Spinning of Polysulfone Hollow Fiber Membranes Using Constant Dope Solution Composition: Viscosity Control via Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. The Dope Solution Preparation

2.3. Measurement of the Dope Solution Viscosity

2.4. Hollow Fiber Membranes Preparation

2.5. Study of the Phase Inversion Kinetics at Different Temperatures

2.6. Gas Transport Properties

2.7. Porosimetry

2.8. Scanning Electron Microscopy

3. Results and Discussion

3.1. Effect of Temperature on the Dope Solution Viscosity

3.2. The Study of Phase Inversion Kinetics

3.3. Influence of the Dope Solution Viscosity on Other Spinning Parameters

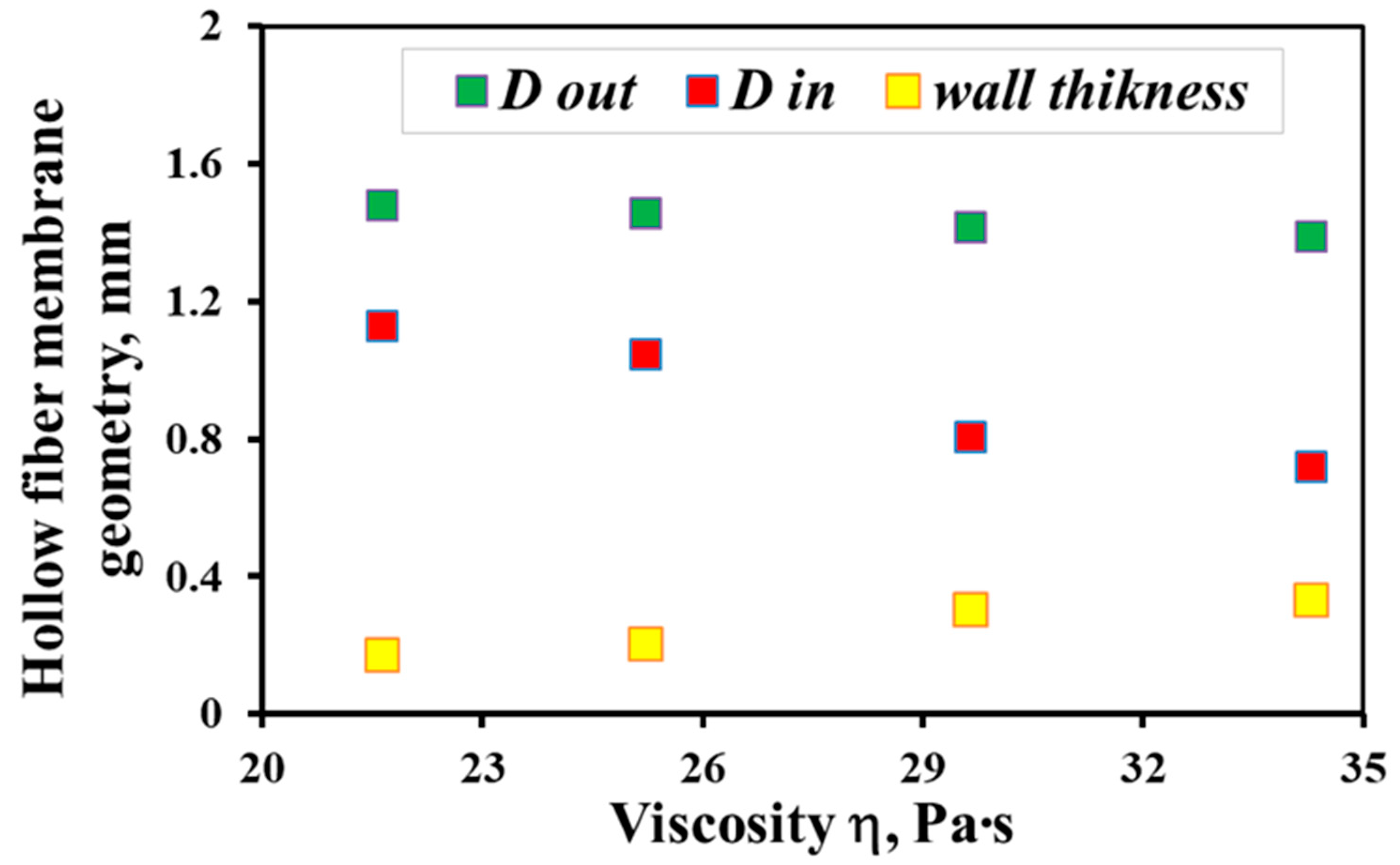

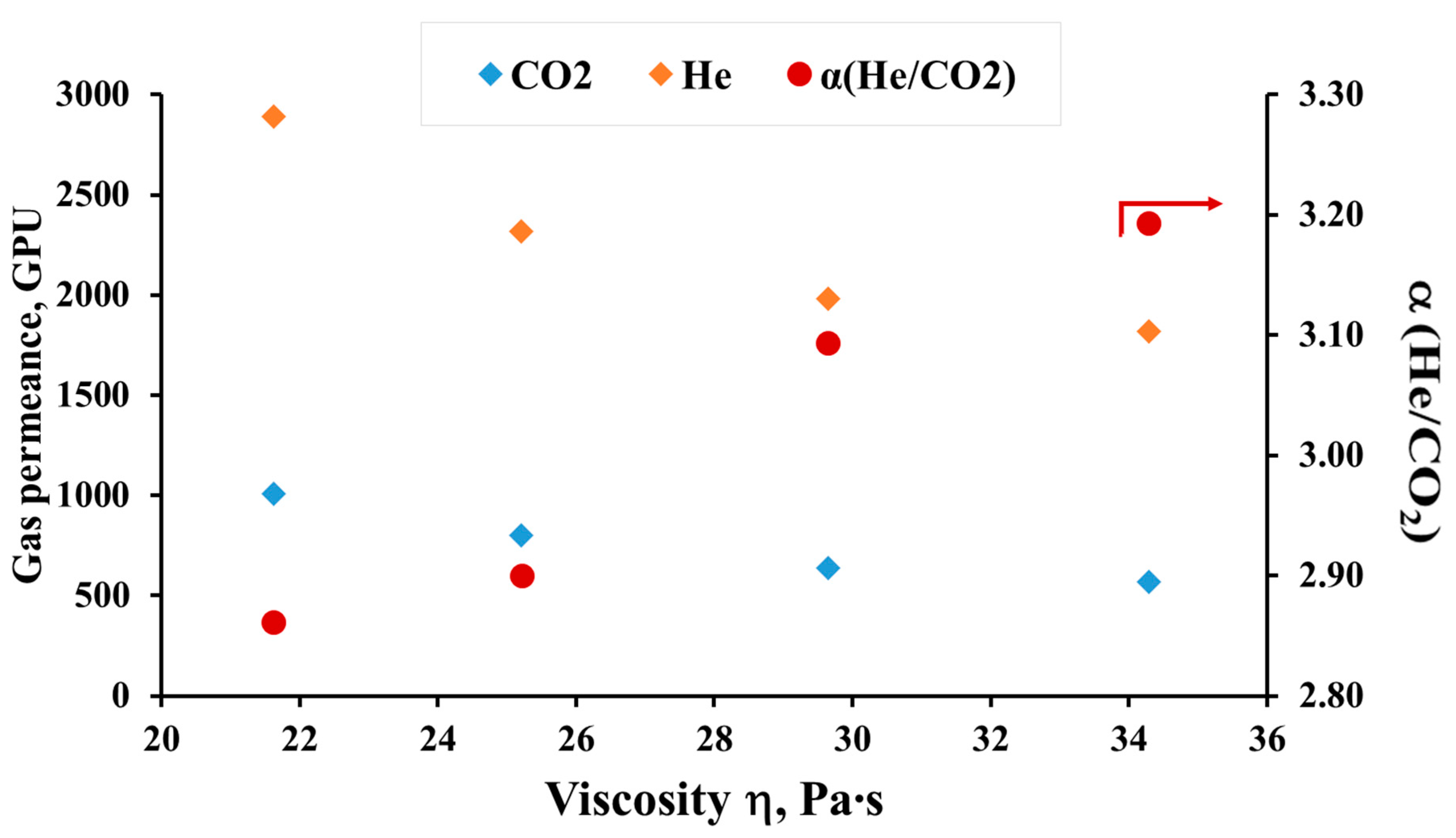

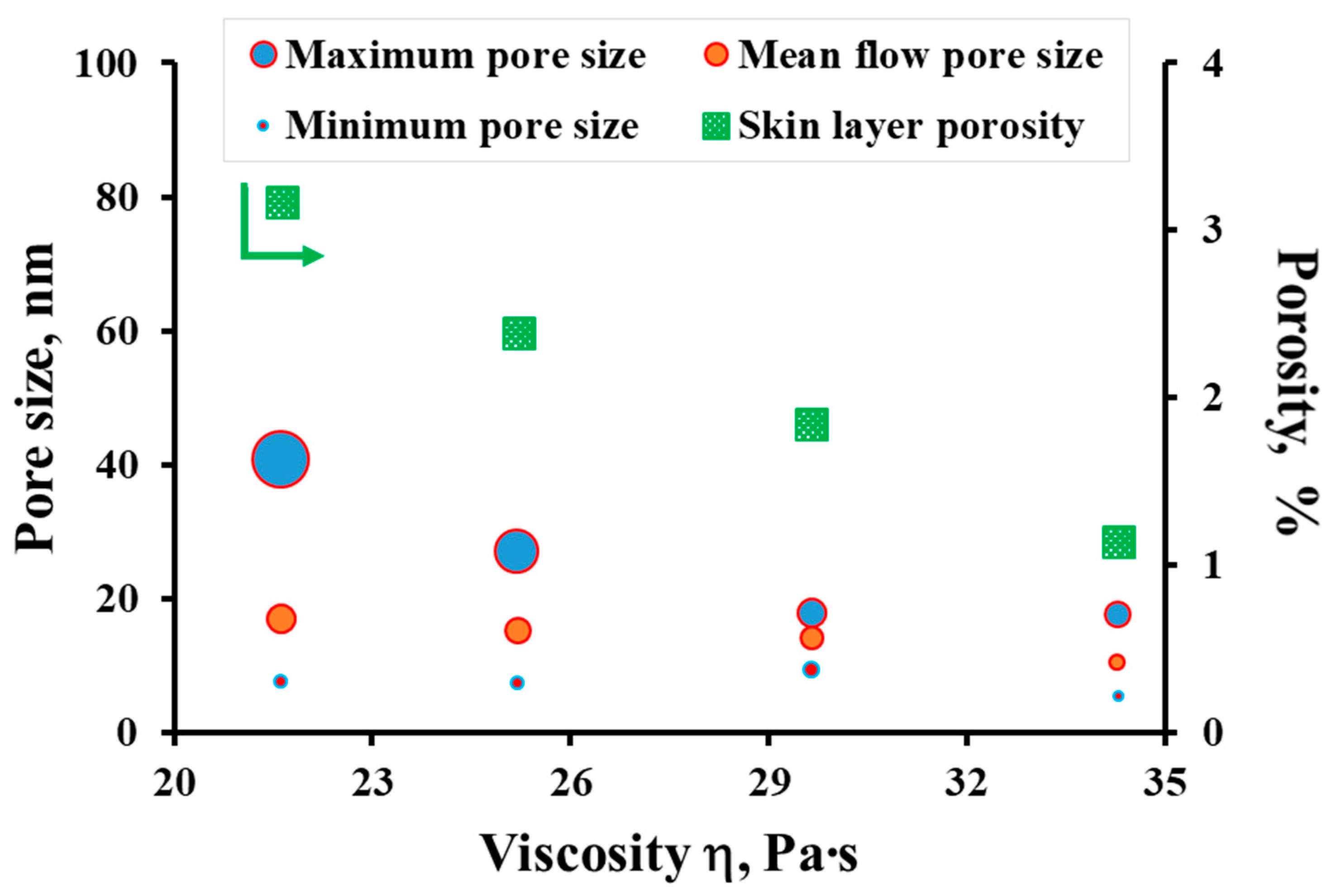

3.4. Properties of Hollow Fiber Membranes

4. Conclusions

- The rate of the polymer solution coagulation front changes by a factor of 2.8, from 16.5 to 5.8 cm/s;

- The speed of the hollow fiber membrane formation increases 1.4 times, from 4.8 to 6.7 cm/s, and the draw ratio also increases;

- The thickness of the skin layer decreases from 1.0 to 0.8 µm; the wall thickness of the hollow fiber membrane decreases from 340 µm to 180 µm with a simultaneous increase in both the outer and inner diameters;

- The gas permeance for individual gases He and CO2 increases 1.6–1.8 times, from 1820 to 2890 GPU and from 570 to 1010 GPU, respectively, while the selectivity decreases from 3.19 to 2.86;

- The mean flow pore size of hollow fiber membranes increases from 10.4 to 17.0 nm, the surface porosity also increases by about three times.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peng, N.; Widjojo, N.; Sukitpaneenit, P.; Teoh, M.M.; Lipscomb, G.G.; Chung, T.S.; Lai, J.Y. Evolution of polymeric hollow fibers as sustainable technologies: Past, present, and future. Prog. Polym. Sci. 2012, 37, 1401–1424. [Google Scholar] [CrossRef]

- Feng, C.Y.; Khulbe, K.C.; Matsuura, T.; Ismail, A.F. Recent progresses in polymeric hollow fiber membrane preparation, characterization and applications. Sep. Purif. Technol. 2013, 111, 43–71. [Google Scholar] [CrossRef]

- Khan, I.U.; Othman, M.H.D.; Ismail, A.F.; Matsuura, T.; Hashim, H.; Nordin, N.A.H.M.; Rahman, M.A.; Jaafar, J.; Jilani, A. Status and improvement of dual-layer hollow fiber membranes via co-extrusion process for gas separation: A review. J. Nat. Gas Sci. Eng. 2018, 52, 215–234. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Otitoju, T.A.; Ooi, B.S. Hollow fiber (HF) membrane fabrication: A review on the effects of solution spinning conditions on morphology and performance. J. Ind. Eng. Chem. 2019, 70, 35–50. [Google Scholar] [CrossRef]

- Matveev, D.N.; Vasilevskii, V.P.; Borisov, I.L.; Volkov, V.V.; Volkov, A.V. Effects of dry-jet wet spinning parameters on properties of polysulfone hollow fiber membranes. Russ. J. Appl. Chem. 2020, 93, 554–563. [Google Scholar] [CrossRef]

- Ivanov, M.V.; Dibrov, G.A.; Loyko, A.V.; Varezhkin, A.V.; Kagramanov, G.G. Techniques to manage geometry characteristics of hollow-fiber membranes. Theor. Found. Chem. Eng. 2016, 50, 316–324. [Google Scholar] [CrossRef]

- Dibrov, G.; Kagramanov, G.; Sudin, V.; Molchanov, S.; Grushevenko, E.; Yushkin, A.; Volkov, V. Influence of draw ratio and take-up velocity on properties of ultrafiltration hollow fiber membranes from polyethersulfone. Fibers 2022, 10, 29. [Google Scholar] [CrossRef]

- Han, M.-J.; Nam, S.-T. Thermodynamic and rheological variation in polysulfone solution by PVP and its effect in the preparation of phase inversion membrane. J. Membr. Sci. 2002, 202, 55–61. [Google Scholar] [CrossRef]

- Li, Q.; Xu, Z.-L.; Yu, L.-Y. Effects of mixed solvents and PVDF types on performances of PVDF microporous membranes. J. Appl. Polym. Sci. 2010, 115, 2277–2287. [Google Scholar] [CrossRef]

- Chang, Y.; Shih, Y.-J.; Ruaan, R.-C.; Higuchi, A.; Chen, W.-Y.; Lai, J.-Y. Preparation of poly(vinylidene fluoride) microfiltration membrane with uniform surface-copolymerized poly(ethylene glycol) methacrylate and improvement of blood compatibility. J. Membr. Sci. 2008, 309, 165–174. [Google Scholar] [CrossRef]

- Matveev, D.; Vasilevsky, V.; Volkov, V.; Plisko, T.; Shustikov, A.; Volkov, A.; Bildyukevich, A. Fabrication of ultrafiltration membranes from non-toxic solvent dimethylsulfoxide: Benchmarking of commercially available acrylonitrile co-polymers. J. Environ. Chem. Eng. 2022, 10, 107061. [Google Scholar] [CrossRef]

- Anokhina, T.; Raeva, A.; Makaev, S.; Borisov, I.; Vasilevsky, V.; Volkov, A. Express Method of Preparation of Hollow Fiber Membrane Samples for Spinning Solution Optimization: Polysulfone as Example. Membranes 2021, 11, 396. [Google Scholar] [CrossRef] [PubMed]

- Roslan, R.A.; Lau, W.J.; Zulhairun, A.K.; Goh, P.S.; Ismail, A.F. Improving CO2/CH4 and O2/N2 separation by using surface-modified polysulfone hollow fiber membranes. J. Polym. Res. 2020, 27, 119. [Google Scholar] [CrossRef]

- Naim, R.; Ismail, A.F. Effect of polymer concentration on the structure and performance of PEI hollow fiber membrane contactor for CO2 stripping. J. Hazard. Mater. 2013, 250–251, 354–361. [Google Scholar] [CrossRef] [PubMed]

- Karkhanechi, H.; Rajabzadeh, S.; Di Nicolò, E.; Usuda, H.; Shaikh, A.R.; Matsuyama, H. Preparation and characterization of ECTFE hollow fiber membranes via thermally induced phase separation (TIPS). Polymer 2016, 97, 515–524. [Google Scholar] [CrossRef]

- Bakeri, G.H.; Ismail, A.F.; Rahimnejad, M.; Matsuura, T. Porous polyethersulfone hollow fiber membrane in gas-liquid contacting processes. Chem. Eng. Res. Des. 2014, 92, 1381–1390. [Google Scholar] [CrossRef]

- Li, G.; Kujawski, W.; Knozowska, K.; Kujawa, J. The Effects of PEI Hollow Fiber Substrate Characteristics on PDMS/PEI Hollow Fiber Membranes for CO2/N2 Separation. Membranes 2021, 11, 56. [Google Scholar] [CrossRef]

- Zhang, P.; Fang, C.; Rajabzadeh, S.; Liu, W.; Jia, Y.; Shen, Q.; Zhang, L.; Wang, S.; Kato, N.; Matsuyama, H. Effect of polymer molecular weight on structure and performance of PVDF hollow fiber membranes prepared via TIPS process with co-extrusion of solvent using triple orifice spinneret. J. Membr. Sci. 2020, 620, 118854. [Google Scholar] [CrossRef]

- Thong, Z.; Gao, J.; Lim, Z.L.J.; Wang, K.-Y.; Chung, T.-S. Fabrication of loose outer-selective nanofiltration (NF) polyethersulfone (PES) hollow fibers via single-step spinning process for dye removal. Sep. Purif. Technol. 2018, 192, 483–490. [Google Scholar] [CrossRef]

- Dou, Y.; Dong, X.; Ma, Y.; Ge, P.; Li, C.; Zhu, A.; Liu, Q.; Zhang, Q. Hollow fiber ultrafiltration membranes of poly(biphenyl-trifluoroacetone). J. Membr. Sci. 2022, 659, 120779. [Google Scholar] [CrossRef]

- Behboudi, A.; Ghiasi, S.; Mohammadi, T.; Ulbricht, M. Preparation and characterization of asymmetric hollow fiber polyvinyl chloride (PVC) membrane for forward osmosis application. Sep. Purif. Technol. 2021, 270, 118801. [Google Scholar] [CrossRef]

- Heidari, A.; Abdollahi, E.; Mohammadi, T.; Asadi, A.A. Improving permeability, hydrophilicity and antifouling characteristic of PES hollow fiber UF membrane using carboxylic PES: A promising substrate to fabricate NF layer. Sep. Purif. Technol. 2021, 270, 118811. [Google Scholar] [CrossRef]

- Giwa, A.; Chakraborty, S.; Mavukkandy, M.O.; Arafat, H.A.; Hasan, S.W. Nanoporous hollow fiber polyethersulfone membranes for the removal of residual contaminants from treated wastewater effluent: Functional and molecular implications. Sep. Purif. Technol. 2017, 189, 20–31. [Google Scholar] [CrossRef]

- Zou, L.; Gusnawan, P.; Jiang, Y.-B.; Zhang, G.; Yu, J. Macrovoid-Inhibited PVDF Hollow Fiber Membranes via Spinning Process Delay for Direct Contact Membrane Distillation. ACS Appl. Mater. Interfaces 2020, 12, 28655–28668. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Li, B.; Sun, D.; Miao, X.; Gu, Y. SiO2-PDMS-PVDF hollow fiber membrane with high flux for vacuum membrane distillation. Desalination 2018, 429, 33–43. [Google Scholar] [CrossRef]

- Mansourizadeh, A.; Ismail, A.F. Effect of LiCl concentration in the polymer dope on the structure and performance of hydrophobic PVDF hollow fiber membranes for CO2 absorption. Chem. Eng. J. 2010, 165, 980–988. [Google Scholar] [CrossRef]

- Wang, L.-Y.; Yong, W.F.; Yu, L.E.; Chung, T.-S. Design of High Efficiency PVDF-PEG Hollow Fibers for Air Filtration of Ultrafine Particles. J. Membr. Sci. 2017, 535, 342–349. [Google Scholar] [CrossRef]

- Ghasem, N.; Al-Marzouqi, M.; Rahim, N.A. Effect of polymer extrusion temperature on poly(vinylidene fluoride) hollow fiber membranes: Properties and performance used as gas–liquid membrane contactor for CO2 absorption. Sep. Purif. Technol. 2012, 99, 91–103. [Google Scholar] [CrossRef]

- Kajekar, A.J.; Dodamani, B.M.; Isloor, A.M.; Karim, Z.A.; Cheer, N.B.; Ismail, A.F.; Shilton, S.J. Preparation and characterization of novel PSf/PVP/PANI-nanofiber nanocomposite hollow fiber ultrafiltration membranes and their possible applications for hazardous dye rejection. Desalination 2015, 365, 117–125. [Google Scholar] [CrossRef] [Green Version]

- Abed, M.R.M.; Kumbharkar, S.C.; Groth, A.M.; Li, K. Economical production of PVDF-g-POEM for use as a blend in preparation of PVDF based hydrophilic hollow fibre membranes. Sep. Purif. Technol. 2013, 106, 47–55. [Google Scholar] [CrossRef]

- Plisko, T.V.; Bildyukevich, A.V.; Zhao, L.; Huang, W.; Volkov, V.V.; Huang, Z. Formation of Polysulfone Hollow Fiber Membranes Using the Systems with Lower Critical Solution Temperature. Fibers 2021, 9, 28. [Google Scholar] [CrossRef]

- Ursino, C.; Russo, F.; Ferrari, R.M.; De Santo, M.P.; Di Nicolo, E.; He, T.; Galiano, F.; Figoli, A. Polyethersulfone hollow fiber membranes prepared with Polarclean® as a more sustainable solvent. J. Membr. Sci. 2020, 608, 118216. [Google Scholar] [CrossRef]

- Ismail, A.F.; Lorna, W. Suppression of plasticization in polysulfone membranes for gas separations by heat-treatment technique. Sep. Purif. Technol. 2003, 30, 37–46. [Google Scholar] [CrossRef]

- Borisov, I.; Vasilevsky, V.; Matveev, D.; Ovcharova, A.; Volkov, A.; Volkov, V. Effect of Temperature Exposition of Casting Solution on Properties of Polysulfone Hollow Fiber Membranes. Fibers 2019, 7, 110. [Google Scholar] [CrossRef] [Green Version]

- Malakhov, A.O.; Bazhenov, S.D.; Vasilevsky, V.P.; Borisov, I.L.; Ovcharova, A.A.; Bildyukevich, A.V.; Volkov, V.V.; Giorno, L.; Volkov, A.V. Thin-film composite hollow fiber membranes for ethylene/ethane separation in gas-liquid membrane contactor. Sep. Purif. Technol. 2019, 219, 64–73. [Google Scholar] [CrossRef]

- Ovcharova, A.; Vasilevsky, V.; Borisov, I.; Bazhenov, S.; Volkov, A.; Bildyukevich, A.; Volkov, V. Polysulfone porous hollow fiber membranes for ethylene-ethane separation in gas-liquid membrane contactor. Sep. Purif. Technol. 2017, 183, 162–172. [Google Scholar] [CrossRef]

- Borisov, I.; Ovcharova, A.; Bakhtin, D.; Bazhenov, S.; Volkov, A.; Ibragimov, R.; Gallyamov, R.; Bondarenko, G.; Mozhchil, R.; Bildyukevich, A.; et al. Development of Polysulfone Hollow Fiber Porous Supports for High Flux Composite Membranes: Air Plasma and Piranha Etching. Fibers 2017, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- Matveev, D.N.; Kutuzov, K.A.; Vasilevsky, V.P. Effect of Draw Ratio on the Morphology of Polysulfone Hollow Fiber Membranes. Membr. Membr. Technol. 2020, 2, 351–356. [Google Scholar] [CrossRef]

- Anokhina, T.; Borisov, I.; Yushkin, A.; Vaganov, G.; Didenko, A.; Volkov, A. Phase Separation within a Thin Layer of Polymer Solution as Prompt Technique to Predict Membrane Morphology and Transport Properties. Polymers 2020, 12, 2785. [Google Scholar] [CrossRef]

- Frenkel, Y.I. Kinetic Theory of Liquids; Oxford University Press: Oxford, UK, 1946. [Google Scholar]

- Vinogradov, G.V.; Malkin, A.Y. Rheology of Polymers; Springer Verlag: Berlin, Germany, 1980. [Google Scholar]

- Mulder, M. Basic Principles of Membrane Technology, 2nd ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1997. [Google Scholar]

- Çulfaz, P.Z.; Rolevink, E.; van Rijn, C.; Lammertink, R.G.H.; Wessling, M. Microstructured hollow fibers for ultrafiltration. J. Membr. Sci. 2010, 347, 32–41. [Google Scholar] [CrossRef]

- Shukla, S.; Benes, N.E.; Vankelecom, I.; Méricq, J.P.; Belleville, M.P.; Hengl, N.; Marcano, J.S. Sweep gas membrane distillation in a membrane contactor with metallic hollow-fibers. J. Membr. Sci. 2015, 493, 167–178. [Google Scholar] [CrossRef]

- Sengur, R.; de Lannoy, C.F.; Turken, T.; Wiesner, M.; Koyuncu, I. Fabrication and characterization of hydroxylated and carboxylated multiwalled carbon nanotube/polyethersulfone (PES) nanocomposite hollow fiber membranes. Desalination 2015, 359, 123–140. [Google Scholar] [CrossRef]

- Wu, D.; Huang, Y.; Yu, S.; Lawless, D.; Feng, X. Thin film composite nanofiltration membranes assembled layer-by-layer via interfacial polymerization from polyethylenimine and trimesoyl chloride. J. Membr. Sci. 2014, 472, 141–153. [Google Scholar] [CrossRef]

- Chen, C.C.; Qiu, W.; Miller, S.J.; Koros, W.J. Plasticization-resistant hollow fiber membranes for CO2/CH4 separation based on a thermally crosslinkable polyimide. J. Membr. Sci. 2011, 382, 212–221. [Google Scholar] [CrossRef]

- Bildyukevich, A.V.; Plisko, T.V.; Usosky, V.V. The formation of polysulfone hollow fiber membranes by the free fall spinning method. Pet. Chem. 2016, 56, 379–400. [Google Scholar] [CrossRef]

- Shi, L.; Wang, R.; Cao, Y. Effect of the rheology of poly(vinylidene fluo-ride-co-hexafluropropylene) (PVDF–HFP) dope solutions on the formation of microporous hollow fibers used as membrane contactors. J. Membr. Sci. 2009, 344, 112–122. [Google Scholar] [CrossRef]

- McKelvey, S.A.; Clausi, D.T.; Koros, W.J. A guide to establishing hollow fiber macroscopic properties for membrane applications. J. Membr. Sci. 1997, 124, 223–232. [Google Scholar] [CrossRef]

- Grushevenko, E.A.; Borisov, I.L.; Bakhtin, D.S.; Bondarenko, G.N.; Levin, I.S.; Volkov, A.V. Silicone rubbers with alkyl side groups for C3+ hydrocarbon separation. React. Funct. Polym. 2019, 134, 156–165. [Google Scholar] [CrossRef]

- Grushevenko, E.A.; Borisov, I.L.; Knyazeva, A.A.; Volkov, V.V.; Volkov, A.V. Polyalkylmethylsiloxanes composite membranes for hydrocarbon/methane separation: Eight component mixed-gas permeation properties. Sep. Purif. Technol. 2020, 241, 116696. [Google Scholar] [CrossRef]

| Pol. | Solv. | Add. | Method | Way to Viscosity Change | Effect of Viscosity Increasing | Application | Ref. |

|---|---|---|---|---|---|---|---|

| PSF | DMAc/THF | Ethanol | NIPS | Polymer concentration ↗ | Gas permeance ↘ Gas selectivity ↗ | HF support | [13] |

| PEI | NMP | - | NIPS | Polymer concentration ↗ | N2 permeance, surface porosity, pore size, hydrophobicity ↘ | CO2 absorption | [14] |

| ECTFE | DEP, GTA | - | TIPS | Polymer concentration ↗ | Skin layer thickness, tensile strength ↗ Water permeability ↘ | MF | [15] |

| PES | NMP | - | NIPS | Polymer concentration ↗ | Pore size, surface porosity, He permeance ↘ | CO2 absorption | [16] |

| PEI | NMP | - | NIPS | Polymer concentration ↗ | Skin layer thickness, gas selectivity ↗ Gas permeability ↘ | HF support | [17] |

| PVDF | DPC | - | TIPS | -Polymer concentration ↗ -Polymer Mw ↗ | Water permeability, pore size ↗ | UF | [18] |

| PES/sPSF | NMP | LiBr | NIPS | -Ratio of polymers -Polymer concentration ↗ | Surface porosity, water permeability, MWCO ↘ | NF | [19] |

| PBT | NMP | PEG-6000 | NIPS | -Polymer concentration ↗ -Additive concentration ↗ | Porosity, pore size, water permeability ↘ | UF | [20] |

| PVP/PVC | NMP/THF | - | NIPS | Polymer weight ratio | Porosity, water permeability, MWCO ↘ Salt rejection ↗ | Forward osmosis | [21] |

| CPES/PES | DMAc | PEG-200 | NIPS | CPES content in total polymer concentration ↗ | Hydrophilicity, water permeability ↗ Tensile strength, rejection ↘ | UF | [22] |

| PES | NMP, DMAc | Ethanol, glycerol, PVP | NIPS | Additive types | Tensile strength, water permeability ↗ Rejection ↘ | NF | [23] |

| PVDF | NMP | H2O | NIPS | -Additive concentration ↗ -Storing in closed vessels ↗ | Structure: finger-like→sponge-like Porosity, pore size ↗ | Membrane distillation | [24] |

| PVDF | DMAc/TEP | PVP, SiO2 | NIPS | Additive (SiO2) concentration ↗ | Breaking strength, Young’s modulus, water permeability, rejection ↗ | Vacuum membrane distillation | [25] |

| PVDF | NMP | LiCl | NIPS | Additive concentration ↗ | Microvoid size, N2 permeance, pore size, overall porosity ↘ | CO2 absorption | [26] |

| PVDF | NMP | PEG | NIPS | Additive Mw ↗ | Structure: finger-like→sponge-like N2 permeance ↗ | Air filtration | [27] |

| PVDF | Triacetin | - | TIPS | Extrusion temperature (140–170 °C) | Pore size, hydrophobicity, membrane strength, porosity, CO2 flux ↘ | CO2 absorption | [28] |

| Parameters | |

|---|---|

| Dope solution composition (PSF/PEG-400/NMP, wt %) | 22/30/48 |

| Dope solution temperature (°C) | 17, 20, 24, 27 |

| Extrusion pressure (atm) | 5 |

| External coagulant | Tap water |

| Coagulant bath temperature (°C) | 20 ± 1 |

| Bore fluid type | NMP/water (70/30 wt %) |

| Bore fluid temperature (°C) | 20 ± 1 |

| Bore fluid flow rate (mL/min) | 3.5 ± 0.3 |

| Spinneret dimension (mm) | OD/ID = 1.7/0.8 |

| Wet air gap (cm) | 50 |

| T, °C | Viscosity, Pa s | Cross-Section | Inner Surface | Outer Surface |

|---|---|---|---|---|

| 17 | 34.3 |  |  |  |

| 20 | 29.6 |  |  |  |

| 24 | 25.2 |  |  |  |

| 27 | 21.6 |  |  |  |

| T, °C | η, Pa∙s | υ, µm/s | Dout, mm | Wall Thickness, mm | P/l (CO2), GPU | α (He/CO2) | dmax, nm | dMFP, nm | ε,% |

|---|---|---|---|---|---|---|---|---|---|

| 17 | 34.3 | 5.76 | 1.39 | 0.34 | 570 | 3.19 | 17.7 | 10.4 | 1.14 |

| 20 | 29.6 | 7.79 | 1.42 | 0.31 | 640 | 3.09 | 17.9 | 14.3 | 1.84 |

| 24 | 25.2 | 13.05 | 1.46 | 0.21 | 800 | 2.90 | 27 | 15.3 | 2.39 |

| 27 | 21.6 | 16.45 | 1.48 | 0.18 | 1010 | 2.86 | 40.8 | 17 | 3.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matveev, D.; Borisov, I.; Vasilevsky, V.; Karpacheva, G.; Volkov, V. Spinning of Polysulfone Hollow Fiber Membranes Using Constant Dope Solution Composition: Viscosity Control via Temperature. Membranes 2022, 12, 1257. https://doi.org/10.3390/membranes12121257

Matveev D, Borisov I, Vasilevsky V, Karpacheva G, Volkov V. Spinning of Polysulfone Hollow Fiber Membranes Using Constant Dope Solution Composition: Viscosity Control via Temperature. Membranes. 2022; 12(12):1257. https://doi.org/10.3390/membranes12121257

Chicago/Turabian StyleMatveev, Dmitry, Ilya Borisov, Vladimir Vasilevsky, Galina Karpacheva, and Vladimir Volkov. 2022. "Spinning of Polysulfone Hollow Fiber Membranes Using Constant Dope Solution Composition: Viscosity Control via Temperature" Membranes 12, no. 12: 1257. https://doi.org/10.3390/membranes12121257

APA StyleMatveev, D., Borisov, I., Vasilevsky, V., Karpacheva, G., & Volkov, V. (2022). Spinning of Polysulfone Hollow Fiber Membranes Using Constant Dope Solution Composition: Viscosity Control via Temperature. Membranes, 12(12), 1257. https://doi.org/10.3390/membranes12121257