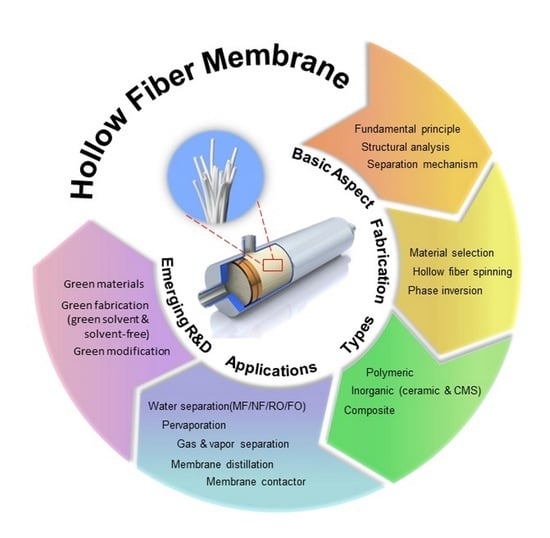

State-of-the-Art Organic- and Inorganic-Based Hollow Fiber Membranes in Liquid and Gas Applications: Looking Back and Beyond

Abstract

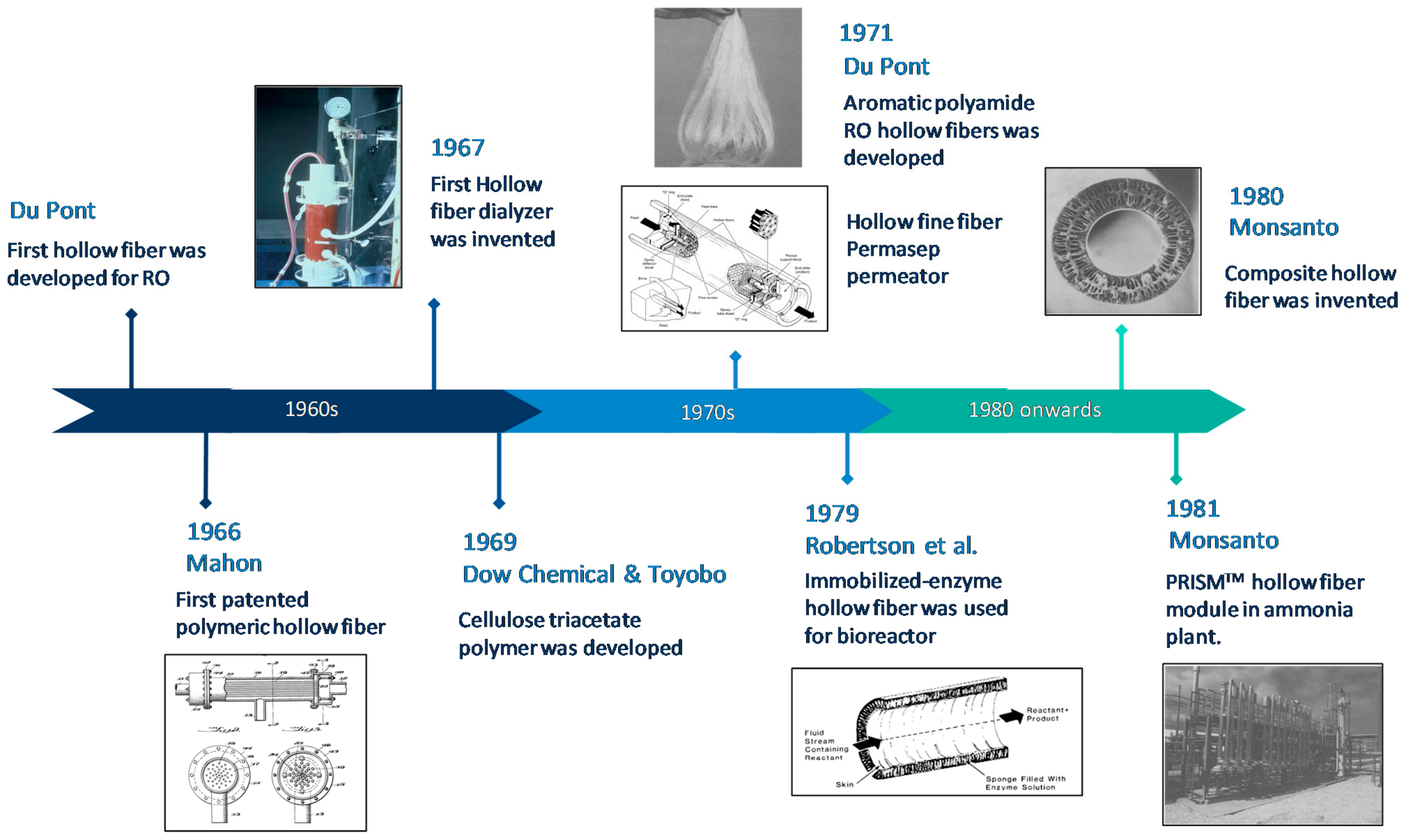

:1. Introduction

2. Fundamental Aspects of Hollow Fiber Membranes

2.1. Structural Analyses on Hollow Fiber Membrane

2.2. Phase Inversion Mechanism during Hollow Fiber Formation

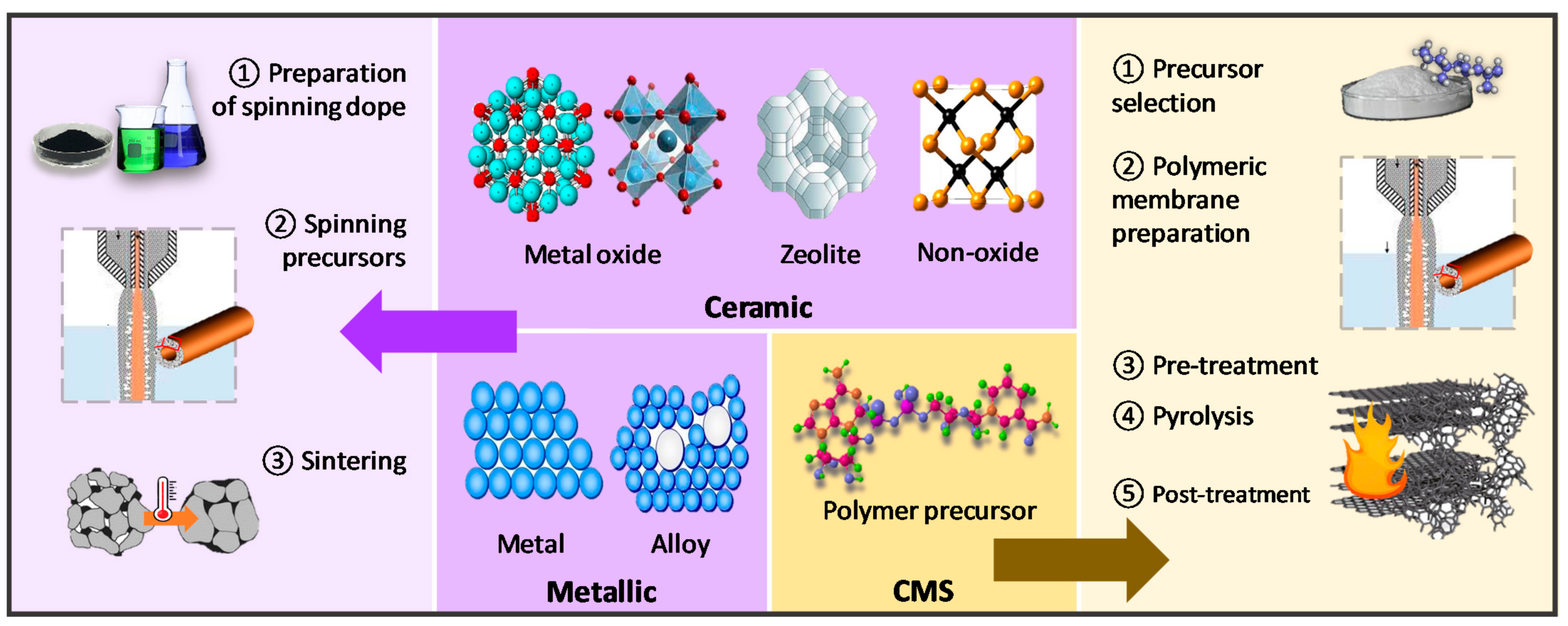

3. Types of Hollow Fiber and Their Preparation Route

3.1. Organic and Inorganic Materials-Derived Hollow Fiber Membranes

3.2. Composite Hollow Fiber Membranes

4. Applications of Hollow Fiber Membranes

4.1. Microfiltration (MF)

4.2. Nanofiltration (NF)/Organic Solvent Nanofiltration (OSN)

4.3. Reverse Osmosis (RO)/Organic Solvent Reverse Osmosis (OSRO)

4.4. Forward Osmosis (FO)/Organic Solvent Forward Osmosis (OSFO)

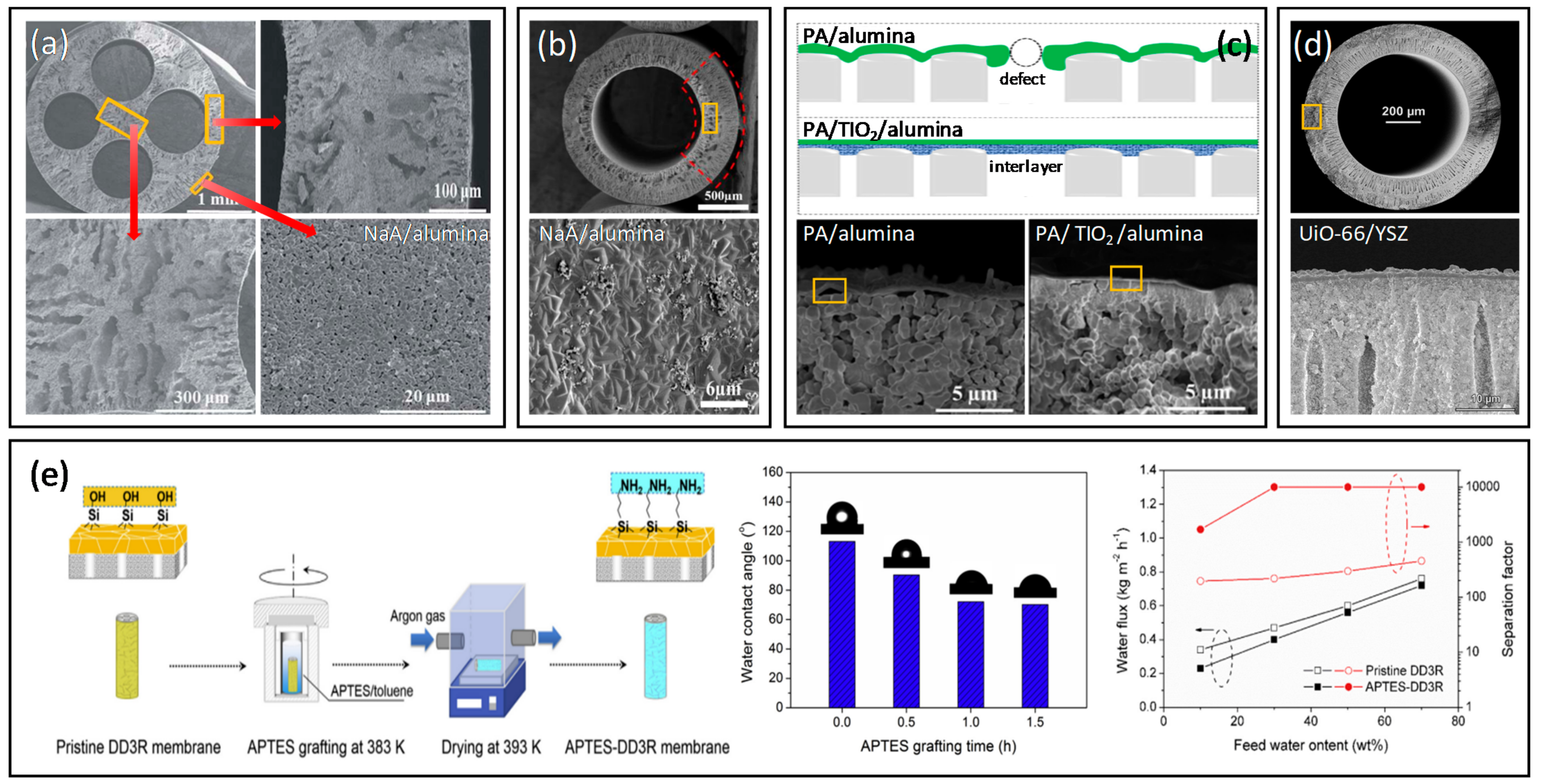

4.5. Pervaporation

| Membrane a | Water-Organic Mixture | Feed Composition (wt%) | Operating Temperature (°C) | Water Flux (kg/m2 h) | Separation Factor | Reference |

|---|---|---|---|---|---|---|

| CS-PSS/ceramic b | water-ethanol | 10/90 | 70 | 0.495 | 904 | [355] |

| NaA/alumina b | water-ethanol | 10/90 | 75 | 12.8 | 10,000 | [356] |

| NaA/alumina b | water-ethanol | 10/90 | 75 | 19.7 | >80,000 | [357] |

| T-type zeolite/YSZ b | water-ethanol | 10/90 | 70 | 0.78 | >90 | [358] |

| CTA/UiO-66-NH2/Ultem c | water-ethanol | 15/85 | 50 | 2.667 | 152 | [359] |

| PA/PES/silicon rubber d | water-ethanol | 15/85 | 50 | 7.5 | 60 | [360] |

| PA/TEPA/PAN d | water-ethanol | 10/90 | 25 | 0.342 | 366 | [361] |

| CS-PVA/PVDF b | water-isopropanol | 10/90 | 60 | 0.306 | 2140 | [362] |

| CS-TMC/alumina b | water-isopropanol | 10/90 | 70 | 0.908 | 8993 | [363] |

| CTA/Ultem b | water-isopropanol | 13.3/86.7 | 125 | 13.41 | 1332 | [364] |

| MoS2-PEI/TiO2/ceramic b | water-isopropanol | 10/90 | 70 | 5.697 | 320 | [365] |

| PA/Ultem/PDMS b | water-isopropanol | 15/85 | 50 | 2.65 | 246 | [366] |

| Teflon/Ultem b | water-isopropanol | 5/95 | 125 | 4.625 | 383 | [367] |

| T-type zeolite/YSZ b | water-isopropanol | 10/90 | 75 | 7.36 | >10,000 | [368] |

| PA/TiO2/alumina d | water-isopropanol | 10/90 | 60 | 6.44 | >12,000 | [188] |

| UiO-66/YSZ b | water-isobutanol | 5/95 | 50 | 4.81 | >45,000 | [369] |

| SA/TDI-GA/CTA-PAN d | water-isobutanol | 2/98 | 25 | 0.021 | 3229 | [370] |

| CHA zeolite/YSZ b | water-acetic acid | 50/50 | 75 | 12 | >10,000 | [372] |

| DD3R/ceramic b | water-acetic acid | 70/30 | 95 | 0.58 | 800 | [191] |

| DD3R-APTES/ceramic b | water-acetic acid | 10/90 | 75 | 0.23 | 1700 | [373] |

| SA-TDI-GA/CTA-PAN b | water-acetic acid | 5/95 | 25 | 0.012 | 708 | [370] |

| P84/EDA b | water-acetone | 15/85 | 50 | 1.8 | 53 | [374] |

| PBI/PEI’ b | water-ethyl acetate | 2/98 | 60 | 0.82 | 2478 | [375] |

| UiO-66/YSZ b | water-furfural | 5/95 | 50 | 5.95 | >45,000 | [369] |

| water-tetrahydrofuran | 5/95 | 70 | 4.06 | >45,000 | [369] | |

| T-type zeolite/alumina b | water-ethanol-acetic acid | 9.3/83.8/6.9 | 75 | 2.25 | 1348 | [395] |

| GO-PVA-TEOS/alumina b | water-isopropanol-epichlorohydrin | 20/30/50 | 30 | 0.09 | 4844 | [396] |

4.6. Gas and Vapor Separation

4.7. Membrane Distillation (MD)

4.8. Membrane Contactor

4.9. Other

5. Emerging R&D on Hollow Fiber Membranes

5.1. Green Fabrication Technique

5.1.1. Green Solvent

5.1.2. Solvent-Free Method

5.2. Modification of Hollow Fiber Membranes via Greener Approach

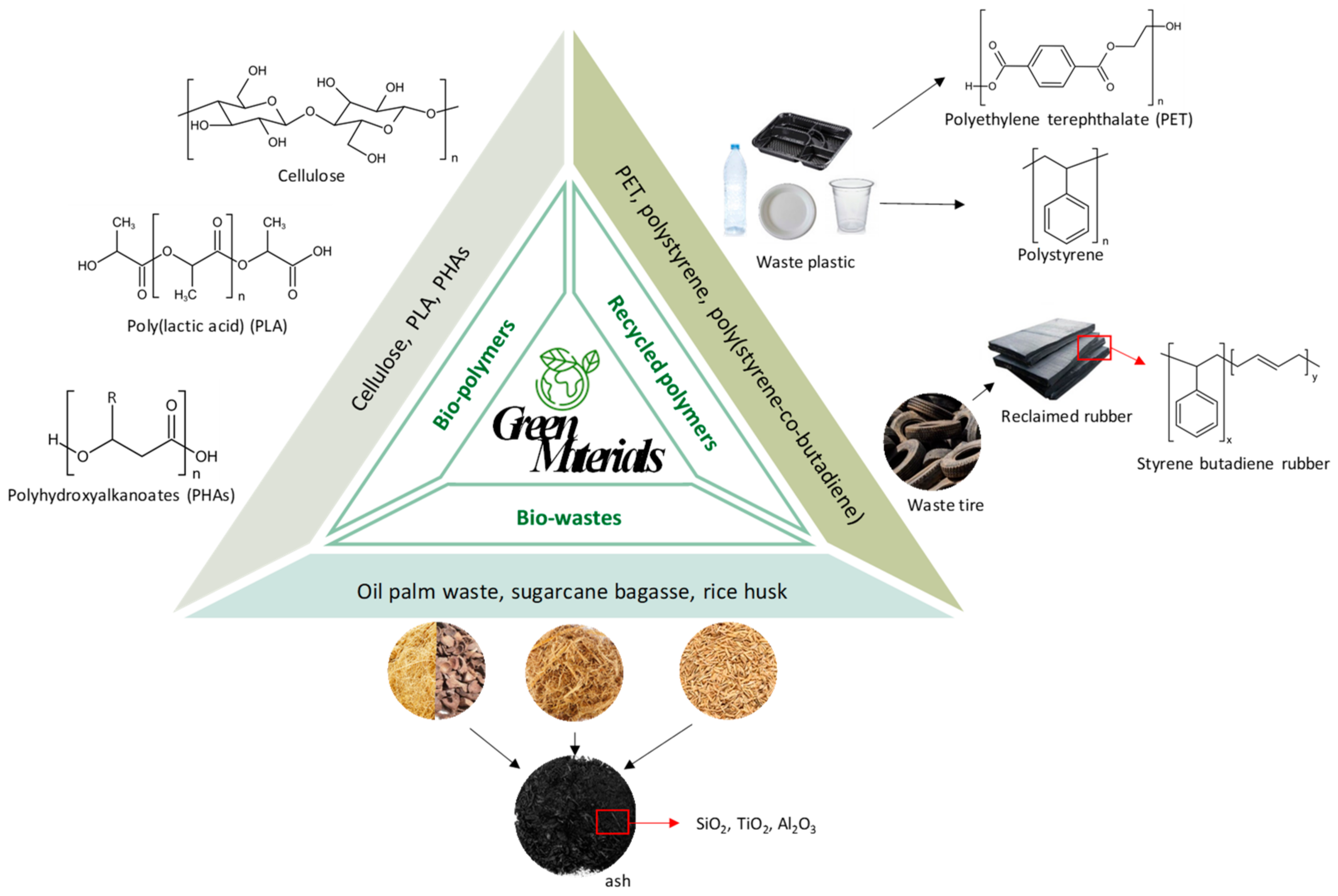

5.3. Green Materials for Hollow Fiber Membranes Fabrication

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 2D | Two-dimensional |

| 6FDA | 4,4′-(hexafluoroisopropylidene) diphthalic anhydride |

| Abn-NH | Amino functionalized acid activated bentonite clay |

| AF | Acid Fuchsin |

| Ag | Silver |

| Al2O3 | Aluminium oxide |

| APTES | 3-aminopropyltriethoxysilane |

| AR88 | Acid Red 88 |

| B2RL | Direct Fast Blue B2RL |

| BBR | Brilliant Blue R |

| BCBZ | BaCo0.85Bi0.05Zr0.1O3−δ |

| BPDA | 3,3′-4,4′-biphenyl tetracarboxylic acid dianhydride |

| BSA | Bovine serum albumin |

| BSCF | Ba0.5Sr0.5Co0.8Fe0.2O3−δ |

| BTB | Bromothymol Blue |

| C2H4 | Ethane or ethylene |

| C3H6 | Propylene or propene or paraffin |

| C3H8 | Propane or olefin |

| CECs | Contaminants of emerging concern |

| CFB | Chromatrope FB |

| CHA | Chabazite |

| CL | Chitosan lactate |

| Cl− | Chloride ions |

| CMPs | Conjugated microporous polymers |

| CMS | Carbon molecular sieve |

| CO2 | Carbon dioxide |

| COF(s) | Covalent organic framework(s) |

| CQDs | Carbon quantum dots |

| CR | Congo Red |

| CTA | Cellulose triacetate |

| c-TiO2 | Carboxylated TiO2 |

| DABA | Diaminobenzoic acid |

| DAM | 2,4,6-trimethyl-1,3-phenylene diamine |

| DAPE | 1,3-diaminopropane |

| DCMD | Direct contact membrane distillation |

| DD3R | Decadodecasil 3R |

| DES(s) | Deep eutectic solvent(s) |

| DETDA | Diethyltoluenediamine |

| DIPS | Diffusion-induced phase separation |

| DMAc | Dimethylacetamide |

| DMF | Dimethylformamide |

| DMSO | Dimethyl sulfoxide |

| DR23 | Direct Red 23 |

| EBT | Eriochrome Black T |

| ECHA | European Chemical Agency |

| EDA | Ethylenediamine |

| ETS-4 | Engelhard titanosilicate-4 |

| EVAL | Poly(ethylene vinyl) alcohol |

| Fe | Iron |

| FESEM | Field emission scanning electron microscope |

| FO | Forward osmosis |

| FRR | flux recovery ratio |

| GA | Glutaraldehyde |

| GBL | γ-butyrolactone |

| GO | Graphene oxide |

| GRL | Cationic Red X-GRL |

| GTL | Cationic red GTL |

| H2 | Hydrogen |

| H2S | Hydrogen sulfide |

| IL(s) | Ionic liquid(s) |

| K2S2O8 | Potassium persulphate |

| KNO3/KNO2-BSCF | potassium nitrate/potassium nitrite-BSCF |

| LCCF | (La0.6Ca0.4)(Co0.8Fe0.2)O3−δ |

| LCF | La0.8Ca0.2Fe0.94O3−a |

| LSC | La0.6Sr0.4CoO3−δ |

| LSCF | La0.6Sr0.4Co0.2Fe0.8O3−δ |

| MB | Methylene Blue |

| MD | Membrane distillation |

| MF | Microfiltration |

| MgCl2 | Magnesium chloride |

| MIL | Materials of Institute Lavoisier |

| MO | Methyl Orange |

| MOF(s) | Metal organic framework(s) |

| MoS2 | Molybdenum disulfide |

| MPD | M-phenylenediamine |

| MR | Methyl Red |

| MS-S | Melt-spinning and stretching |

| MWCNT | Multi-walled carbon nanotubes |

| MWCO | Molecular weight cut off |

| N2 | Nitrogen |

| Na+ | Sodium ions |

| Na+-CQDs | Sodium-functionalized CQDs |

| Na2SO4 | Sodium sulfate |

| NaCl | Sodium chloride |

| NADES | Natural deep eutectic solvent |

| NaOH | Sodium hydroxide |

| NF | Nanofiltration |

| NH2-MWCNT | Amine-functionalized MWCNT |

| NIPS | Non-solvent induced phase separation |

| NMP | N-methyl-2-pyrrolidone |

| NO | Nitric oxide |

| O2 | Oxygen |

| OARO | Osmotically assisted reverse osmosis |

| OSFO | Organic solvent forward osmosis |

| OSN | Organic solvent nanofiltration |

| OSRO | Organic solvent reverse osmosis |

| P(VTES-AA-SSNa) | Poly(triethoxyvinylsilane-acrylic acid-sodium 4-vinylbenzenssulfonate) |

| PA | Polyamide |

| PAA | Polyamic acid |

| PAN | Polyacrylonitrile |

| PANI | Polyaniline |

| PBI | Polybenzimidazole |

| PC | Polycarbonate |

| PCL | Polycaprolactone |

| Pd | Palladium |

| PDA | Polydopamine |

| PDMS | Polydimethylsiloxane |

| PEG | Polyethylene glycol |

| PEI | Polyethyleneimine |

| PEO | Polyethylene oxide |

| PES | Polyethersulfone |

| PET | Polyethylene terephthalate |

| PHAs | Polyhydroxyalkanoates |

| PI/LPSQ | Polyimide/ladder-structured polysilsesquioxane |

| PIMs | Polymers of intrinsic microporosity |

| PIP | Piperazine |

| PLA | Polylactic acid |

| PMDA-MDA | Pyromellitic dianhydride-4,4′-diaminodiphenylmethane |

| PMDA-ODA | Poly(4,4′-oxydiphenylene pyromellitimide) |

| PMIA | Poly(m-phenylene isophthalamide) |

| PMMOF | Polymer-modification-enabled in-site metal-organic framework |

| PMP | Poly(4-methyl-1-pentene) |

| PPA | Poly(piperazine-amide) |

| PPTA | Poly(p-phenylene terephthalamide) |

| PPTA | Poly(p-phenylene terephthalamide) |

| PSF | Polysulfone |

| PSS | Poly(4-styrenesulfonic acid) |

| PTFE | Polytetrafluoroethylene |

| PVA | Poly(vinyl alcohol) |

| PVDF | Polyvinylidene fluoride |

| PWP | Pure water permeability |

| RB | Rose Bengal |

| RB5 | Reactive Black 5 |

| RBB | Remazol Brilliant Blue |

| RDB | Rhodamine B |

| rGO | Reduced GO |

| RhB | Rhodamine B |

| RO | Reverse osmosis |

| RR195 | Reactive Red 195 |

| RY3 | Reactive Yellow 3 |

| SAPO-34 | Silicoaluminophosphate chabazite |

| SEM | Scanning electron microscope |

| SILMs | Supported ionic liquid membrane(s) |

| SiO2 | Silicon dioxide |

| SMA | Styrene maleic anhydride |

| SO2 | Sulfur dioxide |

| ST | Safranine T |

| TDI | 2,4-toluene diisocyanate |

| TEOS | Tetraethyl orthosilicate |

| TEP | Triethyl phosphate |

| TEPA | Tetraethylenepentamine |

| TFC | Thin film composite |

| TFN | Thin film nanocomposite |

| THF | Tetrahydrofuran |

| TiO2 | Titanium dioxide |

| TIPS | Thermally induced phase separation |

| TMC | Trimesoyl chloride |

| TR | Thermally rearraged |

| UF | Ultrafiltration |

| UiO | Universitetet i Oslo |

| VTMS | Vinyltrimethoxysilane |

| XDLVO | Extended Derjaguin-Landau-Verwey-Overbeek |

| YSZ | Yttria-stabilized zirconia |

| ZIF(s) | Zeolitic imidazolate framework(s) |

| ZnCl2 | Zinc chloride |

| ZrO2 | Zirconium dioxide |

| β-CD | β-cyclodextrin |

References

- Guo, Y.; Tong, L.; Mei, L. Evaluation and influencing factors of industrial pollution in Jilin restricted development zone: A spatial econometric analysis. Sustainability 2021, 13, 4194. [Google Scholar] [CrossRef]

- Kim, S. Membranes for water, gas and ion separation. Membranes 2021, 11, 325. [Google Scholar] [CrossRef] [PubMed]

- Brunetti, A.; Macedonio, F.; Barbieri, G.; Drioli, E. Membrane engineering for environmental protection and sustainable industrial growth: Options for water and gas treatment. Environ. Eng. Res. 2015, 20, 307–328. [Google Scholar] [CrossRef]

- Font-Palma, C.; Cann, D.; Udemu, C. Review of cryogenic carbon capture innovations and their potential applications. C 2021, 7, 58. [Google Scholar] [CrossRef]

- Sircar, S.; Golden, T. Purification of hydrogen by pressure swing adsorption. Sep. Sci. Technol. 2000, 35, 667–687. [Google Scholar] [CrossRef]

- Sholl, D.S.; Lively, R.P. Seven chemical separations to change the world. Nature 2016, 532, 435–437. [Google Scholar] [CrossRef]

- Liang, C.Z.; Chung, T.-S.; Lai, J.-Y. A review of polymeric composite membranes for gas separation and energy production. Prog. Polym. Sci. 2019, 97, 101141. [Google Scholar] [CrossRef]

- Pagliero, M.; Khayet, M.; Garcia-Payo, C.; García-Fernández, L. Hollow fibre polymeric membranes for desalination by membrane distillation technology: A review of different morphological structures and key strategic improvements. Desalination 2021, 516, 115235. [Google Scholar] [CrossRef]

- Chung, T.-S.; Feng, Y. Hollow Fiber Membranes: Fabrication and Applications; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Pagliero, M.; Comite, A.; Soda, O.; Costa, C. Effect of support on PVDF membranes for distillation process. J. Membr. Sci. 2021, 635, 119528. [Google Scholar] [CrossRef]

- Peng, N.; Widjojo, N.; Sukitpaneenit, P.; Teoh, M.M.; Lipscomb, G.G.; Chung, T.-S.; Lai, J.-Y. Evolution of polymeric hollow fibers as sustainable technologies: Past, present, and future. Prog. Polym. Sci. 2012, 37, 1401–1424. [Google Scholar] [CrossRef]

- Lau, H.S.; Yong, W.F. Recent progress and prospects of polymeric hollow fiber membranes for gas application, water vapor separation and particulate matter removal. J. Mater. Chem. A 2021, 9, 26454–26497. [Google Scholar] [CrossRef]

- Moch, I., Jr. Membranes, Hollow-Fiber; John Wiley & Sons Inc.: New York, NY, USA, 2000. [Google Scholar]

- Mahon, H.I. Permeability Separatory Apparatus, Permeability Separatory Membrane Element, Method of Making the Same and Process Utilizing the Same. U.S. Patent 3,228,876A, 11 January 1966. [Google Scholar]

- Lonsdale, H. The growth of membrane technology. J. Membr. Sci. 1982, 10, 31–181. [Google Scholar] [CrossRef]

- Mclain, E.A. Wound Hollow Fiber Permeability Apparatus and Process of Making the Same. U.S. Patent 3,422,008, 14 January 1969. [Google Scholar]

- Li, N.N.; Fane, A.G.; Ho, W.W.; Matsuura, T. Advanced Membrane Technology and Applications; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Henis, J.M.; Tripodi, M.K. A novel approach to gas separations using composite hollow fiber membranes. Sep. Sci. Technol. 1980, 15, 1059–1068. [Google Scholar] [CrossRef]

- Henis, J.M.; Tripodi, M.K. Composite hollow fiber membranes for gas separation: The resistance model approach. J. Membr. Sci. 1981, 8, 233–246. [Google Scholar] [CrossRef]

- Henis, J.M.; Tripodi, M.K. Multicomponent Membranes for Gas Separations. U.S. Patent 4,230,463, 28 October 1980. [Google Scholar]

- Waterland, L.R.; Robertson, C.R.; Michaels, A.S. Enzymatic catalysis using asymmetric hollow fiber membranes. Chem. Eng. Commun. 1975, 2, 37–47. [Google Scholar] [CrossRef]

- Bollinger, W.; Chen, G.; Metzer, T. Commerical Hydrogen Purification and Recovery Using PRISM Separators; Monsanto Co.: St. Louis, MO, USA, 1981. [Google Scholar]

- Moattari, R.M.; Mohammadi, T.; Rajabzadeh, S.; Dabiryan, H.; Matsuyama, H. Reinforced hollow fiber membranes: A comprehensive review. J. Taiwan Inst. Chem. Eng. 2021, 122, 284–310. [Google Scholar] [CrossRef]

- Jung, J.T.; Wang, H.H.; Kim, J.F.; Lee, J.; Kim, J.S.; Drioli, E.; Lee, Y.M. Tailoring nonsolvent-thermally induced phase separation (N-TIPS) effect using triple spinneret to fabricate high performance PVDF hollow fiber membranes. J. Membr. Sci. 2018, 559, 117–126. [Google Scholar] [CrossRef]

- Hassankiadeh, N.T.; Cui, Z.; Kim, J.H.; Shin, D.W.; Sanguineti, A.; Arcella, V.; Lee, Y.M.; Drioli, E. PVDF hollow fiber membranes prepared from green diluent via thermally induced phase separation: Effect of PVDF molecular weight. J. Membr. Sci. 2014, 471, 237–246. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Lu, X.; Xiao, C. Morphology changes of polyvinylidene fluoride membrane under different phase separation mechanisms. J. Membr. Sci. 2008, 320, 277–482. [Google Scholar] [CrossRef]

- Li, G.; Kujawski, W.; Válek, R.; Koter, S. A review-The development of hollow fibre membranes for gas separation processes. Int. J. Greenh. Gas Control 2021, 104, 103195. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Peng, N.; Chung, T.-S. Gas separation membranes developed through integration of polymer blending and dual-layer hollow fiber spinning process for hydrogen and natural gas enrichments. J. Membr. Sci. 2010, 349, 156–166. [Google Scholar] [CrossRef]

- Li, D.F.; Chung, T.-S.; Wang, R.; Liu, Y. Fabrication of fluoropolyimide/polyethersulfone (PES) dual-layer asymmetric hollow fiber membranes for gas separation. J. Membr. Sci. 2002, 198, 211–223. [Google Scholar] [CrossRef]

- Jo, E.-S.; An, X.; Ingole, P.G.; Choi, W.-K.; Park, Y.-S.; Lee, H.-K. CO2/CH4 separation using inside coated thin film composite hollow fiber membranes prepared by interfacial polymerization. Chin. J. Chem. Eng. 2017, 25, 278–287. [Google Scholar] [CrossRef]

- Wenten, I.; Khoiruddin, K.; Wardani, A.; Aryanti, P.; Astuti, D.; Komaladewi, A. Preparation of antifouling polypropylene/ZnO composite hollow fiber membrane by dip-coating method for peat water treatment. J. Water Process. Eng. 2020, 34, 101158. [Google Scholar] [CrossRef]

- Sharma, A.K.; Juelfs, A.; Colling, C.; Sharma, S.; Conover, S.P.; Puranik, A.A.; Chau, J.; Rodrigues, L.; Sirkar, K.K. Porous hydrophobic–hydrophilic composite hollow fiber and flat membranes prepared by plasma polymerization for direct contact membrane distillation. Membranes 2021, 11, 120. [Google Scholar] [CrossRef]

- Park, H.J.; Bhatti, U.H.; Nam, S.C.; Park, S.Y.; Lee, K.B.; Baek, I.H. Nafion/TiO2 nanoparticle decorated thin film composite hollow fiber membrane for efficient removal of SO2 gas. Sep. Purif. Technol. 2019, 211, 377–390. [Google Scholar] [CrossRef]

- Liang, C.Z.; Yong, W.F.; Chung, T.-S. High-performance composite hollow fiber membrane for flue gas and air separations. J. Membr. Sci. 2017, 541, 367–377. [Google Scholar] [CrossRef]

- Li, M.; Zhu, Z.; Zhou, M.; Jie, X.; Wang, L.; Kang, G.; Cao, Y. Removal of CO2 from biogas by membrane contactor using PTFE hollow fibers with smaller diameter. J. Membr. Sci. 2021, 627, 119232. [Google Scholar] [CrossRef]

- Naderi, A.; Chung, T.-S.; Weber, M.; Maletzko, C. High performance dual-layer hollow fiber membrane of sulfonated polyphenylsulfone/polybenzimidazole for hydrogen purification. J. Membr. Sci. 2019, 591, 117292. [Google Scholar] [CrossRef]

- Yang, D.; Barbero, R.S.; Devlin, D.J.; Cussler, E.; Colling, C.W.; Carrera, M.E. Hollow fibers as structured packing for olefin/paraffin separations. J. Membr. Sci. 2006, 279, 21–69. [Google Scholar] [CrossRef]

- Qi, Z.; Cussler, E. Microporous hollow fibers for gas absorption: II. Mass transfer across the membrane. J. Membr. Sci. 1985, 23, 333–345. [Google Scholar] [CrossRef]

- Huang, Y.; Xiao, C.; Huang, Q.; Liu, H.; Zhao, J. Progress on polymeric hollow fiber membrane preparation technique from the perspective of green and sustainable development. Chem. Eng. J. 2021, 403, 126295. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, C.; Hu, X.; Bai, Q. Preparation and properties of homogeneous-reinforced polyvinylidene fluoride hollow fiber membrane. Appl. Surf. Sci. 2013, 264, 801–810. [Google Scholar] [CrossRef]

- Hu, X.; Chen, Y.; Liang, H.; Xiao, C. Preparation of polyurethane/poly (vinylidene fluoride) blend hollow fibre membrane using melt spinning and stretching. Mater. Sci. Technol. 2011, 27, 661–665. [Google Scholar] [CrossRef]

- Aslan, T.; Arslan, S.; Eyvaz, M.; Güçlü, S.; Yüksel, E.; Koyuncu, I. A novel nanofiber microfiltration membrane: Fabrication and characterization of tubular electrospun nanofiber (TuEN) membrane. J. Membr. Sci. 2016, 520, 616–629. [Google Scholar] [CrossRef]

- Park, H.B.; Kamcev, J.; Robeson, L.M.; Elimelech, M.; Freeman, B.D. Maximizing the right stuff: The trade-off between membrane permeability and selectivity. Science 2017, 356, eaab0530. [Google Scholar] [CrossRef] [Green Version]

- Hays, S.S.; Sanyal, O.; León, N.E.; Arab, P.; Koros, W.J. Envisioned role of slit bypass pores in physical aging of carbon molecular sieve membranes. Carbon 2020, 157, 385–394. [Google Scholar] [CrossRef]

- Chen, C.-C.; Qiu, W.; Miller, S.J.; Koros, W.J. Plasticization-resistant hollow fiber membranes for CO2/CH4 separation based on a thermally crosslinkable polyimide. J. Membr. Sci. 2011, 382, 212–221. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Paul, D.R. Physical aging of thin glassy polymer films: Free volume interpretation. J. Membr. Sci. 2006, 277, 219–229. [Google Scholar] [CrossRef]

- Dong, G.; Li, H.; Chen, V. Plasticization mechanisms and effects of thermal annealing of Matrimid hollow fiber membranes for CO2 removal. J. Membr. Sci. 2011, 369, 206–220. [Google Scholar] [CrossRef]

- Alklaibi, A.M.; Lior, N. Membrane-distillation desalination: Status and potential. Desalination 2005, 171, 111–131. [Google Scholar] [CrossRef]

- Lau, S.K.; Yong, W.F. Recent progress of zwitterionic materials as antifouling membranes for ultrafiltration, nanofiltration, and reverse osmosis. ACS Appl. Polym. Mater. 2021, 3, 4390–4412. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, Y.; He, M.; Su, Y.; Zhao, X.; Elimelech, M.; Jiang, Z. Antifouling membranes for sustainable water purification: Strategies and mechanisms. Chem. Soc. Rev. 2016, 45, 5888–5924. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.U.; Othman, M.H.D.; Ismail, A.; Matsuura, T.; Hashim, H.; Nordin, N.A.H.M.; Rahman, M.A.; Jaafar, J.; Jilani, A. Status and improvement of dual-layer hollow fiber membranes via co-extrusion process for gas separation: A review. J. Nat. Gas Sci. Eng. 2018, 52, 215–234. [Google Scholar] [CrossRef]

- Castro-Muñoz, R.; Galiano, F.; Figoli, A. Recent advances in pervaporation hollow fiber membranes for dehydration of organics. Chem. Eng. Res. Des. 2020, 164, 68–85. [Google Scholar] [CrossRef]

- Sirkar, K.K. Membranes, phase interfaces, and separations: Novel techniques and membranes—An overview. Ind. Eng. Chem. Res. 2008, 47, 5250–5266. [Google Scholar] [CrossRef]

- Sewerin, T.; Elshof, M.G.; Matencio, S.; Boerrigter, M.; Yu, J.; de Grooth, J. Advances and applications of hollow fiber nanofiltration membranes: A review. Membranes 2021, 11, 890. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, Y.; Feng, Z.; Rui, X.; Zhang, T.; Zhang, Z. A review on reverse osmosis and nanofiltration membranes for water purification. Polymers 2019, 11, 1252. [Google Scholar] [CrossRef] [Green Version]

- Turken, T.; Sengur-Tasdemir, R.; Ates-Genceli, E.; Tarabara, V.V.; Koyuncu, I. Progress on reinforced braided hollow fiber membranes in separation technologies: A review. J. Water Process. Eng. 2019, 32, 100938. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Otitoju, T.A.; Ooi, B.S. Hollow fiber (HF) membrane fabrication: A review on the effects of solution spinning conditions on morphology and performance. J. Ind. Eng. Chem. 2019, 70, 35–50. [Google Scholar] [CrossRef]

- Dashti, A.; Asghari, M. Recent progresses in ceramic hollow-fiber membranes. ChemBioEng Rev. 2015, 2, 54–70. [Google Scholar] [CrossRef]

- Feng, C.; Khulbe, K.; Matsuura, T.; Ismail, A. Recent progresses in polymeric hollow fiber membrane preparation, characterization and applications. Sep. Purif. Technol. 2013, 111, 43–71. [Google Scholar] [CrossRef]

- Feng, Y.; Chung, T.-S. Chapter 1—Introduction. In Hollow Fiber Membranes; Chung, T.-S., Feng, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–11. [Google Scholar]

- Baker, R.W.; Low, B.T. Gas separation membrane materials: A perspective. Macromolecules 2014, 47, 6999–7013. [Google Scholar] [CrossRef]

- Dai, Z.; Ansaloni, L.; Deng, L. Recent advances in multi-layer composite polymeric membranes for CO2 separation: A review. Green Energy Environ. 2016, 1, 102–128. [Google Scholar] [CrossRef] [Green Version]

- Baker, R.W. Membrane Technology and Applications, 3rd ed.; John Wiley & Sons, Ltd.: San Francisco, CA, USA, 2012. [Google Scholar]

- Matsuyama, H.; Karkhanechi, H.; Rajabzadeh, S. Chapter 3—Polymeric membrane fabrication via thermally induced phase separation (TIPS) method. In Hollow Fiber Membranes; Chung, T.-S., Feng, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 57–83. [Google Scholar]

- Mulder, M.; Mulder, J. Basic Principles of Membrane Technology, 2nd ed.; Springer: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Yong, W.F.; Chung, T.-S.; Weber, M.; Maletzko, C. New polyethersulfone (PESU) hollow fiber membranes for CO2 capture. J. Membr. Sci. 2018, 552, 305–314. [Google Scholar] [CrossRef]

- Li, M.; Feng, Y.; Wang, K.; Yong, W.F.; Yu, L.; Chung, T.-S. Novel hollow fiber air filters for the removal of ultrafine particles in PM2.5 with repetitive usage capability. Environ. Sci. Technol. 2017, 51, 10041–10049. [Google Scholar] [CrossRef]

- Li, Y.; Cao, B.; Li, P. Fabrication of PMDA-ODA hollow fibers with regular cross-section morphologies and study on the formation mechanism. J. Membr. Sci. 2017, 544, 1–11. [Google Scholar] [CrossRef]

- Tham, H.M.; Wang, K.Y.; Hua, D.; Japip, S.; Chung, T.-S. From ultrafiltration to nanofiltration: Hydrazine cross-linked polyacrylonitrile hollow fiber membranes for organic solvent nanofiltration. J. Membr. Sci. 2017, 542, 289–299. [Google Scholar] [CrossRef]

- Liang, C.Z.; Liu, J.T.; Lai, J.-Y.; Chung, T.-S. High-performance multiple-layer PIM composite hollow fiber membranes for gas separation. J. Membr. Sci. 2018, 563, 93–106. [Google Scholar] [CrossRef]

- Cheng, D.; Zhao, L.; Li, N.; Smith, S.J.; Wu, D.; Zhang, J.; Ng, D.; Wu, C.; Martinez, M.R.; Batten, M.P. Aluminum fumarate MOF/PVDF hollow fiber membrane for enhancement of water flux and thermal efficiency in direct contact membrane distillation. J. Membr. Sci. 2019, 588, 117204. [Google Scholar] [CrossRef]

- Ren, J.; Wang, R. Preparation of polymeric membranes. In Membrane and Desalination Technologies; Wang, L.K., Chen, J.P., Hung, Y.-T., Shammas, N.K., Eds.; Springer: New York, NY, USA, 2011; pp. 47–100. [Google Scholar]

- Tompa, H. Polymer Solutions; Butterworths Scientific Publications: London, UK, 1956. [Google Scholar]

- Strathmann, H.; Scheible, P.; Baker, R. A rationale for the preparation of Loeb-Sourirajan-type cellulose acetate membranes. J. Appl. Polym. Sci. 1971, 15, 811–828. [Google Scholar] [CrossRef]

- Michaels, A.S. High Flow Membrane. U.S. Patent 3,615,024, 26 October 1971. [Google Scholar]

- Figoli, A.; Cassano, A.; Basile, A. Membrane Technologies for Biorefining; Woodhead Publishing: Duxford, UK, 2016. [Google Scholar]

- Purkait, M.K.; Sinha, M.K.; Mondal, P.; Singh, R. Introduction to membranes. In Interface Science and Technology; Elsevier: Amsterdam, The Netherlands, 2018; Volume 25, pp. 1–37. [Google Scholar]

- Kapantaidakis, G.; Koops, G.; Wessling, M. Effect of spinning conditions on the structure and the gas permeation properties of high flux polyethersulfone-polyimide blend hollow fibers. Desalination 2002, 144, 121–125. [Google Scholar] [CrossRef]

- Tasselli, F.; Jansen, J.; Sidari, F.; Drioli, E. Morphology and transport property control of modified poly(ether ether ketone)(PEEKWC) hollow fiber membranes prepared from PEEKWC/PVP blends: Influence of the relative humidity in the air gap. J. Membr. Sci. 2005, 255, 13–22. [Google Scholar] [CrossRef]

- Da Silva Barbosa Ferreira, R.; Dias, R.A.; Araújo, E.M.; Oliveira, S.S.L.; da Nóbrega Medeiros, V.; de Lucena Lira, H. Hollow fiber membranes of polysulfone/attapulgite for oil removal in wastewater. Polym. Bull. 2022, 1–21. [Google Scholar] [CrossRef]

- Mondal, R.; De, S. Removal of copper (II) from aqueous solution using zinc oxide nanoparticle impregnated mixed matrix hollow fiber membrane. Environ. Technol. Innov. 2022, 26, 102300. [Google Scholar] [CrossRef]

- Lim, Y.-G.; Bak, C.-u.; Kim, Y.-D. Comprehensive experimental and theoretical insights into the performance of polysulfone hollow-fiber membrane modules in biogas purification process. Chem. Eng. J. 2022, 433, 134616. [Google Scholar] [CrossRef]

- Zou, D.; Kim, H.W.; Jeon, S.M.; Lee, Y.M. Fabrication and modification of PVDF/PSF hollow-fiber membranes for ginseng extract and saline water separations via direct contact membrane distillation. J. Membr. Sci. 2022, 644, 120101. [Google Scholar] [CrossRef]

- Dibrov, G.; Kagramanov, G.; Sudin, V.; Molchanov, S.; Grushevenko, E.; Yushkin, A.; Volkov, V. Influence of draw ratio and take-up velocity on properties of ultrafiltration hollow fiber membranes from polyethersulfone. Fibers 2022, 10, 29. [Google Scholar] [CrossRef]

- Liang, C.Z.; Yong, W.F.; Wu, J.; Weber, M.; Maletzko, C.; Lai, J.-Y.; Chung, T.-S. Plasticization-enhanced trimethylbenzene functionalized polyethersulfone hollow fiber membranes for propylene and propane separation. J. Membr. Sci. 2022, 647, 120293. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Y.; Hu, X.; Guo, P. Engineering novel high-flux thin-film composite (TFC) hollow fiber nanofiltration membranes via a facile and scalable coating procedure. Desalination 2022, 526, 115531. [Google Scholar] [CrossRef]

- Czieborowski, M.; Kemperman, A.J.; Rolevink, E.; Blom, J.; Visser, T.; Philipp, B. A two-step bioluminescence assay for optimizing antibacterial coating of hollow-fiber membranes with polydopamine in an integrative approach. J. Microbiol. Methods 2022, 196, 106452. [Google Scholar] [CrossRef] [PubMed]

- Vatanpour, V.; Pasaoglu, M.E.; Barzegar, H.; Teber, O.O.; Kaya, R.; Bastug, M.; Khataee, A.; Koyuncu, I. Cellulose acetate in fabrication of polymeric membranes: A review. Chemosphere 2022, 295, 133914. [Google Scholar] [CrossRef] [PubMed]

- Sunder, N.; Fong, Y.Y.; Bustam, M.A. Investigation on the effects of air gap distance on the formation of cellulose triacetate hollow fiber membrane for CO2 and CH4 gases permeation. Mater. Today Proc. 2022, in press. [Google Scholar] [CrossRef]

- Nakao, T.; Goda, S.; Miura, Y.; Yasukawa, M.; Ishibashi, M.; Nakagawa, K.; Shintani, T.; Matsuyama, H.; Yoshioka, T. Development of cellulose triacetate asymmetric hollow fiber membranes with highly enhanced compaction resistance for osmotically assisted reverse osmosis operation applicable to brine concentration. J. Membr. Sci. 2022, 653, 120508. [Google Scholar] [CrossRef]

- Theodorakopoulos, G.V.; Karousos, D.S.; Mansouris, K.G.; Sapalidis, A.A.; Kouvelos, E.P.; Favvas, E.P. Graphene nanoplatelets based polyimide/Pebax dual-layer mixed matrix hollow fiber membranes for CO2/CH4 and He/N2 separations. Int. J. Greenh. Gas Control 2022, 114, 103588. [Google Scholar] [CrossRef]

- Wang, Z.-Y.; Li, S.; Xu, S.; Tian, L.; Su, B.; Han, L.; Mandal, B. Fundamental understanding on the preparation conditions of high-performance polyimide-based hollow fiber membranes for organic solvent nanofiltration (OSN). Sep. Purif. Technol. 2021, 254, 117600. [Google Scholar] [CrossRef]

- Wang, Q.; Wei, X.; Wang, G.-R.; Lu, T.-D.; Shi, Q.; Sun, S.-P. Inner-selective coordination nanofiltration hollow fiber membranes from assist-pressure modified substrate. J. Membr. Sci. 2021, 626, 119186. [Google Scholar] [CrossRef]

- Chen, M.; Yang, R.; Li, P. Preparation of defect-free hollow fiber membranes derived from PMDA-ODA polyimide for gas separation. Chem. Eng. Res. Des. 2022, 179, 154–161. [Google Scholar] [CrossRef]

- Mousavi, S.A.; Aboosadi, Z.A.; Mansourizadeh, A.; Honarvar, B. Surface modified porous polyetherimide hollow fiber membrane for sweeping gas membrane distillation of dyeing wastewater. Colloids. Surf. A Physicochem. Eng. Asp. 2021, 610, 125439. [Google Scholar] [CrossRef]

- Mousavi, S.; Arab Aboosadi, Z.; Mansourizadeh, A.; Honarvar, B. Modification of porous polyetherimide hollow fiber membrane by dip-coating of Zonyl® BA for membrane distillation of dyeing wastewater. Water Sci. Technol. 2021, 83, 3092–3109. [Google Scholar] [CrossRef]

- Li, G.; Knozowska, K.; Kujawa, J.; Tonkonogovas, A.; Stankevičius, A.; Kujawski, W. Fabrication of polydimethysiloxane (PDMS) dense layer on polyetherimide (PEI) hollow fiber support for the efficient CO2/N2 separation membranes. Polymers 2021, 13, 756. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Kujawski, W.; Knozowska, K.; Kujawa, J. The effects of PEI hollow fiber substrate characteristics on PDMS/PEI hollow fiber membranes for CO2/N2 separation. Membranes 2021, 11, 56. [Google Scholar] [CrossRef] [PubMed]

- Alihemati, Z.; Hashemifard, S.; Matsuura, T.; Ismail, A. On performance and fouling of thin film composite hollow Fiber membranes using polycarbonate/polyvinylchloride as porous substrates for forward osmosis applications. J. Environ. Chem. Eng. 2022, 10, 106828. [Google Scholar] [CrossRef]

- Zheng, M.; Yang, Y.; Qiao, S.; Zhou, J.; Quan, X. A porous carbon-based electro-Fenton hollow fiber membrane with good antifouling property for microalgae harvesting. J. Membr. Sci. 2021, 626, 119189. [Google Scholar] [CrossRef]

- Zou, L.; Gusnawan, P.; Jiang, Y.-B.; Zhang, G.; Yu, J. Macrovoid-inhibited PVDF hollow fiber membranes via spinning process delay for direct contact membrane distillation. ACS Appl. Mater. Interfaces 2020, 12, 28655–28668. [Google Scholar] [CrossRef]

- El-badawy, T.; Othman, M.H.D.; Adam, M.R.; Kamaludin, R.; Ismail, A.; Rahman, M.A.; Jaafar, J.; Rajabzadeh, S.; Matsuyama, H.; Usman, J. Braid-reinforced PVDF hollow fiber membranes for high-efficiency separation of oily wastewater. J. Environ. Chem. Eng. 2022, 10, 107258. [Google Scholar] [CrossRef]

- Madupathi, M.; Nandala, S.; Sundergopal, S. Experimental and modeling investigation of ultrafine polyvinylidene fluoride hollow fiber membrane module for recovery of lactic acid from aqueous solutions. Polym. Eng. Sci. 2022, 62, 758–771. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, K.-J.; Liang, C.Z.; Chung, T.-S. Mechanically strong Janus tri-bore hollow fiber membranes with asymmetric pores for anti-wetting and anti-fouling membrane distillation. Chem. Eng. J. 2022, 429, 132455. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Y.; Yang, K.; Hu, X.; Zhang, Y. Fabrication of tight GO/PVDF hollow fiber membranes with improved permeability for efficient fractionation of dyes and salts in textile wastewater. Polym. Bull. 2022, 79, 443–462. [Google Scholar] [CrossRef]

- Zakaria, N.; Zaliman, S.; Leo, C.; Ahmad, A.; Ooi, B.; Poh, P.E. 3D imprinted superhydrophobic polyvinylidene fluoride/carbon black membrane for membrane distillation with electrochemical cleaning evaluation. J. Environ. Chem. Eng. 2022, 10, 107346. [Google Scholar] [CrossRef]

- Zou, L.; Zhang, G.; Yu, J. Desirable PVDF hollow fiber membrane engineered with synergism between small molecular weight additives for DCMD treating of a hypersaline brine. J. Water Process. Eng. 2022, 45, 102528. [Google Scholar] [CrossRef]

- Zhao, B.; Shi, G.M.; Wang, K.Y.; Lai, J.-Y.; Chung, T.-S. Employing a green cross-linking method to fabricate polybenzimidazole (PBI) hollow fiber membranes for organic solvent nanofiltration (OSN). Sep. Purif. Technol. 2021, 255, 117702. [Google Scholar] [CrossRef]

- Dahe, G.J.; Singh, R.P.; Dudeck, K.W.; Yang, D.; Berchtold, K.A. Influence of non-solvent chemistry on polybenzimidazole hollow fiber membrane preparation. J. Membr. Sci. 2019, 577, 91–103. [Google Scholar] [CrossRef]

- Yong, W.F.; Li, F.Y.; Xiao, Y.C.; Chung, T.-S.; Tong, Y.W. High performance PIM-1/Matrimid hollow fiber membranes for CO2/CH4, O2/N2 and CO2/N2 separation. J. Membr. Sci. 2013, 443, 156–169. [Google Scholar] [CrossRef]

- Anderson, M.R.; Mattes, B.R.; Reiss, H.; Kaner, R.B. Conjugated polymer films for gas separations. Science 1991, 252, 1412–1415. [Google Scholar] [CrossRef]

- Pellegrino, J. The use of conducting polymers in membrane-based separations. Ann. N. Y. Acad. Sci. 2003, 984, 289–305. [Google Scholar] [CrossRef]

- Chen, D.; Miao, Y.-E.; Liu, T. Electrically conductive polyaniline/polyimide nanofiber membranes prepared via a combination of electrospinning and subsequent in situ polymerization growth. ACS Appl. Mater. Interfaces 2013, 5, 1206–1212. [Google Scholar] [CrossRef]

- Hardison, L.M.; Zhao, X.; Jiang, H.; Schanze, K.S.; Kleiman, V.D. Energy transfer dynamics in a series of conjugated polyelectrolytes with varying chain length. J. Phys. Chem. C 2008, 112, 16140–16147. [Google Scholar] [CrossRef]

- Zhao, X.; Pinto, M.R.; Hardison, L.M.; Mwaura, J.; Müller, J.; Jiang, H.; Witker, D.; Kleiman, V.D.; Reynolds, J.R.; Schanze, K.S. Variable band gap poly(arylene ethynylene) conjugated polyelectrolytes. Macromolecules 2006, 39, 6355–6366. [Google Scholar] [CrossRef]

- Masuda, T. Substituted polyacetylenes. J. Polym. Sci. Part A Polym. Chem. 2007, 45, 165–180. [Google Scholar] [CrossRef]

- Saini, N.; Pandey, K.; Awasthi, K. Conjugate polymer-based membranes for gas separation applications: Current status and future prospects. Mater. Today Chem. 2021, 22, 100558. [Google Scholar] [CrossRef]

- Bini, K.; Xu, X.; Andersson, M.R.; Wang, E. Alcohol-soluble conjugated polymers as cathode interlayers for all-polymer solar cells. ACS Appl. Energy Mater. 2018, 1, 2176–2182. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, L.; Ju, X.; He, T.; Chen, P. Molten salt assisted synthesis of microporous polyaniline nanosheets with superior gas sorption properties. Microporous Mesoporous Mater. 2018, 267, 100–106. [Google Scholar] [CrossRef]

- Majumdar, S.; Sarmah, K.; Mahanta, D. A simple route to prepare polypyrrole-coated filter papers via vapor phase polymerization and their gas sensing application. ACS Appl. Polym. Mater. 2020, 2, 1933–1942. [Google Scholar] [CrossRef]

- Huang, Y.; Zang, Y.; Xu, L.; Lei, T.; Cui, J.; Xie, Y.; Wang, J.; Jia, H.; Miao, F. Synthesis of chiral conjugated microporous polymer composite membrane and improvements in permeability and selectivity during enantioselective permeation. Sep. Purif. Technol. 2021, 266, 118529. [Google Scholar] [CrossRef]

- Monga Mulunda, M. Development of Conjugated Polymer Membranes for Gas Separation; KU Leuven: Leuven, Belgium, 2018. [Google Scholar]

- García-Fernández, L.; Wang, B.; García-Payo, M.; Li, K.; Khayet, M. Morphological design of alumina hollow fiber membranes for desalination by air gap membrane distillation. Desalination 2017, 420, 226–240. [Google Scholar] [CrossRef]

- Ko, C.C.; Chen, C.H.; Chen, Y.R.; Wu, Y.H.; Lu, S.C.; Hu, F.C.; Li, C.L.; Tung, K.L. Increasing the performance of vacuum membrane distillation using micro-structured hydrophobic aluminum hollow fiber membranes. Appl. Sci. 2017, 7, 357. [Google Scholar] [CrossRef] [Green Version]

- Magnone, E.; Lee, H.J.; Che, J.W.; Park, J.H. High-performance of modified Al2O3 hollow fiber membranes for CO2 absorption at room temperature. J. Ind. Eng. Chem. 2016, 42, 19–22. [Google Scholar] [CrossRef]

- Han, N.; Zhang, C.; Tan, X.; Wang, Z.; Kawi, S.; Liu, S. Re-evaluation of La0.6Sr0.4Co0.2Fe0.8O3−δ hollow fiber membranes for oxygen separation after long-term storage of five and ten years. J. Membr. Sci. 2019, 587, 117180. [Google Scholar] [CrossRef]

- Han, N.; Zhang, W.; Guo, W.; Xie, S.; Zhang, C.; Zhang, X.; Fransaer, J.; Liu, S. Novel oxygen permeable hollow fiber perovskite membrane with surface wrinkles. Sep. Purif. Technol. 2021, 261, 118295. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, G.; Liu, G.; Liu, Z.; Jin, W.; Xu, N. Perovskite hollow fibers with precisely controlled cation stoichiometry via one-step thermal processing. Adv. Mater. 2017, 29, 1606377. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Zheng, Q.; Wang, S.; Zhang, Z.; Liu, Z.; Zhang, G.; Jin, W. Fabrication of molten nitrate/nitrite dual-phase four-channel hollow fiber membranes for nitrogen oxides separation. J. Membr. Sci. 2021, 635, 119506. [Google Scholar] [CrossRef]

- Araki, S.; Li, T.; Li, K.; Yamamoto, H. Preparation of zeolite hollow fibers for high-efficiency cadmium removal from waste water. Sep. Purif. Technol. 2019, 221, 393–398. [Google Scholar] [CrossRef]

- Makhtar, S.N.N.M.; Rahman, M.A.; Ismail, A.F.; Othman, M.H.D.; Jaafar, J. Preparation and characterization of glass hollow fiber membrane for water purification applications. Environ. Sci. Pollut. Res. 2017, 24, 15918–15928. [Google Scholar] [CrossRef]

- Hubadillah, S.K.; Othman, M.H.D.; Ismail, A.; Rahman, M.A.; Jaafar, J. A low cost hydrophobic kaolin hollow fiber membrane (h-KHFM) for arsenic removal from aqueous solution via direct contact membrane distillation. Sep. Purif. Technol. 2019, 214, 31–39. [Google Scholar] [CrossRef]

- Lohaus, T.; De Wit, P.; Kather, M.; Menne, D.; Benes, N.; Pich, A.; Wessling, M. Tunable permeability and selectivity: Heatable inorganic porous hollow fiber membrane with a thermo-responsive microgel coating. J. Membr. Sci. 2017, 539, 451–457. [Google Scholar] [CrossRef]

- Wang, M.; Huang, M.L.; Cao, Y.; Ma, X.H.; Xu, Z.L. Fabrication, characterization and separation properties of three-channel stainless steel hollow fiber membrane. J. Membr. Sci. 2016, 515, 144–153. [Google Scholar] [CrossRef]

- Wang, M.; Song, J.; Wu, X.; Tan, X.; Meng, B.; Liu, S. Metallic nickel hollow fiber membranes for hydrogen separation at high temperatures. J. Membr. Sci. 2016, 509, 156–163. [Google Scholar] [CrossRef]

- Allioux, F.-M.; David, O.; Merenda, A.; Maina, J.W.; Benavides, M.E.; Tanaka, A.P.; Dumée, L.F. Catalytic nickel and nickel–copper alloy hollow-fiber membranes for the remediation of organic pollutants by electrocatalysis. J. Mater. Chem. A 2018, 6, 6904–6915. [Google Scholar] [CrossRef]

- Lei, L.; Pan, F.; Lindbråthen, A.; Zhang, X.; Hillestad, M.; Nie, Y.; Bai, L.; He, X.; Guiver, M.D. Carbon hollow fiber membranes for a molecular sieve with precise-cutoff ultramicropores for superior hydrogen separation. Nat. Commun. 2021, 12, 268. [Google Scholar] [CrossRef]

- Liu, L.; Liu, D.; Zhang, C. High-temperature hydrogen/propane separations in asymmetric carbon molecular sieve hollow fiber membranes. J. Membr. Sci. 2022, 642, 119978. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, K.; Sanyal, O.; Koros, W.J. Carbon molecular sieve membrane preparation by economical coating and pyrolysis of porous polymer hollow fibers. Angew. Chem. Int. Ed. 2019, 58, 12149–12153. [Google Scholar] [CrossRef]

- Qiu, W.; Xu, L.; Liu, Z.; Liu, Y.; Arab, P.; Brayden, M.; Martinez, M.; Liu, J.; Roy, A.; Koros, W.J. Surprising olefin/paraffin separation performance recovery of highly aged carbon molecular sieve hollow fiber membranes by a super-hyperaging treatment. J. Membr. Sci. 2021, 620, 118701. [Google Scholar] [CrossRef]

- Qiu, W.; Vaughn, J.; Liu, G.; Xu, L.; Brayden, M.; Martinez, M.; Fitzgibbons, T.; Wenz, G.; Koros, W.J. Hyperaging tuning of a carbon molecular-sieve hollow fiber membrane with extraordinary gas-separation performance and stability. Angew. Chem. Int. Ed. 2019, 58, 11700–11703. [Google Scholar] [CrossRef] [PubMed]

- Kamath, M.G.; Fu, S.; Itta, A.K.; Qiu, W.; Liu, G.; Swaidan, R.; Koros, W.J. 6FDA-DETDA: DABE polyimide-derived carbon molecular sieve hollow fiber membranes: Circumventing unusual aging phenomena. J. Membr. Sci. 2018, 546, 197–205. [Google Scholar] [CrossRef]

- Zhang, C.; Wenz, G.B.; Williams, P.J.; Mayne, J.M.; Liu, G.; Koros, W.J. Purification of aggressive supercritical natural gas using carbon molecular sieve hollow fiber membranes. Ind. Eng. Chem. Res. 2017, 56, 10482–10490. [Google Scholar] [CrossRef]

- Seong, J.G.; Lewis, J.C.; Matteson, J.A.; Craddock, E.; Martinez, U.; Thakkar, H.; Benavidez, A.D.; Berchtold, K.A.; Singh, R.P. Polybenzimidazole-derived carbon molecular sieve hollow fiber membranes with tailored oxygen selective transport. Carbon 2022, 192, 71–83. [Google Scholar] [CrossRef]

- Shin, J.H.; Yu, H.J.; An, H.; Lee, A.S.; Hwang, S.S.; Lee, S.Y.; Lee, J.S. Rigid double-stranded siloxane-induced high-flux carbon molecular sieve hollow fiber membranes for CO2/CH4 separation. J. Membr. Sci. 2019, 570–571, 504–512. [Google Scholar] [CrossRef]

- Ismail, A.F.; Li, K. From polymeric precursors to hollow fiber carbon and ceramic membranes. Membr. Sci. Technol. 2008, 13, 81–119. [Google Scholar]

- Reed, J.S. Principles of Ceramics Processing, 2nd ed.; Wiley: New York, NY, USA, 1995. [Google Scholar]

- Jue, M.L.; Ma, Y.; Lively, R.P. Streamlined fabrication of asymmetric carbon molecular sieve hollow fiber membranes. ACS Appl. Polym. Mater. 2019, 1, 1960–1964. [Google Scholar] [CrossRef]

- Ma, Y.; Jue, M.L.; Zhang, F.; Mathias, R.; Jang, H.Y.; Lively, R.P. Creation of well-defined “mid-sized” micropores in carbon molecular sieve membranes. Angew. Chem. Int. Ed. 2019, 58, 13259–13265. [Google Scholar] [CrossRef] [PubMed]

- Salinas, O.; Ma, X.; Litwiller, E.; Pinnau, I. Ethylene/ethane permeation, diffusion and gas sorption properties of carbon molecular sieve membranes derived from the prototype ladder polymer of intrinsic microporosity (PIM-1). J. Membr. Sci. 2016, 504, 133–140. [Google Scholar] [CrossRef] [Green Version]

- Seong, K.H.; Song, J.S.; Koh, H.C.; Ha, S.Y.; Han, M.H.; Cho, C.H. Effect of carbonization conditions on gas permeation of methyl imide based carbon molecular sieve hollow fiber membranes. Membr. J. 2013, 23, 332–342. [Google Scholar]

- Haider, S.; Lindbråthen, A.; Lie, J.A.; Andersen, I.C.T.; Hägg, M.-B. CO2 separation with carbon membranes in high pressure and elevated temperature applications. Sep. Purif. Technol. 2018, 190, 177–189. [Google Scholar] [CrossRef] [Green Version]

- Richter, H.; Voss, H.; Kaltenborn, N.; Kämnitz, S.; Wollbrink, A.; Feldhoff, A.; Caro, J.; Roitsch, S.; Voigt, I. High-flux carbon molecular sieve membranes for gas separation. Angew. Chem. Int. Ed. 2017, 56, 7760–7763. [Google Scholar] [CrossRef]

- Wijmans, J.; Hao, P. Influence of the porous support on diffusion in composite membranes. J. Membr. Sci. 2015, 494, 78–85. [Google Scholar] [CrossRef]

- Xia, Q.-C.; Liu, M.-L.; Cao, X.-L.; Wang, Y.; Xing, W.; Sun, S.-P. Structure design and applications of dual-layer polymeric membranes. J. Membr. Sci. 2018, 562, 85–111. [Google Scholar] [CrossRef]

- Xia, Q.-C.; Wang, J.; Wang, X.; Chen, B.-Z.; Guo, J.-L.; Jia, T.-Z.; Sun, S.-P. A hydrophilicity gradient control mechanism for fabricating delamination-free dual-layer membranes. J. Membr. Sci. 2017, 539, 392–402. [Google Scholar] [CrossRef]

- Hermans, S.; Bernstein, R.; Volodin, A.; Vankelecom, I.F. Study of synthesis parameters and active layer morphology of interfacially polymerized polyamide-polysulfone membranes. React. Funct. Polym. 2015, 86, 199–208. [Google Scholar] [CrossRef]

- Chen, H.Z.; Xiao, Y.C.; Chung, T.-S. Multi-layer composite hollow fiber membranes derived from poly(ethylene glycol) (PEG) containing hybrid materials for CO2/N2 separation. J. Membr. Sci. 2011, 381, 211–220. [Google Scholar] [CrossRef]

- Li, P.; Chen, H.Z.; Chung, T.-S. The effects of substrate characteristics and pre-wetting agents on PAN–PDMS composite hollow fiber membranes for CO2/N2 and O2/N2 separation. J. Membr. Sci. 2013, 434, 18–25. [Google Scholar] [CrossRef]

- Liang, C.Z.; Chung, T.-S. Robust thin film composite PDMS/PAN hollow fiber membranes for water vapor removal from humid air and gases. Sep. Purif. Technol. 2018, 202, 345–356. [Google Scholar] [CrossRef]

- Liang, C.Z.; Chung, T.S. Ultrahigh flux composite hollow fiber membrane via highly crosslinked PDMS for recovery of hydrocarbons: Propane and propene. Macromol. Rapid Commun. 2018, 39, 1700535. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.Z.; Thong, Z.; Li, P.; Chung, T.-S. High performance composite hollow fiber membranes for CO2/H2 and CO2/N2 separation. Int. J. Hydrog. Energy 2014, 39, 5043–5053. [Google Scholar] [CrossRef]

- Veríssimo, S.; Peinemann, K.V.; Bordado, J. Thin-film composite hollow fiber membranes: An optimized manufacturing method. J. Membr. Sci. 2005, 264, 48–55. [Google Scholar] [CrossRef]

- Park, C.H.; Kwak, S.J.; Choi, J.; Lee, K.; Lee, J.H. Fabrication of a pilot scale module of thin film composite hollow fiber membrane for osmotic pressure-driven processes. J. Appl. Polym. Sci. 2018, 135, 46110. [Google Scholar] [CrossRef]

- Ren, J.; McCutcheon, J.R. Making thin film composite hollow fiber forward osmosis membranes at the module scale using commercial ultrafiltration membranes. Ind. Eng. Chem. Res. 2017, 56, 4074–4082. [Google Scholar] [CrossRef]

- Sun, S.-P.; Chung, T.-S. Outer-selective pressure-retarded osmosis hollow fiber membranes from vacuum-assisted interfacial polymerization for osmotic power generation. Environ. Sci. Technol. 2013, 47, 13167–13174. [Google Scholar] [CrossRef]

- Choi, O.; Peck, D.-H.; Park, C.H. High-performance nanofiltration of outer-selective thin-film composite hollow-fiber membranes via continuous interfacial polymerization. J. Ind. Eng. Chem. 2021, 103, 373–380. [Google Scholar] [CrossRef]

- Khulbe, K.C.; Matsuura, T. Thin film composite and/or thin film nanocomposite hollow fiber membrane for water treatment, pervaporation, and gas/vapor separation. Polymers 2018, 10, 1051. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Wang, Z.; Li, S.; Zhang, C.; Wang, J.; Wang, S. A high performance antioxidative and acid resistant membrane prepared by interfacial polymerization for CO2 separation from flue gas. Energy Environ. Sci. 2013, 6, 539–551. [Google Scholar] [CrossRef]

- Hu, L.; Cheng, J.; Li, Y.; Liu, J.; Zhou, J.; Cen, K. Amino-functionalized surface modification of polyacrylonitrile hollow fiber-supported polydimethylsiloxane membranes. Appl. Surf. Sci. 2017, 413, 27–34. [Google Scholar] [CrossRef]

- Zhou, F.; Tien, H.N.; Xu, W.L.; Chen, J.T.; Liu, Q.; Hicks, E.; Fathizadeh, M.; Li, S.; Yu, M. Ultrathin graphene oxide-based hollow fiber membranes with brush-like CO2-philic agent for highly efficient CO2 capture. Nat. Commun. 2017, 8, 2107. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, F.; Tien, H.N.; Dong, Q.; Xu, W.L.; Li, H.; Li, S.; Yu, M. Ultrathin, ethylenediamine-functionalized graphene oxide membranes on hollow fibers for CO2 capture. J. Membr. Sci. 2019, 573, 184–191. [Google Scholar] [CrossRef]

- Yong, W.F.; Zhang, H. Recent advances in polymer blend membranes for gas separation and pervaporation. Prog. Mater. Sci. 2021, 116, 100713. [Google Scholar] [CrossRef]

- Govardhan, B.; Chandrasekhar, S.; Sridhar, S. Purification of surface water using novel hollow fiber membranes prepared from polyetherimide/polyethersulfone blends. J. Environ. Chem. Eng. 2017, 5, 1068–1078. [Google Scholar] [CrossRef]

- Ter Beek, O.; Pavlenko, D.; Stamatialis, D. Hollow fiber membranes for long-term hemodialysis based on polyethersulfone-SlipSkin™ polymer blends. J. Membr. Sci. 2020, 604, 118068. [Google Scholar] [CrossRef]

- Wu, P.; Jiang, L.Y.; Hu, B. Fabrication of novel PVDF/(PVDF-co-HFP) blend hollow fiber membranes for DCMD. J. Membr. Sci. 2018, 566, 442–454. [Google Scholar] [CrossRef]

- Noor, N.; Koll, J.; Scharnagl, N.; Abetz, C.; Abetz, V. Hollow fiber membranes of blends of polyethersulfone and sulfonated polymers. Membranes 2018, 8, 54. [Google Scholar] [CrossRef] [Green Version]

- Sikorska, W.; Wasyłeczko, M.; Przytulska, M.; Wojciechowski, C.; Rokicki, G.; Chwojnowski, A. Chemical degradation of PSF-PUR blend hollow fiber membranes-assessment of changes in properties and morphology after hydrolysis. Membranes 2021, 11, 51. [Google Scholar] [CrossRef]

- Fosi-Kofal, M.; Mustafa, A.; Ismail, A.; Rezaei-DashtArzhandi, M.; Matsuura, T. PVDF/CaCO3 composite hollow fiber membrane for CO2 absorption in gas-liquid membrane contactor. J. Nat. Gas Sci. Eng. 2016, 31, 428–436. [Google Scholar] [CrossRef]

- Villalobos, L.F.; Hilke, R.; Akhtar, F.H.; Peinemann, K.V. Fabrication of polybenzimidazole/palladium nanoparticles hollow fiber membranes for hydrogen purification. Adv. Energy Mater. 2018, 8, 1701567. [Google Scholar] [CrossRef]

- Jamil, A.; Oh, P.C.; Shariff, A.M. Polyetherimide-montmorillonite mixed matrix hollow fibre membranes: Effect of inorganic/organic montmorillonite on CO2/CH4 separation. Sep. Purif. Technol. 2018, 206, 256–267. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, K.; Zhang, C.; Koros, W.J. Carbon molecular sieve hollow fiber membranes derived from dip-coated precursor hollow fibers comprising nanoparticles. J. Membr. Sci. 2022, 649, 120279. [Google Scholar] [CrossRef]

- Choi, O.; Kim, Y.; Jeon, J.-D.; Kim, T.-H. Preparation of thin film nanocomposite hollow fiber membranes with polydopamine-encapsulated Engelhard titanosilicate-4 for gas separation applications. J. Membr. Sci. 2021, 620, 118946. [Google Scholar] [CrossRef]

- Dong, Z.; Zhu, H.; Hang, Y.; Liu, G.; Jin, W. Polydimethylsiloxane (PDMS) composite membrane fabricated on the inner surface of a ceramic hollow fiber: From single-channel to multi-channel. Engineering 2020, 6, 89–99. [Google Scholar] [CrossRef]

- Wan, C.F.; Yang, T.; Gai, W.; De Lee, Y.; Chung, T.-S. Thin-film composite hollow fiber membrane with inorganic salt additives for high mechanical strength and high power density for pressure-retarded osmosis. J. Membr. Sci. 2018, 555, 388–397. [Google Scholar] [CrossRef]

- Abdullah, N.; Rahman, M.A.; Othman, M.H.D.; Ismail, A.; Jaafar, J.; Abd Aziz, A. Preparation and characterization of self-cleaning alumina hollow fiber membrane using the phase inversion and sintering technique. Ceram. Int. 2016, 42, 12312–12322. [Google Scholar] [CrossRef]

- Lin, Y.; Xu, Y.; Loh, C.H.; Wang, R. Development of robust fluorinated TiO2/PVDF composite hollow fiber membrane for CO2 capture in gas-liquid membrane contactor. Appl. Surf. Sci. 2018, 436, 670–681. [Google Scholar] [CrossRef]

- Liu, X.-W.; Cao, Y.; Li, Y.-X.; Xu, Z.-L.; Li, Z.; Wang, M.; Ma, X.-H. High-performance polyamide/ceramic hollow fiber TFC membranes with TiO2 interlayer for pervaporation dehydration of isopropanol solution. J. Membr. Sci. 2019, 576, 26–35. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, Y.; Zhang, X.; Hu, X.; Wang, C.; Yang, Y. Preparation and characterization of PSF-TiO2 hybrid hollow fiber UF membrane by sol-gel method. J. Polym. Res. 2020, 27, 1–9. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, J.; Pati, S.; Chen, T.; Deng, Y.; Dewangan, N.; Meng, L.; Lin, J.Y.; Kawi, S. High H2 permeable SAPO-34 hollow fiber membrane for high temperature propane dehydrogenation application. AIChE J. 2020, 66, e16278. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Shi, R.; Du, P.; Qiu, X.; Gu, X. Pervaporation dehydration of acetic acid through hollow fiber supported DD3R zeolite membrane. Sep. Purif. Technol. 2018, 204, 234–242. [Google Scholar] [CrossRef]

- Muhamad, N.; Makhtar, S.N.N.M.; Abdullah, N.; Pauzi, M.Z.M.; Mahpoz, N.M.A.; Othman, M.H.D.; Jaafar, J.; Abas, K.H.; Fadil, N.A.; Rahman, M.A. Composite zeolite hollow fiber membrane for the removal of nickel using forward osmosis. J. Water Process. Eng. 2021, 40, 101806. [Google Scholar] [CrossRef]

- Amirabedi, P.; Akbari, A.; Yegani, R. Fabrication of hydrophobic PP/CH3SiO2 composite hollow fiber membrane for membrane contactor application. Sep. Purif. Technol. 2019, 228, 115689. [Google Scholar] [CrossRef]

- Gong, H.; Pang, H.; Du, M.; Chen, Z. Fabrication of a superhydrophobic mixed matrix PVDF-SiO2-HDTMS hollow fiber membrane for membrane contact carbon dioxide absorption. Clean. Eng. Technol. 2021, 5, 100278. [Google Scholar] [CrossRef]

- Zhang, H.; Li, B.; Sun, D.; Miao, X.; Gu, Y. SiO2-PDMS-PVDF hollow fiber membrane with high flux for vacuum membrane distillation. Desalination 2018, 429, 33–43. [Google Scholar] [CrossRef]

- Marti, A.M.; Wickramanayake, W.; Dahe, G.; Sekizkardes, A.; Bank, T.L.; Hopkinson, D.P.; Venna, S.R. Continuous flow processing of ZIF-8 membranes on polymeric porous hollow fiber supports for CO2 capture. ACS Appl. Mater. Interfaces 2017, 9, 5678–5682. [Google Scholar] [CrossRef]

- Etxeberria-Benavides, M.; Johnson, T.; Cao, S.; Zornoza, B.; Coronas, J.; Sanchez-Lainez, J.; Sabetghadam, A.; Liu, X.; Andres-Garcia, E.; Kapteijn, F.; et al. PBI mixed matrix hollow fiber membrane: Influence of ZIF-8 filler over H2/CO2 separation performance at high temperature and pressure. Sep. Purif. Technol. 2020, 237, 116347. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, Y.; Wang, R. Thin film nanocomposite hollow fiber membranes incorporated with surface functionalized HKUST-1 for highly-efficient reverses osmosis desalination process. J. Membr. Sci. 2019, 589, 117249. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Li, Q.; Liu, G.; Liu, G.; Jin, W. Mixed-matrix hollow fiber composite membranes comprising of PEBA and MOF for pervaporation separation of ethanol/water mixtures. Sep. Purif. Technol. 2019, 214, 2–10. [Google Scholar] [CrossRef]

- Zhu, J.; Meng, X.; Zhao, J.; Jin, Y.; Yang, N.; Zhang, S.; Sunarso, J.; Liu, S. Facile hydrogen/nitrogen separation through graphene oxide membranes supported on YSZ ceramic hollow fibers. J. Membr. Sci. 2017, 535, 143–150. [Google Scholar] [CrossRef]

- Qu, K.; Dai, L.; Xia, Y.; Wang, Y.; Zhang, D.; Wu, Y.; Yao, Z.; Huang, K.; Guo, X.; Xu, Z. Self-crosslinked MXene hollow fiber membranes for H2/CO2 separation. J. Membr. Sci. 2021, 638, 119669. [Google Scholar] [CrossRef]

- Janakiram, S.; Espejo, J.L.M.; Høisæter, K.K.; Lindbråthen, A.; Ansaloni, L.; Deng, L. Three-phase hybrid facilitated transport hollow fiber membranes for enhanced CO2 separation. Appl. Mater. Today 2020, 21, 100801. [Google Scholar] [CrossRef]

- Syed Ibrahim, G.; Isloor, A.M.; Ismail, A.; Farnood, R. One-step synthesis of zwitterionic graphene oxide nanohybrid: Application to polysulfone tight ultrafiltration hollow fiber membrane. Sci. Rep. 2020, 10, 6880. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, W.; Zhang, X.; Qin, L.; Li, X.; Meng, Q.; Shen, C.; Zhang, G. Enhanced MPBR with polyvinylpyrrolidone-graphene oxide/PVDF hollow fiber membrane for efficient ammonia nitrogen wastewater treatment and high-density Chlorella cultivation. Chem. Eng. J. 2020, 379, 122368. [Google Scholar] [CrossRef]

- Xu, Y.; Lin, Y.; Lee, M.; Malde, C.; Wang, R. Development of low mass-transfer-resistance fluorinated TiO2-SiO2/PVDF composite hollow fiber membrane used for biogas upgrading in gas-liquid membrane contactor. J. Membr. Sci. 2018, 552, 253–264. [Google Scholar] [CrossRef]

- Zhu, L.; Ji, J.; Wang, S.; Xu, C.; Yang, K.; Xu, M. Removal of Pb (II) from wastewater using Al2O3-NaA zeolite composite hollow fiber membranes synthesized from solid waste coal fly ash. Chemosphere 2018, 206, 278–284. [Google Scholar] [CrossRef]

- Wang, S.; Tian, J.; Wang, Q.; Zhao, Z.; Cui, F.; Li, G. Low-temperature sintered high-strength CuO doped ceramic hollow fiber membrane: Preparation, characterization and catalytic activity. J. Membr. Sci. 2019, 570, 333–342. [Google Scholar] [CrossRef]

- Charcosset, C. Membrane Processes in Biotechnology and Pharmaceutics; Elsevier: Oxford, UK, 2012. [Google Scholar]

- Manni, A.; Achiou, B.; Karim, A.; Harrati, A.; Sadik, C.; Ouammou, M.; Alami Younssi, S.; El Bouari, A. New low-cost ceramic microfiltration membrane made from natural magnesite for industrial wastewater treatment. J. Environ. Chem. Eng. 2020, 8, 103906. [Google Scholar] [CrossRef]

- Goswami, L.; Kumar, R.V.; Pakshirajan, K.; Pugazhenthi, G. A novel integrated biodegradation-microfiltration system for sustainable wastewater treatment and energy recovery. J. Hazard. Mater. 2019, 365, 707–715. [Google Scholar] [CrossRef] [PubMed]

- Carter, B.; DiMarzo, L.; Pranata, J.; Barbano, D.M.; Drake, M. Efficiency of removal of whey protein from sweet whey using polymeric microfiltration membranes. J. Dairy Sci. 2021, 104, 8630–8643. [Google Scholar] [CrossRef] [PubMed]

- Doulia, D.S.; Anagnos, E.K.; Liapis, K.S.; Klimentzos, D.A. Removal of pesticides from white and red wines by microfiltration. J. Hazard. Mater. 2016, 317, 135–146. [Google Scholar] [CrossRef] [PubMed]

- Rouquié, C.; Dahdouh, L.; Delalonde, M.; Wisniewski, C. New prospects for immersed hollow-fiber membranes in fruit juices microfiltration: Case of grapefruit juice. J. Food Eng. 2019, 246, 75–85. [Google Scholar] [CrossRef]

- Liu, D.; Zhu, J.; Qiu, M.; He, C. Antifouling performance of poly (lysine methacrylamide)-grafted PVDF microfiltration membrane for solute separation. Sep. Purif. Technol. 2016, 171, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Hernández, S.; Lei, S.; Rong, W.; Ormsbee, L.; Bhattacharyya, D. Functionalization of flat sheet and hollow fiber microfiltration membranes for water applications. ACS Sustain. Chem. Eng. 2016, 4, 907–918. [Google Scholar] [CrossRef] [Green Version]

- Zhu, L.; Chen, M.; Dong, Y.; Tang, C.Y.; Huang, A.; Li, L. A low-cost mullite-titania composite ceramic hollow fiber microfiltration membrane for highly efficient separation of oil-in-water emulsion. Water Res. 2016, 90, 277–285. [Google Scholar] [CrossRef]

- Schopf, R.; Schmidt, F.; Linner, J.; Kulozik, U. Comparative assessment of tubular ceramic, spiral wound, and hollow fiber membrane microfiltration module systems for milk protein fractionation. Foods 2021, 10, 692. [Google Scholar] [CrossRef]

- Schopf, R.; Schmidt, F.; Kulozik, U. Impact of hollow fiber membrane length on the milk protein fractionation. J. Membr. Sci. 2021, 620, 118834. [Google Scholar] [CrossRef]

- Giacobbo, A.; Meneguzzi, A.; Bernardes, A.M.; de Pinho, M.N. Pressure-driven membrane processes for the recovery of antioxidant compounds from winery effluents. J. Clean. Prod. 2017, 155, 172–178. [Google Scholar] [CrossRef]

- Mondal, M.; De, S. Enrichment of (−) epigallocatechin gallate (EGCG) from aqueous extract of green tea leaves by hollow fiber microfiltration: Modeling of flux decline and identification of optimum operating conditions. Sep. Purif. Technol. 2018, 206, 107–117. [Google Scholar] [CrossRef]

- Behroozi, A.H.; Ataabadi, M.R. Improvement in microfiltration process of oily wastewater: A comprehensive review over two decades. J. Environ. Chem. Eng. 2021, 9, 104981. [Google Scholar] [CrossRef]

- Abd Aziz, M.H.; Othman, M.H.D.; Hashim, N.A.; Adam, M.R.; Mustafa, A. Fabrication and characterization of mullite ceramic hollow fiber membrane from natural occurring ball clay. Appl. Clay Sci. 2019, 177, 51–62. [Google Scholar] [CrossRef]

- Bai, Z.; Zhang, R.; Wang, S.; Gao, S.; Tian, J. Membrane fouling behaviors of ceramic hollow fiber microfiltration (MF) membranes by typical organic matters. Sep. Purif. Technol. 2021, 274, 118951. [Google Scholar] [CrossRef]

- He, Z.; Lyu, Z.; Gu, Q.; Zhang, L.; Wang, J. Ceramic-based membranes for water and wastewater treatment. Colloids. Surf. A Physicochem. Eng. Asp. 2019, 578, 123513. [Google Scholar] [CrossRef]

- Abadikhah, H.; Wang, J.-W.; Xu, X.; Agathopoulos, S. SiO2 nanoparticles modified Si3N4 hollow fiber membrane for efficient oily wastewater microfiltration. J. Water Process. Eng. 2019, 29, 100799. [Google Scholar] [CrossRef]

- Hubadillah, S.K.; Othman, M.H.D.; Rahman, M.A.; Ismail, A.; Jaafar, J. Preparation and characterization of inexpensive kaolin hollow fibre membrane (KHFM) prepared using phase inversion/sintering technique for the efficient separation of real oily wastewater. Arab. J. Chem. 2020, 13, 2349–2367. [Google Scholar] [CrossRef]

- Paul, M.; Jons, S.D. Chemistry and fabrication of polymeric nanofiltration membranes: A review. Polymer 2016, 103, 417–456. [Google Scholar] [CrossRef]

- Labban, O.; Liu, C.; Chong, T.H. Fundamentals of low-pressure nanofiltration: Membrane characterization, modeling, and understanding the multi-ionic interactions in water softening. J. Membr. Sci. 2017, 521, 18–32. [Google Scholar] [CrossRef]

- Setiawan, L.; Shi, L.; Wang, R. Dual layer composite nanofiltration hollow fiber membranes for low-pressure water softening. Polymer 2014, 55, 1367–1374. [Google Scholar] [CrossRef]

- Lidén, A.; Lavonen, E.; Persson, K.M.; Larson, M. Integrity breaches in a hollow fiber nanofilter–Effects on natural organic matter and virus-like particle removal. Water Res. 2016, 105, 231–240. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Dorji, P.; Shon, H.K.; Hong, S. Applications of capacitive deionization: Desalination, softening, selective removal, and energy efficiency. Desalination 2019, 449, 118–130. [Google Scholar] [CrossRef]

- Sengur-Tasdemir, R.; Urper-Bayram, G.M.; Turken, T.; Ates-Genceli, E.; Tarabara, V.V.; Koyuncu, I. Hollow fiber nanofiltration membranes for surface water treatment: Performance evaluation at the pilot scale. J. Water Process. Eng. 2021, 42, 102100. [Google Scholar] [CrossRef]

- Conidi, C.; Castro-Muñoz, R.; Cassano, A. Membrane-based operations in the fruit juice processing industry: A review. Beverages 2020, 6, 18. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Zeng, X.; Shi, W.; Zhang, H.; Huang, S.; Zhou, R.; Qin, X. Recovery and purification of potato proteins from potato starch wastewater by hollow fiber separation membrane integrated process. Innov. Food Sci. Emerg. Technol. 2020, 63, 102380. [Google Scholar] [CrossRef]

- Paltrinieri, L.; Remmen, K.; Müller, B.; Chu, L.; Köser, J.; Wintgens, T.; Wessling, M.; de Smet, L.C.; Sudhölter, E.J. Improved phosphoric acid recovery from sewage sludge ash using layer-by-layer modified membranes. J. Membr. Sci. 2019, 587, 117162. [Google Scholar] [CrossRef]

- Remmen, K.; Müller, B.; Köser, J.; Wessling, M.; Wintgens, T. Assessment of layer-by-layer modified nanofiltration membrane stability in phosphoric acid. Membranes 2020, 10, 61. [Google Scholar] [CrossRef] [Green Version]

- Remmen, K.; Schäfer, R.; Hedwig, S.; Wintgens, T.; Wessling, M.; Lenz, M. Layer-by-layer membrane modification allows scandium recovery by nanofiltration. Environ. Sci. Water Res. Technol. 2019, 5, 1683–1688. [Google Scholar] [CrossRef]

- Kazemabad, M.; Verliefde, A.; Cornelissen, E.R.; D’Haese, A. Crown ether containing polyelectrolyte multilayer membranes for lithium recovery. J. Membr. Sci. 2020, 595, 117432. [Google Scholar] [CrossRef]

- Bóna, Á.; Bakonyi, P.; Galambos, I.; Bélafi-Bakó, K.; Nemestóthy, N. Separation of volatile fatty acids from model anaerobic effluents using various membrane technologies. Membranes 2020, 10, 252. [Google Scholar] [CrossRef]

- Monte, J.; Sá, M.; Galinha, C.F.; Costa, L.; Hoekstra, H.; Brazinha, C.; Crespo, J.G. Harvesting of Dunaliella salina by membrane filtration at pilot scale. Sep. Purif. Technol. 2018, 190, 252–260. [Google Scholar] [CrossRef]

- Avram, A.M.; Ahmadiannamini, P.; Vu, A.; Qian, X.; Sengupta, A.; Wickramasinghe, S.R. Polyelectrolyte multilayer modified nanofiltration membranes for the recovery of ionic liquid from dilute aqueous solutions. J. Appl. Polym. Sci. 2017, 134, 45349. [Google Scholar] [CrossRef]

- Wang, Q.; Lu, T.-D.; Yan, X.-Y.; Zhao, L.-L.; Yin, H.; Xiong, X.-X.; Zhou, R.; Sun, S.-P. Designing nanofiltration hollow fiber membranes based on dynamic deposition technology. J. Membr. Sci. 2020, 610, 118336. [Google Scholar] [CrossRef]

- He, Y.; Miao, J.; Chen, S.; Zhang, R.; Zhang, L.; Tang, H.; Yang, H. Preparation and characterization of a novel positively charged composite hollow fiber nanofiltration membrane based on chitosan lactate. RSC Adv. 2019, 9, 4361–4369. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Haghighat, N.; Vatanpour, V. Fouling decline and retention increase of polyvinyl chloride nanofiltration membranes blended by polypyrrole functionalized multiwalled carbon nanotubes. Mater. Today Commun. 2020, 23, 100851. [Google Scholar] [CrossRef]

- Rohani, R.; Yusoff, I.I. Towards electrically tunable nanofiltration membranes: Polyaniline-coated polyvinylidene fluoride membranes with tunable permeation properties. Iran. Polym. J. 2019, 28, 789–800. [Google Scholar] [CrossRef]

- Ma, G.; Zhao, S.; Wang, Y.; Wang, Z.; Wang, J. Conjugated polyaniline derivative membranes enable ultrafast nanofiltration and organic-solvent nanofiltration. J. Membr. Sci. 2022, 645, 120241. [Google Scholar] [CrossRef]

- Xia, L.; Ren, J.; McCutcheon, J.R. Braid-reinforced thin film composite hollow fiber nanofiltration membranes. J. Membr. Sci. 2019, 585, 109–114. [Google Scholar] [CrossRef]

- Wang, T.; He, X.; Li, Y.; Li, J. Novel poly (piperazine-amide)(PA) nanofiltration membrane based poly (m-phenylene isophthalamide)(PMIA) hollow fiber substrate for treatment of dye solutions. Chem. Eng. J. 2018, 351, 1013–1026. [Google Scholar] [CrossRef]

- Tian, L.; Jiang, Y.; Li, S.; Han, L.; Su, B. Graphene oxide interlayered thin-film nanocomposite hollow fiber nanofiltration membranes with enhanced aqueous electrolyte separation performance. Sep. Purif. Technol. 2020, 248, 117153. [Google Scholar] [CrossRef]

- Liu, G.; Jin, W.; Xu, N. Graphene-based membranes. Chem. Soc. Rev. 2015, 44, 5016–5030. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Guo, Y.; Meng, B.; Wang, Z.; Liu, G.; Jin, W. Two-dimensional MXene hollow fiber membrane for divalent ions exclusion from water. Chin. J. Chem. Eng. 2022, 41, 260–266. [Google Scholar] [CrossRef]

- Van der Bruggen, B.; Daems, B.; Wilms, D.; Vandecasteele, C. Mechanisms of retention and flux decline for the nanofiltration of dye baths from the textile industry. Sep. Purif. Technol. 2001, 22, 519–528. [Google Scholar] [CrossRef]

- Koyuncu, I.; Topacik, D.; Yuksel, E. Reuse of reactive dyehouse wastewater by nanofiltration: Process water quality and economical implications. Sep. Purif. Technol. 2004, 36, 77–85. [Google Scholar] [CrossRef]

- Chu, Z.; Chen, K.; Xiao, C.; Ji, D.; Ling, H.; Li, M.; Liu, H. Improving pressure durability and fractionation property via reinforced PES loose nanofiltration hollow fiber membranes for textile wastewater treatment. J. Taiwan Inst. Chem. Eng. 2020, 108, 71–81. [Google Scholar] [CrossRef]

- Song, C.; Tang, S.; Yue, S.; Cui, Z.; Du, X.; Jiang, T.; He, B.; Li, J. Design of microstructure for hollow fiber loose nanofiltration separation layer and its compactness-tailoring mechanism. J. Hazard. Mater. 2022, 421, 126800. [Google Scholar] [CrossRef] [PubMed]

- Shi, W.; Li, T.; Li, H.; Du, Q.; Zhang, H.; Qin, X. An attempt to enhance water flux of hollow fiber polyamide composite nanofiltration membrane by the incorporation of hydrophilic and compatible PPTA/PSF microparticles. Sep. Purif. Technol. 2022, 280, 119821. [Google Scholar] [CrossRef]

- Tan, Z.; Chen, S.; Peng, X.; Zhang, L.; Gao, C. Polyamide membranes with nanoscale Turing structures for water purification. Science 2018, 360, 518–521. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marchetti, P.; Jimenez Solomon, M.F.; Szekely, G.; Livingston, A.G. Molecular separation with organic solvent nanofiltration: A critical review. Chem. Rev. 2014, 114, 10735–10806. [Google Scholar] [CrossRef] [PubMed]

- Lim, S.K.; Goh, K.; Bae, T.-H.; Wang, R. Polymer-based membranes for solvent-resistant nanofiltration: A review. Chin. J. Chem. Eng. 2017, 25, 1653–1675. [Google Scholar] [CrossRef]

- Shi, G.M.; Feng, Y.; Li, B.; Tham, H.M.; Lai, J.-Y.; Chung, T.-S. Recent progress of organic solvent nanofiltration membranes. Prog. Polym. Sci. 2021, 123, 101470. [Google Scholar] [CrossRef]

- Li, Y.; Cao, B.; Li, P. Effects of dope compositions on morphologies and separation performances of PMDA-ODA polyimide hollow fiber membranes in aqueous and organic solvent systems. Appl. Surf. Sci. 2019, 473, 1038–1048. [Google Scholar] [CrossRef]

- Li, Y.; Xue, J.; Zhang, X.; Cao, B.; Li, P. Formation of macrovoid-free PMDA-MDA polyimide membranes using a gelation/non-solvent-induced phase separation method for organic solvent nanofiltration. Ind. Eng. Chem. Res. 2019, 58, 6712–6720. [Google Scholar] [CrossRef]

- Goh, K.S.; Chong, J.Y.; Chen, Y.; Fang, W.; Bae, T.-H.; Wang, R. Thin-film composite hollow fibre membrane for low pressure organic solvent nanofiltration. J. Membr. Sci. 2020, 597, 117760. [Google Scholar] [CrossRef]

- Goh, K.S.; Chen, Y.; Chong, J.Y.; Bae, T.H.; Wang, R. Thin film composite hollow fibre membrane for pharmaceutical concentration and solvent recovery. J. Membr. Sci. 2021, 621, 119008. [Google Scholar] [CrossRef]

- Tashvigh, A.A.; Chung, T.-S. Robust polybenzimidazole (PBI) hollow fiber membranes for organic solvent nanofiltration. J. Membr. Sci. 2019, 572, 580–587. [Google Scholar] [CrossRef]

- Farahani, M.H.D.A.; Chung, T.-S. A novel crosslinking technique towards the fabrication of high-flux polybenzimidazole (PBI) membranes for organic solvent nanofiltration (OSN). Sep. Purif. Technol. 2019, 209, 182–192. [Google Scholar] [CrossRef]

- Chen, D.; Yan, C.; Li, X.; Liu, L.; Wu, D.; Li, X. A highly stable PBI solvent resistant nanofiltration membrane prepared via versatile and simple crosslinking process. Sep. Purif. Technol. 2019, 224, 15–22. [Google Scholar] [CrossRef]

- Jiang, J.X.; Su, F.; Trewin, A.; Wood, C.D.; Campbell, N.L.; Niu, H.; Dickinson, C.; Ganin, A.Y.; Rosseinsky, M.J.; Khimyak, Y.Z. Conjugated microporous poly (aryleneethynylene) networks. Angew. Chem. Int. Ed. 2007, 119, 8728–8732. [Google Scholar] [CrossRef]

- Liang, B.; Wang, H.; Shi, X.; Shen, B.; He, X.; Ghazi, Z.A.; Khan, N.A.; Sin, H.; Khattak, A.M.; Li, L. Microporous membranes comprising conjugated polymers with rigid backbones enable ultrafast organic-solvent nanofiltration. Nat. Chem. 2018, 10, 961–967. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Sin, H.; Liang, B.; Ghazi, Z.A.; Khattak, A.M.; Khan, N.A.; Alanagh, H.R.; Li, L.; Lu, X.; Tang, Z. Controlling the selectivity of conjugated microporous polymer membrane for efficient organic solvent nanofiltration. Adv. Funct. Mater. 2019, 29, 1900134. [Google Scholar] [CrossRef]

- Gong, J.; Lin, R.-B.; Chen, B. Conjugated microporous polymers with rigid backbones for organic solvent nanofiltration. Chem 2018, 4, 2269–2271. [Google Scholar] [CrossRef] [Green Version]

- Farahani, M.H.D.A.; Hua, D.; Chung, T.-S. Cross-linked mixed matrix membranes (MMMs) consisting of amine-functionalized multi-walled carbon nanotubes and P84 polyimide for organic solvent nanofiltration (OSN) with enhanced flux. J. Membr. Sci. 2018, 548, 319–331. [Google Scholar] [CrossRef]

- Ran, J.; Zhang, P.; Chu, C.; Cui, P.; Ai, X.; Pan, T.; Wu, Y.; Xu, T. Ultrathin lamellar MoS2 membranes for organic solvent nanofiltration. J. Membr. Sci. 2020, 602, 117963. [Google Scholar] [CrossRef]

- Guo, B.-Y.; Jiang, S.-D.; Tang, M.-J.; Li, K.; Sun, S.; Chen, P.-Y.; Zhang, S. MoS2 membranes for organic solvent nanofiltration: Stability and structural control. J. Phys. Chem. Lett. 2019, 10, 4609–4617. [Google Scholar] [CrossRef]

- Li, S.; Li, C.; Song, X.; Su, B.; Mandal, B.; Prasad, B.; Gao, X.; Gao, C. Graphene quantum dots-doped thin film nanocomposite polyimide membranes with enhanced solvent resistance for solvent-resistant nanofiltration. ACS Appl. Mater. Interfaces 2019, 11, 6527–6540. [Google Scholar] [CrossRef]

- Li, S.; Li, C.; Su, B.; Hu, M.Z.; Gao, X.; Gao, C. Amino-functionalized graphene quantum dots (aGQDs)-embedded thin film nanocomposites for solvent resistant nanofiltration (SRNF) membranes based on covalence interactions. J. Membr. Sci. 2019, 588, 117212. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Soria, R.B.; Volodine, A.; Van der Bruggen, B. Aramid nanofiber and modified ZIF-8 constructed porous nanocomposite membrane for organic solvent nanofiltration. J. Membr. Sci. 2020, 603, 118002. [Google Scholar] [CrossRef]

- Karimi, A.; Khataee, A.; Safarpour, M.; Vatanpour, V. Development of mixed matrix ZIF-8/polyvinylidene fluoride membrane with improved performance in solvent resistant nanofiltration. Sep. Purif. Technol. 2020, 237, 116358. [Google Scholar] [CrossRef]

- Dai, J.; Li, S.; Liu, J.; He, J.; Li, J.; Wang, L.; Lei, J. Fabrication and characterization of a defect-free mixed matrix membrane by facile mixing PPSU with ZIF-8 core–shell microspheres for solvent-resistant nanofiltration. J. Membr. Sci. 2019, 589, 117261. [Google Scholar] [CrossRef]

- Wang, S.; Mahalingam, D.; Sutisna, B.; Nunes, S.P. 2D-dual-spacing channel membranes for high performance organic solvent nanofiltration. J. Mater. Chem. A 2019, 7, 11673–11682. [Google Scholar] [CrossRef] [Green Version]

- Fei, F.; Cseri, L.; Szekely, G.; Blanford, C.F. Robust covalently cross-linked polybenzimidazole/graphene oxide membranes for high-flux organic solvent nanofiltration. ACS Appl. Mater. Interfaces 2018, 10, 16140–16147. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, M.-L.; Wang, J.; Guo, J.-L.; Lu, T.-D.; Cao, X.-L.; Sun, S.-P. Graphene oxide/cross-linked polyimide (GO/CLPI) composite membranes for organic solvent nanofiltration. Chem. Eng. Res. Des. 2019, 146, 182–189. [Google Scholar] [CrossRef]

- Su, J.; Lv, X.; Li, S.; Jiang, Y.; Liu, S.; Zhang, X.; Li, H.; Su, B. High separation performance thin film composite and thin film nanocomposite hollow fiber membranes via interfacial polymerization for organic solvent nanofiltration. Sep. Purif. Technol. 2021, 278, 119567. [Google Scholar] [CrossRef]

- Abadikhah, H.; Kalali, E.N.; Behzadi, S.; Khan, S.A.; Xu, X.; Shabestari, M.E.; Agathopoulos, S. High flux thin film nanocomposite membrane incorporated with functionalized TiO2@ reduced graphene oxide nanohybrids for organic solvent nanofiltration. Chem. Eng. Sci. 2019, 204, 99–109. [Google Scholar] [CrossRef]

- Farahani, M.H.D.A.; Chung, T.-S. Solvent resistant hollow fiber membranes comprising P84 polyimide and amine-functionalized carbon nanotubes with potential applications in pharmaceutical, food, and petrochemical industries. Chem. Eng. J. 2018, 345, 174–185. [Google Scholar] [CrossRef]

- Elimelech, M.; Phillip, W.A. The future of seawater desalination: Energy, technology, and the environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef]

- Xu, J.; Feng, X.; Gao, C. Surface modification of thin-film-composite polyamide membranes for improved reverse osmosis performance. J. Membr. Sci. 2011, 370, 116–123. [Google Scholar] [CrossRef]

- Yang, T.; Wan, C.F.; Zhang, J.; Gudipati, C.; Chung, T.-S. Optimization of interfacial polymerization to fabricate thin-film composite hollow fiber membranes in modules for brackish water reverse osmosis. J. Membr. Sci. 2021, 626, 119187. [Google Scholar] [CrossRef]

- Zhao, D.L.; Japip, S.; Zhang, Y.; Weber, M.; Maletzko, C.; Chung, T.-S. Emerging thin-film nanocomposite (TFN) membranes for reverse osmosis: A review. Water Res. 2020, 173, 115557. [Google Scholar] [CrossRef]

- Teow, Y.H.; Mohammad, A.W. New generation nanomaterials for water desalination: A review. Desalination 2019, 451, 2–17. [Google Scholar] [CrossRef]

- Gai, W.; Zhang, Y.; Zhao, Q.; Chung, T.-S. Highly permeable thin film composite hollow fiber membranes for brackish water desalination by incorporating amino functionalized carbon quantum dots and hypochlorite treatment. J. Membr. Sci. 2021, 620, 118952. [Google Scholar] [CrossRef]

- Teramura, K.; Iguchi, S.; Mizuno, Y.; Shishido, T.; Tanaka, T. Photocatalytic conversion of CO2 in water over layered double hydroxides. Angew. Chem. Int. Ed. 2012, 51, 8008–8011. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Zhao, D.L.; Feng, F.; Chung, T.-S.; Chen, S.B. Thin-film nanocomposite reverse osmosis membranes incorporated with citrate-modified layered double hydroxides (LDHs) for brackish water desalination and boron removal. Desalination 2022, 527, 115583. [Google Scholar] [CrossRef]