Modelling and Optimisation of Multi-Stage Flash Distillation and Reverse Osmosis for Desalination of Saline Process Wastewater Sources

Abstract

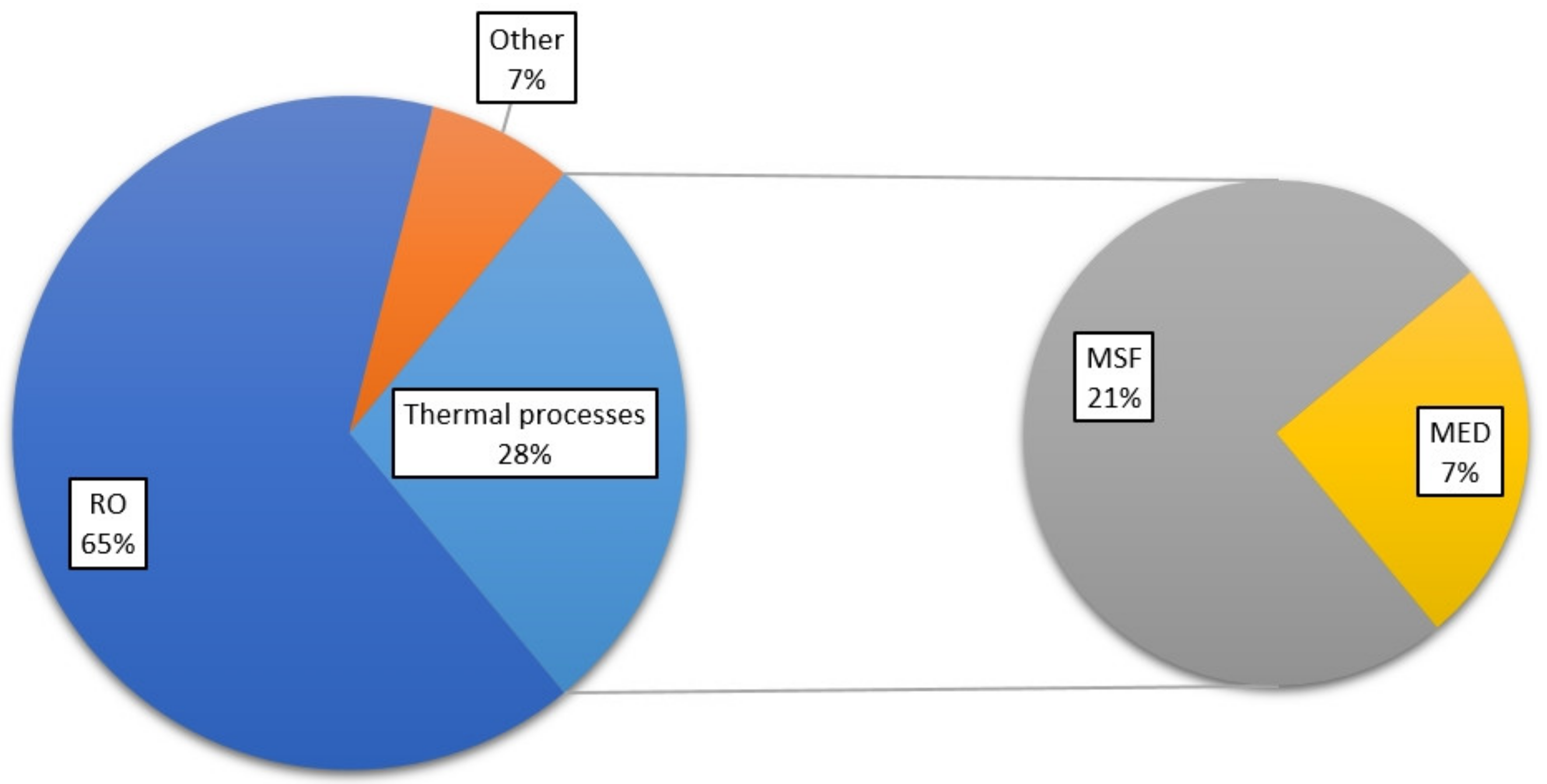

:1. Introduction

- relatively low cost,

- long-lasting and reliable structure,

- resistance to creep deformation,

- chemical and thermal stability in saline water,

- resistance to all kinds of fouling (inorganic, organic, colloidal and microbiological),

- resistance to oxidizing agents, especially chlorine,

- resistance to high temperature,

- high permeability to water,

- high salt rejection [10].

2. Materials and Methods

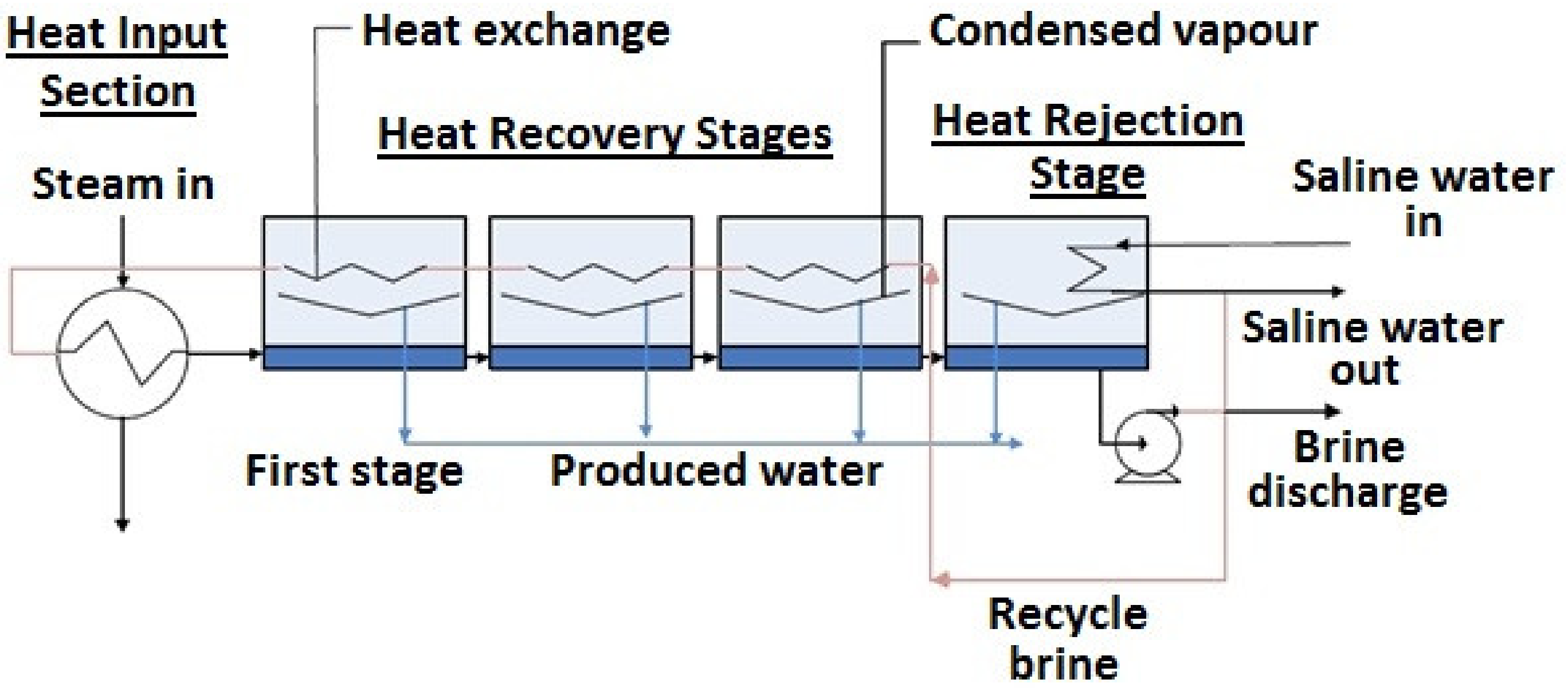

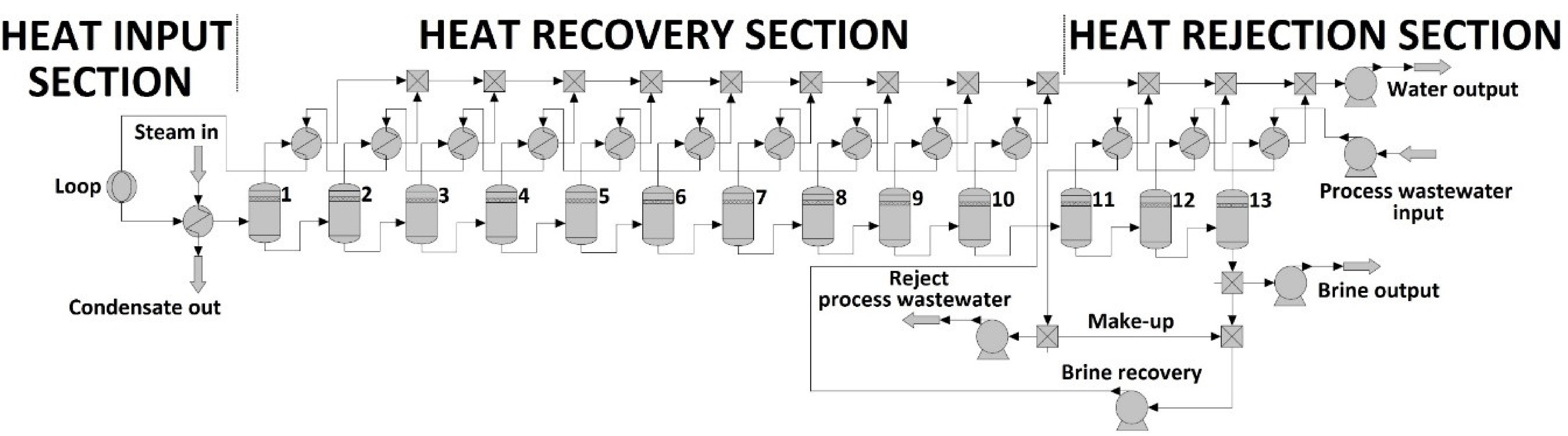

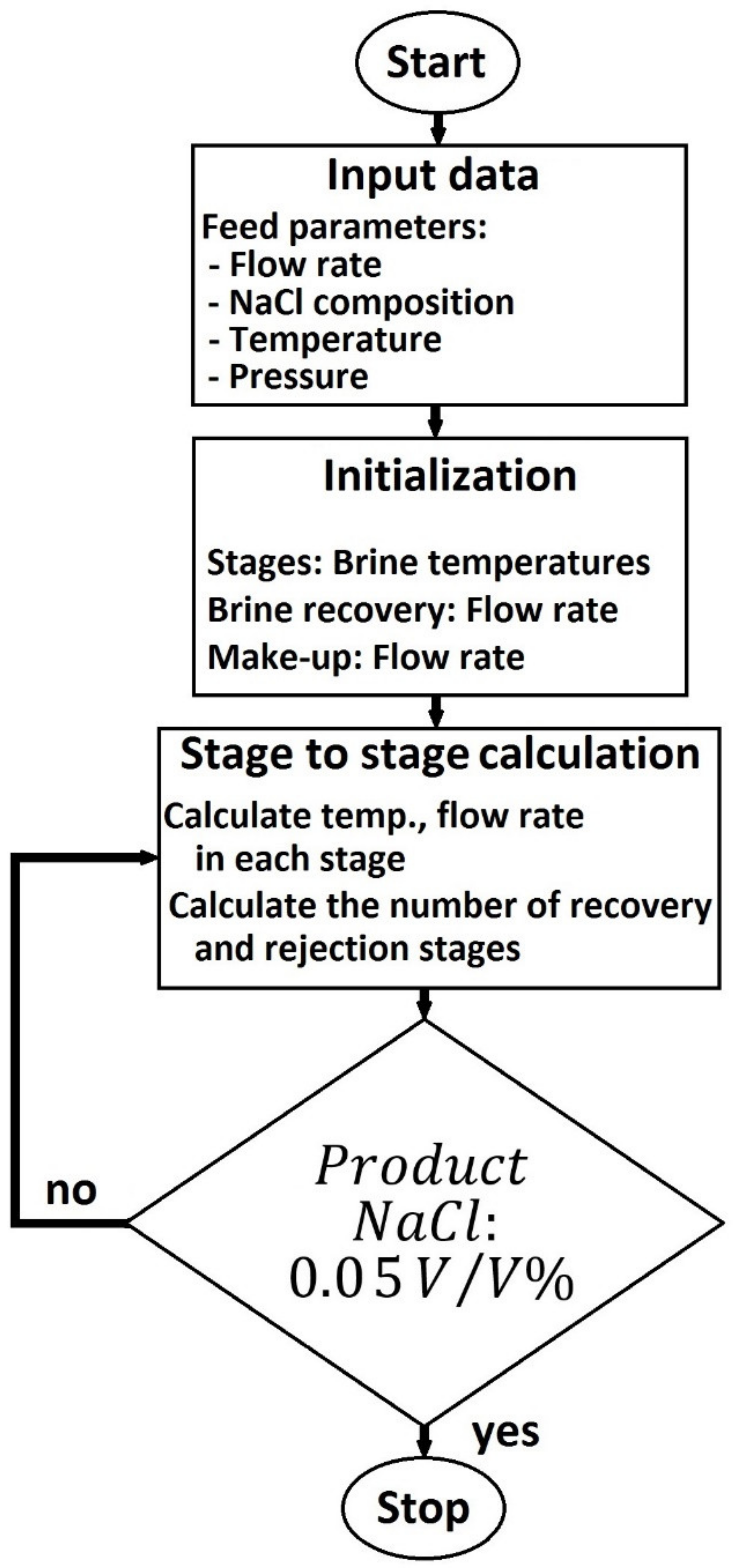

2.1. Multi-Stage Flash Distillation

- (1)

- Defining the flowsheet configuration by specifying:

- (a)

- Unit operations and

- (b)

- Process streams flowing between unit operations.

- (2)

- Specifying chemical compositions to be separated.

- (3)

- Choosing the thermodynamic model to represent the physical properties of the components and mixture in the method.

- (4)

- Specifying flow rates and thermodynamic conditions of the feed streams: i.e., pressure, temperature and phase conditions.

- (5)

- Optimizing operating conditions of unit operations in order to reduce NaCl content under 500 ppm of outlet water.

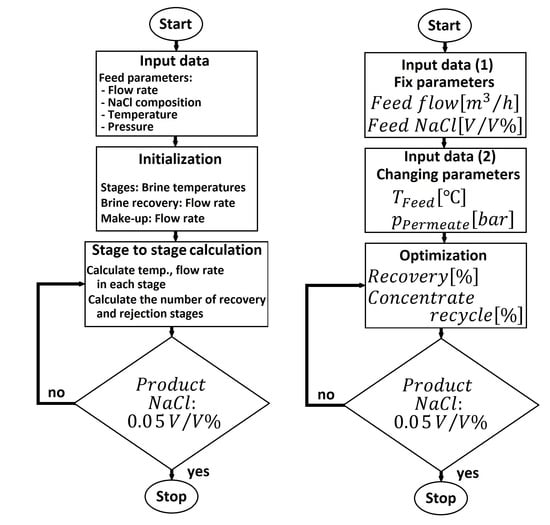

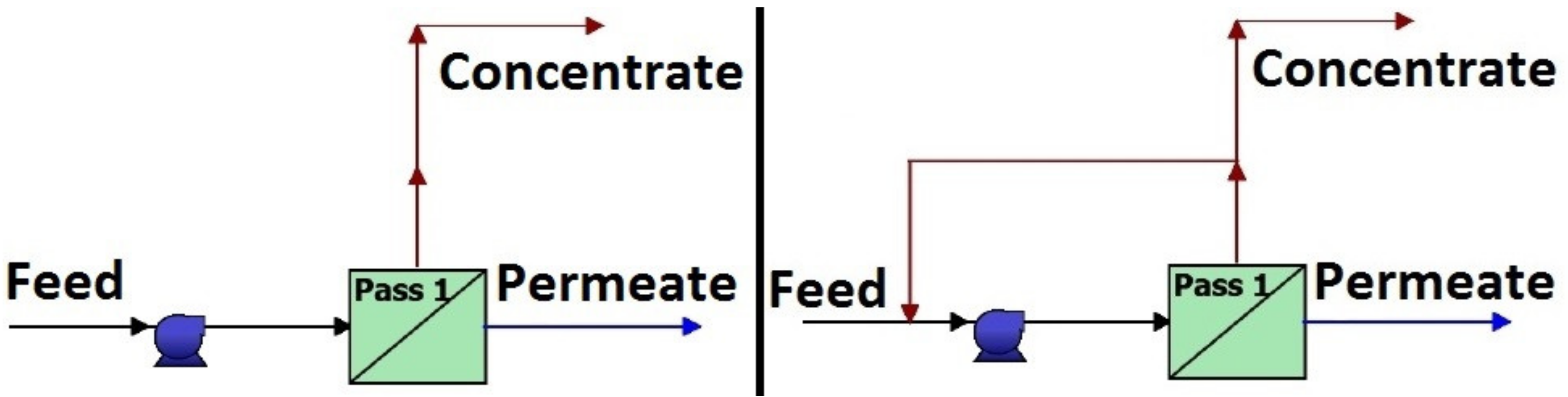

2.2. Reverse Osmosis

- (1)

- Estimation of feed pressure based on the feed osmotic pressure of the initial solution and the desired recovery rate of the system.

- (2)

- From the estimated feed pressure, estimation of the initial flow rate.

- (3)

- Calculation of initial recovery rate, permeate concentration and rejection rate for the module.

- (4)

- Next, estimation of the average salt concentration and water permeability to calculate an approximate flow rate for the membrane module.

- (5)

- The feeding of the concentrate from the first module to the second module.

- (6)

- In accordance with the previous steps, calculation of the flow rate and recovery for the second module, and then proceeding from module to module.

3. Results and Discussion

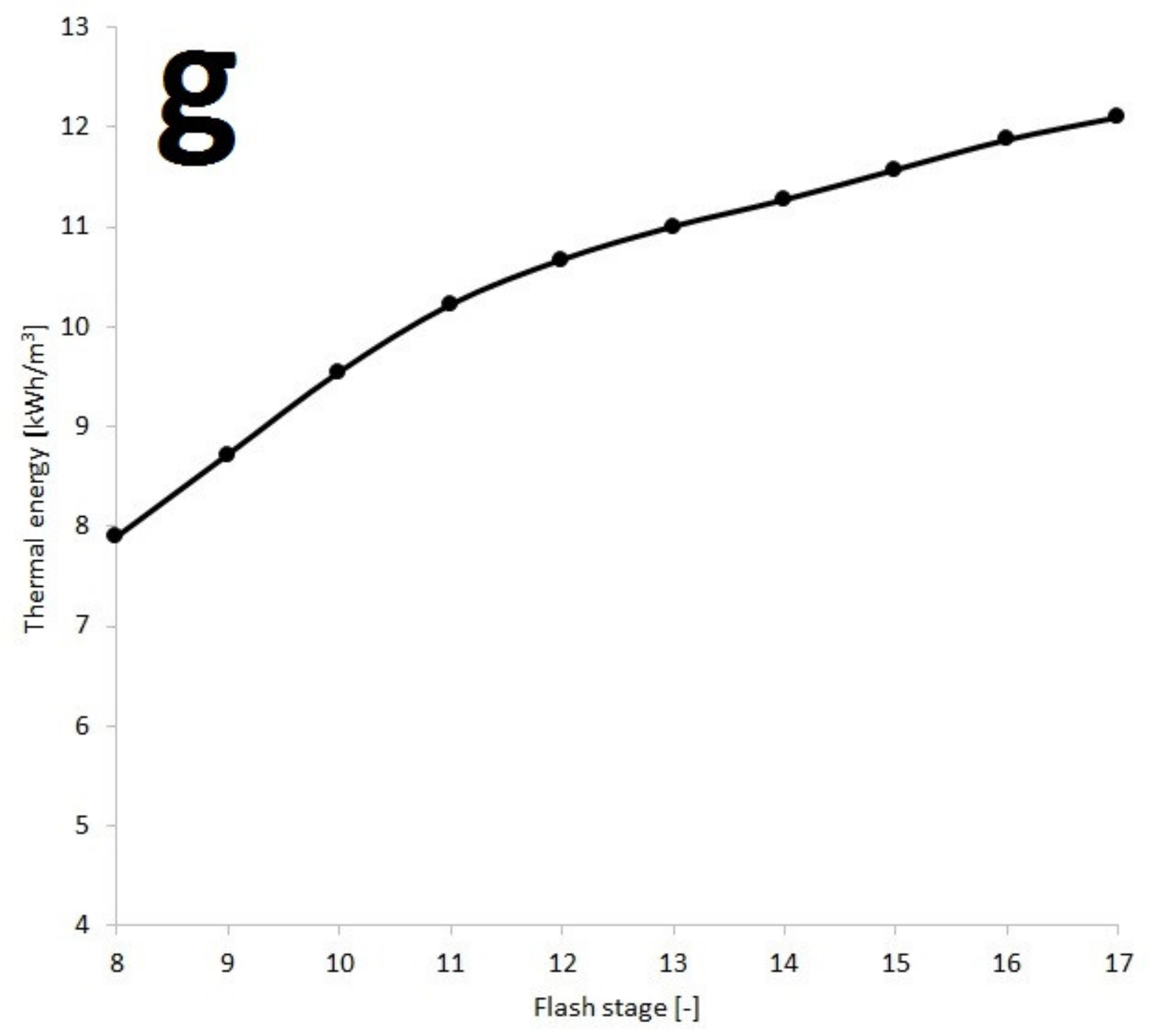

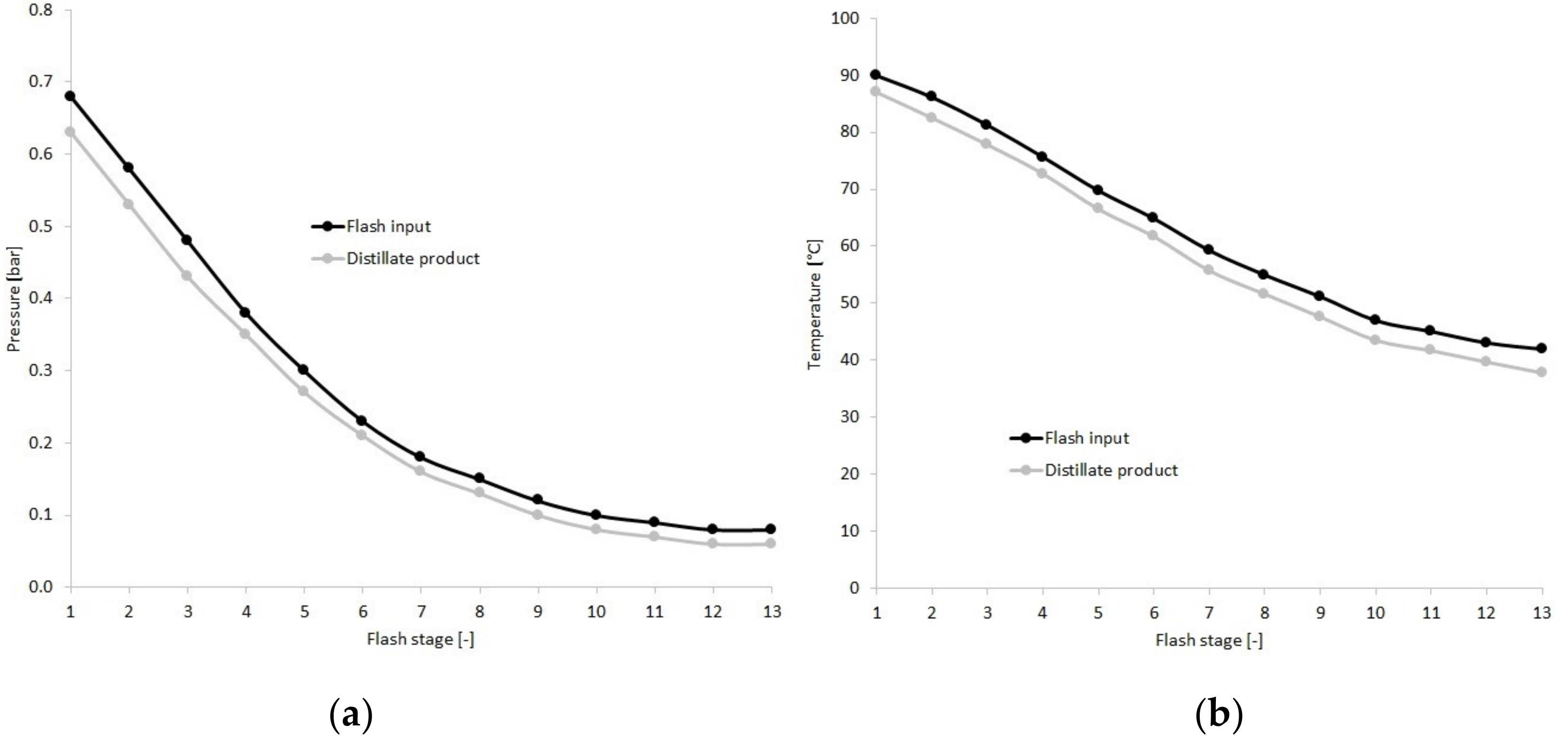

3.1. Multi-Stage Flash Distillation

- (1)

- Water output NaCl [V/V%]

- (2)

- Water output temperature [°C]

- (3)

- Water output pressure [bar]

- (4)

- Water output flow rate [m3/h]

- (5)

- Consumed steam [m3/h]

- (6)

- Performance ratio: PR [–]

- (7)

- Thermal energy [kWh/m3]

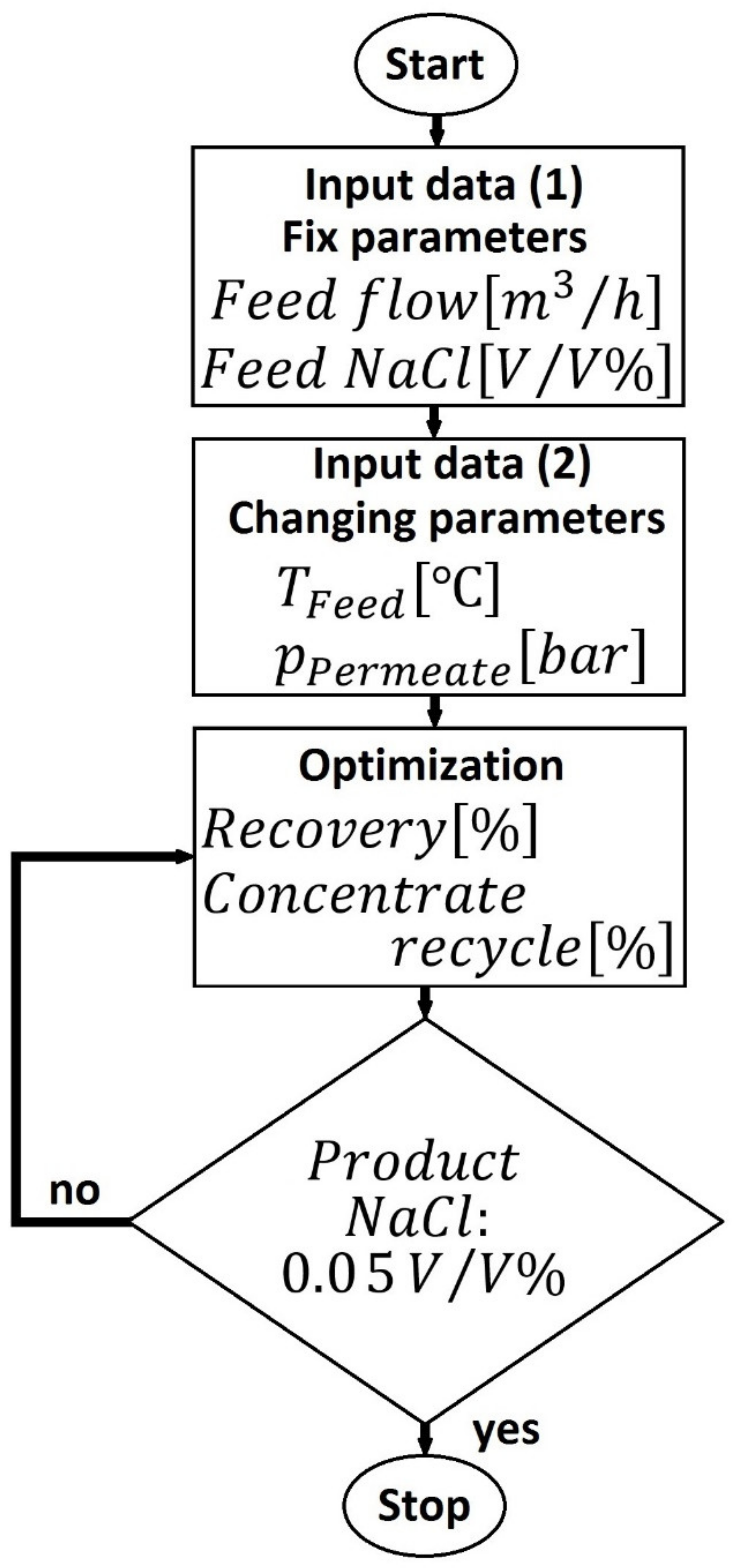

3.2. Reverse Osmosis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| CFD | Computational Fluid Dynamics |

| GOR | Gained Output Ratio |

| LLVF | Liquid-Liquid-Vapour Flash |

| MED | Multiple Effect Distillation |

| MSF | Multi-Stage Flash Distillation |

| NaCl | Sodium chloride |

| PR | Performance Ratio |

| PWW | Process Wastewater |

| RO | Reverse Osmosis |

| ROSA | Reverse Osmosis System Analysis |

| SRK | Soave-Redlich-Kwong |

| SWRO | Saline Water Reverse Osmosis |

| WAVE | Water Application Value Engine |

References

- Gude, G. Emerging Technologies for Sustainable Desalination Handbook, 1st ed.; Elsevier Science: Starkwell, MS, USA, 2018; pp. 1–110. [Google Scholar]

- Camacho, L.M.; Dumée, L.; Zhang, J.; Li, J.-D.; Duke, M.; Gomez, J.; Gray, S. Advances in Membrane Distillation for Water Desalination and Purification Applications. Water 2013, 5, 94–196. [Google Scholar] [CrossRef] [Green Version]

- Piacentino, A. Application of advanced thermodynamics, thermoeconomics and exergy costing to a Multiple Effect Distillation plant: In-depth analysis of cost formation process. Desalination 2015, 371, 88–103. [Google Scholar] [CrossRef]

- Kouhikamali, R. Thermodynamic analysis of feed water pre-heaters in multiple effect distillation systems. Appl. Therm. Eng. 2013, 50, 1157–1163. [Google Scholar] [CrossRef]

- Catrini, P.; Cipollina, A.; Giacalone, F.; Micale, G.; Piacentino, A.; Tamburini, A. Chapter 12—Thermodynamic, Exergy, and Thermoeconomic analysis of Multiple Effect Distillation Processes. In Renewable Energy Powered Desalination Handbook, 1st ed.; Gude, V.G., Ed.; Butterworth-Heinemann: Starkwell, MS, USA, 2018; pp. 445–489. [Google Scholar] [CrossRef]

- Ghaffour, N.; Missimer, T.M.; Amy, G.L. Technical review and evaluation of the economics of water desalination: Current and future challenges for better water supply sustainability. Desalination 2013, 309, 197–207. [Google Scholar] [CrossRef] [Green Version]

- Al-Obaidi, M.A.; Filippini, G.; Manenti, F.; Mujtaba, I.M. Cost evaluation and optimisation of hybrid multi effect distillation and reverse osmosis system for seawater desalination. Desalination 2019, 456, 136–149. [Google Scholar] [CrossRef] [Green Version]

- Ismail, A.F.; Khulbe, K.C.; Matsuura, T. Chapter 7—RO Economics. In Reverse Osmosis, 1st ed.; Ismail, A.F., Khulbe, K.C., Matsuura, T., Eds.; Elsevier: Ottawa, ON, Canada, 2019; pp. 163–187. [Google Scholar] [CrossRef]

- Al-Sahali, M.; Ettouney, H. Developments in thermal desalination processes: Design, energy, and costing aspects. Desalination 2007, 214, 227–240. [Google Scholar] [CrossRef]

- Al-Shayji, K.A. Modeling, Simulation, and Optimization of Large-Scale Commercial Desalination Plants. Ph.D. Thesis, Faculty of the Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 1998. [Google Scholar]

- Namboodiri, V.; Rajagopalan, N. 2.6-Desalination. In Comprehensive Water Quality and Purification, 1st ed.; Ahuja, S., Ed.; Elsevier: Waltham, MA, USA, 2014; Volume 2, pp. 98–119. [Google Scholar] [CrossRef]

- Morris, R.M. The development of the multi-stage flash distillation process: A designer’s viewpoint. Desalination 1993, 93, 57–68. [Google Scholar] [CrossRef]

- Tokui, Y.; Moriguchi, H.; Nishi, Y. Comprehensive environmental assessment of seawater desalination plants: Multistage flash distillation and reverse osmosis membrane types in Saudi Arabia. Desalination 2014, 351, 145–150. [Google Scholar] [CrossRef]

- Hanshik, C.; Jeong, H.; Jeong, K.-W.; Choi, S.-H. Improved productivity of the MSF (multi-stage flashing) desalination plant by increasing the TBT (top brine temperature). Energy 2016, 107, 683–692. [Google Scholar] [CrossRef]

- Kotb, O.A. Optimum numerical approach of a MSF desalination plant to be supplied by a new specific 650MW power plant located on the Red Sea in Egypt. Ain Shams Eng. J. 2015, 6, 257–265. [Google Scholar] [CrossRef] [Green Version]

- Rosso, M.; Beltramini, A.; Mazzotti, M.; Morbidelli, M. Modeling multistage flash desalination plants. Desalination 1997, 108, 365–374. [Google Scholar] [CrossRef]

- Al-Hengari, S.; El-Bousiffi, M.; El-Mudir, W. Performance analysis of a MSF desalination unit. Desalination 2005, 182, 73–85. [Google Scholar] [CrossRef]

- El-Ghonemy, A.M.K. Performance test of a sea water multi-stage flash distillation plant: Case study. Alex. Eng. J. 2018, 57, 2401–2413. [Google Scholar] [CrossRef]

- Curcio, E.; Profio, G.D.; Fontananova, E.; Drioli, E. 13-Membrane technologies for seawater desalination and brackish water treatment. In Advances in Membrane Technologies for Water Treatment, 1st ed.; Basile, A., Cassano, A., Rastogi, N.K., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 411–441. [Google Scholar] [CrossRef]

- Thabit, M.S.; Hawari, A.H.; Ammar, M.H.; Zaidi, S.; Zaragoza, G.; Altaee, A. Evaluation of forward osmosis as a pretreatment process for multi stage flash seawater desalination. Desalination 2019, 461, 22–29. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Hashaikeh, R.; Diabat, A.; Hilal, N. Mathematical and optimization modelling in desalination: State-of-the-art and future direction. Desalination 2019, 469, 114092. [Google Scholar] [CrossRef]

- Ettouney, H.M.; El-Dessouky, H. A simulator for thermal desalination processes. Desalination 1999, 125, 277–291. [Google Scholar] [CrossRef]

- Ang, W.L.; Mohammad, A.W. 12-Mathematical modeling of membrane operations for water treatment. In Advances in Membrane Technologies for Water Treatment, 1st ed.; Basile, A., Cassano, A., Rastogi, N.K., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 379–407. [Google Scholar] [CrossRef]

- Sassi, K.M.; Mujtaba, I.M. Effective design of reverse osmosis based desalination process considering wide range of salinity and seawater temperature. Desalination 2012, 306, 8–16. [Google Scholar] [CrossRef]

- Skiborowski, M.; Mhamdi, A.; Kraemer, K.; Marquardt, W. Model-based structural optimization of seawater desalination plants. Desalination 2012, 292, 30–44. [Google Scholar] [CrossRef]

- Lv, H.; Wang, Y.; Wu, L.; Hu, Y. Numerical simulation and optimization of the flash chamber for multi-stage flash seawater desalination. Desalination 2019, 465, 69–78. [Google Scholar] [CrossRef]

- Filippini, G.; Al-Obaidi, M.A.; Manenti, F.; Mujtaba, I.M. Performance analysis of hybrid system of multi effect distillation and reverse osmosis for seawater desalination via modelling and simulation. Desalination 2018, 448, 21–35. [Google Scholar] [CrossRef] [Green Version]

- Rao, G.P. Unity of control and identification in multistage flash desalination processes. Desalination 1993, 92, 103–124. [Google Scholar] [CrossRef]

- Helal, A.M.; Medani, M.S.; Soliman, M.A.; Flower, J.R. A tridiagonal matrix model for multistage flash desalination plants. Comput. Chem. Eng. 1986, 10, 327–342. [Google Scholar] [CrossRef]

- Husain, A.; Woldai, A.; Ai-Radif, A.; Kesou, A.; Borsani, R.; Sultan, H.; Deshpandey, P.B. Modelling and simulation of a multistage flash (MSF) desalination plant. Desalination 1994, 97, 555–586. [Google Scholar] [CrossRef]

- Belghaieb, J.; Aboussaoud, W.; Abdo, M.-I.; Hajji, N. Simulation and Optimization of a Triple-Effect Distillation Unit. In Proceedings of the 14th Conference on Process Integration, Modelling and Optimisation for Energy Saving and Pollution Reduction, Florence, Italy, 8–11 May 2011; Klemes, J.J., Pierucci, S., Eds.; AIDIC: Milano, Italy, 2011. [Google Scholar]

- Altaee, A. Computational model for estimating reverse osmosis system design and performance: Part-one binary feed solution. Desalination 2012, 291, 101–105. [Google Scholar] [CrossRef]

- Haaz, E.; Fozer, D.; Nagy, T.; Valentinyi, N.; Andre, A.; Matyasi, J.; Balla, J.; Mizsey, P.; Toth, A.J. Vacuum evaporation and reverse osmosis treatment of process wastewaters containing surfactant material: COD reduction and water reuse. Clean Technol. Environ. Policy 2019, 21, 861–870. [Google Scholar] [CrossRef] [Green Version]

- Haaz, E.; Toth, A.J. Methanol dehydration with pervaporation: Experiments and modelling. Sep. Purif. Technol. 2018, 205, 121–129. [Google Scholar] [CrossRef]

- Toth, A.J. Comprehensive evaluation and comparison of advanced separation methods on the separation of ethyl acetate-ethanol-water highly non-ideal mixture. Sep. Purif. Technol. 2019, 224, 490–508. [Google Scholar] [CrossRef]

- Edgar, T.F.; Himmelblau, D.M.; Lasdon, L.S. Optimization of Chemical Processes, 2nd ed.; McGraw-Hill: Michigan, CA, USA, 2001. [Google Scholar]

- Nagy, J.; Kaljunen, J.; Toth, A.J. Nitrogen recovery from wastewater and human urine with hydrophobic gas separation membrane: Experiments and modelling. Chem. Pap. 2019, 73, 1903–1915. [Google Scholar] [CrossRef] [Green Version]

- DuPont, WAVE Manual. 2020. Available online: https://www.dupont.com/Wave/Default.htm (accessed on 7 August 2020).

| Process | Thermal Energy [kWh/m3] | Electrical Energy [kWh/m3] | Total Energy [kWh/m3] | Investment Cost [USD/m3/d] | Total Water Cost [USD/m3] |

|---|---|---|---|---|---|

| MSF | 7.5–12 | 2.5–4 | 10–16 | 1200–2500 | 0.8–1.5 |

| MED | 4–7 | 1.5–2 | 5.5–9 | 900–2500 | 0.7–1.2 |

| RO | – | 3–4 | 3–4 | 900–2500 | 0.5–1.2 |

| SWRO Plant | Productivity [m3/day] | Unit Water Cost [USD/m3] |

|---|---|---|

| Ashkelon (Israel) | 320,000 | 0.52 |

| Palmachim (Israel) | 83,000 | 0.78 |

| Perth (Australia) | 144,000 | 0.75 |

| Carlsbad (California) | 189,000 | 0.76 |

| Skikda (Algeria) | 100,000 | 0.73 |

| Hamma (Algeria) | 200,000 | 0.82 |

| Hadera (Israel) | 348,000 | 0.63 |

| Membrane Module | SW30XHR-440i | SW30HRLE-440i | SW30XLE-440i |

|---|---|---|---|

| Membrane type | Polyamide Thin-Film | Polyamide Thin-Film | Polyamide Thin-Film |

| Composite | Composite | Composite | |

| Active area [m2] | 41 | 41 | 41 |

| Max. operating pressure [bar] | 83 | 83 | 83 |

| Permeate flow rate [m3/d] | 25 | 31 | 37.5 |

| Min. salt rejection [%] | 99.70 | 99.65 | 99.60 |

| Stabilized salt rejection [%] | 99.82 | 99.80 | 99.70 |

| Max. operating temp. [°C] | 45 | 45 | 45 |

| Parameters | Industrial Data [10] | Simulated Data | Error [%] |

|---|---|---|---|

| Top brine temperature [°C] | 90.6 | 89.9 | −0.7 |

| Recycled brine flow rate [Ton/min] | 238.10 | 238.12 | 0.01 |

| Distillate produced [Ton/min] | 18.80 | 18.82 | 0.09 |

| Flow Rate | Temp. [°C] | Pressure [bar] | Flow Rate [m3/h] | Water [V/V%] | NaCl [V/V%] |

|---|---|---|---|---|---|

| PWW input | 20.0 | 3.00 | 1000 | 95.50 | 4.50 |

| Flash 1 input | 89.9 | 0.70 | 1484 | 93.25 | 6.75 |

| Flash 10 input | 45.7 | 0.10 | 1378 | 92.67 | 7.26 |

| Flash 13 output | 40.0 | 0.07 | 1366 | 92.67 | 7.33 |

| Make-up | 36.5 | 2.50 | 304 | 95.49 | 4.51 |

| Brine recovery | 40.5 | 4.60 | 1484 | 93.26 | 6.75 |

| Brine output | 40.0 | 0.07 | 186 | 92.70 | 7.35 |

| Reject PWW | 36.5 | 0.07 | 696 | 95.51 | 4.51 |

| Water output | 63.0 | 0.07 | 117 | 99.95 | 0.05 |

| Feed Temp. [°C] | Concentrate Recycled [%] | Permeate Pressure [bar] | Total Energy [kWh/m3] | Yield [%] | Brine-Reduction [–] |

|---|---|---|---|---|---|

| 10 | 0 | 10 | 0.7 | 4.3 | 0.99 |

| 10 | 0 | 20 | 0.8 | 4.4 | 0.99 |

| 10 | 0 | 30 | 1.0 | 4.5 | 0.99 |

| 10 | 30 | 10 | 4.4 | 3.0 | 0.99 |

| 10 | 30 | 20 | 5.2 | 3.2 | 0.99 |

| 10 | 30 | 30 | 5.9 | 3.3 | 0.99 |

| Feed Temp. [°C] | Concentrate Recycled [%] | Permeate Pressure [bar] | Total Energy [kWh/m3] | Yield [%] | Brine-Reduction [–] |

|---|---|---|---|---|---|

| 20 | 0 | 10 | 0.9 | 6.4 | 0.99 |

| 20 | 0 | 20 | 1.0 | 6.5 | 0.99 |

| 20 | 0 | 30 | 1.2 | 6.6 | 0.99 |

| 20 | 60 | 10 | 4.5 | 5.2 | 0.99 |

| 20 | 60 | 20 | 5.0 | 5.3 | 0.99 |

| 20 | 60 | 30 | 5.6 | 5.4 | 0.99 |

| Feed temp. [°C] | Concentrate recycled [%] | Permeate pressure [bar] | Total Energy [kWh/m3] | Yield [%] | Brine- Reduction [–] |

|---|---|---|---|---|---|

| 25 | 0 | 10 | 1.4 | 8.4 | 0.99 |

| 25 | 0 | 20 | 1.6 | 8.5 | 0.99 |

| 25 | 0 | 30 | 1.9 | 8.6 | 0.99 |

| 25 | 70 | 10 | 5.1 | 6.7 | 0.99 |

| 25 | 70 | 20 | 5.9 | 6.8 | 0.99 |

| 25 | 70 | 30 | 6.7 | 6.9 | 0.99 |

| Feed Temp. [°C] | Concentrate Recycled [%] | Permeate Pressure [bar] | Total Energy [kWh/m3] | Yield [%] | Brine- Reduction [–] |

|---|---|---|---|---|---|

| 10 | 0 | 10 | 0.9 | 5.3 | 0.99 |

| 10 | 0 | 20 | 1.0 | 5.4 | 0.99 |

| 10 | 0 | 30 | 1.2 | 5.5 | 0.99 |

| 10 | 45 | 10 | 4.3 | 3.8 | 0.99 |

| 10 | 45 | 20 | 5.0 | 3.9 | 0.99 |

| 10 | 45 | 30 | 5.8 | 4.0 | 0.99 |

| Feed Temp. [°C] | Concentrate Recycled [%] | Permeate Pressure [bar] | Total Energy [kWh/m3] | Yield [%] | Brine- Reduction [–] |

|---|---|---|---|---|---|

| 20 | 0 | 10 | 1.1 | 8.3 | 0.99 |

| 20 | 0 | 20 | 1.3 | 8.4 | 0.99 |

| 20 | 0 | 30 | 1.4 | 8.6 | 0.99 |

| 20 | 70 | 10 | 5.0 | 6.7 | 0.99 |

| 20 | 70 | 20 | 5.7 | 6.8 | 0.99 |

| 20 | 70 | 30 | 6.5 | 6.9 | 0.99 |

| Feed temp. [°C] | Concentrate Recycled [%] | Permeate Pressure [bar] | Total Energy [kWh/m3] | Yield [%] | Brine- Reduction [–] |

|---|---|---|---|---|---|

| 25 | 0 | 10 | 2.0 | 10.4 | 0.99 |

| 25 | 0 | 20 | 2.4 | 10.5 | 0.99 |

| 25 | 0 | 30 | 2.8 | 10.6 | 0.99 |

| 25 | 75 | 10 | 5.2 | 7.9 | 0.99 |

| 25 | 75 | 20 | 6.0 | 8.0 | 0.99 |

| 25 | 75 | 30 | 6.7 | 8.1 | 0.99 |

| Feed Temp. [°C] | Concentrate Recycled [%] | Permeate Pressure [bar] | Total Energy [kWh/m3] | Yield [%] | Brine- Reduction [–] |

|---|---|---|---|---|---|

| 10 | 0 | 10 | 1.1 | 6.2 | 0.99 |

| 10 | 0 | 20 | 1.3 | 6.4 | 0.99 |

| 10 | 0 | 30 | 1.5 | 6.5 | 0.99 |

| 10 | 55 | 10 | 4.1 | 4.6 | 0.99 |

| 10 | 55 | 20 | 4.9 | 4.7 | 0.99 |

| 10 | 55 | 30 | 5.7 | 4.8 | 0.99 |

| Feed Temp. [°C] | Concentrate Recycled [%] | Permeate Pressure [bar] | Total Energy [kWh/m3] | Yield [%] | Brine- Reduction [–] |

|---|---|---|---|---|---|

| 20 | 0 | 10 | 1.4 | 10.4 | 0.99 |

| 20 | 0 | 20 | 1.6 | 10.5 | 0.99 |

| 20 | 0 | 30 | 1.9 | 10.5 | 0.99 |

| 20 | 75 | 10 | 4.6 | 7.9 | 0.99 |

| 20 | 75 | 20 | 5.4 | 8.0 | 0.99 |

| 20 | 75 | 30 | 6.2 | 8.1 | 0.99 |

| Feed Temp. [°C] | Concentrate Recycled [%] | Permeate Pressure [bar] | Total Energy [kWh/m3] | Yield [%] | Brine- Reduction [–] |

|---|---|---|---|---|---|

| 25 | 0 | 10 | 2.0 | 12.4 | 0.99 |

| 25 | 0 | 20 | 2.4 | 12.5 | 0.99 |

| 25 | 0 | 30 | 2.8 | 12.6 | 0.99 |

| 25 | 80 | 10 | 5.0 | 11.4 | 0.99 |

| 25 | 80 | 20 | 5.8 | 11.6 | 0.99 |

| 25 | 80 | 30 | 6.6 | 11.8 | 0.99 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toth, A.J. Modelling and Optimisation of Multi-Stage Flash Distillation and Reverse Osmosis for Desalination of Saline Process Wastewater Sources. Membranes 2020, 10, 265. https://doi.org/10.3390/membranes10100265

Toth AJ. Modelling and Optimisation of Multi-Stage Flash Distillation and Reverse Osmosis for Desalination of Saline Process Wastewater Sources. Membranes. 2020; 10(10):265. https://doi.org/10.3390/membranes10100265

Chicago/Turabian StyleToth, Andras Jozsef. 2020. "Modelling and Optimisation of Multi-Stage Flash Distillation and Reverse Osmosis for Desalination of Saline Process Wastewater Sources" Membranes 10, no. 10: 265. https://doi.org/10.3390/membranes10100265

APA StyleToth, A. J. (2020). Modelling and Optimisation of Multi-Stage Flash Distillation and Reverse Osmosis for Desalination of Saline Process Wastewater Sources. Membranes, 10(10), 265. https://doi.org/10.3390/membranes10100265