1. Introduction

Currently, one of the most critical issues is the efficient use of available energy sources. Therefore, in rural or remote geographic locations, the generation and distribution of energy is a significant challenge for many areas of engineering such as control, power electronics or planning, among others. In recent years, microgrids (MGs) have been a reliable solution for the power supply in separate areas, provided that there is adequate operational planning of the MG energy sources [

1].

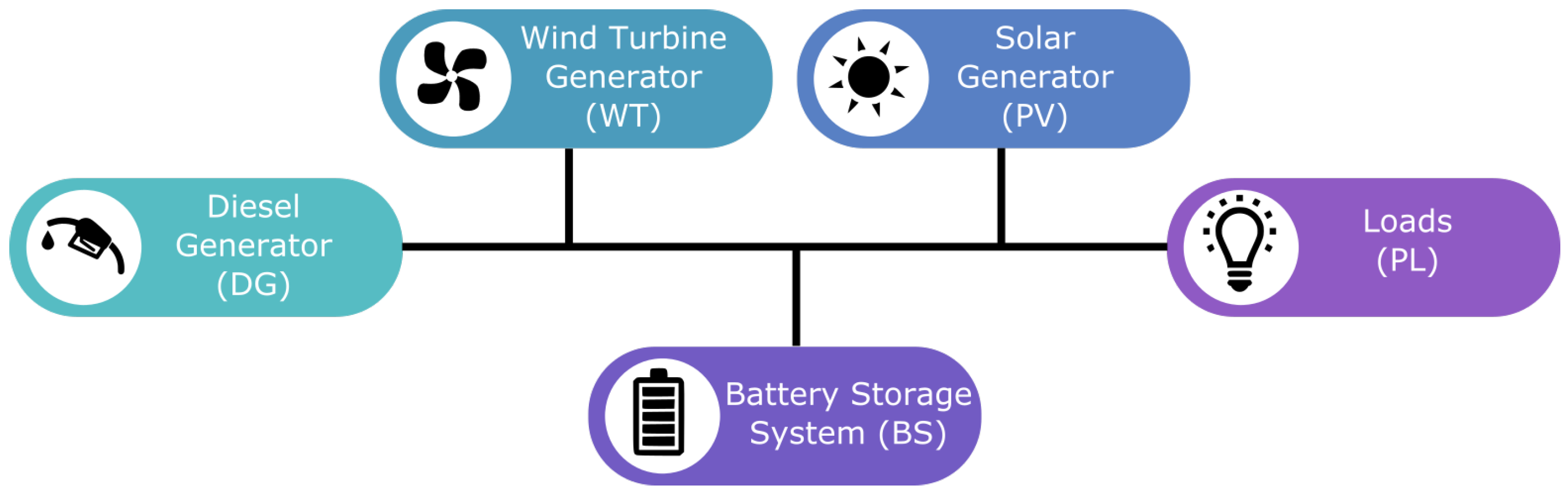

In general, an MG is composed of energy storage systems (ESS),hybrid power generation systems (HPGS) from renewable energy sources (RES) and conventional generation systems (CGS); with all elements working in a coordinated way for the power generation. It is important to highlight that CGSs have a high operating cost due to the materials and transportation logistics. Moreover, ESSs are integrated by costly devices requiring a safe manner operation, thus guaranteeing a long service life. Finally, uncertainty in the appropriate operation of the RES due to the origin of wind and sunlight must take into account. These theoretical considerations are some of the reasons why optimal management of power generation resources for the appropriate operation of the MG is required.

In isolated microgrids (IMGs), a hybrid power generation system (HPGS) is responsible for the generation of reliable energy. This is done by integrating into the IMG at least one of the RES, CGS, and ESS systems such as a wind turbine generator, solar generator, diesel generator, or battery storage systems. However, due to the RES generation intermittency, the ESS become the main factor in the steady performance of the IMGs [

2,

3,

4]. When a steady state is reached, the best performance of the whole system is obtained. HPGSs have been studied by several authors [

5,

6,

7], describing conditions of remote localities having variable demand and power dispatch by generators minimizing the cost of generation, while maintaining a balance between the generation of energy and the load.

Usually, the power supply to the load in an IMG can be calculated as an economic dispatch function for generators at a large-scale power level [

8]. This cost function should be minimized, subject to constraints related to the generator’s capacity and the energy balance between generation and load demand. The load demand must be computed for a 24 h period in an IMG, and several scenarios can be presented in the HPGS such as: (1) RESs cannot produce energy for 24 h; (2) all the RES in the IMG can always dispatch energy, but not the total demand capacity of the load; (3) the main costs are the fuel costs and the generation of the diesel generator; and (4) the operation cost of the HPGSs are non-linear, generally due to the cost of the diesel generator.

On the other hand, there is a kind of problems, specifically in real-world applications, where it is impossible to find an optimal solution using a viable amount of resources employing traditional techniques such as numerical methods or graphic analysis. These cases correspond to the hard optimization category and have a similar nature to the NP (nondeterministic polynomial time) decision problems since they can not be solved in an optimal way or up to a guaranteed point using deterministic methods in polynomial time.

Metaheuristics are an alternative to find feasible and optimal solutions to NP problems, where any problem modeled as a constrained numerical optimization problem (CNOP) can have at least one optimal feasible solution. A CNOP also known as a general problem of non-linear programming can be defined as: minimize subject to: , or , . Here, such that , is the solution vector , where each , is delimited by the lower and upper limit ; m is the number of inequality constraints and p is the number of equality constraints (in both cases, the constraints can be linear or non-linear). If we denote by F the feasible region (where all the solutions that satisfy the problem are found) and by S the entire search space, then .

Metaheuristics are well-known algorithms, most of them are inspired by nature, that have successfully solved CNOPs. Metaheuristics are divided into two broad groups: (1) evolutionary algorithms (EAs), whose operation is based on emulating the process of natural evolution and survival of the fittest [

9], and (2) swarm intelligence algorithms (SIAs) that base their operation on social and cooperative behaviors of simple organisms such as insects, birds, and bacteria [

10].

From the initial ideas of Bremermann [

11], in 2002 Passino proposed a novel SIA called Bacterial Foraging Optimization Algorithm (BFOA) [

12], based on E.Coli bacteria foraging. In BFOA, each bacterium

E. Coli tries to maximize the energy obtained per unit of time spent on the foraging process, while avoiding harmful substances. Moreover, bacteria can communicate with each other by segregating certain substances. There are four main processes in BFOA: (1) chemotaxis (swim-tumble movements), (2) swarming (communication between bacteria), (3) reproduction (cloning of the best bacteria), and (4) elimination-dispersal (replacement of the worst bacteria). Bacteria are potential solutions to the problem and their location represents the values of the problem decision variables. Bacteria can move (generate new solutions) through the chemotaxis cycle; additionally, a movement through the attraction of solutions in promising areas of the search space is generated (as it allows the reproduction of the best solutions). Finally, those bacteria located in areas of low quality are deleted.

In 2009, a simplified BFOA version was proposed, called modified bacterial foraging optimization algorithm (MBFOA) [

13], which implements fewer parameters with respect to the original BFOA. MBFOA includes a mechanism for the management of constraints based on feasibility rules, consisting of (a) between two feasible solutions, that with the best value in the objective function is selected, (b) between a feasible solution and a non-feasible solution, the feasible one is selected, and (c) between two non-feasible solutions, the one with the smallest amount of constraint violations is selected [

14]. MBFOA has been used to solve a number of problems of a different nature. For example, solving a set of chemical and mechanical engineering design problems, obtaining competitive results [

13], and the solution of a bi-objective mechanical design problem with constraints [

15].

In 2016, a recent algorithm based on MBFOA, called two-swim MBFOA (TS-MBFOA) [

16], was proposed. This version includes an operation similar to the mutation operator, used in EAs, as a swimming operator within the chemotaxis process. It also implements a random swim in the chemotaxis process, along with a skew mechanism for the initial population based on the variables range. TS-MBFOA has been used to solve real-world problems of mechatronic design and also in the nutrition field by generating successful healthy menus [

17].

There is a number of proposals in the specialized literature using metaheuristics algorithms to optimize particular mathematical models minimizing or maximizing an MG. Some of the EAs employed are Differential Evolution and Genetic Algorithms. SIAs employed are limited to particle swarm optimization (PSO) and BFOA. Other paradigms such as artificial neural networks, harmony search, and hybridizations between harmony search and differential evolution have also been used [

18,

19,

20]. A common factor in this works is the management of constraints using the penalty technique, which implies adding more parameters to be defined by the end user.

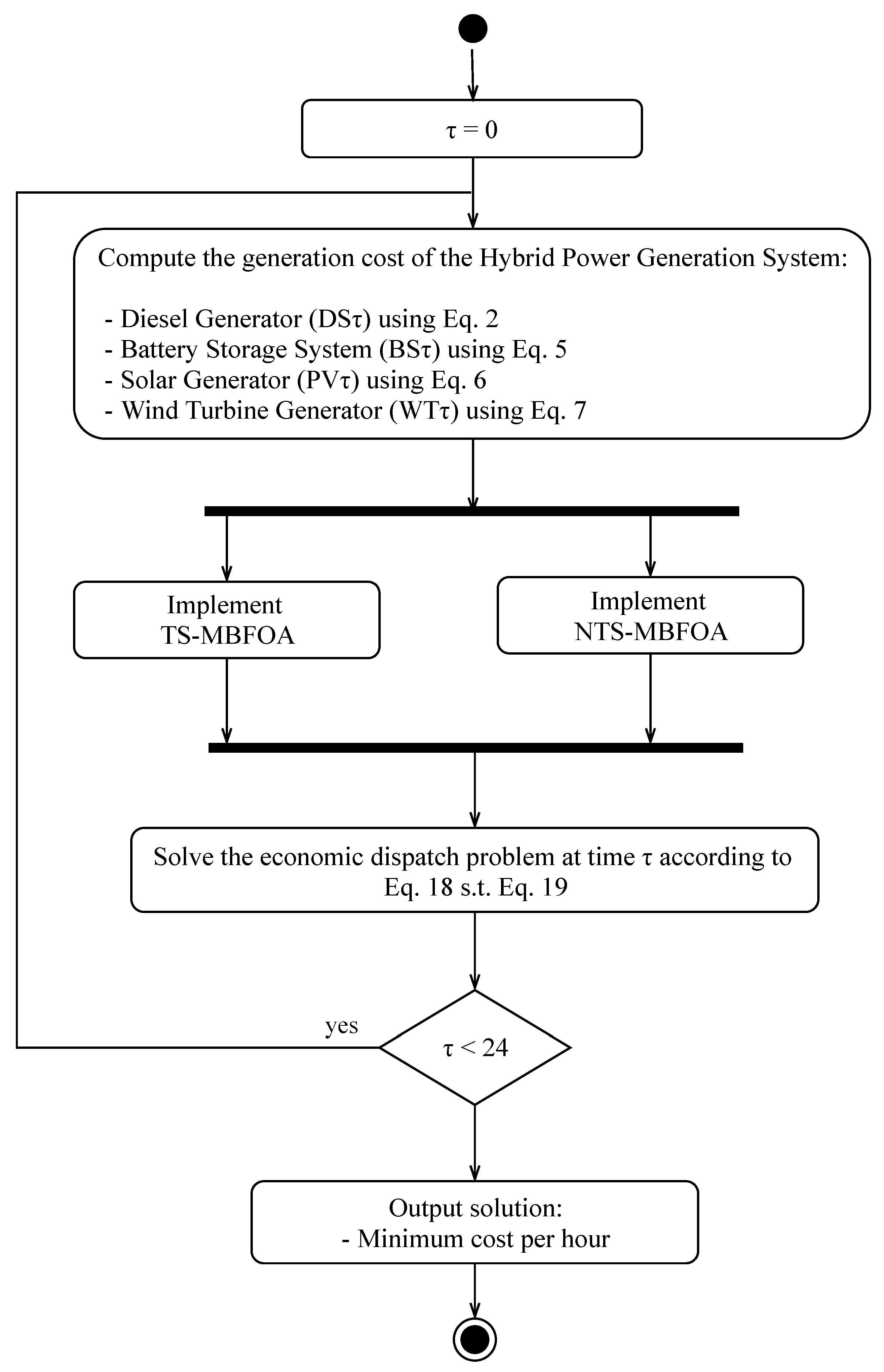

In

Table 1, main proposals based on BFOA were grouped according to particular characteristics. Moreover, other proposals were added—each proposal derived in several contributions. In the first row, representing this work, BFOA is implemented in order to optimize a mathematical model minimizing an IMG, including renewable energy sources such as wind and solar, as well as a conventional generation unit based on diesel fuel. Two novel versions of the BFOA are implemented and tested: TS-MBFOA, and a new proposal called NTS-MBFOA. Results showed that TS-MBFOA obtained better numerical solutions compared to NTS-MBFOA and compared to LSHADE-CV, an EA found in the literature solving the same problem. However, the best solution found by NTS-MBFOA is better from a mechatronic point of view because it favors the lifetime of the IMG and therefore resulting in economic savings in the long term.

In the second row of

Table 1, Ahmad and others [

21] proposed the bacterial foraging tabu search (BFTS) technique, a hybridization of BFOA and tabu search (TS) using different operational time interval (OTI) to schedule appliances while balancing user comfort (UC). His goal was to reduce both the waiting time and electricity cost simultaneously. Real-time pricing (RTP) scheme was used to get the total cost of electricity consumed. For simulations, they studied an average size modern home with 11 appliances. The simulation results of BFTS-based scheduled clearly shows that the proposed technique is better as compared to BFOA, TS, and unscheduled electricity consumption. The electricity cost and waiting time were minimized thus increasing UC.

In the third row of

Table 1, Hasan and others [

22] implemented two algorithms aimed at minimizing electricity cost and peak to average ratio (PAR) in a smartgrid by using BFOA and strawberry algorithm (SBA). Real-time pricing (RTP) pricing scheme was used to calculate the electricity cost. A single home with three types of appliances; fixed, shiftable and elastic appliances composed the simulated model. Authors found that these optimization schemes reduce the total electricity cost and peak to the average ratio by shifting the load from on-peak hours to off-peak hours. BFOA performed better than SBA regarding electricity cost minimization. However, the authors concluded that trade-off always exists between cost and user comfort.

In the fourth row of

Table 1, Saadia and others [

23] gained electricity cost reduction up to 40% in a home energy management system (HEMS) with a single home using BFOA and pigeon inspired optimization (PIO). Cost, PAR and waiting time of the appliances were calculated on the bases of a 120 h time slot. Two types of appliances were used: interruptible and non-interruptible. Critical peak pricing (CPP) was used as a pricing signal to calculate the electricity bills. Simulation results showed that PIO was identified as the best technique as it performs well in reducing cost. PIO gives 37% more waiting time than BFOA; it has 60% less cost by BFOA and PAR is 3% less by BFOA.

In the fifth row of

Table 1, Wang and others [

24] implemented a genetic algorithm to optimize a micro-grid operation considering distributed generation, environmental factors and demand response (DR). Experiments were conducted on a smart micro-grid from Tianjin, China. The building micro-grid system mainly includes distributed generation, energy storage device, electric vehicle, and various load resources. Two prices mechanisms were used, fixed price and DR prices. The main finding of this model is to optimize the cost in the context of considering demand response and system operation without reducing user comfort. Also, the authors found that the natural gas price dramatically influences both the operation cost of the micro-grid and demand response.

In the sixth row of

Table 1, Ma and others [

25] focus on minimizing the overall system generating cost, including the depreciation cost, the operation cost, the pollutant emission cost, and economic subsidies available for renewable energy source (RES) over the entire dispatch period of an IMG. For experimentation, they use an actual IMG in Dongao Island, China. Authors applied a modified PSO algorithm to solve this optimization problem. Results showed that this algorithm was able to minimize both the fuel consumption cost and pollution emission cost.

In the seventh row of

Table 1, Wang and others [

26] proposed a distributed locational marginal pricing (DLMP)-based unified energy management system (uEMS) model, which considers both increasing profit benefits for distribution generations (DGs) and increasing stability of the distributed power system (DPS). The model contains two parts: (1) a game theory-based loss reduction allocation (LRA); and (2) a load feedback control (LFC) with price elasticity. Simulation results based on a modified IEEE 37-bus system show that uEMS can lead to a more fairly competitive environment for DGs, where the model can increase DGs’ benefits, reduce system losses, and improve stability.

In the last row of

Table 1, Zhu and others [

27] aimed to find the optimal placement and control parameter settings of multiple battery energy storage System (BESS) units to improve oscillation damping in a power transmission system. They formulated a mixed-integer optimization problem and solved it using PSO. Experiments were conducted on two power systems, the New England 39-bus system, and a Nordic test system. This optimization design can be adapted to seasonal load changes and the minimum number of BESS units to be placed. The superiority of the proposed model was validated with another typical type of controllers in the existing literature.

On the other hand, Aziz and others [

28] investigated the techno-economic and environmental performance of a hybrid energy system (HES) under the load following (LF) and cycle charging (CC) strategies using HOMER software as a tool for optimization analysis. Experiments were conducted in a photovoltaic (PV)–diesel–battery configuration. Results show that variations in critical parameters, such as battery minimum state of charge, time step, solar radiation, diesel price, and load growth have considerable effects on the performance of the proposed system.

In summary, the problem of optimal management of energy sources in an IMG can be solved as a dispatch control problem, which deals with the energy flow management from the various sources to load for cost minimization.

This document is organized as follows:

Section 2 presents the mathematical modeling of the Isolated Microgrid proposed.

Section 3 and

Section 4 briefly describe TS-MBFOA and the normalized version called NTS-MBFOA. In

Section 5, results obtained and the discussion of these are presented. Finally, in

Section 6, the conclusions and future works are presented.

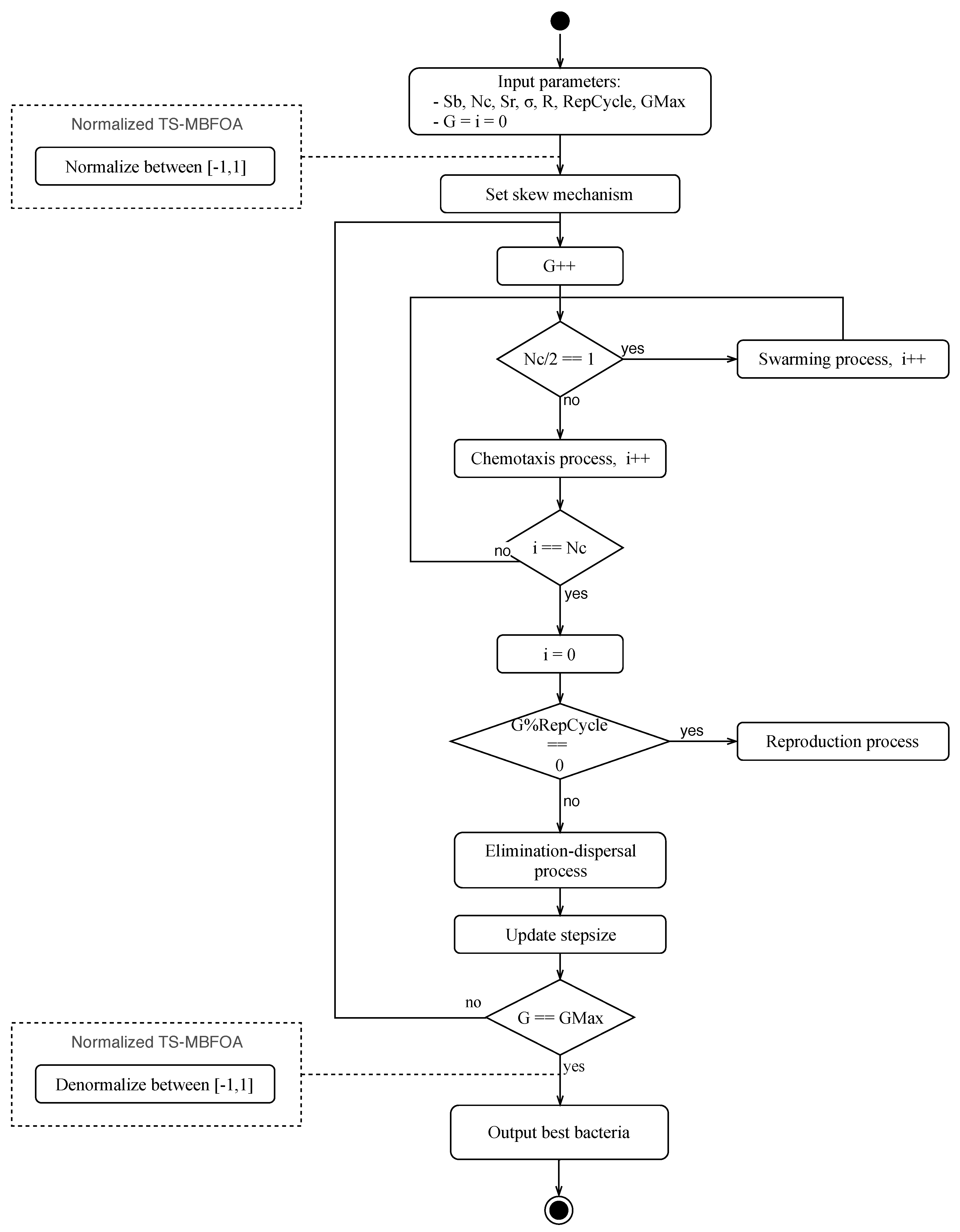

3. Two-Swim Modified Bacterial Foraging Optimization Algorithm (TS-

MBFOA)

TS-MBFOA is an algorithm derived from MBFOA proposed to solve CNOPs [

16]. In this metaheuristic, a bacterium

i represents a potential solution to the CNOP (i.e., a n-dimensional real-value vector identified as

), and it is defined as

, into a population of bacteria (

), where

j is the chemotaxis loop (

).

G is the generational loop that ends up reaching a maximum number of generations (

) or using a number of evaluations, defined by the user, calculated as:

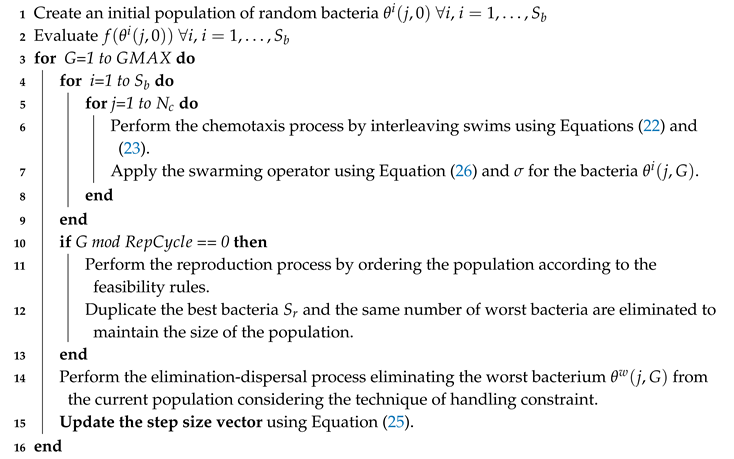

A generation includes the following processes: (1) a chemotaxis process with loops; (2) a swarming towards the best bacterium of the swarm ; (3) a reproduction process, if the frequency parameter (defined by the user) allows it, with the best bacteria of the swarm ; and finally (4) an elimination-dispersal process that eliminates the worst bacterium of the swarm.

Chemotaxis: In this process, two swims are interleaved in each generation: either the exploitation swim or exploration swim is performed. The process starts with the exploitation swim (classical swim). Yet, a bacterium will not necessarily interleave exploration and exploitation swims, because if the new position of a given swim has better fitness (based on the feasibility rules) than the original position , another swim at the same direction will take place in the next loop. Otherwise, a new tumble is computed. The process stops after attempts.

The exploration swim uses the mutation between bacteria and is calculated by:

where

and

are two different randomly selected bacteria from the population. Additionally,

is a parameter defined by the user used in the swarming operator, which defines the proximity of the new position of a bacterium with respect to the position of the best bacteria in the population

. In this operator,

is a positive control parameter for scaling the different vectors in (0,1), i.e., scales of the area where a bacterium can move.

The exploitation swim is calculated as:

where

is calculated with the original tumble operator of BFOA:

where

is a random vector with elements within the range

.

is the random step size of each bacterium updated by:

where

is a randomly generated vector of size

n with elements within the range of each decision variable:

,

, and

R is a user-defined parameter for scaling the step size (this value must be close to zero, for example 5.00E-04). The initial

is generated using

. This random step size allows bacteria to move in different directions within the search space and prevents premature convergence, as suggested in [

31]. Step size

R can be randomly, statically, and dynamically adjusted [

32].

Swarming: At the half number of the chemotaxis process, the swarming operator is applied with (where

is a user-defined positive parameter between (0,1)):

where

is the new position of the bacterium

i,

is the current position of the best generational bacterium and

, is a parameter called scaling factor, which regulates how close the bacterium

i will be from the best bacterium

. In this proposal, if a solution violates the boundary of decision variables then a new solution of

is randomly generated between the lower and upper limits

of the decision variables. The swarming operator movement applies twice in a chemotaxis loop, while in the remaining steps the tumble-swim movement is carried out.

Reproduction: In this process, bacteria are ordered based on the handling constraint technique, duplicating the best bacteria , and eliminating the same number of worst bacteria to maintain the size of the population. The process is carried out once every certain number of cycles which is a user-defined parameter , it aims to allow the diversity in the swarm.

Elimination-dispersal: Finally, the worst bacterium of the population is eliminated based on the feasibility rules, and a new one is randomly generated.

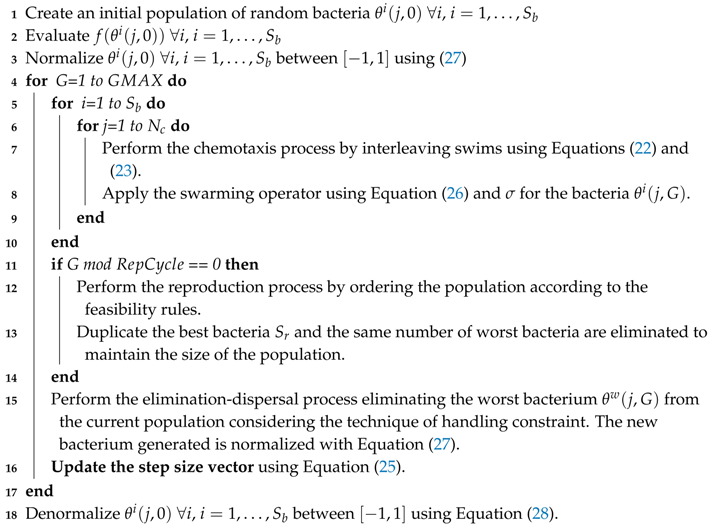

The original proposal of TS-MBFOA includes a skew mechanism to generate the random initial population and a local search engine. However, in this study we did not include this mechanism in order to reduce computational cost. The pseudocode of TS-MBFOA is presented in Algorithm 1.

| Algorithm 1: TS-MBFOA pseudocode. is the number of bacteria, is the number of chemotaxis cycles, is the scaling factor, R is the stepsize, is the number of bacteria to reproduce, is the

reproduction frequency and is the number of generations. |

![Applsci 09 01261 i001 Applsci 09 01261 i001]() |

5. Results

We implemented TS-BFOA and NTS-MBFOA to solve the IMG problem on three computers with the following characteristics: a PC with 4 GB RAM, 2.3 Ghz processor; and two PCs with 8.0 GB RAM, 2.4 GHz processor. We use the Matlab R2018b development platform over a 64 bit Windows operating system.

5.1. First Experiment

First, we calibrate the parameters for TSM-BFOA and NTS-MBFOA via 87 independent runs with a diverse combination of parameters and 15,000 generations. The ranges tested for each parameter were: between [10, 200], between [5,100], between [1, ], between [10, 200], between [0,1] and between [5000,15,000]. The best result obtained from all the independent runs was the value −564,959.112. During the calibration phase, we noticed that the higher the number of bacteria and chemotaxis cycles, the execution time of both algorithms increased from an order of seconds to minutes, due to the number of evaluations needed (number of times that a solution is evaluated in the objective function and constraints), which is calculated by . TS-MBFOA takes ∼14 min, on average, using the best combination of parameters. In the case of NTS-MBFOA, the algorithm takes ∼16 min on average. This time can be improved using a computer with a better processor.

We found that, by increasing the reproduction frequency () to values greater than 60, the results quality of the algorithm decreased, that is, the population of bacteria loses diversity. Therefore, a lower number of bacteria favors the performance of the algorithm.

Finally, values close to zero for the step size R and scaling factor B allow a better balance between exploitation and exploration of the search space and have a positive impact on the performance of the algorithm when generating higher quality solutions according to the objective function.

From these experiments, the best parameter calibration is presented in

Table 4.

5.2. Second Experiment

We ran independently both TS-MBFOA and NTS-MBFOA 30 times with the parameter configuration obtained in the previous experiment. The statistical results of both algorithms are shown in

Table 5. The standard deviation is calculated using the best solution found in each of the 30 independent runs, where the best solution is the sum of the 24 objective functions in a run.

TS-MBFOA obtained the best solution with a value of −551,960.121 followed by NTS-MBFOA with a value −549,369.785 in the objective function. Values are negative because they represent an economic saving when operating with RES, instead of using only the diesel generator and the ESS (battery). The more energy supplied by the RES and the less supplied by the DG and the ESS, the higher the savings.

A convergence graph was generated for TS-MBFOA and NTS-MBFOA using the data of the independent run number 15 (representing the median). In

Figure 4, we can observe the behavior of each algorithm during the 24 h, both algorithms starting with infeasible solutions. For the NTS-MBFOA, feasible solutions arise in the first ∼10 generations, except for hours 16:00, 17:00, and 23:00, where the algorithm requires more generations. For the TS-MBFOA, solutions are found beyond 200 generations. As can be observed in

Figure 4, the NTS-MBFOA converges more quickly on feasible solutions, which indicates a lower computational cost than TS-BFOA.

With respect to the quality of the solutions found by the algorithms in each of the 24 h, the convergence graphs indicate that both algorithms behave differently along the day, but in hours 00:00, 02:00–04:00, 06:00–07:00, 13:00–14:00, 16:00–18:00 and 22:00–23:00 the TS-MBFOA algorithm generates better feasible solutions. In the rest of the hours, NTS-MBFOA generates a better solution to the objective function. In run number 15, the TS-MBFOA obtained a value of −525,869.49 in the objective function, in the case of NTS-MBFOA the value found was −422,989.41.

Results of bacterial foraging-based algorithms are better when compared against the LSHADE-CV algorithm. However, a higher number of evaluations is required. Parameters reported by the authors of LSHADE-CV algorithm are presented in

Table 6. LSHADE-CV dynamically tuned the parameters using operators such as parameter memory and linear population reduction [

35]. The best numeric solution was −532,508.057. Besides, BFOAs obtained a better median, average, standard deviation and the worst value found is close to the average.

Analyzing the results of the TS-MBFOA and the NTS-MBFOA, we observed that NTS-MBFOA has a lower standard deviation than the TS-MBFOA because it finds the better among the worst results, that is, results closer to the average. To know if there is a significant difference between the NTS-MBFOA and TS-MBFOA algorithms, we conducted the non-parametric Wilcoxon Signed Rank Test, with a confidence level of 95% to the set of the 30 best solutions obtained of the 30 independent runs of each algorithm. The result obtained by this test was a p value of 0.00112, which implies that there is a significant difference between the results of both algorithms.

To analyze results from the mechatronic point of view, we used the values of the best solution generated by TS-MBFOA, NTS-MBFOA, and LSHADE-CV, respectively, for the IMG during the 24 h. Values presented in

Table 7,

Table 8 and

Table 9 were used to generate the IMG behavior graphs shown in

Figure 5, respectively. In these graphs, each resource is marked with different lines. In the case of the BFOAs, it is important to highlight that the conditions established for the use of solar and wind energy favor the high demand for diesel consumption (see

Table 3).

Analyzing the behavior graphs of the TS-MBFOA and the NTS-MBFOA, we can observe that both algorithms produce similar results, i.e., both allow the consumption of solar and wind energy while decreasing the use of the diesel generator and the intervention of the battery (ESS).

Specifically, the use of solar power increases from 07:00 h onwards and decreases after 17:00 h, when the sun begins to hide. Concerning the wind power, both graphs show variations of peaks in the first hours, reaching a maximum production of energy close to 1250 watts between the 13:00 and 19:00 h. The ESS operates in a considerable and constant way between 13:00 h and 18:00 h. However, in the early hours of the day, the solution generated by TS-MBFOA presents several peaks (state transitions of the battery operation) that fall and rise abruptly, which decreases the battery’s lifetime.

The behavior of the solar and wind power, as well as ESS, tends to reduce the diesel demand from 12:00 h. Moreover, diesel is even not used for one hour, between 14:00 and 15:00 h, in both algorithms. However, when solar power is depleted, diesel power begins to rapidly increase. Analyzing the behavior of the use of diesel in the early hours of the day, it is evident that the NTS-MBFOA solution allows less diesel generator starts by having fewer peaks during the first hours of the day, which increases the lifetime of the diesel generator.

TS-MBFOA obtained a better solution in numbers, with in the objective function value, compared to NTS-MBFOA, that obtained a value of in the objective function. The behavior of the graph lines, which correspond to the resources used in the IMG, favors the NTS-MBFOA because this solution increases the useful lifetime of the ESS and the DG, allowing economic savings on the long term.

Comparing the behavior graphs of the NTS-MBFOA and LSHADE-CV, we observe similar behavior in all the components of the IMG. Only from the hour 15:00 to 16:00 h it is evident how the EA delays the start of the diesel generator. On the other hand, from the hour 21:00 to 22:00 h, this algorithm starts the diesel generator slightly, something that does not happen in NTS-MBFOA. Since the graphs are very similar, we can take the numerical values as a point of comparison, where the best results of both algorithms were −549,369.785 and 532,508.057, respectively. We can conclude that both algorithms are competitive, but NTS-MBFOA obtains better results. However, the competitiveness of the evolutionary algorithm is evident, even with fewer generations than our proposal.

6. Conclusions

Two algorithms, TS-MBFOA and NTS-MBFOA, based on the foraging of the E. Coli bacteria were implemented to solve a CNOP minimizing an isolated microGrid (IMG). An IMG is an intelligent energy network that uses distributed generators allowing the exploitation of renewable energy sources, such as wind and solar, as well as fuels (e.g., diesel, petrol). The CNOP is based on a mathematical model, wherein the optimum values of a network of power generation devices are computed to supply a load during 24 h. In essence, every hour an optimization problem is solved, according to the conditions and operation restrictions of the network. As a result, we generate behavior graphs of the optimal powers, i.e., the sum of the 24 objective functions, which represents the best solution.

Two experiments were designed to monitor the behavior of the algorithms while minimizing the IMG. In the first experiment, 87 independent runs were conducted with different values to the parameters of the TS-MBFOA algorithm in order to obtain the best configuration of parameters that allows the optimal performance of the algorithm. As a result of this experiment, we obtained that the best performance of the algorithm was using a population of 10 bacteria, eight chemotaxis cycles, five bacteria to reproduce every 60 generations with a step size of 0.015 and a scaling factor of 0.040. We also noticed that, the higher the number of bacteria and chemotaxis cycles, the longer the execution time required by the algorithm.

In the second experiment, 30 independent runs of both TS-MBFOA and NTS-MBFOA were conducted, using the parameter tuning obtained in the previous experiment. The best solution obtained by TS-MBFOA was −551,960.121 and by NTS-MBFOA was −549,369.785, where a lower value is better, meaning economic savings. Both results are the sum of the 24 objective functions.

A non-parametric Wilcoxon signed rank test was conducted for the 30 best solutions of each of the algorithms, resulting in a significant difference between both algorithms.

Results obtained by TS-MBFOA and NTS-MBFOA were compared against the LSHADE-CV algorithm, where the best solution found by our proposals were better, although at a higher computational cost.

According to results, TS-MBFOA found a better numerical solution to the problem. From the mechatronic point of view, however, it is important to notice that NTS-MBFOA obtained a better result because it favors the useful life both of the diesel generator and the energy storage system (battery). This conclusion arises from a behavior analysis of each resource used by the IMG during the 24 h of a day.

As future work, more experiments will be conducted on TS-MBFOA and NTS-MBFOA to reduce the number of evaluations and find highly competitive solutions against other state-of-the-art algorithms. We are motivated in advance in the study of IMG for a real implementation in a low-consumption energy housing.