Evaluation of the Specific Energy Consumption of Sea Water Reverse Osmosis Integrated with Membrane Distillation and Pressure–Retarded Osmosis Processes with Theoretical Models

Abstract

:1. Introduction

2. Materials and Methods

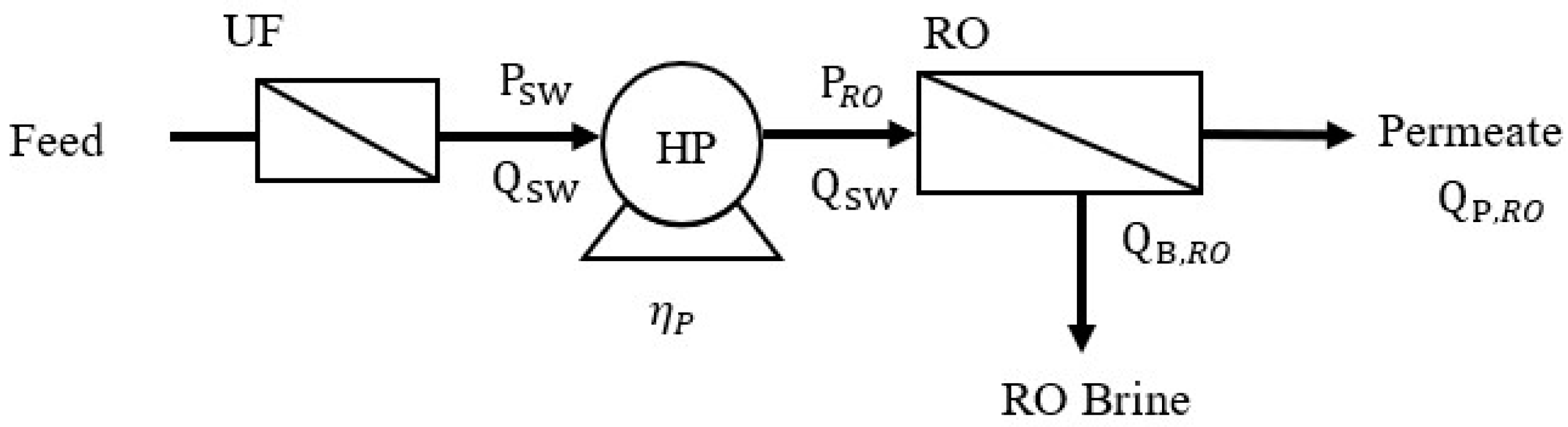

2.1. SEC of the RO Process

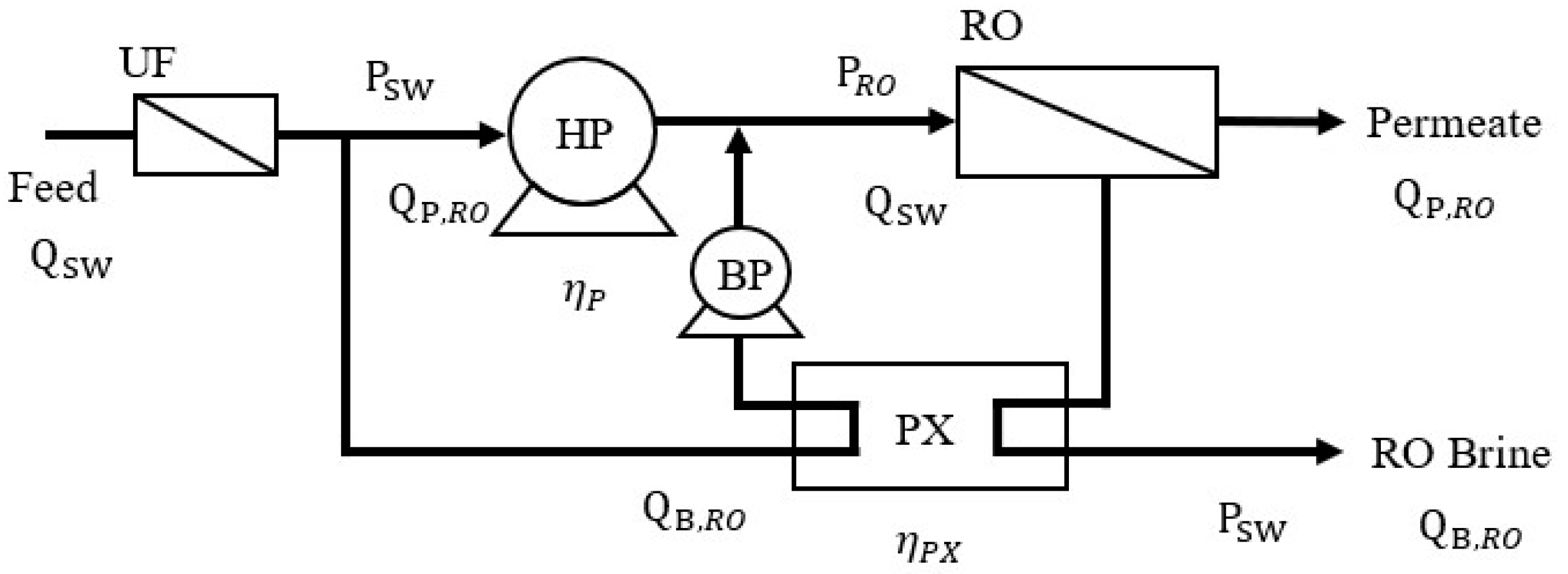

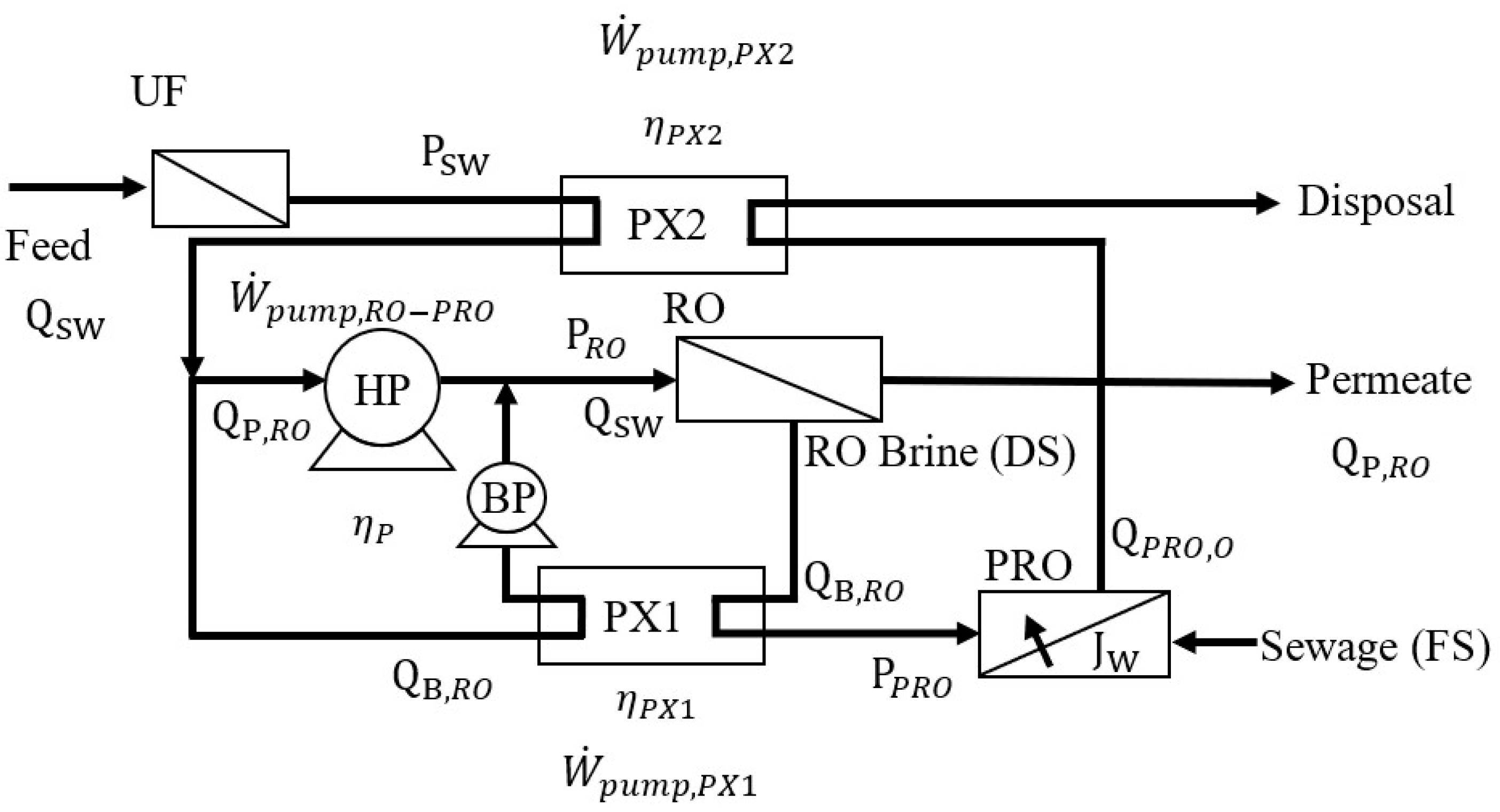

2.2. SEC of the RO-PRO Process

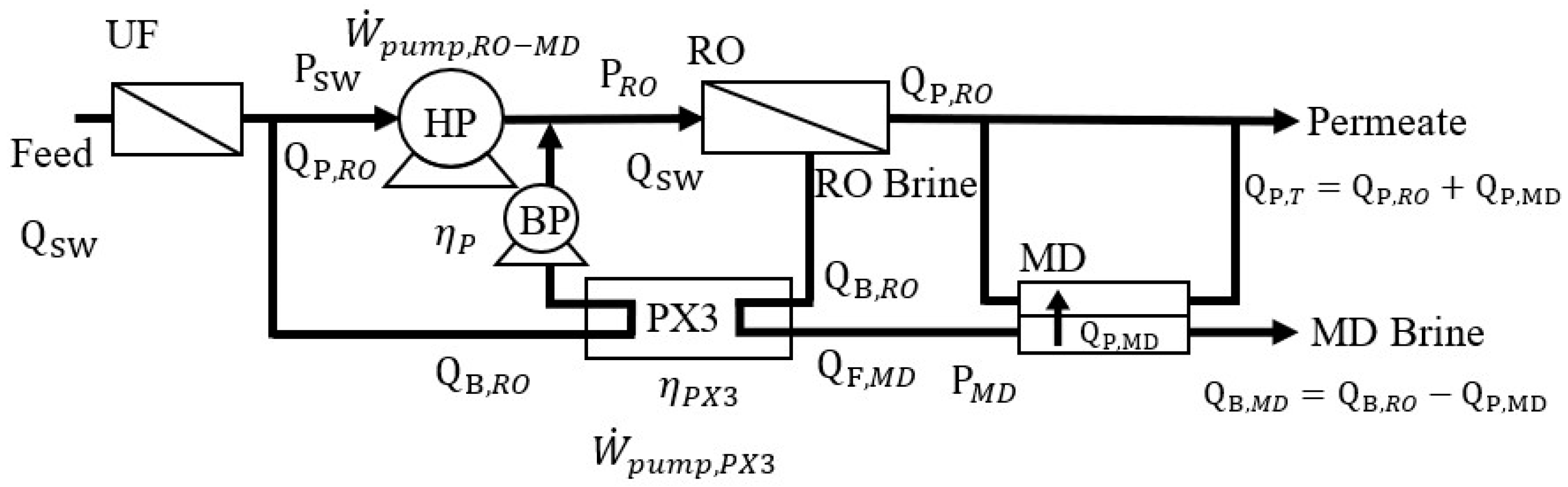

2.3. SEC of the RO-MD Process

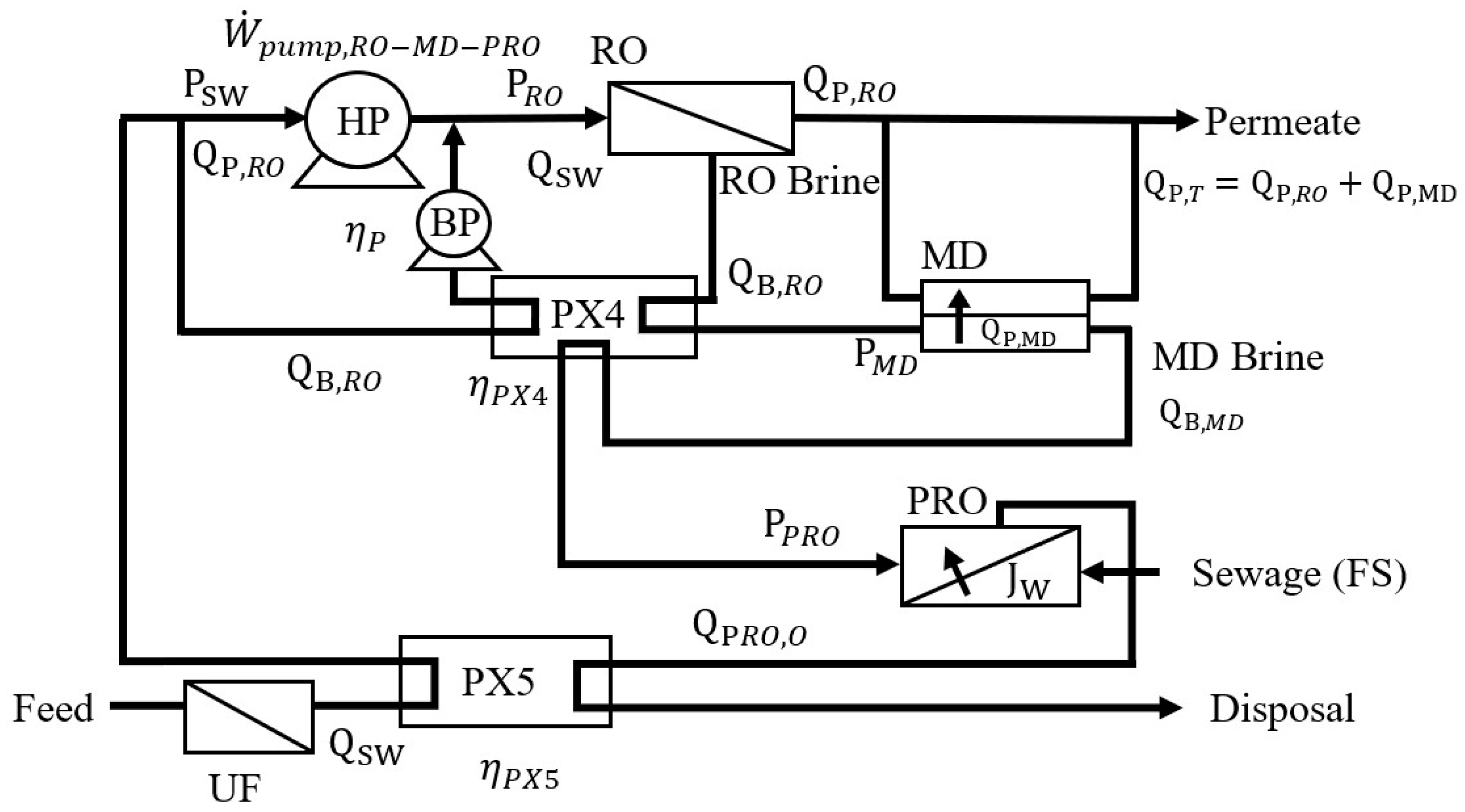

2.4. SEC of the RO-MD-PRO Process

2.5. The Fractional Energy Savings

3. Results and Discussion

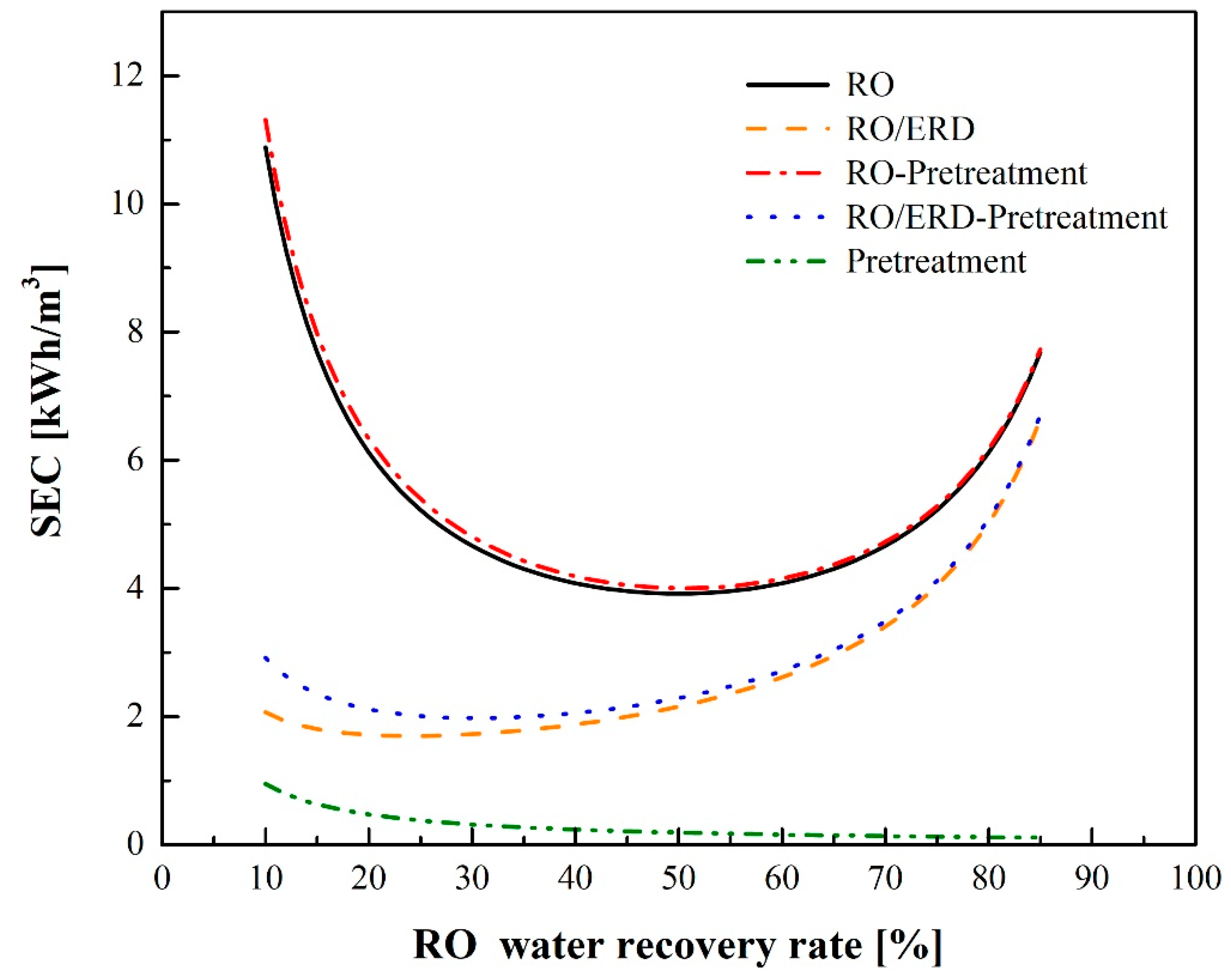

3.1. RO Process

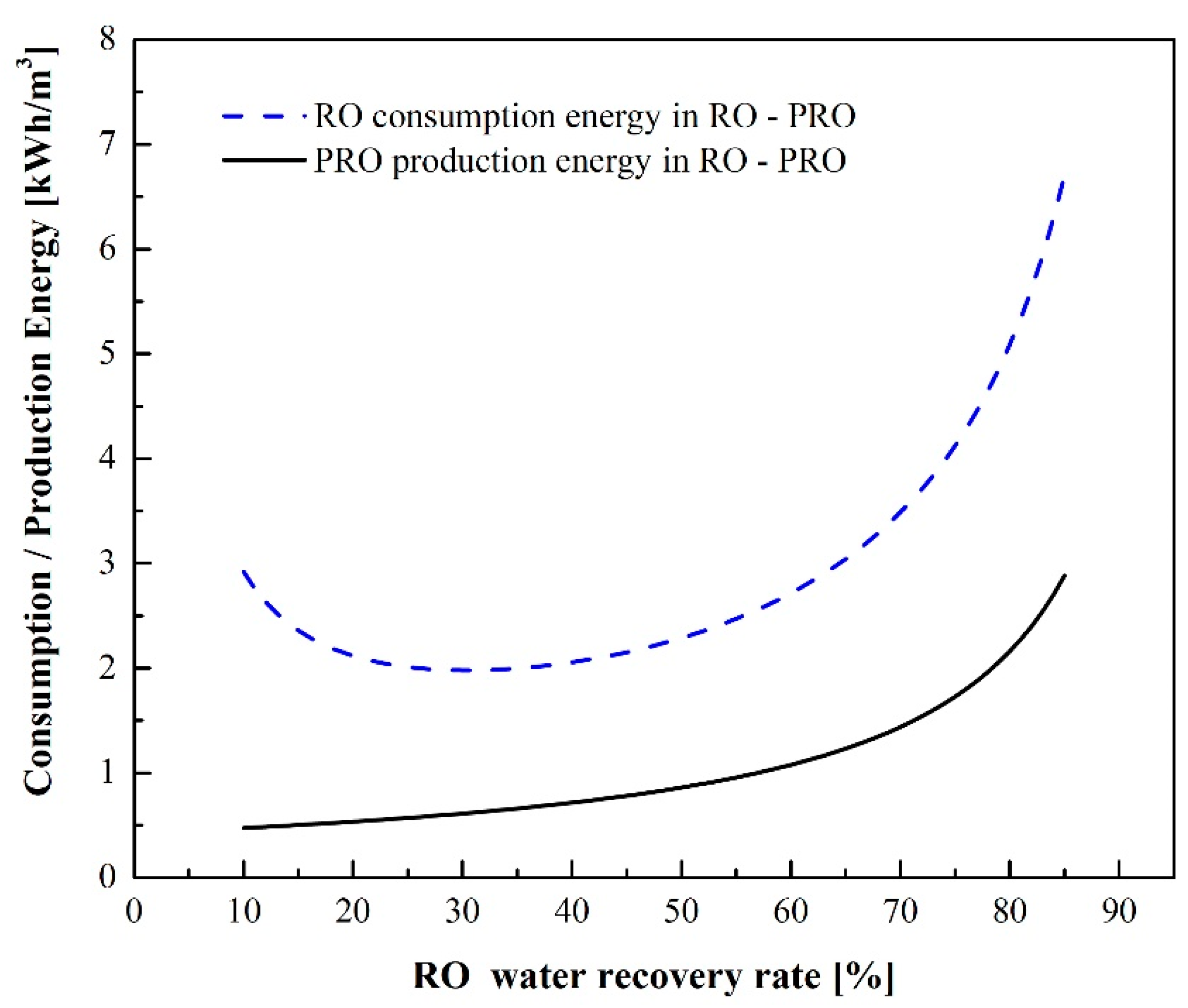

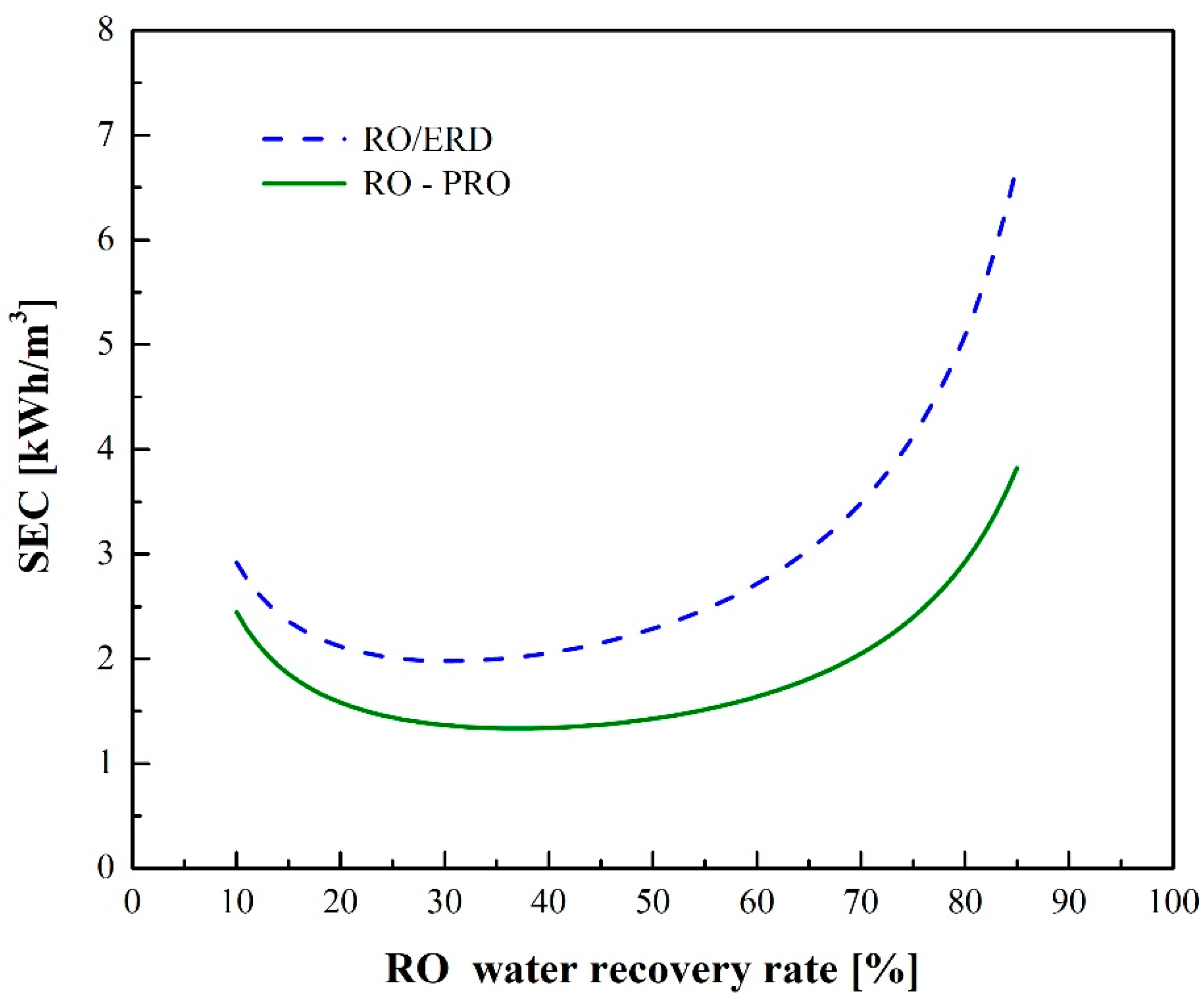

3.2. RO-PRO Process

3.3. RO-MD Process

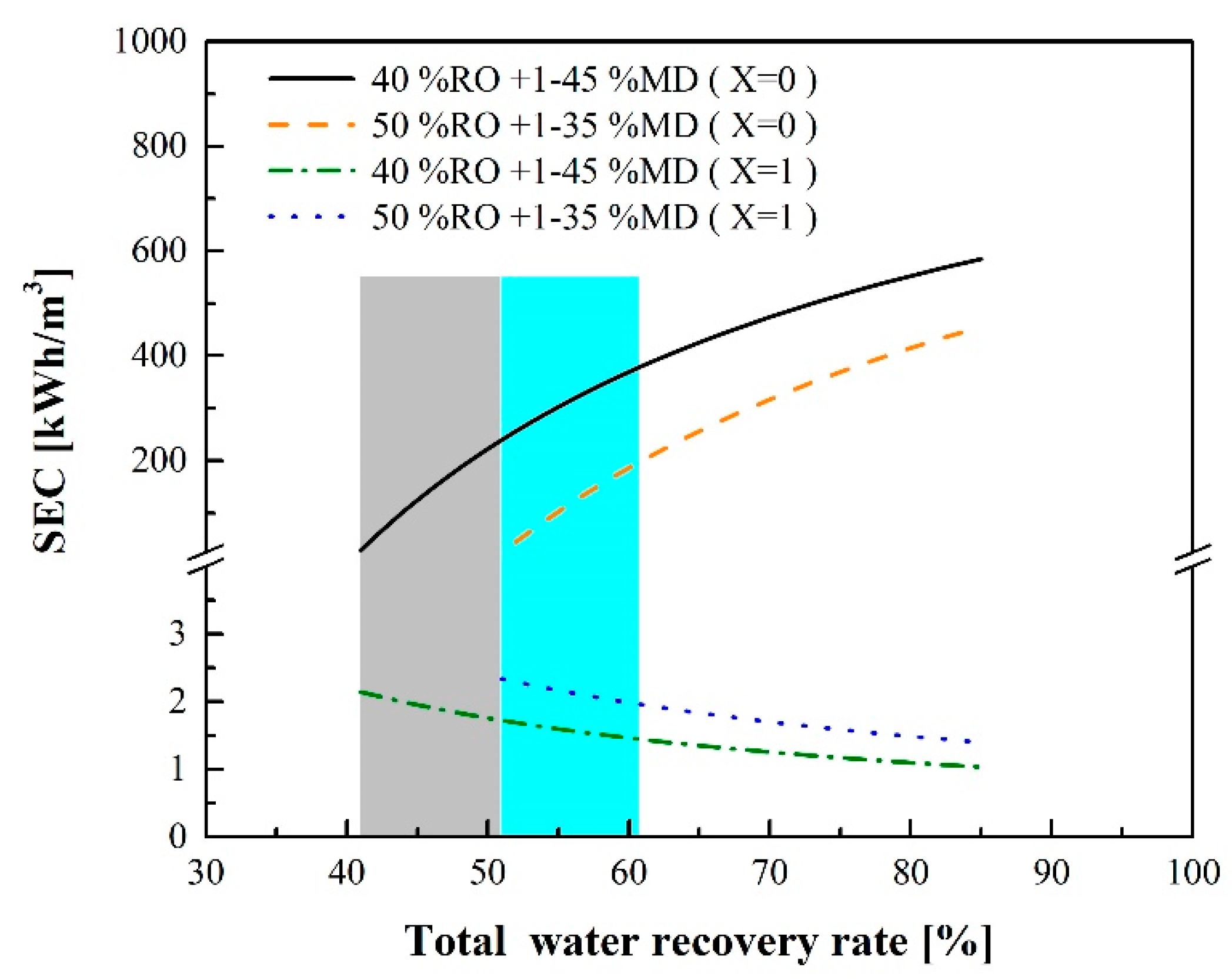

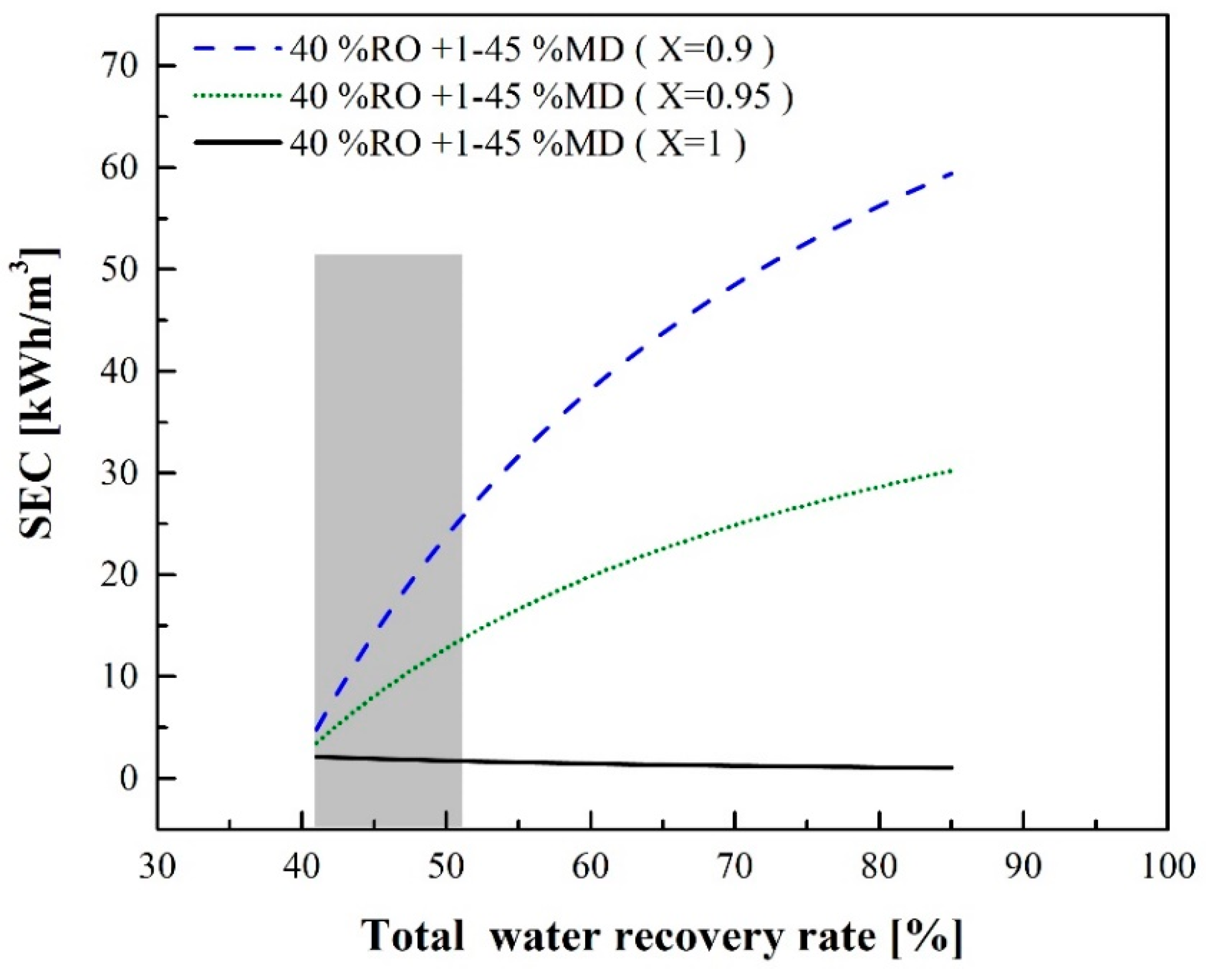

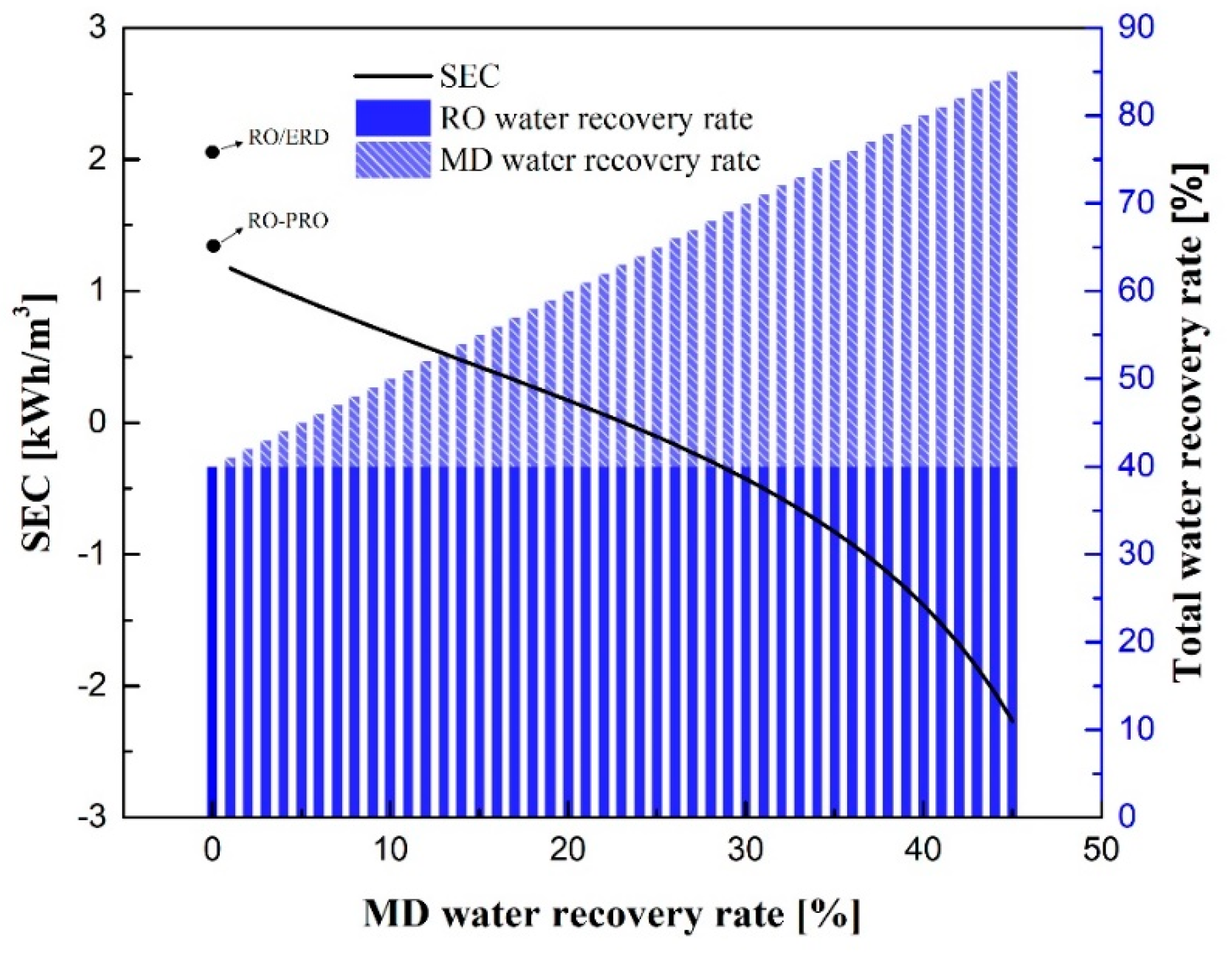

3.4. RO-MD-PRO Process

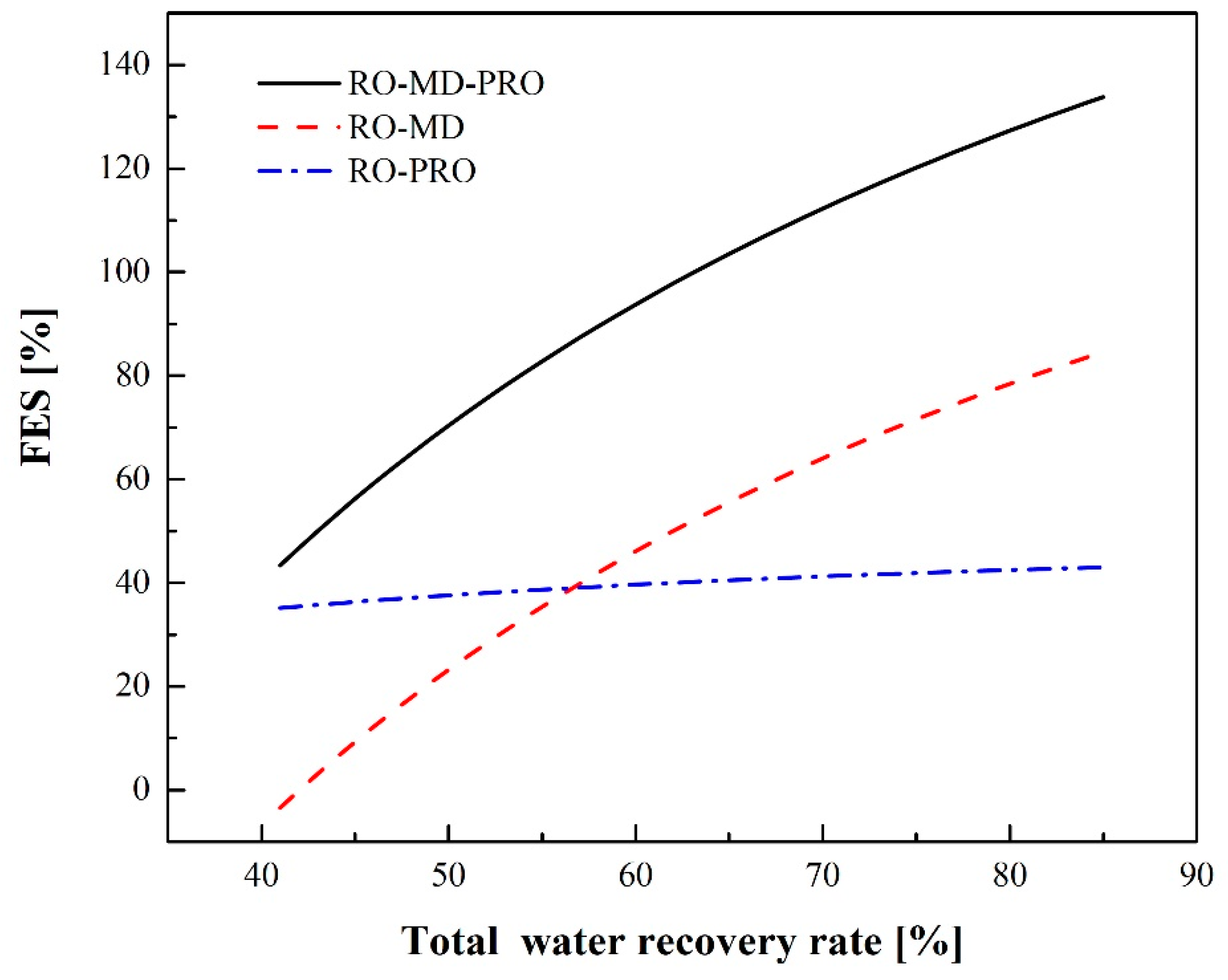

3.5. The Fractional Energy Savings(FES) of Integrated Processes

3.6. Comparison with RO-Integrated Processes in the Literature

4. Conclusions

- (1)

- The brine flow rate decreases as RO water recovery increases. When the water recovery rate is greater than 30%, recyclable mechanical energy in the PX begins decreasing in availability, and SEC starts increasing. The minimum SEC is 1.97 kWh/m3 at a recovery rate of 30% for the RO/ERD process.

- (2)

- For the RO-PRO process, SEC reaches a minimum value of 1.33 kWh/m3 at a recovery rate of 38%. RO-PRO can give a lower SEC than RO due to the energy generation by PRO, and a higher water recovery rate is obtained at the minimum SEC.

- (3)

- For the RO-MD process, when the RO water recovery rate remains constant and there is sufficient waste heat as the MD heat source, SEC can be reduced as the MD water recovery rate increases. If the water recovery rate of RO is fixed at 40% and the total water recovery rate is 85%, SEC is 1.03 kWh/m3.

- (4)

- For the RO-MD-PRO process and an RO water recovery rate that is constant at 40%, the energy consumption due to pumping and energy generation by PRO reaches a balance at a total water recovery rate of 64%, which means that SEC is zero under these conditions. When the total recovery rate exceeds 64%, the FES of the integrated process is greater than 100%.

- (5)

- The limit of the water recovery rate for SWRO is generally 50%. Thus, if we assume that the RO water recovery rate is 50%, the recovery rate of water for MD is 10%, and sufficient waste heat is available as a heat source for the MD unit; the SECs of the RO, RO-PRO, RO-MD and RO-MD-PRO processes are found to be 2.28, 1.47, 1.75, and 0.67 kWh/m3, respectively. The corresponding FES values of the integrated processes are 37%, 23% and 70% when compared with the baseline RO process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Nomenclature | |

| BP | Booster pump |

| C | Salt concentration |

| DS | Draw solution |

| EE | Energy efficiency |

| ERDs | Energy recovery devices |

| FES | Fractional energy savings |

| FS | Feed solution |

| HP | High-pressure pump |

| MD | Membrane distillation |

| P | Pressure |

| PRO | Pressure–retarded osmosis |

| PX | Pressure exchanger |

| Q | Volumetric flowrate |

| RO | Reverse osmosis |

| Rt | Salt rejection rate |

| SEC | Specific energy consumption |

| SW | Seawater |

| T | Temperature |

| Y | Water recovery rate |

| Greek letters | |

| ρ | Density of water |

| π | Osmotic pressure of the feed solution |

| η | Efficiency |

| ΔH | Enthalpy |

| Subscripts | |

| p | RO pump |

| pre | Pretreatment unit |

| r | RO |

| m | MD |

| t | Total |

| vap | Vaporization |

| FMD | MD feed solution |

| BRO | RO brine |

References

- Guirguis, M.J. Energy Recovery Devices in Seawater Reverse Osmosis Desalination Plants with Emphasis on Efficiency and Economical Analysis of Isobaric versus Centrifugal Devices; University of South Florida: Tampa, FL, USA, 2011. [Google Scholar]

- Zhu, A.; Christofides, P.D.; Cohen, Y. Minimization of energy consumption for a two-pass membrane desalination: Effect of energy recovery, membrane rejection and retentate recycling. J. Membr. Sci. 2009, 339, 126–137. [Google Scholar] [CrossRef]

- Zhu, A.; Christofides, P.D.; Cohen, Y. Effect of thermodynamic restriction on energy cost optimization of RO membrane water desalination. Ind. Eng. Chem. Res. 2009, 48, 6010–6021. [Google Scholar] [CrossRef]

- Altaee, A.; Millar, G.J.; Zaragoza, G. Integration and optimization of pressure retarded osmosis with reverse osmosis for power generation and high efficiency desalination. Energy 2016, 103, 110–118. [Google Scholar] [CrossRef] [Green Version]

- Sakai, H.; Ueyama, T.; Irie, M.; Matsuyama, K.; Tanioka, A.; Saito, K.; Kumano, A. Energy recovery by PRO in sea water desalination plant. Desalination 2016, 389, 52–57. [Google Scholar] [CrossRef]

- Basile, A.; Cassano, A.; Rastogi, N.K. Advances in Membrane Technologies for Water Treatment: Materials, Processes and Applications; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Sauvet-Goichon, B. Ashkelon desalination plant—A successful challenge. Desalination 2007, 203, 75–81. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Han, G. Pressure Retarded Osmosis-Membrane Distillation. In Membrane Distillation; CRC Press: Boca Raton, FL, USA, 2019; pp. 285–300. [Google Scholar]

- Achilli, A.; Cath, T.Y.; Childress, A.E. Power generation with pressure retarded osmosis: An experimental and theoretical investigation. J. Membr. Sci. 2009, 343, 42–52. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Li, X.; Chung, T.-S. The forward osmosis-pressure retarded osmosis (FO-PRO) hybrid system: A new process to mitigate membrane fouling for sustainable osmotic power generation. J. Membr. Sci. 2018, 559, 63–74. [Google Scholar] [CrossRef]

- Chou, S.; Wang, R.; Shi, L.; She, Q.; Tang, C.; Fane, A.G. Thin-film composite hollow fiber membranes for pressure retarded osmosis (PRO) process with high power density. J. Membr. Sci. 2012, 389, 25–33. [Google Scholar] [CrossRef]

- Gonzales, R.R.; Abdel-Wahab, A.; Adham, S.; Han, D.S.; Phuntsho, S.; Suwaileh, W.; Hilal, N.; Shon, H.K. Salinity gradient energy generation by pressure retarded osmosis: A review. Desalination 2021, 500, 114841. [Google Scholar] [CrossRef]

- Ullah, R.; Khraisheh, M.; Esteves, R.J.; McLeskey, J.T., Jr.; AlGhouti, M.; Gad-el-Hak, M.; Tafreshi, H.V. Energy efficiency of direct contact membrane distillation. Desalination 2018, 433, 56–67. [Google Scholar] [CrossRef]

- Lin, S.; Yip, N.Y.; Elimelech, M. Direct contact membrane distillation with heat recovery: Thermodynamic insights from module scale modeling. J. Membr. Sci. 2014, 453, 498–515. [Google Scholar] [CrossRef]

- Lawson, K.W.; Lloyd, D.R. Membrane distillation. J. Membr. Sci. 1997, 124, 1–25. [Google Scholar] [CrossRef]

- Phattaranawik, J.; Jiraratananon, R.; Fane, A.G. Heat transport and membrane distillation coefficients in direct contact membrane distillation. J. Membr. Sci. 2003, 212, 177–193. [Google Scholar] [CrossRef]

- Bui, V.; Vu, L.T.; Nguyen, M.H. Modelling the simultaneous heat and mass transfer of direct contact membrane distillation in hollow fibre modules. J. Membr. Sci. 2010, 353, 85–93. [Google Scholar] [CrossRef]

- Yadav, A.; Labhasetwar, P.K.; Shahi, V.K. Membrane distillation using low-grade energy for desalination: A review. J. Environ. Chem. Eng. 2021, 9, 105818. [Google Scholar] [CrossRef]

- Stover, R.L. Seawater reverse osmosis with isobaric energy recovery devices. Desalination 2007, 203, 168–175. [Google Scholar] [CrossRef]

- Hauge, L.J. The pressure exchanger—A key to substantial lower desalination cost. Desalination 1995, 102, 219–223. [Google Scholar] [CrossRef]

- Guan, G.; Yang, X.; Wang, R.; Field, R.; Fane, A.G. Evaluation of hollow fiber-based direct contact and vacuum membrane distillation systems using aspen process simulation. J. Membr. Sci. 2014, 464, 127–139. [Google Scholar] [CrossRef]

- Kim, J.; Park, M.; Snyder, S.A.; Kim, J.H. Reverse osmosis (RO) and pressure retarded osmosis (PRO) hybrid processes: Model-based scenario study. Desalination 2013, 322, 121–130. [Google Scholar] [CrossRef]

- Park, Y.; Chung, K.; Yeo, I.; Lee, W.; Park, T. Development of a SWRO-PRO hybrid desalination system: Pilot plant investigations. Water Sci. Technol. Water Supply 2018, 18, 473–481. [Google Scholar] [CrossRef]

- Mericq, J.-P.; Laborie, S.; Cabassud, C. Vacuum membrane distillation of seawater reverse osmosis brines. Water Res. 2010, 44, 5260–5273. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Park, M.; Shon, H.K.; Kim, J.H. Performance analysis of reverse osmosis, membrane distillation, and pressure-retarded osmosis hybrid processes. Desalination 2016, 380, 85–92. [Google Scholar] [CrossRef] [Green Version]

- Prante, J.L.; Ruskowitz, J.A.; Childress, A.E.; Achilli, A. RO-PRO desalination: An integrated low-energy approach to seawater desalination. Appl. Energy 2014, 120, 104–114. [Google Scholar] [CrossRef]

- Wan, C.F.; Chung, T.-S. Energy recovery by pressure retarded osmosis (PRO) in SWRO–PRO integrated processes. Appl. Energy 2016, 162, 687–698. [Google Scholar] [CrossRef]

- Ruiz-García, A.; Nuez, I. Performance Assessment of SWRO Spiral-Wound Membrane Modules with Different Feed Spacer Dimensions. Processes 2020, 8, 692. [Google Scholar] [CrossRef]

- Glueckstern, P.; Priel, M. Comparative cost of UF vs conventional pretreatment for SWRO systems. Int. Desalination Water Reuse Q. 2003, 13, 34–39. [Google Scholar]

- Karnland, O. Bentonite Swelling Pressure in Strong NaCl Solutions. Correlation between Model Calculations and Experimentally Determined Data; Swedish Nuclear Fuel and Waste Management Co.: Solna, Sweden, 1997. [Google Scholar]

- Lee, K.; Baker, R.; Lonsdale, H. Membranes for power generation by pressure-retarded osmosis. J. Membr. Sci. 1981, 8, 141–171. [Google Scholar] [CrossRef]

- Wan, C.F.; Yang, T.; Gai, W.; De Lee, Y.; Chung, T.-S. Thin-film composite hollow fiber membrane with inorganic salt additives for high mechanical strength and high power density for pressure-retarded osmosis. J. Membr. Sci. 2018, 555, 388–397. [Google Scholar] [CrossRef]

- Guillen-Burrieza, E.; Servi, A.; Lalia, B.S.; Arafat, H.A. Membrane structure and surface morphology impact on the wetting of MD membranes. J. Membr. Sci. 2015, 483, 94–103. [Google Scholar] [CrossRef]

- Achilli, A.; Prante, J.L.; Hancock, N.T.; Maxwell, E.B.; Childress, A.E. Experimental results from RO-PRO: A next generation system for low-energy desalination. Environ. Sci. Technol. 2014, 48, 6437–6443. [Google Scholar] [CrossRef]

- Lee, S.; Choi, J.; Park, Y.-G.; Shon, H.; Ahn, C.H.; Kim, S.-H. Hybrid desalination processes for beneficial use of reverse osmosis brine: Current status and future prospects. Desalination 2019, 454, 104–111. [Google Scholar] [CrossRef]

| Seawater salt concentration (M) | 0.589 | |

| Salt rejection percentage of the membrane (-) | 99% | |

| RO pump efficiency (-) | 80% | |

| Pressure exchanger efficiency (-) | 95% | |

| 100,000 |

| RO water recovery rate (-) | 40%, 50% | |

| MD water recovery rate (-) | 1~45%, 1~35% | |

| Total water recovery rate (-) | ≤85% | |

| MD pressure [4] | 3 | |

| Enthalpy of vaporization (kJ⁄kg) | 2382 | |

| EE | Energy efficiency of MD (-) | 60% |

| Temperature of the MD feed solution (°C) | 70 | |

| Temperature of the RO brine (°C) | 30 |

| RO Process | RO-PRO Process | RO-MD Process | RO-MD-PRO Process | Ref |

|---|---|---|---|---|

| Yr = 20, 30% SEC = 3.73, 3.38 kWh/m3 | Yr = 20, 30% SEC = 3.08, 2.64 kWh/m3 | [34] | ||

| Yr = 50% SEC = 2 kWh/m3 | Yr = 50% SEC = 1.2 kWh/m3 | [26] | ||

| Yr = 25, 50% SEC = 1.79, 2.27 kWh/m3 | Yr = 25, 50% SEC = 1.08, 1.14 kWh/m3 | [27] | ||

| Yr = 50% SEC = 1.91 kWh/m3 | Yr = 50% SEC = 1.78 kWh/m3 | Yr = 50%, Ym =2% SEC = 1.60 kWh/m3 | [25] | |

| SEC = 3.32 kWh/m3 | SEC = 2.869 kWh/m3 | SEC = 2.809 kWh/m3 | SEC = 2.683 kWh/m3 | [35] |

| Yr = 10 ~ 85% SEC = 1.91 ~ 8 kWh/m3 | Yr = 10 ~ 85% SEC = 1.33 ~ 4 kWh/m3 | Yr = 10 ~ 85% SEC = 1.03 ~ 2.28 kWh/m3 | Yr = 10 ~ 85% SEC = 0 ~ 1.33 kWh/m3 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, S.-C.; Huang, W.-Z.; Lin, G.-S.; Wang, Z.; Tung, K.-L.; Chuang, C.-J. Evaluation of the Specific Energy Consumption of Sea Water Reverse Osmosis Integrated with Membrane Distillation and Pressure–Retarded Osmosis Processes with Theoretical Models. Membranes 2022, 12, 432. https://doi.org/10.3390/membranes12040432

Tsai S-C, Huang W-Z, Lin G-S, Wang Z, Tung K-L, Chuang C-J. Evaluation of the Specific Energy Consumption of Sea Water Reverse Osmosis Integrated with Membrane Distillation and Pressure–Retarded Osmosis Processes with Theoretical Models. Membranes. 2022; 12(4):432. https://doi.org/10.3390/membranes12040432

Chicago/Turabian StyleTsai, Shao-Chi, Wei-Zhi Huang, Geng-Sheng Lin, Zhen Wang, Kuo-Lun Tung, and Ching-Jung Chuang. 2022. "Evaluation of the Specific Energy Consumption of Sea Water Reverse Osmosis Integrated with Membrane Distillation and Pressure–Retarded Osmosis Processes with Theoretical Models" Membranes 12, no. 4: 432. https://doi.org/10.3390/membranes12040432

APA StyleTsai, S.-C., Huang, W.-Z., Lin, G.-S., Wang, Z., Tung, K.-L., & Chuang, C.-J. (2022). Evaluation of the Specific Energy Consumption of Sea Water Reverse Osmosis Integrated with Membrane Distillation and Pressure–Retarded Osmosis Processes with Theoretical Models. Membranes, 12(4), 432. https://doi.org/10.3390/membranes12040432