Assessment of an Integrated and Sustainable Multistage System for the Treatment of Poultry Slaughterhouse Wastewater

Abstract

:1. Introduction

2. Materials and Methods

2.1. PSW Sampling

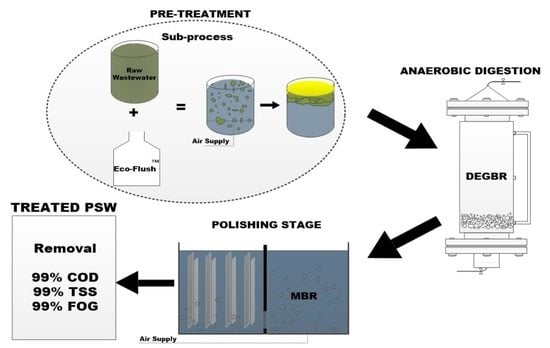

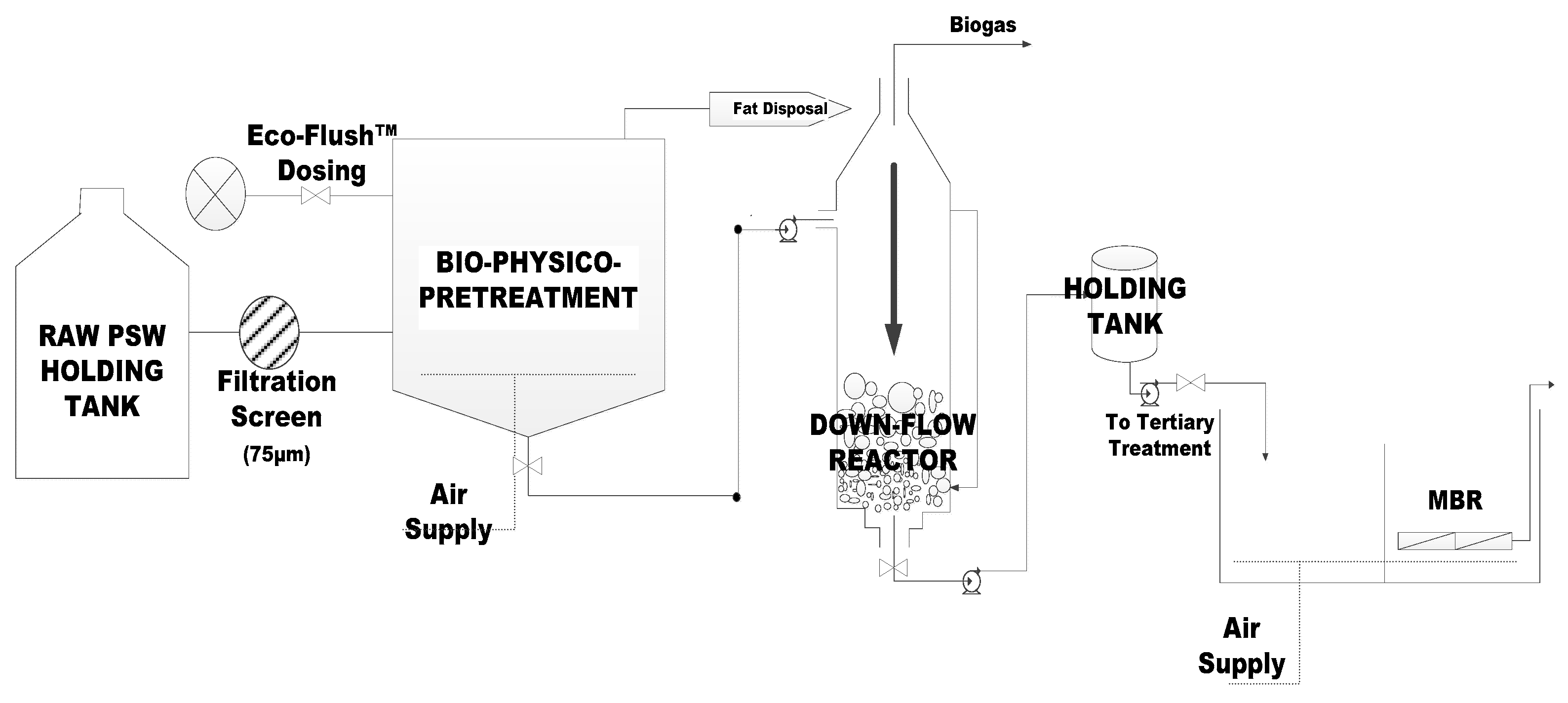

2.2. Experimental Set-Up

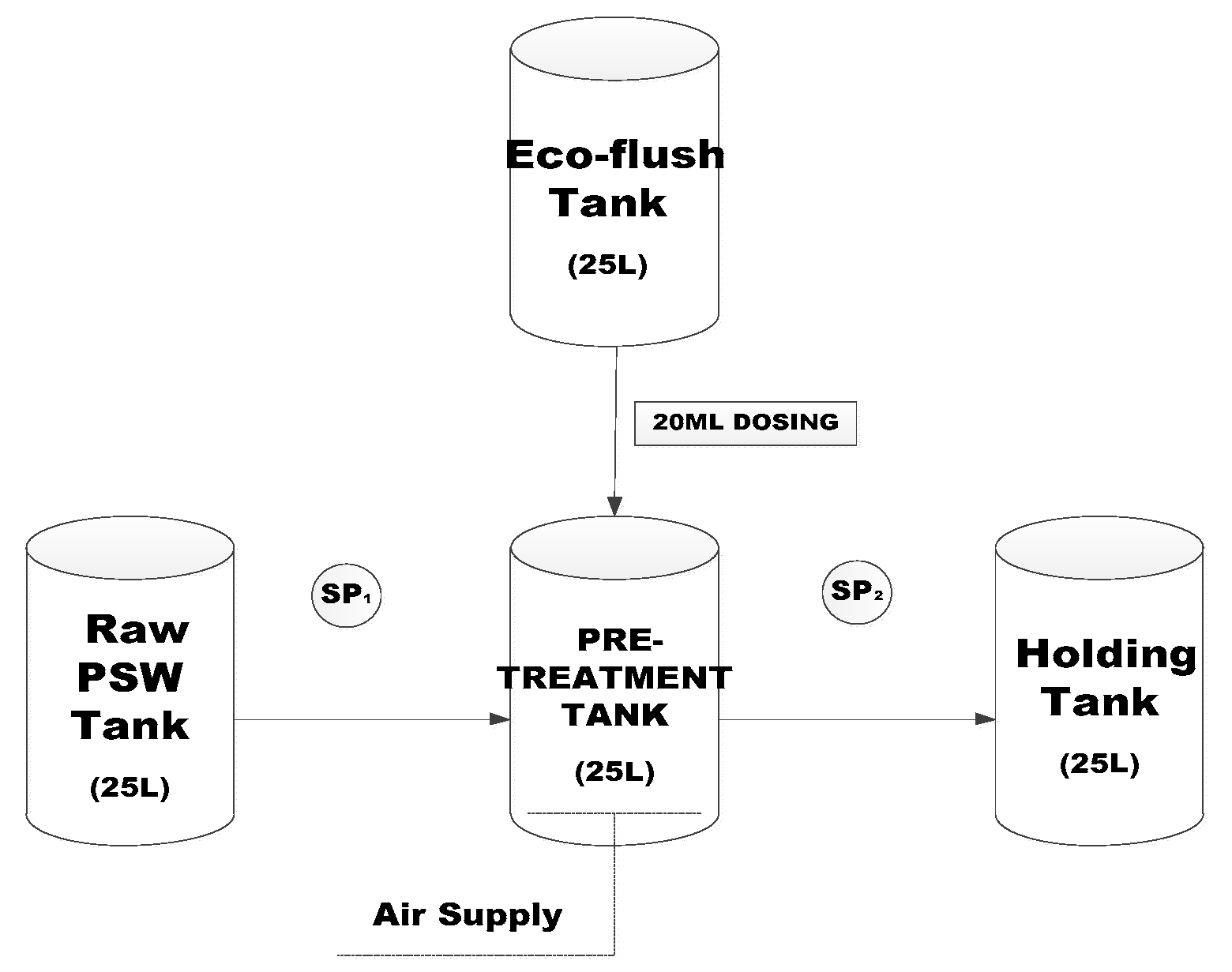

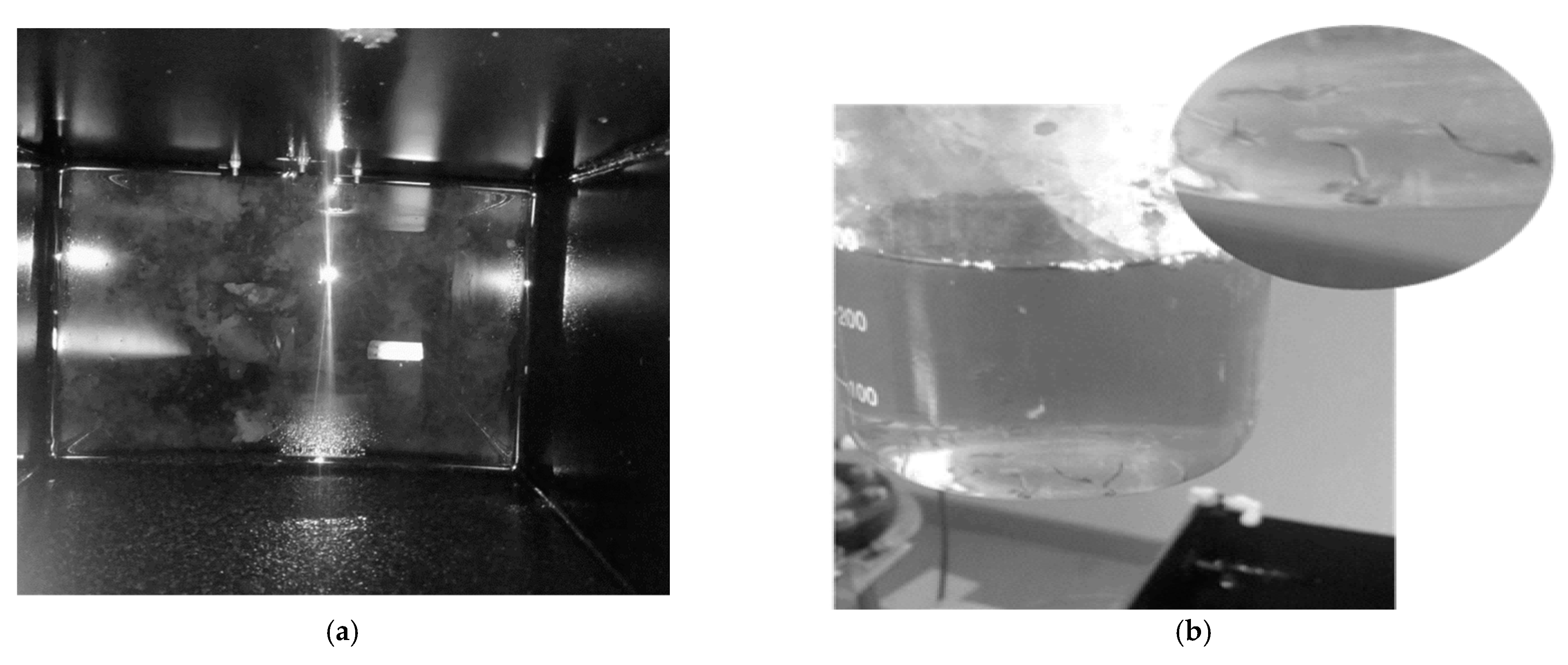

2.2.1. Pre-Treatment Unit Set-Up

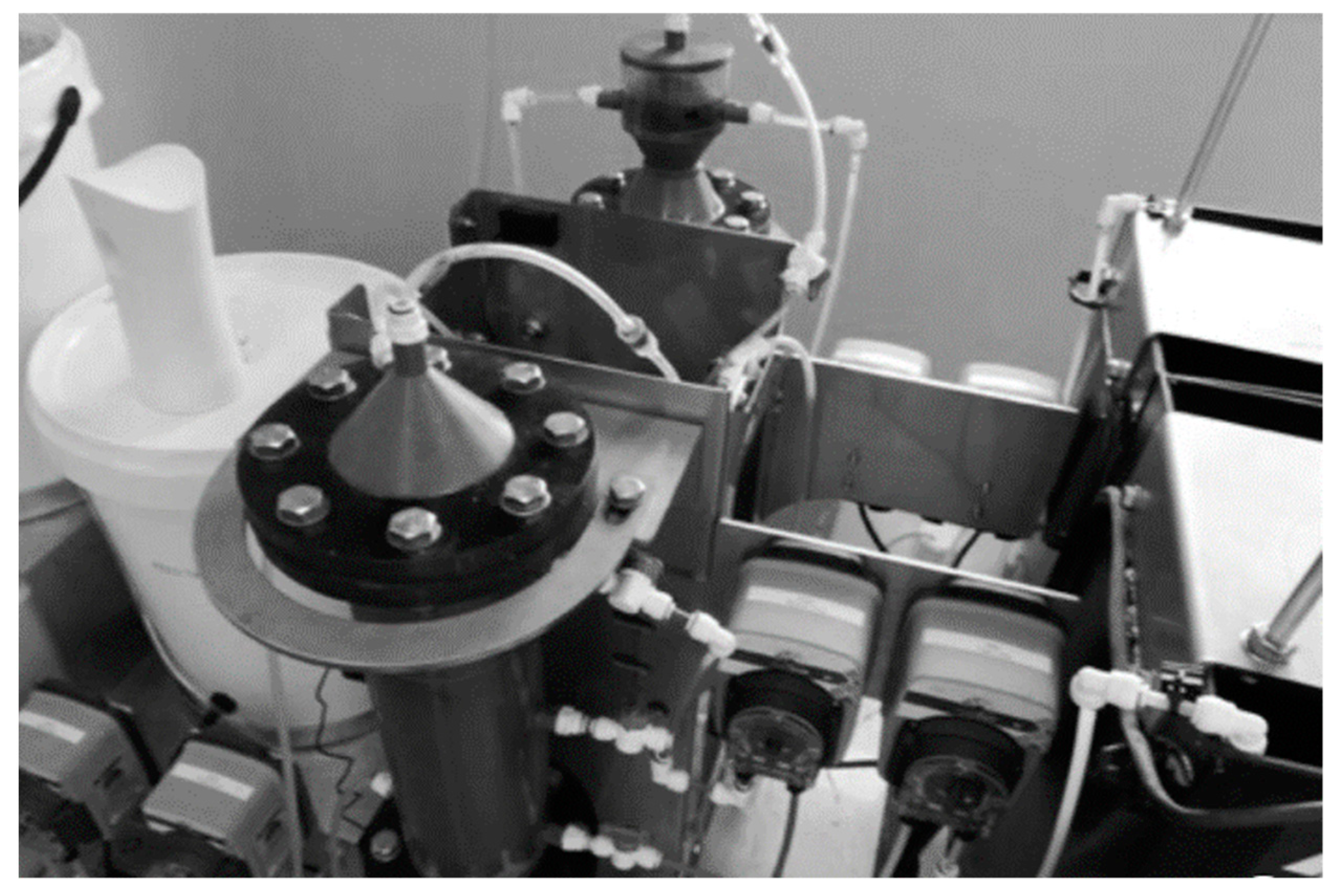

2.2.2. Bioreactor Experimental Set-Up

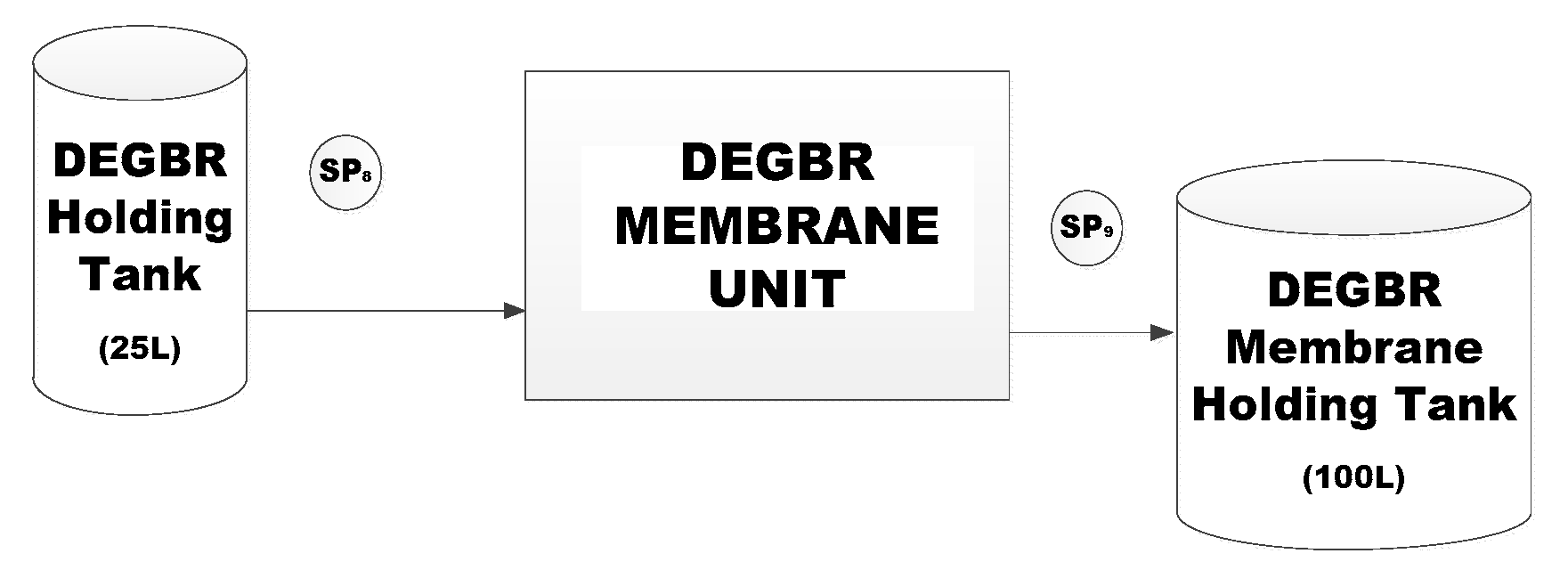

2.2.3. Membrane Bioreactor Units Set-Up

- Membrane Bioreactor design

- Inoculation and Operating Conditions

2.3. Sampling Points and Analysis

3. Results and Discussion

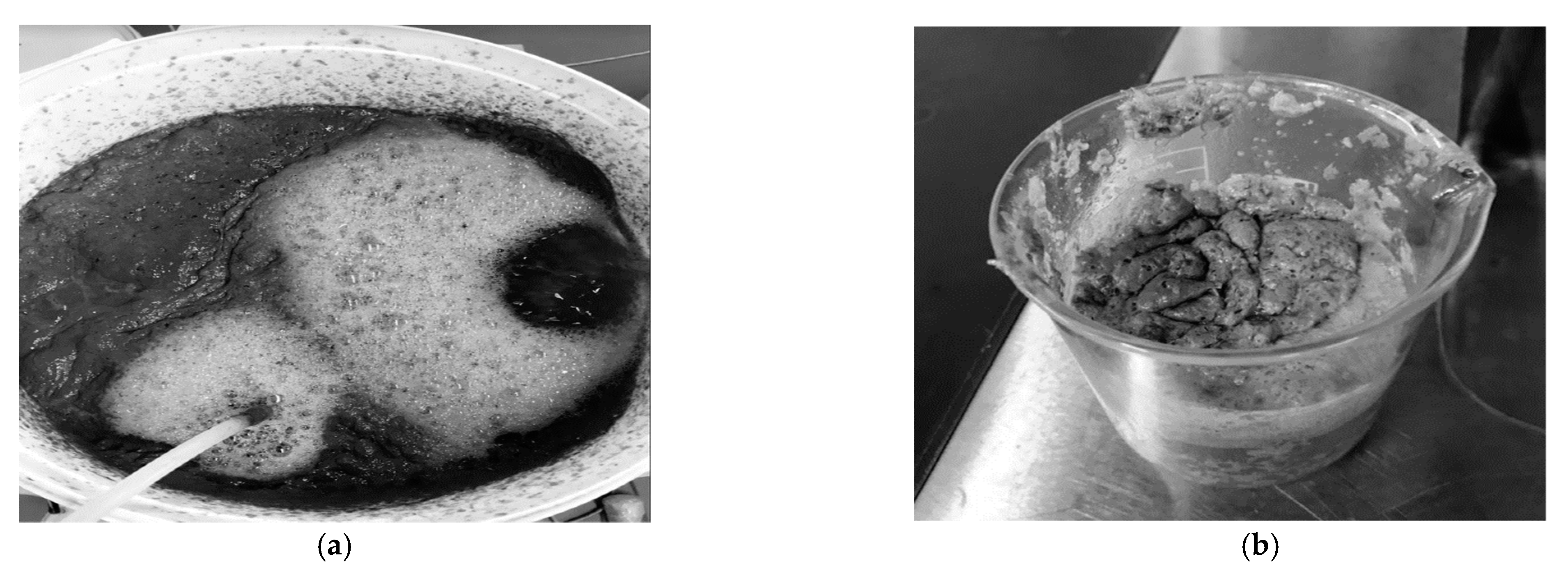

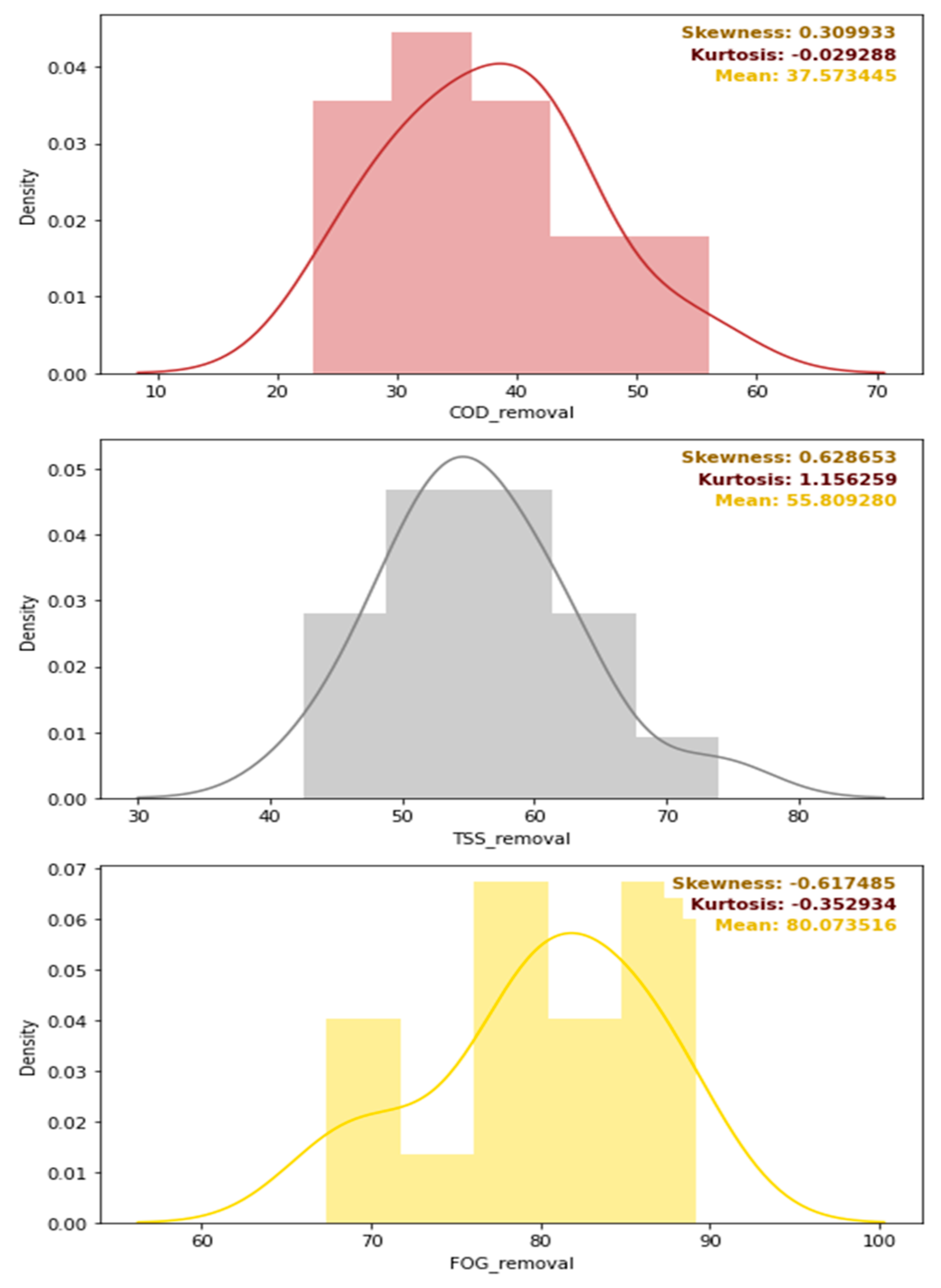

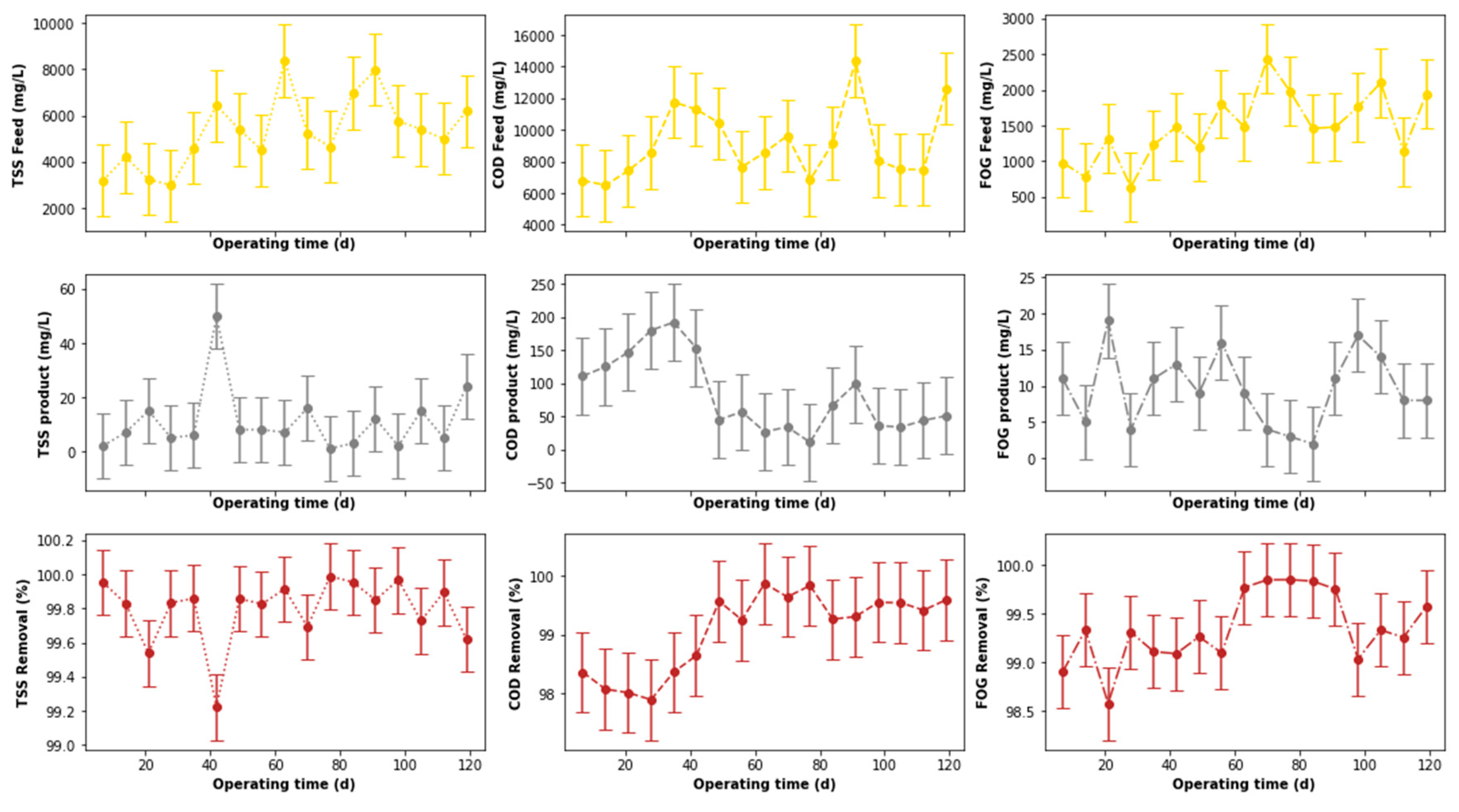

3.1. Pre-Treatment Performance Evaluation

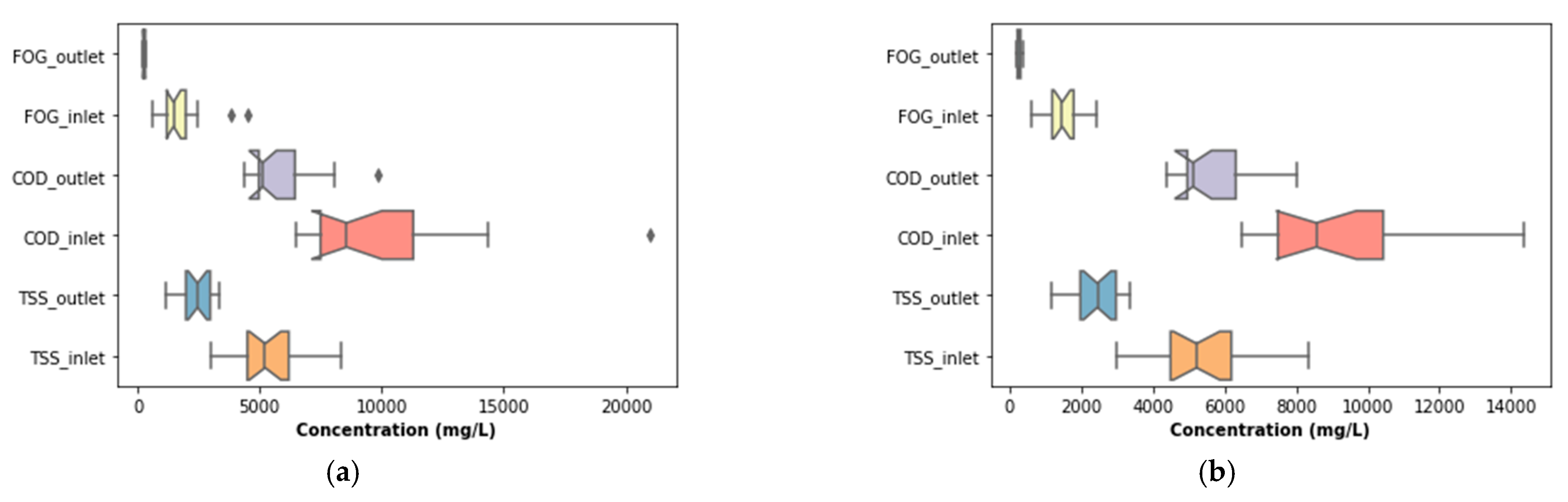

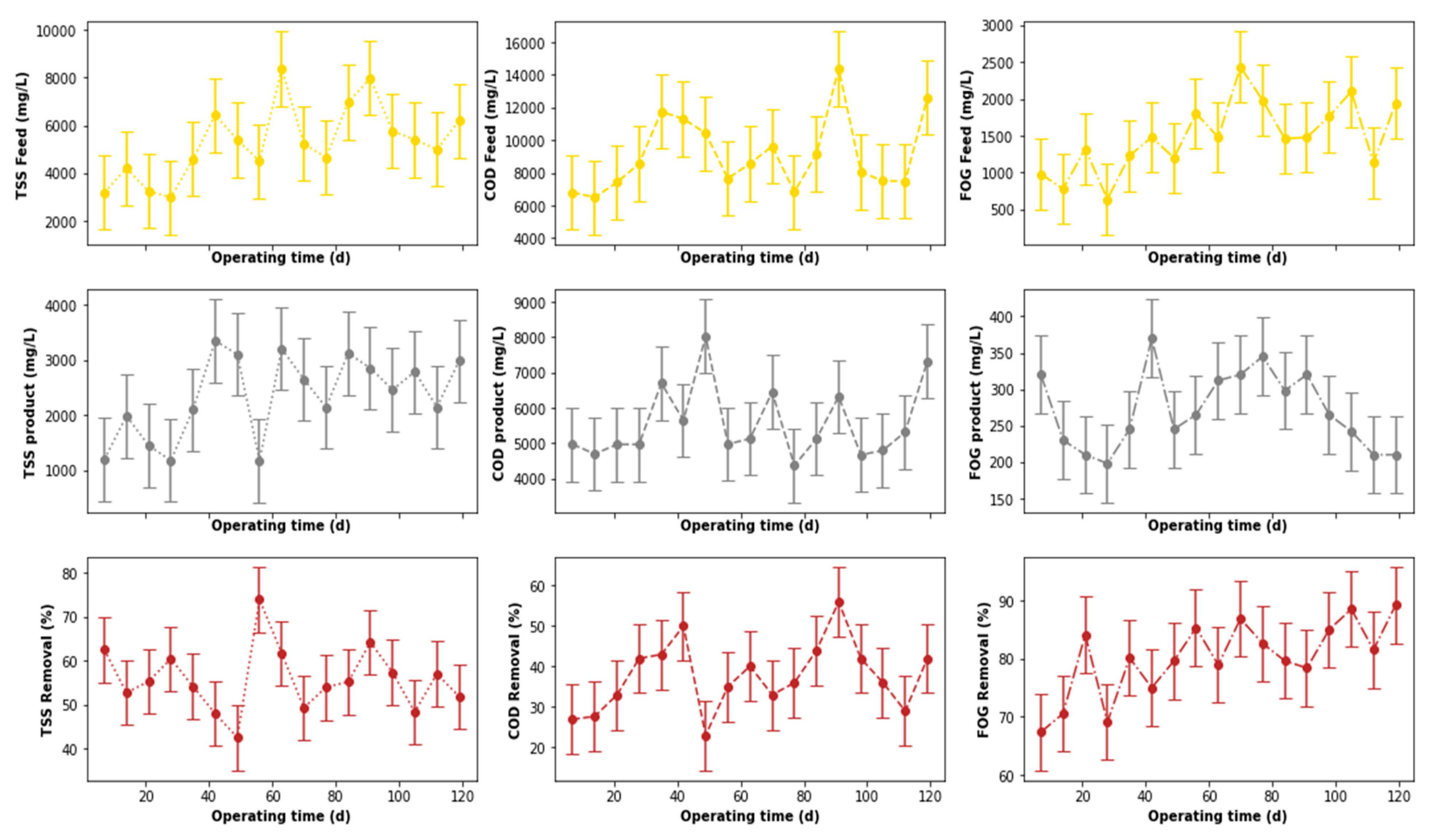

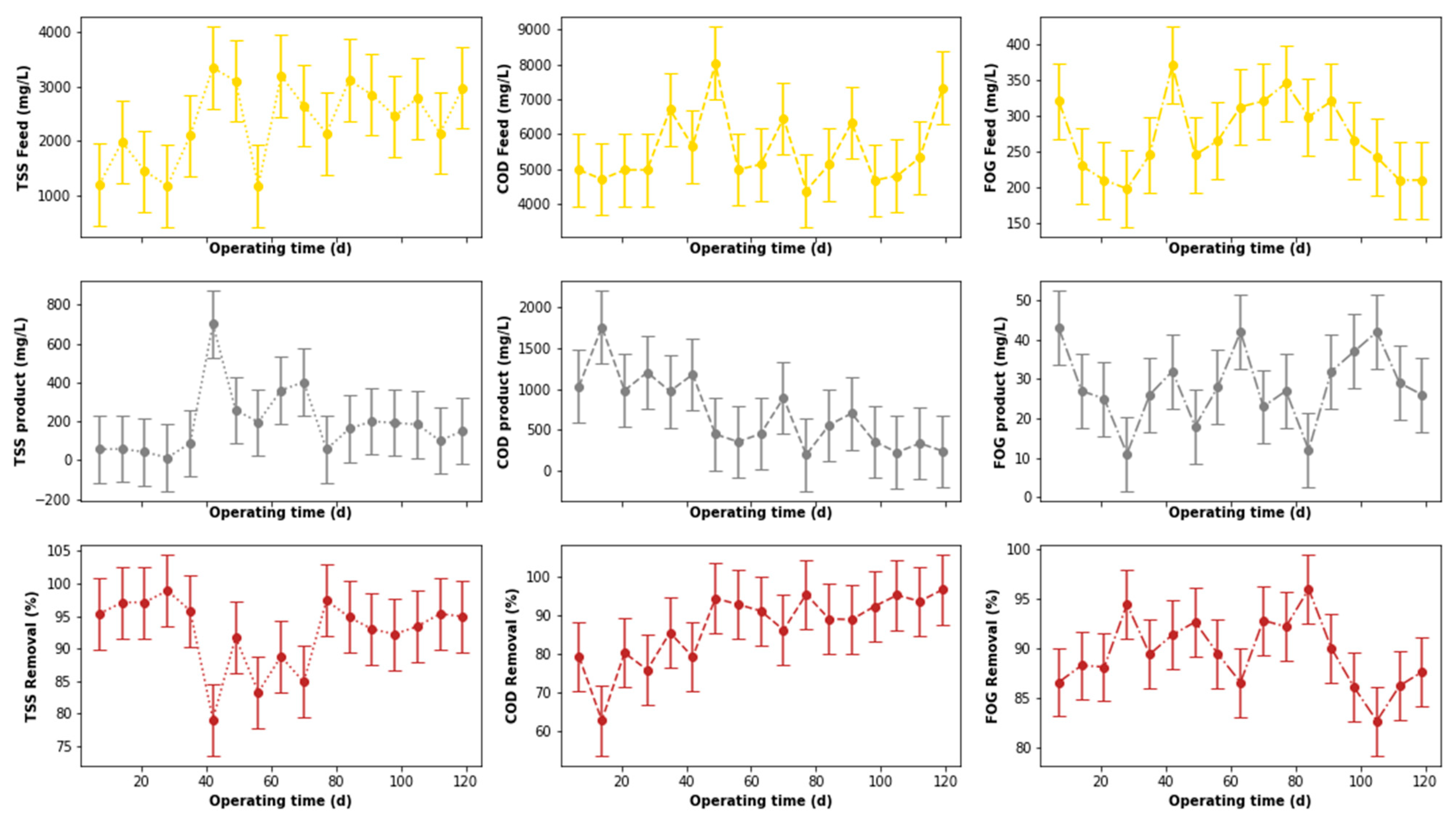

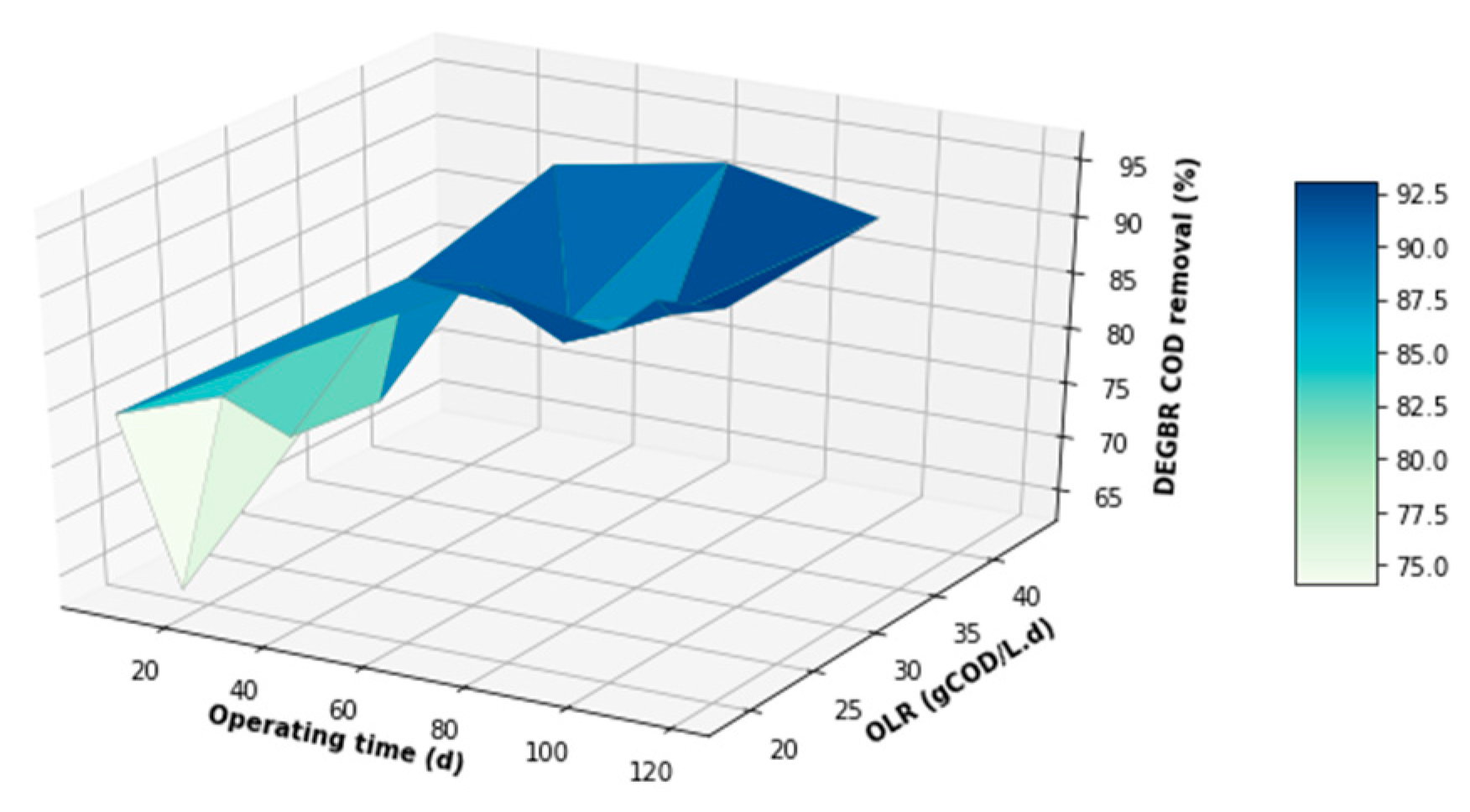

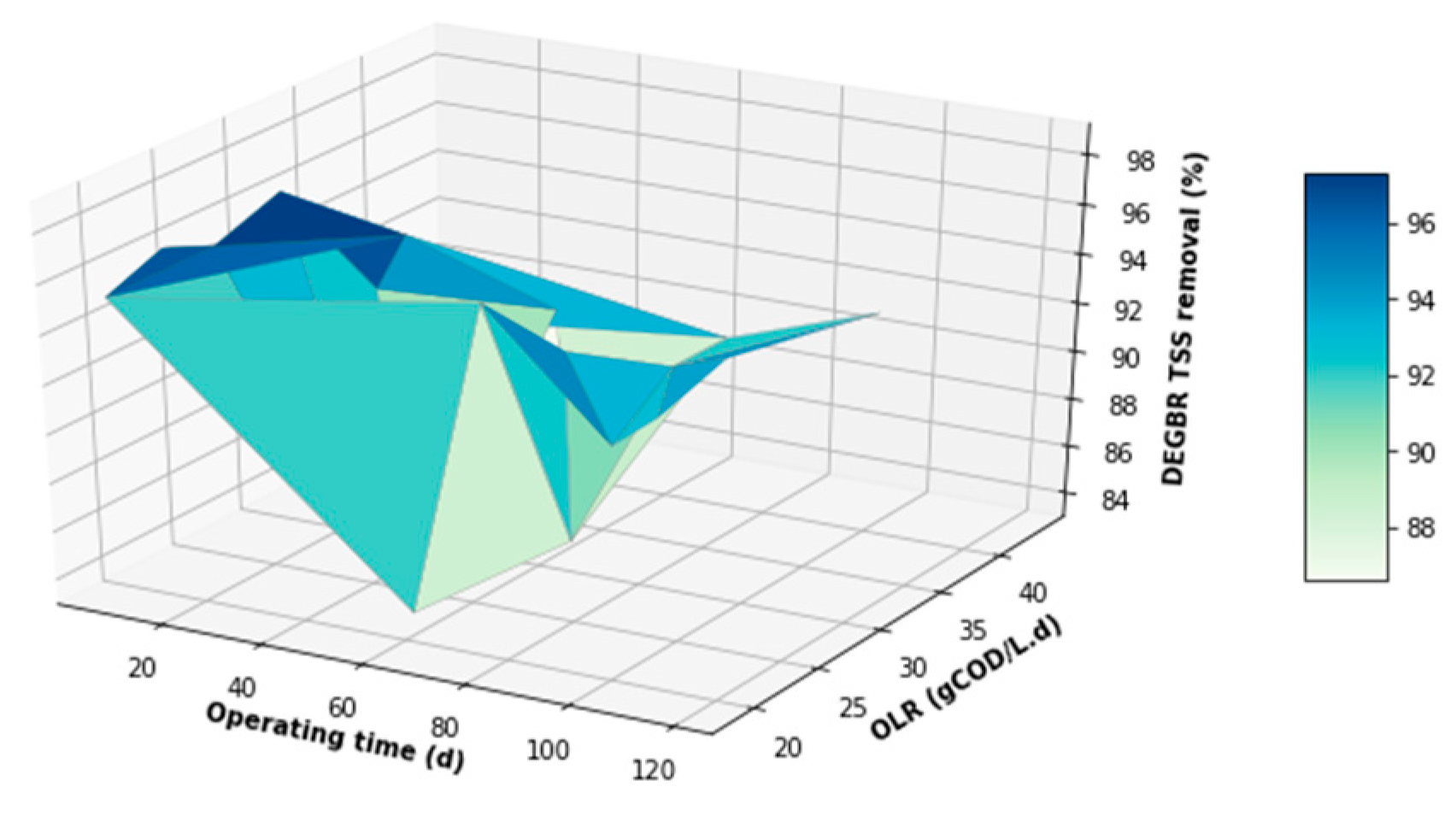

3.2. DEGBR Treatment Performance

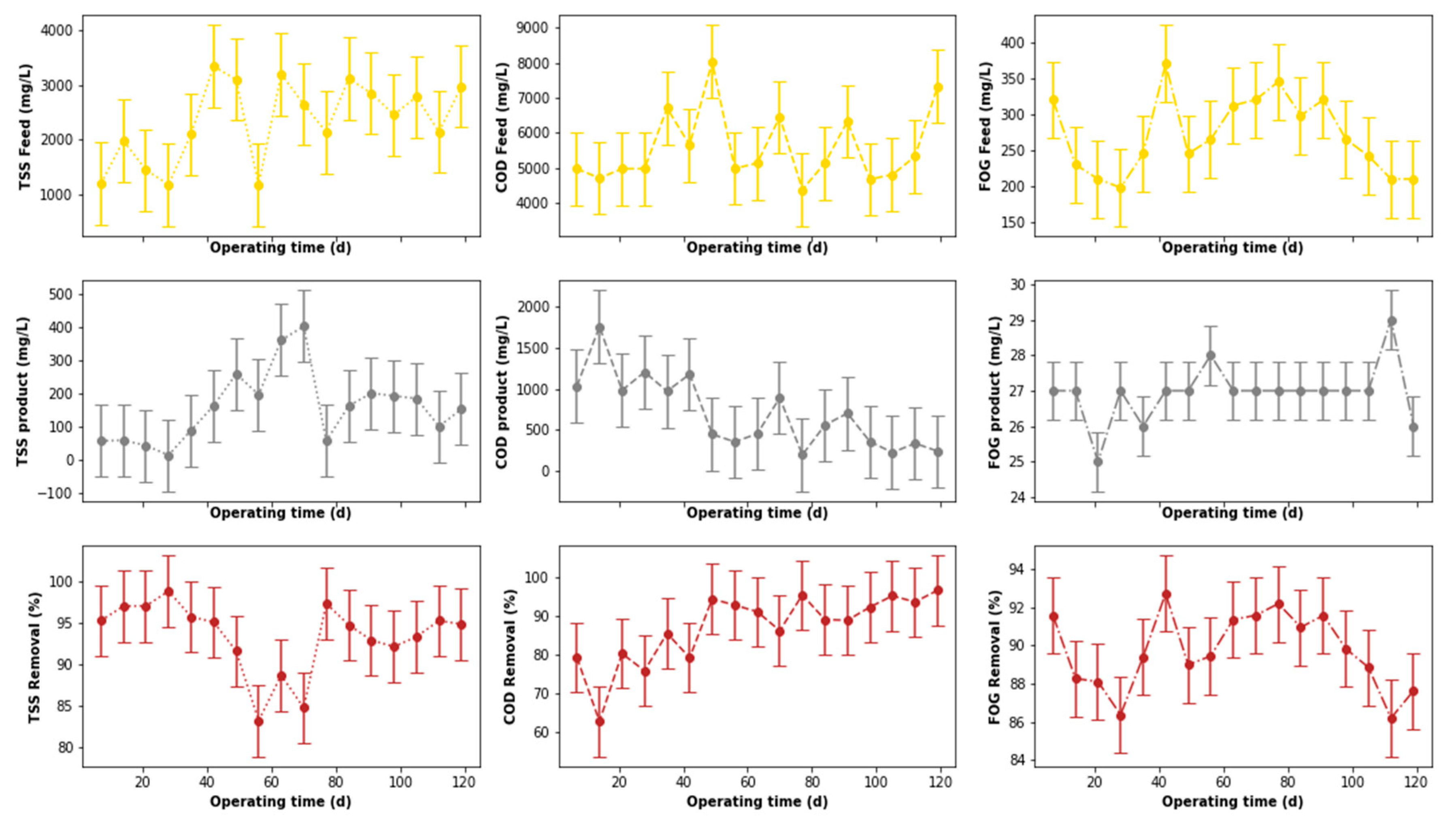

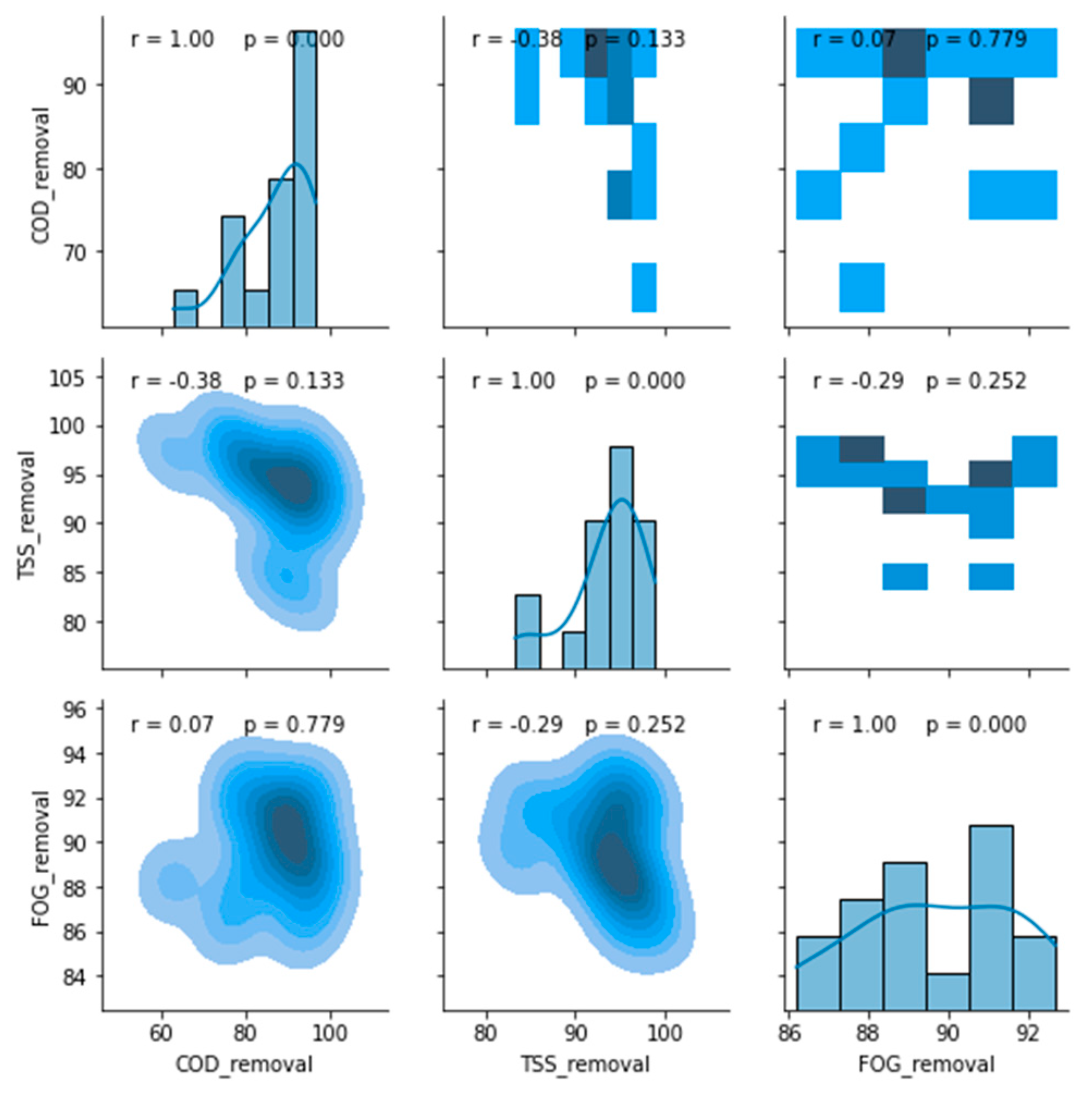

3.2.1. DEGBR-MBR Post-Treatment

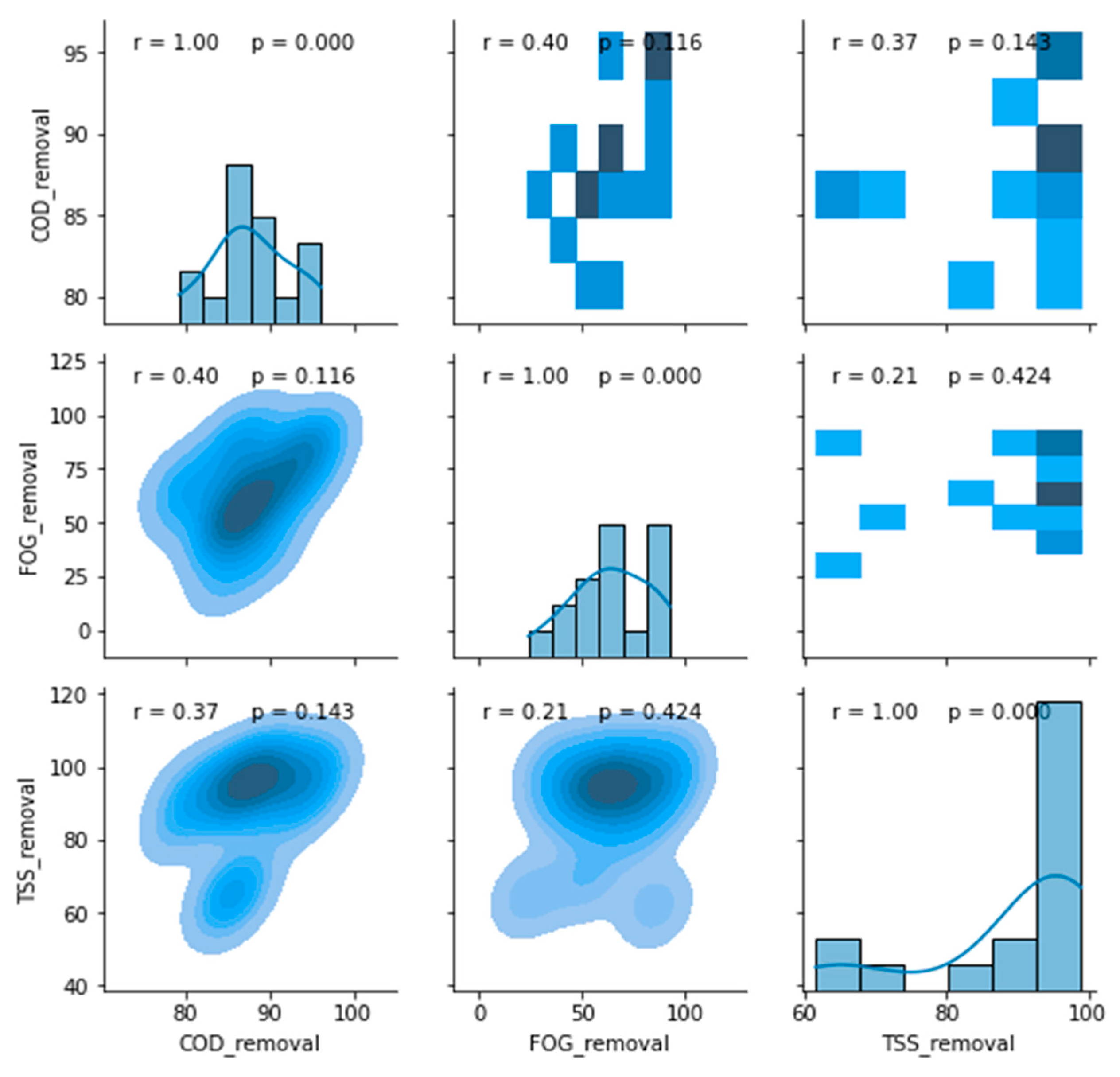

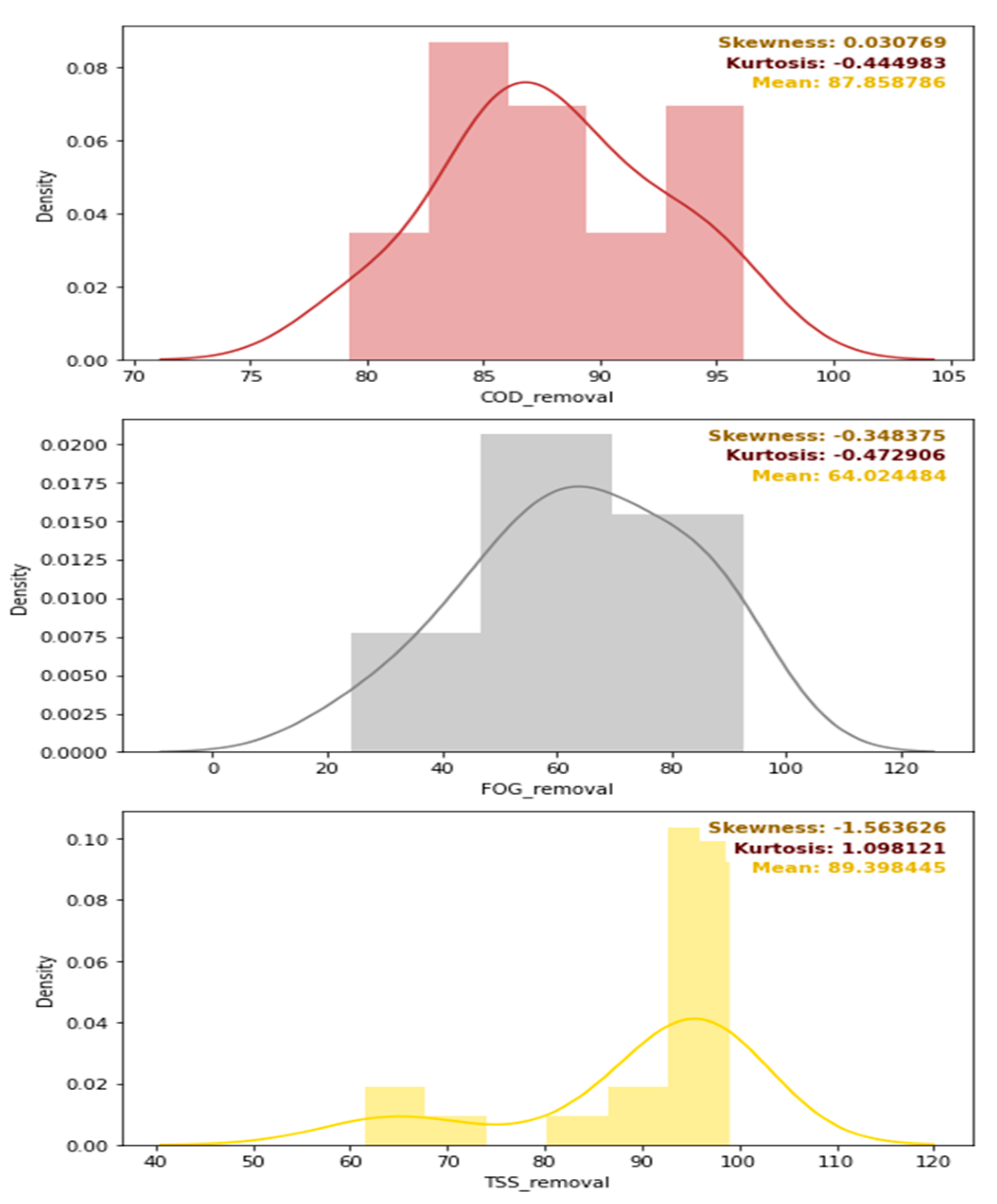

3.2.2. Overall Performance of Pre-Treatment-DEGBR-MBR System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Basitere, M.; Williams, Y.; Sheldon, M.S.; Ntwampe, S.K.O.; de Jager, D. Performance of an expanded granular sludge bed (EGSB) reactor coupled with anoxic and aerobic bioreactors for treating poultry slaughterhouse wastewater. Water Pract. Technol. 2016, 11, 86–92. [Google Scholar] [CrossRef]

- Aljuboori, A.H.R.; Idris, A.; Abdullah, N.; Mohamad, R. Production and characterization of a bioflocculant produced by Aspergillus flavus. Bioresour. Technol. 2013, 127, 489–493. [Google Scholar] [CrossRef] [PubMed]

- Njoya, M.; Basitere, M.; Ntwampe, S.K.O. Analysis of the characteristics of poultry slaughterhouse wastewater (PSW) and its treatability. Water Pract. Technol. 2019, 14, 959–970. [Google Scholar] [CrossRef]

- Bustillo-Lecompte, C.; Mehrvar, M. Slaughterhouse Wastewater: Treatment, Management and Resource Recovery. Phys. Chem. Wastewater Treat. Resour. Recovery 2017, 153–174. [Google Scholar] [CrossRef] [Green Version]

- Aziz, A.; Basheer, F.; Sengar, A.; Ullah, S.; Haq, I. Science of the Total Environment Biological wastewater treatment (anaerobic-aerobic) technologies for safe discharge of treated slaughterhouse and meat processing wastewater. Sci. Total. Environ. 2019, 686, 681–708. [Google Scholar] [CrossRef] [PubMed]

- Lippi, M.; Ley, M.B.R.G.; Mendez, G.P.; Junior, R.A.F.C. State of Art of Landfill Leachate Treatment: Literature Review and Critical Evaluation. Ciência e Nat. 2018, 40, 78. [Google Scholar] [CrossRef]

- Koli, S.K.; Hussain, A. Status of Electronic Waste Management in India. Adv. Treat. Tech. Ind. Wastewater. 2018, 238–250. [Google Scholar] [CrossRef]

- Njoya, M.; Basitere, M.; Ntwampe, S.K.O. Treatment of poultry slaughterhouse wastewater using a down-flow expanded granular bed reactor. Water Pract. Technol. 2019, 14, 549–559. [Google Scholar] [CrossRef]

- Wett, B.; Buchauer, K. Comparison of Aerobic and Anaerobic Technologies for Domestic Wastewater Treatment Based on Case Studies in Latin America. In Proceedings of the Seminario Problemas y Soluciones Ambientales, Aguas Residuales y Residuos Solidos, Medellin-Bogota-Quito, 2003; pp. 1–14. Available online: http://www.araconsult.at/download/literature/bogota_wett_lg.pdf (accessed on 15 May 2021).

- Bustillo-Lecompte, C.F.; Mehrvar, M. Treatment of actual slaughterhouse wastewater by combined anaerobic–aerobic processes for biogas generation and removal of organics and nutrients: An optimization study towards a cleaner production in the meat processing industry. J. Clean. Prod. 2017, 141, 278–289. [Google Scholar] [CrossRef]

- Sheldon, M.S.; Zeelie, P.J.; Edwards, W. Treatment of paper mill effluent using an anaerobic/aerobic hybrid side-stream Membrane Bioreactor. Water Sci. Technol. 2012, 65, 1265–1272. [Google Scholar] [CrossRef] [Green Version]

- Damasceno, F.R.C.; Cavalcanti-Oliveira, E.D.; Kookos, I.K.; Koutinas, A.A.; Cammarota, M.C.; Freire, D.M.G. Treatment of wastewater with high fat content employing an enzyme pool and biosurfactant: Technical and economic feasibility. Braz. J. Chem. Eng. 2018, 35, 531–542. [Google Scholar] [CrossRef] [Green Version]

- Polizelli, P.P.; Facchini, F.D.A.; Bonilla-Rodriguez, G.O. Stability of a lipase extracted from seeds of pachira aquatica in commercial detergents and application tests in poultry wastewater pretreatment and fat particle hydrolysis. Enzym. Res. 2013. [CrossRef] [Green Version]

- Hernández-Fydrych, V.C.; Benítez-Olivares, G.; Meraz-Rodríguez, M.A.; Salazar-Peláez, M.L.; Fajardo-Ortiz, M.C. Methane production kinetics of pretreated slaughterhouse wastewater. Biomass Bioenergy 2019, 130, 105385. [Google Scholar] [CrossRef]

- de Nardi, I.R.; Fuzi, T.P.; del Nery, V. Performance evaluation and operating strategies of dissolved-air flotation system treating poultry slaughterhouse wastewater. Resour. Conserv. Recycl. 2008, 52, 533–544. [Google Scholar] [CrossRef]

- Dors, G.; Mendes, A.A.; Pereira, E.B.; de Castro, H.F.; Furigo, A. Simultaneous enzymatic hydrolysis and anaerobic biodegradation of lipid-rich wastewater from poultry industry. Appl. Water Sci. 2013, 3, 343–349. [Google Scholar] [CrossRef] [Green Version]

- Liew, Y.X.; Chan, Y.J.; Manickam, S.; Chong, M.F.; Chong, S.; Tiong, T.J.; Lim, J.W.; Pan, G.-T. Enzymatic pretreatment to enhance anaerobic bioconversion of high strength wastewater to biogas: A review. Sci. Total. Environ. 2020, 713, 136373. [Google Scholar] [CrossRef] [PubMed]

- Gogate, P.R.; Thanekar, P.D.; Oke, A.P. Strategies to improve biological oxidation of real wastewater using cavitation based pre-treatment approaches. Ultrason. Sonochemistry 2020, 64, 105016. [Google Scholar] [CrossRef] [PubMed]

- Wachinski, A.M. Membrane Processes for Water Reuse; Mc Graw Hill: New York, NY, USA, 2013; pp. 81–114. ISBN 10:0071748954. [Google Scholar]

- Basitere, M.; Rinquest, Z.; Njoya, M.; Sheldon, M.S.; Ntwampe, S.K.O. Treatment of poultry slaughterhouse wastewater using a static granular bed reactor (SGBR) coupled with ultrafiltration (UF) membrane system. Water Sci. Technol. 2017, 76, 106–114. [Google Scholar] [CrossRef] [PubMed]

- Meyo, H.B.; Njoya, M.; Basitere, M.; Ntwampe, S.K.O.; Kaskote, E. Treatment of Poultry Slaughterhouse Wastewater (PSW) Using a Pretreatment Stage, an Expanded Granular Sludge Bed Reactor (EGSB), and a Membrane Bioreactor (MBR). Membranes 2021, 11, 345. [Google Scholar] [CrossRef] [PubMed]

- Dlamini, D.N.; Basitere, M.; Njoya, M.; Karabo, S.; Ntwampe, O.; Kaskote, E. Applied Sciences Performance Evaluation of a Biological Pre-Treatment Coupled with the Down-Flow Expanded Granular Bed Reactor (DEGBR) for Treatment of Poultry Slaughterhouse Wastewater. Appl. Sci. 2021, 11, 6536. [Google Scholar] [CrossRef]

- Rinquest, Z.; Basitere, M.; Ntwampe, S.K.O.; Njoya, M. Poultry slaughterhouse wastewater treatment using a static granular bed reactor coupled with single stage nitrification-denitrification and ultrafiltration systems. J. Water Process. Eng. 2019, 29, 100778. [Google Scholar] [CrossRef]

- Debik, E.; Coskun, T. Use of the Static Granular Bed Reactor (SGBR) with anaerobic sludge to treat poultry slaughterhouse wastewater and kinetic modeling. Bioresour. Technol. 2009, 100, 2777–2782. [Google Scholar] [CrossRef]

- Ergofito. Poultry Farming, in Cape Town. 2019, p. 4. Available online: https://www.ergofito.co.za/application/Grease-Fats-Overview (accessed on 15 May 2021).

- Water Environment Federation. Membrane Bioreactors: WEF Manual of Practice No. 36 (McGraw-Hilll Education: New York, Chicago, San Francisco, Lisbon, London, Madrid, Mexico City, Milan, New Delhi, San Juan, Seoul, Singapore, Sydney, Toronto, 2012). Available online: https://www.accessengineeringlibrary.com/content/book/9780071753661 (accessed on 15 May 2021).

| Reactor Technology | Year of Development | Reactor Development Rationale and Challenges | Performance Results | Reference |

|---|---|---|---|---|

| Expanded Granular Sludge Bed (EGSB) | - | Side recycle stream improves efficiency due to the increase in sludge expansion. Up-flow configuration resulted in sludge washout during high FOG and TSS loading, thus resulting in methanogen loss, which reduced biological degradation. | 65% tCOD removal | [1] |

| Static Granular Bed Reactor (SGBR) | 2000 | An SGBR with a down flow configuration was developed. Challenges include clogging of the underdrain. Hence, requiring periodic alleviation through backwash, disturbing the underdrain and granular bed build-up. | 95% COD removal, 95% TSS removal, 90% FOG removal | [13,14] |

| Down-flow Expanded Granular Bed Reactor (DEGBR) | 2019 | A hybrid of EGSB and SGBR, with down/top feeding configuration and a recycle. | 99,6% COD removal, 93,7% FOG removal | [8] |

| Pre-Treatment Technology | Reactor Coupled with the Pre-Treatment Unit | Limitations | Performance Results | Study of Reference |

|---|---|---|---|---|

| Thermal Autoclaving | - | Additional physical separation of the clear liquid and semi solid sludge is necessary. | 81% COD removal, 59% FOG removal, 43% TSS removal. | [14] |

| Chemical Dissolved Air Flotation (DAF) | UASB | System showed instability due to the varying PSW influent. Additionally, system efficiency is highly affected by chemical used. | 43% ± 15% suspended solids (SS) removal and 49% ± 8% oil and grease (O&G) removal. | [15] |

| Biological Enzymatic Pre-treatment | - | Optimal enzyme dose is not yet established. Though the increase in dose results in increased free fatty acid and VSS treatment, the dose has an optimal point where higher doses do not contribute to increased effectiveness. | Increase in free fatty acids and 10% hydrolysis promotion due to lipase, 88% COD reduction in PSW. | [13,16,17] |

| Hydrodynamic Cavitation | - | Optimum conditions included addition of Fenton reagent. | Increased COD treatment to 44.2%. Biological oxidation treatment time reduction from 60 to 36 h. | [18] |

| Parameter | Units | Minimum | Maximum | Average | Reference | This Study |

|---|---|---|---|---|---|---|

| COD | mg/L | 4100 | 9100 | 4317 | [23] | 6500–21,000 |

| TSS | mg/L | 1580 | 3750 | 2800 ± 950 | [23,24] | 2985–8363 |

| FOG | mg/L | 280 | 8228 | 1655 ± 1880 | [8] | 640–4500 |

| Parameter | Method |

|---|---|

| Temperature | EPA method 9040C |

| Total suspended solids (TSS) | EPA method 160.2 |

| Total chemical oxygen demand (tCOD) | EPA method 410.4 |

| Fats, oils, and grease (FOG) | EPA method 10056 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dyosile, P.A.; Mdladla, C.; Njoya, M.; Basitere, M.; Ntwampe, S.K.O.; Kaskote, E. Assessment of an Integrated and Sustainable Multistage System for the Treatment of Poultry Slaughterhouse Wastewater. Membranes 2021, 11, 582. https://doi.org/10.3390/membranes11080582

Dyosile PA, Mdladla C, Njoya M, Basitere M, Ntwampe SKO, Kaskote E. Assessment of an Integrated and Sustainable Multistage System for the Treatment of Poultry Slaughterhouse Wastewater. Membranes. 2021; 11(8):582. https://doi.org/10.3390/membranes11080582

Chicago/Turabian StyleDyosile, Phumeza Akhona, Cebisa Mdladla, Mahomet Njoya, Moses Basitere, Seteno Karabo Obed Ntwampe, and Ephraim Kaskote. 2021. "Assessment of an Integrated and Sustainable Multistage System for the Treatment of Poultry Slaughterhouse Wastewater" Membranes 11, no. 8: 582. https://doi.org/10.3390/membranes11080582

APA StyleDyosile, P. A., Mdladla, C., Njoya, M., Basitere, M., Ntwampe, S. K. O., & Kaskote, E. (2021). Assessment of an Integrated and Sustainable Multistage System for the Treatment of Poultry Slaughterhouse Wastewater. Membranes, 11(8), 582. https://doi.org/10.3390/membranes11080582