Mechanical Characteristics and Water Absorption Properties of Blast-Furnace Slag Concretes with Fly Ashes or Microsilica Additions

Abstract

1. Introduction

2. Materials and Methods

- (1)

- Concrete + slag + fly-ashes;

- (2)

- concrete + slag + microsilica.

2.1. Materials

- -

- High strength Portland cement (following the EC2 prescriptions [45]);

- -

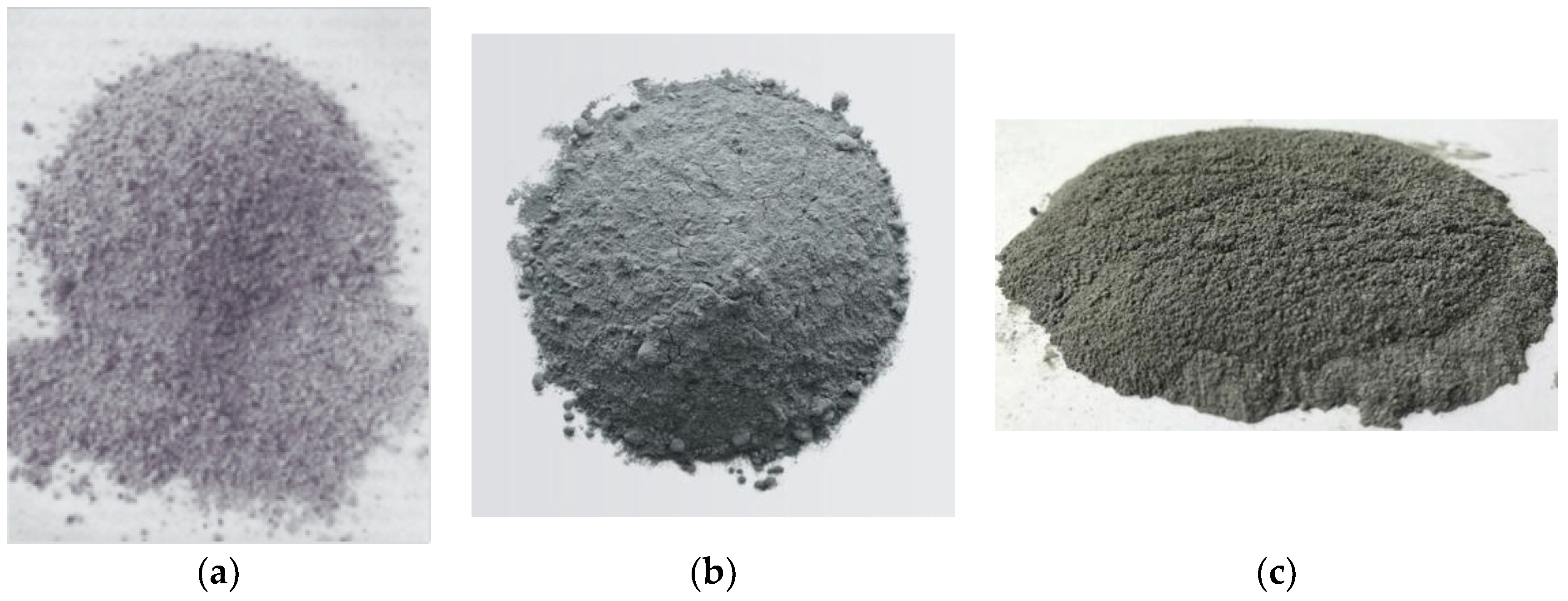

- Blast-furnace slag produced by the ILVA factory, Taranto, Italy (Figure 1a);

- -

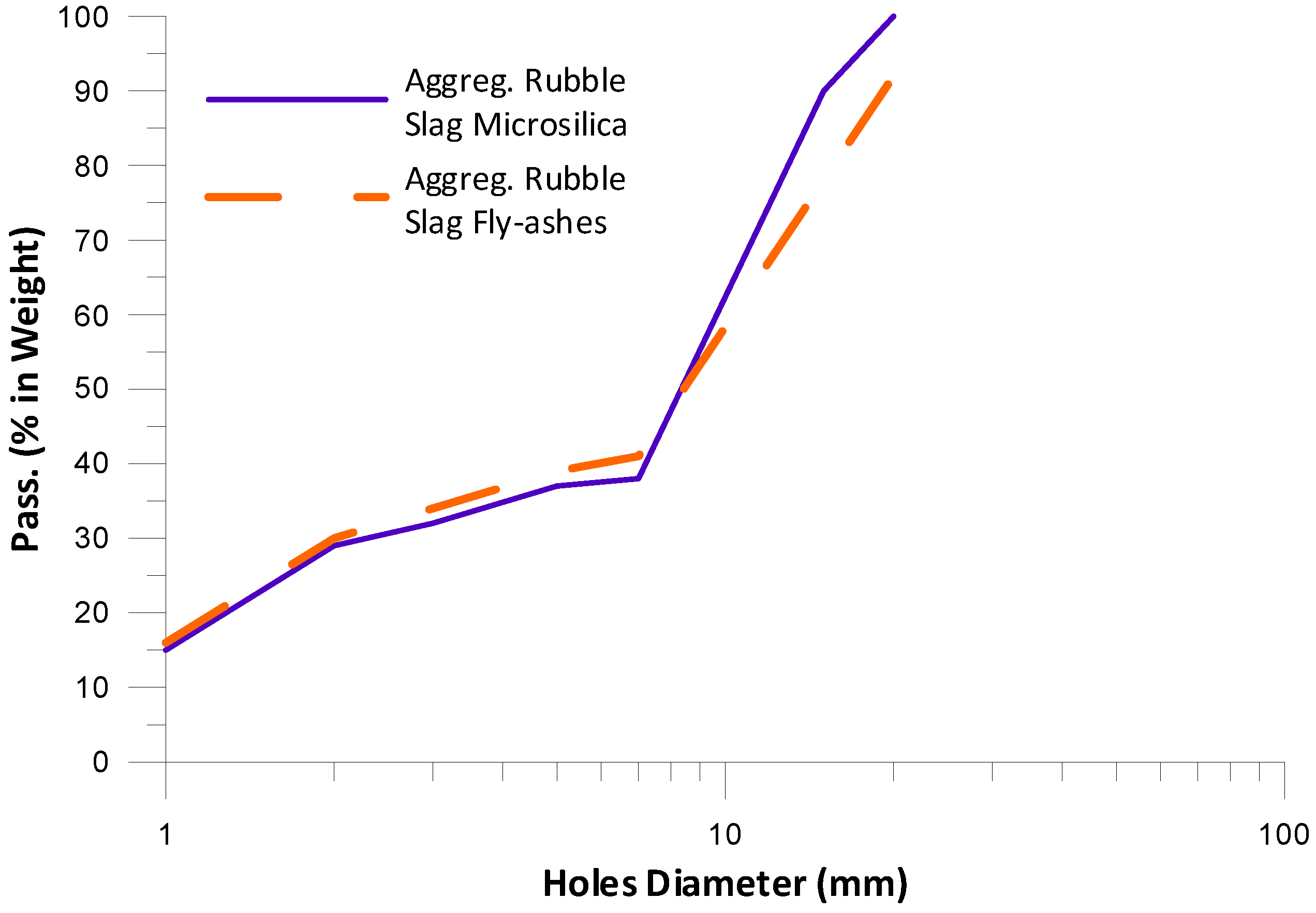

- Fly ashes coming from ENEL power station of Brindisi, Italy (Figure 1b); it is constituted on average by 90% of granules with dimensions smaller than 0.3 mm, by 60% of granules smaller than 0.04 mm, and by 10% of granules smaller than 0.01 mm;

- -

- Microsilica of ELKEM MATERIALS a/s Kristiansand, Norway (Figure 1c);

- -

- Calcareous rubble;

- -

- Super-plasticizer RHEO-BUILD 1000 from MAC S.p.A.

2.1.1. Concretes with Slag and Fly Ashes (FA)

2.1.2. Concretes with Slag and Microsilica (SF)

2.2. Test Methods

2.3. Results

2.3.1. Strength Tests

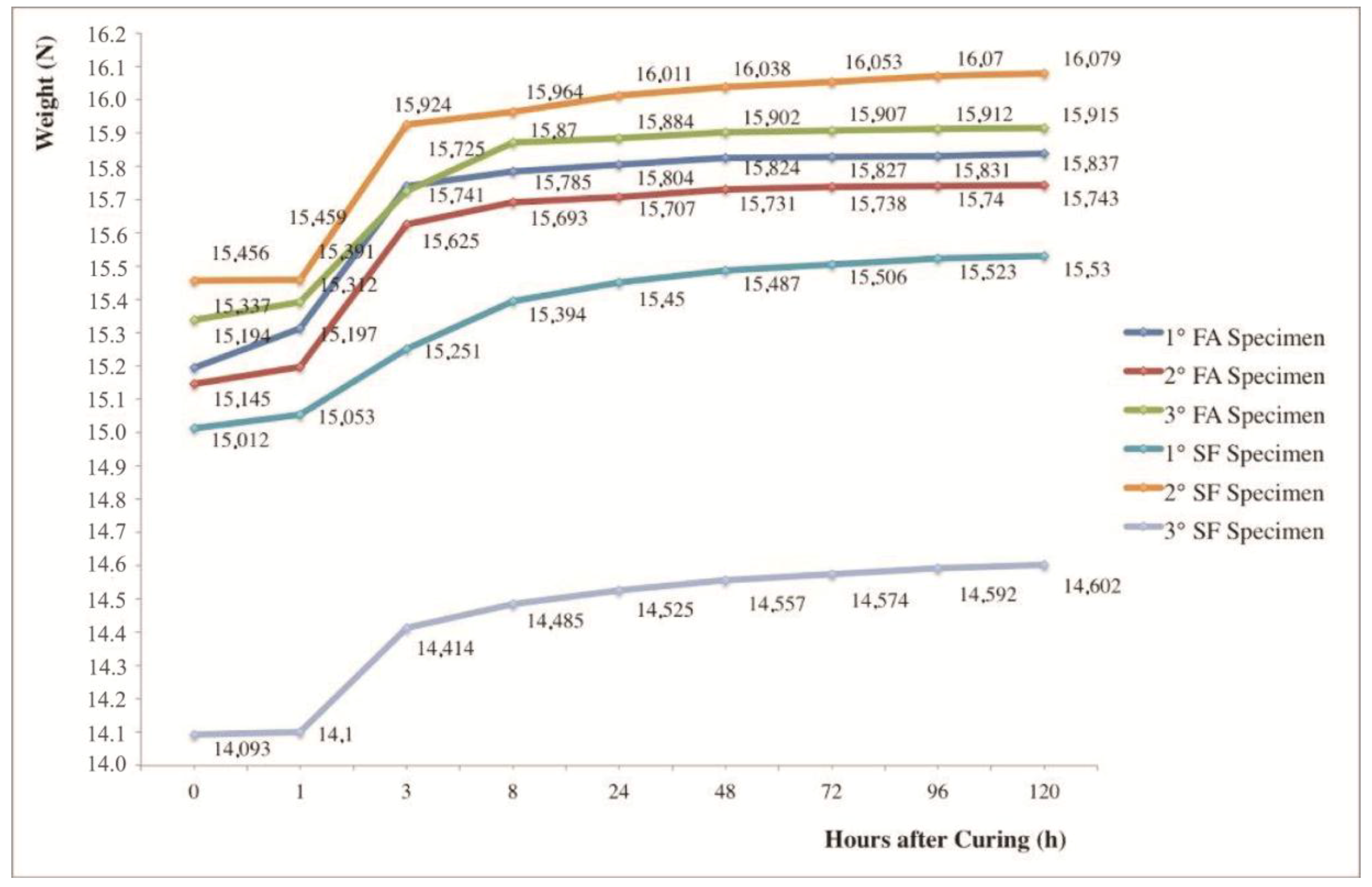

2.3.2. Water Absorption Tests

- Wi = average weight of dry sample (g),

- Ws = the average weight of the wet sample (g).

2.4. Discussion

3. Conclusions

- The use of fly-ashes, and especially silica fume, together with slag in concrete enhances the compressive strength of concrete mixes and shows very high water/cement ratios.

- Microsilica concretes present a specific weight lower than slag and fly-ash concretes.

- For both concretes, the tensile strengths are consistent with the compressive ones, while bending strengths are rather low, especially for slag and silica fume concretes.

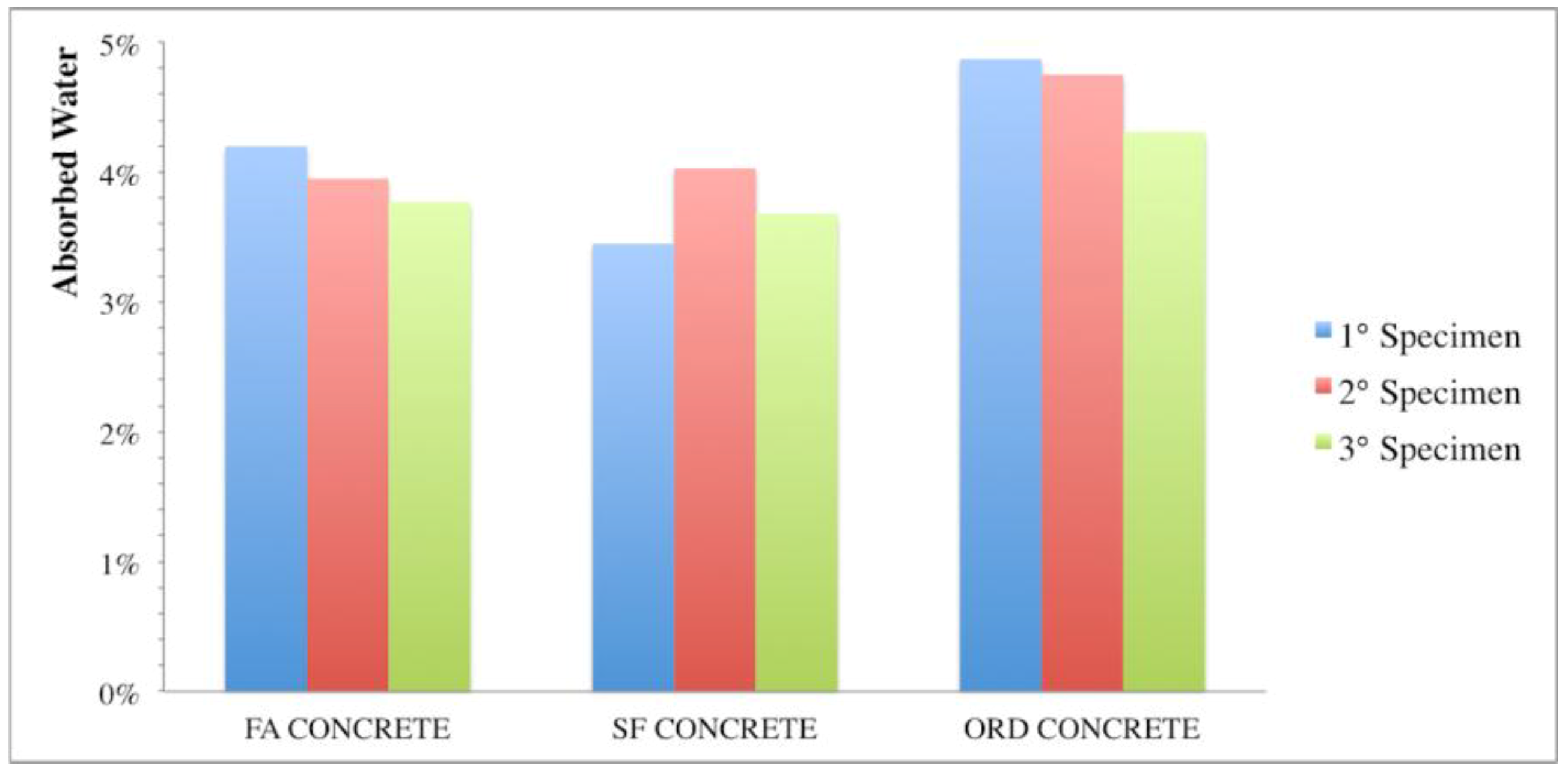

- Compared to an ordinary concrete, the types of concrete examined in this research have a lower water absorption value, especially the silica fume concrete.

Author Contributions

Funding

Conflicts of Interest

References

- Glasser, F.P.; Marchand, J.; Samson, E. Durability of concrete—Degradation phenomena involving detrimental chemical reactions. Cem. Concr. Res. 2008, 38, 226–246. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Martinez-Abella, F.; Vazquez-Herrero, C.; Perez-Ordonez, J.L. Properties of plain concrete made with mixed recycled coarse aggregate. Constr. Build. Mater. 2012, 37, 171–176. [Google Scholar] [CrossRef]

- Li, G.; Zhao, X. Properties of concrete incorporating fly-ash and ground granulated blast-furnace slag. Cem. Concr. Compos. 2003, 25, 293–299. [Google Scholar] [CrossRef]

- Václavík, V.; Dirner, V.; Dvorský, T.; Daxner, J. The use of blast furnace slag. Metalurgija 2012, 51, 461–464. [Google Scholar]

- Sekhar, D.C.; Nayak, S. Utilization of granulated blast furnace slag and cement in the manufacture of compressed stabilized earth blocks. Constr. Build. Mater. 2018, 166, 531–536. [Google Scholar] [CrossRef]

- Pazhani, K.; Jeyaraj, R. Study on durability of high performance concrete with industrial wastes. Appl. Technol. Innov. 2010, 2, 19–28. [Google Scholar] [CrossRef]

- Hiraskar, K.G.; Patil, C. Use of Blast furnace slag aggregate in concrete. Int. J. Sci. Eng. Res. 2013, 4, 95–98. [Google Scholar]

- Ulubeyli, G.C.; Artir, R. Sustainability for Blast Furnace Slag: Use of Some Construction Wastes. Procedia Soc. Behav. Sci. 2015, 195, 2191–2198. [Google Scholar] [CrossRef]

- Yuksel, I. Blast-furnace slag. In Waste and Supplementary Cementitious Materials in Concrete; Siddique, R., Cachim, P., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2018; pp. 361–415. [Google Scholar]

- Escalante-Garcia, J.I.; Espinoza-Perez, L.J.; Gorokhovsky, A.; Gomez-Zamorano, L.Y. Coarse blast furnace slag as a cementitious material, comparative study as a partial replacement of Portland cement and as an alkali activated cement. Constr. Build. Mater. 2009, 23, 2511–2517. [Google Scholar] [CrossRef]

- Gaurav, S.; Souvik, D.; Abdulaziz, A.A.; Showmen, S.; Somnath, K. Study of Granulated Blast Furnace Slag as Fine Aggregates in Concrete for Sustainable Infrastructure. Procedia Soc. Behav. Sci. 2015, 195, 2272–2279. [Google Scholar]

- Senani, M.; Ferhoune, N.; Guettala, A. Substitution of the natural sand by crystallized slag of blast furnace in the composition of concrete. Alex. Eng. J. 2018, 57, 851–857. [Google Scholar] [CrossRef]

- Ivorra, S.; Foti, D.; Bru, D.; Baeza, F.J. Dynamic Behavior of a Pedestrian Bridge in Alicante (Spain). J. Perform. Constr. Facil. 2015, 29, 04014132. [Google Scholar] [CrossRef]

- Foti, D.; Vacca, S. Comportamiento mecánico de columnas de hormigón armado reforzadas con mortero reoplástico/Mechanical behavior of concrete columns reinforced with rheoplastic mortar. Mater. Constr. 2013, 63, 267–282. [Google Scholar] [CrossRef]

- Foti, D.; Romanazzi, A. Experimental analysis of fiber-reinforced mortar for walls in rectified brick blocks [Analisi sperimentale di malte fibrorinforzate per pareti in blocchi di laterizio rettificati]. C Ca 2011, 41, 109–118. [Google Scholar]

- Foti, D. Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Mehta, P.K. Reducing the environmental impact of concrete. Concr. Int. 2001, 23, 61–65. [Google Scholar]

- Mehta, P.K. Building durable structures in the 21st century. Concr. Int. 2001, 23, 57–63. [Google Scholar]

- Foti, D. Use of recycled waste pet bottles fibers for the reinforcement of concrete. Compos. Struct. 2013, 96, 396–404. [Google Scholar] [CrossRef]

- Foti, D.; Paparella, F. Impact Behavior of Structural Elements in Concrete Reinforced with Pet Fibers. Mech. Res. Commun. 2014, 57, 57–66. [Google Scholar] [CrossRef]

- Foti, D. Innovative techniques for concrete reinforcement with polymers. Constr. Build. Mater. 2016, 112, 202–209. [Google Scholar] [CrossRef]

- Mehta, P.K. Durability critical issues for the future. Concr. Int. 1997, 19, 69–76. [Google Scholar]

- Mehta, P.K. Advancements in concrete technology. Concr. Int. 1999, 21, 27–33. [Google Scholar]

- Mehta, P.K. Greening of the concrete industry for sustainable development. Concr. Int. 2002, 24, 23–27. [Google Scholar]

- Hefni, Y.; El Zaher, Y.A.; Wahab, M.A. Influence of activation of fly ash on the mechanical properties of concrete. Constr. Build. Mater. 2018, 172, 728–734. [Google Scholar] [CrossRef]

- Babu, K.G.; Kumar, V.S.R. Efficiency of GGBS in concrete. Cem. Concr. Res. 2000, 30, 1031–1036. [Google Scholar] [CrossRef]

- Giner, V.T.; Ivorra, S.; Baeza, F.J.; Zornoza, E.; Ferrer, B. Silica fume admixture effect on the dynamic properties of concrete. Constr. Build. Mater. 2011, 25, 3272–3277. [Google Scholar] [CrossRef]

- Giner, V.T.; Baeza, F.J.; Ivorra, S.; Zornoza, E.; Galao, Ó. Effect of steel and carbon fiber additions on the dynamic properties of concrete containing silica fume. Mater. Des. 2012, 34, 332–339. [Google Scholar] [CrossRef]

- Fidjestøl, P.; Lewis, R. Microsilica as an Addition. In Lea’s Chemistry of Cement and Concrete, 4th ed.; Hewlett, P., Ed.; Elsevier Science: Amsterdam, The Netherlands, 1998; Chapter 12; pp. 679–712. [Google Scholar]

- Pedro, D.; De Brito, J.; Evangelista, L. Durability performance of high-performance concrete made with recycled aggregates, fly ash and densified silica fume. Cem. Concr. Compos. 2018, 93, 63–74. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of silica fume in concrete: Review of hardened properties. Resour. Conserv. Recycl. 2011, 55, 923–932. [Google Scholar] [CrossRef]

- Denisiewicz, A.; Kula, K.; Socha, T.; Kwiatkowski, G. Influence of Silica Fume Addition on Selected Properties of Fine-Grained Concrete. Civ. Environ. Eng. Rep. 2018, 28, 166–176. [Google Scholar] [CrossRef]

- Pedro, D.; De Brito, J.; Evangelista, L. Mechanical characterization of high performance concrete prepared with recycled aggregates and silica fume from precast industry. J. Clean. Prod. 2017, 164, 939–949. [Google Scholar] [CrossRef]

- Bhanjaa, S.; Senguptab, B. Modified water-cement ratio law for silica fume concretes. Cem. Concr Res. 2003, 33, 447–450. [Google Scholar] [CrossRef]

- Barbhuiya, S.A.; Gbagbo, J.K.; Russell, M.I.; Basheer, P.A.M. Properties of fly ash concrete modified with hydrated lime and silica fume. Constr. Build. Mater. 2009, 23, 3233–3239. [Google Scholar] [CrossRef]

- Köksal, F.; Altun, F.; Yiğit, I.; Șahin, Y. Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater. 2008, 22, 1874–1880. [Google Scholar] [CrossRef]

- Bhanjaa, S.; Senguptab, B. Influence of silica fume on the tensile strength of concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- Langan, B.W.; Weng, K.; Ward, M.A. Effect of silica fume and fly ash on heat of hydration of Portland cement. Cem. Concr. Res. 2002, 32, 1045–1051. [Google Scholar] [CrossRef]

- Bleszynski, R.; Hooton, R.D.; Thomas, M.D.A.; Rogers, C.A. Durability of Ternary Blend Concrete with Silica Fume and Blast-Furnace Slag: Laboratory and Outdoor Exposure Site Studies. ACI Mater. J. 2002, 99, 499–508. [Google Scholar]

- Chalee, W.; Ausapanit, P.; Jaturapitakkul, C. Utilization of fly ash concrete in marine environment for long term design life analysis. Mater. Des. 2010, 31, 1242–1249. [Google Scholar] [CrossRef]

- Elahi, A.; Basheer, P.A.M.; Nanukuttan, S.V.; Khan, Q.U.Z. Mechanical and durability properties of high performance concretes containing supplementary cementitious materials. Constr. Build. Mater. 2010, 24, 292–299. [Google Scholar] [CrossRef]

- Song, H.-W.; Jang, J.-C.; Saraswathy, V.; Byun, K.-J. An estimation of the diffusivity of silica fume concrete. Build. Environ. 2007, 42, 1358–1367. [Google Scholar] [CrossRef]

- Song, H.-W.; Pack, S.-W.; Nam, S.-H.; Jang, J.-C.; Saraswathy, V. Estimation of the permeability of silica fume concrete. Constr. Build. Mater. 2010, 24, 315–321. [Google Scholar] [CrossRef]

- Eurocode, C.E.N. 2: Design of Concrete Structures–Part 1-1: General Rules and Rules for Buildings: EN 1992-1-1; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- A.C.I. Commettee 211. Standard Practice for Selecting Proportions for Normal, Heavyweight and Mass Concrete; American Concrete Institute: Detroit, MI, USA, 2002. [Google Scholar]

- British DOE (Department of Environment). Method—Design of Normal Concrete Mixes: BSI; British DOE (Department of Environment): London, UK, 1988.

- Puccio, M.; Ferrari, F. L’uso Delle Ceneri Leggere da Carbone nei Conglomerati Cementizi, 1° e 2° Parte. La Prefabbricazione 1986, 5. (In Italian) [Google Scholar]

- Mačiulaitis, R.; Vaičiene, M.; Žurauskiene, R. The effect of concrete composition and aggregates properties on performance of concrete. J. Civ. Eng. Manag. 2009, 15, 317–324. [Google Scholar] [CrossRef]

- EN UNI 7699:2018. Prova sul Calcestruzzo Indurito—Determinazione Dell’assorbimento di Acqua Alla Pressione Atmosferica; Ente Nazionale Italiano di Unificazione: Roma, Italy, 2018. (In Italian) [Google Scholar]

- Fraay, A.L.A.; Bijen, J.M.; De Haan, Y.M. The reaction of fly ash in concrete a critical examination. Cem. Concr. Res. 1989, 19, 235–246. [Google Scholar] [CrossRef]

- Hanehara, S.; Tomosawa, F.; Kobayakawa, M.; Hwang, K. Effects of water/powder ratio, mixing ratio of fly ash, and curing temperature on pozzolanic reaction of fly ash in cement paste. Cem. Concr. Res. 2001, 31, 31–39. [Google Scholar] [CrossRef]

- Papadakis, V.G. Experimental investigation and theoretical modeling of silica fume activity in concrete. Cem. Concr. Res. 1999, 29, 79–86. [Google Scholar] [CrossRef]

- Bagheri, A.; Zanganeh, H.; Alizadeh, H.; Shakerinia, M.; Marian, M.A.S. Comparing the performance of fine fly ash and silica fume in enhancing the properties of concretes containing fly ash. Constr. Build. Mater. 2013, 47, 1402–1408. [Google Scholar] [CrossRef]

- Elsayed, A.A. Influence of silica fume, fly ash, super pozz and high slag cement on water permeability and strength of concrete. Jordan J. Civ. Eng. 2011, 159, 1–13. [Google Scholar]

- Uzal, B.; Turanlı, L.; Yücel, H.; Göncüoğlu, M.C.; Çulfaz, A. Pozzolanic activity of clinoptilolite: A comparative study with silica fume, fly ash and a non-zeolitic natural pozzolan. Cem. Concr. Res. 2010, 40, 398–404. [Google Scholar] [CrossRef]

- Malhotra, V.M.; Carette, G.G. Silica fume. A pozzolan of new interestfor use in some concretes. Concr. Constr. 1982, 27, 443–446. [Google Scholar]

| Cement (daN/m3) | Slag (daN/m3) | Fly Ashes (daN/m3) | Microsilica (daN/m3) | |

|---|---|---|---|---|

| Absolute specific weight | 3100 | 2720 | 2140 | 2160 |

| Bulk density | 1400 | 1110 | 700 | 737 |

| Chemical Composition % | ||||

| SiO2 | 17–25 | 30–40 | 40–55 | 88–98 |

| Al2O3 | 2–8 | 6–18 | 20–30 | 0.5–3 |

| CaO | 60–67 | 38–50 | 3–7 | 0.1–0.5 |

| MgO | 0.1–5 | 2–6 | 1–4 | 0.3–1.5 |

| SO3 | 1–4.8 | - | 0.4–2 | - |

| Na2O | - | - | - | 0.2–1.4 |

| K2O | 0.2–1.5 | - | 1–5 | 0.4–1 |

| Rubble | Fly Ashes | Water | Slag | Cement | Super-Plasticizer |

|---|---|---|---|---|---|

| 1080 daN/m3 | 130 daN/m3 | 220 L/m3 | 522 daN/m3 | 340 daN/m3 | 4.7 L/m3 |

| Components Ratio | |||||

| water/cement | water/(ashes + cement) | ashes/cement | super-plasticizer/(ashes + cement) | ||

| 0.65 | 0.47 | 0.38 | 0.01 | ||

| Rubble | Microsilica | Water | Slag | Cement | Super-Plasticizer |

|---|---|---|---|---|---|

| 1080 daN/m3 | 131 daN/m3 | 296 L/m3 | 522 daN/m3 | 340 daN/m3 | 7.22 L/m3 |

| Components Ratio | |||||

| water/cement | water/(microsilica + cement) | microsilica/cement | super-plasticizer/(microsilica + cement) | ||

| 0.87 | 0.63 | 0.38 | 0.015 | ||

| Rubble | Sand | Water | Cement | Super-Plasticizer |

|---|---|---|---|---|

| 1080 daN/m3 | 700 daN/m3 | 204 L/m3 | 340 daN/m3 | 4.0 L/m3 |

| Curing Days | Specific Weight (daN/m3) | Compressive Failure Stress (N/mm2) | Flexural Failure Stress (N/mm2) | Tensile Failure Stress (N/mm2) | |||

|---|---|---|---|---|---|---|---|

| Value | σ | Value | σ | Value | σ | ||

| 7 | 2222 | 26.0 | ±3.74 | - | - | ||

| 28 | 2185 | 36.5 | ±2.12 | 4.4 | ±3.0 | 2.3 | ±3.61 |

| 90 | 2185 | 43.0 | ±3.74 | - | - | ||

| Curing Days | Specific Weight (daN/m3) | Compressive Failure Stress (N/mm2) | Flexural Failure Stress (N/mm2) | Tensile Failure Stress (N/mm2) | |||

|---|---|---|---|---|---|---|---|

| Value | σ | Value | σ | Value | σ | ||

| 7 | 2140 | 31.2 | ±3.10 | - | - | ||

| 28 | 2140 | 42.6 | ±5.724 | 3.3 | ±3.74 | 2.2 | ±1.73 |

| 60 | 2115 | 45.3 | ±4.32 | - | - | ||

| 90 | 2113 | 47.1 | ±1.34 | - | - | ||

| Curing Days | Ordinary Concrete (N/mm2) | Slag and Fly Ashes Concrete (N/mm2) | Slag and Microsilica Concrete (N/mm2) | ||

|---|---|---|---|---|---|

| Value | Value | σ | Value | σ | |

| 28 | 47 | 36.5 | ±2.12 | 42.6 | ±5.724 |

| Concrete of Slag and Fly Ashes | Concrete of Slag and Microsilica | Ordinary Concrete (Ord) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Specimens | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |

| D × H (or L for cubic specimens) [mm] | 96 × 96 | 96 × 96 | 96 × 96 | 96 × 96 | 96 × 99 | 96 × 92 | 10 × 10 × 10 | 10 × 10 × 10 | 10 × 10 × 10 | |

| Weight after curing = Ms [N] | 15.19 | 15.15 | 15.34 | 15.01 | 15.46 | 14.09 | 22.34 | 22.26 | 22.78 | |

| Weight increasing during the phase of immersion in water [N] | After 1 h | 15.31 | 15.20 | 15.39 | 15.05 | 15.46 | 14.10 | 22.52 | 22.44 | 22.82 |

| After 3 h | 15.74 | 15.63 | 15.73 | 15.25 | 15.92 | 14.41 | 22.81 | 22.72 | 23.08 | |

| After 8 h | 15.79 | 15.70 | 15.87 | 15.39 | 15.96 | 14.49 | 23.02 | 22.97 | 23.31 | |

| After 24 h | 15.80 | 15.71 | 15.88 | 15.45 | 16.01 | 14.53 | 23.40 | 23.30 | 23.75 | |

| After 48 h | 15.82 | 15.73 | 15.90 | 15.49 | 16.04 | 14.56 | 23.41 | 23.31 | 23.76 | |

| After 72 h | 15.83 | 15.74 | 15.91 | 15.51 | 16.05 | 14.57 | 23.42 | 23.31 | 23.76 | |

| After 96 h | 15.83 | 15.74 | 15.91 | 15.52 | 16.07 | 14.59 | 23.42 | 23.31 | 23.76 | |

| After 120 h = Mi | 15.84 | 15.74 | 15.92 | 15.53 | 16.08 | 14.60 | 23.42 | 23.31 | 23.76 | |

| Absorbed Water [%] = Wmax * | 4.20 | 3.95 | 3.77 | 3.45 | 4.03 | 3.68 | 4.87 | 4.75 | 4.31 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foti, D.; Lerna, M.; Sabbà, M.F.; Vacca, V. Mechanical Characteristics and Water Absorption Properties of Blast-Furnace Slag Concretes with Fly Ashes or Microsilica Additions. Appl. Sci. 2019, 9, 1279. https://doi.org/10.3390/app9071279

Foti D, Lerna M, Sabbà MF, Vacca V. Mechanical Characteristics and Water Absorption Properties of Blast-Furnace Slag Concretes with Fly Ashes or Microsilica Additions. Applied Sciences. 2019; 9(7):1279. https://doi.org/10.3390/app9071279

Chicago/Turabian StyleFoti, Dora, Michela Lerna, Maria Francesca Sabbà, and Vitantonio Vacca. 2019. "Mechanical Characteristics and Water Absorption Properties of Blast-Furnace Slag Concretes with Fly Ashes or Microsilica Additions" Applied Sciences 9, no. 7: 1279. https://doi.org/10.3390/app9071279

APA StyleFoti, D., Lerna, M., Sabbà, M. F., & Vacca, V. (2019). Mechanical Characteristics and Water Absorption Properties of Blast-Furnace Slag Concretes with Fly Ashes or Microsilica Additions. Applied Sciences, 9(7), 1279. https://doi.org/10.3390/app9071279