Self-Oscillating Liquid Gating Membranes with Periodic Gas Transport

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Fabrication of SOLGM

2.3. Characterizations

2.4. Transmembrane Pressure Measurements

2.5. Contact Angle Measurements

3. Results and Discussions

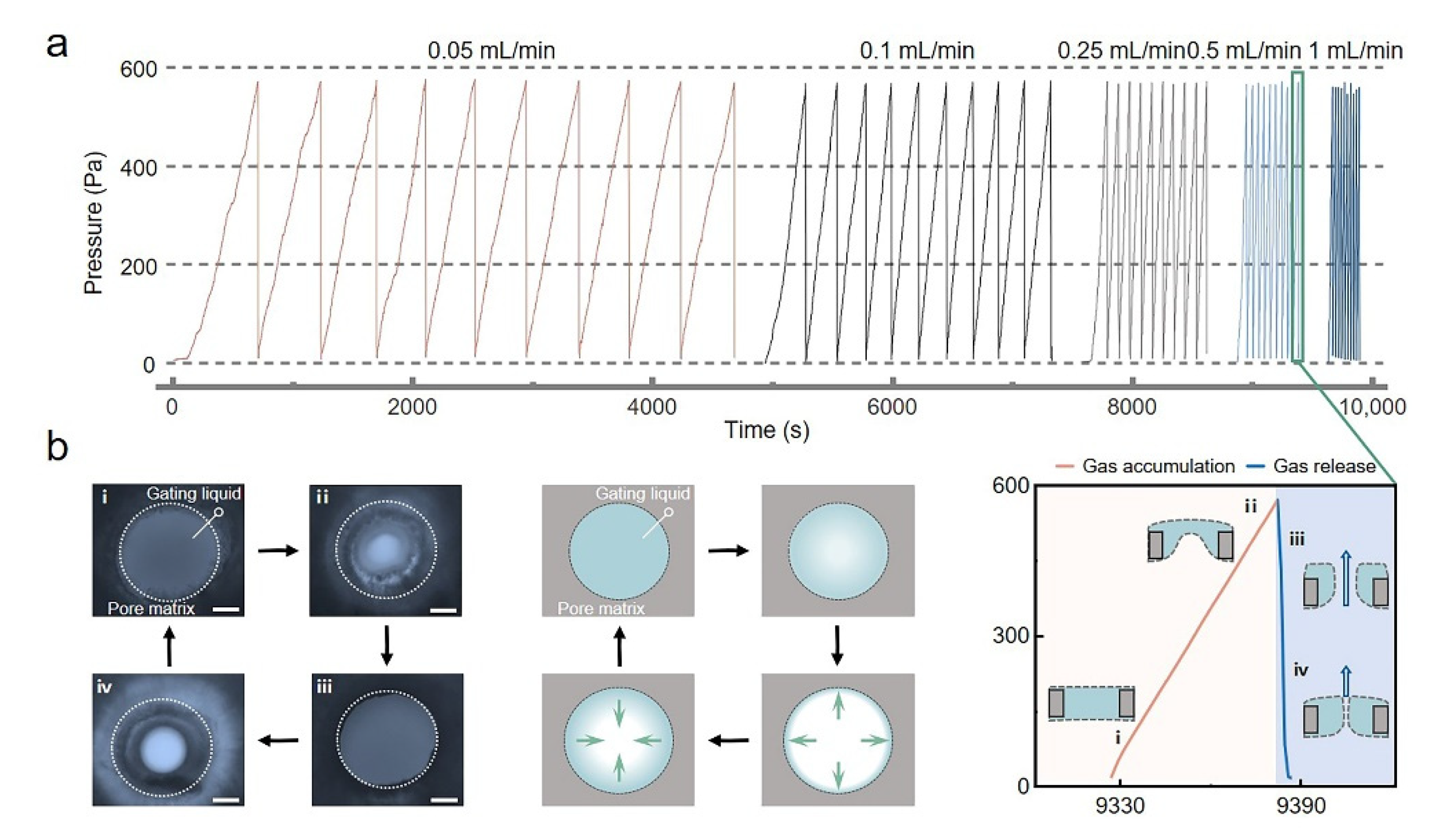

3.1. Operation Mechanism of SOLGM

3.2. Characterization of Self-Oscillating Behavior with Periodic Gas Transport

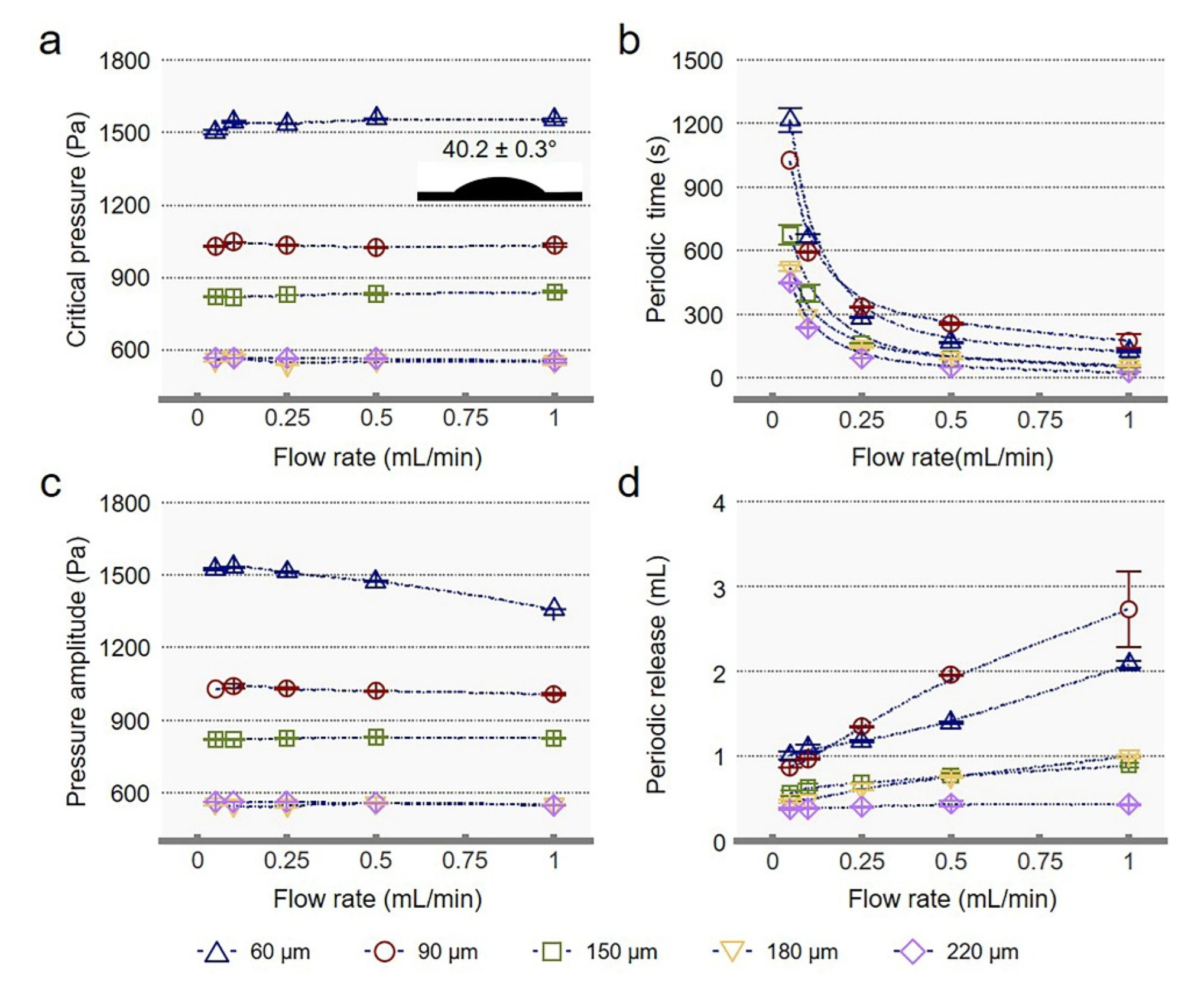

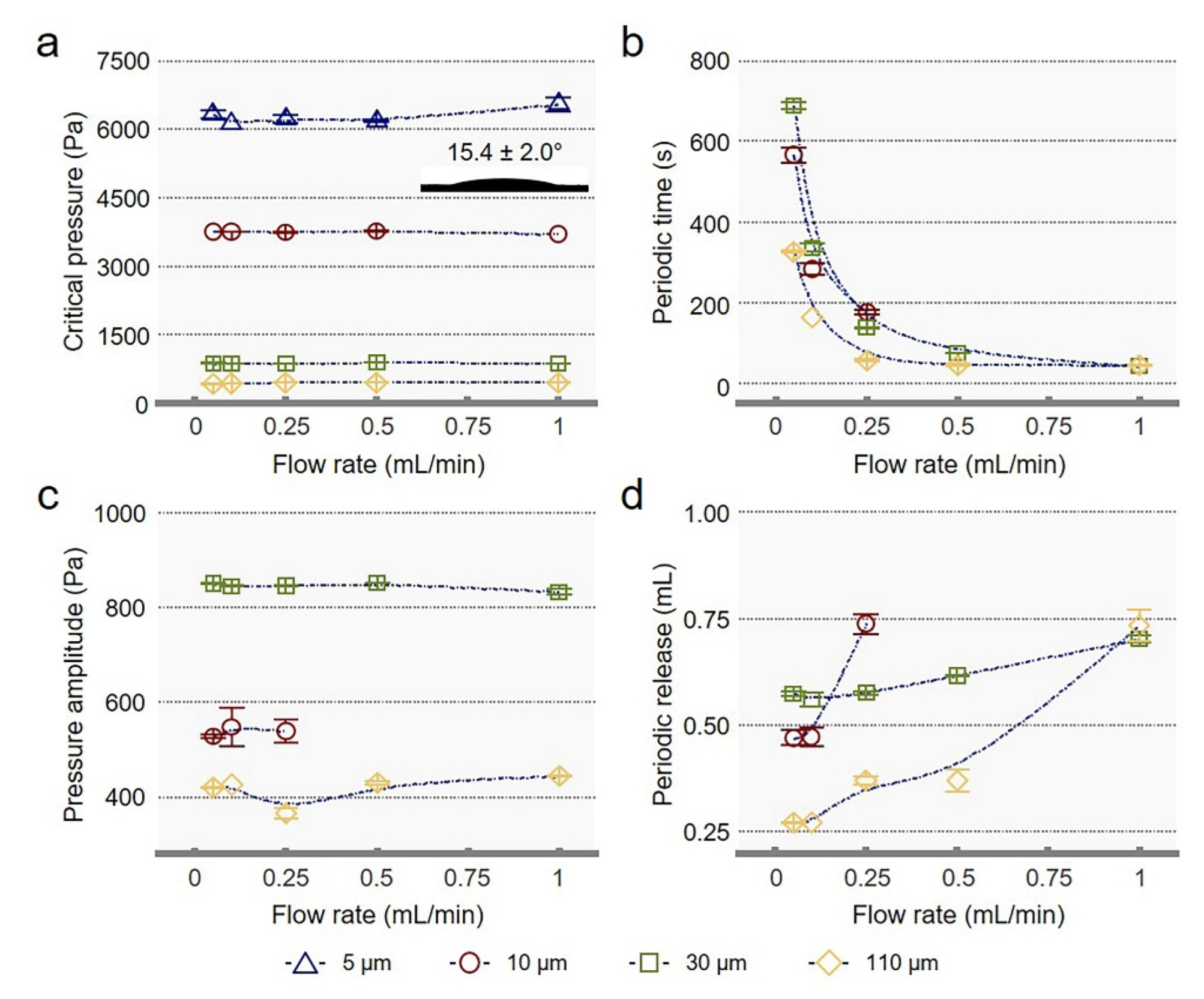

3.3. Design Strategy and Parameter Regulation of SOLGM

3.3.1. Stable Single-Pore Systems

3.3.2. Stable Porous Systems

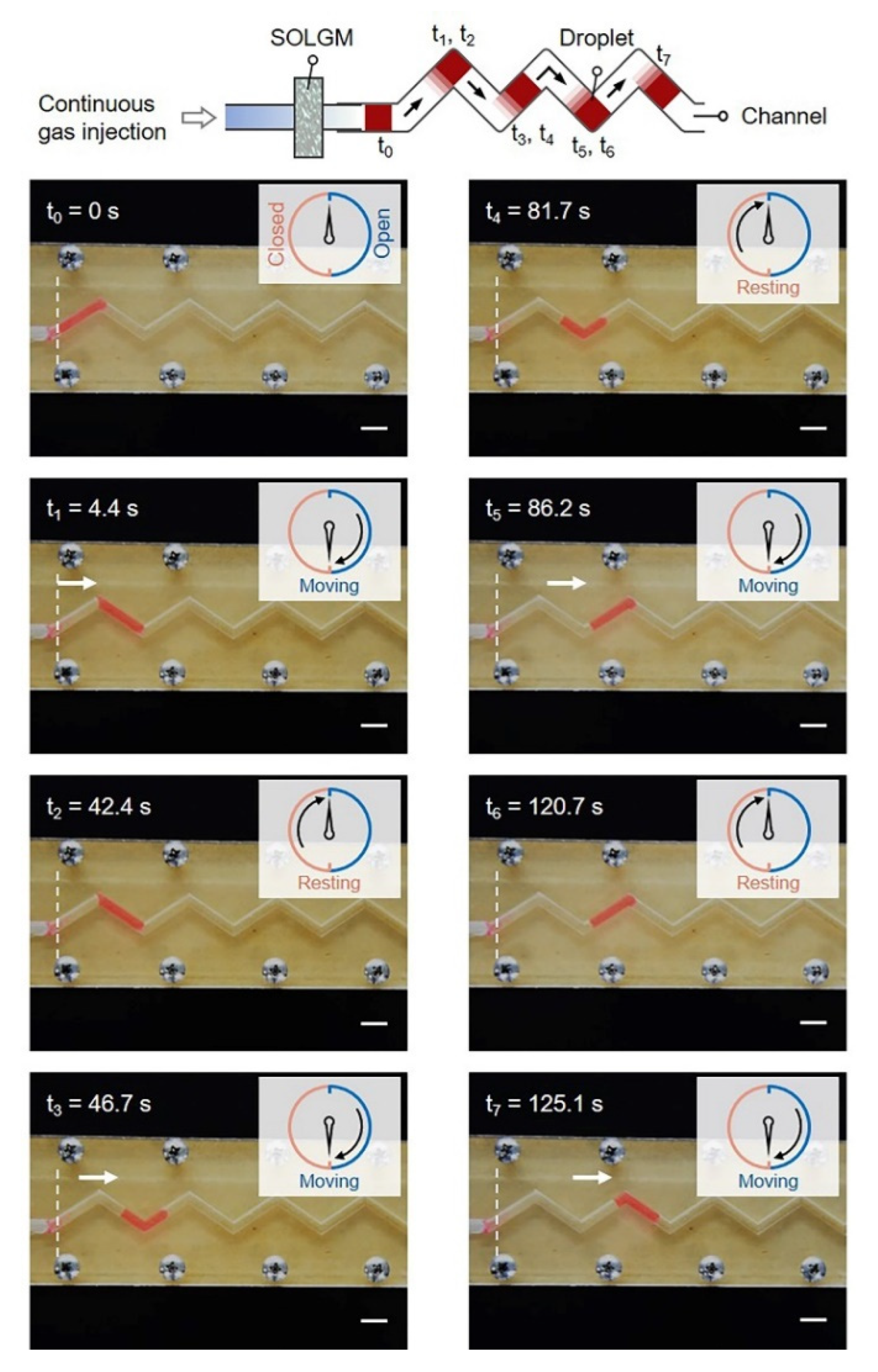

3.4. Demonstration of SOLGM for Periodic Gas Transport in Droplet Microfluidics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hou, X.; Hu, Y.; Grinthal, A.; Khan, M.; Aizenberg, J. Liquid-based gating mechanism with tunable multiphase selectivity and antifouling behaviour. Nature 2015, 519, 70–73. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhang, Y.; Han, Y.; Hou, Y.; Fan, Y.; Hou, X. Design of porous membranes by liquid gating technology. Acc. Mater. Res. 2021, 2, 407–419. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, B.; Chen, X.; Hou, X. Liquid-based adaptive structural materials. Adv. Mater. 2021, 33, 2005664. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Z.; Zhang, M.; Liu, J.; Malgaretti, P.; Li, J.; Wang, S.; Lv, W.; Zhang, R.; Fan, Y.; Zhang, Y.; et al. Reconfiguring confined magnetic colloids with tunable fluid transport behavior. Natl. Sci. Rev. 2021, 8, nwaa301. [Google Scholar] [CrossRef] [PubMed]

- Zhan, K.; Hou, X. Tunable microscale porous systems with dynamic liquid interfaces. Small 2018, 14, e1703283. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Sheng, Z.; Chen, J.; Pan, H.; Chen, B.; Wu, F.; Wang, S.; Chen, X.; Hou, X. Visual chemical detection mechanism by a liquid gating system with dipole-induced interfacial molecular reconfiguration. Angew. Chem. Int. Ed. 2019, 58, 4007–4011. [Google Scholar] [CrossRef]

- Sheng, Z.; Zhang, J.; Liu, J.; Zhang, Y.; Chen, X.; Hou, X. Liquid-based porous membranes. Chem. Soc. Rev. 2020, 49, 7907–7928. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, R.; Hou, Y.; Zhang, J.; Chen, S.; Han, Y.; Chen, X.; Hou, X. Light-responsive and corrosion-resistant gas valve with non-thermal effective liquid-gating positional flow control. Light Sci. Appl. 2021, 10, 127. [Google Scholar] [CrossRef]

- Lei, J.; Hou, Y.; Wang, H.; Fan, Y.; Zhang, Y.; Chen, B.; Yu, S.; Hou, X. Carbon dioxide chemically responsive switchable gas valves with protonation-induced liquid gating self-adaptive systems. Angew. Chem. Int. Ed. 2022, 61, e202201109. [Google Scholar] [CrossRef]

- Namati, E.; Thiesse, J.; de Ryk, J.; McLennan, G. Alveolar dynamics during respiration: Are the pores of Kohn a pathway to recruitment. Am. J. Respir. Cell Mol. Biol. 2008, 38, 572–578. [Google Scholar] [CrossRef] [Green Version]

- Peleg, O.; Lim, R. Converging on the function of intrinsically disordered nucleoporins in the nuclear pore complex. Biol. Chem. 2010, 391, 719–730. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stroock, A.; Pagay, V.; Zwieniecki, M.; Holbrook, N. The physicochemical hydrodynamics of vascular plants. Annu. Rev. Fluid Mech. 2014, 46, 615–642. [Google Scholar] [CrossRef] [Green Version]

- Friess, K.; Izák, P.; Kárászová, M.; Pasichnyk, M.; Lanč, M.; Nikolaeva, D.; Luis, P.; Jansen, J. A review on ionic liquid gas separation membranes. Membranes 2021, 11, 97. [Google Scholar] [CrossRef]

- Liu, J.; Xu, X.; Lei, Y.; Zhang, M.; Sheng, Z.; Wang, H.; Cao, M.; Zhang, J.; Hou, X. Liquid gating meniscus-shaped deformable magnetoelastic membranes with self-driven regulation of gas/liquid release. Adv. Mater. 2022, 34, e2107327. [Google Scholar] [CrossRef]

- Yu, S.; Pan, L.; Zhang, Y.; Chen, X.; Hou, X. Liquid gating technology. Pure. Appl. Chem. 2021, 93, 1353–1370. [Google Scholar] [CrossRef]

- Zhang, R.; Lei, J.; Xu, J.; Fu, H.; Jing, Y.; Chen, B.; Hou, X. Bioinspired photo-responsive liquid gating membrane. Biomimetics 2022, 7, 47. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, H.; Mao, J.; Di, Y. An ICLS-based method for solving two-phase seepage free surface considering compressible gas in porous media. Comput. Geotech. 2022, 141, 104528. [Google Scholar] [CrossRef]

- Mietton-Peuchot, M.; Condat, C.; Courtois, T. Use of gas-liquid porometry measurements for selection of microfiltration membranes. J. Membr. Sci. 1997, 133, 73–82. [Google Scholar] [CrossRef]

- Sheng, Z.; Wang, H.; Tang, Y.; Wang, M.; Huang, L.; Min, L.; Meng, H.; Chen, S.; Jiang, L.; Hou, X. Liquid gating elastomeric porous system with dynamically controllable gas/liquid transport. Sci. Adv. 2018, 4, eaao6724. [Google Scholar] [CrossRef] [Green Version]

- Butt, H.; Graf, K.; Kappl, M. Physics and Chemistry of Interfaces; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003; pp. 118–144. [Google Scholar]

- Raturi, P.; Singh, J. An intelligent dual mode filtration device for separation of immiscible oil/water mixtures and emulsions. Appl. Surf. Sci. 2019, 484, 97–104. [Google Scholar] [CrossRef]

- Qu, M.; Abdelaziz, O.; Gao, Z.; Yin, H. Isothermal membrane-based air dehumidification: A comprehensive review. Renew. Sust. Energ. Rev. 2018, 82, 4060–4069. [Google Scholar] [CrossRef]

- Bazyar, H.; Javadpour, S.; Lammertink, R. On the gating mechanism of slippery liquid infused porous membranes. Adv. Mater. Interfaces 2016, 3, 1600025. [Google Scholar] [CrossRef]

- Bazyar, H.; Lv, P.; Wood, J.; Porada, S.; Lohse, D.; Lammertink, R. Liquid–liquid displacement in slippery liquid-infused membranes (SLIMs). Soft Matter 2018, 14, 1780–1788. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, R.; Gao, C.; Tian, L.; Wang, R.; Hong, J.; Gao, M.; Gui, L. Dynamic pneumatic rails enabled microdroplet manipulation. Lab Chip 2021, 21, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Hone, C.; Kappe, C. Membrane microreactors for the on-demand generation, separation, and reaction of gases. Chemistry 2020, 26, 13108–13117. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, G.; Yue, J. Manipulation of gas-liquid-liquid systems in continuous flow microreactors for efficient reaction processes. J. Flow. Chem. 2020, 10, 103–121. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Wang, M.; Sheng, Z.; Zhang, Y.; Wang, S.; Qiao, L.; Hou, Y.; Zhang, M.; Chen, X.; Hou, X. Mobile liquid gating membrane system for smart piston and valve applications. Ind. Eng. Chem. Res. 2019, 58, 11976–11984. [Google Scholar] [CrossRef]

- Drotman, D.; Jadhav, S.; Sharp, D.; Chan, C.; Tolley, M.T. Electronics-free pneumatic circuits for controlling soft-legged robots. Sci. Robot. 2021, 6, eaay2627. [Google Scholar] [CrossRef]

- Belding, L.; Baytekin, B.; Baytekin, H.; Rothemund, P.; Verma, M.; Nemiroski, A.; Sameoto, D.; Grzybowski, B.; Whitesides, G. Slit tubes for semisoft pneumatic actuators. Adv. Mater. 2018, 30, 1704446. [Google Scholar] [CrossRef] [Green Version]

- Akhmetshina, A.; Davletbaeva, I.; Grebenschikova, E.; Sazanova, T.; Petukhov, A.; Atlaskin, A.; Razov, E.; Zaripov, I.; Martins, C.; Neves, L.; et al. The effect of microporous polymeric support modification on surface and gas transport properties of supported ionic liquid membranes. Membranes 2016, 6, 4. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, Y.; Zhang, M.; Chen, B.; Chen, X.; Hou, X. Photothermally induced liquid gate with navigation control of the fluid transport. Fundam. Res. 2021, 1, 800–806. [Google Scholar] [CrossRef]

- Lv, W.; Sheng, Z.; Zhu, Y.; Liu, J.; Lei, Y.; Zhang, R.; Chen, X.; Hou, X. Highly stretchable and reliable graphene oxide-reinforced liquid gating membranes for tunable gas/liquid transport. Microsyst. Nanoeng. 2020, 6, 43. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Liu, J.; Cao, M.; Zhang, J.; Huang, X.; Hou, X. Self-Oscillating Liquid Gating Membranes with Periodic Gas Transport. Membranes 2022, 12, 642. https://doi.org/10.3390/membranes12070642

Xu X, Liu J, Cao M, Zhang J, Huang X, Hou X. Self-Oscillating Liquid Gating Membranes with Periodic Gas Transport. Membranes. 2022; 12(7):642. https://doi.org/10.3390/membranes12070642

Chicago/Turabian StyleXu, Xue, Jing Liu, Min Cao, Jian Zhang, Xinlu Huang, and Xu Hou. 2022. "Self-Oscillating Liquid Gating Membranes with Periodic Gas Transport" Membranes 12, no. 7: 642. https://doi.org/10.3390/membranes12070642

APA StyleXu, X., Liu, J., Cao, M., Zhang, J., Huang, X., & Hou, X. (2022). Self-Oscillating Liquid Gating Membranes with Periodic Gas Transport. Membranes, 12(7), 642. https://doi.org/10.3390/membranes12070642