Guided Wave-Based Monitoring of Evolution of Fatigue Damage in Glass Fiber/Epoxy Composites

Abstract

Featured Application

Abstract

1. Introduction

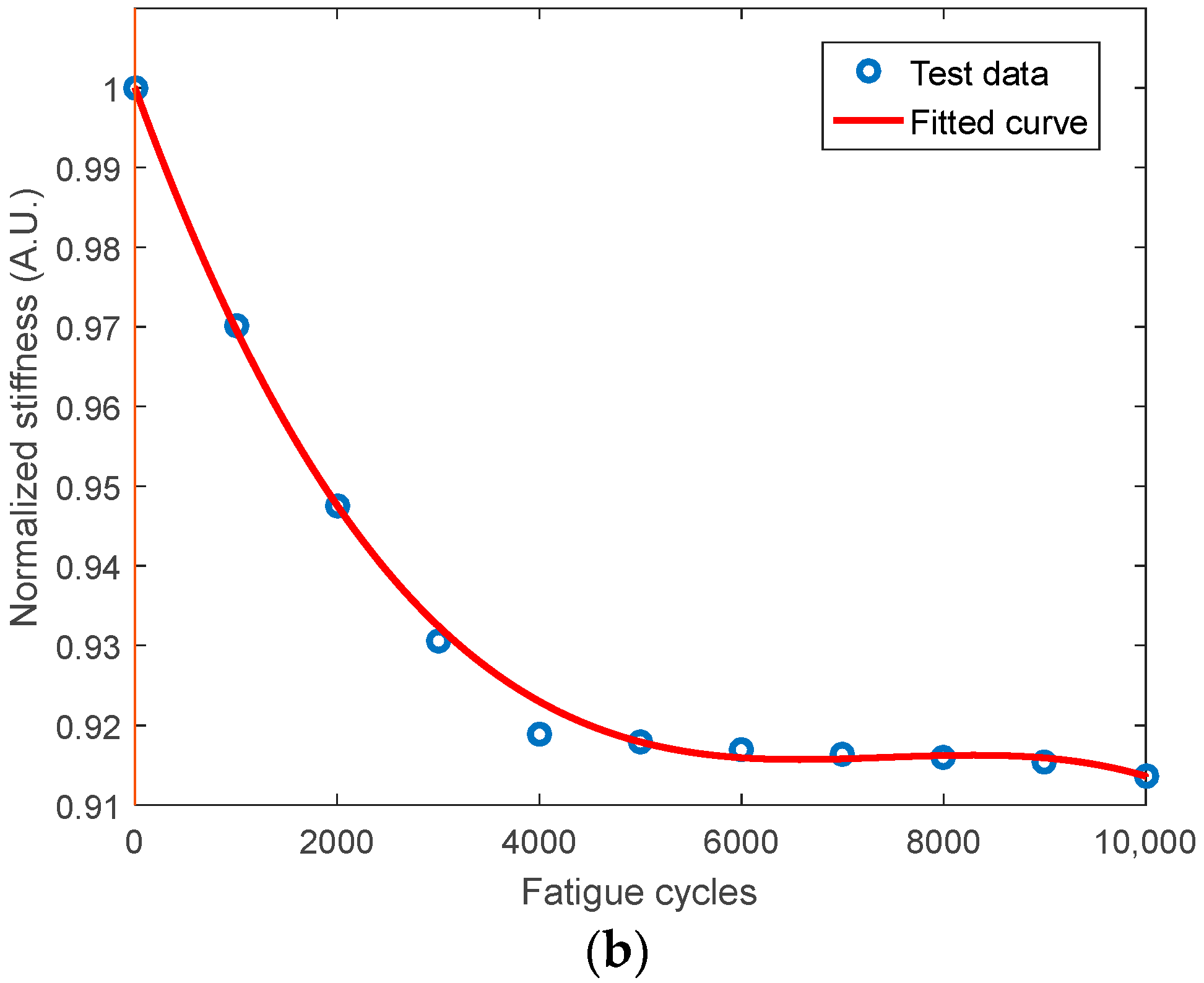

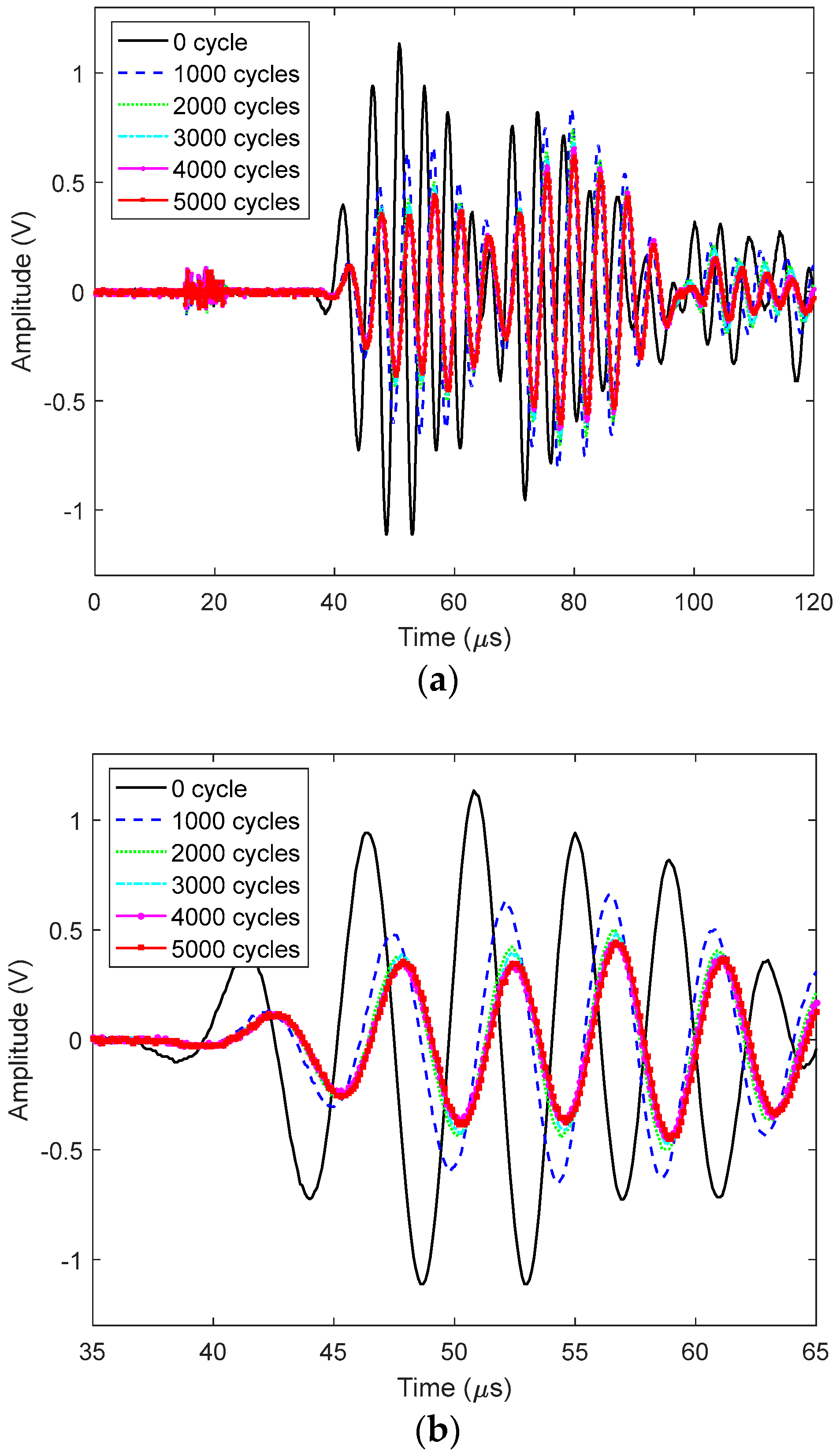

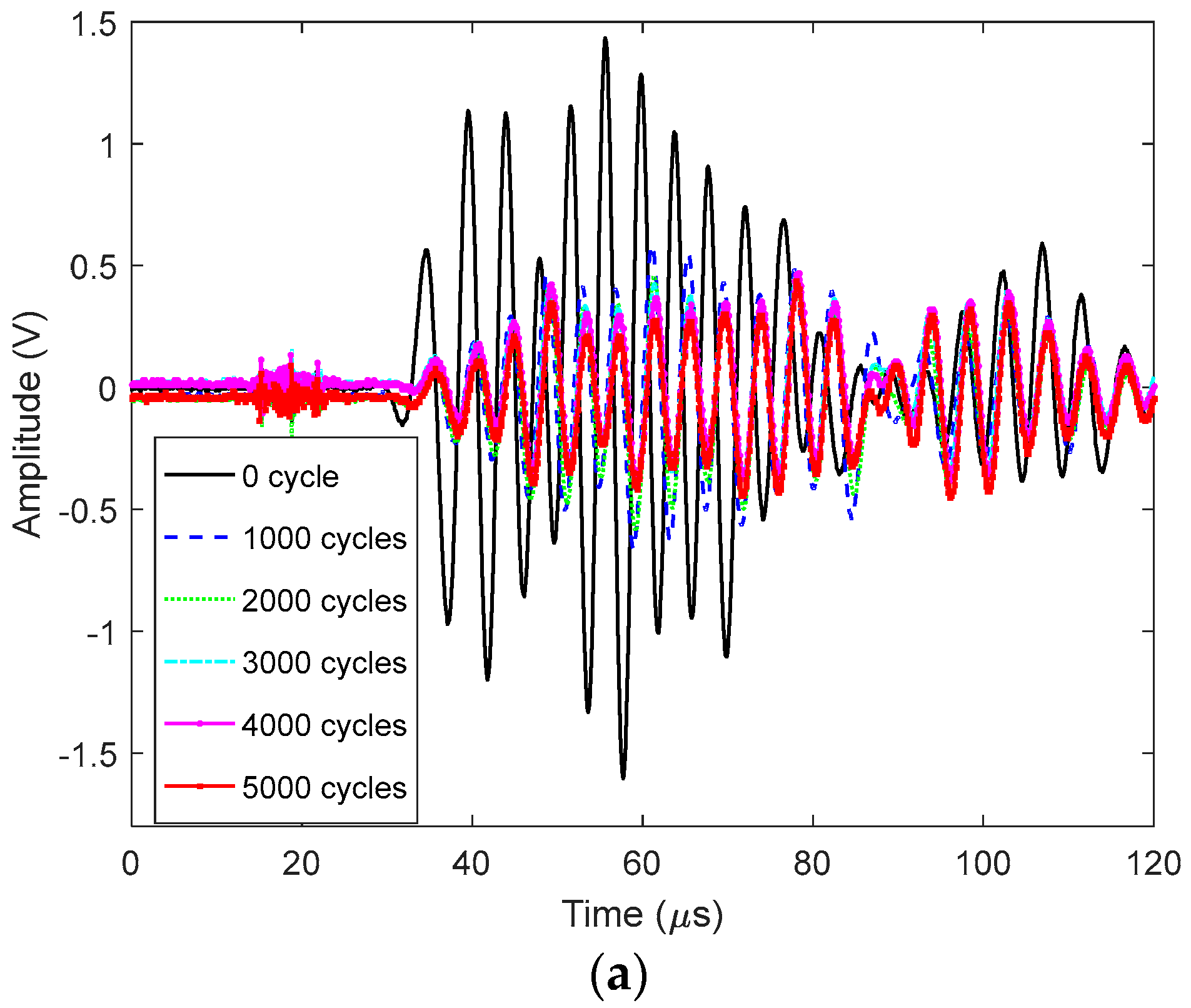

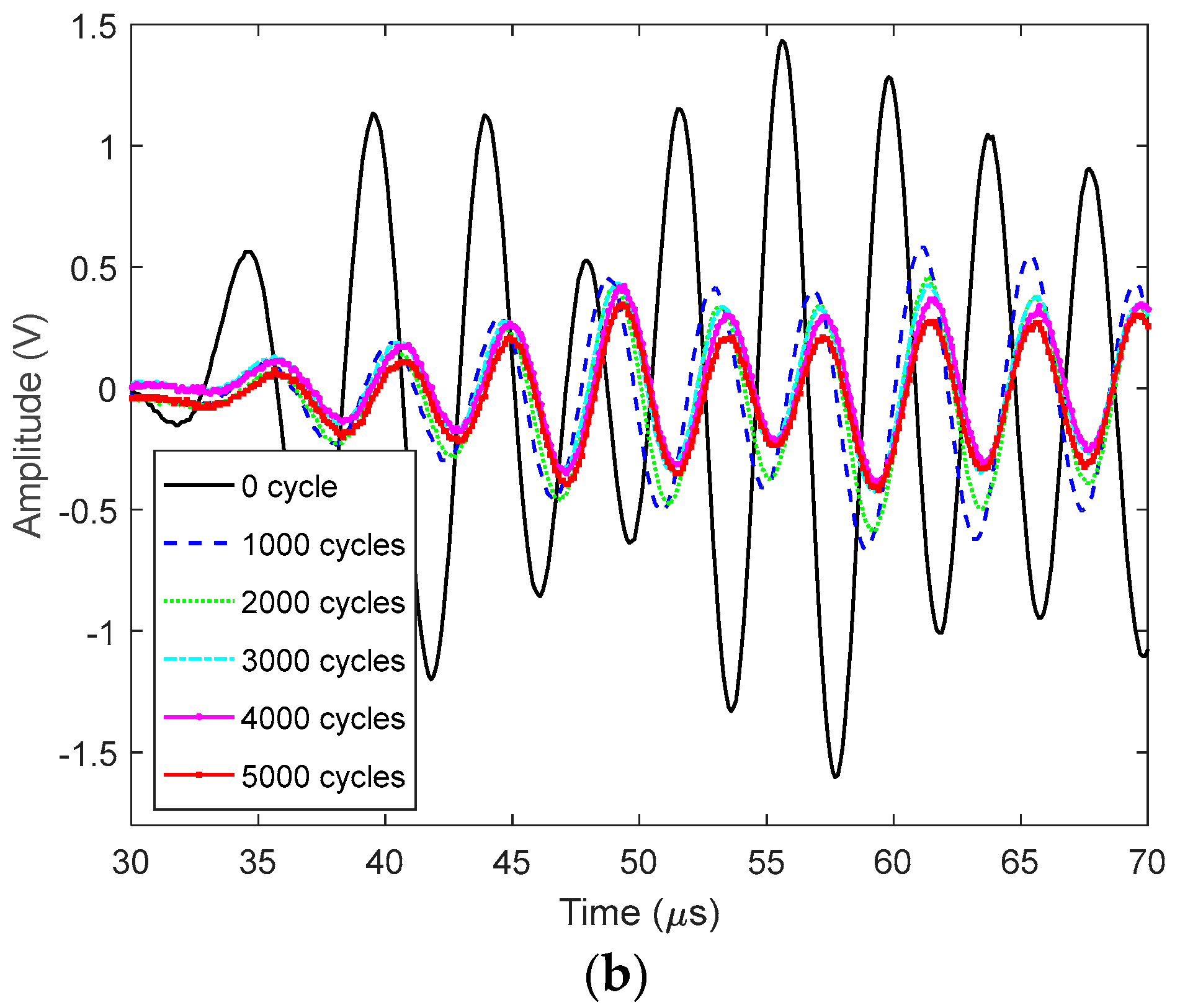

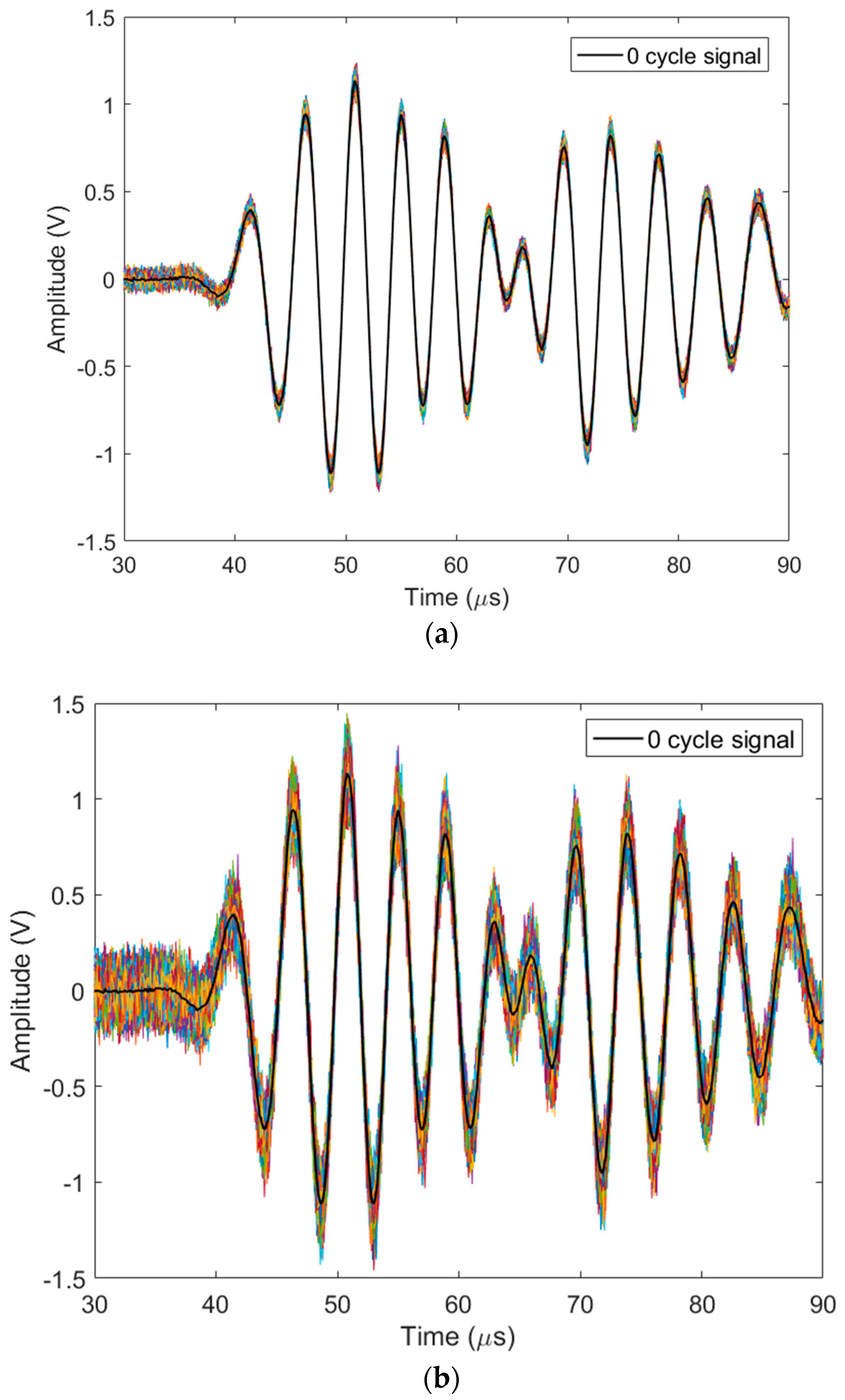

2. Experimental Test

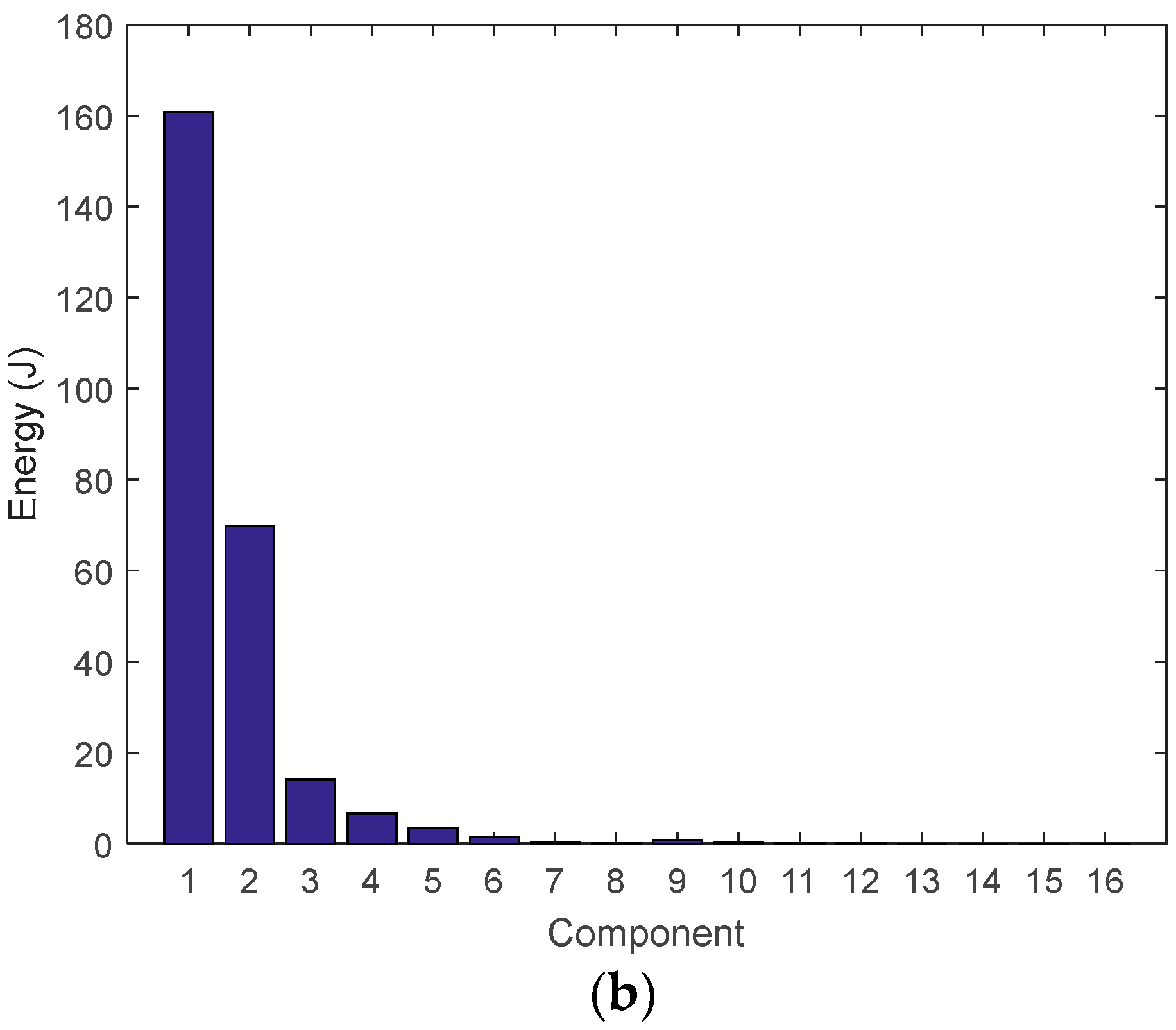

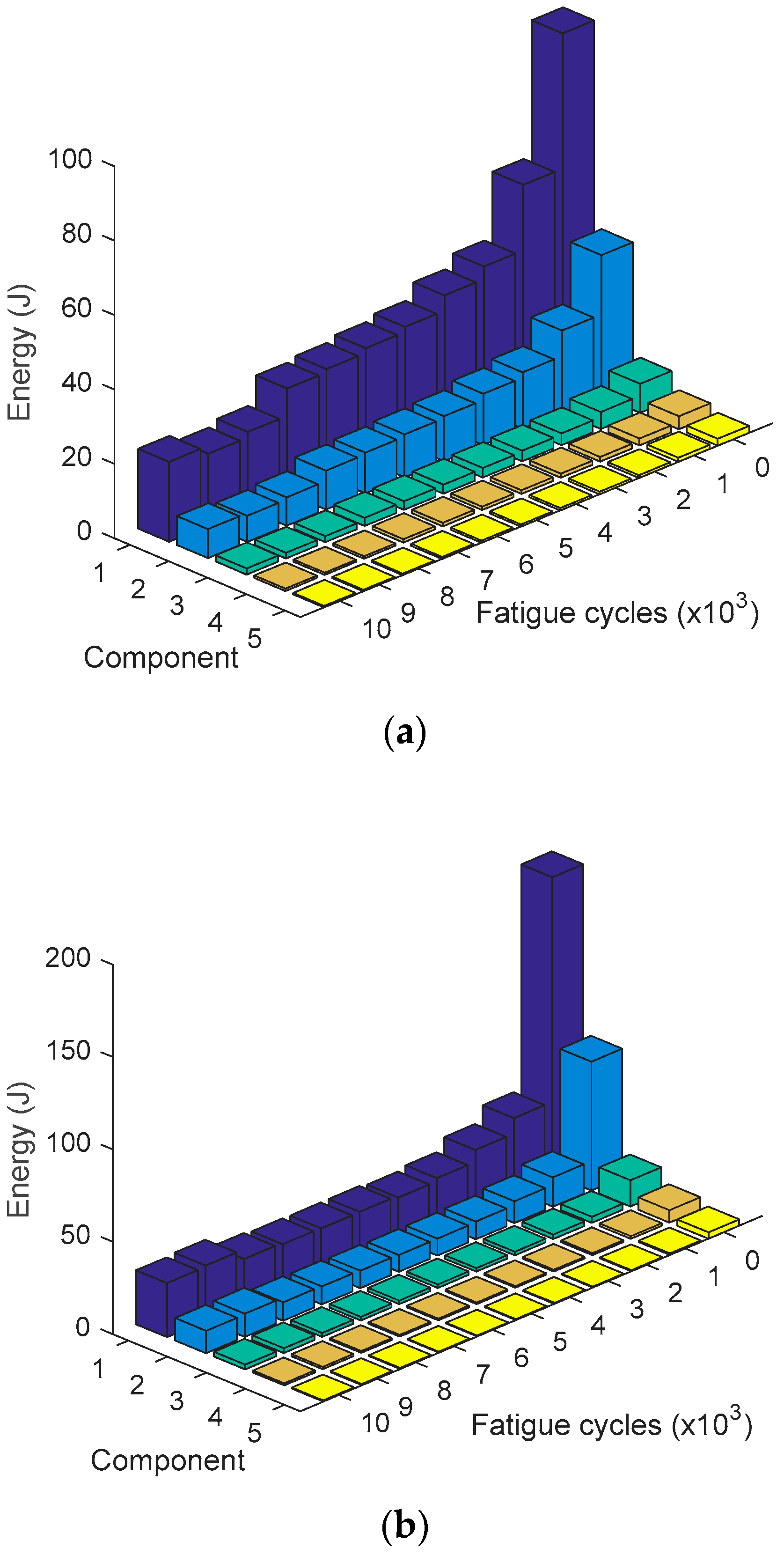

3. Signal Processing and Feature Extraction

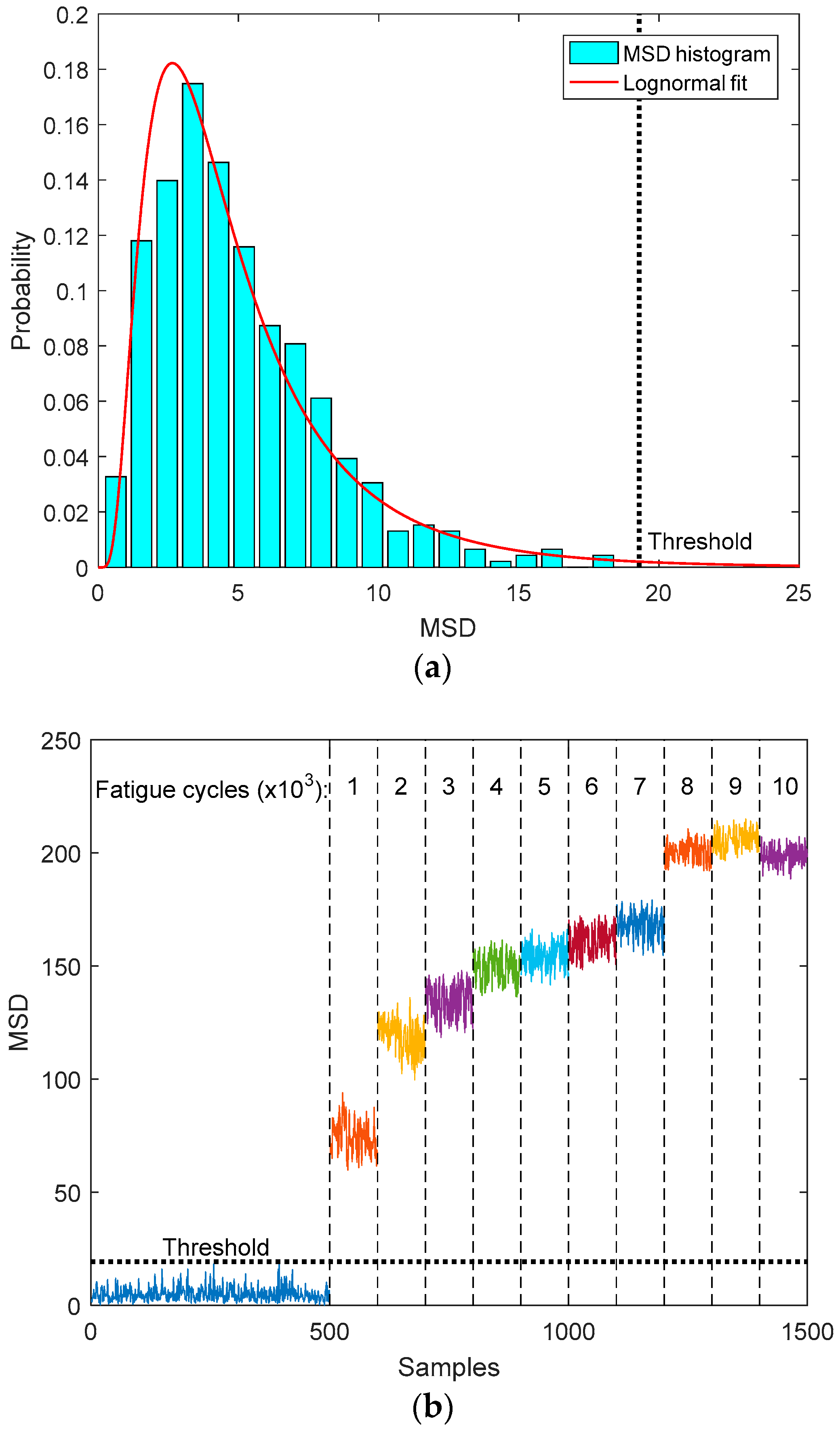

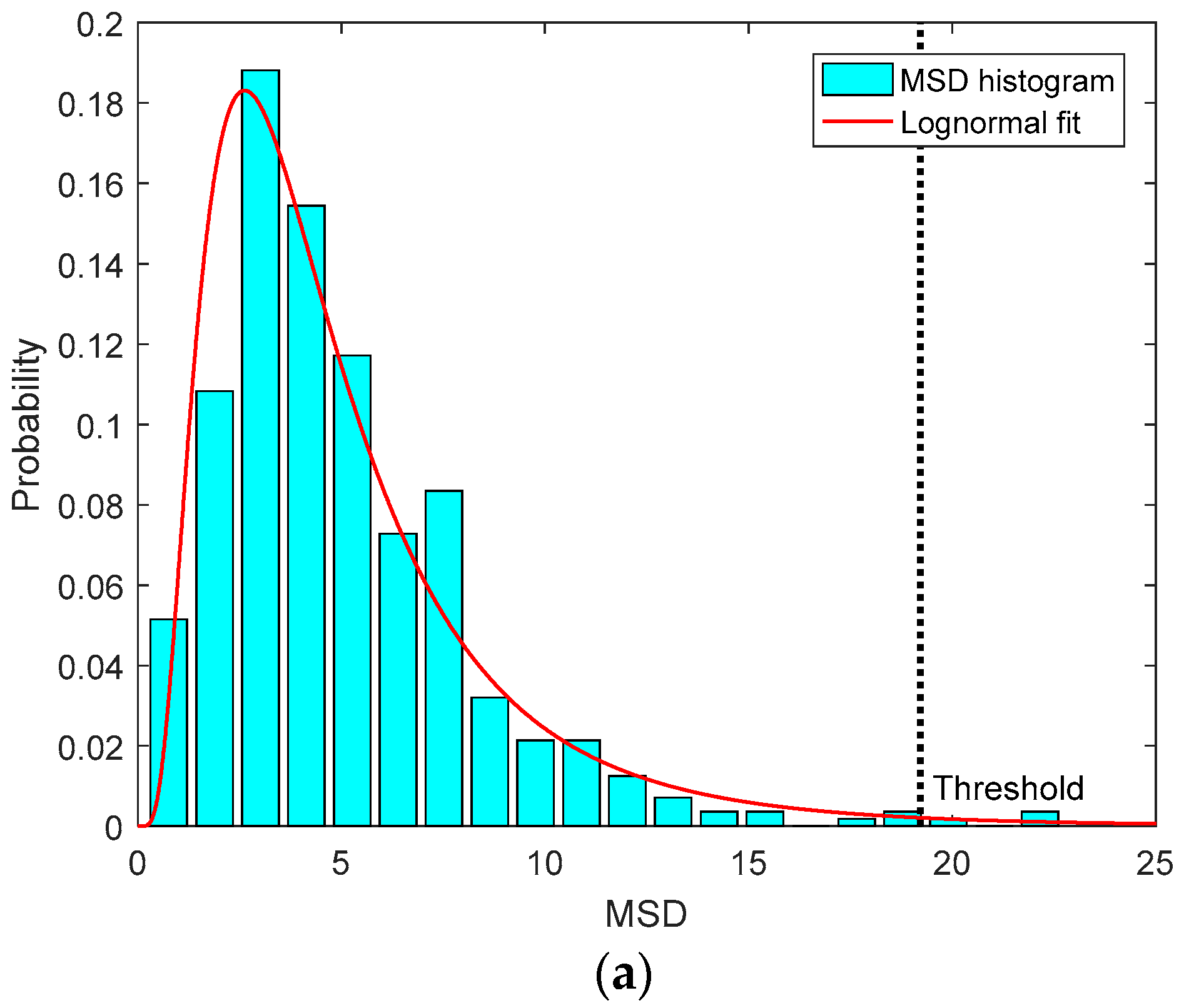

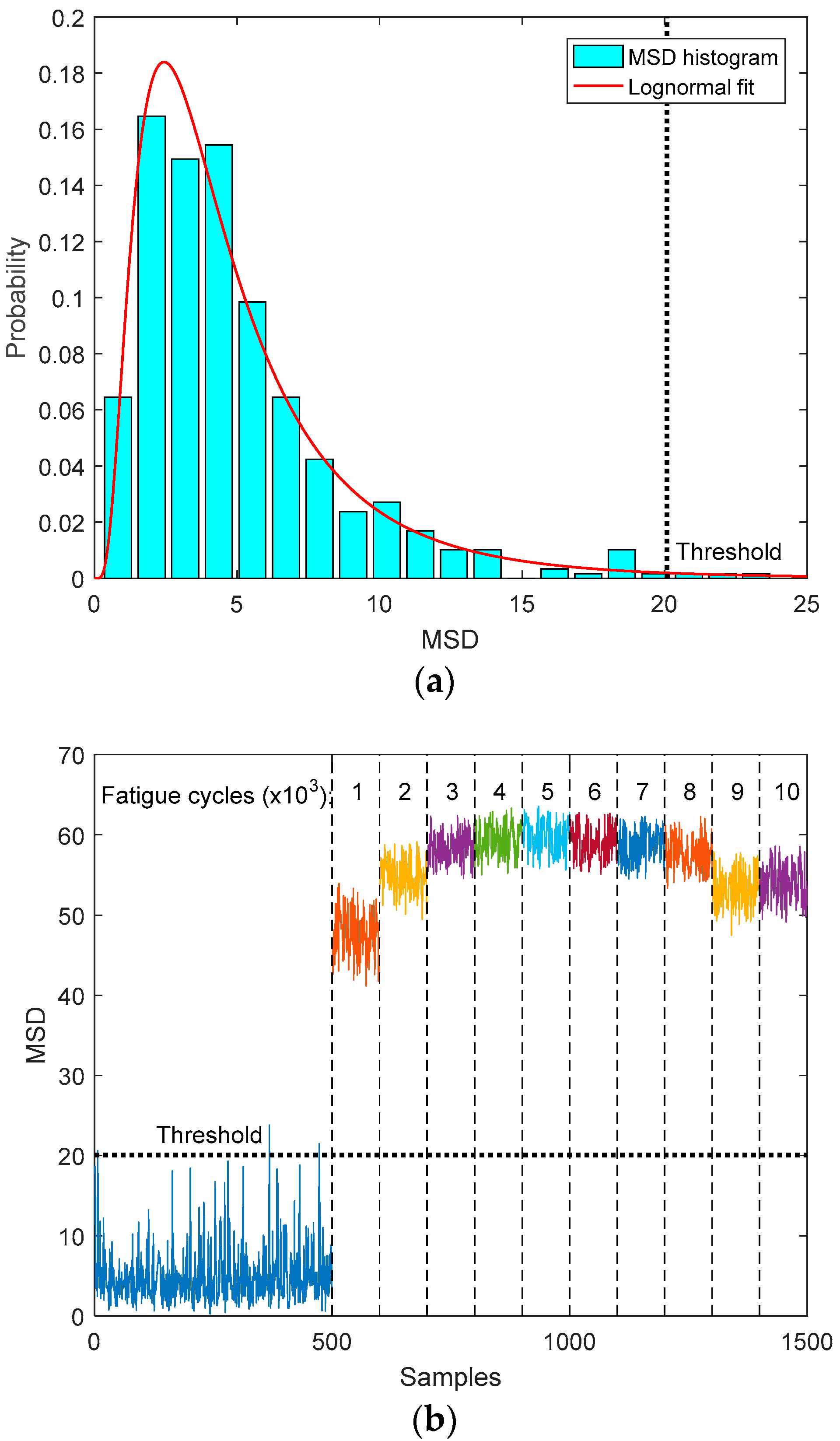

4. Statistical Multivariate Outlier Analysis

5. Experimental Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Talreja, R. Multi-scale modelling in damage mechanics of composite materials. J. Mater. Sci. 2006, 41, 6800–6812. [Google Scholar] [CrossRef]

- Reifsnider, K.L. Fatigue of Composite Materials; Elsevier: New York, NY, USA, 2012. [Google Scholar]

- Reis, P.; Ferreira, J.; Richardson, M. Fatigue damage characterization by NDT in polypropylene/glass fibre composites. Appl. Compos. Mater. 2011, 18, 409–419. [Google Scholar] [CrossRef]

- Shin, C.S.; Chiang, C.C. Fatigue damage monitoring in polymetric composites using multiple fiber bragg gratings. Int. J. Fatigue 2006, 28, 1315–1321. [Google Scholar] [CrossRef]

- Gao, L.; Thostenson, E.T.; Zhang, Z.G.; Chou, T.W. Sensing of damage mechanisms in fiber-reinforced composites under cyclic loading using carbon nanotubes. Adv. Sci. 2009, 19, 123–130. [Google Scholar] [CrossRef]

- De Baere, I.; van Paepegem, W.; Degrieck, J. Electrical resistance measurement for in situ monitoring of fatigue of carbon fabric composites. Int. J. Fatigue 2010, 32, 197–207. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Townsend, C.; Shah Khan, M.Z. Non-destructive detection of fatigue damage in thick composites by pulse-echo ultrasonics. Compos. Sci. Technol. 2000, 60, 23–32. [Google Scholar] [CrossRef]

- Toubal, L.; Karama, M.; Lorrain, B. Damage evolution and infrared thermography in woven composite laminates under fatigue loading. Int. J. Fatigue 2006, 28, 1867–1872. [Google Scholar] [CrossRef]

- Bourchak, M.; Farrow, I.R.; Bond, I.P.; Rowland, C.W.; Menan, F. Acoustic emission energy as a fatigue damage parameter for CFRP composites. Int. J. Fatigue 2007, 29, 457–470. [Google Scholar] [CrossRef]

- Jespersen, K.M.; Zangenberg, J.; Lowe, T.; Withers, P.J.; Mikkelsen, L.P. Fatigue damage assessment of uni-directional non-crimp fabric reinforced polyester composite using X-ray computed tomography. Compos. Sci. Technol. 2016, 136, 94–103. [Google Scholar] [CrossRef]

- Ling, Y.; Mahadevan, S. Integration of structural health monitoring and fatigue damage prognosis. Mech. Syst. Signal Process. 2012, 28, 89–104. [Google Scholar] [CrossRef]

- Staszewski, W.J.; Mahzan, S.; Traynor, R. Health monitoring of aerospace composite structures—Active and passive approach. Compos. Sci. Technol. 2009, 69, 1678–1685. [Google Scholar] [CrossRef]

- Diamanti, K.; Soutis, C. Structural health monitoring techniques for aircraft composite structures. Prog. Aerosp. Sci. 2010, 46, 342–352. [Google Scholar] [CrossRef]

- Kinet, D.; Megret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber bragg grating sensors toward structural health monitoring in composite materials: Challenges and solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef] [PubMed]

- Giurgiutiu, V.; Santoni-Bottai, G. Structural health monitoring of composite structures with piezoelectric-wafer active sensors. AIAA J. 2011, 49, 565–581. [Google Scholar] [CrossRef]

- Bosse, S.; Lechleiter, A. A hybrid approach for structural monitoring with self-organizing multi-agent systems and inverse numerical methods in material-embedded sensor networks. Mechatronics 2016, 34, 12–37. [Google Scholar] [CrossRef]

- Neuschwander, K.; Moll, J.; Memmolo, V.; Schmit, M.; Bucker, M. Simultaneous load and structural monitoring of a carbon fiber rudder stock: Experimental results from a quasi-static tensile test. J. Intell. Mater. Syst. Struct. 2019, 30, 272–282. [Google Scholar] [CrossRef]

- Lemistre, M.; Balageas, D. Structural health monitoring system based on diffracted Lamb waves analysis by multiresolution processing. Smart Mater. Struct. 2001, 10, 504–511. [Google Scholar] [CrossRef]

- Seth, S.K.; Spearing, S.M.; Constantinos, S. Damage detection in composite materials using Lamb wave methods. Smart Mater. Struct. 2002, 11, 269–278. [Google Scholar]

- Basri, R.; Chiu, W.K. Numerical analysis on the interaction of guided lamb waves with a local elastic stiffness reduction in quasi-isotropic composite plate structures. Compos. Struct. 2004, 66, 87–99. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L.; Lu, Y. Guided lamb waves for identification of damage in composite structures: A review. J. Sound Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Ng, C.T.; Veidt, M. A lamb-wave-based technique for damage detection in composite laminates. Smart Mater. Struct. 2009, 18, 074006. [Google Scholar] [CrossRef]

- Polimeno, U.; Meo, M. Detecting barely visible impact damage on aircraft composite structures. Compos. Struct. 2009, 91, 398–402. [Google Scholar] [CrossRef]

- Yan, G.; Zhou, L. Damage detection for composite structure using statistical outlier analysis with temperature effect. Trans. Nanjing Univ. Aero. Astro. 2011, 28, 231–239. [Google Scholar]

- Watkins, R.; Jha, R. A modified time reversal method for Lamb wave based diagnostics of composite structures. Mech. Syst. Signal Process. 2012, 31, 345–354. [Google Scholar] [CrossRef]

- Rogge, M.D.; Leckey, C.A.C. Characterization of impact damage in composite laminates using guided wavefield imaging and local wavenumber domain analysis. Ultrasonics 2013, 53, 1217–1226. [Google Scholar] [CrossRef]

- Capriotti, M.; Kim, H.E.; Lanza di Scalea, F.; Kim, H. Non-destructive inspection of impact damage in composite aircraft panels by ultrasonic guided waves and statistical processing. Materials 2017, 10, 616. [Google Scholar] [CrossRef]

- Seale, M.D.; Madaras, E.I. Lamb wave evaluation of the effects of thermal-mechanical aging on composite stiffness. J. Compos. Mater. 2000, 34, 27–38. [Google Scholar] [CrossRef]

- Rheinfurth, M.; Kosmann, N.; Sauer, D.; Busse, G.; Schulte, K. Lamb waves for non-contact fatigue state evaluation of composites under various mechanical loading conditions. Compos. Part A 2012, 43, 1203–1211. [Google Scholar] [CrossRef]

- Marzani, A.; Marchi, L.D. Characterization of the elastic moduli in composite plates via dispersive guided waves data and genetic algorithms. J. Intell. Mater. Syst. Struct. 2013, 24, 2135–2147. [Google Scholar] [CrossRef]

- Zhao, J.L.; Qiu, J.; Ji, H.L. Reconstruction of the nine stiffness coefficients of composites using a laser generation based imaging method. Compos. Sci. Technol. 2016, 126, 27–34. [Google Scholar] [CrossRef]

- Tao, C.C.; Ji, H.L.; Qiu, J.H.; Zhang, C.; Wang, Z.; Yao, W. Characterization of fatigue damages in composite laminates using Lamb wave velocity and prediction of residual life. Compos. Struct. 2017, 166, 219–228. [Google Scholar] [CrossRef]

- Peng, T.; Liu, Y.; Saxena, A.; Goebel, K. In-situ fatigue life prognosis for composite laminates based on stiffness degradation. Compos. Struct. 2015, 132, 155–165. [Google Scholar] [CrossRef]

- Wilson, C.L.; Chang, F.K. Monitoring fatigue-induced transverse matrix cracks in laminated composites using built-in acousto-ultrasonic techniques. Struct. Health Monit. 2016, 15, 335–350. [Google Scholar] [CrossRef]

- Deng, M.; Pei, J. Assessment of accumulated fatigue damage in solid plates using nonlinear lamb wave approach. Appl. Phys. Lett. 2007, 90, 121902. [Google Scholar] [CrossRef]

- Li, W.; Cho, Y.; Achenbach, J.D. Detection of thermal fatigue in composites by second harmonic lamb waves. Smart Mater. Struct. 2012, 21, 085019. [Google Scholar] [CrossRef]

- Rizzo, P.; Sorrivi, E.; Lanza di Scalea, F.; Viola, E. Wavelet-based outlier analysis for guided wave structural monitoring: Application to multi-wire strands. J. Sound Vib. 2007, 307, 52–68. [Google Scholar] [CrossRef]

- Sohn, H.; Park, G.; Wait, J.R.; Limback, N.P.; Farrar, C.R. Wavelet-based active sensing for delamination detection in composite structures. Smart Mater. Struct. 2004, 13, 153–160. [Google Scholar] [CrossRef]

- Mallat, S. A theory for multiresolution signal decomposition: The wavelet representation. IEEE Trans. Pattern Anal. Mach. Intell. 1989, 11, 674–693. [Google Scholar] [CrossRef]

- Worden, K.; Manson, G.; Fieller, N.R.J. Damage detection using outlier analysis. J. Sound Vib. 2000, 229, 647–667. [Google Scholar] [CrossRef]

- Worden, K.; Manson, G. The application of machine learning to structural health monitoring. Philos. Trans. R. Soc. A 2007, 365, 515–537. [Google Scholar] [CrossRef] [PubMed]

- Cheung, A.; Cabrera, C.; Sarabandi, P.; Nair, K.K.; Kiremidjian, A.; Wenzel, H. The application of statistical pattern recognition methods for damage detection to field data. Smart Mater. Struct. 2008, 17, 065023. [Google Scholar] [CrossRef]

- Park, S.; Inman, D.J.; Yun, C.B. An outlier analysis of MFC-based impedance sensing data for wireless structural health monitoring of railroad tracks. Eng. Struct. 2008, 30, 2792–2799. [Google Scholar] [CrossRef]

- Pavlopoulou, S.; Worden, K.; Soutis, C. Novelty detection and dimension reduction via guided ultrasonic waves: Damage monitoring of scarf repairs in composite laminates. J. Intell. Mater. Syst. Struct. 2016, 27, 549–566. [Google Scholar] [CrossRef]

| Fatigue Cycles | 0 | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10,000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Specimen S_A | 25.30 | 23.70 | 23.32 | 22.90 | 22.67 | 22.58 | 22.55 | 22.49 | 22.51 | 22.50 | 22.46 |

| Specimen S_B | 18.14 | 17.60 | 17.19 | 16.88 | 16.67 | 16.65 | 16.63 | 16.62 | 16.61 | 16.60 | 16.58 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, G.; Lu, X.; Tang, J. Guided Wave-Based Monitoring of Evolution of Fatigue Damage in Glass Fiber/Epoxy Composites. Appl. Sci. 2019, 9, 1394. https://doi.org/10.3390/app9071394

Yan G, Lu X, Tang J. Guided Wave-Based Monitoring of Evolution of Fatigue Damage in Glass Fiber/Epoxy Composites. Applied Sciences. 2019; 9(7):1394. https://doi.org/10.3390/app9071394

Chicago/Turabian StyleYan, Gang, Xiang Lu, and Jianfei Tang. 2019. "Guided Wave-Based Monitoring of Evolution of Fatigue Damage in Glass Fiber/Epoxy Composites" Applied Sciences 9, no. 7: 1394. https://doi.org/10.3390/app9071394

APA StyleYan, G., Lu, X., & Tang, J. (2019). Guided Wave-Based Monitoring of Evolution of Fatigue Damage in Glass Fiber/Epoxy Composites. Applied Sciences, 9(7), 1394. https://doi.org/10.3390/app9071394