Life-Cycle Optimization of a Chiller Plant with Quantified Analysis of Uncertainty and Reliability in Commercial Buildings

Abstract

Featured Application

Abstract

1. Introduction

1.1. Conventional and Optimal Design of a Chiller Plant

- The cooling load of a typical design day is determined according to the statistic historical outdoor weather conditions and maximum boundaries.

1.2. Uncertainty Research for Building Energy System

1.3. Reliability Research for Building Energy System

2. Outline and Objective of Robust Optimal Design

2.1. Outline of the Proposed Method

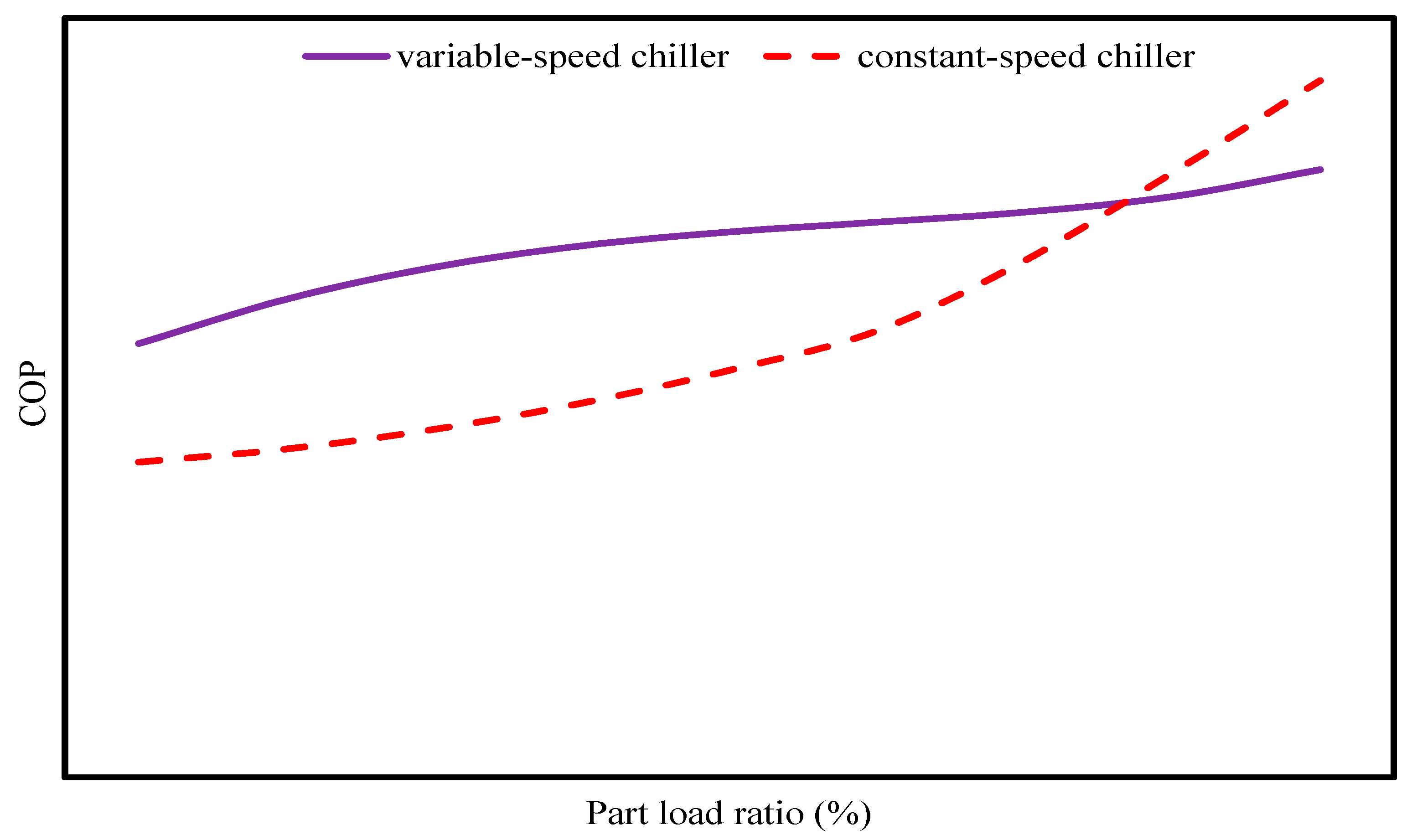

- A chiller plant consists of several constant-speed chillers, and no more than two variable-speed chillers.

- The failure rate of a constant-speed chiller is smaller than that of variable-speed chillers.

- All the constant-speed chillers are equally sized and have the same failure rate.

- All the variable-speed chillers are equally sized and have the same failure rate.

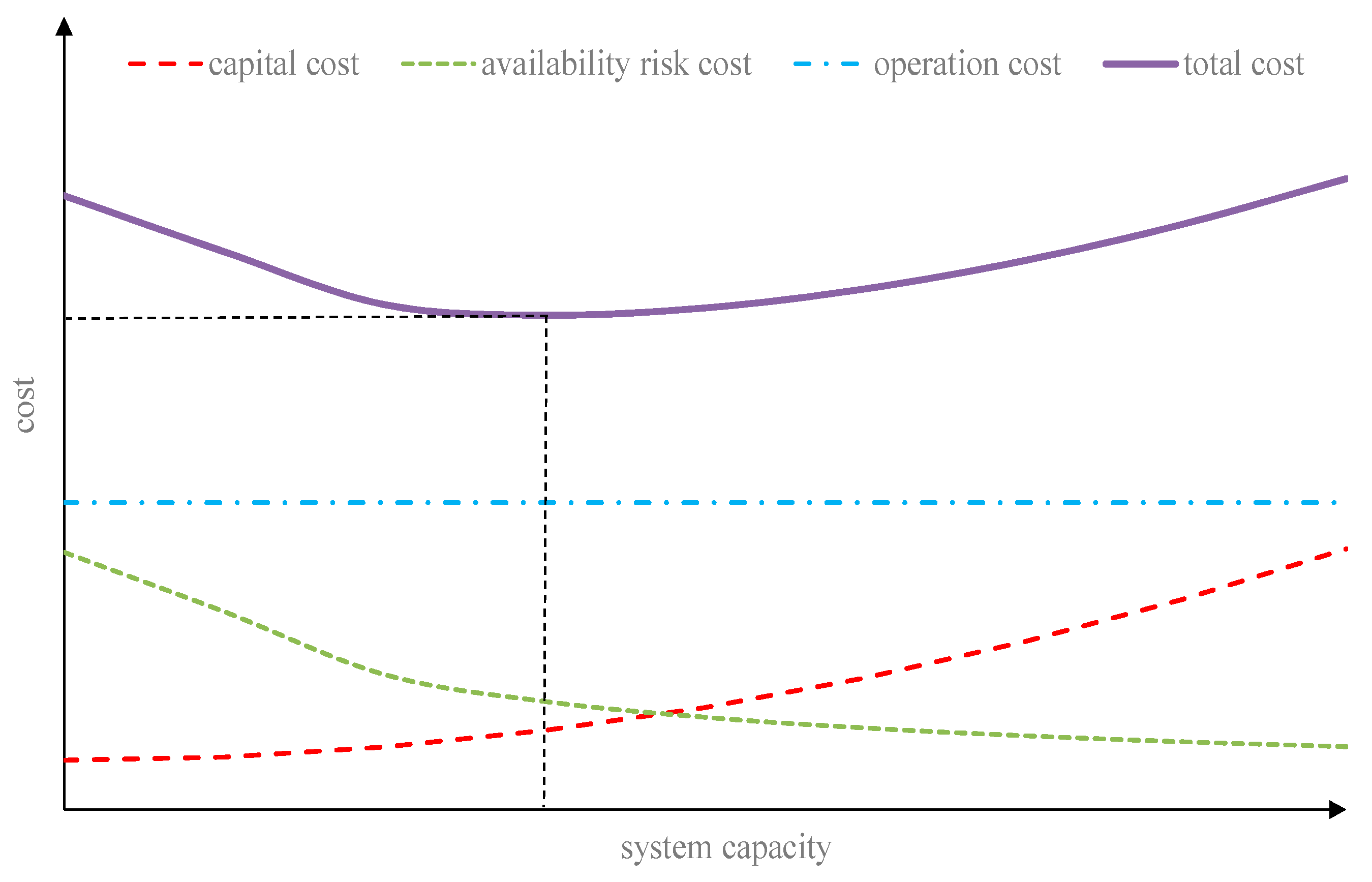

2.2. Objective of Design Optimization

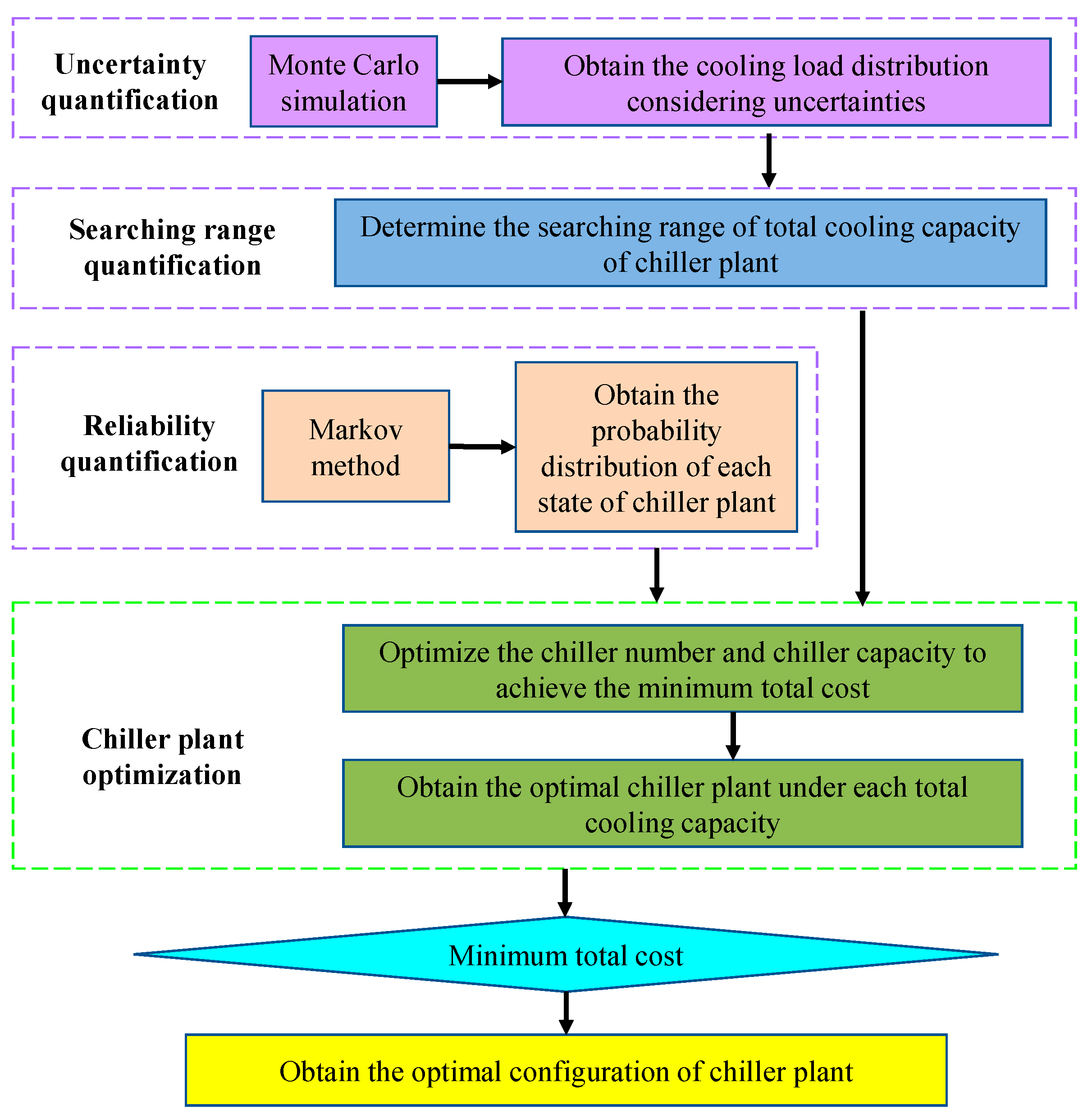

3. Implementation of Robust Optimal Design for Chiller Plant Optimization

- Uncertainty quantification: Monte Carlo simulation is employed to obtain the cooling load distribution by considering the uncertainties of main design inputs;

- Searching range quantification: the searching range of total chiller plant cooling capacity is specified according to the corresponding unmet hours in a cooling load distribution;

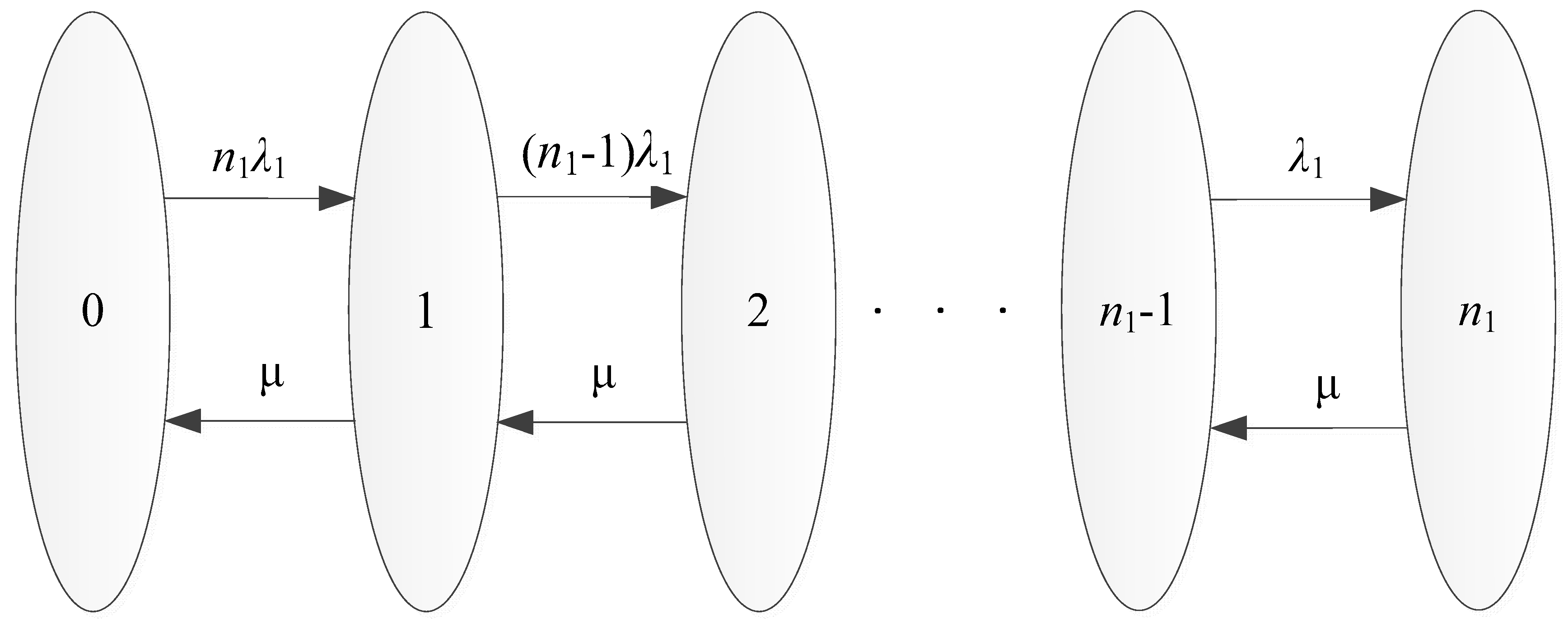

- Reliability quantification: Markov method is used to generate the probability distribution of various states of chiller plant by considering the failure rates of both constant-speed and variable-speed chillers;

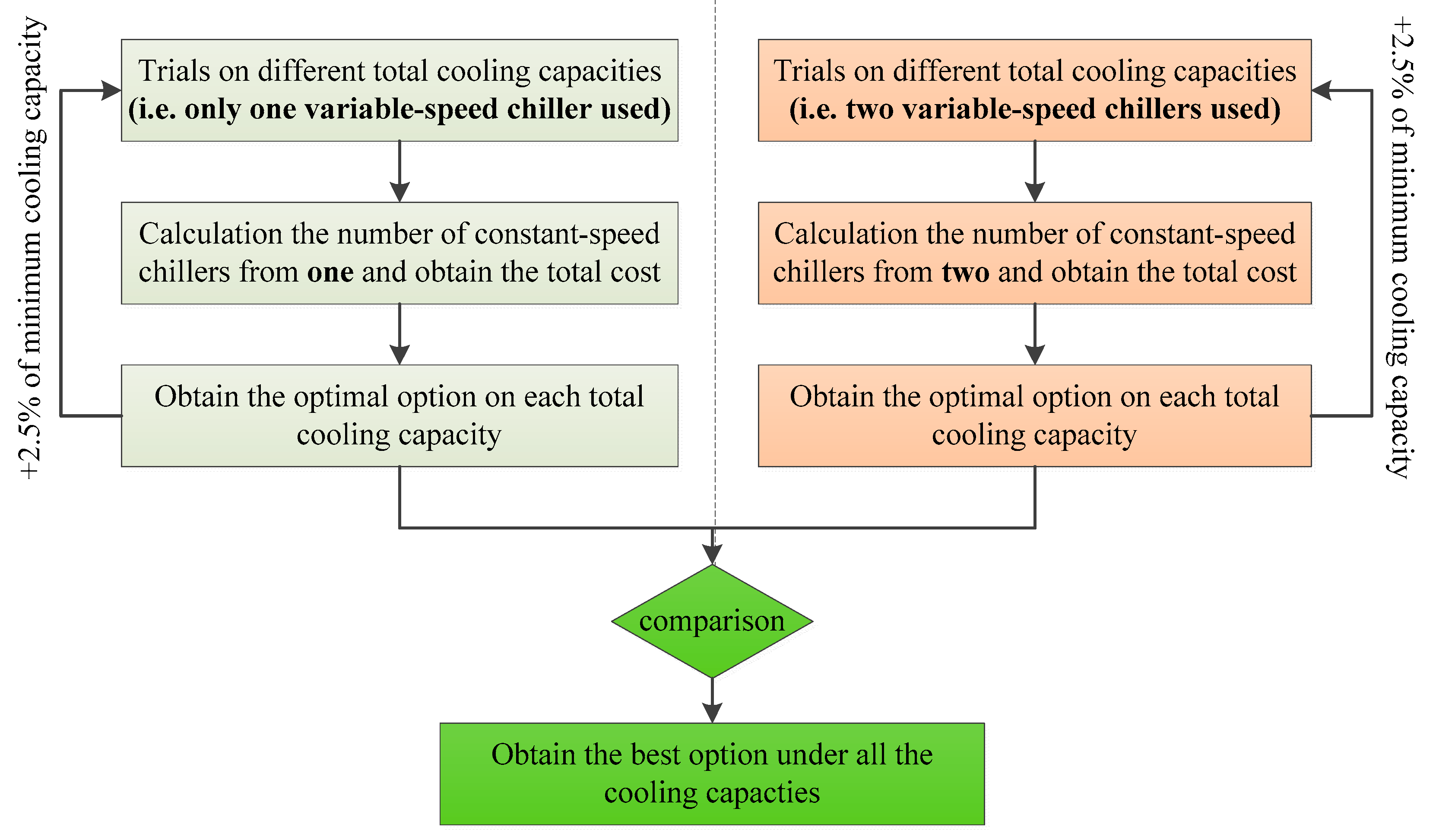

- Chiller plant optimization: Trials of simulations focusing on the number/size of chillers and the sum of their cooling capacities to conduct trials on each total cooling capacity gradually, to obtain the total cost under various number/size of chillers on each total cooling capacity, and to obtain the optimal chiller plant option under each total cooling capacity.

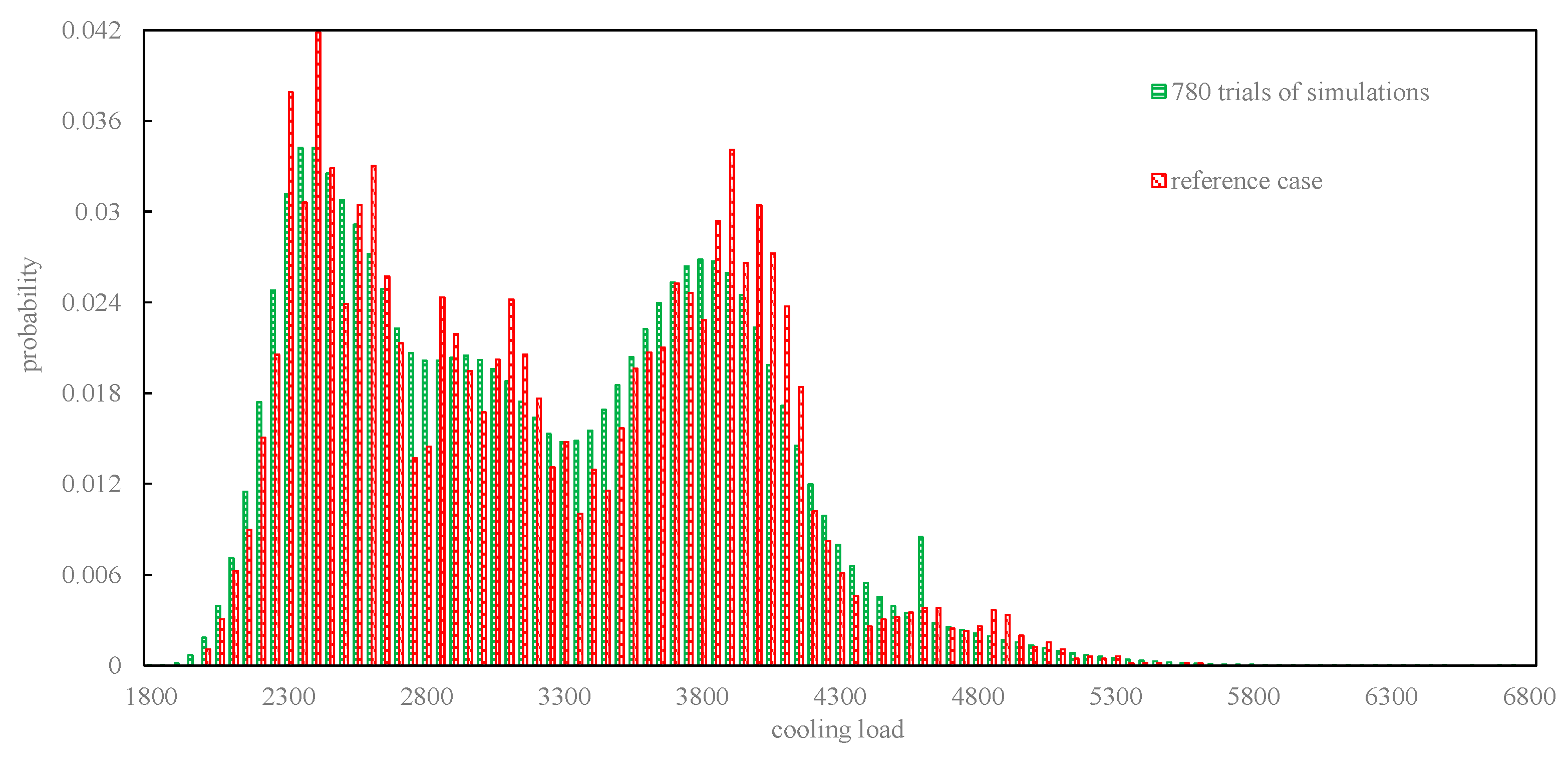

3.1. Quantification of Cooling Load Distribution Considering Uncertainties

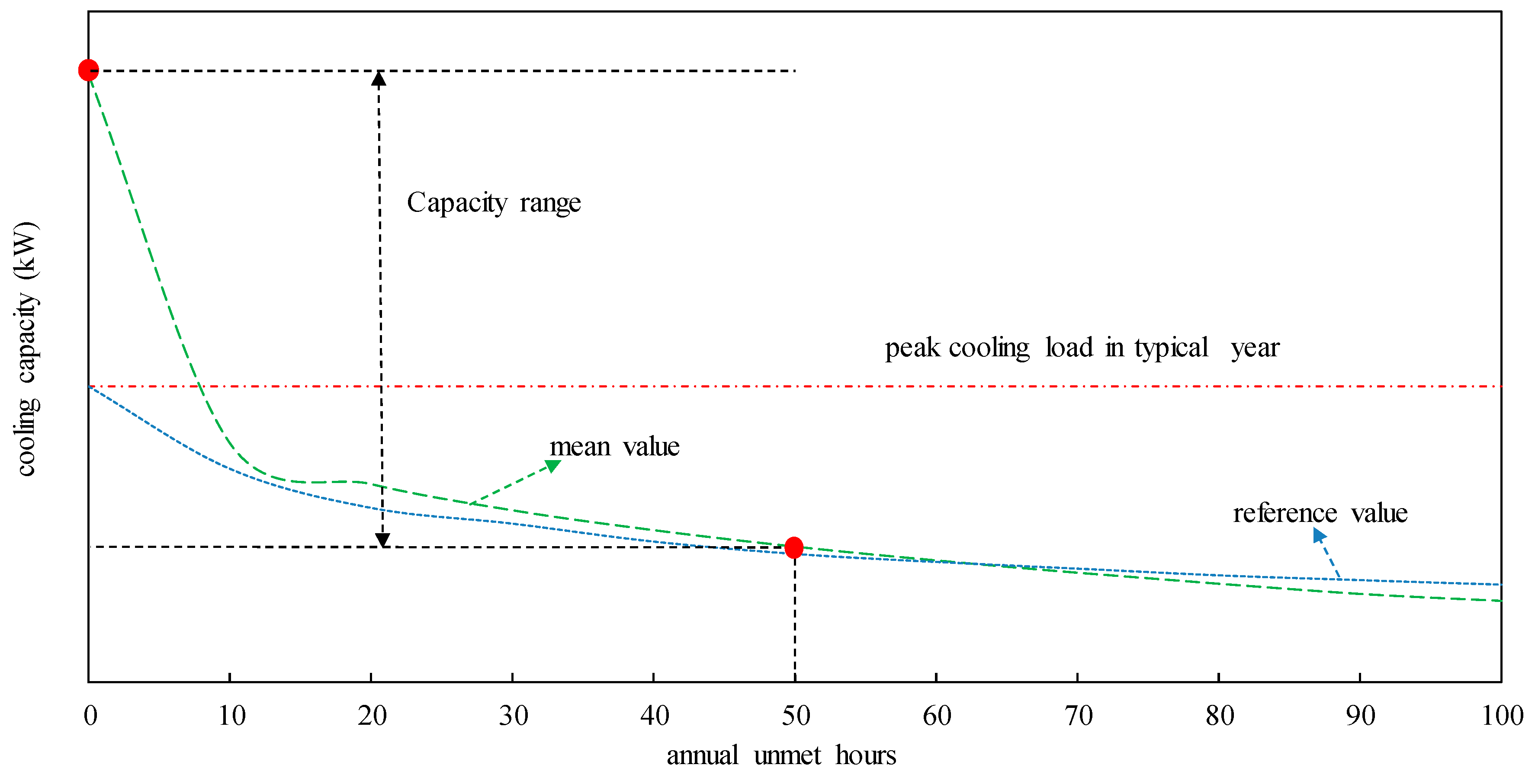

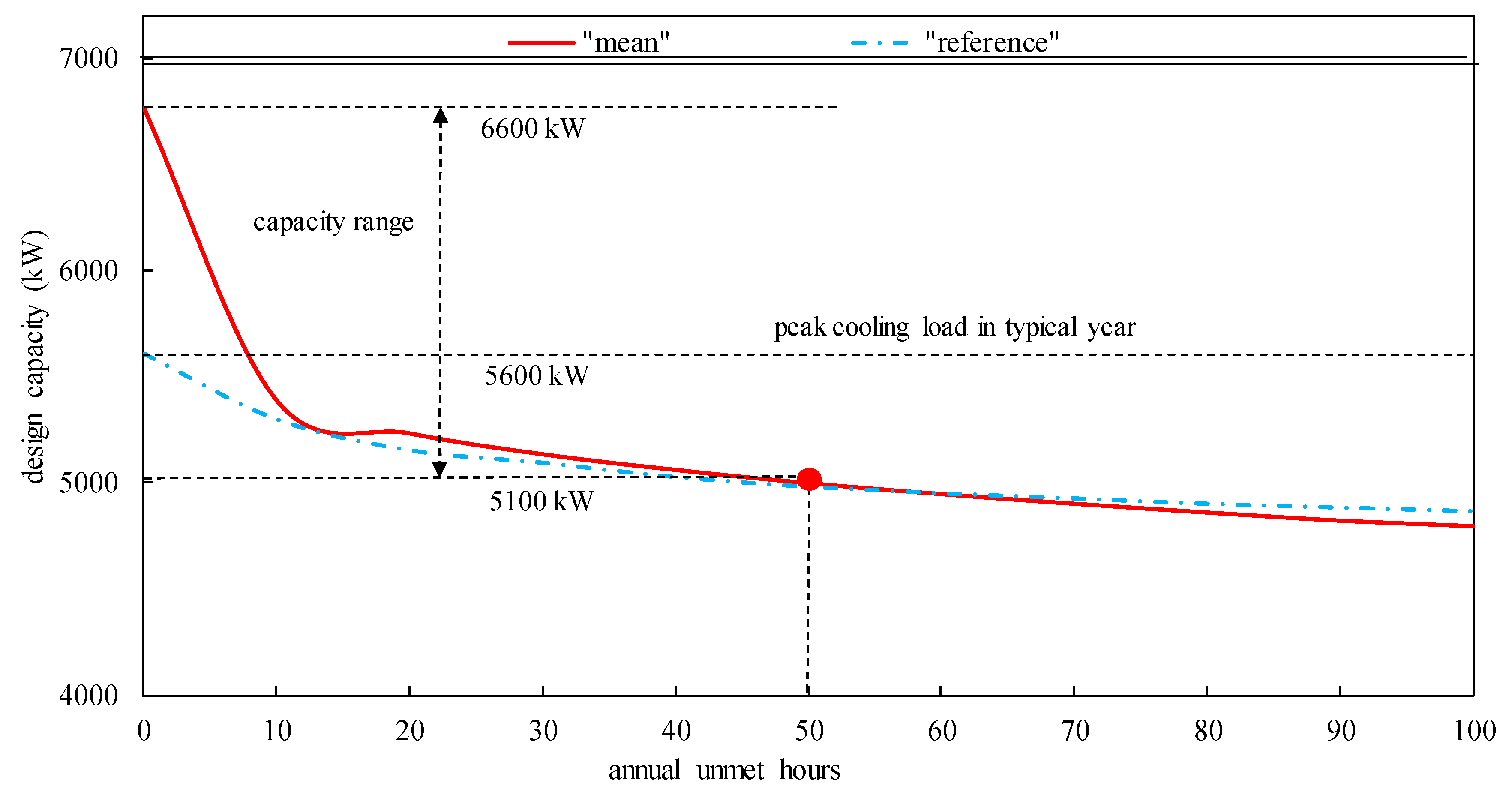

3.2. Quantification of Searching Range of Total Cooling Capacity

3.3. Quantification of Probability Distribution of State for Chiller Plant

3.4. Optimization of the Configuration of Chiller Plant

4. Case Study and Discussion

4.1. Cooling Load Distribution and Searching Range of Design Cooling Capacity

4.2. Probability Distribution of Chiller Plant State

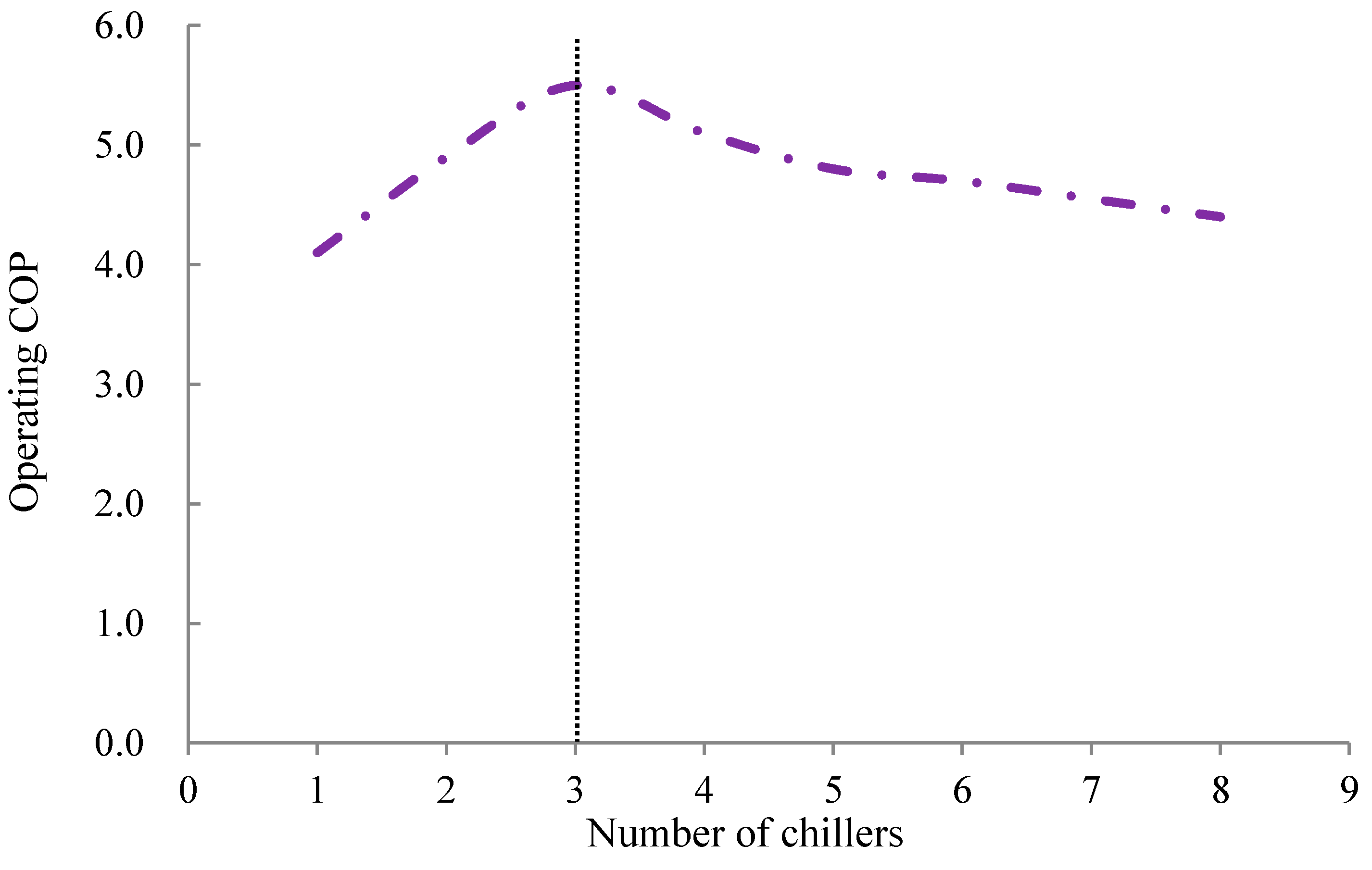

4.3. Tests on Total Cooling Capacity and Number/Size of Chillers

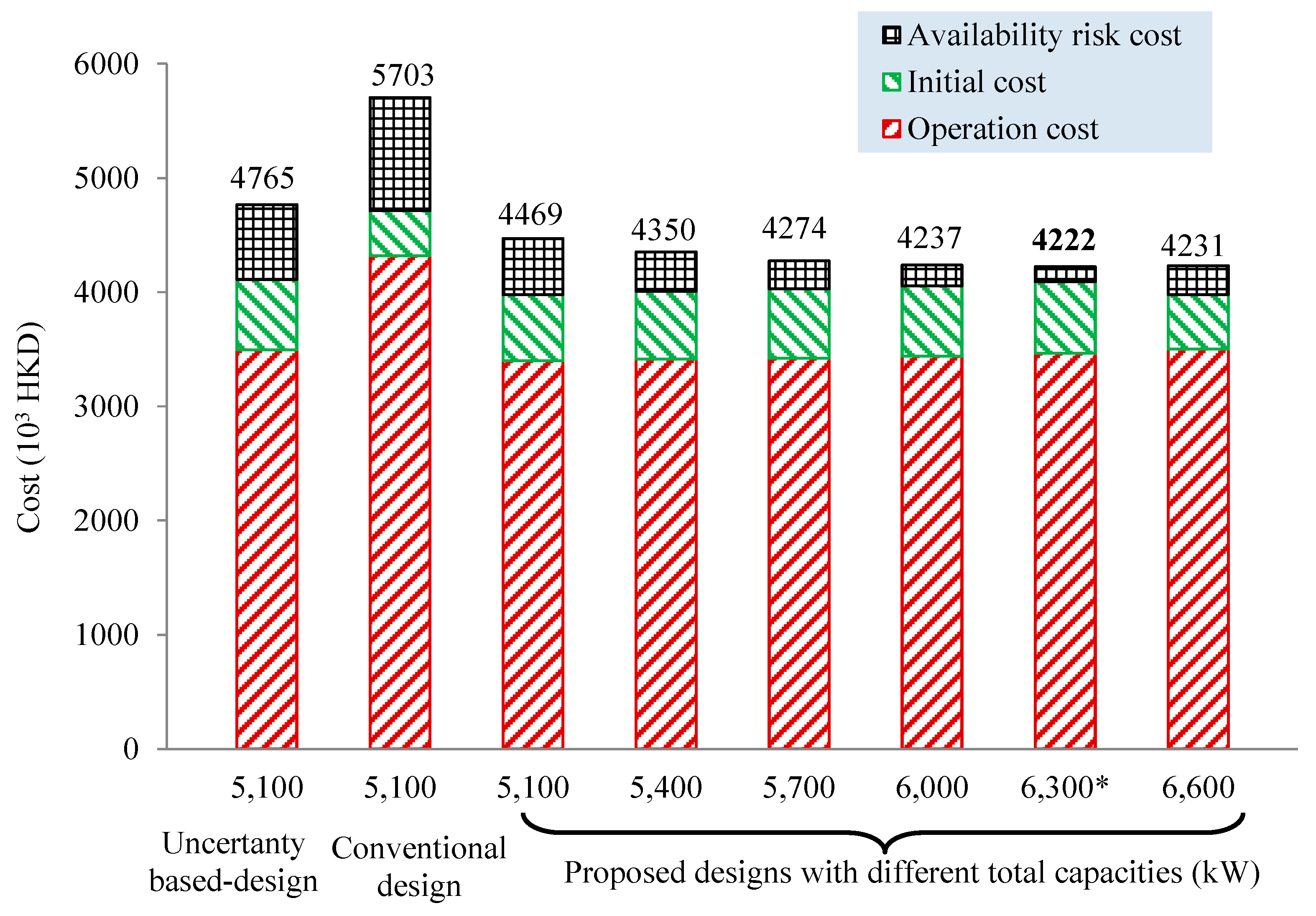

4.4. Comparison among Different Configurations Using Design Methods

5. Conclusions

- The searching range of total cooling capacity of a chiller plant can be determined by the cooling capacities with predefined unmet hours under the cooling load distribution. In the case study, the minimum cooling capacity is 5100 kW and the maximum cooling capacity is 6600 kW.

- Although the chiller plant with one variable-speed chiller might operate at a lower efficiency than that with two variable-speed chillers, the design option with one variable-speed chiller is still more economical when the life-cycle total cost is considered.

- The design option of a chiller plant using the proposed method can operate with a relatively high efficiency, and has a relatively sufficient cooling capacity to supply the cooling under various cooling load scenarios. The lowest total cost can be achieved by considering both design uncertainties and reliabilities for a chiller plant.

- Results show that the life-cycle total cost of optimal and robust design is reduced by 26% and 11.4%, respectively, when compared with those from uncertainty-based and conventional design methods.

Author Contributions

Funding

Conflicts of Interest

References

- EMSD Hong Kong Energy End-Use Data. Available online: https://www.emsd.gov.hk/filemanager/en/content_762/HKEEUD2012.pdf (accessed on 12 April 2019).

- Sun, Y.J.; Wang, S.W.; Xiao, F. In situ performance comparison and evaluation of three chiller sequencing control strategies in a super high-rise building. Energy Build. 2013, 61, 333–343. [Google Scholar] [CrossRef]

- Lee, W.L.; Yik FW, H.; Jones, P. Energy saving by realistic design data for commercial buildings in Hong Kong. Appl. Energy 2001, 70, 59–75. [Google Scholar]

- ASHRAE Handbook—HVAC Systems and Equipment; ASHRAE: Atlanta, GA, USA, 2012.

- Rudoy, W.; Cuba, J.F. Cooling and Heating Load Calculation Manual; ASHRAE: Atlanta, GA, USA, 1979. [Google Scholar]

- EnergyPlus energy simulation software, 2015.

- TRNSYS. TRNSYS 16 Documentation. 2004. Available online: http://sel.me.wisc.edu/trnsys (accessed on 12 April 2019).

- Cheng, Q.; Wang, S.; Yan, C. Robust optimal design of chilled water systems in buildings with quantified uncertainty and reliability for minimized life-cycle cost. Energy Build. 2016, 126, 159–169. [Google Scholar] [CrossRef]

- Cheng, Q.; Wang, S.; Yan, C.; Xiao, F. Probabilistic approach for uncertainty-based optimal design of chiller plants in buildings. Appl. Energy 2017, 185, 1613–1624. [Google Scholar] [CrossRef]

- Domínguez-Muñoz, F.; Cejudo-López, J.M.; Carrillo-Andrés, A. Uncertainty in peak cooling load calculations. Energy Build. 2010, 42, 1010–1018. [Google Scholar] [CrossRef]

- Sun, Y.; Gu, L.; Wu, C.F. Exploring HVAC system sizing under uncertainty. Energy Build. 2014, 81, 243–252. [Google Scholar] [CrossRef]

- Yik, F.W.H.; Lee, W.L.; Burnett, J. Chiller plant sizing by cooling load simulation as a means to avoid oversized plant. HKIE Trans. 1999, 6, 19–25. [Google Scholar] [CrossRef]

- Djunaedy, E.; Van Den Wymelenberg, K.; Acker, B.; Thimmana, H. Oversizing of HVAC system: Signatures and penalties. Energy Build. 2011, 43, 468–475. [Google Scholar] [CrossRef]

- Woradechjumroen, D.; Yu, Y.; Li, H.; Yu, D.; Yang, H. Analysis of HVAC system oversizing in commercial buildings through field measurements. Energy Build. 2014, 69, 131–143. [Google Scholar]

- Braun, J.E.; Klein, S.A.; Mitcelj, W. Applications of optimal control to chilled water systems without storage. ASHRAE Trans. 1989, 95, 663–675. [Google Scholar]

- Gidwani, B.N. Optimization of chilled water systems. Energy Eng. 1987, 84, 83–91. [Google Scholar]

- Kaya, A. Improving efficiency in existing chillers with optimization technology. ASHRAE J. 1991, 33, 30–38. [Google Scholar]

- Chang, Y.C.; Lin, J.K.; Chuang, M.H. Optimal chiller loading by genetic algorithm for reducing energy consumption. Energy Build. 2005, 37, 147–155. [Google Scholar] [CrossRef]

- Yu, F.W.; Chan, K.T. Strategy for designing more energy efficient chiller plants serving air-conditioned buildings. Build. Environ. 2007, 42, 3737–3746. [Google Scholar] [CrossRef]

- Hartman, T. All-variable speed centrifugal chiller plants. ASHRAE J. 2001, 43, 43–53. [Google Scholar]

- Celuch, J. Hybrid chilled water plant. ASHRAE J. 2001, 43, 34–35. [Google Scholar]

- Ashouri, A.; Petrini, F.; Bornatico, R.; Ben, M.J. Sensitivity analysis for robust design of building energy systems. Energy 2014, 76, 264–275. [Google Scholar] [CrossRef]

- Van Gelder, L.; Janssen, H.; Roels, S. Effective and robust measures for energy efficient dwellings: Probabilistic determination. Build. Simul. 2013, 2013, 3465–3472. [Google Scholar]

- Fiksel, J. Designing resilient, sustainable systems. Environ. Sci. Technol. 2003, 37, 5330–5339. [Google Scholar] [CrossRef]

- Morari, M. Flexibility and resiliency of process systems. Comput. Chem. Eng. 1983, 7, 423–437. [Google Scholar] [CrossRef]

- Pettersen, T.D. Variation of energy consumption in dwellings due to climate, building and inhabitants. Energy Build. 1994, 21, 209–218. [Google Scholar] [CrossRef]

- Li, C.Z.; Shi, Y.M.; Huang, X.H. Sensitivity analysis of energy demands on performance of CCHP system. Energy Convers. Manage. 2008, 49, 3491–3497. [Google Scholar] [CrossRef]

- Smith, A.; Luck, R.; Mago, P.J. Analysis of a combined cooling, heating, and power system model under different operating strategies with input and model data uncertainty. Energy Build. 2010, 42, 2231–2240. [Google Scholar] [CrossRef]

- Menassa, C.C. Evaluating sustainable retrofits in existing buildings under uncertainty. Energy Build. 2011, 43, 3576–3583. [Google Scholar] [CrossRef]

- Stapelberg, R.F. Handbook of Reliability, Availability, Maintainability and Safety in Engineering Design; Springer: London, UK, 2009. [Google Scholar]

- Vanderhaegen, F.A. Non-probabilistic prospective and retrospective human reliability analysis method—Application to railway system. Reliab. Eng. Syst. Safe. 2001, 71, 1–13. [Google Scholar] [CrossRef]

- Peruzzi, L.; Salata, F.; De Lieto Vollaro, A.; De Lieto Vollaro, R. The reliability of technological systems with high energy efficiency in residential buildings. Energy Build. 2014, 68, 19–24. [Google Scholar] [CrossRef]

- Au-Yong, C.P.; Ali, A.S.; Ahmad, F. Improving occupants’ satisfaction with effective maintenance management of HVAC system in office buildings. Automat. Constr. 2014, 43, 31–37. [Google Scholar] [CrossRef][Green Version]

- Kwak, R.Y.; Takakusagi, A.; Sohn, J.Y.; Fujii, S.; Park, B.Y. Development of an optimal preventive maintenance model based on the reliability assessment for air-conditioning facilities in office buildings. Build. Environ. 2004, 39, 1141–1156. [Google Scholar] [CrossRef]

- Cheng, Q.; Wang, S.; Yan, C. Sequential Monte Carlo Simulation for Robust Optimal Design of Cooling Water System with Quantified Uncertainty and Reliability. Energy 2017, 118, 489–501. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M.; Esen, M. Technoeconomic appraisal of a ground source heat pump system for a heating season in eastern Turkey. Energy Convers. Manage. 2006, 47, 1281–1297. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M.; Esen, M. A techno-economic comparison of ground-coupled and air-coupled heat pump system for space cooling. Build. Environ. 2007, 42, 1955–1965. [Google Scholar] [CrossRef]

- Esen, M.; Yuksel, T. Experimental evaluation of using various renewable energy sources for heating a greenhouse. Energy Build. 2013, 65, 340–351. [Google Scholar] [CrossRef]

- Stanford, H.W., III. HVAC Water Chillers and Cooling Towers: Fundamentals, Application, and Operation; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Lisnianski, A.; Levitin, G. Multi-State System Reliability: Assessment, Optimization and Applications; World Scientific: Singapore, 2003. [Google Scholar]

- Lisnianski, A. Extended block diagram method for a multi-state system reliability assessment. Reliab. Eng. Syst. Safe. 2007, 92, 1601–1607. [Google Scholar] [CrossRef]

- Harvey, D. A Handbook on Low-Energy Buildings and District-Energy Systems: Fundamentals, Techniques and Examples; Routledge: Abingdon, UK, 2012. [Google Scholar]

- Blanchard, A.; Roy, B.N. Savannah River Site Generic Data Base Development; WSRC-TR-93-262, REV.1; Westinghouse Safety Management: Aiken, SC, USA, 1998. [Google Scholar]

- Guthrie, K.M. Capital cost estimating. Chem. Eng. 1969, 3, 114–142. [Google Scholar]

- Biegler, L.T.; Grossmann, I.E.; Westerberg, A.W. Systematic Methods for Chemical Process Design; Prentice Hall PTR: Upper Saddle River, NJ, USA, 1997. [Google Scholar]

- Taal, M.; Bulatov, I.; Klemeš, J.; StehlíK, P. Cost estimation and energy price forecasts for economic evaluation of retrofit projects. Appl. Therm. Eng. 2003, 23, 1819–1835. [Google Scholar] [CrossRef]

| Parameters | Distributions |

|---|---|

| Outdoor temperature (°C) (T) | T × [1 + N(0, 1)] |

| Relative Humidity (%) (RH) | RH × [1 + N(0, 1.35)] |

| Number of Occupants (NO) | NO × T(0.3, 1.2, 0.9) |

| Fresh air rate (m3/person) | U(27, 33) |

| Light and equipment load (kW) | Design load × U(0.9, 1.1) |

| State | Variable-Speed Chillers | |

|---|---|---|

| 1 | 2 | |

| 0 | 0.9412 | 0.8828 |

| 1 | 0.0588 | 0.1103 |

| 2 | - | 0.0069 |

| State | Number of Constant-Speed Chillers | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| 0 | 0.9524 | 0.9050 | 0. 8578 | 0.8109 | 0.7644 |

| 1 | 0.0476 | 0.0905 | 0.1278 | 0.1622 | 0.1911 |

| 2 | - | 0.0045 | 0.0129 | 0.0243 | 0.0382 |

| 3 | - | - | 0.0006 | 0.0024 | 0.0057 |

| 4 | - | - | - | 0.0001 | 0.0006 |

| 5 | - | - | - | - | 0 |

| Probability Distribution of Chiller Plant | State of Variable-Speed Chillers | |||

|---|---|---|---|---|

| 0 | 1 | 2 | ||

| State of constant-speed chillers | 0 | 0.67481 | 0.08431 | 0.00527 |

| 1 | 0.16870 | 0.02108 | 0.00132 | |

| 2 | 0.03372 | 0.00421 | 0.00026 | |

| 3 | 0.00503 | 0.00063 | 0.00004 | |

| 4 | 0.00053 | 0.00007 | 0 | |

| 5 | 0 | 0 | 0 | |

| Chiller Number | Chiller Plant Option (Size (kW) × Number) | Operation Cost (103 HKD) | Capital Cost (103 HKD) |

|---|---|---|---|

| 2 | 3200 × 1CSD + 2800 × 1VSD | 3502 | 373 |

| 3 | 2100 × 2CSD + 1800 × 1VSD | 3478 | 461 |

| 4 | 1550 × 3CSD + 1350 × 1VSD | 3461 | 542 |

| 4 | 1600 × 2CSD + 1400 × 2VSD | 3446 | 580 |

| 5 | 1250 × 4CSD + 1000 × 1VSD | 3436 | 616 |

| 5 | 1300 × 3CSD + 1050 × 2VSD | 3403 | 653 |

| 6 | 1050 × 5CSD + 750 × 1VSD | 3435 | 685 |

| 6 | 1050 × 4CSD + 900 × 2VSD | 3392 | 723 |

| Penalty Ratio (HKD/kW) | 1 | 10 | 100 | |||

|---|---|---|---|---|---|---|

| Option (Size(kW) × Number) | RC | TC | RC | TC | RC | TC |

| 3200 × 1CSD + 2800 × 1VSD | 102 | 3978 | 1021 | 4897 | 10,210 | 14,085 |

| 2100 × 2CSD + 1800 × 1VSD | 39 | 3977 | 387 | 4326 | 3871 | 7810 |

| 1550 × 3CSD + 1350 × 1VSD | 25 | 4140 | 247 | 4362 | 2468 | 6583 |

| 1600 × 2CSD + 1400 × 2VSD | 25 | 4053 | 254 | 4282 | 2542 | 6570 |

| 1250 × 4CSD + 1000 × 1VSD | 19 | 4070 | 185 | 4237 | 1851 | 5903 |

| 1300 × 3CSD + 1050 × 2VSD | 28 | 4084 | 275 | 4331 | 2755 | 6811 |

| 1050 × 5CSD + 750 × 1VSD | 15 | 4135 | 145 | 4265 | 1451 | 5571 |

| 1050 × 4CSD + 900 × 2VSD | 22 | 4165 | 216 | 4331 | 2161 | 6276 |

| Total Cooling Capacity (kW) | Best Option (Size (kW) × Number) | Availability Risk Cost (103 HKD) | Operation Cost (103 HKD) | Total Cost (103 HKD) |

|---|---|---|---|---|

| 5100 | 1050 × 4CSD + 900 × 1VSD | 490 | 3397 | 4469 |

| 5400 | 1100 × 4CSD + 1000 × 1VSD | 343 | 3412 | 4350 |

| 5700 | 1150 × 4CSD + 1100 × 1VSD | 246 | 3421 | 4274 |

| 6000 | 1250 × 4CSD + 1100 × 1VSD | 185 | 3436 | 4237 |

| 6300 | 1300 × 4CSD + 1100 × 1VSD | 131 | 3463 | 4222 |

| 6600 | 2300 × 2CSD + 2000 × 1VSD | 253 | 3501 | 4231 |

| Total Cooling Capacity (kW) | Best Configuration (Size (kW) × Number) | Availability Risk Cost (103 HKD) | Operation Cost (103 HKD) | Total Cost (103 HKD) | |

|---|---|---|---|---|---|

| Robust optimal design | 6300 | 1300 × 4CSD + 1100 × 1VSD | 131 | 3463 | 4222 |

| Uncertainty-based design | 5100 | 1400 × 3CSD + 900 × 1VSD | 656 | 3495 | 4765 |

| Conventional design | 5100 | 1700 × 3CSD | 992 | 4318 | 5703 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, C.; Cheng, Q.; Cai, H. Life-Cycle Optimization of a Chiller Plant with Quantified Analysis of Uncertainty and Reliability in Commercial Buildings. Appl. Sci. 2019, 9, 1548. https://doi.org/10.3390/app9081548

Yan C, Cheng Q, Cai H. Life-Cycle Optimization of a Chiller Plant with Quantified Analysis of Uncertainty and Reliability in Commercial Buildings. Applied Sciences. 2019; 9(8):1548. https://doi.org/10.3390/app9081548

Chicago/Turabian StyleYan, Chengchu, Qi Cheng, and Hao Cai. 2019. "Life-Cycle Optimization of a Chiller Plant with Quantified Analysis of Uncertainty and Reliability in Commercial Buildings" Applied Sciences 9, no. 8: 1548. https://doi.org/10.3390/app9081548

APA StyleYan, C., Cheng, Q., & Cai, H. (2019). Life-Cycle Optimization of a Chiller Plant with Quantified Analysis of Uncertainty and Reliability in Commercial Buildings. Applied Sciences, 9(8), 1548. https://doi.org/10.3390/app9081548