Impact of Innovative Technologies on the Content of Vitamin C and Its Bioavailability from Processed Fruit and Vegetable Products

Abstract

1. Introduction

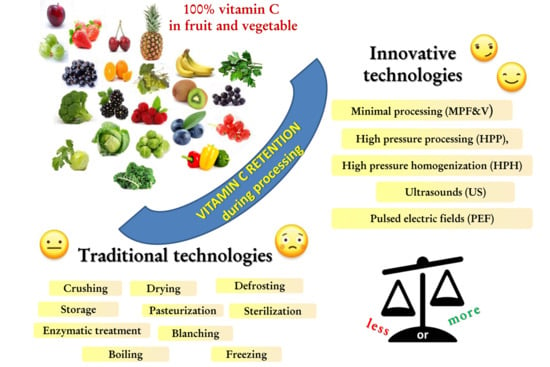

2. Traditional Processing—Critical Points

2.1. Low Temperature—Freezing Technology

2.2. High Temperature—Pasteurization, Sterilization, Blanching, Cooking, Steaming, etc.

2.3. Drying Technology

3. Consumers Expectations of Food

4. Innovative, Non-Thermal Technologies in Fruit and Vegetable Processing

4.1. High-Pressure Processing (HPP)

4.2. High-Pressure Homogenization (HPH)

4.3. Ultrasound (US)

4.4. Pulsed Electric Fields (PEFs)

4.5. Minimally Processed Fruit and Vegetables (MPFV)

5. Effect of Innovative Processing on Vitamin C Bioavailability

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Southon, S. Increased consumption of fruits and vegetables within the EU: Potential health benefits. In Proceedings of the 3rd Karlsruhe Nutrition Symposium European Research towards Safer and Better Foods, Karlsruhe, Germany, 18–20 October 1998; pp. 149–158. [Google Scholar]

- Sosnowska, D. Vitamin C. Structure and properties. In Antioxidants in Food. Health, Technological, Molecular and Analytical Aspects; Grajek, W., Ed.; WN-T: Warsaw, Poland, 2007; pp. 163–171. [Google Scholar]

- Nijoku, P.C.; Ayuk, A.A.; Okoye, C.V. Temperature effects on vitamin C content in citrus fruits. Pak. J. Nutr. 2011, 10, 1168–1169. [Google Scholar] [CrossRef]

- El-Ishaq, A.; Obirinakem, S. Effect of temperature and storage on vitamin C content in fruits juice. Int. J. Chem. Biomol. Sci. 2015, 2, 17–21. [Google Scholar]

- Baron, J.H. Sailors’ scurvy before and after James Lind—A reassessment. Nutr. Rev. 2009, 67, 315–332. [Google Scholar] [CrossRef]

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on Dietary Reference Values for vitamin C. EFSA J. 2013, 11, 3418. [Google Scholar]

- Commission Regulation (EU). No 432/2012 of 16 May 2012 establishing a list of permitted health claims made on foods, other than those referring to the reduction of disease risk and to children’s development and health. Off. J. Eur. Union 2012, 136, 1–40. [Google Scholar]

- Regulation (EU). No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers, amending. Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council. Off. J. Eur. Union 2009, 77, 81. [Google Scholar]

- DGE—German Nutrition Society. New Reference Values for Vitamin C Intake. Review Article. Ann. Nutr. Metab. 2015, 67, 13–20. [Google Scholar] [CrossRef]

- Landete, J.M. Dietary intake of natural antioxidants: Vitamins and polyphenols. Crit. Rev. Food Sci. Nutr. 2013, 53, 706–721. [Google Scholar] [CrossRef]

- Belitz, H.D.; Grosch, W.; Schieberle, P. Food Chemistry. Vitamins. In Food Chemistry; Springer: Berlin/Heidelberg, Germany, 2009; pp. 403–420. [Google Scholar]

- USDA. Composition of Foods Raw, Processed, Prepared National Nutrient Database for Standard Reference, Release 28. 2015. Available online: https://health.gov/sites/default/files/2019-09/2015-2020_Dietary_Guidelines.pdf (accessed on 15 October 2020).

- Gamboa-Santos, J.; Soria, A.C.; Pérez-Mateos, M.; Carrasco, J.A.; Montilla, A.; Villamiel, M. Vitamin C content and sensorial properties of dehydrated carrots blanched conventionally or by ultrasound. Food Chem. 2013, 136, 782–788. [Google Scholar] [CrossRef]

- Oyetade, O.A.; Oyeleke, G.O.; Adegoke, B.M.; Akintunde, A.O. Stability studies on ascorbic acid (vitamin C) from different sources. J. Appl. Chem. 2012, 2, 20–24. [Google Scholar]

- Santos, P.H.S.; Silva, M.A. Retention of vitamin C in drying processes of fruits and vegetables—A review. Dry. Technol. 2008, 26, 1421–1437. [Google Scholar] [CrossRef]

- Demiray, E.; Tulek, Y.; Yilmaz, Y. Degradation kinetics of lycopene, b-carotene and ascorbic acid in tomatoes during hot air drying. LTW Food Sci. Technol. 2013, 50, 172–176. [Google Scholar] [CrossRef]

- Erenturk, S.; Gulaboglu, M.S.; Gultekin, S. The effects of cutting and drying medium on the vitamin C content of rosehip during drying. J. Food Eng. 2005, 68, 513–518. [Google Scholar] [CrossRef]

- Marfil, P.H.M.; Santos, E.M.; Telis, V.R.N. Ascorbic acid degradation kinetics in tomatoes at different drying conditions. LWT Food Sci. Technol. 2008, 41, 1642–1647. [Google Scholar] [CrossRef]

- Qiu, J.; Vuist, J.E.; Boom, R.M.; Schutyser, M.A.I. Formation and degradation kinetics of organic acids during heating and drying of concentrated tomato juice. LWT Food Sci. Technol. 2018, 87, 112–121. [Google Scholar] [CrossRef]

- Gamboa-Santos, J.; Megías-Pérez, R.; Soria, A.C.; Olano, A.; Montilla, A.; Villamiel, M. Impact of processing conditions on the kinetic of vitamin C degradation and 2-furoylmethyl amino acid formation in dried strawberries. Food Chem. 2014, 153, 164–170. [Google Scholar] [CrossRef]

- Hung, L.H.; Horagai, Y.; Adachi, S. Decomposition and discoloration of L-ascorbic acid freeze-dried with saccharides. Innov. Food Sci. Emerg. Technol. 2007, 8, 500–506. [Google Scholar] [CrossRef]

- Cruz, R.M.S.; Viera, M.C.; Silvia, C.L.M. Effect of heat and thermosonication treatments on watercress (Nasturtium officinale) vitamin C degradation kinetics. Innov. Food Sci. Emerg. Technol. 2008, 9, 483–488. [Google Scholar] [CrossRef]

- Leong, S.Y.; Oey, I. Effects of processing on anthocyanins, carotenoids and vitamin C in summer fruits and vegetables. Food Chem. 2012, 133, 1577–1587. [Google Scholar] [CrossRef]

- Uddin, M.S.; Hawlader, M.N.A.; Ding, L.; Mujumdar, A.S. Degradation of ascorbic acid in dried guava during storage. J. Food Eng. 2002, 52, 21–26. [Google Scholar] [CrossRef]

- Ali, M.A.; Yusof, Y.A.; Chin, N.L.; Ibrahim, M.N. Effect of different drying treatments on colour quality and ascorbic acid concentration of guava fruit. Int. Food Res. J. 2016, 23, S155–S161. [Google Scholar]

- Munyaka, A.W.; Makule, E.E.; Oey, I.; Loey, A.V.; Hendrickx, M. Thermal stability of L-ascorbic acid and ascorbic acid oxidase in broccoli (Brassica oleracea var. italic). J. Food Sci. 2010, 75, C336–C340. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Pegg, R.B.; Eitenmiller, R.R.; Chun, J.Y.; Kerrihard, A.L. Selected nutrient analysis of fresh, fresh-stored, and frozen fruits and vegetables. J. Food Compost. Anal. 2017, 59, 8–17. [Google Scholar] [CrossRef]

- Rickman, J.C.; Barrett, D.M.; Bruhn, C.M. Nutritional comparison of fresh, frozen and canned fruits and vegetables. Part 1. Vitamins. C and B and phenolic compounds. J. Sci. Food Agric. 2007, 87, 930–944. [Google Scholar] [CrossRef]

- Piekut, J.; Krasowska, M.; Kowczyk-Sadowy, M.; Polewko, K.; Dec, D. Impact of heat treatment and freezing on vitamin C content in selected vegetables and fruits. Carpathian J. Food Sci. Technol. 2018, 10, 136–141. [Google Scholar]

- Georgé, S.; Tourniaire, F.; Gautier, H.; Goupy, P.; Rock, E.; Cais-Veyrat, C. Changes in the contents of carotenoids, phenolic compounds and vitamin C during technical processing and lyophilisation of red and yellow tomatoes. Food Chem. 2011, 124, 1603–1611. [Google Scholar] [CrossRef]

- Klopotek, I.; Otto, K.; Böhm, V. Processing strawberries to different products alters contents of vitamin C, total phenolics, total anthocyanins, and antioxidant capacity. J. Agric. Food Chem. 2005, 53, 5640–5646. [Google Scholar] [CrossRef]

- Inversen, C.K. Black currant nectar: Effect of processing and storage on anthocyanin and ascorbic acid content. J. Food Sci. 1999, 64, 37–41. [Google Scholar] [CrossRef]

- Mieszczakowska-Frąc, M.; Markowski, J.; Zbrzeźniak, M.; Płocharski, W. Impact of enzyme on quality of blackcurrant and plum juices. LWT Food Sci. Technol. 2012, 49, 251–256. [Google Scholar] [CrossRef]

- Zhang, D.; Hamauzu, Y. Phenolics, ascorbic acid, carotenoids and antioxidant activity of broccoli and their changes during conventional and microwave cooking. Food Chem. 2004, 88, 503–509. [Google Scholar] [CrossRef]

- Lafarga, T.; Viñas, I.; Bobo, G.; Simó, J.; Aguiló-Aguayo, I. Effect of steaming and sous vide processing on the total phenolic content, vitamin C and antioxidant potential of the genus Brassica. Innov. Food Sci. Emerg. Technol. 2018, 47, 412–420. [Google Scholar] [CrossRef]

- Tao, Y.; Han, M.; Gao, X.; Han, Y.; Show, P.L.; Liu, C.; Ye, X.; Xie, G. Applications of water blanching, surface contacting ultrasound-assisted air drying, and their combination for dehydration of white cabbage: Drying mechanism, bioactive profile, color and rehydration property. Ultrason. Sonochem. 2019, 53, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Choi, Y.; Jeong, H.S.; Lee, J.; Sung, J. Effect of different cooking methods on the content of vitamins and true retention in selected vegetables. Food Sci. Biotechnol. 2018, 27, 333–342. [Google Scholar] [CrossRef]

- Popova, A.T. The effect of heating on the vitamin C content of selected vegetables. World J. Adv. Res. Rev. 2019, 3, 27–32. [Google Scholar] [CrossRef]

- Koutchma, T.; Popović, V.; Ros-Polski, V.; Popielarz, A. Effects of Ultraviolet light and high-pressure processing on quality and health-related constituents of fresh juice products. Compr. Rev. Food Sci. Food Saf. 2016, 15, 844–867. [Google Scholar] [CrossRef]

- Lewicki, P.P. Design of hot air for better foods. Trends Food Sci. Technol. 2006, 17, 153–163. [Google Scholar] [CrossRef]

- Dorofejeva, K.; Rakcejeva, R.; Galoburdaa, R.; Dukalskaa, L.; Kviesis, J. Vitamin C content in Latvian cranberries dried in convective and microwave vacuum driers. Procedia Food Sci. 2011, 1, 433–440. [Google Scholar] [CrossRef]

- Kurozawa, L.M.; Terng, I.; Hubinger, M.D.; Park, K.J. Ascorbic acid degradation of papaya during drying: Effect of process conditions and glass transition phenomenon. J. Food Eng. 2014, 123, 157–164. [Google Scholar] [CrossRef]

- Sonowane, S.K.; Arya, S.S. Effect of drying and storage on bioactive components of jambhul and wood apple. J. Food Sci. Technol. 2014, 52, 2833–2841. [Google Scholar] [CrossRef]

- Nemzer, B.; Vargas, L.; Xia, X.; Sintara, M.; Feng, H. Phytochemical and physical properties of blueberries, tart cherries, strawberries, and cranberries as affected by different drying methods. Food Chem. 2018, 262, 242–250. [Google Scholar] [CrossRef]

- Sakooei-Vayghan, R.; Peighambardoust, S.H.; Hesari, J.; Peressini, D. Effects of osmotic dehydration (with and without sonication) and pectin-based coating pretreatments on functional properties and color of hot-air dried apricot cubes. Food Chem. 2020, 311, 125978. [Google Scholar] [CrossRef] [PubMed]

- Timoumi, S.; Mihoubia, D.; Zagrouba, F. Shrinkage, vitamin C degradation and aroma losses during infra-red drying of apple slices. LWT Food Sci. Technol. 2007, 40, 1648–1654. [Google Scholar] [CrossRef]

- Erbay, Z.; Icier, F. A review of thin layer drying of foods: Theory, modeling, and experimental results. Crit. Rev. Food Sci. Nutr. 2009, 50, 441–464. [Google Scholar] [CrossRef] [PubMed]

- Mujumdar, A.S.; Law, C.L. Drying technology: Trends and applications in postharvest processing. Food Bioprocess Technol. 2010, 3, 843–852. [Google Scholar] [CrossRef]

- Horuz, E.; Bozkurt, H.; Karatas, H.; Maskan, M. Effect of hybrid (microwave-convectional) and convectional drying on drying kinetics, total phenolics, antioxidant capacity, vitamin C, color and rehydration capacity of sour cherries. Food Chem. 2017, 230, 295–305. [Google Scholar] [CrossRef] [PubMed]

- Du, G.; Zhu, Y.; Wang, X.; Zhang, J.; Tian, C.; Liu, L.; Meng, Y.; Guo, Y. Phenolic composition of apple products and by-products based on cold pressing technology. J. Food Sci. Technol. 2019, 56, 1389–1397. [Google Scholar] [CrossRef]

- Hatab, S.; Athanasio, R.; Holley, R.; Rodas-Gonzalez, A.; Norvaez-Bravo, C. Survival and reduction of shiga toxin-producing Escherichia coli in a fresh cold-pressed juice treated with antimicrobial plant extract. J. Food Sci. 2016, 81, M1987–M1995. [Google Scholar] [CrossRef]

- Barba, F.J.; Mariutti, L.R.B.; Bragagnolo, N.; Mercadante, A.Z.; Barbosa-Cánovas, G.V.; Orlien, V. Bioaccessibility of bioactive compounds from fruits and vegetables after thermal and nonthermal processing. Trends Food Sci. Technol. 2017, 67, 195–206. [Google Scholar] [CrossRef]

- Usaga, J.; Worobo, R.W. Microbial safety and quality evaluation of UV-treated, cold-pressed colored and turbid juices and beverages. J. Food Prot. 2018, 81, 1549–1556. [Google Scholar] [CrossRef]

- Evrendilek, G.A. Effects of high pressure processing on bioavailability of food components. J. Nutr. Food Sci. 2018, 8, 676. [Google Scholar] [CrossRef]

- Czapski, J.; Radaś, A. Modern technologies of fruit and vegetable processing. In Vegetables and Fruit, Processing and Role in Human Nutrition; Gawęcki, J., Czapski, J., Eds.; WUPP: Poznań, Poland, 2017; pp. 137–150. (In Polish) [Google Scholar]

- Patras, A.; Brunton, N.P.; Pieve, S.D.; Butler, R. Impact of high pressure processing on total antioxidant activity, phenolic, ascorbic acid, anthocyanin content and colour of strawberry and blackberry purées. Innov. Food Sci. Emerg. Technol. 2009, 40, 308–313. [Google Scholar] [CrossRef]

- Chaikham, P. Comparison of high hydrostatic pressure and thermal processing on physicochemical and antioxidant properties of Maoberry (Antidesma thwaitesianum Müell. Arg.) juice. Int. Food Res. J. 2015, 22, 1993–2001. [Google Scholar]

- Kadam, P.S.; Jadhav, B.A.; Salve, R.V.; Machewad, G.M. Review on the high pressure technology (HPT) for food preservation. Food Process Technol. 2012, 3, 135. [Google Scholar]

- Tewari, S.; Sehrawat, R.; Nema, P.K.; Kaur, B.P. Preservation effect of high pressure processing on ascorbic acid of fruits and vegetables: A review. J. Food Biochem. 2017, 41, e12319. [Google Scholar] [CrossRef]

- Hsu, K.C.; Tan, F.J.; Chi, H.Y. Evaluation of microbial inactivation and physicochemical properties of pressurized tomato juice during refrigerated storage. LWT Food Sci. Technol. 2008, 41, 367–375. [Google Scholar] [CrossRef]

- Gong, Y.; Yu, J.Y.; Qian, P.; Meng, J.; Zhang, X.J.; Lu, R.R. Comparative study of the microbial stability and quality of carrot juice treated by high-pressure processing combined with mild temperature and conventional heat treatment. J. Food Process Eng. 2015, 38, 395–404. [Google Scholar] [CrossRef]

- Chaimoon, R.; Apichartsrangkoon, A.; Hiran, S. Processing longan in syrup by ultra-high pressure and pasteurization. J. Agric. 2009, 23, 313–320. [Google Scholar]

- Torres, B.; Tiwari, B.K.; Patras, A.; Cullen, P.J.; Brunton, N.; O’Donnell, C.P. Stability of anthocyanins and ascorbic acid of high pressure processed blood orange juice during storage. Innov. Food Sci. Emerg. Technol. 2011, 12, 93–97. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, Y.; Zhang, F.; Wang, Y.; Yi, J.; Liao, X. Effects of high hydrostatic pressure on enzymes, phenolic compounds, anthocyanins, polymeric color and color of strawberry pulps. J. Sci. Food Agric. 2011, 91, 877–885. [Google Scholar] [CrossRef]

- Keenan, D.F.; Rößle, C.; Gormley, R.; Butler, F.; Brunton, N.P. Effect of high hydrostatic pressure and thermal processing on the nutritional quality and enzyme activity of fruit smoothies. LWT Food Sci. Technol. 2012, 45, 50–57. [Google Scholar] [CrossRef]

- Yu, Y.; Lin, Y.; Zhan, Y.; He, J.; Zhu, S. Effect of high pressure processing on the stability of anthocyanin, ascorbic acid and color of Chinese bayberry juice during storage. J. Food Eng. 2013, 119, 701–706. [Google Scholar] [CrossRef]

- Kaushik, N.; Kaur, B.P.; Rao, P.S. Application of high pressure processing for shelf life extension of litchi fruits (Litchi chinensis cv. Bombai) during refrigerated storage. Innov. Food Sci. Emerg. Technol. 2013, 20, 527–541. [Google Scholar] [CrossRef] [PubMed]

- Marszałek, K.; Mitek, M.; Skąpska, S. The effect of thermal pasteurization and high pressure processing at cold and mild temperatures on the chemical composition, microbial and enzyme activity in strawberry purée. Innov. Food Sci. Emerg. Technol. 2015, 27, 48–56. [Google Scholar] [CrossRef]

- Pedro, A.E.D.; Albert, I.; Marcelo, C. Effect of high pressure homogenization (HPH) on the rheological properties of tomato juice: Time-dependent and steady-state shear. J. Food Eng. 2012, 111, 570–579. [Google Scholar]

- Thiago, S.L.; Pedro, E.D.A.; Marcelo, C. Using high pressure homogenization (HPH) to change the physical properties of cashew apple juice. Food Biophys. 2015, 10, 169–180. [Google Scholar]

- Liu, J.; Wang, R.; Wang, X.; Yang, L.; Shan, J.; Zhang, Q.; Ding, S. Effects of high-pressure homogenization on the structural, physical, and rheological properties of lily pulp. Foods 2019, 8, 472. [Google Scholar] [CrossRef]

- Mesa, J.; Hinestroza-Córdoba, L.I.; Barrera, C.; Seguí, L.; Betoret, E.; Betoret, N. High Homogenization Pressures to Improve Food Quality, Functionality and Sustainability. Review. Molecules 2020, 25, 3305. [Google Scholar] [CrossRef]

- Dumay, E.; Chevalier-Lucia, D.; Picart-Palmade, L.; Benzaria, A.; Grácia-Juliá, A.; Blayo, C. Technological aspects and potential applications of (ultra) high-pressure homogenization. Review. Trends Food Sci. Technol. 2013, 31, 13–26. [Google Scholar] [CrossRef]

- Donsì, F.; Annunziata, M.M.; Ferrari, G. Microbial inactivation by high pressure homogenization: Effect of the disruption valve geometry. J. Food Eng. 2013, 115, 362–370. [Google Scholar] [CrossRef]

- Duda, M.; Sokołowska, B. Application of high-pressure homogenization to preserve vegetable and fruit juices. Ferment. F&V Ind. 2017, 8, 44–48. (In Polish) [Google Scholar]

- Szczepańska, J.; Marszałek, K.; Skąpska, S. High-pressure homogenization in the food industry. Food Ind. 2018, 72, 28–30. [Google Scholar]

- Welti-Chanes, J.; Ochoa-Velasco, C.E.; Guerrero-Beltrán, J.Á. High-pressure homogenization of orange juice to inactivate pectinmethylesterase. Innov. Food Sci. Emerg. Technol. 2009, 10, 457–462. [Google Scholar] [CrossRef]

- Velázquez-Estrada, R.M.; Hernández-Herrero, M.M.; Rüfer, C.E.; Guamis-López, B.; Roig-Sagués, A.X. Influence of ultra-high pressure homogenization processing on bioactive compounds and antioxidant activity of orange juice. Innov. Food Sci. Emerg. Technol. 2013, 18, 89–94. [Google Scholar] [CrossRef]

- Karacam, C.G.; Sahin, S.; Oztop, M.H. Effect of high pressure homogenization (microfluidization) on the quality of Ottoman Strawberry (F. Ananassa) juice. LWT Food Sci. Technol. 2015, 62, 932–937. [Google Scholar] [CrossRef]

- Frank, K.; Köhler, K.; Schuchmann, H.P. Stability of anthocyanins in high pressure homogenisation. Food Chem. 2012, 130, 716–719. [Google Scholar] [CrossRef]

- Suárez-Jacobo, A.; Rüfer, C.E.; Gervilla, R.; Guamis, B.; Roig-Sagués, A.X.; Saldo, J. Influence of ultra-high pressure homogenisation on antioxidant capacity, polyphenol and vitamin content of clear apple juice. Food Chem. 2011, 127, 447–454. [Google Scholar] [CrossRef]

- Svelander, C.A.; Lopez-Sanchez, P.; Pudney, P.D.A.; Schumm, S.; Alminger, M.A.G. High pressure homogenization increases the in vitro bioaccessibility of α- and β-carotene in carrot emulsions but not of lycopene in tomato emulsions. J. Food Sci. 2011, 76, H215–H225. [Google Scholar] [CrossRef]

- Benjamin, O.; Gamrasni, D. Microbial, nutritional, and organoleptic quality of pomegranate juice following high-pressure homogenization and low-temperature pasteurization. J. Food Sci. 2020, 85, 592–599. [Google Scholar] [CrossRef]

- Saricaoglu, F.T.; Atalar, I.; Yilmaz, V.A.; Odabas, H.I.; Gul, O. Application of multi pass high pressure homogenization to improve stability, physical and bioactive properties of rosehip (Rosa canina L.) nectar. Food Chem. 2019, 282, 67–75. [Google Scholar] [CrossRef]

- Jayasooriya, S.D.; Bhandari, B.R.; Torley, P.; D’Arcy, B.R. Effect of high power ultrasound waves on properties of meat: A review. Int. J. Food Prop. 2004, 7, 301–319. [Google Scholar] [CrossRef]

- Kentish, S.; Ashokkumar, M. The physical and chemical effects of ultrasound. In Ultrasound Technologies for Food and Bioprocessing; Feng, H., Barbosa-Canovas, G.V., Weiss, J., Eds.; Springer: New York, NY, USA; Dordrecht, The Netherlands; Heidelberg, Germany; London, UK, 2012; pp. 1–12. [Google Scholar]

- Mothibe, K.J.; Zhang, M.; Nsor-atindana, J.; Wang, Y.C. Use of ultrasound pretreatment in drying of fruits: Drying rate, quality attributes, and shelf life extension. Dry. Technol. 2011, 29, 1611–1621. [Google Scholar] [CrossRef]

- Nowacka, M.; Wiktor, A.; Śledź, M.; Jurek, N.; Witrowa-Rajchert, D. Drying of ultrasound pretreated apple and its selected physical properties. J. Food Eng. 2012, 113, 427–433. [Google Scholar] [CrossRef]

- Knorr, D.; Zenker, M.; Heinz, V.; Lee, D.U. Applications and potential of ultrasonics in food processing. Trends Food Sci. Technol. 2004, 15, 261–266. [Google Scholar] [CrossRef]

- Zafra-Rojas, Q.Y.; Cruz-Cansino, N.; Ramírez-Moreno, E.; Delgado-Olivares, L.; Villanueva- Sánchez, J.; Alanís-García, E. Effects of ultrasound treatment in purple cactus pear (Opuntia ficus-indica) juice. Ultrason. Sonochem. 2013, 20, 1283–1288. [Google Scholar] [CrossRef] [PubMed]

- Ferrario, M.; Alzamora, S.M.; Guerrero, S. Study of the inactivation of spoilage microorganisms in apple juice by pulsed light and ultrasound. Food Microbiol. 2015, 46, 635–642. [Google Scholar] [CrossRef]

- Khandpur, P.; Gogate, P.R. Evaluation of ultrasound based sterilization approaches in terms of shelf life and quality parameters of fruit and vegetable juices. Ultrason. Sonochem. 2016, 29, 337–353. [Google Scholar] [CrossRef]

- Tiwari, B.K.; O’Donnell, C.P.; Patras, A.; Brunton, N.; Cullen, P.J. Stability of anthocyanins and ascorbic acid in sonicated strawberry juice during storage. Eur. Food Res. Technol. 2009, 228, 717–724. [Google Scholar] [CrossRef]

- Dolatowski, Z.J.; Stadnik, J.; Stasiak, D. Applications of ultrasound in food technology. Acta Sci. Pol. Technol. Aliment. 2007, 6, 89–99. [Google Scholar]

- Rastogi, N.K. Opportunities and challenges in application of ultrasound in food processing. Crit. Rev. Food Sci. Nutr. 2011, 51, 705–722. [Google Scholar] [CrossRef]

- Aadil, R.M.; Zeng, X.A.; Han, A.; Sun, D.W. Effects of ultrasound treatments on quality of grapefruit juice. Food Chem. 2013, 14, 3201–3206. [Google Scholar] [CrossRef]

- Santhirasegaram, V.; Razali, Z.; Samasundram, C. Effects of thermal treatment and sonication on quality attributes of Chokanan mango (Mangifera indica L.) juice. Ultrason. Sonochem. 2013, 20, 1276–1282. [Google Scholar] [CrossRef] [PubMed]

- Galvan d’Alessandro, L.; Kriaa, K.; Nikov, I.; Dimitrov, K. Ultrasound assisted extraction of polyphenols from black chokeberry. Sep. Purif. Technol. 2012, 93, 42–47. [Google Scholar] [CrossRef]

- Galmohamadi, A.; Moller, G.; Powers, J.; Nindo, C. Effect of ultrasound frequency on antioxidant activity, total phenolic and anthocyanin content of red raspberry puree. Ultrason. Sonochem. 2013, 20, 1316–1323. [Google Scholar] [CrossRef] [PubMed]

- Aadil, R.M.; Zeng, X.A.; Sun, D.W.; Wang, M.S.; Liu, Z.W.; Zhang, A.H. Combined effects of sonication and pulsed electric field on selected quality parameters of grapefruit juice. LWT Food Sci. Technol. 2015, 62, 890–893. [Google Scholar] [CrossRef]

- Rojas, M.L.; Leite, T.S.; Cristianini, M.; Alvim, I.D.; Augusto, P.E.D. Peach juice processed by the ultrasound technology: Changes in its microstructure improve its physical properties and stability. Food Res. Int. 2016, 82, 22–33. [Google Scholar] [CrossRef]

- Cervantes-Elizarrarás, A.; Piloni-Martini, J.; Ramírez-Moreno, E.; Alanís-García, E.; Güemes-Vera, N.; Gómez-Aldapa, C.A.; Zafra-Rojas, Q.Y.; Cruz-Cansino, N.S. Enzymatic inactivation and antioxidant properties of blackberry juice after thermoultrasound: Ptimization using response surface methodology. Ultrason. Sonochem. 2017, 34, 371–379. [Google Scholar] [CrossRef]

- Cebulak, T.; Oszmiański, J.; Kapusta, I.; Lachowicz, S. Effect of UV-C radiation, ultra-sonication, electromagnetic field and microwaves on changes in polyphenolic compounds in chokeberry (Aronia melanocarpa). Molecules 2017, 22, 1161. [Google Scholar] [CrossRef]

- Chandrapala, J.; Oliver, C.; Kentish, S.; Ashokkumar, M. Ultrasonics in food processing. Ultrason. Sonochem. 2012, 19, 975–983. [Google Scholar] [CrossRef]

- Siucińska, K.; Mieszczakowska-Frąc, M.; Połubok, A.; Konopacka, D. Effects of ultrasound assistance on dehydration processes and bioactive component retention of osmo-dried sour cherries. J. Food Sci. 2016, 81, C1654–C1661. [Google Scholar] [CrossRef]

- Celejewska, K.; Mieszczakowska-Frąc, M.; Konopacka, D.; Krupa, T. The Influence of Ultrasound and Cultivar Selection on the Biocompounds and Physicochemical Characteristics of Dried Blueberry (Vaccinium corymbosum L.) Snacks. J. Food Sci. 2018, 83, 2305–2316. [Google Scholar] [CrossRef]

- Simal, S.; Benedito, J.; Sánchez, E.S.; Roselló, C. Use of ultrasound to increase mass transport rates during osmotic dehydration. J. Food Eng. 1998, 36, 323–336. [Google Scholar] [CrossRef]

- Cárcel, J.A.; García-Pérez, J.V.; Riera, E.; Mulet, A. Influence of high intensity ultrasound on drying kinetics of persimmon. Dry. Technol. 2007, 25, 185–193. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Linhares, F.R., Jr.; Rodrigues, S. Ultrasound as pretreatment for drying of pineapple. Ultrason. Sonochem. 2008, 15, 1049–1054. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, F.A.N.; Rodrigues, S. Application of ultrasound and ultrasound-assisted osmotic dehydration in drying of fruits. Dry. Technol. 2008, 26, 1509–1516. [Google Scholar] [CrossRef]

- Garcia-Noguera, J.; Weller, C.L.; Oliveira, F.I.P.; Fernandes, F.A.N.; Rodrigues, S. Ultrasound assisted osmotic dehydration as a pre-treatment for freeze dried strawberries. In Proceedings of the 17th International Drying Symposium (IDS 2010), Magdeburg, Germany, 3–6 October 2010; pp. 1285–1290. [Google Scholar]

- Schössler, K.; Jäger, H.; Knorr, D. Effect of continuous and intermittent ultrasound on drying time and effective diffusivity during convective drying of apple and red pepper. J. Food Eng. 2012, 108, 103–110. [Google Scholar] [CrossRef]

- Mieszczakowska-Frąc, M.; Dyki, B.; Konopacka, D. Effects of ultrasound on polyphenol retention in apples after the application of predrying treatments in liquid medium. Food Bioprocess. Technol. 2016, 9, 543–552. [Google Scholar] [CrossRef]

- Celejewska, K.; Mieszczakowska-Frąc, M.; Konopacka, D. The effect of hybrid drying (convective-microwave-ultrasound) on the bioactive properties of osmo-treated sour cherries. J. Hort. Res. 2018, 26, 23–26. [Google Scholar] [CrossRef]

- Da Silva Junior, E.V.; De Melo, L.L.; De Medeiros, R.A.B.; Barros, Z.M.P.; Azoubel, P.M. Influence of ultrasound and vacuum assisted drying on papaya quality parameters. LWT Food Sci. Technol. 2018, 97, 317–322. [Google Scholar] [CrossRef]

- Skowron, M.; Wantuch, A. New technologies of food preservation—Model studies. Electrotech. Rev. 2020, 96, 125–128. (In Polish) [Google Scholar]

- Toepfl, S. Pulsed electric field food treatment—Scale up from lab to industrial scale. Procedia Food Sci. 2011, 1, 776–779. [Google Scholar] [CrossRef]

- Wiktor, A.; Witrowa-Rajchert, D. The use of a pulsed electric field to support the processes of removing water from plant tissues. Food. Sci. Technol. Qual. 2012, 81, 22–23. (In Polish) [Google Scholar]

- Oms-Oliu, G.; Odriozola-Serrano, I.; Solvia-Fortuny, R.; Martin-Belloso, O. Effects of high-intensity pulsed electric field processing conditions on lycopene, vitamin C and antioxidant capacity of watermelon juice. Food Chem. 2009, 115, 1312–1319. [Google Scholar] [CrossRef]

- Elez-Martínez, P.; Martín-Belloso, O. Effects of high intensity pulsed electric field processing conditions on vitamin C and antioxidant capacity of orange juice and gazpacho, a cold vegetable soup. Food Chem. 2007, 102, 201–209. [Google Scholar] [CrossRef]

- Quitão-Teixeria, L.J.; Odriozolo-Serrano, I.; Soliva-Fortuny, R.; Mota-Ramos, A.; Martín-Belloso, O. Comparative study on antioxidant properties of carrot juice stabilized by high-intensity pulsed electric fields or heat treatments. J. Sci. Food Agric. 2009, 89, 2363–2642. [Google Scholar]

- Yeom, H.W.; Streaker, C.B.; Zhang, Q.H.; Min, D.B. Effects of pulsed electric fields on the quality of orange juice and comparison with heat pasteurization. J. Agric. Food Chem. 2000, 48, 4597–4605. [Google Scholar] [CrossRef]

- Sánchez-Moreno, C.; Plaza, L.; Elez-Martínez, P.; De Ancos, B.; Martín-Belloso, O.; Cano, M.P. Impact of high-pressure and pulsed electric fields on bioactive compounds and antioxidant activity of orange juice in comparison with traditional thermal processing. J. Agric. Food Chem. 2005, 53, 4403–4409. [Google Scholar] [CrossRef]

- Elez-Martínez, P.; Soliva-Fortuny, R.; Martín-Belloso, O. Impact of High-Intensity Pulsed Electric Fields on Bioactive Compounds in Mediterranean Plant-based Foods. Nat. Prod. Commun. 2009, 4, 741–746. [Google Scholar] [CrossRef]

- Odriozola-Serrano, I.; Aguiló-Aguayo, I.; Solivia-Fortuny, R.; Martín-Belloso, O. Pulsed electric fields processing effects on quality and health-related constituents of plant-based foods. Trends Food Sci. Technol. 2013, 29, 98–107. [Google Scholar] [CrossRef]

- Torregrosa, F.; Esteve, M.J.; Fígola, A.; Cortés, C. Ascorbic acid stability during refrigerated storage of orange–carrot juice treated by high pulsed electric field and comparison with pasteurized juice. J. Food Eng. 2006, 73, 339–345. [Google Scholar] [CrossRef]

- Cantwell, M. Fresh-Cut Fruit and Vegetables. Postharvest Short Course. UC Davis 2013 (Computer Presentation). Available online: http://ucce.ucdavis.edu/files/datastore/234-2580.pdf (accessed on 15 October 2020).

- Cantwell, M.; Suslow, T. Fresh-Cut Fruits and Vegetables: Aspects of Physiology, Preparation and Handling That Affect Quality. 2002. Available online: https://ucanr.edu/datastoreFiles/608-357.pdf (accessed on 30 December 2020).

- Opara, U.L.; Al-Ani, M.R. Antioxidant contents of pre-packed fresh-cut versus whole fruit and vegetables. Br. Food J. 2010, 112, 797–810. [Google Scholar] [CrossRef]

- Gil, M.I.; Gómez-López, V.M.; Hung, Y.C.; Allende, A. Potential of electrolyzed water as an alternative disinfectant agent in the fresh-cut industry. Food Bioprocess. Technol. 2015, 8, 1336–1348. [Google Scholar] [CrossRef]

- Vandekinderen, I.; Camp, J.; Meulenaer, B.; Veramme, K.; Bernaert, N.; Denon, Q.; Ragaert, P.; Devlieghere, F. Moderate and high doses of sodium hypochlorite, neutral electrolyzed oxidizing water, peroxyacetic acid, and gaseous chlorine dioxide did not affect the nutritional and sensory qualities of fresh-cut iceberg lettuce (Lactuca sativa var. capitata L.) after washing. J. Agric. Food Chem. 2009, 57, 4195–4203. [Google Scholar] [PubMed]

- Vandekinderen, I.; Camp, J.; van Devlieghere, F.; Veramme, K.; Bernaert, N.; Denon, Q.; Ragaert, P.; Meulenaer, B. Effect of decontamination on the microbial load, the sensory quality and the nutrient retention of ready-to-eat white cabbage. Eur. Food Res. Technol. 2009, 229, 443–455. [Google Scholar] [CrossRef]

- Ogawa, Y.; Hashimoto, M.; Takiguchi, Y.; Usami, Y.; Suthiluk, P.; Yoshida, K.; Yamamoto, N.; Hung, Y. Effect of decontamination treatment on vitamin C and potassium attributes of fresh-cut bell pepper at post-washing stage. Food Bioprocess. Technol. 2018, 11, 1230–1235. [Google Scholar] [CrossRef]

- Cocetta, G.; Baldassarre, V.; Spinardi, A.; Ferrante, A. Effect of cutting on ascorbic acid oxidation and recycling in fresh-cut baby spinach (Spinacia oleracea L.) leaves. Postharvest Biol. Technol. 2014, 88, 8–16. [Google Scholar] [CrossRef]

- Radziejewska-Kubzdela, E. The effect of pretreatment and modified atmosphere packaging on bioactive compound content in coleslaw mix. LWT Food Sci. Technol. 2017, 75, 505–511. [Google Scholar] [CrossRef]

- Soares, C.D.F.; Martin, J.G.P.; Berno, N.D.; Kluge, R.A. Antioxidant chemical treatment affects physiology and quality of minimally-processed escarole. Horticulturae 2019, 5, 75. [Google Scholar] [CrossRef]

- Gutiérrez, D.R.; Lemos, L.; Rodríguez, S.D.C. Effect of UV-C and ozone on the bioactive compounds and antioxidant capacity of minimally processed rocket (Eruca sativa Mill.). Int. J. New Technol. Res. 2018, 4, 23–29. [Google Scholar] [CrossRef]

- Parada, J.; Aguilera, J.M. Food Microstructure affects the bioavailability of several nutrients. J. Food Sci. 2007, 72, R21–R32. [Google Scholar] [CrossRef]

- Carbonell-Capella, J.M.; Buniowska, M.; Barba, F.J.; Esteve, M.J.; Frígola, A. Analytical methods for determining bioavailability and bioaccessibility of bioactive compounds from fruits and vegetables: A Review. Compr. Rev. Food Sci. Food Saf. 2014, 13, 155–171. [Google Scholar] [CrossRef]

- Yuanqing, H.; Min, C.; Lingling, S.; Quancai, S.; Pengyao, Y.; Rui, G.; Sijia, W.; Yuqing, D.; Haihui, Z.; Haile, M. Ultrasound Pretreatment Increases the Bioavailability of Dietary Proteins by Dissociating Protein Structure and Composition. Food Biophys. 2020, 15, 409–415. [Google Scholar] [CrossRef]

- Dima, C.; Assadpour, E.; Dima, S.; Jafari, S.M. Bioavailability of nutraceuticals: Role of the food matrix, processing conditions, the gastrointestinal tract, and nanodelivery systems. Compr. Rev. Food Sci. Food Saf. 2020, 19, 954–994. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Moreno, C.; Cano, M.P.; de Ancos, B.; Plaza, L.; Olmedilla, B.; Granado, F.; Elez-Martínez, P.; Martín-Belloso, O.; Martín, A. Pulsed electric fields–processed orange juice consumption increases plasma vitamin C and decreases F2-isoprostanes in healthy humans. J. Nutr. Biochem. 2004, 15, 601–607. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Moreno, C.; Cano, M.P.; De Ancos, B.; Plaza, L.; Olmedilla, B.; Granada, F.; Elez-Martínez, P.; Martín-Belloso, O.; Martín, A. Intake of Mediterranean vegetable soup treated by pulsed electric fields affects plasma vitamin C and antioxidant biomarkers in humans. Int. J. Food Sci. Nutr. 2005, 56, 115–124. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Moreno, C.; Cano, M.P.; de Ancos, B.; Plaza, L.; Olmedilla, B.; Granado, F.; Martí, A. High-Pressurized orange juice consumption affects plasma vitamin C, antioxidative status and inflammatory markers in healthy humans. J. Nutr. 2003, 133, 2204–2209. [Google Scholar] [CrossRef]

- Sánchez-Moreno, C.; de Ancos, B.; Plaza, L.; Elez-Martínez, P.; Cano, M.P. Nutritional approaches and health-related properties of plant foods processed by high pressure and pulsed electric fields. Crit. Rev. Food Sci. Nutr. 2009, 49, 552–576. [Google Scholar] [CrossRef]

- Rodríguez-Roque, M.J.; de Ancos, B.; Sánchez-Moreno, C.; Cano, M.P.; Elez-Martínez, P.; Martín-Belloso, O. Impact of food matrix and processing on the in vitro bioaccessibility of vitamin C, phenolic compounds, and hydrophilic antioxidant activity from fruit juice-based beverages. J. Funct. Foods 2015, 14, 33–34. [Google Scholar] [CrossRef]

- Yilmaz, M.; Evrendilek, G.A. Impact of the pulsed electric field treatment on bioactive food compounds: Bioaccessibility and bioavailability. J. Nutr. Food Sci. 2017, 7, 2490–2500. [Google Scholar] [CrossRef]

| Fruit Species | Content mg/100 g | Fruit Species | Content mg/100 g |

|---|---|---|---|

| Blackurrants | 181.0 | Blackberries | 21.0 |

| Green kiwi fruits | 92.7 | Quinces | 15.0 |

| Pummelo | 61.0 | Cranberries | 14.0 |

| Papayas | 60.9 | Pomegranates | 10.2 |

| Oranges, navels | 59.1 | Apricots | 10.0 |

| Strawberries | 58.8 | Red sour cherries | 10.0 |

| Oranges, common variety | 53.2 | Avocados | 10.0 |

| Lemons, without peel | 53.0 | Blueberries | 9.7 |

| Pineapple | 47.8 | Plums | 9.5 |

| Oranges, Florida | 45.0 | Bananas | 8.7 |

| Red and white currants | 41.0 | Persimmons, Japanse | 7.5 |

| Mangos | 36.4 | Sweet cherries, | 7.0 |

| Elderberries | 36.0 | Yellow peaches, | 6.6 |

| White grapefruit, | 33.3 | Grapes, Muscadine | 6.5 |

| Pink and red grapefruit | 31.2 | Nectarines | 5.4 |

| Limes | 29.1 | Apples, with skin | 4.6 |

| Gooseberries | 27.7 | Pears | 4.3 |

| Tangerines, (mandarin) | 26.7 | Apples, without skin | 4.0 |

| Raspberries | 26.2 | Red or green Grapes | 3.2 |

| Vegetable Species | Content mg/100 g | Vegetable Species | Content mg/100 g |

|---|---|---|---|

| Green peppers, hot chili | 242.5 | Beet greens | 30.0 |

| Red peppers, hot chili | 143.7 | New Zealand spinach | 30.0 |

| Parsley | 133.0 | Green soybeans | 29.0 |

| Red peppers, sweet | 127.7 | Spinach | 28.1 |

| Kale | 120.0 | Cabbage, Chinese (Pe-Tsai), | 27.0 |

| Broccoli | 89.2 | Rutabagas raw | 25.0 |

| Green cauliflower | 88.1 | Green chicory | 24.0 |

| Brussels sprouts | 85.0 | Green tomatoes | 23.4 |

| Green peppers, sweet | 80.4 | Turnips | 21.0 |

| Kohlrabi | 62.0 | Potatoes, flesh, and skin | 19.7 |

| Turnip greens | 60.0 | Melons, honeydew | 18.0 |

| Peas, edible-podded | 60.0 | Squash, summer, zucchini | 17.9 |

| Chives | 58.1 | Parsnips | 17.0 |

| Red cabbage | 57.0 | Squash, summer | 17.0 |

| Cabbage, common, freshly harvested | 51.0 | Yellow beans, snap | 16.3 |

| Cauliflower | 48.2 | Orange tomatoes | 16.0 |

| Cabbage, chinese (Pak-Choi) | 45.0 | Arugula | 15.0 |

| Green peas | 40.0 | Radishes | 14.8 |

| Melons, cantaloupe | 36.7 | Red Tomatoes, ripe | 13.7 |

| Cabbage | 36.6 | Squash, winter, all varieties, | 12.3 |

| Squash, zucchini, baby | 34.1 | Green beans, snap | 12.2 |

| Broadbeans, immature seeds | 33.0 | Leeks (bulb and lower leaf-portion) | 12.0 |

| Cabbage, Savoy | 31.0 | Lettuce, green leaf | 9.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mieszczakowska-Frąc, M.; Celejewska, K.; Płocharski, W. Impact of Innovative Technologies on the Content of Vitamin C and Its Bioavailability from Processed Fruit and Vegetable Products. Antioxidants 2021, 10, 54. https://doi.org/10.3390/antiox10010054

Mieszczakowska-Frąc M, Celejewska K, Płocharski W. Impact of Innovative Technologies on the Content of Vitamin C and Its Bioavailability from Processed Fruit and Vegetable Products. Antioxidants. 2021; 10(1):54. https://doi.org/10.3390/antiox10010054

Chicago/Turabian StyleMieszczakowska-Frąc, Monika, Karolina Celejewska, and Witold Płocharski. 2021. "Impact of Innovative Technologies on the Content of Vitamin C and Its Bioavailability from Processed Fruit and Vegetable Products" Antioxidants 10, no. 1: 54. https://doi.org/10.3390/antiox10010054

APA StyleMieszczakowska-Frąc, M., Celejewska, K., & Płocharski, W. (2021). Impact of Innovative Technologies on the Content of Vitamin C and Its Bioavailability from Processed Fruit and Vegetable Products. Antioxidants, 10(1), 54. https://doi.org/10.3390/antiox10010054