1. Introduction

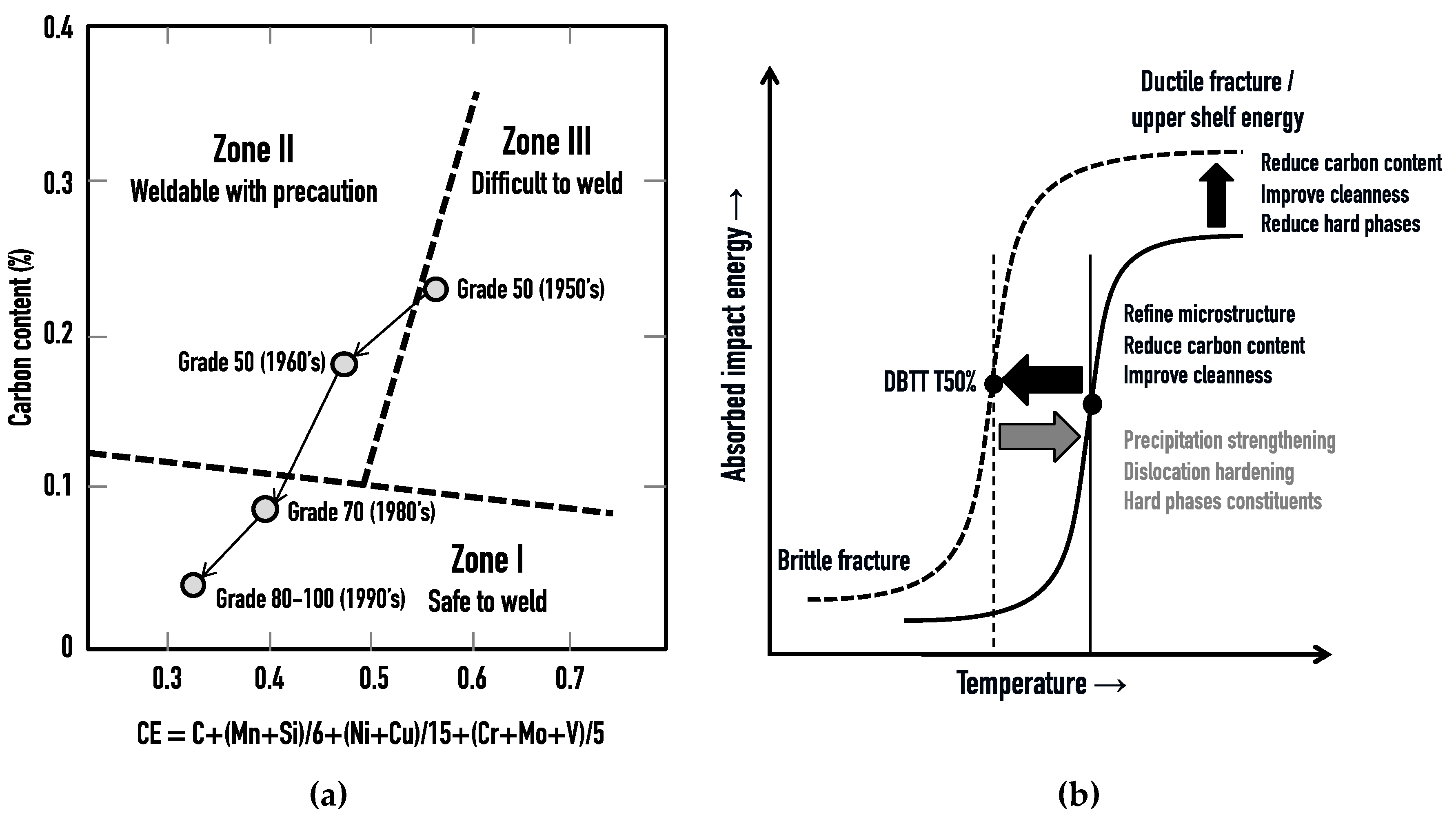

The development of steel for use in pipeline, structural and automotive applications has seen a remarkable evolution since the late 1960s [

1]. The increasing demands in terms of strength and toughness in general and weldability, in particular, have led to the design of alloys with reduced carbon content (

Figure 1a). Nowadays, steel of 700 MPa yield strength (grade 100) is achievable with a maximum carbon content of 0.05 percent [

2]. Reducing carbon increases upper shelf energy and lowers the ductile-to-brittle transition temperature (

Figure 1b). The required strength is provided by either microstructural refinement, precipitation hardening or dislocation hardening. Typically a combination of these mechanisms is used. Since grain refinement is the only mechanism simultaneously improving strength and toughness (

Figure 1b), it should be always applied in the first place before employing other strengthening mechanisms. Microstructural refinement is efficiently achieved by niobium micro-alloying in combination with thermo-mechanical controlled processing (TMCP). This approach of producing high strength low alloy (HSLA) steel containing below 0.1 percent carbon and niobium micro-alloying between 0.02 and 0.04 percent is covering a wide portfolio of applications in the yield strength range of 300 to 500 MPa. Typically, the carbon content is between 0.06 and 0.09 percent for many of these steel grades resulting in a ferritic-pearlitic or pearlite-reduced ferritic microstructure. The trend of further reducing the carbon content is reasoned by improving upper shelf toughness and reducing ductile-to-brittle-transition temperature (DBTT). Besides, avoiding the peritectic range has clear benefits with regards to slab surface quality. In the 1980s, Hulka and Gray [

3] proposed an extraordinary alloy concept using particularly low carbon content in combination with a high niobium micro-alloy addition of 0.1 percent.

The intrinsic benefits of modern low-carbon alloy concepts are a particularly high upper shelf toughness and very low DBTT. The microstructure of such alloys is nearly pearlite-free ferrite or by using increased cooling rate, acicular ferritic. The high recrystallization stop temperature of such high-niobium alloyed steel principally widens the processing window for TMCP rolling and enables higher production throughput, especially on hot strip mills. On the other hand, it allows producing ferritic-bainitic microstructure even by air-cooling after finish rolling. Fine-tuning of the original low-carbon high-niobium alloyed steel concept using chromium and molybdenum as co-alloying elements has opened a wide range of interesting applications for producing steel in the range of 460 to 700 MPa yield strength. These can be found in pipe as well as automotive applications. Considering structural applications, some traditional specifications do not allow the use of such innovative alloy concepts since the niobium content is often restricted although several studies indicated that concerns may not be justified [

4,

5,

6]. Historically, the limitation of niobium addition relates to concerns about weldability and low heat affected zone (HAZ) toughness. Thereby, it is not accounted for that higher niobium additions are typically used in extra-low-carbon steels. Previous investigations applying industrial welding processes to such steels revealed that heat-affected zone toughness is not negatively affected by niobium additions in the range from 0.02 to 0.11% [

7,

8]. The present study will focus on the metallurgical effects and microstructural changes occurring in the individual sub-zones of the heat-affected zone in extra-low-carbon steel (0.035% C) primarily considering the effects of niobium and molybdenum alloying. The effects of titanium and silicon alloying are additionally addressed. Post-weld heat treatment (PWHT) is used in selected applications for weld stress relaxation in thicker gaged components fabricated from high strength steel [

9]. Micro-alloyed steels can show embrittlement by such treatment. Thus, simulations of PWHT are performed in this study to investigate the embrittlement sensitivity of these steels in the coarse-grained heat affected zone.

3. Results

The experimental program as described in paragraph 2 delivered a large amount of data of which only part is reported here allowing to draw relevant conclusions on the effect of alloying elements such as niobium, molybdenum, manganese and silicon. Regarding toughness, the upper-shelf energy values measured in the ICZ and CGZ are similar to those found in the base material. Again, the industrial reference steel X65 shows in comparison to laboratory material V2-c much higher upper-shelf energies and lower DBTT values in the ICZ and CGZ. A thorough analysis of all toughness data revealed that the DBTT T50% data exhibit the strongest correlation with the alloy variations. Therefore, only DBTT T50% data are considered in the following analysis.

3.1. Mechanical Characteristics of HAZ Sub-Zones

Figure 5 indicates the change in mechanical characteristics for alloy V3 after exposure to peak temperatures in the range of 300 to 1300 °C. The hardness measurements indicate significant softening in the ICZ, i.e., after heating to 900 °C peak temperature. The softening is most pronounced for the Nb-free steel losing 72 HV10 compared to the base material. For the alloy with the highest Nb addition, the hardness drop is only 36 HV10. In the CGZ, the behavior is similar yet less strong. Here the Nb-free alloy is softening by 52 HV10 while the highest Nb-alloyed variant shows no hardness loss. Already the smallest Nb addition of 0.02% reveals a significant softening resistance in both, ICZ and CGZ. The measured HV10 hardness relates quite well to the measured tensile strength by a factor of 3.2.

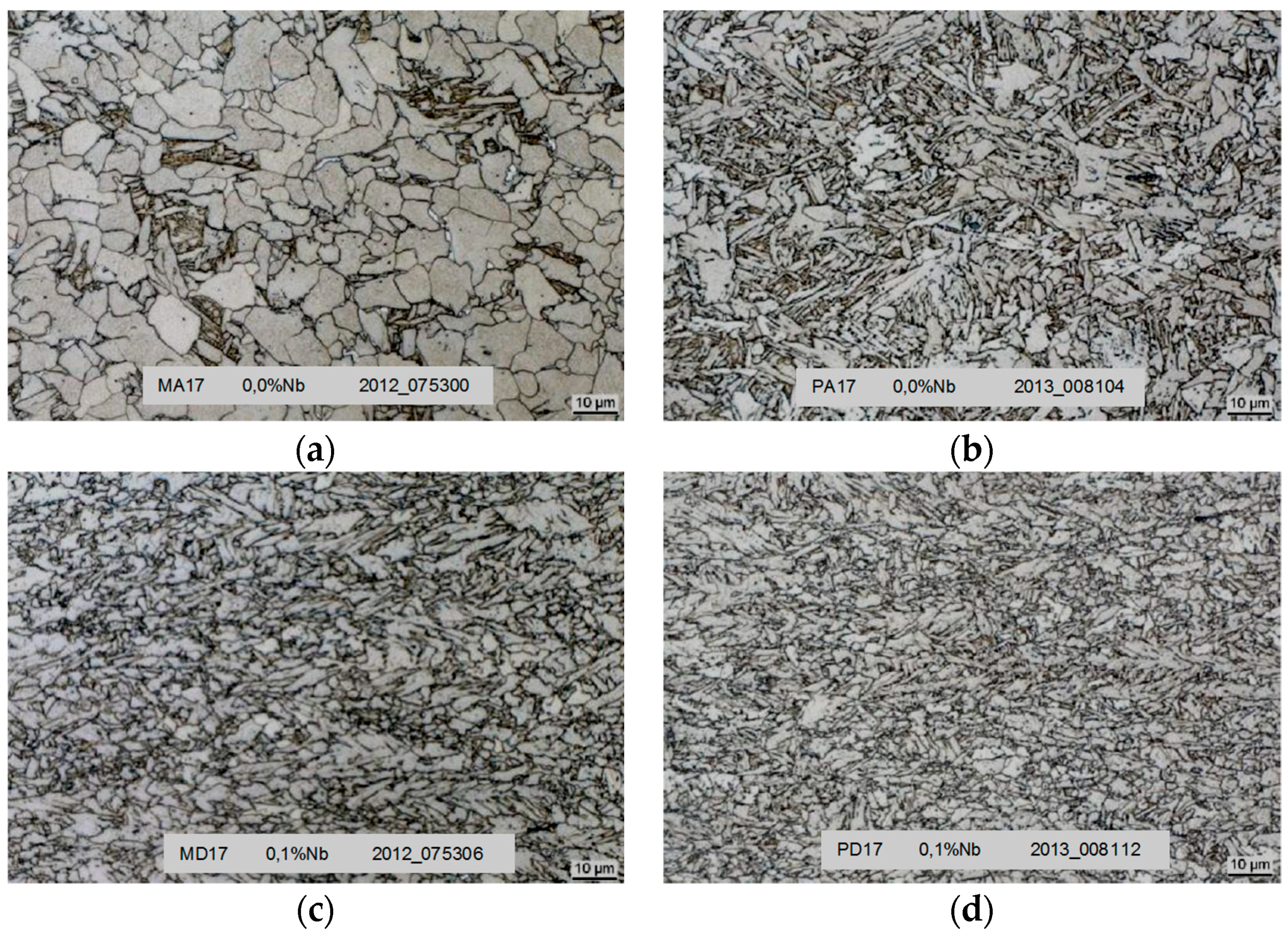

Instead of reporting yield and tensile strength data as a function of the peak temperature, it is more interesting looking at the evolution of the yield-to-tensile ratio (YTR). The latter is more conclusive with regard to microstructural changes. In

Figure 5 the YTR evolution is plotted as an interpolation of the data obtained at 300, 600, 800, 900, 1100 and 1300 °C for the Nb-free and 0.1%Nb containing alloy V3. Generally, the YTR of the 0.1%Nb steel is consistently higher than that of the Nb-free steel. The YTR increases form its base material when the peak temperature is raised to sub-critical values (<A

c1p). A maximum of the YTR appears between 600 and 800 °C, which is more pronounced and appears at a somewhat higher temperature in the 0.1%Nb alloy as compared to the Nb-free alloy. In the latter, the YTR shows a sharp drop to a pronounced minimum value of 0.54 in the ICZ. The YTR of the 0.1%Nb alloy, on the contrary, drops only to 0.75 in the ICZ. In the CGZ, the YTR increases from its minimum value in the ICZ to a level between 0.7 and 0.8.

The increase of the YTR in the sub-critical temperature range of 600–800 °C is typically related to tempering and precipitation phenomena. Tempering of hard carbon-enriched phases in the original material reduces primarily the tensile strength while precipitation of solute micro-alloys primarily increases the yield strength. Particularly the precipitation behavior of Nb will be discussed in paragraph 4 in more detail. The very low YTR of the Nb-free steel in the ICZ is a clear indicator for a microstructure with dual-phase character. The dispersion of the martensitic phase in a soft matrix provides a low yield and high tensile strength. Such dual-phase steels are deliberately produced by annealing in the inter-critical temperature range followed by fast cooling. Metallographic analysis using Le Pera etchant reveals the presence of martensite in the ICZ material. In the optical microscope, these phases appear with a white or brownish color.

Figure 5b shows the presence of a small fraction of martensite islands dispersed in a fully recrystallized polygonal ferrite matrix of the Nb-free steel. The original acicular ferritic microstructure of the base material has completely disappeared. In the 0.1%Nb-alloyed steel (

Figure 5c) the ICZ microstructure also appears fully recrystallized. However, the polygonal ferrite grains are much finer than those in the Nb-free alloy. The amount of martensite islands in the microstructure is almost negligible. Grain refinement has a stronger effect (Hall-Petch relationship) on the yield strength than on the tensile strength. Thus, with decreasing grain size the YTR increases. The strength of the refined polygonal ferrite is however still lower compared to the acicular ferritic base material as the sub-structure within the grain is lost due to recrystallization.

Adding molybdenum in alloy V4 shows qualitatively the same mechanical behavior as in alloy V3 (

Figure 6a) and similar effects of niobium. However, the hardness scattering range between Nb-free and 0.1%Nb containing alloys in the ICZ and CGZ is less wide. Particularly the Nb-free alloy softens less, which is a known effect caused by Mo. The 0.1%Nb steel, on the contrary, shows a greater hardness loss in the CGZ compared to the base material. This can indicate less precipitation hardening by niobium in the CGZ. The YTR indicates less softening in the sub-critical zone of the Nb-free alloy while the dual phase character in the ICZ (YTR = 0.54) is identical to alloy V3. The YTR in the CGZ is somewhat lower as in alloy V3, regardless of the Nb content.

Reducing the silicon content in alloy V6 leads to somewhat more softening of the Nb-free alloy in the ICZ as compared to alloy V4. The hardness is however still higher than in alloy V3 for the same condition. The 0.1%Nb containing steel V6 shows no softening in the CGZ. Regarding the YTR, a comparably higher minimum value of 0.57 is observed for the Nb-free alloy in the ICZ indicating a less pronounced dual phase character. For the 0.1%Nb containing steel, the YTR in the ICZ is also higher than in the previous alloys. Although these differences appear to be relatively modest, the observed effects can be attributed to the silicon alloy variation. In dual phase steel production silicon is standardly used to promote the partitioning of carbon to inter-critical austenite and, thus, to stabilize it for transformation into martensite upon quenching. This effect is based on silicon increasing the activity of carbon and also preventing the precipitation of cementite. The low-Si alloys exhibit the highest YTR values in the CGZ.

The transformation temperature A

c1P is very similar for the three Nb-free variants of V3, V4 and V6 ranging between 804 and 810 °C whereas the A

3cp temperature is lower for the Mo-alloyed variants. The addition of 0.1%Nb clearly shifts the A

c1p temperature upwards, particularly in combination with Mo-alloying. This is also the case for the A

c3p temperature in alloys V3-d and V4-d. Remarkably, the combined alloying of Mo and 0.1%Nb at reduced Si content leads to a much lower A

c3p temperature, diminishing the transition range to only 37 K while it is between 110 and 130 K for the other alloys (

Figure 5 and

Figure 6).

3.2. Toughness Characteristics of HAZ Sub-Zones

Principally, the transition from ductile to brittle fracture mode occurs in bcc-type steel when the yield strength approaches the cleavage stress level [

10]. Lower temperature and higher strain rate increase the yield strength so that under impact loading conditions at a certain low temperature the yield strength exceeds the cleavage stress causing brittle failure as a consequence. Refining the microstructure also increases the yield strength (Hall-Petch relationship), yet the refinement has an even larger effect in terms of increasing the cleavage stress. Hence, microstructural refinement effectively lowers the DBTT. The yield strength is also increased by solid solution, precipitation and dislocation strengthening. These mechanisms have an adverse effect on the DBTT. Accordingly, for evaluating the alloy influence on the heat affected zone toughness it is most interesting to analyze the transition temperature (DBTT T50%) as a function of the actual yield strength in the inter-critical and coarse-grained sub-zones.

Figure 7a displays the measured DBTT values as a function of the yield strength for the ICZ. The most obvious observation is that the DBTT decreases with increasing Nb content, despite strongly increasing yield strength. This can be due to pronounced grain refinement by Nb in the ICZ (

Figure 5b,c). Molybdenum alloyed variants tend to have a higher DBTT at a given yield strength level than Mo-free alloys. This discrepancy, however, diminishes with increasing Nb content. The Mo-alloyed variants at lower Nb contents contain an increased amount of carbon-rich phase, which probably is tempered martensite. The highest DBTT is observed for the steel without micro-alloy (no Ti, no Nb). The low-Si Mo-alloyed variant, however, shows a low DBTT in the micro-alloy-free state.

In the CGZ the DBTT values are generally much higher than in the ICZ for all alloy variants. This can be due to the significantly coarser grain size and the absence of ductile polygonal ferrite in the microstructure. The absence of Ti in the alloy leads to clearly higher DBTT in comparison to the Ti-alloyed variant. A significant influence of molybdenum for otherwise identical alloys cannot be detected. In several of the alloy systems, the addition of Nb results in a slight decrease of the DBTT, followed by a marked increase for the highest Nb content of 0.1%. The difference in DBTT is most obvious between alloys V4 (MoNbTi) and V5 (MoNb). Comparing the microstructures of the CGZ indicates that the Ti-free alloy V5 has generally large prior austenite grain size (

Figure 8), which decreases somewhat towards the highest Nb addition. The grain size distribution is also quite inhomogeneous. This is congruent with the high DBTT found for these alloys. On the contrary, alloy V4 has much smaller and rather homogeneous grain size. Yet, for alloy V4 containing 0.1%Nb individual large grains are observed, which are probably the result of abnormal grain growth. The occurrence of individual large grains appears to have a significant negative influence on the DBTT.

The comparison of alloy V2-c with the corresponding industrial reference X65 steel reveals that the DBTT T50% is approximately 30 K lower in the HAZ sub-zones. In the ICZ the industrial steel has a DBTT of −130 °C as compared to −103 °C in alloy V2-c. In the CGZ the DBTT of the industrial steel is −65 °C whereas for alloy V2-c it is −32°C. If this difference, being related to steel cleanness was applicable to all other laboratory alloys, one can assume that the DBTT in the CGZ of industrially produced clean steels would be generally in the sub-zero temperature range.

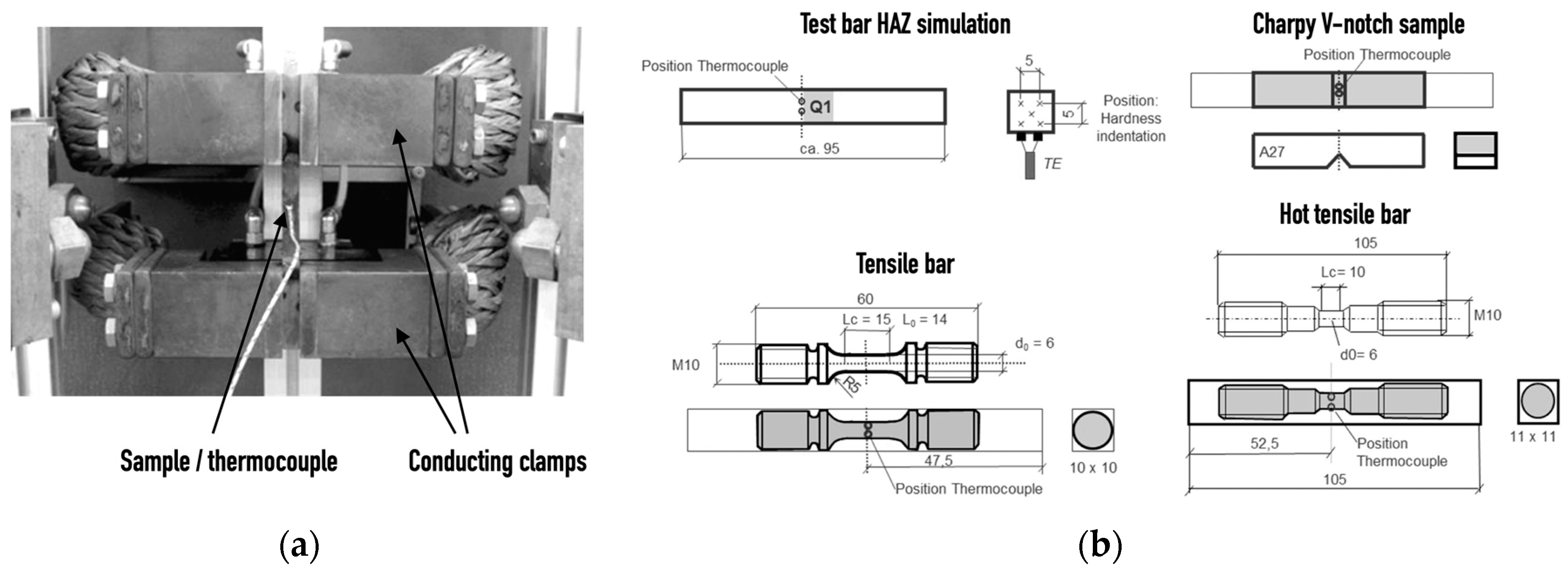

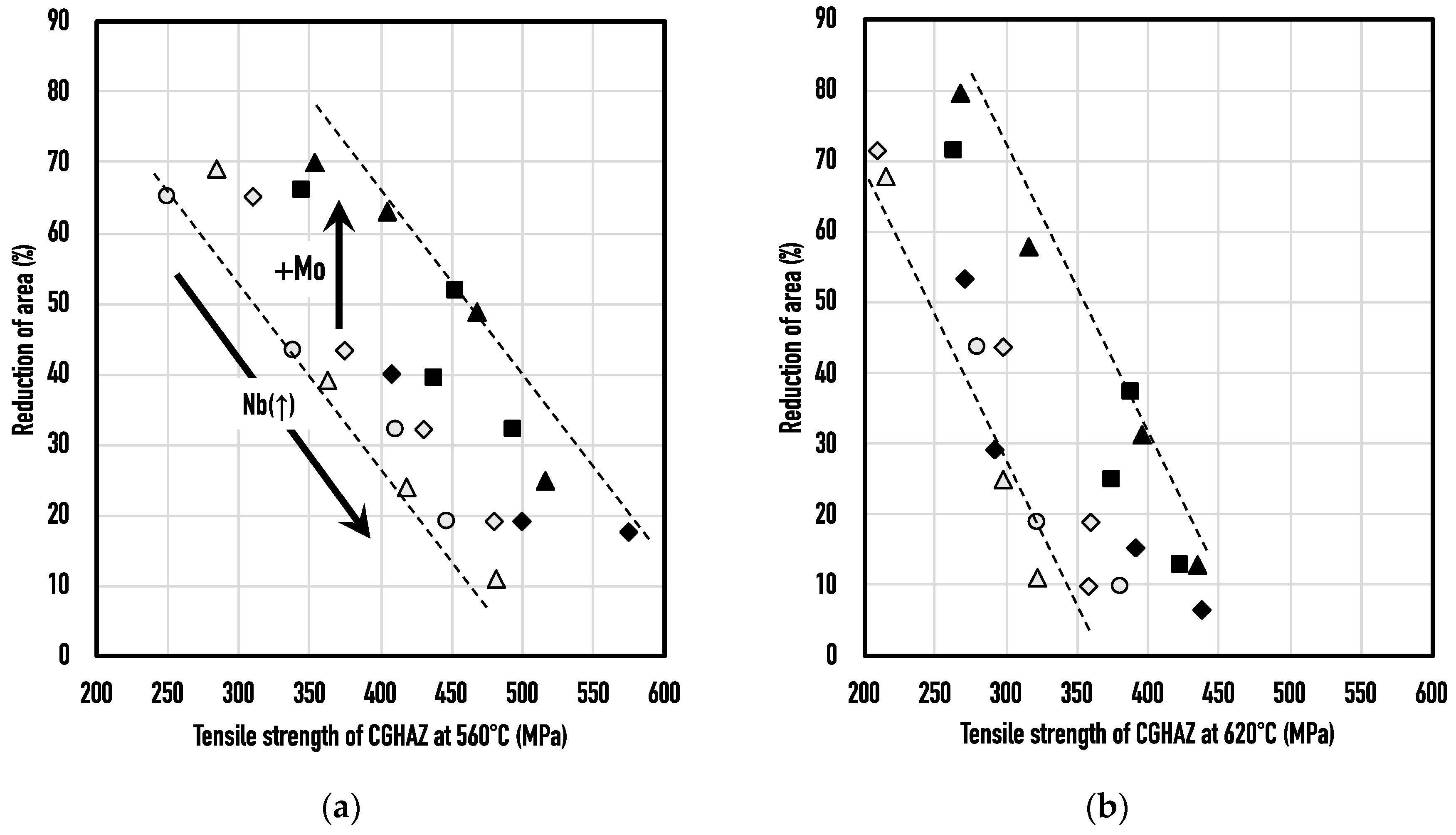

3.3. Post-Weld Heat Treatment

During post-weld heat treatment, the strength of the material is lowered, thus, residual stresses introduced to the weld zone can relax by plastic deformation. The reduction of area during a hot-tensile test indicates how much deformation the steel can withstand without cracking. Hot-tensile testing was performed at 560 and 620 °C with steel that was prior subjected to the CGZ simulation heat cycle.

Figure 9 shows the measured reduction of area as a function of the measured hot tensile strength.

Taking the original tensile strength in the CGZ as the reference, heating to 560 °C reduces the tensile strength by 150–200 MPa. When heating to 620 °C the strength reduction is in the range of 230–330 MPa. At both temperatures, the steels alloyed with molybdenum reveal a higher strength than those without it. Increasing the niobium content systematically raises the strength. The reduction of area decreases with increasing tensile strength for all alloys at both temperatures. This decreasing effect is stronger at higher temperatures. At the same hot-tensile strength level, molybdenum alloyed steels allow a significantly higher reduction of area. The comparison of the reduction of area at 560 °C between alloy V2-c (RA = 32%) and the industrial X65 steel (RA = 50%) reveals again the better performance of the latter.

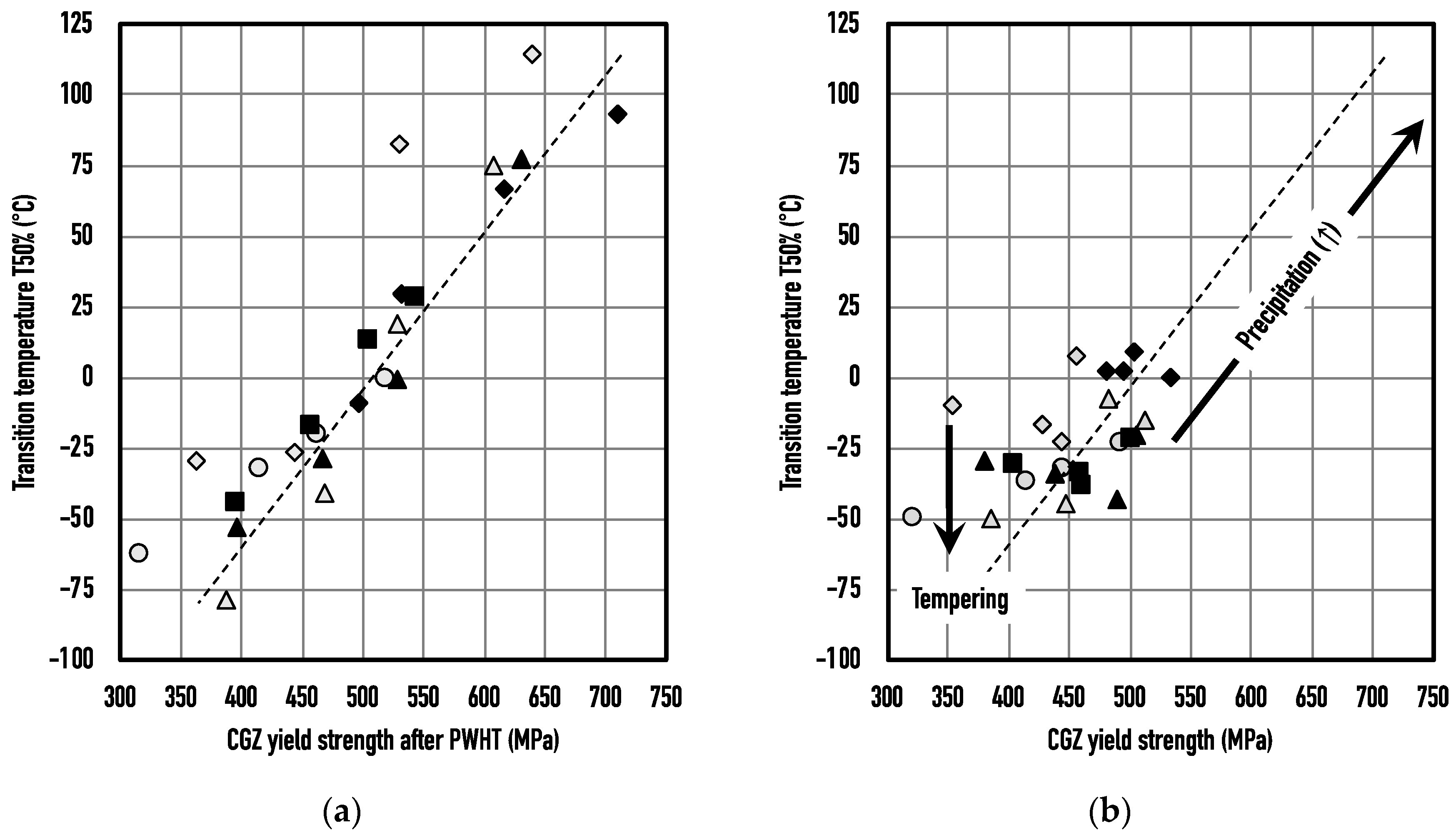

Finally, the toughness behavior after the post-weld heat treatment at 560 °C for 30 min is analyzed in

Figure 10a. One finds a strong correlation of the DBTT T50% with the measured yield strength. The majority of the data can be fitted very well by a linear relationship indicated by the dashed line. Only the data of alloy V1 are deviating from this line. The yield strength of the higher Nb-alloyed variants (0.05%Nb and 0.10%Nb) significantly increases after the heat treatment by values in the range of 50 to 175 MPa. The Nb-free alloys show little change in yield strength. For the alloys containing 0.02%Nb, the strength increase is in the range of 20 to 30 MPa. In the higher Nb-alloyed variants the DBTT increases severely by 50 to 100 K. In the Nb-free variants, the DBTT drops by 10 to 30 K. In alloys containing 0.02%Nb the DBTT increases in the range of 10 to 30 K. For comparing the data sets before and after heat treatment,

Figure 7b is re-plotted in

Figure 9b on the same scale as

Figure 9a. It is apparent that Nb precipitation moves the data points to higher strength and DBTT. For the Nb-free alloys, tempering appears to lower the DBTT while the yield strength remains nearly unaffected. Alloying of molybdenum does not seem to have a particular influence on the toughness behavior after this heat treatment. Performing the same post-weld heat treatment on the CGZ of the industrial X65 steel results in a DBTT of –55 °C whereas in the comparable laboratory steel V2-c it is –21°C.

4. Discussion

The present study has demonstrated that the influence of various alloying elements on the HAZ properties requires a careful analysis of individual metallurgical effects such as grain size, hardenability and precipitation status. In the investigated alloy variants, Nb and Ti are the elements with potential for precipitation, Mo and Mn reduce the carbon activity and increase the hardenability, and Si increases the carbon activity in austenite [

11,

12]. Both, Mo and Nb are large atoms having the tendency of segregating to grain boundaries and exerting solute drag [

13,

14]. Titanium added up to the stoichiometric ratio with respect to nitrogen contained in the steel forms very temperature-stable TiN particles, which exert grain boundary pinning in hot austenite. Niobium carbide precipitates provide also grain boundary pinning. However, NbC precipitates form at a lower temperature than TiN and typically niobium’s precipitation is incomplete. Thus, in the interpretation of the present results, one always has to reflect on the status of niobium, which in thermodynamic equilibrium is described by established solubility equations.

The solubility of niobium carbide, where [Nb] and [C] are the alloy concentrations in mass percent, is described as a function of the absolute temperature, T, as [

15]:

Accordingly, niobium additions of 0.02, 0.05 and 0.10% to the present 0.035% carbon steel dissolve at temperatures of 960, 1040 and 1120 °C, respectively. The solubility of titanium nitride carbide is similarly described as [

15]:

In the present alloys, the nitrogen content [N] is 0.0070% so that according to Equation (2) TiN is stable beyond the upper-temperature limit of the austenite phase field for these alloys being around 1450 °C. Consequently, at a peak temperature of 900 °C simulating the inter-critical sub-zone both, NbC and TiN particles are both stable. At a peak temperature of 1300 °C simulating the coarse-grained sub-zone, however, NbC particles should be dissolved whereas TiN particles are still stable.

Therefore, TiN particles are available to control the austenite grain size in the CGZ simulation at 1300 °C. This is indeed obvious when comparing the CGZ microstructures of Ti-free alloys (coarse-grained) with those of Ti-added alloys (fine-grained). Niobium carbide particles will fully re-dissolve during the up-heat cycle to 1300 °C. Solute Nb acts in the hot stage only by solute drag on austenite grain boundaries, which can contribute to finer grain size especially in combination with TiN particle pinning. This combined effect reflects an improved toughness. It is, however, also seen that for high Nb addition (0.10%) individual grains can grow abnormally large, leading to a significant decrease in toughness.

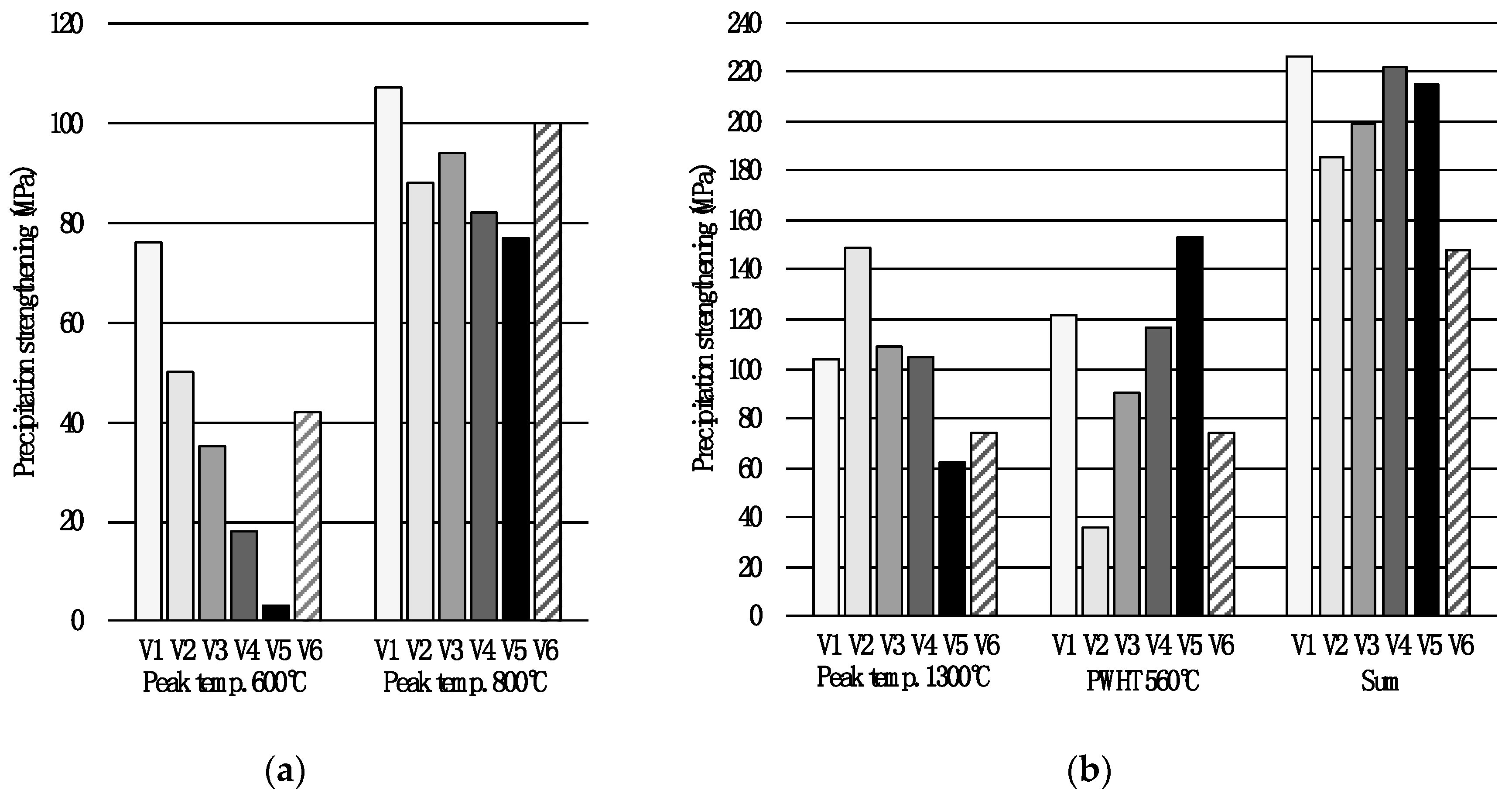

In the as-rolled plates, a significant amount of niobium is expected to be in solution, out of equilibrium. This is due to the strong cooling after rolling and the low cool-stop temperature, preventing substantial precipitation of niobium as its precipitation kinetics is rather slow. Hence, any heat treatment of such an Nb super-saturated steel above temperatures of 500 °C and below the equilibrium dissolution temperature given by Equation (1) will effectively lead to Nb precipitation. The higher the temperature is within that range, the more complete will be the precipitation. Accordingly, Nb precipitation can be expected for the HAZ simulations at sub-critical and inter-critical peak temperatures. Differential analysis of the tensile data allows us to estimate the contribution by Nb precipitation strengthening. The result of this analysis is shown for the alloys with the highest Nb content for the two sub-critical temperatures in

Figure 11a. The precipitation strengthening is generally larger at 800 °C than at 600 °C. Furthermore, the magnitude of the strengthening is with 80 to 100 MPa rather equal in all alloys. At 600 °C, the precipitation kinetics is slower and differences between the alloy systems become apparent. In alloys with an increased Mn content, the strength increase remains smaller and this effect is becoming even more pronounced when Mo is added. This can be due to the lower activity of carbon caused by Mn and Mo retarding the precipitation kinetics of Nb. On the other hand, when Si is reduced as in alloy V6, precipitation appears to be accelerated. It is assumed that the lower Si content allows for the better formation of nano-cementite particles [

16], which serve as a precursor for the nucleation of NbC [

17].

In the ICZ at a 900 °C peak temperature, niobium precipitation will occur even faster. Yet it is difficult to estimate the precipitation strengthening effect since simultaneously the entire matrix microstructure changes, also affecting the strength. The very pronounced grain refinement in the ICZ microstructure of Nb-alloyed variants certainly contributes to strength. This is caused for one part by the increased Ac1p temperature of the Nb alloyed steel vs. the Nb-free steel, which is a solute drag effect of Nb. The delayed partial transformation from ferrite to austenite enhances the nucleation rate for austenite grains. Secondly, the precipitation of Nb occurring simultaneous obstructs the growth of recrystallized ferrite and newly formed austenite grains. Re-distribution of carbon is more efficient due to shorter diffusion distances between grains in the refined ICZ microstructure. Therefore, the carbon content in newly formed austenite grains is more balanced and on average lower. This makes the formation of MA phase less likely, which is confirmed by the disappearance of the dual phase character (low YTR) that is clearly observed in the Nb-free steel. Molybdenum increases the hardenability of carbon enriched austenite so that a higher share of the hard phase is present in Mo-alloyed steels. This reflects in lower ICZ toughness values for the Mo-alloyed steels. However, increasing Nb content offsets the Mo effect via the carbon balancing explained before. The respective carbon-reduced austenite grains have a higher martensite-start temperature and will experience severe self-tempering during the down-cooling cycle. Accordingly, toughness improves rapidly in Mo-alloyed steels with increasing Nb content. The reduced Si content in alloy V6-d results in a particularly low Ac3p temperature (875 °C) for a reason that is not yet known. As a consequence, the peak temperature of 900 °C in the ICZ heating cycle causes an almost complete austenite transformation, preventing carbon enrichment in individual grains. Therefore, the formation of hard phases despite Mo alloying is unlikely. Indeed, the toughness of steel V6-d is on the same good level as found for the best Mo-free alloys.

When heating up to the CGZ peak temperature of 1300 °C, all NbC particles present in the as-rolled plate will dissolve. The time required for dissolving such particles having typically a size below 100 nm is estimated to be less than one second. The TiN particles, however, remain stable. Upon down-cooling niobium’s solubility decreases and NbC should re-precipitate. Precipitation of NbC does not easily occur inside the austenite grain in the absence of externally applied plastic deformation. The lattice mismatch between the austenite matrix and the NbC phase, both having an fcc structure, is around 25% [

18]. Better nucleation conditions for precipitation are given in the austenite grain boundaries. Furthermore, niobium, as well as carbon, segregates to the grain boundary resulting in a locally much higher [Nb]∙[C] solubility product. Precipitation of Nb should occur more efficiently during or after the phase transformation from austenite to the bcc phase. However, due to slow kinetics, it is expected to be incomplete. The precipitation strengthening effect has been estimated as shown in

Figure 11b by performing a differential analysis of the tensile data of the CGZ treated steels. The magnitude of precipitation strengthening ranges between 60 and 150 MPa. The highest strengthening is found in alloy V2-d containing lower Mn and no Mo. The otherwise identical Ti-free alloy (V1-d) shows clearly lower strengthening. Likewise, this is observed when comparing alloy V4-d and V5-d, where also the Ti-free alloy exhibits clearly lower strengthening. Possibly, the larger austenite grain size in the Ti-free alloys causes a more unequal distribution of Nb (due to boundary segregation) and increased diffusion distances.

When applying post-weld heat treatment to the CGZ treated steels, two main metallurgical effects can be expected, being a tempering of the matrix and further precipitation of solute Nb. The grain size will not be altered. Based on the tensile data, the softening in the matrix due to recovery processes is for all alloy systems between 40 and 50 MPa. The forthcoming additional precipitation strengthening is displayed in

Figure 11b. It is largest in the Ti-free steels and generally larger in the alloys with the higher Mn addition and those with Mo alloying. This means that more Nb remained in solution after the CGZ treatment due to the slower precipitation kinetics in these particular alloys. Summing up the strengthening contributions after the CGZ and PWHT cycles results in rather similar values for all alloys with the exception of Si-reduced steel.

The lower reduction of area observed in steels with increasing Nb content during the hot tensile deformation can be due to in-situ precipitation. Freshly formed precipitates may obstruct dislocations generated during the hot deformation and reduce the ductility of the matrix. It is feasible that this effect is stronger in the grain interior while the area near to the grain boundaries might be depleted from niobium as it has already precipitated after the CGZ cycle. This can lead to narrow areas in the vicinity of former austenite grain boundaries where plastic deformation will concentrate and cause rupture and a limited reduction of area. The observation that Mo alloying improves the hot ductility can be due to a retardation of in-situ precipitation and also to increased hot strength as Mo segregates to the grain boundary area. This should counteract the local concentration of plastic deformation. At the higher hot deformation temperature of 620 °C (

Figure 9b), the decrease of reduction of area with increasing Nb content is more pronounced since the precipitation kinetics is quicker. Yet also at this temperature, the precipitation retarding effect of Mo is evident.

The understanding that in-situ precipitation of NbC during hot deformation is the main cause for reduced ductility allows designing practical solutions to alleviate problems when post-weld heat treating steel with higher Nb addition. Firstly, the post-weld heat treatment can be done at the lower side of the typical temperature range of 500 to 600 °C, preferably below 550 °C, slowing down the kinetics of in-situ precipitation. Secondly, molybdenum should be co-alloyed to niobium for additionally retarding the precipitation kinetics and stabilizing the niobium-depleted areas in the vicinity of grain boundaries. Titanium micro-alloying restricts the CGZ grain size, thus, providing improved toughness. Thirdly, welding should be executed using the multi-pass technique in a way that the CGZ of an earlier pass obtains sufficient tempering by a subsequent weld pass. In this way, precipitation is already being anticipated in a large part of the CGZ rendering less solute Nb for in-situ precipitation during PWHT. Since PWHT is typically applied to components fabricated from thick plate gages, multi-pass welding is usually applied. The parameters of the individual passes should be optimized to allow a maximum tempering effect on previous passes.

5. Conclusions

Increasing addition of niobium raises yield strength and improves toughness simultaneously in the as-rolled state of the considered extra-low carbon steels. The combined addition of molybdenum and niobium provides the highest strength fulfilling the requirements for grade X80.

Regarding the inter-critical heat-affected zone, niobium-free steels have the lowest yield strength and toughness. These steels exhibit a low yield-to-tensile ratio, which is caused by a fraction of martensite islands dispersed in recrystallized ferrite. Adding niobium in increasing amounts raises the yield strength as well as the yield-to-tensile ratio. The recrystallized ferrite grain size is being severely refined and martensite formation is being suppressed. Consequently, ICZ toughness is improving with increasing niobium content.

Molybdenum addition increases the amount of hard phase in the inter-critical heat-affected zone leading to a decrease of ICZ toughness. The hard phase appears predominantly as tempered martensite. At higher niobium additions this toughness-reducing effect of molybdenum is being diminished. Lowering the silicon content further reduces the formation of hard phases.

Regarding the coarse-grained heat affected zone, titanium-free steels show low CGZ toughness due to excessive grain coarsening. A small addition of titanium, typically in near-stoichiometric ratio to residual nitrogen present in the steel, counteracts pronounced grain coarsening. Increasing niobium content can further improve toughness in combination with titanium. At the highest niobium addition, however, individual grains showed abnormal coarsening in several alloys. The mechanism for this abnormal grain growth must be investigated in more detail. Increasing niobium content leads also to more pronounced precipitation strengthening reducing CGZ toughness. Thus, the actual toughness performance of the coarse-grained heat affected zone is controlled by the counteracting effects of grain refinement and precipitation.

Toughness in the coarse-grained heat affected zone after post-weld heat treatment is controlled by the degree of in-situ precipitation of niobium that was prior dissolved during the CGZ heat cycle. The potential of in-situ precipitation increases naturally with the niobium content in the steel. However, by anticipating or delaying in-situ precipitation, PWHT embrittlement can be reduced to an acceptable level. This requires careful consideration of the integral alloy concept, the selected PWHT temperature and an appropriate multi-pass welding schedule. Molybdenum, particularly, was found to improve hot ductility, which helps to avoid stress relaxation cracking.