A New Hybrid Reciprocating Compressor Model Coupled with Acoustic FEM Characterization and Gas Dynamics

Abstract

1. Introduction

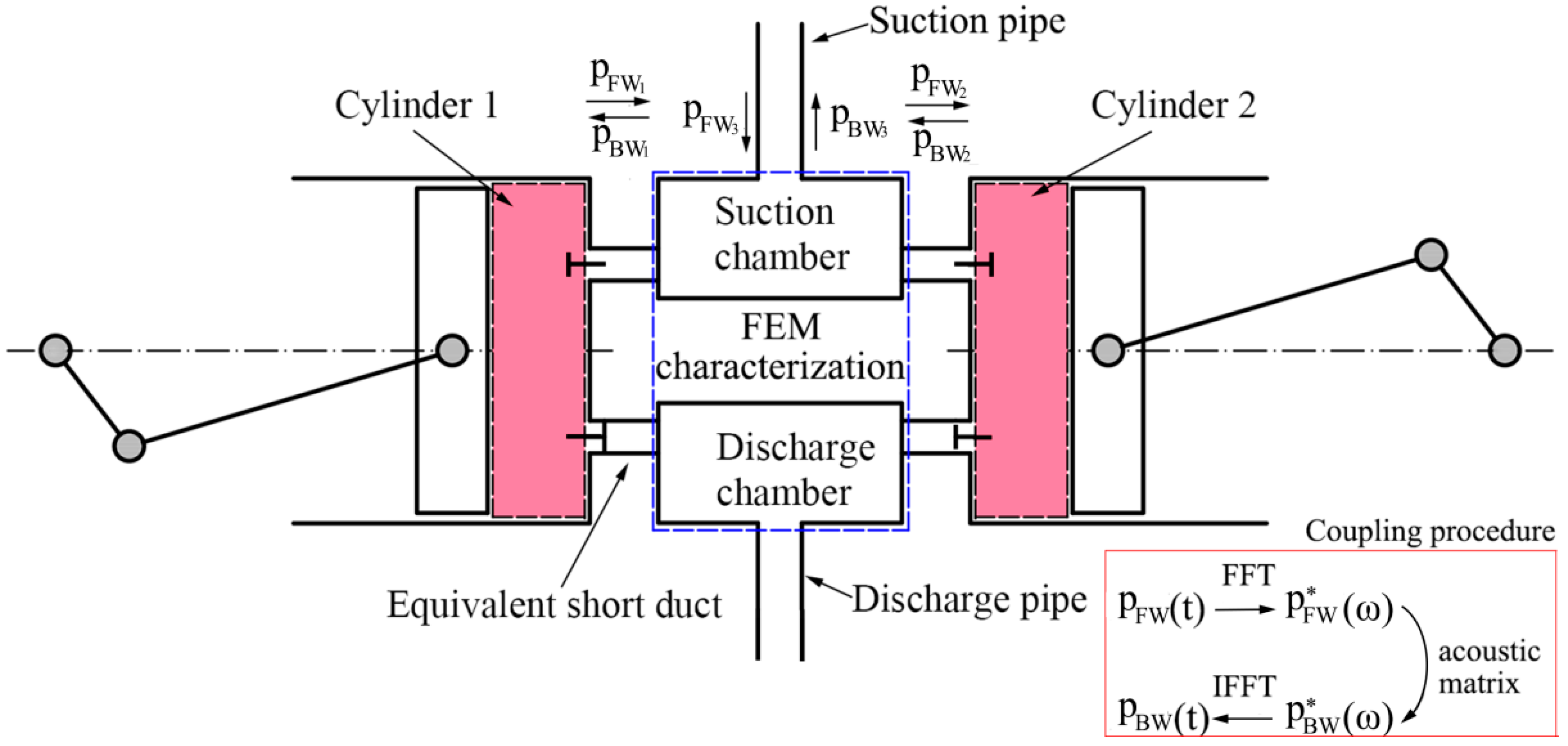

2. Hybrid Model

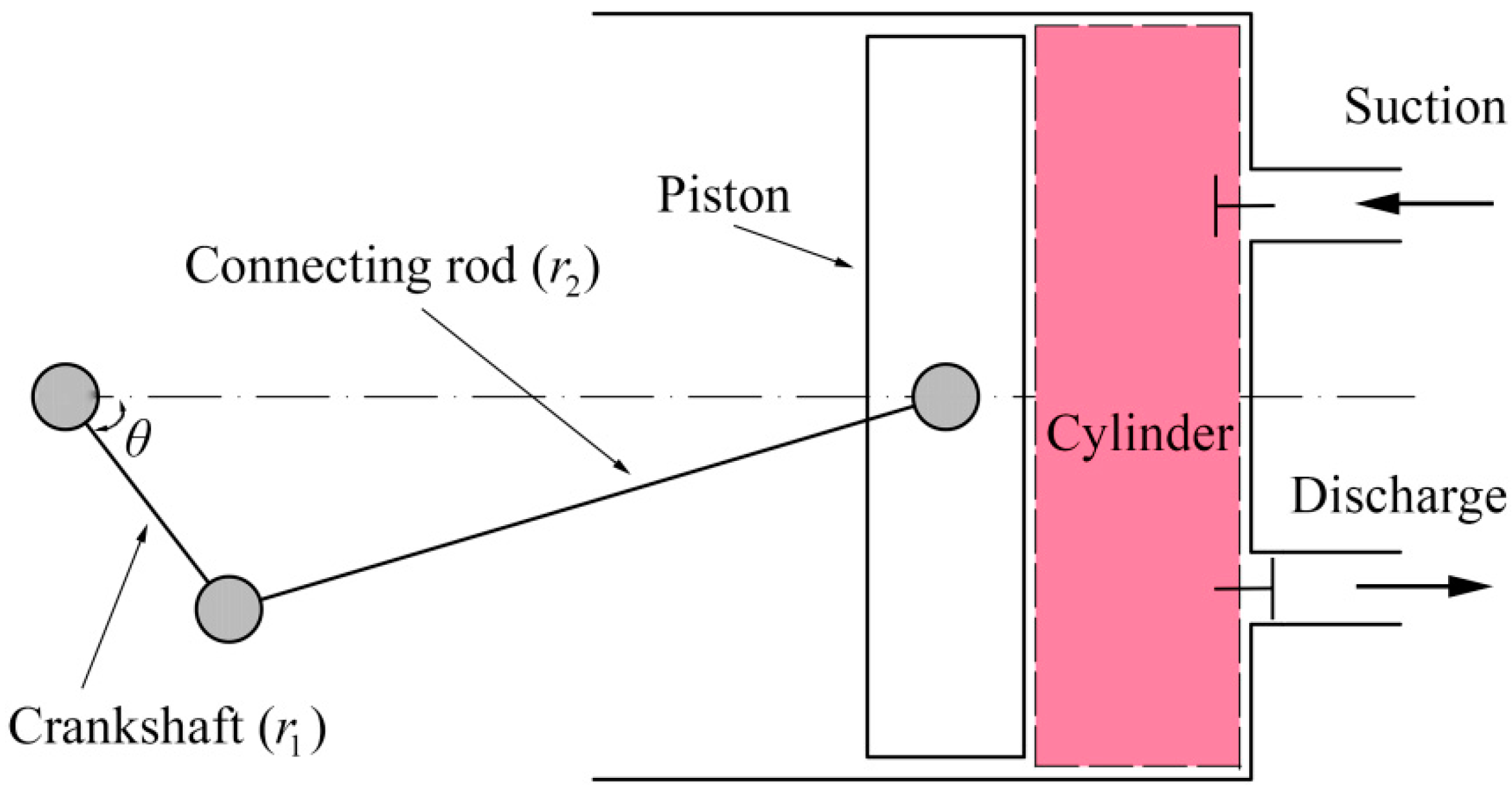

2.1. Reciprocating Compressor Sub-Model

2.2. In-Pipe Gas Dynamic Sub-Model

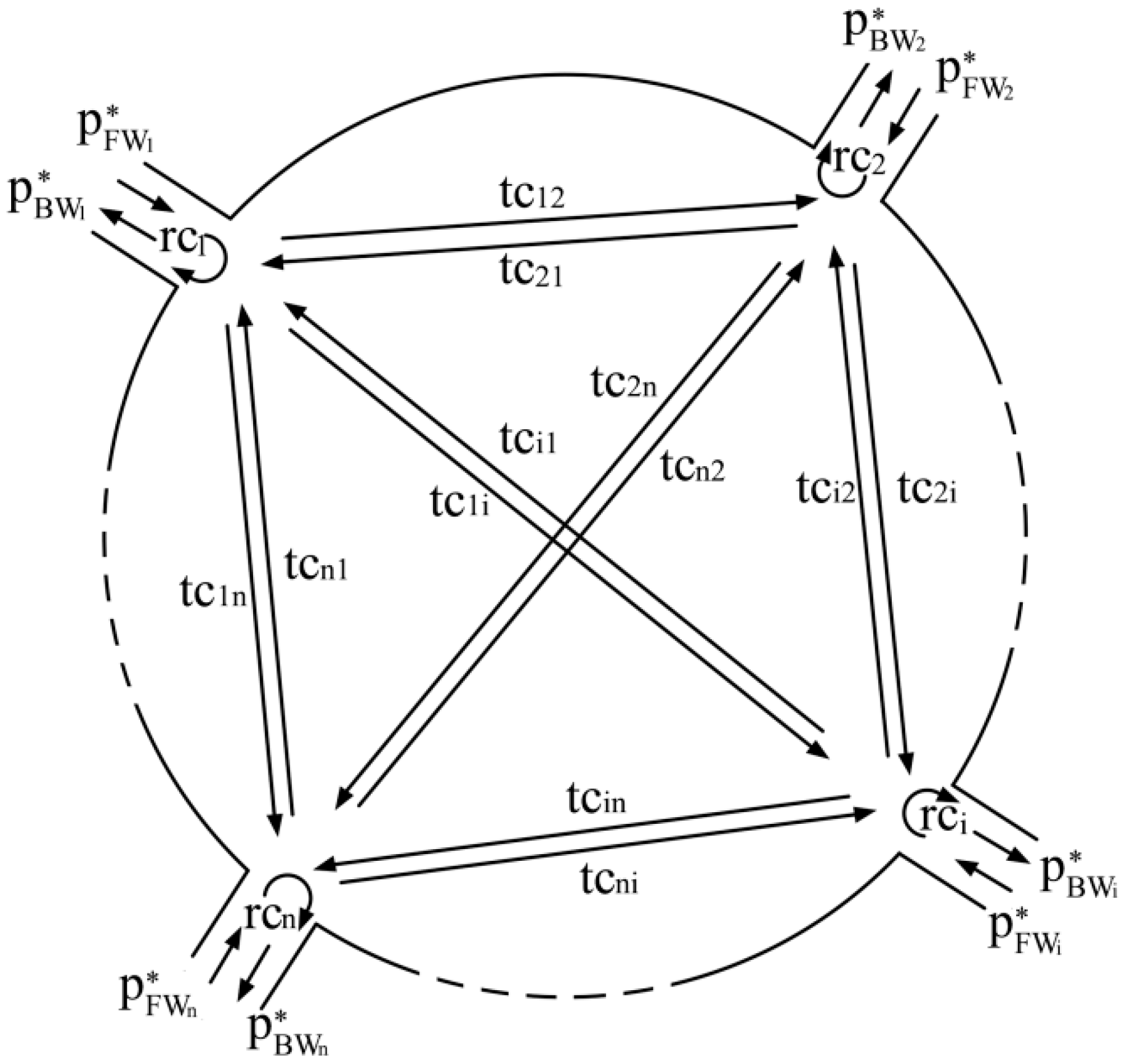

2.3. Acoustic FEM Characterization Sub-Model

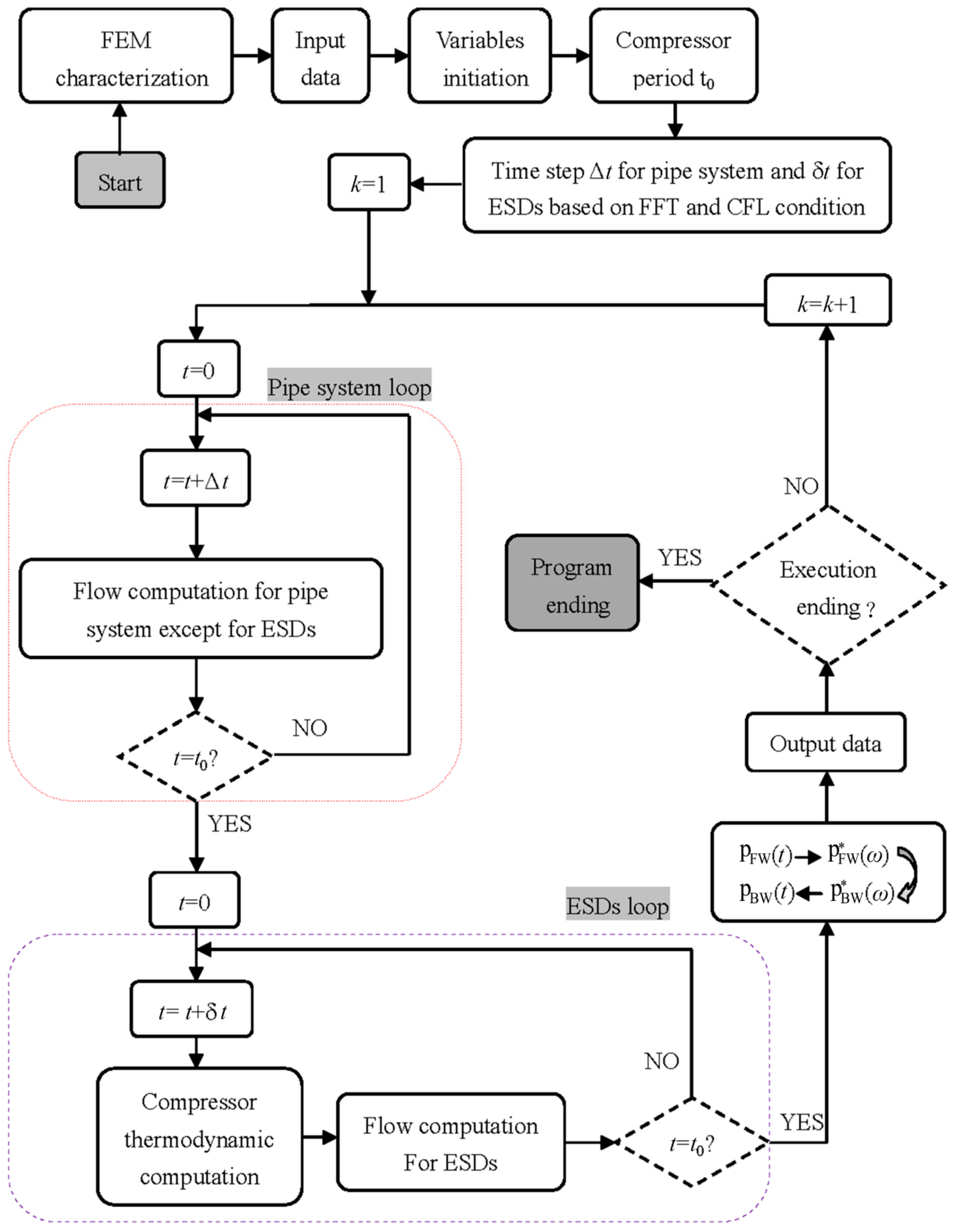

2.4. Numerical Procedure

3. Results and Discussion

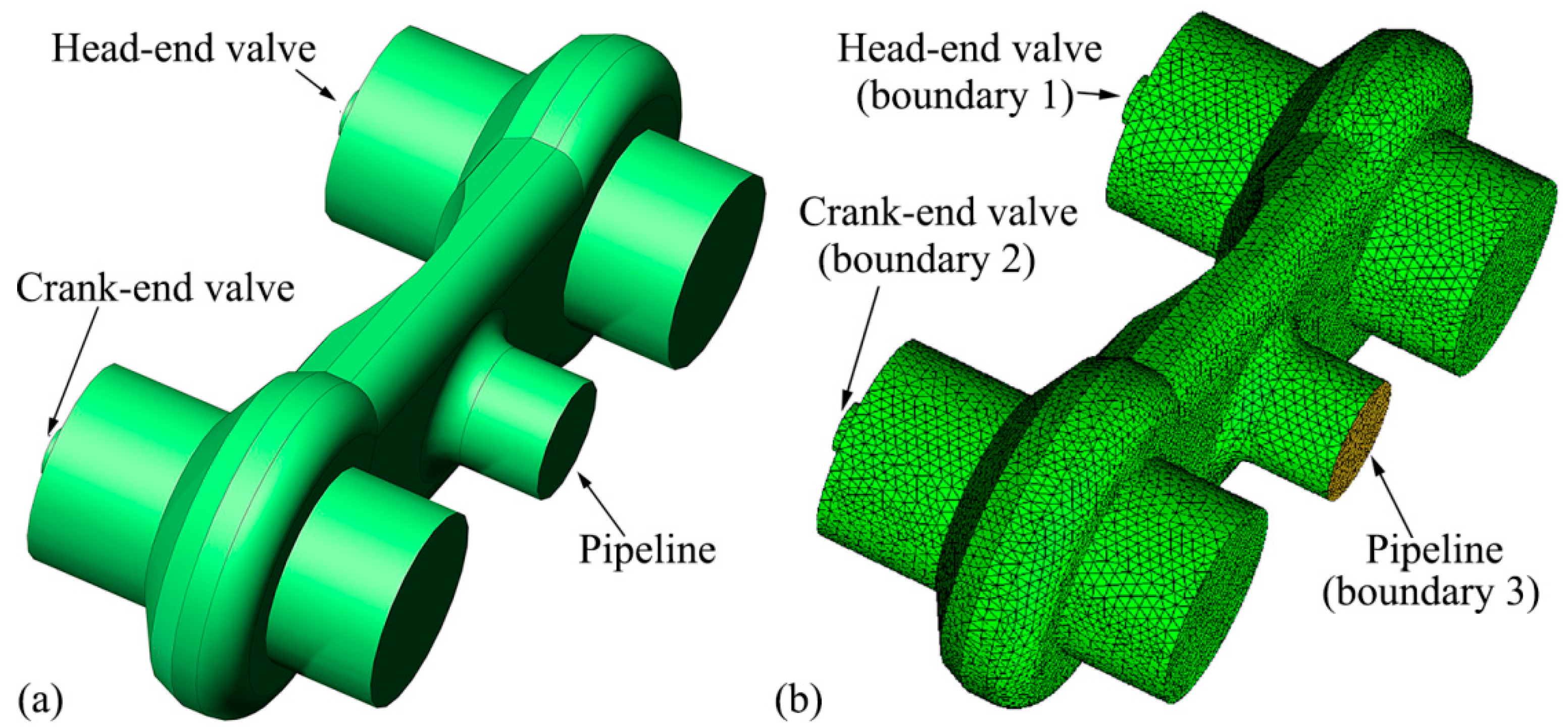

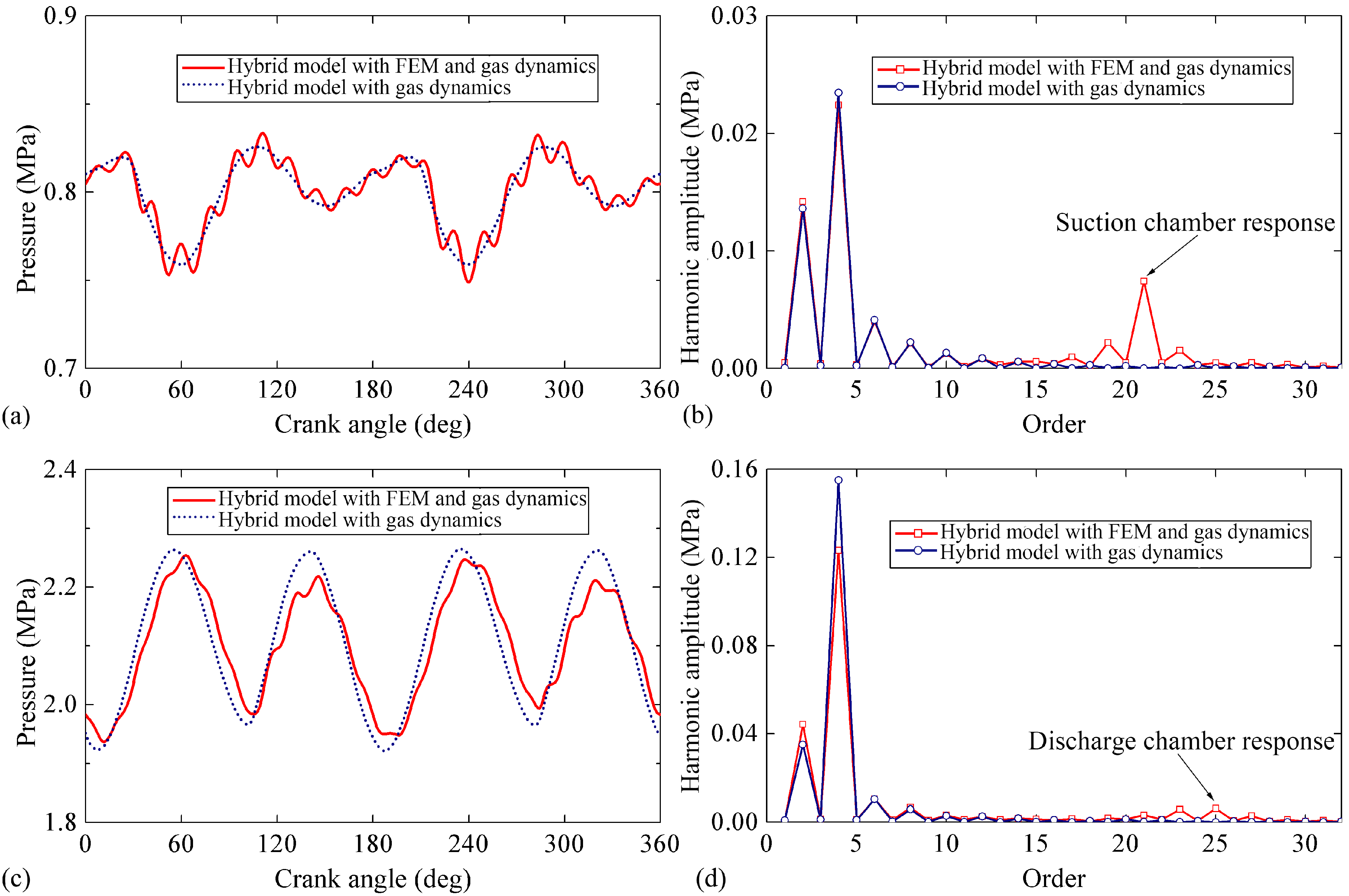

3.1. Case 1: Geometries with Multi Ports

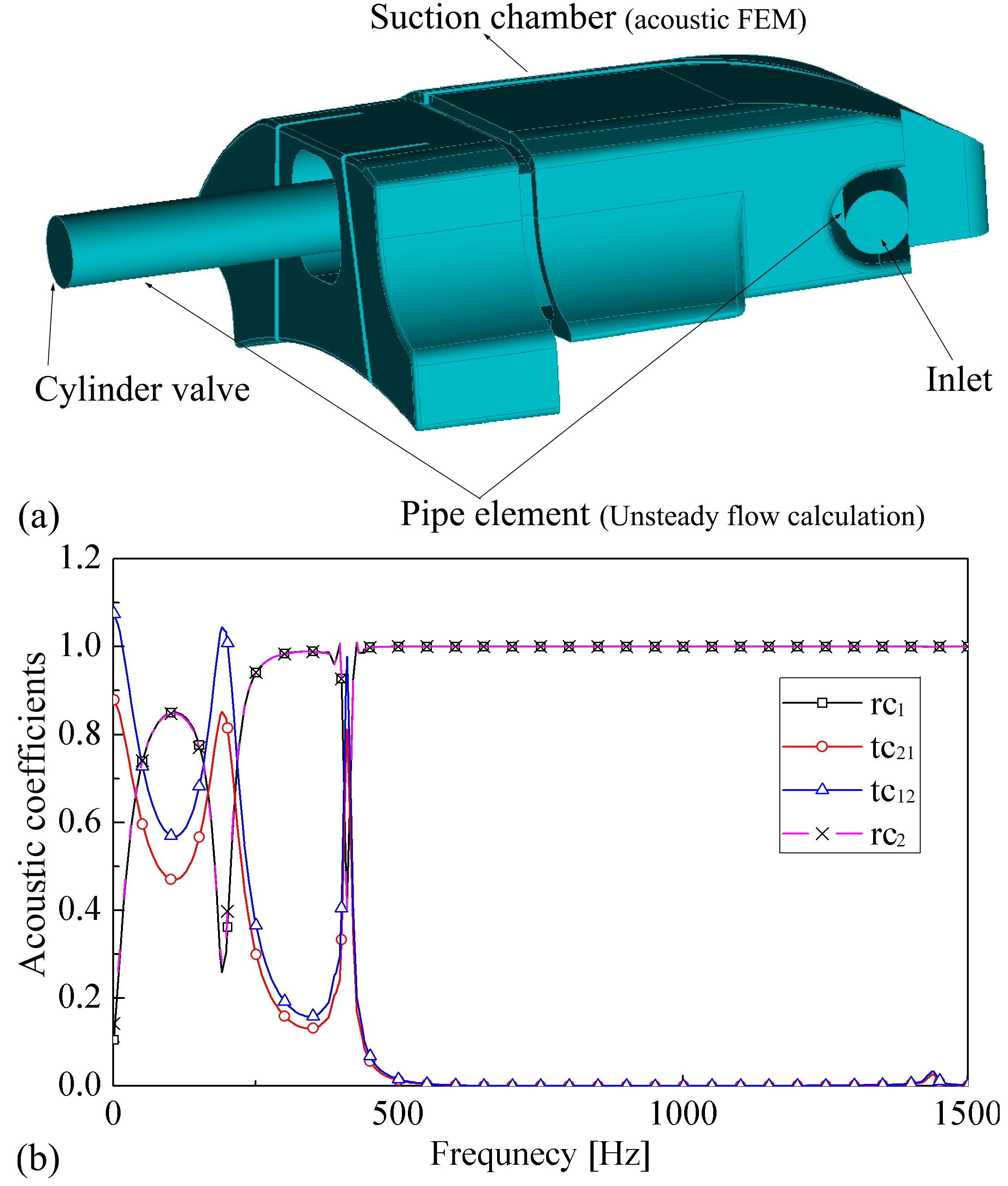

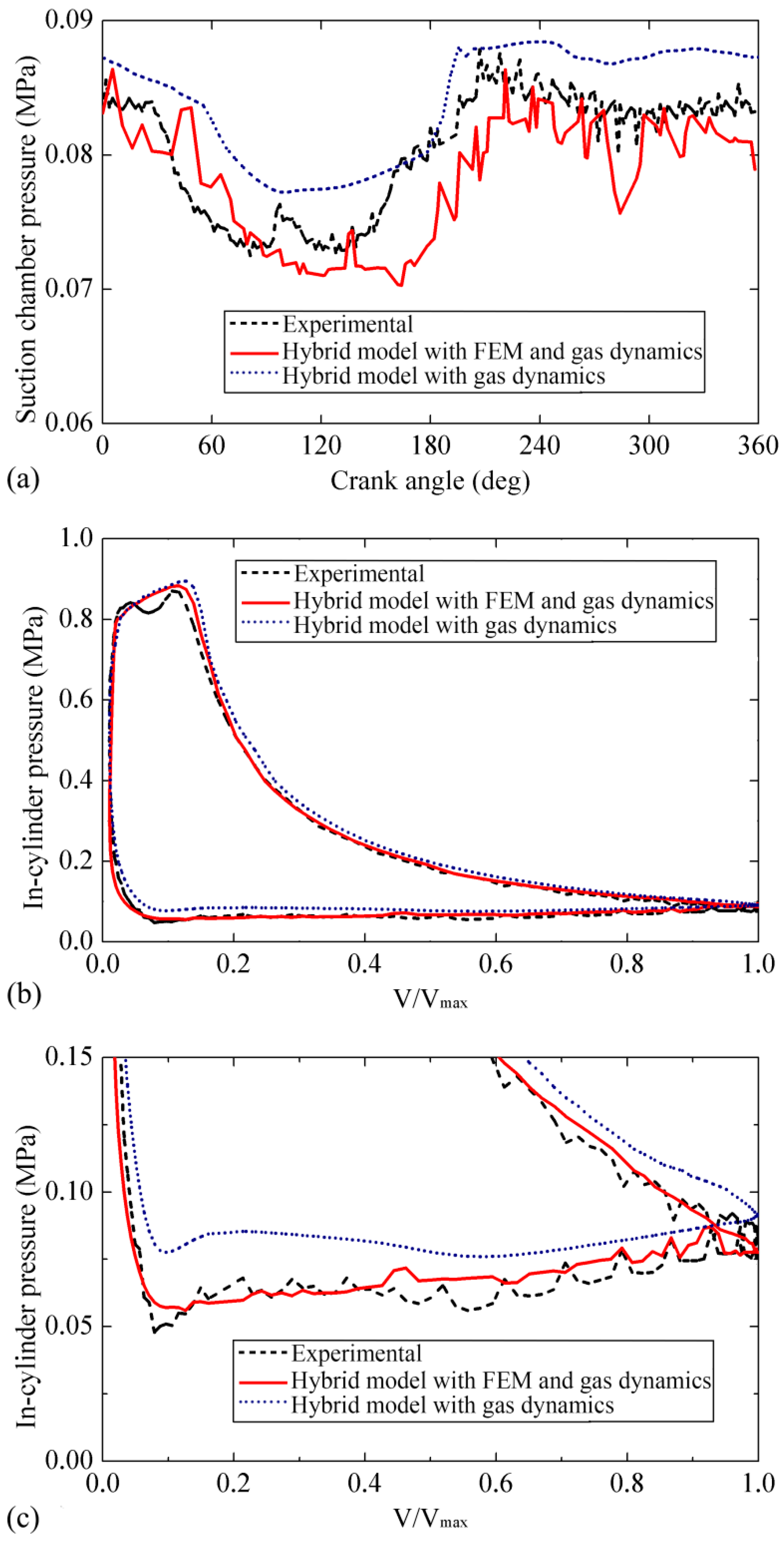

3.2. Case 2: Geometries with Single Input and Output

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbols | |

| t | time (s) |

| m | mass (kg) |

| p | pressure (Pa) |

| A | area (m2) |

| ρ | density (kg·m−3) |

| y | valve displacement (m) |

| Q | heat in the control volume (J) |

| h | specific enthalpy (J·kg−1·K−1) |

| qf | acoustic source power-flux per unit volume |

| V | volume (m3) |

| T | temperature (K) |

| u | characteristic velocity (m·s−1) |

| D | diameter (m) |

| r1 | crank radius (m) |

| r2 | length of connecting rod (m) |

| kk | spring stiffness (N·m−1) |

| AD | valve plate area (m2) |

| Ginit | pre-load force (N) |

| ceq | damping coefficient (N·s·m−1) |

| CD | drag coefficient |

| U | solution vector |

| F | flux vector |

| B | source term vector |

| Gf | friction term |

| rc | reflection coefficient |

| tc | transmission coefficient |

| Y | acoustic impedance |

| a | sound speed (m·s−1) |

| σ | wave number |

| e | specific internal energy (J·kg−1) |

| aA | entropy level (m·s−1) |

| q | heat transferred between gas and |

| walls per unit of mass (W·kg−1) | |

| Y | Acoustic impedance (kg·m−2·s−1) |

| Abbreviations | |

| CFD | computational fluid dynamics |

| 3D | three dimensional |

| 1D | one dimensional |

| 0D | zero dimensional |

| FEM | finite element method |

| MOC | method of characteristics |

| ESD | Equivalent Short Duct |

| Greek symbols | |

| φ | flow coefficient |

| α | heat transfer coefficient (W·m−2·K−1) |

| ω | angular speed (rad·s−1) |

| ξ | damping factor |

| γ | specific heat ratio |

| λ, β | riemann variables |

| Δ | change quantity |

| Superscripts | |

| * | acoustic properties |

| k | period step |

| Subscripts | |

| cv | control volume |

| s | suction |

| d | discharge |

| p | piston |

| cl | clearance |

| eq | equivalent |

| reb | rebound |

| imp | impact |

| 0 | stagnation state |

| FW | forward |

| BW | backward |

| ref | reference condition |

| i, j | port number of chamber |

References

- Sharma, S.S. Determinants of carbon dioxide emissions: Empirical evidence from 69 countries. Appl. Energy 2011, 88, 376–382. [Google Scholar] [CrossRef]

- Aigner, R. Internal Flow and Valve Dynamics in a Reciprocating Compressor. Ph.D. Thesis, Technische Universität Wien, Vienna, Austria, 2007. [Google Scholar]

- Kim, S.; Cheong, C.; Park, J.; Kim, H.; Lee, H. Investigation of flow and acoustic performance of suction mufflers in hermetic reciprocating compressor. Int. J. Refrig. 2016, 69, 74–84. [Google Scholar] [CrossRef]

- Wang, T.; Guo, Y.; He, Z.L.; Peng, X.Y. Investigation on the delayed closure of the suction valve in the refrigerator compressor by FSI modeling. Int. J. Refrig. 2018, 91, 111–121. [Google Scholar]

- Damle, R.; Rigola, J.; Perez-Segarra, C.D.; Oliva, A. Object-oriented simulation of reciprocating compressor: Numerical verification and experimental comparison. Int. J. Refrig. 2011, 34, 1989–1998. [Google Scholar] [CrossRef]

- Yang, B.; Bradshaw, C.R.; Groll, A.A. Modelling of a semi-hermetic CO2 reciprocating compressor including lubrication submodels for piston rings and bearings. Int. J. Refrig. 2013, 36, 1925–1937. [Google Scholar] [CrossRef]

- Liu, Z.; Cao, X.; Wang, T.; Jia, W.G.; Duan, Z.Y. Comparative evaluation of the refrigeration compressor performance under different valve parameters in a trans-critical CO2 cycle. Int. J. Refrig. 2019, 101, 34–46. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Niazmand, A.; Deymi-Dashtebayaz, M.; Rahbari, H.R. Effects of natural gas compositions on CNG (compressed natural gas) reciprocating compressors performance. Energy 2015, 90, 1152–1162. [Google Scholar] [CrossRef]

- Tuhovcak, J.; Hejcik, J.; Jicha, M. Comparison of heat transfer models for reciprocating compressor. Appl. Therm. Eng. 2016, 103, 607–615. [Google Scholar] [CrossRef]

- Elson, J.P.; Soedel, W. A review of discharge and suction line oscillation research. In Proceedings of the Purdue Compressor Technology Conference, West Lafayette, IN, USA, 25–27 July 1972. [Google Scholar]

- Zhou, W.; Kim, J.; Soedel, W. New iterative scheme in computer simulation of positive displacement compressors considering the effect of gas pulsations. ASME J. Mech. Des. 2001, 123, 282–288. [Google Scholar] [CrossRef]

- Keith, N. Influence of shell volume on pressure pulsations in a hermetic reciprocating compressor. In Proceedings of the International Compressor Engineering Conference at Purdue, West Lafayette, IN, USA, 14–17 July 2014. [Google Scholar]

- Stiaccini, I.; Galoppi, G.; Ferrari, L.; Ferrara, G. A reciprocating compressor hybrid model with acoustic FEM characterization. Int. J. Refrig. 2016, 63, 171–183. [Google Scholar] [CrossRef]

- Stiaccini, I.; Galoppi, G.; Ferrari, L.; Ferrara, G. A hybrid time-frequency domain approach for numerical modeling of reciprocating compressors. Energy Procedia 2015, 81, 1102–1112. [Google Scholar] [CrossRef]

- Benson, R.S. The Thermodynamics and Gas Dynamics of Internal Combustion Engines; Clarendon Press: Oxford, UK, 1982. [Google Scholar]

- Xu, B.; Feng, Q.K.; Yu, X.L. Prediction of pressure pulsation for the reciprocating compressor system using finite disturbance theory. ASME J. Vibr. Acoust. 2009, 131, 031007. [Google Scholar] [CrossRef]

- Liu, Z.; Duan, Z.Y. Development of a transient gas dynamic model for the simulation of pulsation in reciprocating compressor piping systems. Proc. IMechE. Part E J. Process Mech. Eng. 2018, 232, 685–695. [Google Scholar]

- Brun, K.; Nored, M.G.; Rainer, K. Impact of piping impedance and acoustic characteristics on centrifugal compressor surge and operating range. ASME J. Eng. Gas. Turbines Power 2014, 137, 032603. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1; NIST: Gaithersburg, MA, USA, 2013.

- Roskosch, D.; Venzik, V.; Atakan, B. Thermodynamic model for reciprocating compressors with the focus on fluid dependent efficiencies. Int. J. Refrig. 2017, 84, 104–116. [Google Scholar] [CrossRef]

- Belman-Flores, J.M.; Ledesma, S.; Barroso-Maldonado, J.M.; Navarro-Esbrí, J. A comparison between the modeling of a reciprocating compressor using artificial neural network and physical model. Int. J. Refrig. 2015, 59, 144–156. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, C.; Jia, X.H.; Peng, X.Y. Fault diagnosis of reciprocating compressor valve with the method integrating acoustic emission signal and simulated valve motion. Mech. Syst. Signal Process 2015, 56–57, 197–212. [Google Scholar] [CrossRef]

- Gascon, L.; Corberan, J.M. Construction of second-order TVD schemes for nonhomogeneous hyperbolic conservation laws. J. Comput. Phys. 2001, 172, 261–297. [Google Scholar] [CrossRef]

- Payri, F.; Desantes, J.M.; Torregrosa, A.J. Acoustic boundary condition for unsteady one-dimensional flow calculations. J. Sound Vib. 1995, 188, 85–110. [Google Scholar] [CrossRef]

- Serrano, J.R.; Climent, H.; Piqueras, P.; García-Afonso, O. Analysis of shock capturing methods for chemical species transport in unsteady compressible flow. Math. Comput. Model 2013, 57, 1751–1759. [Google Scholar] [CrossRef]

| Specification | Value | Unit |

|---|---|---|

| Rotational speed | 950 | rpm |

| Cylinder diameter | 105 | mm |

| Stroke | 110 | mm |

| Diameter of the pipeline | 50 | mm |

| Length of suction pipe | 0.47 | m |

| Length of discharge pipe | 0.65 | m |

| Suction temperature | 304.15 | K |

| Suction pressure | 0.802 | MPa |

| Discharge pressure | 2.1 | MPa |

| Discharge temperature | 367.15 | K |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Lan, Z.; Guo, J.; Zhang, J.; Xie, Y.; Cao, X.; Duan, Z. A New Hybrid Reciprocating Compressor Model Coupled with Acoustic FEM Characterization and Gas Dynamics. Appl. Sci. 2019, 9, 1179. https://doi.org/10.3390/app9061179

Liu Z, Lan Z, Guo J, Zhang J, Xie Y, Cao X, Duan Z. A New Hybrid Reciprocating Compressor Model Coupled with Acoustic FEM Characterization and Gas Dynamics. Applied Sciences. 2019; 9(6):1179. https://doi.org/10.3390/app9061179

Chicago/Turabian StyleLiu, Zhan, Zhujun Lan, Jianzhang Guo, Junmei Zhang, Yushen Xie, Xing Cao, and Zhenya Duan. 2019. "A New Hybrid Reciprocating Compressor Model Coupled with Acoustic FEM Characterization and Gas Dynamics" Applied Sciences 9, no. 6: 1179. https://doi.org/10.3390/app9061179

APA StyleLiu, Z., Lan, Z., Guo, J., Zhang, J., Xie, Y., Cao, X., & Duan, Z. (2019). A New Hybrid Reciprocating Compressor Model Coupled with Acoustic FEM Characterization and Gas Dynamics. Applied Sciences, 9(6), 1179. https://doi.org/10.3390/app9061179