Collective Enhancements on Thermal-Electrical and Mechanical Properties of Graphite-Based Composite Bipolar Plates through the Coupled Manipulations of Molding and Impregnation Pressures

Abstract

:1. Introduction

2. Materials and Methods

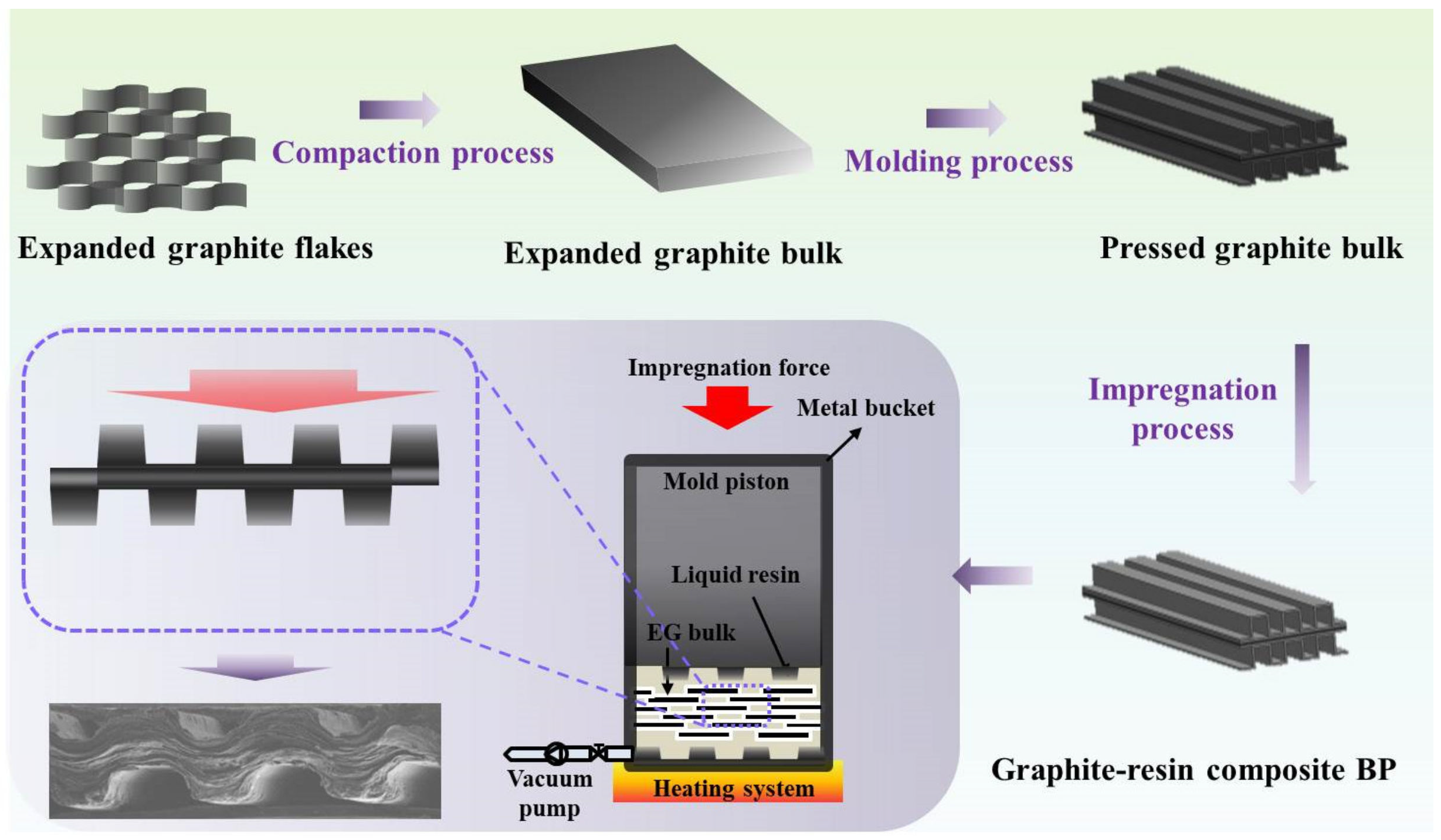

2.1. Fabrication of BPs

2.2. Characterization of BPs

3. Results and Discussions

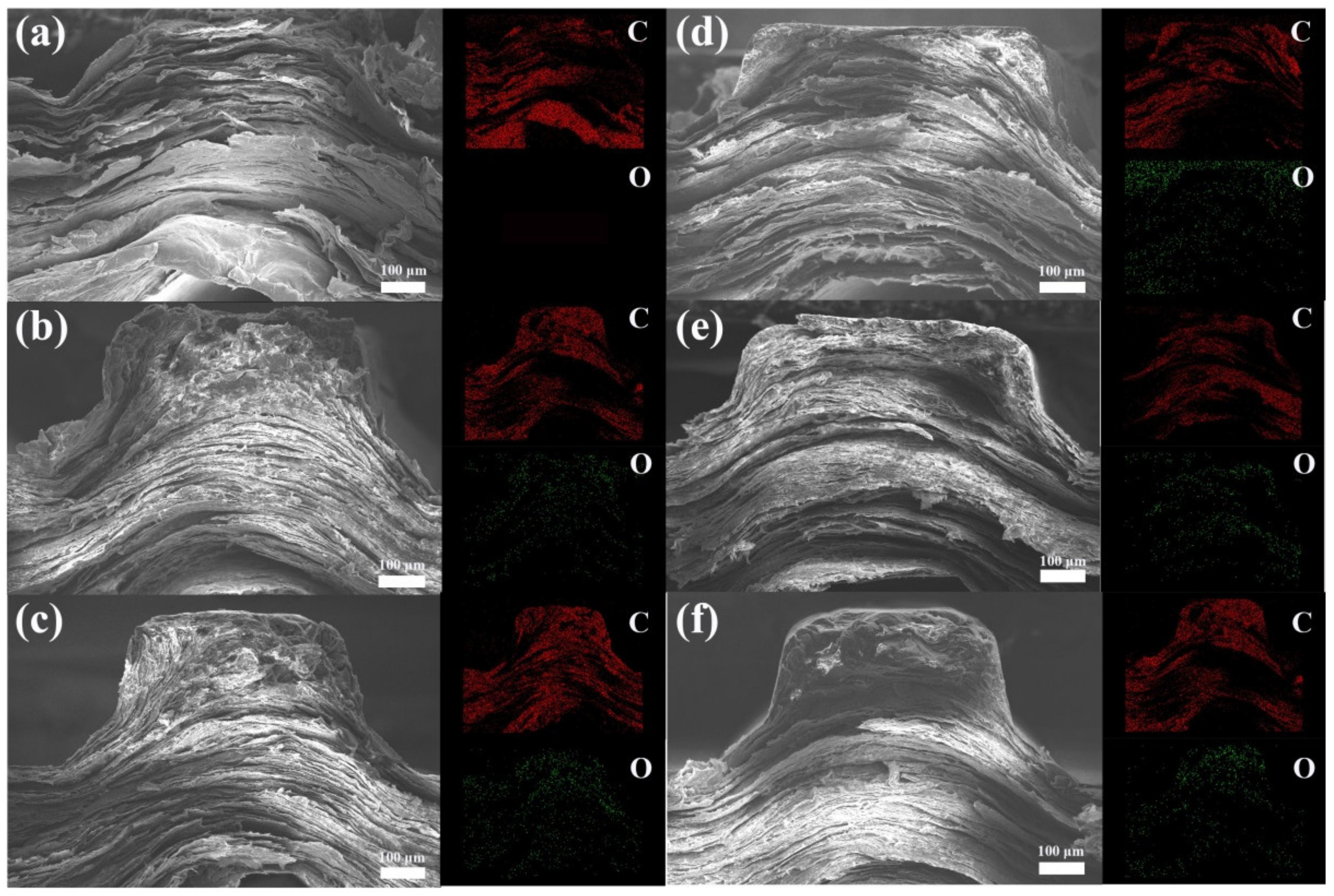

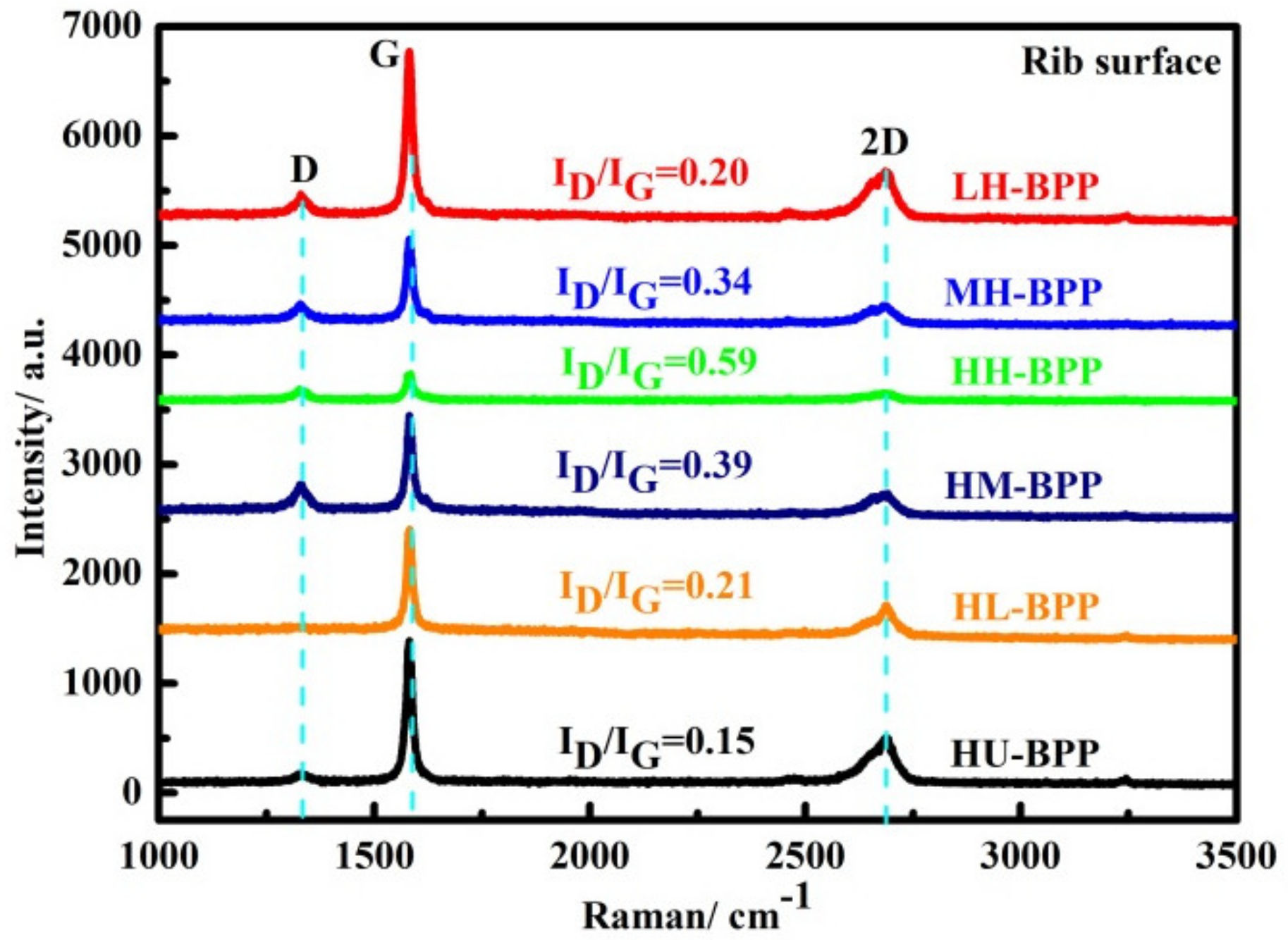

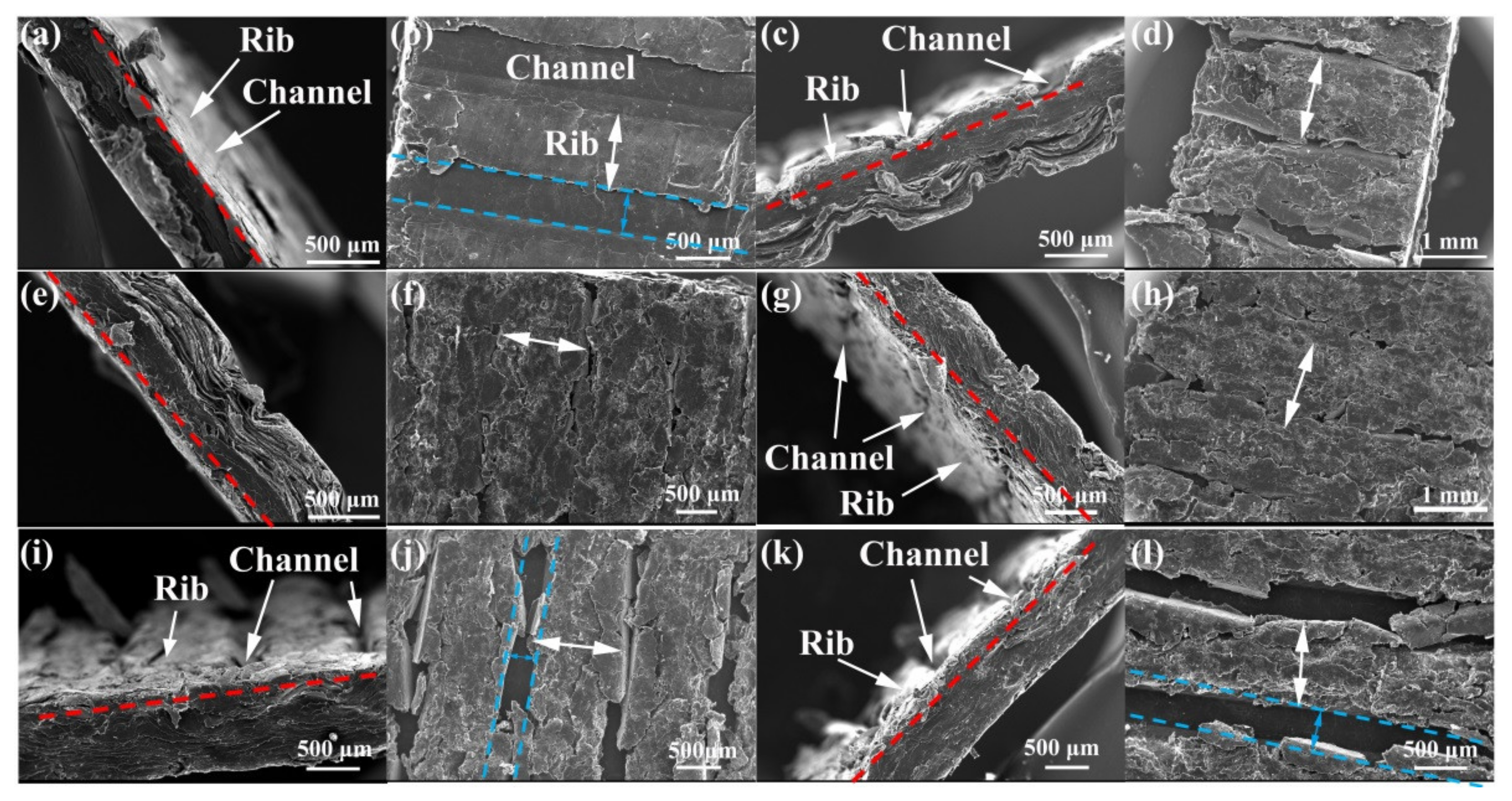

3.1. Microstructure Characterization of BPs

3.2. Thermal Conductivity of BPs

3.2.1. Density of Composite BPs

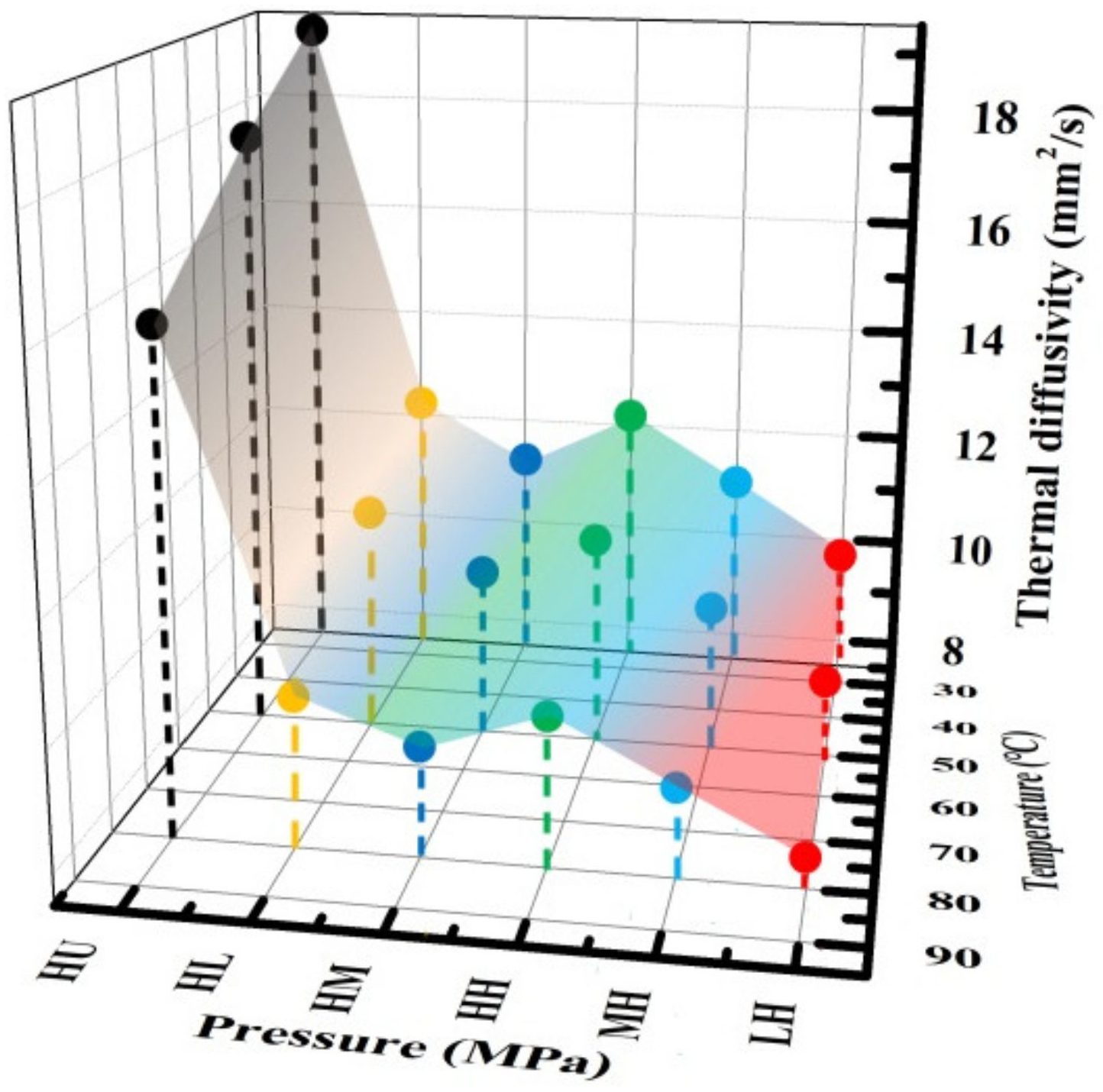

3.2.2. Thermal Diffusivity of Composite BPs

3.3. Electrical Property of BPs

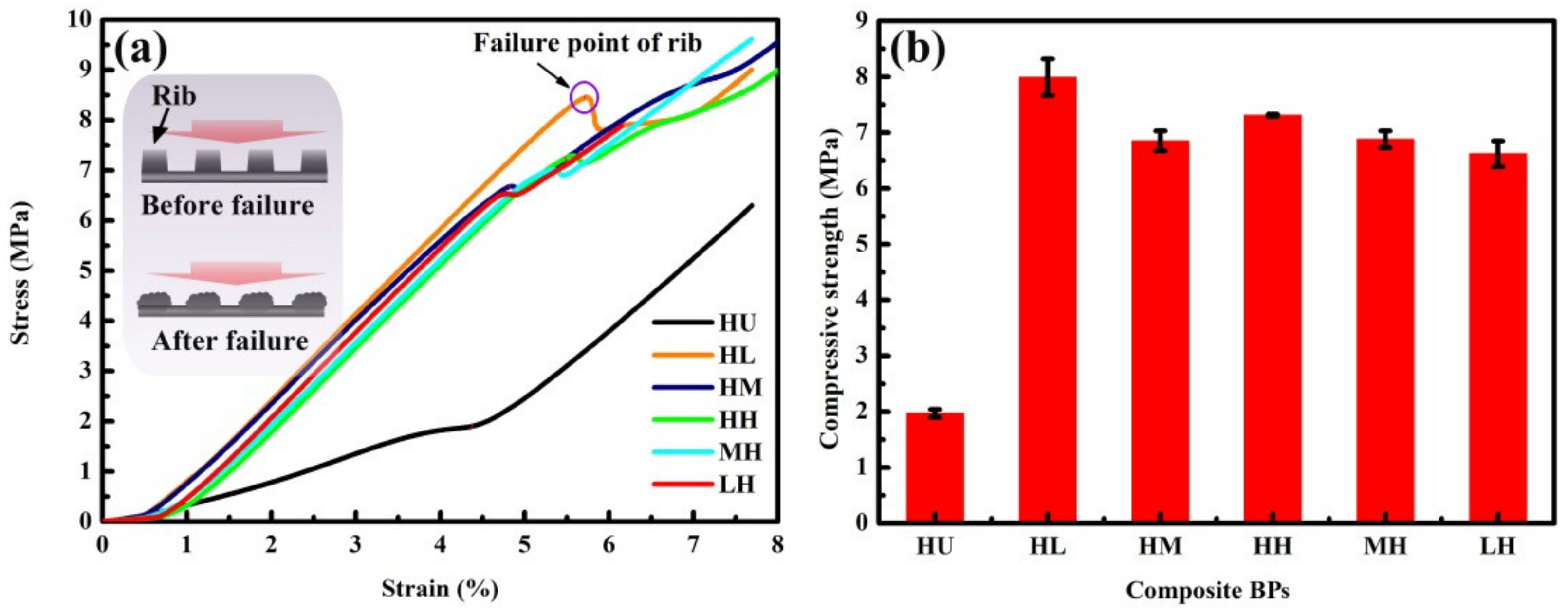

3.4. Compressive Strength of BPs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Awin, Y.; Dukhan, N. Experimental performance assessment of metal-foam flow fields for proton exchange membrane fuel cells. Appl. Energy 2019, 252, 113458. [Google Scholar] [CrossRef]

- Tsai, B.-T.; Tseng, C.-J.; Liu, Z.-S.; Wang, C.-H.; Lee, C.-I.; Yang, C.-C.; Lo, S.-K. Effects of flow field design on the performance of a PEM fuel cell with metal foam as the flow distributor. Int. J. Hydrog. Energy 2012, 37, 13060–13066. [Google Scholar] [CrossRef]

- Jiao, K.; Xuan, J.; Du, Q.; Bao, Z.; Xie, B.; Wang, B.; Zhao, Y.; Fan, L.; Wang, H.; Hou, Z.; et al. Designing the next generation of proton-exchange membrane fuel cells. Nature 2021, 595, 361–369. [Google Scholar] [CrossRef]

- Wang, Y.; Ruiz Diaz, D.F.; Chen, K.S.; Wang, Z.; Adroher, X.C. Materials, technological status, and fundamentals of PEM fuel cells–A review. Mater. Today 2020, 32, 178–203. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, C.; Ling, C.-Y.; Han, M.; Yong, R.-Y.; Sun, D.; Chen, J. Review on current research of materials, fabrication and application for bipolar plate in proton exchange membrane fuel cell. Int. J. Hydrog. Energy 2020, 45, 29832–29847. [Google Scholar] [CrossRef]

- Deyab, M.A.; Mele, G. Stainless steel bipolar plate coated with polyaniline/Zn-Porphyrin composites coatings for proton exchange membrane fuel cell. Sci. Rep. 2020, 10, 3277. [Google Scholar] [CrossRef] [PubMed]

- Mi, B.; Chen, Z.; Wang, Q.; Li, Y.; Qin, Z.; Wang, H. Properties of C-doped CrTiN films on the 316L stainless steel bipolar plate for PEMFC. Int. J. Hydrog. Energy 2021, 46, 32645–32654. [Google Scholar] [CrossRef]

- Zeng, Y.; He, Z.; Hua, Q.; Xu, Q.; Min, Y. Polyacrylonitrile Infused in a Modified Honeycomb Aluminum Alloy Bipolar Plate and Its Acid Corrosion Resistance. ACS Omega 2020, 5, 16976–16985. [Google Scholar] [CrossRef]

- El-Enin, S.A.A.; Abdel-Salam, O.E.; El-Abd, H.; Amin, A.M. New electroplated aluminum bipolar plate for PEM fuel cell. J. Power Sources 2008, 177, 131–136. [Google Scholar] [CrossRef]

- Li, T.; Yan, Z.; Liu, Z.; Yan, Y.; Chen, Y. Surface microstructure and performance of TiN monolayer film on titanium bipolar plate for PEMFC. Int. J. Hydrog. Energy 2021, 46, 31382–31390. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Z.; Zhang, R.; Jiang, T.; Peng, L. Fabrication of micro channels for titanium PEMFC bipolar plates by multistage forming process. Int. J. Hydrog. Energy 2021, 46, 11092–11103. [Google Scholar] [CrossRef]

- Bai, C.-Y.; Ger, M.-D.; Wu, M.-S. Corrosion behaviors and contact resistances of the low-carbon steel bipolar plate with a chromized coating containing carbides and nitrides. Int. J. Hydrog. Energy 2009, 34, 6778–6789. [Google Scholar] [CrossRef]

- Chanda, U.K.; Behera, A.; Roy, S.; Pati, S. Evaluation of Ni-Cr-P coatings electrodeposited on low carbon steel bipolar plates for polymer electrolyte membrane fuel cell. Int. J. Hydrog. Energy 2018, 43, 23430–23440. [Google Scholar] [CrossRef]

- Park, J.-H.; Wada, T.; Naruse, Y.; Hagio, T.; Kamimoto, Y.; Ryoichi, I. Electrodeposition of Ni-W/CNT Composite Plating and Its Potential as Coating for PEMFC Bipolar Plate. Coatings 2020, 10, 1095. [Google Scholar] [CrossRef]

- Kang, K.; Park, S.; Ju, H. Effects of type of graphite conductive filler on the performance of a composite bipolar plate for fuel cells. Solid State Ion. 2014, 262, 332–336. [Google Scholar] [CrossRef]

- Ayotunde Alo, O.; Olatunji Otunniyi, I.; Pienaar, H.; Rotimi Sadiku, E. Electrical and mechanical properties of polypropylene/epoxy blend-graphite/carbon black composite for proton exchange membrane fuel cell bipolar plate. Mater. Today Proc. 2021, 38, 658–662. [Google Scholar] [CrossRef]

- Roncaglia, F.; Romagnoli, M.; Incudini, S.; Santini, E.; Imperato, M.; Spinelli, L.; di Bona, A.; Biagi, R.; Mucci, A. Graphite-epoxy composites for fuel-cell bipolar plates: Wet vs dry mixing and role of the design of experiment in the optimization of molding parameters. Int. J. Hydrog. Energy 2021, 46, 4407–4416. [Google Scholar] [CrossRef]

- Li, W.; Jing, S.; Wang, S.; Wang, C.; Xie, X. Experimental investigation of expanded graphite/phenolic resin composite bipolar plate. Int. J. Hydrog. Energy 2016, 41, 16240–16246. [Google Scholar] [CrossRef]

- Kang, K.; Park, S.; Jo, A.; Lee, K.; Ju, H. Development of ultralight and thin bipolar plates using epoxy-carbon fiber prepregs and graphite composites. Int. J. Hydrog. Energy 2017, 42, 1691–1697. [Google Scholar] [CrossRef]

- Wang, X.L.; Li, B.; Qu, Z.G.; Zhang, J.F.; Jin, Z.G. Effects of graphite microstructure evolution on the anisotropic thermal conductivity of expanded graphite/paraffin phase change materials and their thermal energy storage performance. Int. J. Heat Mass Transf. 2020, 155, 119853. [Google Scholar] [CrossRef]

- Witpathomwong, S.; Okhawilai, M.; Jubsilp, C.; Karagiannidis, P.; Rimdusit, S. Highly filled graphite/graphene/carbon nanotube in polybenzoxazine composites for bipolar plate in PEMFC. Int. J. Hydrog. Energy 2020, 45, 30898–30910. [Google Scholar] [CrossRef]

- Picard, S.; Burns, D.T.; Roger, P. Determination of the specific heat capacity of a graphite sample using absolute and differential methods. Metrologia 2007, 44, 294–302. [Google Scholar] [CrossRef]

- Fang, Z.; Li, M.; Wang, S.; Gu, Y.; Li, Y.; Zhang, Z. Through-thickness thermal conductivity enhancement of carbon fiber composite laminate by filler network. Int. J. Heat Mass Transf. 2019, 137, 1103–1111. [Google Scholar] [CrossRef]

- Alo, O.A.; Otunniyi, I.O.; Pienaar, H. Development of graphite-filled polymer blends for application in bipolar plates. Polym. Compos. 2020, 41, 3364–3375. [Google Scholar] [CrossRef]

- Simaafrookhteh, S.; Khorshidian, M.; Momenifar, M. Fabrication of multi-filler thermoset-based composite bipolar plates for PEMFCs applications: Molding defects and properties characterizations. Int. J. Hydrog. Energy 2020, 45, 14119–14132. [Google Scholar] [CrossRef]

- Hu, B.; Chang, F.-L.; Xiang, L.-Y.; He, G.-J.; Cao, X.-W.; Yin, X.-C. High performance polyvinylidene fluoride/graphite/multi-walled carbon nanotubes composite bipolar plate for PEMFC with segregated conductive networks. Int. J. Hydrog. Energy 2021, 46, 25666–25676. [Google Scholar] [CrossRef]

- Wang, X.; Qu, Z.; Ren, G.; Feng, C.; Cheng, F. Prolonged yield platform in bioinspired three dimensional carbon materials derived from crack deflection. Mater. Lett. 2020, 270, 127759. [Google Scholar] [CrossRef]

| Impregnation | High | Medium | Low | |

|---|---|---|---|---|

| Molding | ||||

| High | HH | HM | HL | |

| Medium | MH | × | × | |

| Low | LH | × | × | |

| HU | HL | HM | HH | MH | LH | |

|---|---|---|---|---|---|---|

| Weight ratio of resin (wt.%) | / | 38.7 | 38.2 | 39.1 | 41.5 | 40.8 |

| Theoretical density (g/cm3) | 2.33 | 1.61 | 1.62 | 1.60 | 1.57 | 1.58 |

| True density (g/cm3) | 1.28 | 1.57 | 1.56 | 1.56 | 1.54 | 1.59 |

| Relative density (%) | 55% | 97.5% | 96.5% | 97.3% | 97.8% | 99.8% |

| Thickness (mm) | 0.895 | 0.901 | 0.931 | 0.921 | 0.971 | 0.952 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Qu, Z.; Yang, H.; Zhang, G.; Zhang, Y.; Liu, C. Collective Enhancements on Thermal-Electrical and Mechanical Properties of Graphite-Based Composite Bipolar Plates through the Coupled Manipulations of Molding and Impregnation Pressures. Membranes 2022, 12, 222. https://doi.org/10.3390/membranes12020222

Wang X, Qu Z, Yang H, Zhang G, Zhang Y, Liu C. Collective Enhancements on Thermal-Electrical and Mechanical Properties of Graphite-Based Composite Bipolar Plates through the Coupled Manipulations of Molding and Impregnation Pressures. Membranes. 2022; 12(2):222. https://doi.org/10.3390/membranes12020222

Chicago/Turabian StyleWang, Xueliang, Zhiguo Qu, Haitao Yang, Guobin Zhang, Yichong Zhang, and Chaofan Liu. 2022. "Collective Enhancements on Thermal-Electrical and Mechanical Properties of Graphite-Based Composite Bipolar Plates through the Coupled Manipulations of Molding and Impregnation Pressures" Membranes 12, no. 2: 222. https://doi.org/10.3390/membranes12020222

APA StyleWang, X., Qu, Z., Yang, H., Zhang, G., Zhang, Y., & Liu, C. (2022). Collective Enhancements on Thermal-Electrical and Mechanical Properties of Graphite-Based Composite Bipolar Plates through the Coupled Manipulations of Molding and Impregnation Pressures. Membranes, 12(2), 222. https://doi.org/10.3390/membranes12020222