Evaluation of Fruit and Vegetable Containers Made from Mulberry Wood (Morus Alba L.) Waste

Abstract

:1. Introduction

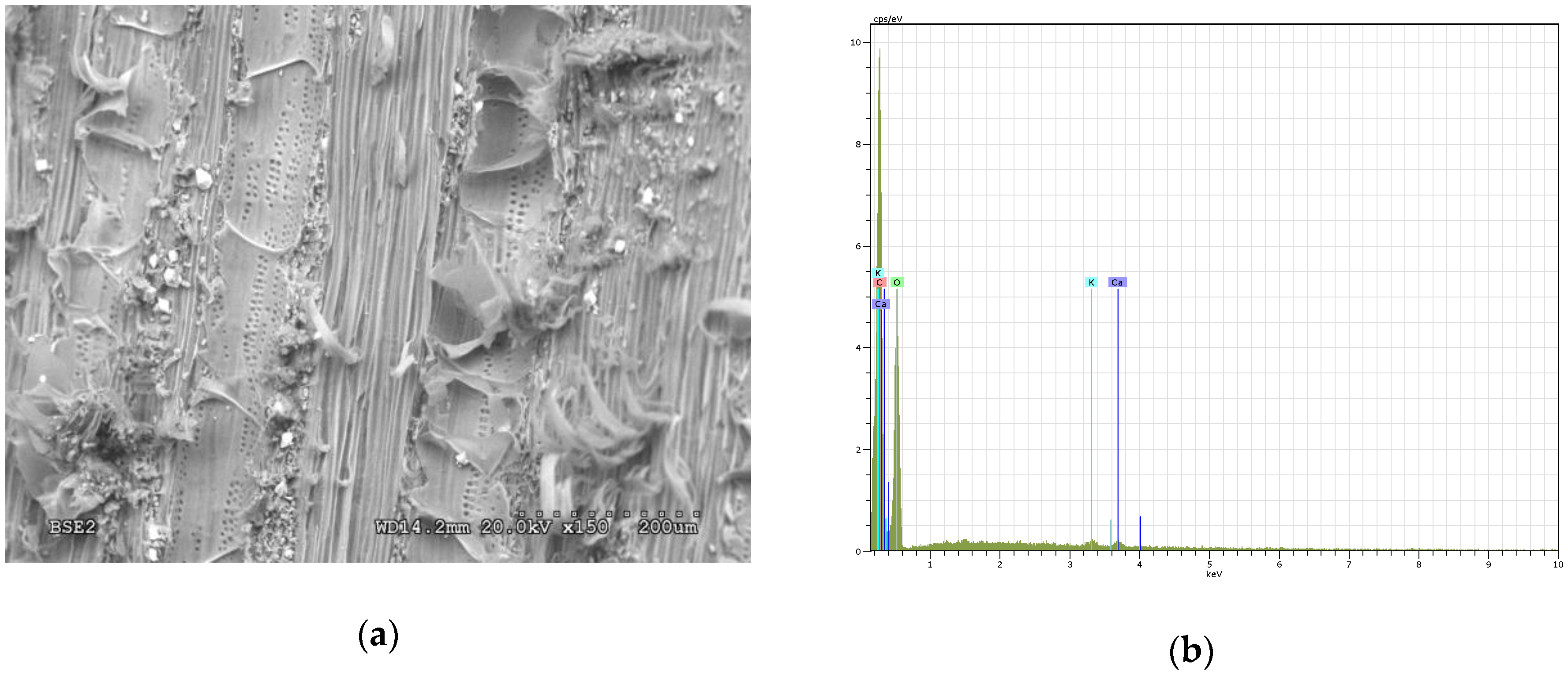

2. Materials and Methods

2.1. Raw Materials

2.2. Particleboard Sample Manufacturing and Testing

2.3. Container Manufacturing

2.4. Container Testing

- M = Weight of the stacked containers

- H = Number of stacked containers

- 1.5 = Safety factor

2.5. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ghandhi Doss, S.; Chakraborti, S.P.; Roychowdhuri, S.; Das, N.K.; Vijayan, K.; Ghosh, P.D. Development of mulberry varieties for sustainable growth and leaf yield in temperate and subtropical regions of India. Euphytica 2012, 185, 215–225. [Google Scholar] [CrossRef]

- Harizanis, P.C. Manual of Sericulture; Ministry of Agricultural Development and Food, Directorate of Animal Production: Athens, Greece, 2007; p. 26.

- He, X.; Fang, J.; Ruan, Y.; Wang, X.; Sun, Y.; Wu, N.; Huang, L. Structures, bioactivities and future prospective of polysaccharides from Morus alba (white mulberry): A review. Food Chem. 2018, 245, 899–910. [Google Scholar] [CrossRef]

- Wen, P.; Hu, T.G.; Linhardt, R.J.; Liao, S.T.; Wu, H.; Zou, Y.X. Mulberry: A review of bioactive compounds and advanced processing technology. Trends Food Sci. Technol. 2019, 83, 138–158. [Google Scholar] [CrossRef]

- Chen, Z.; Du, X.; Yang, Y.; Cui, X.; Zhang, Z.; Li, Y. Comparative study of chemical composition and active components against α-glucosidase of various medicinal parts of Morus alba L. Biomed. Chromatogr. 2018, 32, e4328. [Google Scholar] [CrossRef]

- Qiu, F.; He, T.Z.; Zhang, Y.Q. The isolation and the characterization of two polysaccharides from the branch bark of mulberry (Morus alba L.). Arch. Pharmacal Res. 2016, 39, 887–896. [Google Scholar] [CrossRef]

- Wang, S.; Liu, X.M.; Zhang, J.; Zhang, Y.Q. An efficient preparation of Mulberroside A from the branch bark of mulberry and its effect on the inhibition oftyrosinase activity. PLoS ONE 2014, 9, 109396–109407. [Google Scholar] [CrossRef]

- Chen, W.; Liang, T.; Zuo, W.; Wu, X.; Shen, Z.; Wang, F.; Peng, G. Neuroprotective effect of 1-Deoxynojirimycin on cognitive impairment, β-amyloid deposition, and neuroinflammation in the SAMP8 mice. Biomed. Pharmacother. 2018, 106, 92–97. [Google Scholar] [CrossRef]

- Guo, C.; Li, R.; Zheng, N.; Xu, L.; Liang, T.; He, Q. Anti-diabetic effect of ramulus mori polysaccharides, isolated from Morus alba L., on STZ-diabetic mice through blocking inflammatory response and attenuating oxidative stress. Int. Immunopharmacol. 2013, 16, 93–99. [Google Scholar] [CrossRef]

- Sánchez, M.D. World distribution and utilization of Mulberry and its potential for animal feeding. Anim. Prod. Health Paper 2002, 147, 1–8. [Google Scholar]

- Chen, X.; Sheng, Z.; Qiu, S.; Yang, H.; Jia, J.; Wang, J.; Jiang, C. Purification, characterization and in vitro and in vivo immune enhancement of polysaccharides from mulberry leaves. PLoS ONE 2019, 14, e0208611. [Google Scholar] [CrossRef]

- Zhu, Z.E.; Jiang, J.J.; Jie, J.J.; Mao, X.B.; Bing, Y.U.; Chen, D.W. Effect of dietary supplementation with mulberry (Morus alba L.) leaves on the growth performance, meat quality and antioxidative capacity of finishing pigs. J. Integr. Agric. 2019, 18, 143–151. [Google Scholar] [CrossRef]

- Serpunja, S.; Sankar, K.; Kim, J.K.; Kim, I.H. Impacts of dietary β-glucan (Morus Alba and Curcuma longa) supplementation on growth performance, apparent total tract digestibility, fecal microbial, fecal characteristics, and blood profiles in weanling pigs. J. Appl. Anim. Res. 2018, 46, 1509–1515. [Google Scholar] [CrossRef]

- Mansour, M.M.; Salem, M.Z.M.; Khamis, M.H.; Ali, H.M. Natural durability of Citharexylum spinosum and Morus alba woods against three mold fungi. BioResources 2015, 10, 5330–5344. [Google Scholar] [CrossRef]

- Hassan, B.; Ahmed, S.; Mehmood, N.; Mankowski, M.E.; Misbah-ul-Haq, M. Toxicity potential of heartwood extractives from two mulberry species against Heterotermes indicola. Maderas Ciencia Tecnología 2019, 21. [Google Scholar] [CrossRef]

- Golpayegani, A.S.; Thevenon, M.F.; Gril, J.; Masson, E.; Pourtahmasiç, K. Toxicity potential in the extraneous compounds of white mulbery wood (Morus alba). Maderas Ciencia Tecnología 2014, 16, 227–238. [Google Scholar] [CrossRef]

- Gündüz, G.; Yıldırım, N.; Şirin, G.; Onat, S.M. Some anatomical, chemical, physical and mechanic properties of white mulberry (Morus alba L.) Tree. J. For. 2009, 5, 131–149. [Google Scholar]

- Golpayegani, A.S.; Brémaud, I.; Gril, J.; Thevenon, M.F.; Arnould, O.; Pourtahmasi, K. Effect of extractions on dynamic mechanical properties of white mulberry (Morus alba). J. Wood Sci. 2012, 58, 153–162. [Google Scholar] [CrossRef]

- Proyecto PO07-040. FEDER 80%. Caracterización de Recursos Fitogenéticos de Morera (Morus alba) y Desarrollo de Aprovechamientos para su Revalorización; IMIDA: Murcia, Spain, 2014. [Google Scholar]

- Vivas, N. Manual de Tonelería: Destinado a Usuarios de Toneles; Mundi-Prensa Libros: Madrid, Spain, 2005; p. 231. ISBN 9788484762058. [Google Scholar]

- Martinez-Gil, A.; del Alamo-Sanza, M.; Sánchez-Gómez, R.; Nevares, I. Different Woods in Cooperage for Oenology: A Review. Beverages 2018, 4, 94. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Sajdak, M.; López-Cortés, I. Available residual biomass obtained from pruning Morus alba L. trees cultivated in urban forest. Renew. Energy 2013, 60, 27–33. [Google Scholar] [CrossRef]

- Velazquez-Marti, B.; Sajdak, M.; Lopez-Cortes, I.; Callejón-Ferre, A.J. Wood characterization for energy application proceeding from pruning Morus alba L., Platanus hispanica Munchh. and Sophora japonica L. in urban areas. Renew. Energy 2014, 62, 478–483. [Google Scholar] [CrossRef]

- Moral, R.; Bustamante, M.; Ferrández-García, C.E.; Andréu-Rodríguez, J.; Ferrández-García, M.T.; Garcia-Ortuño, T. New Biomass Sources to Reduce Peat Dependence in Mediterranean Substrates: Validation of Morus alba L., Sorghum vulgare L., and Phoenix canariensis Pruning Wastes. Commun. Soil Sci. Plant Anal. 2015, 46 (Suppl. 1), 10–19. [Google Scholar] [CrossRef]

- Si, L.; Peng, X.; Zhou, J. The suitability of growing mulberry (Morus alba L.) on soils consisting of urban sludge composted with garden waste: A new method for urban sludge disposal. Environ. Sci. Pollut. Res. 2019, 26, 1379–1393. [Google Scholar] [CrossRef]

- Nasser, R.A. Physical and mechanical properties of three-layer particleboard manufactured from the tree pruning of seven wood species. World Appl. Sci. J. 2012, 19, 741–753. [Google Scholar] [CrossRef]

- Turgut Sahin, H.; Burak Arslan, M. Weathering performance of particleboards manufactured from blends of forest residues with Red pine (Pinus brutia) wood. Maderas Ciencia Tecnología 2011, 13, 337–346. [Google Scholar] [CrossRef]

- Hiziroglu, S.; Holcomb, R. Some of the properties of three-layer particleboard made from eastern redcedar. Build. Environ. 2005, 40, 719–723. [Google Scholar] [CrossRef]

- Duarte da Silva, M.J.; Bezerra, B.S.; Gomes Battistelle, R.A.; De Domenico Valareli, I. Prospects for the use of municipal tree pruning wastes in particleboard production. Waste Manag. Res. 2013, 31, 960–965. [Google Scholar] [CrossRef] [PubMed]

- Lykidis, C.; Grigoriou, A.; Barboutis, I. Utilisation of wood biomass residues from fruit tree branches, evergreen hardwood shrubs and Greek fir wood as raw materials for particleboard production. Part A. Mechanical properties. Wood Mater. Sci. Eng. 2014, 9, 202–208. [Google Scholar] [CrossRef]

- Yu, H.X.; Fang, C.R.; Xu, M.P.; Guo, F.Y.; Yu, W.J. Effects of density and resin content on the physical and mechanical properties of scrimber manufactured from mulberry branches. J. Wood Sci. 2015, 61, 159–164. [Google Scholar] [CrossRef]

- Ferrández-García, C.E.; García-Ortuño, T.; Andreu-Rodríguez, J.; Ferrández-Villena, M.; Ferrández-García, M.T. Manufacture and properties of particleboard made from mulberry pruning waste. In Structures and Environmental Technologies, Proceedings of the International Conference of Agricultural Engineering-CIGR-AgEng 2012: Agriculture and engineering for a Healthier Life, Valencia, Spain, 8–12 July 2012; CIGR-EurAgEng: East Lansing, MI, USA, 2012; pp. 468–473. ISBN 84-615-9654-4. [Google Scholar]

- García-Ortuño, T.; Ferrández-Villena, M.; Ferrández-García, M.T.; Andréu-Rodríguez, J.; Ferrández-García, C.E. Properties of particleboards made from mulberry bonded with different natural adhesives. In Proceedings of the VII Iberian Congress of Agroengineering and Horticultural Sciences, Madrid, Spain, 26–29 August 2013; ISBN 978-84-695-9055-3. [Google Scholar]

- Kurt, Ș.; Uysal, B. Combustion properties of mulberry (Morus alba L.) laminated veneer lumbers bonded with PVAC, PF adhesives and impregnated with some fire-retardants. Wood Res. 2010, 55, 99–114. [Google Scholar] [CrossRef]

- Schuur, C.C.M. Packaging for Fruits, Vegetables and Root Crops; FAO, Representative Office in Barbados: Rome, Italy, 1988. [Google Scholar]

- UNE 49051. Packaging—Wood Packaging for Fruit and Vegetables. Base of 300 × 200 mm; Asociación Española de Normalización y Certificación: Madrid, Spain, 2002. [Google Scholar]

- García-Ortuño, T.; Carbonell-Barrachina, A.A.; Andréu-Rodríguez, J.; Ferrández-García, M.T.; Calín-Sánchez, A.; Ferrández-Villena, M.; Ferrández-García, C.E. Turning waste into a resource: Study of the effect of containers made of giant reed weeds on the shelf life and quality of tomatoes and strawberries. Cien. Inv. Agr. 2013, 40, 149–159. [Google Scholar] [CrossRef] [Green Version]

- EN 322. Wood-Based Panels. Determination of Moisture Content; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 323. Wood-Based Panels. Determination of Density; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 310. Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 319. Particleboards and Fiberboards. Determination of Tensile Strength Perpendicular to the Plane of De Board; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 320. Particleboards and Fibreboards—Determination of Resistance to Axial Withdrawal of Screw; Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- EN 317. Particleboards and Fiberboards. Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- UNE 49706. Packaging—Packaging for the Transport of Fruit and Vegetables. Determination of the Static Deflection of the Bottom; Asociación Española de Normalización y Certificación: Madrid, Spain, 2002. [Google Scholar]

- EN ISO 12048. Packaging—Complete, Filled Transport Packages—Compression and Stacking Tests Using a Compression Tester (ISO 12048:1994); ISO: Geneve, Switzerland, 2001. [Google Scholar]

- EN ISO 2234. Packaging—Complete, Filled Transport Packages and Unit Loads—Stacking Tests Using a Static Load (ISO 2234:2000); ISO: Geneve, Switzerland, 2003. [Google Scholar]

- EN ISO 2233. Packaging—Complete, Filled Transport Packages and Unit Loads. Conditioning for Testing (ISO 2233:2000); ISO: Geneve, Switzerland, 2002. [Google Scholar]

- Hermoso, E.; Fernández-Golfín, J.I.; Díez, R. Madera estructural de pino silvestre: Caracterización mecánica. For. Syst. 2002, 11, 425–440. [Google Scholar]

- Fernández-Golfín, J.I.; Oliva, A.G.; Merino, M.B.; Barra, M.D. Características físico-mecánicas de las maderas de especies de crecimiento rápido de procedencia española. For. Syst. 1995, 4, 251–261. [Google Scholar]

- EN 312. Particleboards–Specifications; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- Hays, M.D.; Fine, P.M.; Geron, C.D.; Kleeman, M.J.; Gullett, B.K. Open burning of agricultural biomass: Physical and chemical properties of particle-phase emissions. Atmos. Environ. 2005, 39, 6747–6764. [Google Scholar] [CrossRef]

- Feng, S.; Cheng, S.; Yuan, Z.; Leitch, M.; Xu, C.C. Valorization of bark for chemicals and materials: A review. Renew. Sustain. Energy Rev. 2013, 26, 560–578. [Google Scholar] [CrossRef]

| Wood | Density (kg/m3) | Fm (N/cm2) | Em (N/cm2) | References |

|---|---|---|---|---|

| Mulberry branches with bark | 445–630 | 27–40 | 550–1300 | This study |

| Pinus sylvestris | 478–570 | 28–61 | 8700–11,598 | [48] |

| Poplar | 378 | 6.1 | 700 | [49] |

| Eucalyptus | 790 | 14.1 | 1655 | [49] |

| Particleboard Type | Thickness (mm) | Density (kg/m3) | Moisture Content (%) | TS (24 h) (%) | WA (24 h) (%) |

|---|---|---|---|---|---|

| Mulberry pruning waste particleboard | 3.10 (0.42) | 853.86 (33.92) | 2.5 (0.6) | 21.4 (2.3) | 50.9 (3.6) |

| Conventional plywood | 2.95 (0.03) | 457.57 (7.20) | 5.39 (0.2) | 6.3 (1.2) | 86.5 (6.5) |

| Board Type | MOR (N/mm2) | MOE (N/mm2) | IB (N/mm2) | SH (N/mm) |

|---|---|---|---|---|

| Agglomerate pruning mulberry | 20.51 (2.62) | 1906.70 (327.46) | 1.65 (0.45) | 68.36 (5.83) |

| Industrial plywood | 63.04 (12.40) | 6853.04 (1,924.1) | 0.73 (0.2) | 21.11 (1.58) |

| P3 requirements | 13 | 1800 | 0.50 | 0.8 |

| Container No. | Deformation (mm) |

|---|---|

| 1 | 1.71 |

| 2 | 2.11 |

| 3 | 2.14 |

| 4 | 1.77 |

| 5 | 2.10 |

| 6 | 2.10 |

| mean | 2.00 (0.23) |

| Container No. | “C” Load (N) | Deformation (mm) | Deformation/Height (%) |

|---|---|---|---|

| 7–8 | 1660 | 3.80 | 1.69 |

| 9–10 | 1660 | 3.20 | 1.43 |

| 11–12 | 1660 | 2.45 | 1.09 |

| mean | 1660 | 3.15 (0.65) | 1.40 (0.30) |

| Container No. | Dynamic Load (N) | Deformation (mm) |

|---|---|---|

| 13 | 20,500 | 4.36 |

| 14 | 19,500 | 5.18 |

| 15 | 20,500 | 6.32 |

| 16 | 20,500 | 4.56 |

| 17 | 17,000 | 5.68 |

| 18 | 19,000 | 4.22 |

| mean | 19,500 (1378) | 5.05 (0.83) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrandez-Villena, M.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Garcia, M.T. Evaluation of Fruit and Vegetable Containers Made from Mulberry Wood (Morus Alba L.) Waste. Appl. Sci. 2019, 9, 1806. https://doi.org/10.3390/app9091806

Ferrandez-Villena M, Ferrandez-Garcia CE, Garcia-Ortuño T, Ferrandez-Garcia A, Ferrandez-Garcia MT. Evaluation of Fruit and Vegetable Containers Made from Mulberry Wood (Morus Alba L.) Waste. Applied Sciences. 2019; 9(9):1806. https://doi.org/10.3390/app9091806

Chicago/Turabian StyleFerrandez-Villena, Manuel, Clara Eugenia Ferrandez-Garcia, Teresa Garcia-Ortuño, Antonio Ferrandez-Garcia, and Maria Teresa Ferrandez-Garcia. 2019. "Evaluation of Fruit and Vegetable Containers Made from Mulberry Wood (Morus Alba L.) Waste" Applied Sciences 9, no. 9: 1806. https://doi.org/10.3390/app9091806

APA StyleFerrandez-Villena, M., Ferrandez-Garcia, C. E., Garcia-Ortuño, T., Ferrandez-Garcia, A., & Ferrandez-Garcia, M. T. (2019). Evaluation of Fruit and Vegetable Containers Made from Mulberry Wood (Morus Alba L.) Waste. Applied Sciences, 9(9), 1806. https://doi.org/10.3390/app9091806