33, 399–447. [Google Scholar] [CrossRef]

- Aliabadi, M.; Irani, M.; Ismaeili, J.; Piri, H.; Parnian, M.J. Electrospun nanofiber membrane of PEO/Chitosan for the adsorption of nickel, cadmium, lead and copper ions from aqueous solution. Chem. Eng. J. 2013, 220, 237–243. [Google Scholar] [CrossRef]

- Aliabadi, M.; Irani, M.; Ismaeili, J.; Najafzadeh, S. Design and evaluation of chitosan/hydroxyapatite composite nanofiber membrane for the removal of heavy metal ions from aqueous solution. J. Taiwan Inst. Chem. Eng. 2014, 45, 518–526. [Google Scholar] [CrossRef]

- Haider, S.; Park, S.-Y. Preparation of the electrospun chitosan nanofibers and their applications to the adsorption of Cu(II) and Pb(ii) ions from an aqueous solution. J. Membr. Sci. 2009, 328, 90–96. [Google Scholar] [CrossRef]

- Gupta, N.; Kushwaha, A.K.; Chattopadhyaya, M.C. Adsorptive removal of Pb2+, Co2+ and Ni2+ by hydroxyapatite/chitosan composite from aqueous solution. J. Taiwan Inst. Chem. Eng. 2012, 43, 125–131. [Google Scholar] [CrossRef]

- Chen, A.-H.; Liu, S.-C.; Chen, C.-Y.; Chen, C.-Y. Comparative adsorption of Cu(II), Zn(II), and Pb(II) ions in aqueous solution on the crosslinked chitosan with epichlorohydrin. J. Hazard. Mater. 2008, 154, 184–191. [Google Scholar] [CrossRef]

- Mousa, N.E.; Simonescu, C.M.; Patescu, R.E.; Onose, C.; Tardei, C.; Culita, D.C.; Oprea, O.; Patroi, D.; Lavric, V. Pb2+ removal from aqueous synthetic solutions by calcium alginate and chitosan coated calcium alginate. React. Funct. Polym. 2016, 109, 137–150. [Google Scholar] [CrossRef]

- Simonescu, C.M.; Marin, I.; Tardei, C.; Marinescu, V.; Oprea, O.; Capatina, C. Chitosan and chitosan modified with glutaraldehyde microparticles for Pb(II) biosorption I. Microparticles preparation and characterization. Rev. Chim.-Buchar. 2014, 65, 627–632. [Google Scholar]

- Vakili, M.; Rafatullah, M.; Salamatinia, B.; Abdullah, A.Z.; Ibrahim, M.H.; Tan, K.B.; Gholami, Z.; Amouzgar, P. Application of chitosan and its derivatives as adsorbents for dye removal from water and wastewater: A review. Carbohydr. Polym. 2014, 113, 115–130. [Google Scholar] [CrossRef] [PubMed]

- Sapna; Sharma, R.; Kumar, D. Chitosan-based membranes for wastewater desalination and heavy metal detoxification. Micro Nano Technol. 2019, 799–814. [Google Scholar] [CrossRef]

- Li, M.; Hong, Y.; Wang, Z.; Chen, S.; Gao, M.; Kwok, R.T.K.; Qin, W.; Lam, J.W.Y.; Zheng, Q.; Tang, B.Z. Fabrication of chitosan nanoparticles with aggregation-induced emission characteristics and their applications in long-term live cell imaging. Macromol. Rapid Commun. 2013, 34, 767–771. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Wang, W.; Pan, B.; Zhang, Q.; Zhang, W.; Lv, L. Facile fabrication of magnetic chitosan beads of fast kinetics and high capacity for copper removal. ACS Appl. Mater. Interfaces 2014, 6, 3421–3426. [Google Scholar] [CrossRef] [PubMed]

- Jaiswal, A.; Ghsoh, S.S.; Chattopadhyay, A. Quantum dot impregnated-chitosan film for heavy metal ion sensing and removal. Langmuir 2012, 28, 15687–15696. [Google Scholar] [CrossRef] [PubMed]

- Nayak, V.; Jyothi, M.S.; Balakrishna, R.G.; Padaki, M.; Ismail, A.F. Preparation and characterization of chitosan thin films on mixed-matrix membranes for complete removal of chromium. ChemistryOpen 2015, 4, 278–287. [Google Scholar] [CrossRef]

- Kim, T.-Y.; Park, S.-S.; Cho, S.-Y. Adsorption characteristics of reactive black 5 onto chitosan beads cross-linked with epichlorohydrin. J. Ind. Eng. Chem. 2012, 18, 1458–1464. [Google Scholar] [CrossRef]

- Li, X.-Q.; Tang, R.-C. Crosslinking of chitosan fiber by a water-soluble diepoxy crosslinker for enhanced acid resistance and its impact on fiber structures and properties. React. Funct. Polym. 2016, 100, 116–122. [Google Scholar] [CrossRef]

- Poon, L.; Wilson, L.D.; Headley, J.V. Chitosan-glutaraldehyde copolymers and their sorption properties. Carbohydr. Polym. 2014, 109, 92–101. [Google Scholar] [CrossRef]

- Riegger, B.R.; Baurer, B.; Mirzayeva, A.; Tovar, G.E.M.; Bach, M. A systematic approach of chitosan nanoparticle preparation via emulsion crosslinking as potential adsorbent in wastewater treatment. Carbohydr. Polym. 2018, 180, 46–54. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Chauhan, K.; Priya, V.; Singhal, R.K. A greener approach for impressive removal of As(III)/As(V) from an ultra-low concentration using a highly efficient chitosan thiomer as a new adsorbent. RSC Adv. 2016, 6, 64946–64961. [Google Scholar] [CrossRef]

- Ardila, N.; Daigle, F.; Heuzey, M.C.; Ajji, A. Antibacterial activity of neat chitosan powder and flakes. Molecules 2017, 22, 100. [Google Scholar] [CrossRef] [PubMed]

- Motelica, L.; Ficai, D.; Ficai, A.; Trusca, R.D.; Ilie, C.I.; Oprea, O.C.; Andronescu, E. Innovative antimicrobial chitosan/ZnO/Ag NPs/citronella essential oil nanocomposite—Potential coating for grapes. Foods 2020, 9, 1801. [Google Scholar] [CrossRef] [PubMed]

- Radulescu, M.; Ficai, D.; Oprea, O.; Ficai, A.; Andronescu, E.; Holban, A.M. Antimicrobial chitosan based formulations with impact on different biomedical applications. Curr. Pharm. Biotechnol. 2015, 16, 128–136. [Google Scholar] [CrossRef] [PubMed]

- Marino, T.; Boerrigter, M.; Faccini, M.; Chaumette, C.; Arockiasamy, L.; Bundschuh, J.; Figoli, A. Photocatalytic activity and synthesis procedures of TiO2 nanoparticles for potential applications in membranes. In Application of Nanotechnology in Membranes for Water Treatment; CRC Press: Boca Raton, FL, USA, 2017; pp. 127–146. [Google Scholar]

- Park, J.Y.; Lee, C.; Jung, K.W.; Jung, D. Structure related photocatalytic properties of TiO2. Bull. Korean Chem. Soc. 2009, 30, 402–404. [Google Scholar]

- Ficai, D.; Oprea, O.; Ficai, A.; Holban, A.M. Metal oxide nanoparticles: Potential uses in biomedical applications. Curr. Proteom. 2014, 11, 139–149. [Google Scholar] [CrossRef]

- Vaja, F.; Comanescu, C.; Oprea, O.; Ficai, D.; Guran, C. Effects of ZnO nanoparticles on the wet scrub resistance and photocatalytic properties of acrylic coatings. Rev. Chim.-Buchar. 2012, 63, 722–726. [Google Scholar]

- González-Calderon, J.A.; Vallejo-Montesinos, J.; Martínez-Martínez, H.N.; Cerecero-Enríquez, R.; López-Zamora, L. Effect of chemical modification of titanium dioxide particles via silanization under properties of chitosan/potato starch film. Rev. Mex. Ing. Química 2019, 18, 913–927. [Google Scholar] [CrossRef]

- Li, W.; Zheng, K.; Chen, H.; Feng, S.; Wang, W.; Qin, C. Influence of nano titanium dioxide and clove oil on chitosan-starch film characteristics. Polymers 2019, 11, 1418. [Google Scholar] [CrossRef] [Green Version]

- Anaya-Esparza, L.M.; Ruvalcaba-Gomez, J.M.; Maytorena-Verdugo, C.I.; Gonzalez-Silva, N.; Romero-Toledo, R.; Aguilera-Aguirre, S.; Perez-Larios, A.; Montalvo-Gonzalez, A.E. Chitosan-TiO2: A versatile hybrid composite. Materials 2020, 13, 811. [Google Scholar]

- Razzaz, A.; Ghorban, S.; Hosayni, L.; Irani, M.; Aliabadi, M. Chitosan nanofibers functionalized by TiO2 nanoparticles for the removal of heavy metal ions. J. Taiwan Inst. Chem. Eng. 2016, 58, 333–343. [Google Scholar] [CrossRef]

- Samadi, S.; Khalilian, F.; Tabatabaee, A. Synthesis, characterization and application of Cu–TiO2/chitosan nanocomposite thin film for the removal of some heavy metals from aquatic media. J. Nanostructure Chem. 2014, 4, 84. [Google Scholar] [CrossRef] [Green Version]

- Chien, S.; Abiyu Kerebo, B.; Kuo-Pin, y. Chitosan@TiO2 composites for the adsorption of copper(ii) and antibacterial applications. Sustain. Environ. Res. 2022, 32, 27. [Google Scholar]

- Alizadeh, B.; Delnavaz, M.; Shakeri, A. Removal of Cd(II) and phenol using novel cross-linked magnetic EDTA/chitosan/TiO2 nanocomposite. Carbohydr. Polym. 2018, 181, 675–683. [Google Scholar] [CrossRef]

- Nguyen, U.N.T.; Do, K.H.; Jang, B.; Kim, K.S.; Kim, J.H.; Lee, S.M. Always-on photocatalytic antibacterial facemask with mini uv-led array. Mater. Today Sustain. 2022, 18, 100117. [Google Scholar] [CrossRef]

- Onkani, S.P.; Diagboya, P.N.; Mtunzi, F.M.; Klink, M.J.; Olu-Owolabi, B.I.; Pakade, V. Comparative study of the photocatalytic degradation of 2-chlorophenol under uv irradiation using pristine and ag-doped species of TiO2, ZnO and ZnS photocatalysts. J. Environ. Manag. 2020, 260, 110145. [Google Scholar]

- Yu, X.N.; Lu, Z.Y.; Wu, D.; Yu, P.; He, M.; Chen, T.T.; Shi, W.D.; Huo, P.W.; Yan, Y.S.; Feng, Y.X. Heteropolyacid-chitosan/TiO2 composites for the degradation of tetracycline hydrochloride solution. React. Kinet. Mech. Catal. 2014, 111, 347–360. [Google Scholar]

- Wu, S.J.; Wang, F.; Li, Q.; Wang, J.; Zhou, Y.; Duan, N.; Niazi, S.; Wang, Z.P. Photocatalysis and degradation products identification of deoxynivalenol in wheat using upconversion nanoparticles@TiO2 composite. Food Chem. 2020, 323, 126823. [Google Scholar] [CrossRef]

- Hou, C.T.; Liu, H.Y.; Li, Y.J. The preparation of three-dimensional flower-like TiO2/TiOF2 photocatalyst and its efficient degradation of tetracycline hydrochloride. RSC Adv. 2021, 11, 14957–14969. [Google Scholar] [CrossRef]

- Motelica, L.; Popescu, A.; Razvan, A.G.; Oprea, O.; Trusca, R.D.; Vasile, B.S.; Dumitru, F.; Holban, A.M. Facile use of Zno nanopowders to protect old manual paper documents. Materials 2020, 13, 5452. [Google Scholar]

- Comanescu, A.-F.; Mihaly, M.; Meghea, A. Photocatalytic degradation of organic pollutants using nio based materials. UPB Sci. Bull. Ser. B 2012, 74, 49–60. [Google Scholar]

- Sharma, A.; Karn, R.K.; Pandiyan, S.K. Synthesis of TiO2 nanoparticles by sol-gel method and their characterization. J. Basic Appl. Eng. Res. 2014, 1, 1–5. [Google Scholar]

- Lemnaru Popa, G.M.; Trusca, R.D.; Ilie, C.I.; Tiplea, R.E.; Ficai, D.; Oprea, O.; Stoica-Guzun, A.; Ficai, A.; Ditu, L.M. Antibacterial activity of bacterial cellulose loaded with bacitracin and amoxicillin: In vitro studies. Molecules 2020, 25, 4069. [Google Scholar] [CrossRef] [PubMed]

- Anghel, I.; Holban, A.M.; Grumezescu, A.M.; Andronescu, E.; Ficai, A.; Anghel, A.G.; Maganu, M.; Laz, R.V.; Chifiriuc, M.C. Modified wound dressing with phyto-nanostructured coating to prevent staphylococcal and pseudomonal biofilm development. Nanoscale Res. Lett. 2012, 7, 690. [Google Scholar] [PubMed] [Green Version]

- Cotar, A.I.; Grumezescu, A.M.; Andronescu, E.; Voicu, G.; Ficai, A.; Ou, K.-L.; Huang, K.-S.; Chifiriuc, M.C. Nanotechnological solution for improving the antibiotic e_ciency against biofilms developed by gram-negative bacterial strains. Lett. Appl. NanoBioSci 2013, 2, 97–104. [Google Scholar]

- CLSI. Performance Standards for Antimicrobial Susceptibility Testing; Clinical and Laboratory Standards Institute: Berwyn, PA, USA, 2021. [Google Scholar]

- Branca, C.; D’Angelo, G.; Crupi, C.; Khouzami, K.; Rifici, S.; Ruello, G.; Wanderlingh, U. Role of the oh and nh vibrational groups in polysaccharide-nanocomposite interactions: A ftir-atr study on chitosan and chitosan/clay films. Polymer 2016, 99, 614–622. [Google Scholar]

- Kustiningsih, I.; Ridwan, A.; Abriyani, D.; Syairazy, M.; Kurniawan, T.; Barleany, D.R. Development of chitosan-TiO2 nanocomposite for packaging film and its ability to inactive staphylococcus aureus. Orient. J. Chem. 2019, 35, 1132–1137. [Google Scholar]

- Humelnicu, A.C.; Samoila, P.; Asandulesa, M.; Cojocaru, C.; Bele, A.; Marinoiu, A.T.; Sacca, A.; Harabagiu, V. Chitosan-sulfated titania composite membranes with potential applications in fuel cell: Influence of cross-linker nature. Polymers 2020, 12, 1125. [Google Scholar]

- Kumar, P. Nano-TiO2 doped chitosan scaffold for the bone tissue engineering applications. Int. J. Biomater. 2018, 2018, 6576157. [Google Scholar] [CrossRef] [Green Version]

- Mindru, I.; Gingasu, D.; Patron, L.; Marinescu, G.; Calderon-Moreno, J.M.; Preda, S.; Oprea, O.; Nita, S. Copper aluminate spinel by soft chemical routes. Ceram. Int. 2016, 42, 154–164. [Google Scholar] [CrossRef]

- Vasile, B.S.; Oprea, O.; Voicu, G.; Ficai, A.; Andronescu, E.; Teodorescu, A.; Holban, A. Synthesis and characterization of a novel controlled release zinc oxide/gentamicin-chitosan composite with potential applications in wounds care. Int. J. Pharm. 2014, 463, 161–169. [Google Scholar]

- Rosli, N.A.H.; Loh, K.S.; Wong, W.Y.; Lee, T.K.; Ahmad, A. Hybrid composite membrane of phosphorylated chitosan/poly (vinyl alcohol)/silica as a proton exchange membrane. Membranes 2021, 11, 675. [Google Scholar] [CrossRef]

- Chen, M.H.; Yu, M.D.; Kang, R.F.; Sun, H.M.; Zhang, W.; Wang, S.S.; Wang, N.; Wang, J. Removal of Pb (ii) and V (v) from aqueous solution by glutaraldehyde crosslinked chitosan and nanocomposites. Chemosphere 2022, 297, 134084. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.G.; Ye, L.B.; Pan, J.; Wang, Y.M.; Tang, B. Removal of Pb(II) from aqueous solution on chitosan/TiO2 hybrid film. J. Hazard. Mater. 2009, 161, 718–722. [Google Scholar] [CrossRef]

- Chen, A.W.; Zeng, G.M.; Chen, G.Q.; Hu, X.J.; Yan, M.; Guan, S.; Shang, C.; Lu, L.H.; Zou, Z.J.; Xie, G.X. Novel thiourea-modified magnetic ion-imprinted chitosan/TiO2 composite for simultaneous removal of cadmium and 2,4-dichlorophenol. Chem. Eng. J. 2012, 191, 85–94. [Google Scholar] [CrossRef]

- Wu, S.P.; Kan, J.R.; Dai, X.Z.; Shen, X.J.; Zhang, K.; Zhu, M.Y. Ternary carboxymethyl chitosan-hemicellulose-nanosized TiO2 composite as effective adsorbent for removal of heavy metal contaminants from water. Fibers Polym. 2017, 18, 22–32. [Google Scholar] [CrossRef]

- Chen, Y.S.; Ooi, C.W.; Show, P.L.; Hoe, B.C.; Chai, W.S.; Chiu, C.Y.; Wang, S.S.S.; Chang, Y.K. Removal of ionic dyes by nanofiber membrane functionalized with chitosan and egg white proteins: Membrane preparation and adsorption efficiency. Membranes 2022, 12, 63. [Google Scholar]

- Popa, A.; Visa, A.; Maranescu, B.; Hulka, I.; Lupa, L. Chemical modification of chitosan for removal of Pb(II) ions from aqueous solutions. Materials 2021, 14, 7894. [Google Scholar] [CrossRef]

- Rathinam, K.; Kou, X.W.; Hobby, R.; Panglisch, S. Sustainable development of magnetic chitosan core-shell network for the removal of organic dyes from aqueous solutions. Materials 2021, 14, 7701. [Google Scholar] [CrossRef]

- Alves, D.C.D.; Healy, B.; Yu, T.; Breslin, C.B. Graphene-based materials immobilized within chitosan: Applications as adsorbents for the removal of aquatic pollutants. Materials 2021, 14, 3655. [Google Scholar] [CrossRef] [PubMed]

- Zanfir, A.V.; Voicu, G.; Badanoiu, A.I.; Gogan, D.; Oprea, O.; Vasile, E. Synthesis and characterization of titania-silica fume composites and their influence on the strength of self-cleaning mortar. Compos. Part B Eng. 2018, 140, 157–163. [Google Scholar] [CrossRef]

- Totu, E.E.; Cristache, C.M.; Voicila, E.; Oprea, O.; Agir, I.; Tavukcuoglu, O.; Didilescu, A.C. On physical and chemical characteristics of poly (methylmethacrylate) nanocomposites for dental applications. I. Mater. Plast 2017, 54, 666–672. [Google Scholar] [CrossRef]

- Jawad, A.H.; Mubarak, N.S.A.; Ishak, M.A.M.; Ismail, K.; Nawawi, W.I. Kinetics of photocatalytic decolourization of cationic dye using porous TiO2 film. J. Taibah Univ. Sci. 2016, 10, 352–362. [Google Scholar] [CrossRef] [Green Version]

- Rytwo, G.; Zelkind, A.L. Evaluation of kinetic pseudo-order in the photocatalytic degradation of ofloxacin. Catalysts 2022, 12, 24. [Google Scholar] [CrossRef]

- Alghamdi, Y.G.; Krishnakumar, B.; Malik, M.A.; Alhayyani, S. Design and preparation of biomass-derived activated carbon loaded TiO2 photocatalyst for photocatalytic degradation of reactive red 120 and ofloxacin. Polymers 2022, 14, 880. [Google Scholar] [CrossRef]

- Farhadian, N.; Akbarzadeh, R.; Pirsaheb, M.; Jen, T.C.; Fakhri, Y.; Asadi, A. Chitosan modified N, S-doped TiO2 and N, S-doped ZnO for visible light photocatalytic degradation of tetracycline. Int. J. Biol. Macromol. 2019, 132, 360–373. [Google Scholar] [CrossRef]

- Ikhlef-Taguelmimt, T.; Hamiche, A.; Yahiaoui, I.; Bendellali, T.; Lebik-Elhadi, H.; Ait-Amar, H.; Aissani-Benissad, F. Tetracycline hydrochloride degradation by heterogeneous photocatalysis using TiO2(P25) immobilized in biopolymer (chitosan) under uv irradiation. Water Sci. Technol. 2020, 82, 1570–1578. [Google Scholar] [CrossRef]

- Patehkhor, H.A.; Fattahi, M.; Khosravi-Nikou, M. Synthesis and characterization of ternary chitosan-TiO2-ZnO over graphene for photocatalytic degradation of tetracycline from pharmaceutical wastewater. Sci. Rep. 2021, 11, 24177. [Google Scholar] [CrossRef]

- Rizzi, V.; Gubitosa, J.; Fini, P.; Petrella, A.; Romita, R.; Agostiano, A.; Cosma, P. A “classic” material for capture and detoxification of emergent contaminants for water purification: The case of tetracycline. Environ. Technol. Innov. 2020, 19, 100812. [Google Scholar] [CrossRef]

- Cabrera-Reina, A.; Martinez-Piernas, A.B.; Bertakis, Y.; Xekoukoulotakis, N.P.; Aguera, A.; Perez, J.A.S. TiO2 photocatalysis under natural solar radiation for the degradation of the carbapenem antibiotics imipenem and meropenem in aqueous solutions at pilot plant scale. Water Res. 2019, 166, 115037. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhu, J.Y.; Hu, Y.Q.; Chen, A.N.; Zhou, L.; Gao, H.; Liu, Y.M.; Liu, S.Q. Study on photocatalytic antibacterial and sustained-release properties of cellulose/TiO2/beta-CD composite hydrogel. J. Nanomater. 2019, 2019. [Google Scholar] [CrossRef]

- Rokicka-Konieczna, P.; Wanag, A.; Sienkiewicz, A.; Kusiak-Nejman, E.; Morawski, A.W. Antibacterial effect of TiO2 nanoparticles modified with aptes. Catal. Commun. 2020, 134, 105862. [Google Scholar] [CrossRef]

- López de Dicastillo, C.; Correa, M.G.; Martínez, F.B.; Streitt, C.; Galotto, M.J. Antimicrobial effect of titanium dioxide nanoparticles. In Antimicrobial Resistance—A One Health Perspective; IntechOpen: London, UK, 2020; pp. 1–19. [Google Scholar]

- Lopez de Dicastillo, C.; Patino, C.; Galotto, M.J.; Palma, J.L.; Alburquenque, D.; Escrig, J. Novel antimicrobial titanium dioxide nanotubes obtained through a combination of atomic layer deposition and electrospinning technologies. Nanomaterials 2018, 8, 128. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Azizi-Lalabadi, M.; Ehsani, A.; Divband, B.; Alizadeh-Sani, M. Antimicrobial activity of titanium dioxide and zinc oxide nanoparticles supported in 4a zeolite and evaluation the morphological characteristic. Sci. Rep. 2019, 9, 17439. [Google Scholar] [CrossRef] [Green Version]

- Khashan, K.S.; Sulaiman, G.M.; Abdulameer, F.A.; Albukhaty, S.; Ibrahem, M.A.; Al-Muhimeed, T.; AlObaid, A.A. Antibacterial activity of TiO2 nanoparticles prepared by one-step laser ablation in liquid. Appl. Sci. 2021, 11, 4623. [Google Scholar] [CrossRef]

- Kubacka, A.; Diez, M.S.; Rojo, D.; Bargiela, R.; Ciordia, S.; Zapico, I.; Albar, J.P.; Barbas, C.; Martins dos Santos, V.A.; Fernandez-Garcia, M.; et al. Understanding the antimicrobial mechanism of TiO2-based nanocomposite films in a pathogenic bacterium. Sci. Rep. 2014, 4, 4134. [Google Scholar] [CrossRef] [Green Version]

- Sahariah, P.; Másson, M. Antimicrobial chitosan and chitosan derivatives: A review of the structure–activity relationship. Biomacromolecules 2017, 18, 3846–3868. [Google Scholar] [CrossRef]

- Goy, R.C.; Morais, S.T.B.; Assis, O.B.G. Evaluation of the antimicrobial activity of chitosan and its quaternized derivative on E. coli and S. aureus growth. Rev. Bras. Farmacogn. 2016, 26, 122–127. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Xiao, G.; Wang, Y.; Zhao, Y.; Su, H.; Tan, T. Preparation of chitosan-TiO2 composite film with efficient antimicrobial activities under visible light for food packaging applications. Carbohydr. Polym. 2017, 169, 101–107. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Kaewklin, P. Fabrication and characterization of chitosan-titanium dioxide nanocomposite film as ethylene scavenging and antimicrobial active food packaging. Food Hydrocolloid 2018, 84, 125–134. [Google Scholar] [CrossRef]

| No. | Characteristic Functional Groups | CS 3% (cm−1) | CS/TiO2 1% (cm−1) | CS/TiO2 5% (cm−1) |

|---|---|---|---|---|

| 1 | O-H stretching vibration | 3352 | 3344 | 3356 |

| N-H stretching vibration | 3182 | 3178 | 3187 | |

| 2 | Asymmetric stretching of Csp3-H | 2924 | 2924 | 2924 |

| Symmetric stretching of Csp3-H | 2875 | 2875 | 2875 | |

| 3 | Amide I band C=O stretching | 1631 sh | 1627 sh | 1627 sh |

| 4 | Amide II band in plane N-H bending | 1542 | 1547 | 1551 |

| 5 | δ C-H | 1404 | 1408 | 1408 |

| 6 | Asymmetric stretching C-O-C | 1150 | 1150 | 1150 |

| 7 | C-O stretching | 1065 | 1065 | 1069 |

| 1021 | 1021 | 1021 | ||

| 8 | Ti-O-Ti stretching vibrations | - | 485 | 504 |

| - | 480 | 504 |

| Sample | Mass Loss RT-105 °C | Mass Loss 105–200 °C | Mass Loss 200–370 °C | Residual Mass at 900 °C | Endo | Exo I | Exo II |

|---|---|---|---|---|---|---|---|

| CS 3% | 9.80% | 14.67% | 43.14% | 2.63% | 71.6 °C | 293.1 °C | 490.8 °C |

| CS/TiO2 1% | 7.73% | 13.42% | 40.68% | 11.35% | 78.8 °C | 288.8 °C | 498.3 °C |

| CS/TiO2 5% | 7.76% | 11.89% | 37.80% | 18.00% | 69.0 °C | 294.0 °C | 504.2 °C |

| Sample | Metal Final Concentration | |

|---|---|---|

| Pb (µg/mg) | Cd (µg/mg) | |

| CS/TiO2 1% Pb 1% | 256.1 ± 3.1 | |

| CS/TiO2 1% Pb 5% | 297.0 ± 4.8 | |

| CS/TiO2 1% Cd 1% | 90.7 ± 1.6 | |

| CS/TiO2 1% Cd 5% | 315.1 ± 2.7 | |

| CS/TiO2 5% Pb 1% | 182.2 ± 1.9 | |

| CS/TiO2 5% Pb 5% | 255.1 ± 4.2 | |

| CS/TiO2 5% Cd 1% | 84.2 ± 1.5 | |

| CS/TiO2 5% Cd 5% | 255.0 ± 3.3 | |

| Composite Membrane | Removal Capacity (u.m.) | Pollutant | Reference |

|---|---|---|---|

| Chitosan/TiO2 (1%) | 297.0 mg/g | Pb(II) | This study |

| 315.1 mg/g | Cd(II) | ||

| Chitosan/TiO2 (5%) | 255.1 mg/g | Pb(II) | This study |

| 255.0 mg/g | Cd(II) | ||

| Chitosan/TiO2 | 32.1 mg/g | Pb(II) | [76] |

| Chitosan/TiO2 hybrid film | 36.8 mg/g | Pb(II) | [77] |

| EDTA/Chitosan/TiO2 nanocomposite | 209 mg/g | Cd(II) | [56] |

| Chitosan/TiO2 composite | 256 mg/g | Cd(II) | [78] |

| Chitosan-Hemicellulose-TiO2 composite | 27.6 mg/g | Cd(II) | [79] |

| Antibiotic | Vancomycin | Meropenem | Tetracycline | Clindamycin | Erythromycin |

|---|---|---|---|---|---|

| CS/TiO2 1% | 75.79% | 92.49% | 97.38% | 58.64% | 81.31% |

| CS/TiO2 5% | 86.55% | 98.44% | 99.62% | 68.26% | 88.89% |

| Membrane Parameter/ Antibiotic | CS/TiO2 1% | CS/TiO2 5% | ||||||

|---|---|---|---|---|---|---|---|---|

| kobs1∙10−3 (min−1) | R12 | kobs2 (L∙mg−1∙min−1) | R22 | kobs1∙10−3 (min−1) | R12 | kobs2 (L∙mg−1∙min−1) | R22 | |

| Clindamycin | 0.3715 | 0.8366 | 0.0115 | 0.9803 | 0.4555 | 0.8866 | 0.0159 | 0.9905 |

| Vancomycin | 0.5872 | 0.8269 | 0.0240 | 0.9756 | 0.7967 | 0.8583 | 0.0452 | 0.9925 |

| Erythromycin | 0.7148 | 0.7775 | 0.0343 | 0.9499 | 0.9217 | 0.7993 | 0.0599 | 0.9708 |

| Meropenem | 1.0435 | 0.8551 | 0.0854 | 0.9887 | 1.6095 | 0.9103 | 0.3853 | 0.9337 |

| Tetracycline | 1.6243 | 0.6337 | 0.2863 | 0.9003 | 2.3122 | 0.7018 | 1.5982 | 0.9256 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spoială, A.; Ilie, C.-I.; Dolete, G.; Croitoru, A.-M.; Surdu, V.-A.; Trușcă, R.-D.; Motelica, L.; Oprea, O.-C.; Ficai, D.; Ficai, A.; et al. Preparation and Characterization of Chitosan/TiO2 Composite Membranes as Adsorbent Materials for Water Purification. Membranes 2022, 12, 804. https://doi.org/10.3390/membranes12080804

Spoială A, Ilie C-I, Dolete G, Croitoru A-M, Surdu V-A, Trușcă R-D, Motelica L, Oprea O-C, Ficai D, Ficai A, et al. Preparation and Characterization of Chitosan/TiO2 Composite Membranes as Adsorbent Materials for Water Purification. Membranes. 2022; 12(8):804. https://doi.org/10.3390/membranes12080804

Chicago/Turabian StyleSpoială, Angela, Cornelia-Ioana Ilie, Georgiana Dolete, Alexa-Maria Croitoru, Vasile-Adrian Surdu, Roxana-Doina Trușcă, Ludmila Motelica, Ovidiu-Cristian Oprea, Denisa Ficai, Anton Ficai, and et al. 2022. "Preparation and Characterization of Chitosan/TiO2 Composite Membranes as Adsorbent Materials for Water Purification" Membranes 12, no. 8: 804. https://doi.org/10.3390/membranes12080804

APA StyleSpoială, A., Ilie, C.-I., Dolete, G., Croitoru, A.-M., Surdu, V.-A., Trușcă, R.-D., Motelica, L., Oprea, O.-C., Ficai, D., Ficai, A., Andronescu, E., & Dițu, L.-M. (2022). Preparation and Characterization of Chitosan/TiO2 Composite Membranes as Adsorbent Materials for Water Purification. Membranes, 12(8), 804. https://doi.org/10.3390/membranes12080804