Assessment of Layer-By-Layer Modified Nanofiltration Membrane Stability in Phosphoric Acid

Abstract

1. Introduction

2. Materials and Methods

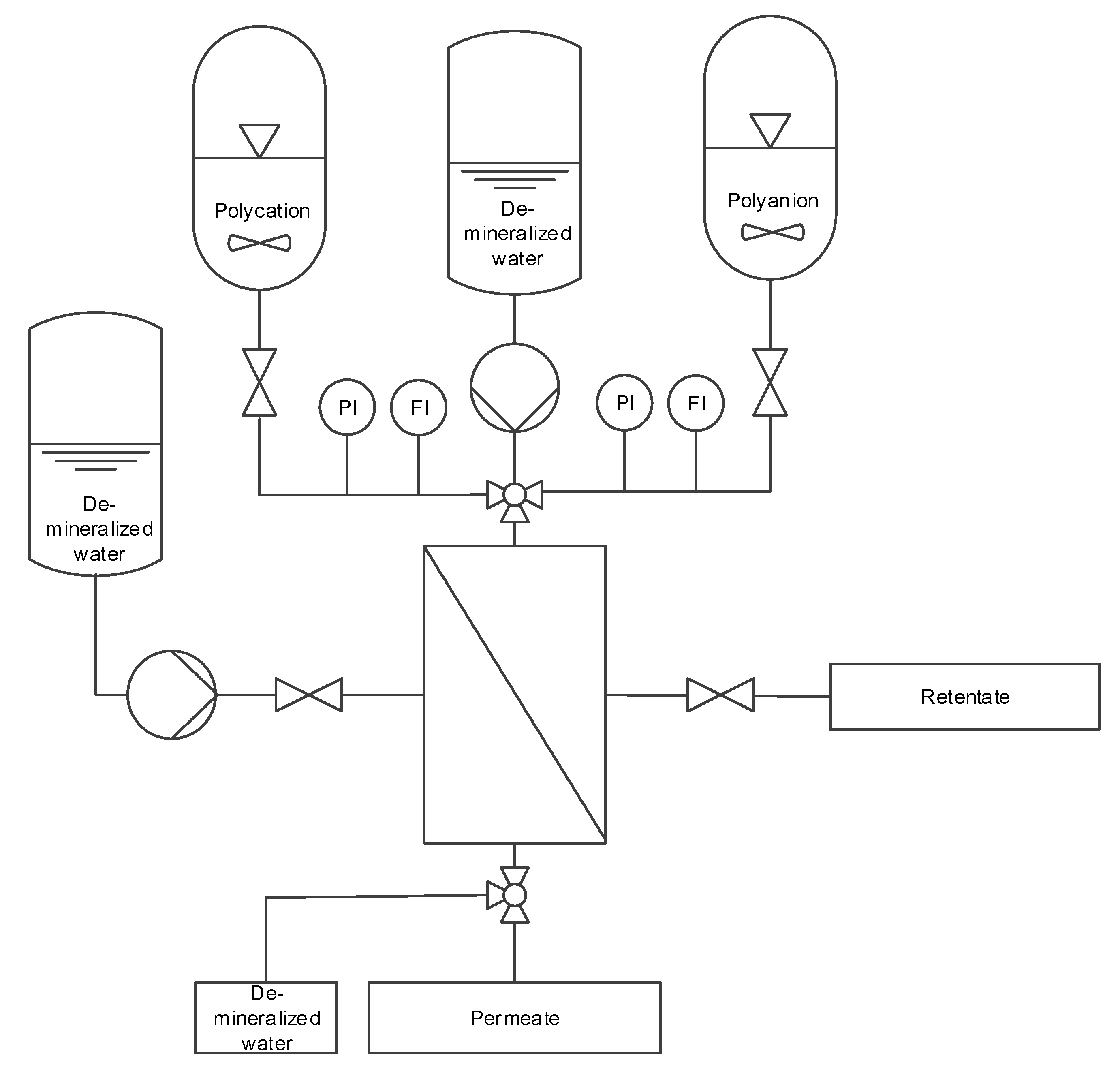

2.1. Module Preparation and Membrane Coating Procedure

2.2. Layer-by-Layer Coating

2.3. Single Hollow Fiber Modules Characterisation

2.4. Multi Hollow Fiber Module Experiment

2.5. Analytical Procedure

3. Results and Discussion

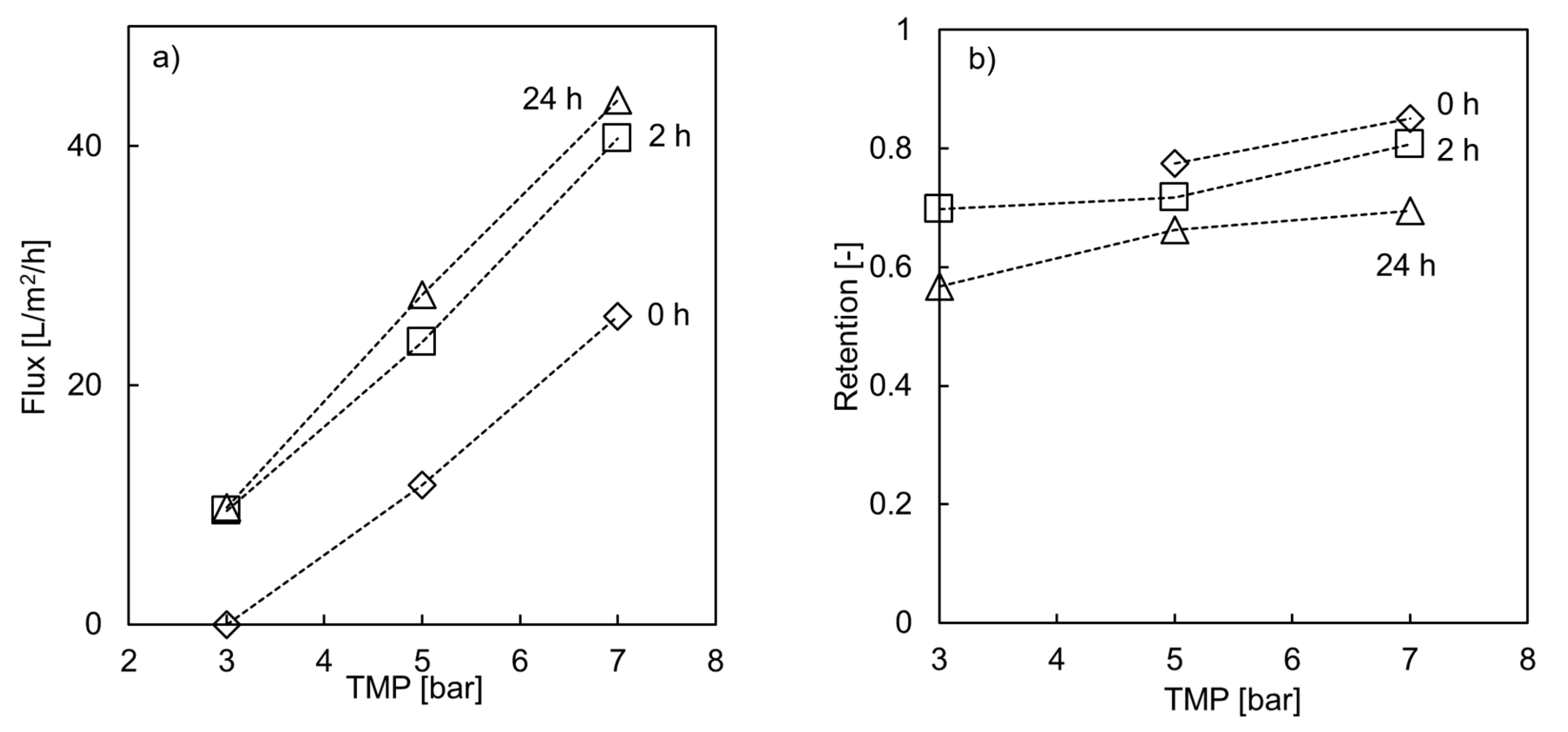

3.1. Evaluation of Membrane Permeability

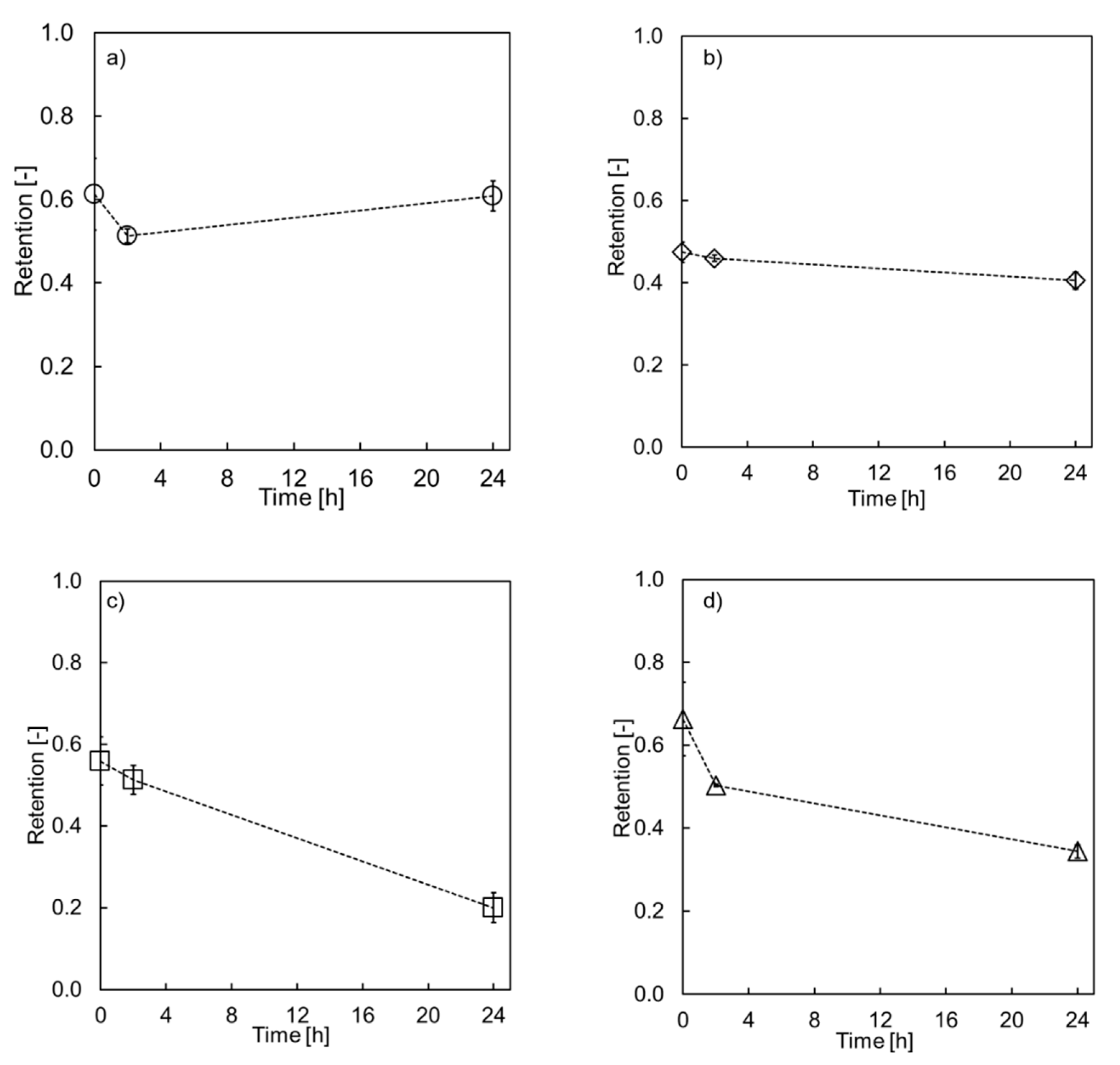

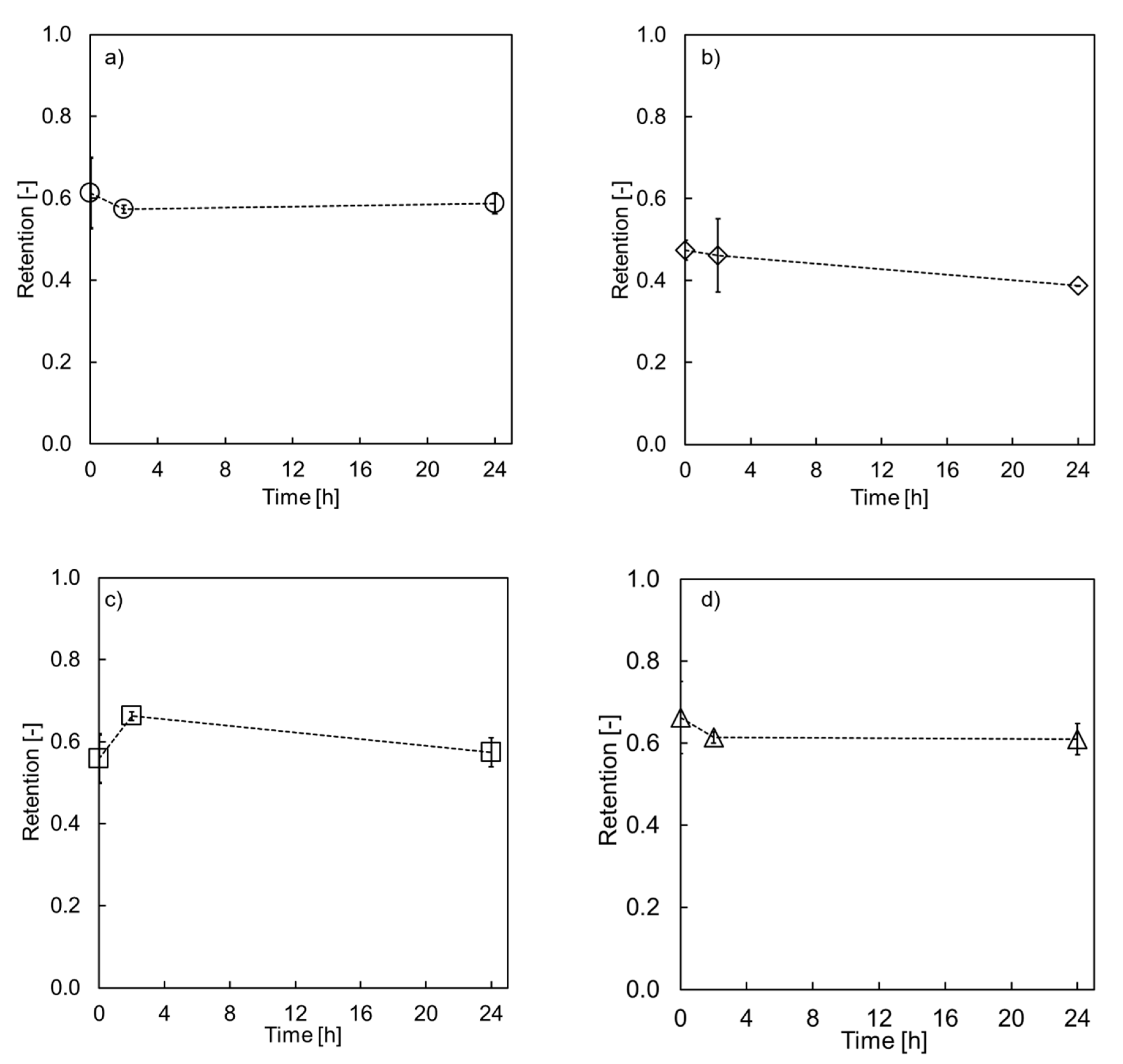

3.2. Membrane Immersion in Phosphoric Acid Versus Filtration of Phosphoric Acid

3.3. Scanning Electron Microscopy Analysis of the Modified Membranes

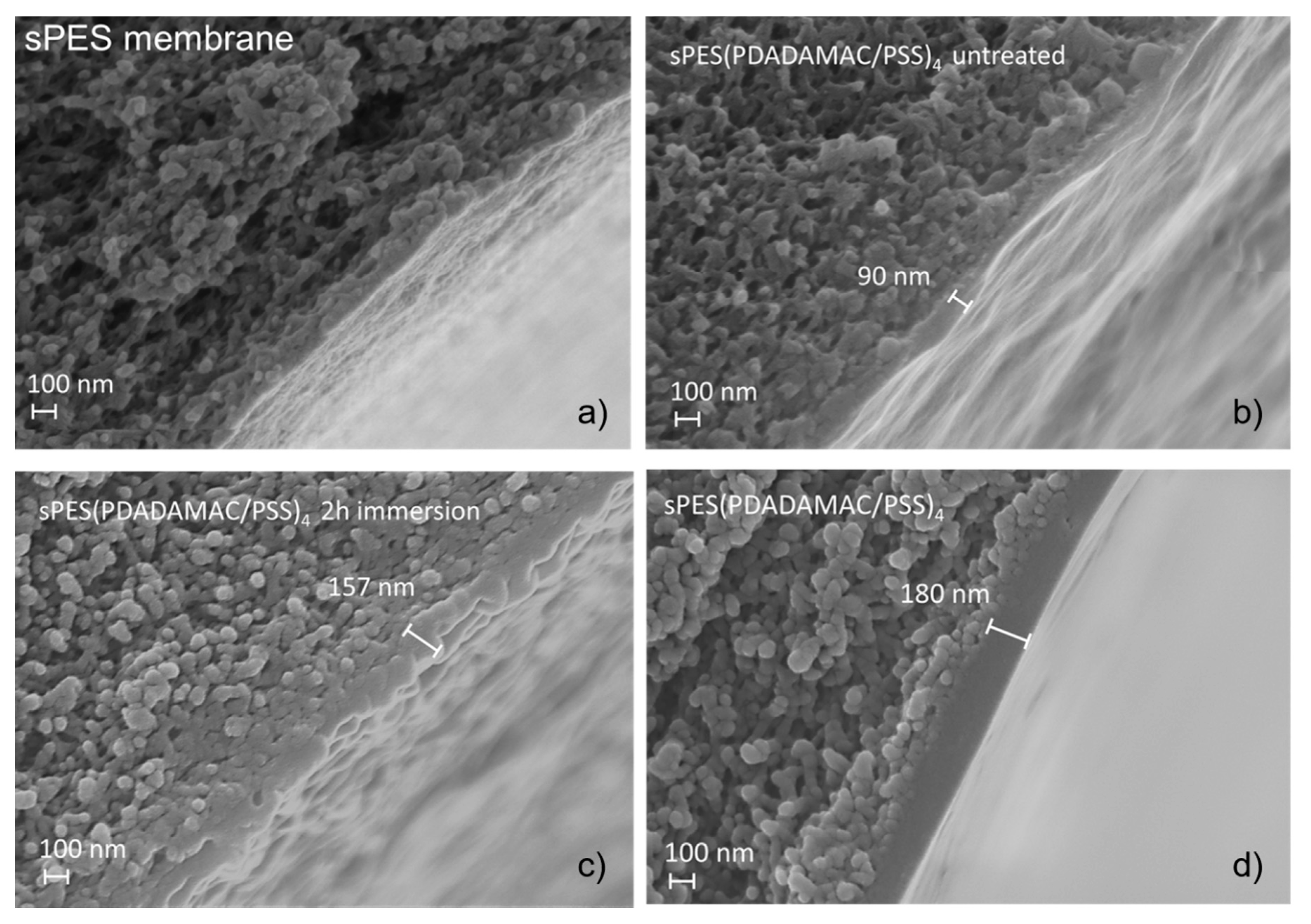

3.4. Influence of High Ionic Strength on the Mg Retention Using LbL Membranes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Agrawal, A.; Sahu, K. An overview of the recovery of acid from spent acidic solutions from steel and electroplating industries. J. Hazard. Mater. 2009, 171, 61–75. [Google Scholar] [CrossRef]

- Regel-Rosocka, M. A review on methods of regeneration of spent pickling solutions from steel processing. J. Hazard. Mater. 2010, 177, 57–69. [Google Scholar] [CrossRef]

- González, M.; Navarro, R.; Saucedo, I.; Avila, M.; Revilla, J.; Bouchard, C. Purification of phosphoric acid solutions by reverse osmosis and nanofiltration. Desalination 2002, 147, 315–320. [Google Scholar] [CrossRef]

- Sun, T.R.; Ottosen, L.M.; Solismaa, S.; Kirkelund, G.M. Effect of pulse current on acidification and removal of Cu, Cd, and As during suspended electrodialytic soil remediation. Electrochim. Acta 2013, 107, 187–193. [Google Scholar] [CrossRef]

- European Commission. Integrated Pollution Prevention and Control Large Volume Inorganic Chemicals—Ammonia, Acids and Fertilisers I; European Commission: Bruxelles, Belgium, 2007. [Google Scholar]

- de Boer, M.A.; Wolzak, L.; Slootweg, J.C. Phopshorus Recovery and Recycling - Phosphorus: Reserves, Production, and Applications; Springer Nature: Singapore, 2019. [Google Scholar]

- Tayibi, H.; Choura, M.; López, F.A.; Alguacil, F.J.; López-Delgado, A. Environmental impact and management of phosphogypsum. J. Environ. Manag. 2009, 90, 2377–2386. [Google Scholar] [CrossRef] [PubMed]

- Tanninen, J. Long-term acid resistance and selectivity of NF membranes in very acidic conditions. J. Membr. Sci. 2004, 240, 11–18. [Google Scholar] [CrossRef]

- Niewersch, C. Nanofiltration for Phosphorus Recycling from Sewage Sludge. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2013. [Google Scholar]

- Schütte, T.; Niewersch, C.; Wintgens, T.; Yuce, S. Phosphorus recovery from sewage sludge by nanofiltration in diafiltration mode. J. Membr. Sci. 2015, 480, 74–82. [Google Scholar] [CrossRef]

- Blöcher, C.; Niewersch, C.; Melin, T. Phosphorus recovery from sewage sludge with a hybrid process of low pressure wet oxidation and nanofiltration. Water Res. 2012, 46, 2009–2019. [Google Scholar] [CrossRef]

- Remmen, K.; Müller, B.; Köser, J.; Wessling, M.; Wintgens, T. Phosphorus recovery in an acidic environment using layer-by-layer modified membranes. J. Membr. Sci. 2019, 582, 254–263. [Google Scholar] [CrossRef]

- Menne, D.; Kamp, J.; Wong, J.E.; Wessling, M. Precise tuning of salt retention of backwashable polyelectrolyte multilayer hollow fiber nanofiltration membranes. J. Membr. Sci. 2016, 499, 396–405. [Google Scholar] [CrossRef]

- De Grooth, J.; Haakmeester, B.; Wever, C.; Potreck, J.; De Vos, W.M.; Nijmeijer, K. Long term physical and chemical stability of polyelectrolyte multilayer membranes. J. Membr. Sci. 2015, 489, 153–159. [Google Scholar] [CrossRef]

- De Grooth, J.; Oborny, R.; Potreck, J.; Nijmeijer, K.; De Vos, W.M. The role of ionic strength and odd–even effects on the properties of polyelectrolyte multilayer nanofiltration membranes. J. Membr. Sci. 2015, 475, 311–319. [Google Scholar] [CrossRef]

- Laakso, T.; Pihlajamäki, A.; Mänttäri, M. Effect of polycation structure on the fabrication of polyelectrolyte multilayer hollow fiber membranes for loose nanofiltration applications. Sep. Purif. Technol. 2018, 194, 141–148. [Google Scholar] [CrossRef]

- Joseph, N.; Ahmadiannamini, P.; Jishna, P.S.; Volodin, A.; Vankelecom, I.F. ‘Up-scaling’ potential for polyelectrolyte multilayer membranes. J. Membr. Sci. 2015, 492, 271–280. [Google Scholar] [CrossRef]

- Joseph, N.; Ahmadiannamini, P.; Hoogenboom, R.; Vankelecom, I.F.J. Layer-by-layer preparation of polyelectrolyte multilayer membranes for separation. Polym. Chem. 2014, 5, 1817–1831. [Google Scholar] [CrossRef]

- Zhang, G.; Gu, W.; Ji, S.; Liu, Z.; Peng, Y.; Wang, Z. Preparation of polyelectrolyte multilayer membranes by dynamic layer-by-layer process for pervaporation separation of alcohol/water mixtures. J. Membr. Sci. 2006, 280, 727–733. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, C.; Tong, T.; Epsztein, R.; Sun, M.; Verduzco, R.; Ma, J.; Elimelech, M. Selective removal of divalent cations by polyelectrolyte multilayer nanofiltration membrane: Role of polyelectrolyte charge, ion size, and ionic strength. J. Membr. Sci. 2018, 559, 98–106. [Google Scholar] [CrossRef]

- Cheng, C.; Yaroshchuk, A.; Bruening, M.L. Fundamentals of Selective Ion Transport through Multilayer Polyelectrolyte Membranes. Langmuir 2013, 29, 1885–1892. [Google Scholar] [CrossRef]

- Hong, S.U.; Ouyang, L.; Bruening, M.L. Recovery of phosphate using multilayer polyelectrolyte nanofiltration membranes. J. Membr. Sci. 2009, 327, 2–5. [Google Scholar] [CrossRef]

- Paltrinieri, L.; Remmen, K.; Müller, B.; Chu, L.; Köser, J.; Wintgens, T.; Wessling, M.; De Smet, L.; Sudhölter, E.J. Improved phosphoric acid recovery from sewage sludge ash using layer-by-layer modified membranes. J. Membr. Sci. 2019, 587, 117162. [Google Scholar] [CrossRef]

- Maza, E.; Tuninetti, J.S.; Politakos, N.; Knoll, W.; Moya, S.E.; Azzaroni, O. pH-responsive ion transport in polyelectrolyte multilayers of poly (diallyldimethylammonium chloride) (PDADMAC) and poly(4-styrenesulfonic acid-co-maleic acid) (PSS-MA) bearing strong- and weak anionic groups. Phys. Chem. Chem. Phys. 2015, 17, 29935–29948. [Google Scholar] [CrossRef] [PubMed]

- Xie, A.F.; Granick, S. Weak versus Strong: A Weak Polyacid Embedded within a Multilayer of Strong Polyelectrolytes. J. Am. Chem. Soc. 2001, 123, 3175–3176. [Google Scholar] [CrossRef]

- Sui, Z.; Schlenoff, J.B. Phase Separations in pH-Responsive Polyelectrolyte Multilayers: Charge Extrusion versus Charge Expulsion. Langmuir 2004, 20, 6026–6031. [Google Scholar] [CrossRef] [PubMed]

- Remmen, K.; Schäfer, R.; Hedwig, S.; Wintgens, T.; Wessling, M.; Lenz, M. Layer-by-layer membrane modification allows scandium recovery by nanofiltration. Environ. Sci. Water Res. Technol. 2019, 5, 1683–1688. [Google Scholar] [CrossRef]

- Nehmé, R.; Perrin, C.; Cottet, H.; Blanchin, M.-D.; Fabre, H. Stability of capillaries coated with highly charged polyelectrolyte monolayers and multilayers under various analytical conditions—Application to protein analysis. J. Chromatogr. A 2011, 1218, 3537–3544. [Google Scholar] [CrossRef] [PubMed]

- Menne, D.; Uzüm, C.; Koppelmann, A.; Erik, J.; Foeken, C.V.; Borre, F.; Dähne, L.; Laakso, T.; Pihlajamäki, A.; Wessling, M. Regenerable polymer / ceramic hybrid nano fi ltration membrane based on polyelectrolyte assembly by layer-by-layer technique. J. Membr. Sci. 2016, 520, 924–932. [Google Scholar] [CrossRef]

- Menne, D. Layer-by-Layer Design of Nanofiltration Membranes. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2017. [Google Scholar]

- Gao, C.; Leporatti, S.; Moya, S.E.; Donath, E.; Möhwald, H. Swelling and Shrinking of Polyelectrolyte Microcapsules in Response to Changes in Temperature and Ionic Strength. Chemistry 2003, 9, 915–920. [Google Scholar] [CrossRef]

- Frueh, J.; Köhler, R.; Möhwald, H.; Krastev, R. Changes of the Molecular Structure in Polyelectrolyte Multilayers under Stress. Langmuir 2010, 26, 15516–15522. [Google Scholar] [CrossRef]

- Irigoyen, J.; Han, L.; Llarena, I.; Mao, Z.; Gao, C.; Moya, S.E. Responsive Polyelectrolyte Multilayers Assembled at High Ionic Strength with an Unusual Collapse at Low Ionic Strength. Macromol. Rapid Commun. 2012, 33, 1964–1969. [Google Scholar] [CrossRef]

- European Commission. Towards A Circular Economy: A Zero Waste Programme for Europe; European Commission: Bruxelles, Belgium, 2014. [Google Scholar]

- Schlenoff, J.B.; Ly, H.; Li, M. Charge and Mass Balance in Polyelectrolyte Multilayers. J. Am. Chem. Soc. 1998, 120, 7626–7634. [Google Scholar] [CrossRef]

- Schlenoff, J.B.; Dubas, S.T. Mechanism of Polyelectrolyte Multilayer Growth: Charge Overcompensation and Distribution. Macromolecules 2001, 34, 592–598. [Google Scholar] [CrossRef]

- Kelly, K.D.; Fares, H.; Shaheen, S.A.; Schlenoff, J.B. Intrinsic Properties of Polyelectrolyte Multilayer Membranes: Erasing the Memory of the Interface. Langmuir 2018, 34, 3874–3883. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Fares, H.; Schlenoff, J.B. Ion-Pairing Strength in Polyelectrolyte Complexes. Macromolecules 2017, 50, 1066–1074. [Google Scholar] [CrossRef]

- Ghostine, R.A.; Markarian, M.Z.; Schlenoff, J.B. Asymmetric Growth in Polyelectrolyte Multilayers. J. Am. Chem. Soc. 2013, 135, 7636–7646. [Google Scholar] [CrossRef] [PubMed]

- Bargeman, G. Transport Phenomena during Nanofiltration of Concentrated Solutions. Ph.D. Thesis, University of Twente, Enschede, The Nederland, 2016. [Google Scholar]

- Bargeman, G.; Westerink, J.; Miguez, O.G.; Wessling, M. The effect of NaCl and glucose concentration on retentions for nanofiltration membranes processing concentrated solutions. Sep. Purif. Technol. 2014, 134, 46–57. [Google Scholar] [CrossRef]

- Ouyang, L.; Malaisamy, R.; Bruening, M.L. Multilayer polyelectrolyte films as nanofiltration membranes for separating monovalent and divalent cations. J. Membr. Sci. 2008, 310, 76–84. [Google Scholar] [CrossRef]

- Liu, C.; Fang, W.; Chou, S.; Shi, L.; Fane, A.; Wang, R. Fabrication of layer-by-layer assembled FO hollow fiber membranes and their performances using low concentration draw solutions. Desalination 2013, 308, 147–153. [Google Scholar] [CrossRef]

- Fritzmann, C.; Lowenberg, J.; Wintgens, T.; Melin, T. State-of-the-art of reverse osmosis desalination. Desalination 2007, 216, 1–76. [Google Scholar] [CrossRef]

- Chekli, L.; Phuntsho, S.; Shon, H.; Vigneswaran, S.; Kandasamy, J.; Chanan, A. A review of draw solutes in forward osmosis process and their use in modern applications. Desalination Water Treat. 2012, 43, 167–184. [Google Scholar] [CrossRef]

- Melin, T.; Rautenbach, R. Membranverfahren Grundlagen der Modulund Anlagenauslegung; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Bowen, W.; Mohammad, A.; Hilal, N. Characterisation of nanofiltration membranes for predictive purposes—Use of salts, uncharged solutes and atomic force microscopy. J. Membr. Sci. 1997, 126, 91–105. [Google Scholar] [CrossRef]

- Adusumilli, M.; Bruening, M.L. Variation of Ion-Exchange Capacity, ζ Potential, and Ion-Transport Selectivities with the Number of Layers in a Multilayer Polyelectrolyte Film. Langmuir 2009, 25, 7478–7485. [Google Scholar] [CrossRef] [PubMed]

| Permeability (L/m2/h/bar) | MgSO4 Retention (%) | MWCO (kDa) | ζ-potential (mV) | |

|---|---|---|---|---|

| PES | 1′100 | - | 100 | −13 |

| sPES | 80 | 22 | 10 | −19 |

| Permeability (L/m2/h/bar) | Decrease Compared to Virgin Membrane (%) | |

|---|---|---|

| PES uncoated | 1′100 | - |

| sPES uncoated | 80 | - |

| PES(PDADMAC/PSS)4 | 17 | 98 |

| PES(PDADMAC/PSS)8 | 15 | 99 |

| sPES(PDADMAC/PSS)4 | 10 | 87 |

| sPES(PDADMAC/PSS)8 | 7 | 91 |

| MgSO4 Feed Concentration (mM) | Retention (-) |

|---|---|

| 5 | 0.90 |

| 500 | 0.77 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Remmen, K.; Müller, B.; Köser, J.; Wessling, M.; Wintgens, T. Assessment of Layer-By-Layer Modified Nanofiltration Membrane Stability in Phosphoric Acid. Membranes 2020, 10, 61. https://doi.org/10.3390/membranes10040061

Remmen K, Müller B, Köser J, Wessling M, Wintgens T. Assessment of Layer-By-Layer Modified Nanofiltration Membrane Stability in Phosphoric Acid. Membranes. 2020; 10(4):61. https://doi.org/10.3390/membranes10040061

Chicago/Turabian StyleRemmen, Kirsten, Barbara Müller, Joachim Köser, Matthias Wessling, and Thomas Wintgens. 2020. "Assessment of Layer-By-Layer Modified Nanofiltration Membrane Stability in Phosphoric Acid" Membranes 10, no. 4: 61. https://doi.org/10.3390/membranes10040061

APA StyleRemmen, K., Müller, B., Köser, J., Wessling, M., & Wintgens, T. (2020). Assessment of Layer-By-Layer Modified Nanofiltration Membrane Stability in Phosphoric Acid. Membranes, 10(4), 61. https://doi.org/10.3390/membranes10040061