Physical Properties of Jatropha curcas L. Fruits and Seeds with Respect to Their Maturity Stage

Abstract

1. Introduction

2. Material and Methods

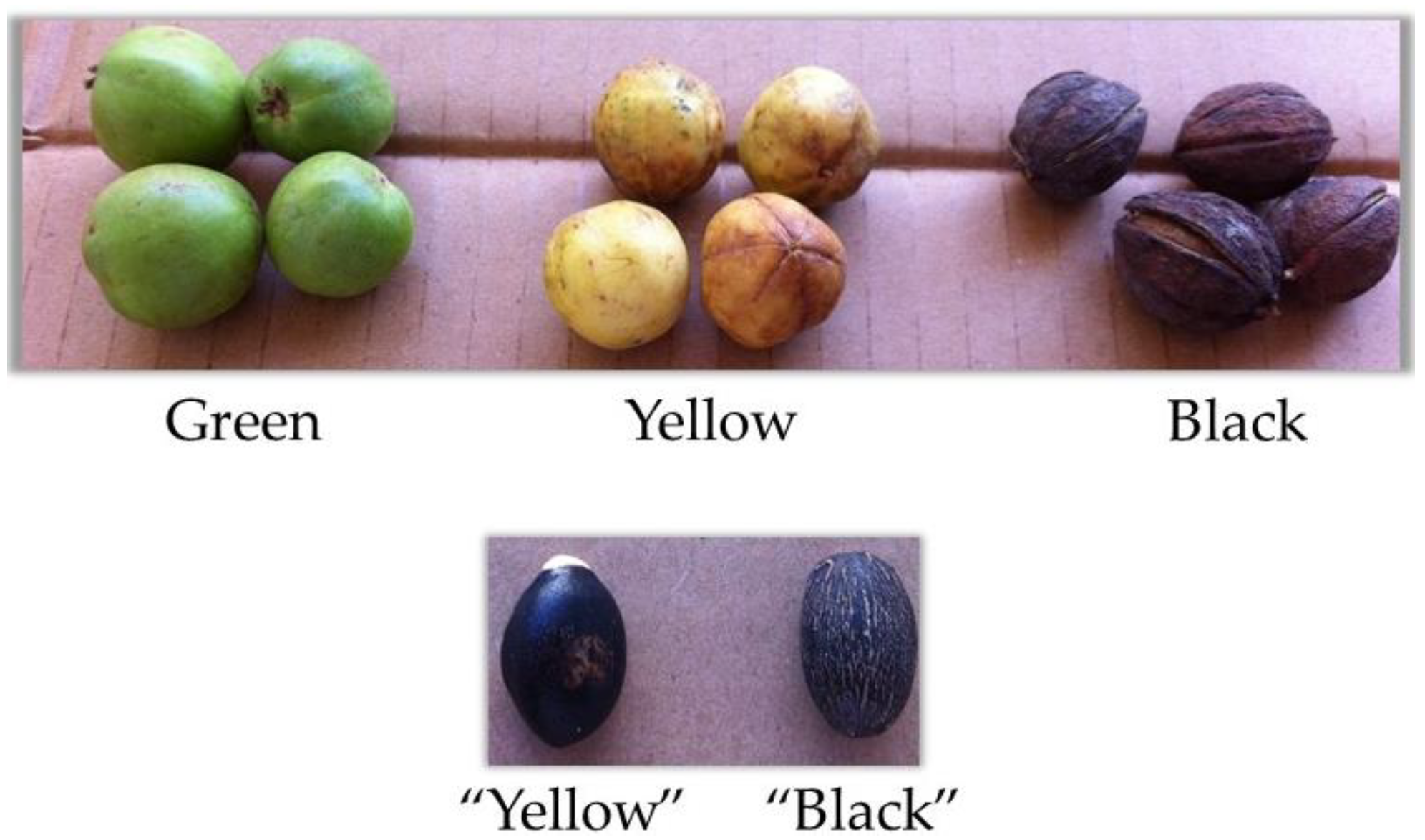

2.1. Material

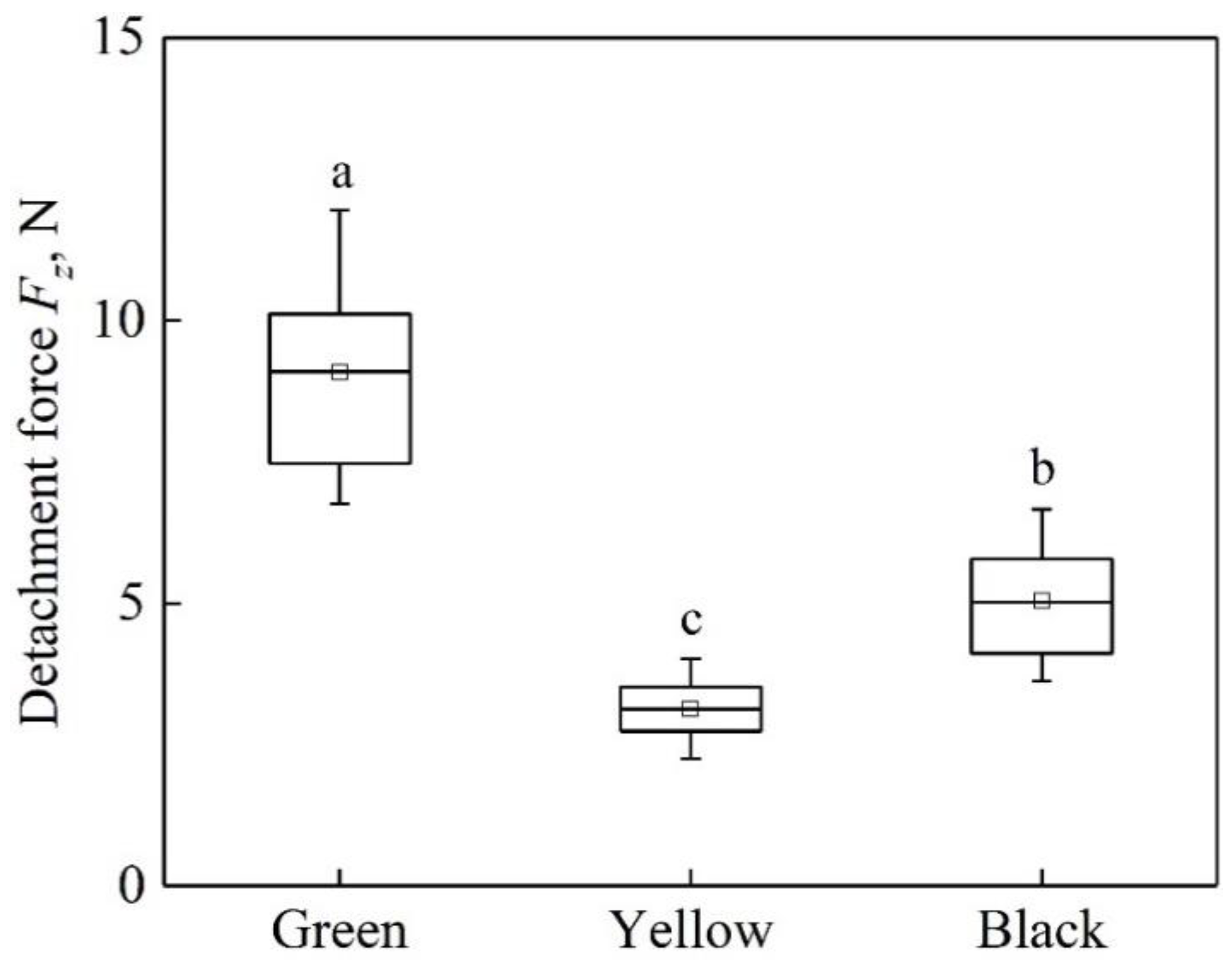

2.2. Detachment Force for Harvesting the Fruits

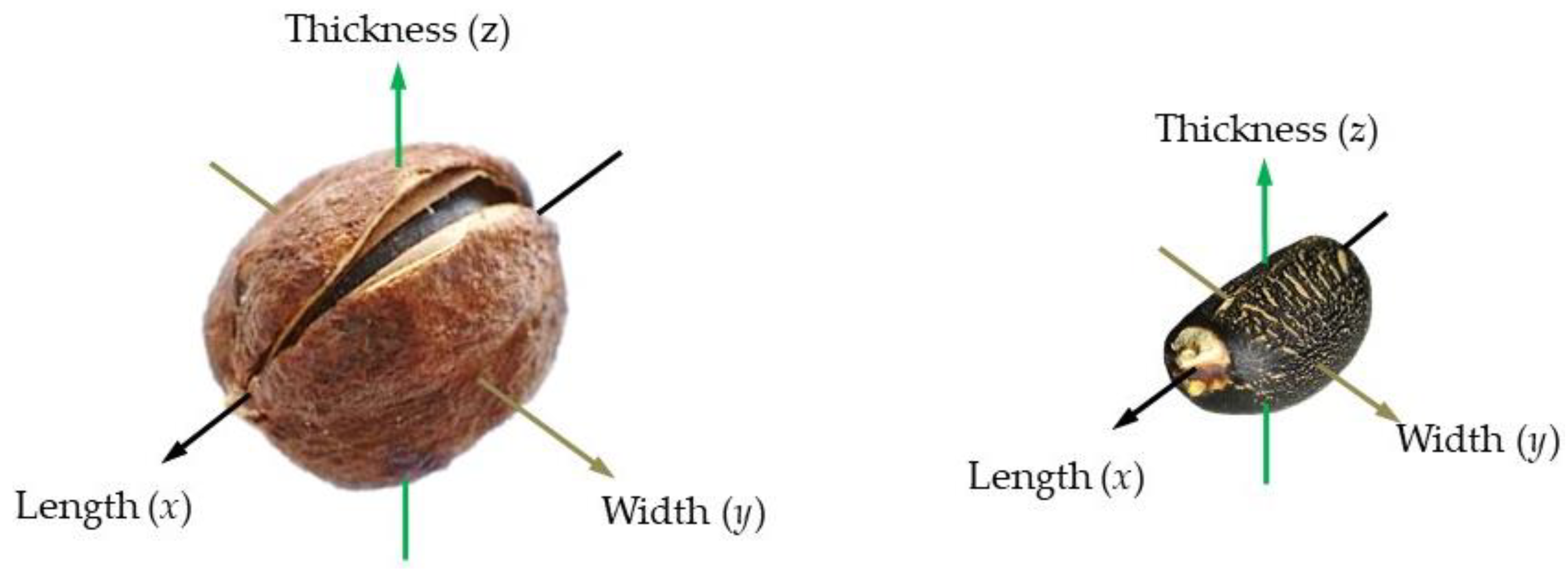

2.3. Moisture Content, Geometric Characteristics, and Bulk Properties

2.4. Determination of Mechanical Properties

2.5. Sliding Friction Characteristics

2.6. Statistical Analysis

3. Results and Discussion

3.1. Detachment Force at Different Maturity Stages

3.2. Geometric Characteristics of J. curcas Fruits and Seeds

3.2.1. Fruits

3.2.2. Seeds

3.3. Bulk Properties as Affected by Different Maturity Stages

3.3.1. Fruits

3.3.2. Seeds

3.4. Effect of Maturity Stage on Mechanical Properties

3.4.1. Fruits

3.4.2. Seeds

3.5. Coefficient of Static Friction on Different Surface Materials

3.5.1. Fruits

3.5.2. Seeds

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Da | Arithmetic diameter | mm |

| Dg | Geometric mean diameter | mm |

| d | Diameter of container | mm |

| ER | Energy for rupture | N mm |

| FE | Force to pull the empty container | N |

| FR | Rupture force | N |

| FT | Force to pull the filled container | N |

| FZ | Detachment force | N |

| H | Hardness | N/mm |

| h | Height of container | mm |

| L | Length | mm |

| M | Moisture content | % |

| m | Unit mass | g |

| mE | Net mass of empty container | g |

| mT | Total mass of filled container | g |

| µ | Coefficient of static friction | - |

| φ | Sphericity | - |

| θs | Static angle of repose | ° |

| θd | Dynamic angle of repose | ° |

| ρb | Bulk density | g/cm3 |

| ρs | Solid density | g/cm3 |

| RDP | Deformation at rupture point | mm |

| RDR | Deformation ratio at rupture point | - |

| S | Surface area | mm2 |

| T | Thickness | mm |

| Ss | Specific surface area | cm2/cm3 |

| V | Volume of container | cm3 |

| Vu | Unit volume | cm3 |

| W | Width | mm |

| WT | Total weight of filled container | N |

| x | Direction of length | |

| y | Direction of width | |

| z | Direction of thickness |

References

- Ma, F.; Hanna, M.A. Biodiesel production: A review. Bioresour. Technol. 1999, 70, 1–15. [Google Scholar] [CrossRef]

- Banković-Ilić, I.B.; Stamenković, O.S.; Veljković, V.B. Biodiesel production from non-edible plant oils. Renew. Sustain. Energy Rev. 2012, 16, 3621–3647. [Google Scholar] [CrossRef]

- Borugadda, V.B.; Goud, V.V. Biodiesel production from renewable feedstocks: Status and opportunities. Renew. Sustain. Energy Rev. 2012, 16, 4763–4784. [Google Scholar] [CrossRef]

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Norhasyima, R.S. Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: A review. Renew. Sustain. Energy Rev. 2011, 15, 3501–3515. [Google Scholar] [CrossRef]

- Achten, W.M.J.; Verchot, L.; Franken, Y.J.; Mathijs, E.; Singh, V.P.; Aerts, R.; Muys, B. Jatropha bio-diesel production and use. Bioresour. Technol. 2008, 32, 1063–1084. [Google Scholar] [CrossRef]

- Achten, W.M.J.; Maes, W.H.; Aerts, R.; Verchot, L.; Trabucco, A.; Mathijs, E.; Singh, V.P.; Muys, B. Jatropha: From global hype to local opportunity. J. Arid. Environ. 2010, 74, 164–165. [Google Scholar] [CrossRef]

- Contran, N.; Chessa, L.; Lubino, M.; Bellavite, D.; Roggero, P.P.; Enne, G. State-of-the-art of the Jatropha curcas productive chain: From sowing to biodiesel and by-products. Ind. Crops Prod. 2013, 42, 202–215. [Google Scholar] [CrossRef]

- Lim, B.Y.; Shamsudin, R.; Baharudin, B.T.H.T.; Yunus, R. A review of processing and machinery for Jatropha curcas L. fruits and seeds in biodiesel production: Harvesting, shelling, pretreatment and storage. Renew. Sustain. Energy Rev. 2015, 52, 991–1002. [Google Scholar] [CrossRef]

- Pradhan, R.C.; Naik, S.N.; Bhatnagar, N.; Vijay, V.K. Design, development and testing of hand-operated decorticator for Jatropha fruit. Appl. Energy 2010, 87, 762–768. [Google Scholar] [CrossRef]

- Lim, B.Y.; Shamsudin, R.; Yunus, R. Development and testing of a Jatropha fruit shelling process for shell-free kernel recovery in biodiesel production. Biosystems Eng. 2014, 121, 46–55. [Google Scholar] [CrossRef]

- King, A.J.; He, W.; Cuevas, J.A.; Freudenberger, M.; Ramiaramanana, D.; Graham, I.A. Potential of Jatropha curcas as a source of renewable oil and animal feed. J. Exp. Bot. 2009, 60, 2897–2905. [Google Scholar] [CrossRef]

- Kratzeisen, M.; Müller, J. Suitability of Jatropha seed shells as fuel for small-scale combustion units. Renew. Energy 2013, 51, 46–52. [Google Scholar] [CrossRef]

- Sharma, D.K.; Pandey, A.K.; Lata. Use of Jatropha curcas hull biomass for bioactive compost production. Biomass Bioenergy 2009, 33, 159–162. [Google Scholar] [CrossRef]

- Karaj, S.; Müller, J. Determination of physical, mechanical and chemical properties of seeds and kernels of Jatropha curcas L. Ind. Crops Prod. 2010, 32, 129–138. [Google Scholar] [CrossRef]

- Pradhan, R.C.; Naik, S.N.; Bhatnagar, N.; Vijay, V.K. Moisture-dependent physical properties of jatropha fruit. Ind. Crops Prod. 2009, 29, 341–347. [Google Scholar] [CrossRef]

- Samsuri, A.; Zoveidavianpoor, M. Does the maturity of Jatropha curcas L. affect the quality and quantity of the yield of oil for biodiesel production? Int. J. Green Energy 2014, 11, 193–205. [Google Scholar] [CrossRef]

- Ramanadane, T.; Narayanan, A.L. Effect of different stages of fruit maturity and size grading on seed quality in jatropha (Jatropha curcas). Indian J. Agric. Sci. 2014, 84, 1558–1560. [Google Scholar]

- Dranski, J.A.L.; Pinto Jr, A.S.; Steiner, F.; Zoz, T.; Malavasi, U.C.; Malavasi, M.M.; Guimarães, V.F. Physiological maturity of seeds and colorimetry of fruits of Jatropha curcas L. Revista Brasileira de Sementes 2010, 32, 158–165. [Google Scholar] [CrossRef]

- DIN CEN/TS 14774-3. Determination of moisture content - oven dry method. In Part 3: Moisture in General Analysis Sample; Deutsches Institut für Normung e.V: Berlin,Germany, 2004. [Google Scholar]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials; Gordon and Breach Science Publishers: New York, NY, USA, 1980; Volume 31, p. 891. [Google Scholar]

- Ghani, M.N.A.; Hudzari, R.M.; Wahab, F.I.A.; Ramli, M.R.H.; Azhar, A.W.M. Design, construction and evaluation of a smart agricultural harvester. In Proceedings of the 2013 International Conference on MEMS and Mechanics, MEMSM 2013, Wuhan, China, 15–16 March 2013; Volume 705, pp. 487–492. [Google Scholar]

- Ramli, M.R.H.; Ghani, M.N.A.; Razali, M.H.; Wahab, F.I.A.; Ngah, N. Determination of vibration properties of Jatropha curcas for mechanical harvesting operations. Songklanakarin J. Sci. Technol. 2012, 34, 9–15. [Google Scholar]

- Yahya, A.; Hamdan, K.; Ishola, T.A.; Suryanto, H. Physical and mechanical properties of Jatropha curcas L. fruits from different planting densities. J. Appl. Sci. 2013, 13, 1004–1012. [Google Scholar]

- Sirisomboon, P.; Kitchaiya, P.; Pholpho, T.; Mahuttanyavanitch, W. Physical and mechanical properties of Jatropha curcas L. fruits, nuts and kernels. Biosystems Eng. 2007, 97, 201–207. [Google Scholar] [CrossRef]

- Dutta, S.K.; Nema, V.K.; Bhardwaj, R.K. Physical properties of gram. J. Agric. Eng. Res. 1988, 39, 259–268. [Google Scholar] [CrossRef]

- Savoire, R.; Lanoisellé, J.L.; Vorobiev, E. Mechanical Continuous Oil Expression from Oilseeds: A Review. Food Bioprocess Technol. 2013, 6, 1–16. [Google Scholar] [CrossRef]

- Karaj, S.; Müller, J. Optimizing mechanical oil extraction of Jatropha curcas L. seeds with respect to press capacity, oil recovery and energy efficiency. Ind. Crops Prod. 2011, 34, 1010–1016. [Google Scholar] [CrossRef]

| Fraction | Moisture Content (%) | Unit Mass (g) | Length L (mm) | Width W (mm) | Thickness T (mm) | Sphericity φ | Arithmetic Diameter Da (mm) | Geometric Diameter Dg (mm) | Volume Vu (cm3) | Surface Area S (mm2) | Specific Surface Area Ss (cm2/cm3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fruits | |||||||||||

| Green | 85.2a ± 1.1 | 8.23a ± 0.28 | 26.61a ± 0.33 | 25.71a ± 0.32 | 26.38a ± 0.30 | 0.99a ± 0.01 | 26.23a ± 0.29 | 26.22a ± 0.29 | 9.50a ± 0.31 | 2164a ± 47 | 1.2b ± 0.04 |

| Yellow | 79.5b ± 3.6 | 5.25b ± 0.27 | 24.64b ± 0.34 | 24.55b ± 0.25 | 25.14b ± 0.34 | 0.98a ± 0.02 | 24.78b ± 0.28 | 24.77b ± 0.27 | 8.00b ± 0.26 | 1931b ± 42 | 1.4b ± 0.07 |

| Black | 8.6c ± 0.5 | 2.51c ± 0.11 | 26.90a ± 0.38 | 21.99c ± 0.21 | 24.59b ± 0.27 | 0.91b ± 0.01 | 24.50b ± 0.24 | 24.40b ± 0.24 | 7.64b ± 0.22 | 1873b ± 36 | 1.6a ± 0.07 |

| Seeds | |||||||||||

| “Yellow” | 58.3a ± 5.5 | 0.41b ± 0.03 | 16.98b ± 0.14 | 10.56a ± 0.21 | 8.17a ± 0.07 | 0.67a ± 0.01 | 11.90b ± 0.09 | 11.30b ± 0.13 | 0.77b ± 0.02 | 468b ± 11 | 4.5a ± 0.31 |

| “Black” | 6.8b ± 0.5 | 0.57a ± 0.02 | 18.33a ± 0.12 | 10.78a ± 0.11 | 8.32a ± 0.07 | 0.64a ± 0.00 | 12.48a ± 0.09 | 11.80a ± 0.09 | 0.87a ± 0.02 | 503a ± 9 | 4.1a ± 0.19 |

| Fraction | Bulk Density ρb (g/cm3) | Solid Density ρs (g/cm3) | Porosity ɛ (%) | Dynamic Angle of Repose θd (°) | Static Angle of Repose θs (°) |

|---|---|---|---|---|---|

| Fruits | |||||

| Green | 0.45a ± 0.006 | 0.88a ± 0.038 | 45.4a ± 1.06 | 23.8c ± 1.11 | 26.9c ± 1.16 |

| Yellow | 0.35b ± 0.003 | 0.66b ± 0.340 | 41.6a ± 0.55 | 27.2b ± 1.25 | 29.6b ± 0.44 |

| Black | 0.21c ± 0.003 | 0.30c ± 0.013 | 25.5b ± 1.81 | 29.8a ± 1.32 | 32.7a ± 0.78 |

| Seeds | |||||

| “Yellow” | 0.32b ± 0.002 | 0.59a ± 0.076 | 49.9a ± 0.36 | 34.7a ± 1.2 | 37.5a ± 0.79 |

| “Black” | 0.42a ± 0.006 | 0.65a ± 0.021 | 45.4b ± 0.54 | 32.9a ± 1.1 | 36.7a ± 0.61 |

| Fraction | Rupture Force FR (N) | Hardness H (N/mm) | Energy for Rupture ER (N mm) | Deformation at Rupture Point RDP (mm) | Deformation Ratio at Rupture Force RDR |

|---|---|---|---|---|---|

| x-direction (Length) | |||||

| Fruits | |||||

| Green | 84.0a ± 14.37 | 15.6ab ± 2.14 | 209.7a ± 50.47 | 4.9ab ± 0.59 | 0.19a ± 0.02 |

| Yellow | 56.7b ± 12.46 | 10.8b ± 2.54 | 201.1a ± 81.39 | 5.5a ± 1.52 | 0.21a ± 0.06 |

| Black | 51.4b ± 10.52 | 26.0a ± 16.18 | 99.3a ± 80.45 | 2.9b ± 1.62 | 0.10b ± 0.06 |

| Seeds | |||||

| “Yellow” | 99.6a ± 33.85 | 63.3b ± 16.39 | 71.5a ± 36.85 | 1.6a ± 0.41 | 0.09a ± 0.02 |

| “Black” | 113.2a ± 35.32 | 91.5a ± 22.94 | 64.6a ± 27.97 | 1.3a ± 0.43 | 0.07a ± 0.02 |

| y-direction (Width) | |||||

| Fruits | |||||

| Green | 108.3ab ± 15.46 | 14.2b ± 3.22 | 476.0a ± 137.84 | 7.9a± 1.80 | 0.34a ± 0.08 |

| Yellow | 98.1b ± 26.18 | 12.5b ± 5.79 | 322.5a ± 57.13 | 8.7a ± 2.01 | 0.36a ± 0.09 |

| Black | 149.9a ± 39.02 | 33.3a ± 7.78 | 327.8a ± 99.57 | 4.5b ± 0.69 | 0.21b ± 0.03 |

| Seeds | |||||

| “Yellow” | 44.9a ± 14.26 | 71.3b ± 18.18 | 19.2a ± 11.19 | 0.7a ± 0.23 | 0.06a ± 0.02 |

| “Black” | 46.0a ± 9.06 | 96.0a ± 14.04 | 12.6a ± 4.78 | 0.5b ± 0.09 | 0.05a ± 0.01 |

| z-direction (Thickness) | |||||

| Seeds | |||||

| “Yellow” | 89.5a ± 36.78 | 74.2a ± 34.90 | 62.4a ± 30.75 | 1.3a ± 0.28 | 0.15a ± 0.04 |

| “Black” | 101.1a ± 31.81 | 90.4a ± 20.40 | 65.6a ± 31.43 | 1.1a ± 0.26 | 0.13a ± 0.03 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romuli, S.; Karaj, S.; Müller, J. Physical Properties of Jatropha curcas L. Fruits and Seeds with Respect to Their Maturity Stage. Appl. Sci. 2019, 9, 1802. https://doi.org/10.3390/app9091802

Romuli S, Karaj S, Müller J. Physical Properties of Jatropha curcas L. Fruits and Seeds with Respect to Their Maturity Stage. Applied Sciences. 2019; 9(9):1802. https://doi.org/10.3390/app9091802

Chicago/Turabian StyleRomuli, Sebastian, Shkelqim Karaj, and Joachim Müller. 2019. "Physical Properties of Jatropha curcas L. Fruits and Seeds with Respect to Their Maturity Stage" Applied Sciences 9, no. 9: 1802. https://doi.org/10.3390/app9091802

APA StyleRomuli, S., Karaj, S., & Müller, J. (2019). Physical Properties of Jatropha curcas L. Fruits and Seeds with Respect to Their Maturity Stage. Applied Sciences, 9(9), 1802. https://doi.org/10.3390/app9091802