The Influence Mechanism of Temperature and Storage Period on Polarization Properties of Poly (Vinylidene Fluoride–Trifluoroethylene) Ultrathin Films

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

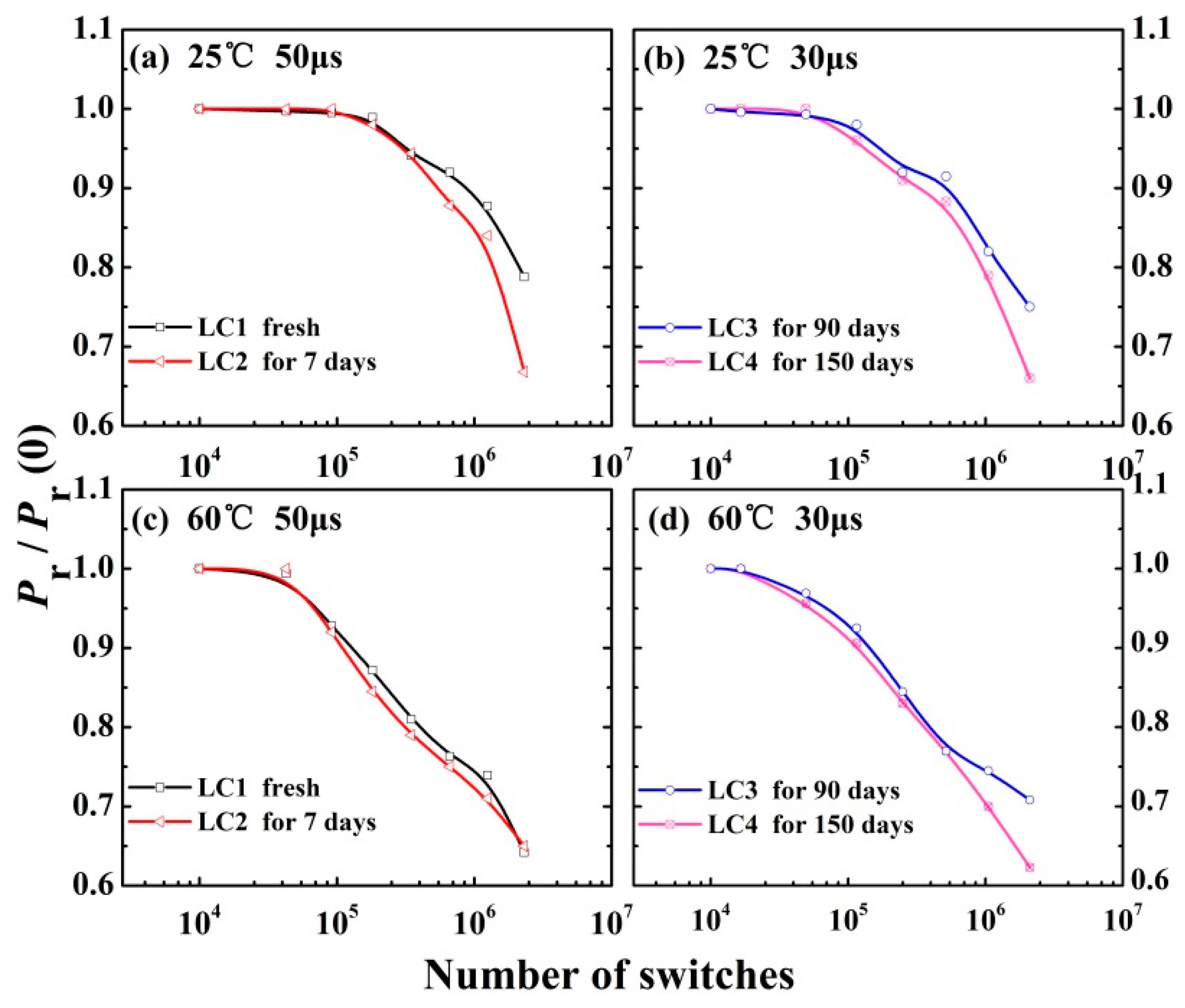

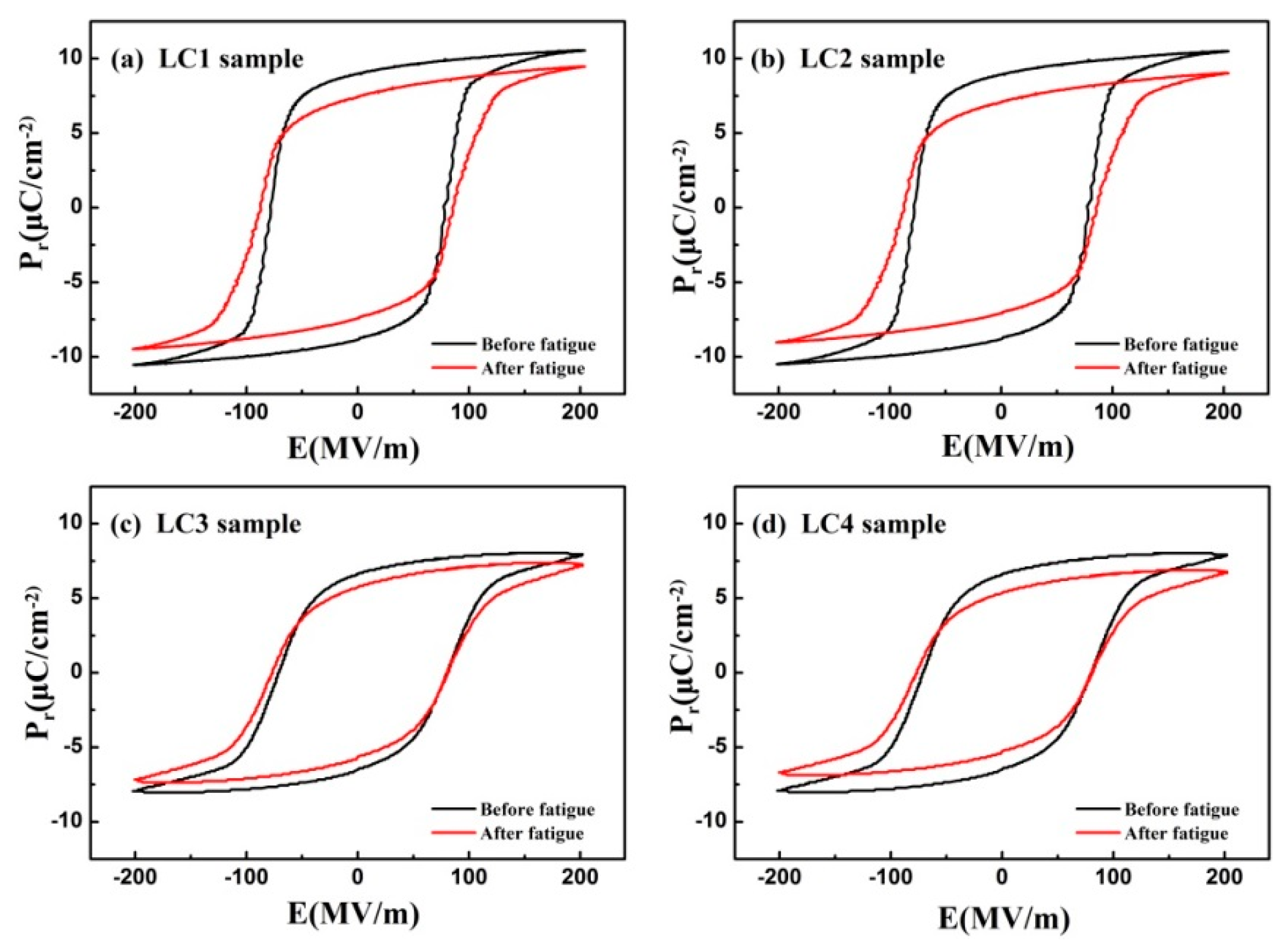

3.1. Temporal Stability under the Influence of Multiple Factors

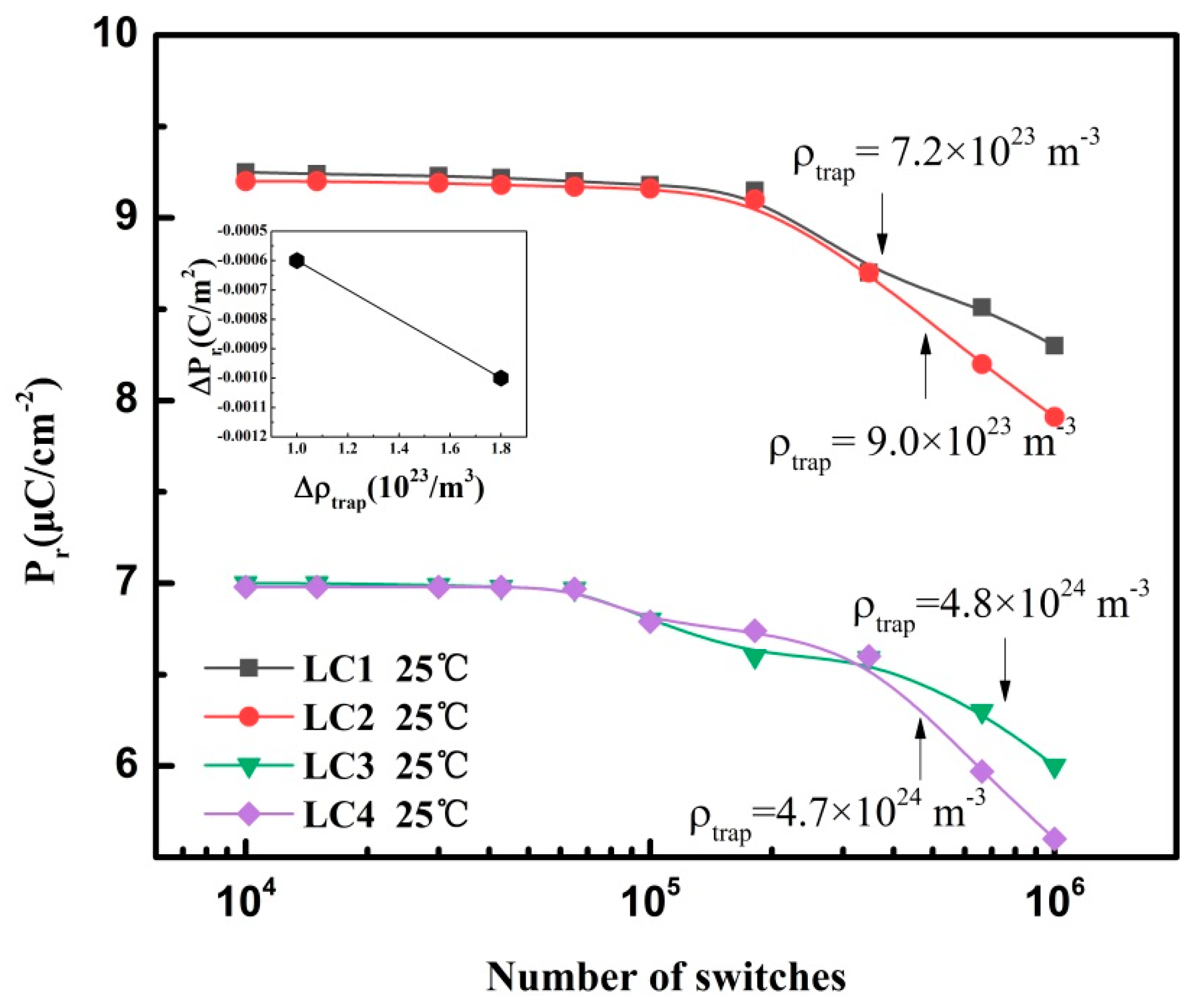

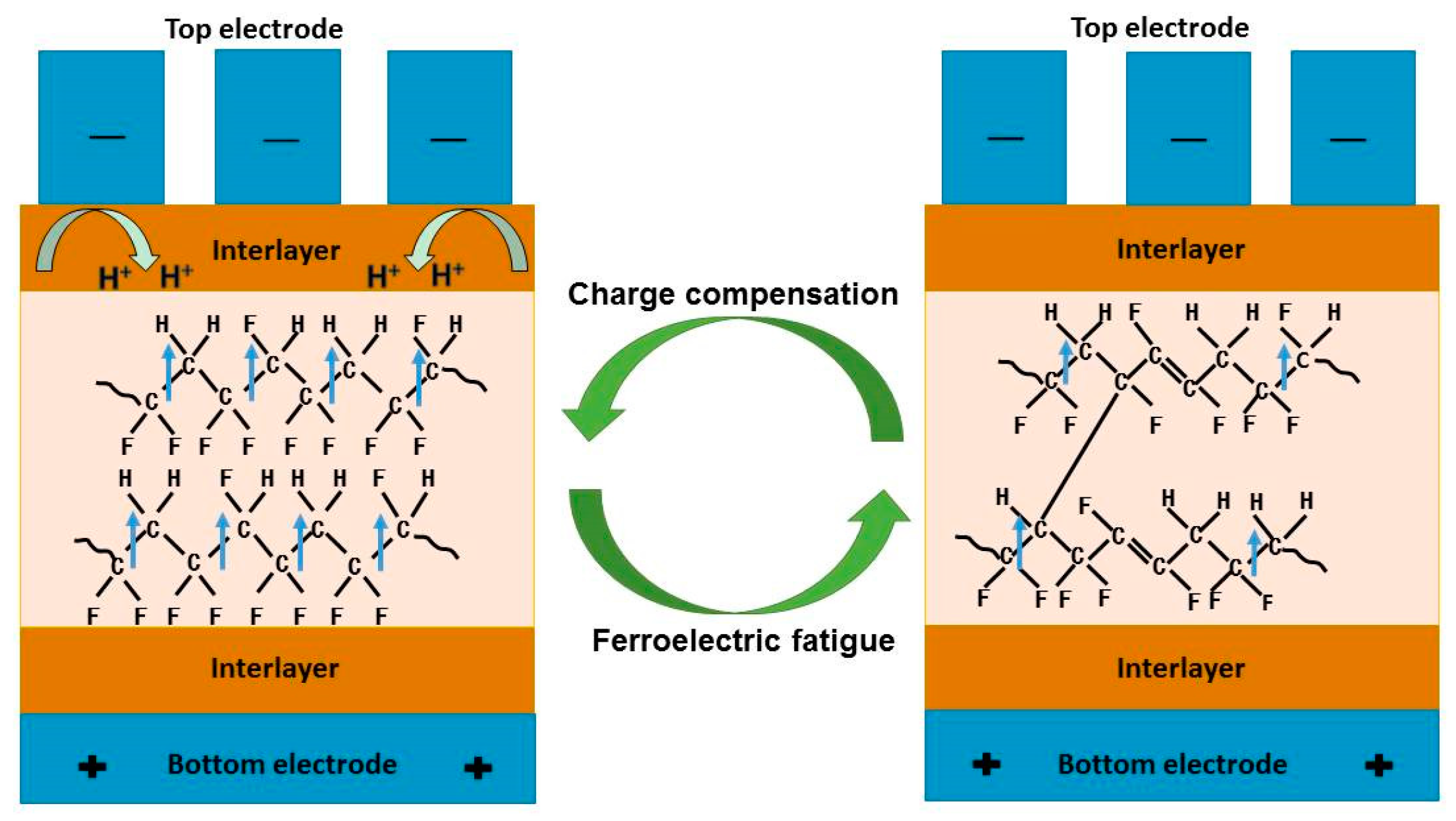

3.2. The Trapped Charge Model of Polarization Switching Regulation

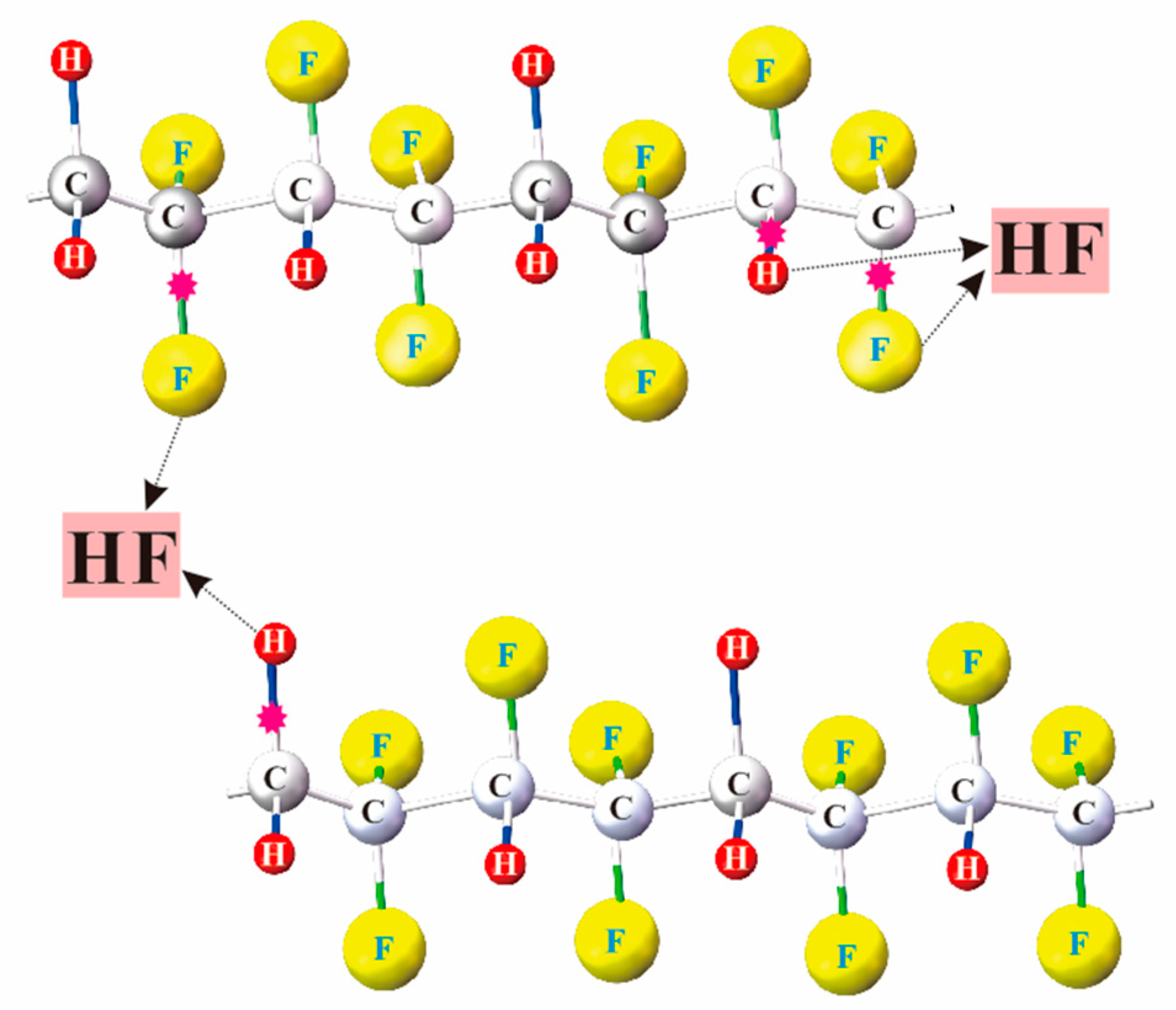

3.3. The Electroactive Interlayer Inhibits HF Elimination

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, F.R.; Tang, W.; Wang, Z.L. Flexible Nanogenerators for Energy Harvesting and Self-Powered Electronics. Adv. Mater. 2016, 28, 4283–4305. [Google Scholar] [CrossRef]

- Kim, S.; Dong, Y.; Hossain, M.; Gorman, S.; Towfeeq, I.; Gajula, D.R.; Childress, A.S.C.; Rao, A.M.; Koley, G. Piezoresistive Graphene/P(VDF-TrFE) Heterostructure Based Highly Sensitive and Flexible Pressure Sensor. ACS Appl. Mater. Interfaces 2019, 11, 16006–16017. [Google Scholar] [CrossRef]

- Schäffner, P.; Zirkl, M.; Schider, G.; Groten, J.; Belegratis, M.R.; Knoll, P.; Stadlober, B. Microstructured single-layer electrodes embedded in P(VDF-TrFE) for flexible and self-powered direction-sensitive strain sensors. Smart Mater. Struct. 2020, 29, 085040. [Google Scholar] [CrossRef]

- Yuan, Y.; Reece, T.J.; Sharma, P.; Poddar, S.; Ducharme, S.; Gruverman, A.; Yang, Y.; Huang, J. Efficiency enhancement in organic solar cells with ferroelectric polymers. Nat. Mater. 2011, 10, 296–302. [Google Scholar] [CrossRef]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.-M. Fiber-Based Wearable Electronics: A Review of Materials, Fabrication, Devices, and Applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef]

- Hwang, B.-U.; Lee, J.-H.; Trung, T.Q.; Roh, E.; Kim, D.-I.; Kim, S.-W.; Lee, N.-E. Transparent Stretchable Self-Powered Patchable Sensor Platform with Ultrasensitive Recognition of Human Activities. ACS Nano 2015, 9, 8801–8810. [Google Scholar] [CrossRef] [PubMed]

- Mao, D.; Mejía, I.; Stiegler, H.; Gnade, B.E.; Quevedo-Lopez, M.A. Polarization behavior of poly(vinylidene fluoride-trifluoroethylene) copolymer ferroelectric thin film capacitors for nonvolatile memory application in flexible electronics. J. Appl. Phys. 2010, 108, 94102. [Google Scholar] [CrossRef]

- Tian, B.B.; Wang, J.L.; Fusil, S.; Liu, Y.; Zhao, X.L.; Sun, S.; Shen, H.; Lin, T.; Sun, J.L.; Duan, C.G.; et al. Tunnel electroresistance through organic ferroelectrics. Nat. Commun. 2016, 7, 11502. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Z.; Cao, W.; Zhang, Z. Temperature and frequency dependence of the coercive field of 0.71PbMb1/3Nb2/3O3–0.29PbTiO3 relaxor-based ferroelectric single crystal. Appl. Phys. Lett. 2017, 111, 172902. [Google Scholar] [CrossRef]

- Naber, R.C.G.; De Boer, B.; Blom, P.W.M.; De Leeuw, D.M. Low-voltage polymer field-effect transistors for nonvolatile memories. Appl. Phys. Lett. 2005, 87, 203509. [Google Scholar] [CrossRef]

- Xu, H.; Fang, X.; Liu, X.; Wu, S.; Gu, Y.; Meng, X.; Sun, J.; Chu, J. Fabrication and properties of solution processed all polymer thin-film ferroelectric device. J. Appl. Polym. Sci. 2010, 120, 1510–1513. [Google Scholar] [CrossRef]

- Du, X.; Zhao, M.; Chen, G.; Zhang, X. Thickness Dependence of Ferroelectric Properties for Ferroelectric Random Access Memory Based on Poly(vinylidene fluoride-trifluoroethylene) Ultrathin Films. Ferroelectr. 2015, 488, 148–153. [Google Scholar] [CrossRef]

- Li, T.; Chen, C.; Zhou, J. Three dimensional phase field study on the thickness effect of ferroelectric polymer thin film. Theor. Appl. Mech. Lett. 2011, 1, 011008. [Google Scholar] [CrossRef]

- Zhu, G.-D.; Luo, X.-Y.; Zhang, J.-H.; Gu, Y.; Jiang, Y.-L. Electrical fatigue in ferroelectric P(VDF-TrFE) copolymer films. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1172–1177. [Google Scholar] [CrossRef]

- Xu, H.; Zhong, J.; Liu, X.; Chen, J.; Shen, N. Ferroelectric and switching behavior of poly(vinylidene fluoride-trifluoroethylene) copolymer ultrathin films with polypyrrole interface. Appl. Phys. Lett. 2007, 90, 092903. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, C.; Li, L.; Yuan, H.; Xu, H. Switching dynamics enhancement in P(VDF-TrFE) copolymer ultrathin films with symmetric organic film electrodes. Org. Electron. 2019, 66, 81–85. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, Y.; Zhang, Y.; Lv, Z.; Xu, G.; Xu, H. The effect of electroactive interlayer on the ferroelectric properties in poly(vinylidene fluoride-trifluoroethylene) copolymer ultrathin films. J. Appl. Phys. 2012, 112, 74111. [Google Scholar] [CrossRef]

- Singh, D.; Deepak, D.; Garg, A. An efficient route to fabricate fatigue-free P(VDF-TrFE) capacitors with enhanced piezoelectric and ferroelectric properties and excellent thermal stability for sensing and memory applications. Phys. Chem. Chem. Phys. 2017, 19, 7743–7750. [Google Scholar] [CrossRef]

- Zhao, D.; Katsouras, I.; Asadi, K.; Blom, P.W.M.; De Leeuw, D.M. Switching dynamics in ferroelectric P(VDF-TrFE) thin films. Phys. Rev. B 2015, 92. [Google Scholar] [CrossRef]

- Liu, H.; Song, W.; Niu, Y.; Zio, E. A generalized cauchy method for remaining useful life prediction of wind turbine gearboxes. Mech. Syst. Signal Process. 2021, 153, 107471. [Google Scholar] [CrossRef]

- Liu, H.; Song, W.; Zhang, Y.; Kudreyko, A. Generalized Cauchy Degradation Model With Long-Range Dependence and Maximum Lyapunov Exponent for Remaining Useful Life. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- Lou, X.J. Polarization fatigue in ferroelectric thin films and related materials. J. Appl. Phys. 2009, 105, 24101. [Google Scholar] [CrossRef]

- Zhu, G.; Zeng, Z.; Zhang, L.; Yan, X. Polarization fatigue in ferroelectric vinylidene fluoride and trifluoroethylene copolymer films. Appl. Phys. Lett. 2006, 89, 102905. [Google Scholar] [CrossRef]

- Pawlaczyk, C.; Tagantsev, A.K.; Brooks, K.; Reaney, I.M.; Klissurska, R.; Setter, N. Fatigue, rejuvenation and self-restoring in ferroelectric thin films. Integr. Ferroelectr. 1995, 9, 293–316. [Google Scholar] [CrossRef]

- Zhu, G.D.; Zeng, Z.G.; Zhang, L.; Yan, X.J. Temperature dependence of polarization fatigue in ferroelectric vinylidene fluoride and trifluoroethylene copolymer films. J. Appl. Polym. Sci. 2007, 107, 3945–3949. [Google Scholar] [CrossRef]

- Lou, X.J.; Zhang, M.; Redfern, S.A.T.; Scott, J.F. Fatigue as a local phase decomposition: A switching-induced charge-injection model. Phys. Rev. B 2007, 75, 224104. [Google Scholar] [CrossRef]

- Warren, W.; Dimos, D. Photo-assisted switching and trapping in BaTiO3 and Pb(Zr, Ti)O3 ferroelectrics. J. Non-Crystalline Solids 1995, 187, 448–452. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I. Effect of water absorption on the mechanical properties of nanoclay filled recycled cellulose fibre reinforced epoxy hybrid nanocomposites. Compos. Part. A: Appl. Sci. Manuf. 2013, 44, 23–31. [Google Scholar] [CrossRef]

- Xiao-Li, D.; Xiu-Li, Z.; Hong-Bo, L.; Xin, J. Study of ferroelectric switching and fatigue behaviors in poly(vinylidene fluoride-trifluoroethylene) copolymer nano-films. Acta Phys. Sin. 2015, 64, 167701. [Google Scholar] [CrossRef]

- Dowben, P.A.; Rosa, L.G.; Ilie, C.C. Water Interactions with Crystalline Polymers with Large Dipoles. Zeitschrift für Physikalische Chemie 2008, 222, 755–778. [Google Scholar] [CrossRef]

- Zhao, D.; Katsouras, I.; Li, M.; Asadi, K.; Tsurumi, J.; Glasser, G.; Takeya, J.; Blom, P.W.M.; De Leeuw, D.M. Polarization fatigue of organic ferroelectric capacitors. Sci. Rep. 2015, 4, 5075. [Google Scholar] [CrossRef] [PubMed]

- Eisenmenger, W.; Schmidt, H. Internal charge generation in polyvinylidene fluoride films during poling. In Proceedings of the 10th International Symposium on Electrets (ISE 10). Proceedings (Cat. No.99 CH36256), Athens, Greece, 20–24 September 1999. [Google Scholar] [CrossRef]

- Singh, D.; Deepak, D.; Garg, A. The combined effect of mechanical strain and electric field cycling on the ferroelectric performance of P(VDF-TrFE) thin films on flexible substrates and underlying mechanisms. Phys. Chem. Chem. Phys. 2016, 18, 29478–29485. [Google Scholar] [CrossRef] [PubMed]

- Macchi, F.; Daudin, B.; Ermolieff, A.; Marthon, S.; Legrand, J.F. Chemical defects induced in P(VDF-TrFe) by electron irradiation. Radiat. Eff. Defects Solids 1991, 118, 117–124. [Google Scholar] [CrossRef]

- Feng, T.; Xie, D.; Zang, Y.; Wu, X.; Ren, T.; Pan, W. Temperature Control of P(VDF-TrFE) Copolymer Thin Films. Integr. Ferroelectr. 2013, 141, 187–194. [Google Scholar] [CrossRef]

- Ko, Y.J.; Jin, D.W.; Kong, D.S.; Jung, J.H. Effects of Humidity on the Microstructure and the Ferroelectric Properties of Sol-Gel grown P(VDF-TrFE) Films. J. Korean Phys. Soc. 2020, 76, 348–351. [Google Scholar] [CrossRef]

- Xu, H.; Liu, X.; Fang, X.; Xie, H.; Li, G.; Meng, X.; Sun, J.; Chu, J. Domain stabilization effect of interlayer on ferroelectric poly(vinylidene fluoride-trifluoroethylene) copolymer ultrathin film. J. Appl. Phys. 2009, 105, 34107. [Google Scholar] [CrossRef]

| LC1 | LC2 | LC3 | LC4 | ||

|---|---|---|---|---|---|

| Fresh | 7 Days | 90 Days | 150 Days | ||

| 25 °C | 9.25 | 9.20 | 7.00 | 6.98 | |

| 8.30 | 7.91 | 6.00 | 5.60 | ||

| 0.90 | 0.86 | 0.85 | 0.80 | ||

| 64.5 | 64.1 | 64.3 | 63.5 | ||

| 71.4 | 70.5 | 65.7 | 65.1 | ||

| 60 °C | 9.05 | 9.02 | 6.90 | 6.85 | |

| 6.80 | 6.40 | 5.20 | 4.80 | ||

| 0.75 | 0.71 | 0.75 | 0.70 | ||

| 64.6 | 63.7 | 62.1 | 61.9 | ||

| 71.1 | 70.9 | 65.7 | 64.9 | ||

| Samples | LC1 | LC2 | LC3 | LC4 |

|---|---|---|---|---|

| 9.00 × 10−2 | 8.90 × 10−2 | 6.72 × 10−2 | 6.66 × 10−2 | |

| 1.0 × 10−3 | 6.0 × 10−4 | |||

| 1.8 × 1023 | 1.0 × 1023 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Shi, Z.; Zhang, X.; Meng, X.; Huang, Z.; Zhang, D. The Influence Mechanism of Temperature and Storage Period on Polarization Properties of Poly (Vinylidene Fluoride–Trifluoroethylene) Ultrathin Films. Membranes 2021, 11, 301. https://doi.org/10.3390/membranes11050301

Li X, Shi Z, Zhang X, Meng X, Huang Z, Zhang D. The Influence Mechanism of Temperature and Storage Period on Polarization Properties of Poly (Vinylidene Fluoride–Trifluoroethylene) Ultrathin Films. Membranes. 2021; 11(5):301. https://doi.org/10.3390/membranes11050301

Chicago/Turabian StyleLi, Xingjia, Zhi Shi, Xiuli Zhang, Xiangjian Meng, Zhiqiang Huang, and Dandan Zhang. 2021. "The Influence Mechanism of Temperature and Storage Period on Polarization Properties of Poly (Vinylidene Fluoride–Trifluoroethylene) Ultrathin Films" Membranes 11, no. 5: 301. https://doi.org/10.3390/membranes11050301

APA StyleLi, X., Shi, Z., Zhang, X., Meng, X., Huang, Z., & Zhang, D. (2021). The Influence Mechanism of Temperature and Storage Period on Polarization Properties of Poly (Vinylidene Fluoride–Trifluoroethylene) Ultrathin Films. Membranes, 11(5), 301. https://doi.org/10.3390/membranes11050301