Biochar as a Multifunctional Component of the Environment—A Review

Abstract

1. Introduction

2. Biochar and its Properties

3. Legal Aspects and Quality Standards

- -

- the object or substance is commonly used for particular purposes,

- -

- there is a market or demand for such objects or substances,

- -

- the object or substance meets the technical requirements for applications related to specific purposes as well as the requirements set out in the rules and standards applicable to the product,

- -

- use of the object or substance does not lead to negative consequences for human life or well-being or for the environment, as well as the requirements defined by regulations of the European Union” [56]. Given the above, biochar is no longer classified as waste.

4. Biochar in Environmental Conservation

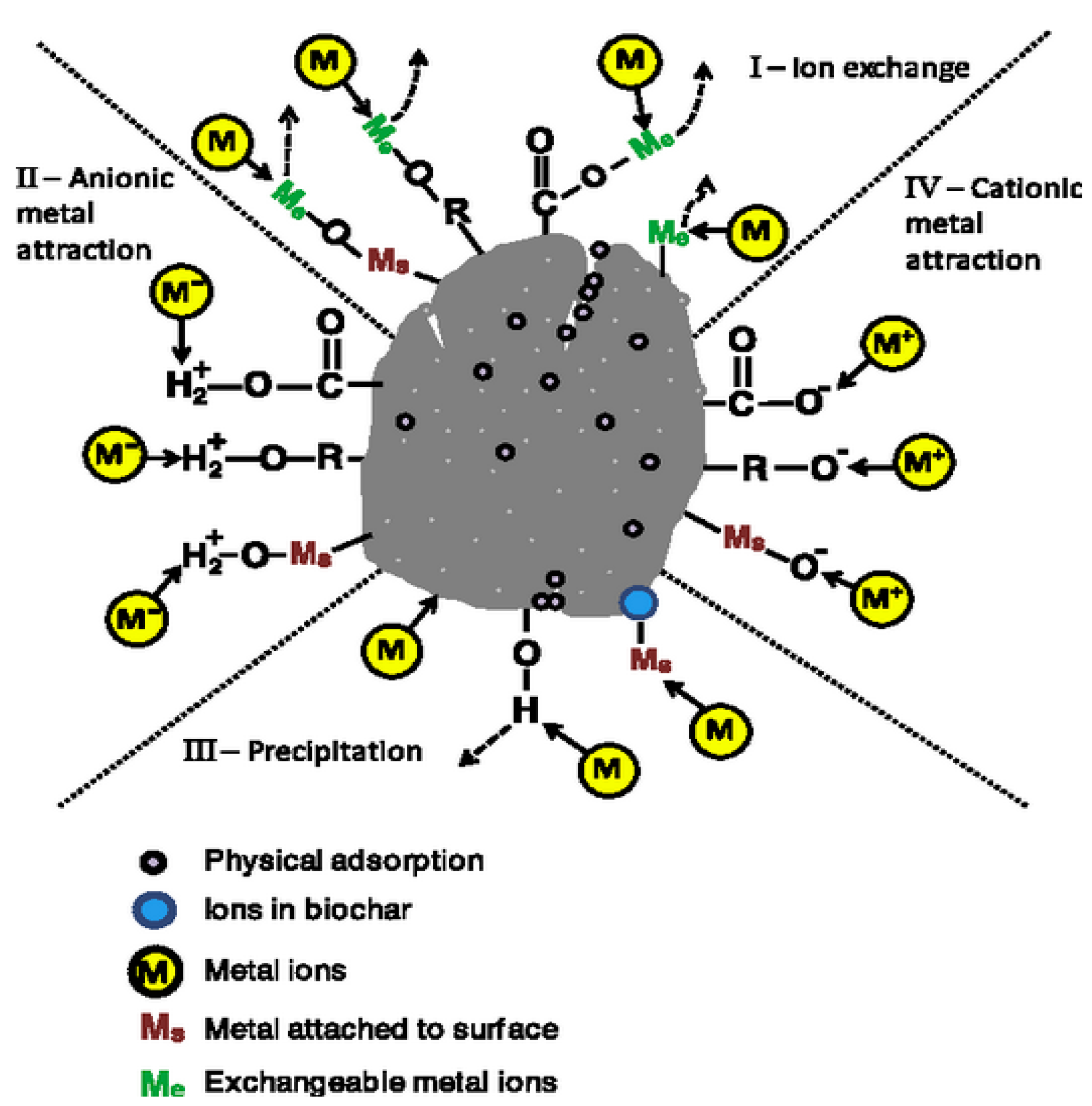

5. Biochar as a Activated Carbons

- -

- ion exchange (Na+, K+ ions are involved),

- -

- precipitation,

- -

- anionic metal attraction,

- -

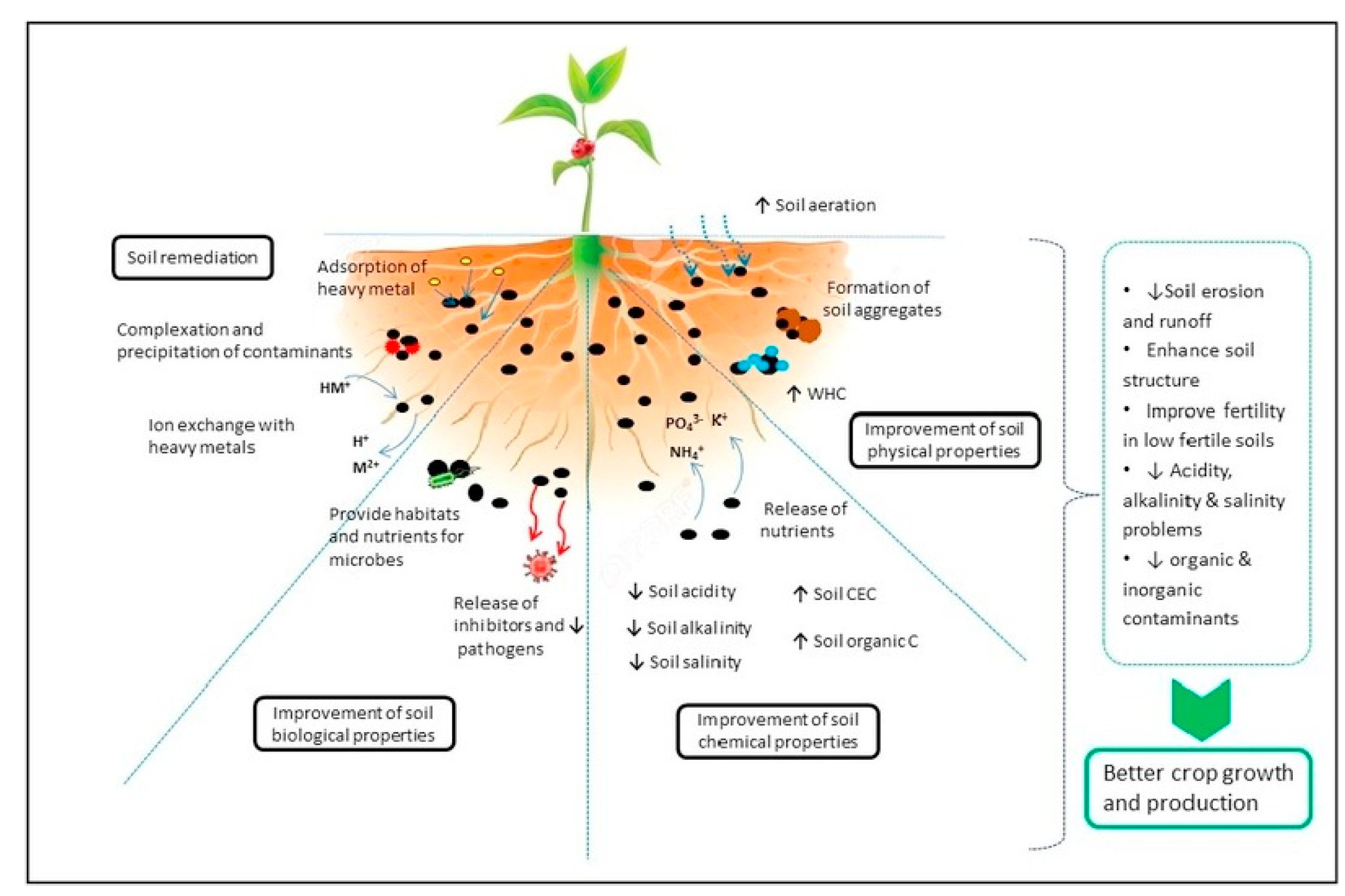

6. Biochar as Soil Conditioner

7. Conclusions

Funding

Conflicts of Interest

References

- IBI Biochar Standards—Standardized Product Definition and Product Testing Guidelines for Biochar That Is Used in Soil, v.2.1. Available online: http://www.biochar-international.org/sites/default/files/IBI_Biochar_Standards_V2.1_Final.pdf (accessed on 1 February 2019).

- Malińska, K. Legal and quality aspects of requirements defined for biochar. Inżynieria i Ochrona Środowiska 2015, 18, 359–371. [Google Scholar]

- Pereira, R.C.; Muetzel, S.; Arbestain, M.C.; Bishop, P.; Hina, K.; Hedley, M. Assessment of the influence of biochar on rumen and silage fermentation: A laboratory–scale experiment. Anim. Feed Sci. Technol. 2014, 196, 22–31. [Google Scholar] [CrossRef]

- Tang, J.; Zhy, W.; Kookana, R.; Katayama, A. Characteristics of biochar and its application in remediation of contaminated soil. J. Biosci. Bioeng. 2013, 116, 653–659. [Google Scholar] [CrossRef] [PubMed]

- Mohan, D.; Sarswat, A.; Ok, S.Y.; Pittman, C.U., Jr. Organic and inorganic contaminants removal from water with biochar, a renewable, low cost and sustainable adsorbent—A critical review. Bioresour. Technol. 2014, 160, 191–202. [Google Scholar] [CrossRef]

- Steiner, C.; Das, K.C.; Melear, N.; Lakly, D. Reducing nitrogen loss during poultry litter composting using biochar. J. Environ. Qual. 2010, 39, 1236–1242. [Google Scholar] [CrossRef]

- Steiner, C.; Melear, N.; Harris, K.; Das, K.C. Biochar as bulking agent for poultry litter composting. Carbon Manag. 2011, 2, 227–230. [Google Scholar] [CrossRef]

- Malińska, K.; Zabochnicka-Świątek, M.; Dach, J. Effects of biochar amendment on ammonia emission during composting of sewage sludge. Ecol. Eng. 2014, 71, 474–478. [Google Scholar] [CrossRef]

- Malińska, K.; Dach, J. Biochar as a supplementary material for biogas production. Ecol. Eng. 2015, 4, 117–124. [Google Scholar] [CrossRef]

- Paethanom, A.; Bartocci, P.; D’ Alessandro, B.; D’ Amico, M.; Testarmata, F.; Moriconi, N.; Slopiecka, K.; Yoshikawa, K.; Fantozzi, F. A low-cost pyrogas cleaning system for power generation: Scaling up from lab to pilot. Appl. Energy 2013, 111, 1080–1088. [Google Scholar] [CrossRef]

- Bartocci, P.; Bidini, G.; Saputo, P.; Fantozzi, F. Biochar pellet carbon footprint. Chem. Eng. Trans. 2016, 50, 217–222. [Google Scholar]

- Bartocci, P.; Zampilli, M.; Bidini, G.; Fantozzi, F. Hydrogen-rich gas production through steam gasification of charcoal pellet. Appl. Therm. Eng. 2018, 132, 817–823. [Google Scholar] [CrossRef]

- Saxena, R.C.; Seal, D.; Kumar, S.; Goyal, H.B. Thermo-chemical routes for hydrogen rich gas from biomass: a review. Renew. Sustain. Energy Rev. 2008, 12, 1909–1927. [Google Scholar] [CrossRef]

- Piskowska-Wasiak, J. Cleaning and conditioning of gas from biomass gasification for production of SNG (Substitute Natural Gas). Nafta-Gaz 2011, 67, 347–360. [Google Scholar]

- Wróblewski, R. The concept of a small cogeneration system integrated with biomass gasification. Energy Policy J. 2014, 17, 159–170. [Google Scholar]

- Chen, W.; Kuo, P. A study on torrefaction of various biomass materials and its impact on lignocellulosic structure simulated by a thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Kopczński, M.; Zuwała, J. Biomass torrefaction as a way for elimination of technical barriers existing in large-scale co-combustion. Energy Policy J. 2013, 16, 271–284. [Google Scholar]

- Piaskowska-Silarska, M. Analysis of the possibility of obtaining energy from biomass in Poland. Energy Policy J. 2014, 17, 239–248. [Google Scholar]

- Uddin, M.N.; Techato, K.; Taweekun, J.; Rahman, M.M.; Rasul, M.G.; Mahlia, T.M.I.; Ashrafur, S.M. An Overview of Recent Developments in Biomass Pyrolysis Technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef]

- Lewandowski, W.M.; Radziemska, E.; Ryms, M.; Ostrowski, P. Modern methods of thermochemical biomass conversion into gas, liquid and solid fuels. Ecol. Chem. Eng. S 2011, 18, 39–47. [Google Scholar]

- Malińska, K. Biochar—A response to current environmental issues. Eng. Prot. Environ. 2012, 15, 387–403. [Google Scholar]

- Montoya, J.I.; Chejne-Janna, F.; Garcia-Pérez, M. Fast pyrolysis of biomass: A review of relevant aspects. Part I: Parametric study. Dyna 2015, 82, 239–248. [Google Scholar] [CrossRef]

- Park, J.; Hung, I.; Gan, Z.; Rojas, O.J.; Lim, K.H.; Park, S. Activated carbon from biochar: influence of its physicochemical properties on the sorption characteristics of phenanthrene. Bioresour. Technol. 2013, 149, 383–389. [Google Scholar] [CrossRef] [PubMed]

- Uchimiya, M.; Wartelle, L.H.; Klasson, K.T.; Fortier, C.A.; Lima, I.M. Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J. Agric. Food Chem. 2011, 59, 2501–2510. [Google Scholar] [CrossRef] [PubMed]

- Kwapinski, W.; Byrne, C.M.P.; Kryachko, E.; Wolfram, P.; Adley, C.; Leahy, J.J.; Novotny, E.H.; Hayes, M.H.B. Biochar from Biomass and Waste. Waste Biomass Valor. 2010, 1, 177–189. [Google Scholar] [CrossRef]

- Sànchez, M.E.; Lindao, E.; Margaleff, D.; Martínez, O.; Morán, A. Pyrolysis of agricultural residues from rape and sunflower: Production and characterization of biofuels and biochar soil management. J. Anal. Appl. Pyrolysis 2009, 85, 142–144. [Google Scholar] [CrossRef]

- Shen, Y.S.; Wang, S.L.; Tzou, Y.M.; Yan, Y.Y.; Kuan, W.H. Removal of hexavalent Cr by coconut coir and derived chars-the effect of surface functionality. Bioresour. Technol. 2012, 104, 165–172. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Gao, B.; Chen, H.; Jiang, L.; Inyang, M.; Zimmerman, A.R.; Cao, X.; Yang, L.; Xue, Y.; Li, H. Adsorption of sulfamethoxazole on biochar and its impact on reclaimed water irrigation. J. Hazard. Mater. 2012, 209, 408–413. [Google Scholar] [CrossRef]

- Qian, L.; Chen, B. Dual role of biochars as adsorbents for aluminum: The effects of oxygen-containing organic components and the scattering of silicate particles. Environ. Sci. Technol. 2013, 47, 8759–8768. [Google Scholar] [CrossRef]

- Xu, X.; Cao, X.; Zhao, L. Comparison of rice husk-and dairy manure–derived biochars for simultaneously removing heavy metals from aqueous solutions: Role of mineral components in biochars. Chemosphere 2013, 92, 955–961. [Google Scholar] [CrossRef]

- Song, W.; Guo, M. Quality variations of poultry litter biochar generated at different pyro lysis temperatures. J. Anal. Appl. Pyrolysis 2012, 94, 138–145. [Google Scholar] [CrossRef]

- Ibarrola, R.; Shackely, S.; Hammond, J. Pyrolysis biochar systems for recovering biodegradable materials: A life cycle carbon assessment. Waste Manag. 2012, 32, 859–868. [Google Scholar] [CrossRef] [PubMed]

- Lehmann, J.; Rilling, M.C.; Thies, J.; Masiello, C.A.; Hockaday, W.C.; Crowley, D. Biochar effects on soil biota—A review. Soil Biol. Biochem. 2011, 43, 1812–1836. [Google Scholar] [CrossRef]

- Atkinson, C.J.; Fitzgerald, J.D.; Hipps, N.A. Potential mechanisms for achieving agricultural benefits from biochar application to temperate soils: Review. Plant Soil 2010, 337, 1–18. [Google Scholar] [CrossRef]

- Burrell, L.D.; Zehetner, F.; Rampazzo, N.; Wimmer, B.; Soja, G. Long-term effects of biochar on soil physical properties. Geoderma 2016, 282, 96–102. [Google Scholar] [CrossRef]

- Yamato, M.; Okimori, Y.; Wibowo, I.F.; Anshori, S.; Ogawa, M. Effects of the application of charred bark in Acacia mangium on the yield of maize, cowpea, peanut and soil chemical properties in south Sumatra, Indonesia. Soil Sci. Plant Nutr. 2006, 52, 489–495. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lee, M.K.; Chang, Y.M. Fast pyrolysis of rice straw, sugarcane bagasse and coconut shell in an induction-heating reactor. J. Anal. Appl. Pyrolysis 2006, 76, 230–237. [Google Scholar] [CrossRef]

- Nguyen, B.T.; Lehmann, J. Black carbon decomposition under varying water regimes. Org. Geochem. 2009, 40, 846–853. [Google Scholar] [CrossRef]

- Chan, K.Y.; Van Zwieten, L.; Meszaros, I.; Downie, A.; Joseph, S. Agronomic values of green waste biochar as a soil amendment. Aust. J. Soil Res. 2007, 45, 629–634. [Google Scholar] [CrossRef]

- Magrini-Bair, K.A.; Czernik, S.; Pilath, H.M.; Evans, R.J.; Maness, P.C.; Leventhal, J. Biomass derived, carbon sequestration, designed fertilizers. Ann. Environ. Sci. 2009, 3, 217–225. [Google Scholar]

- Novak, J.M.; Busscher, W.J.; Laird, D.L.; Ahmedna, M.; Watts, D.W.; Niandou, M.A.S. Impact of biochar amendment on fertility of a Southeastern coastal plain soil. Soil Sci. 2009, 174, 105–112. [Google Scholar] [CrossRef]

- Busscher, W.J.; Novak, J.M.; Evans, D.E.; Watts, D.W.; Niandou, M.A.S.; Ahmedna, M. Influence of pecan biochar on physical properties of Norfolk loamy sand. Soil Sci. 2010, 175, 10–44. [Google Scholar] [CrossRef]

- Bridle, T.R.; Pritchard, D. Energy and nutrient recovery from sewage sludge via pyrolysis. Water Sci. Technol. 2004, 50, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Rondon, M.A.; Lehmann, J.; Ramirez, J.; Hurtado, M. Biological nitrogen fixation by common beans (Phaseolus vulgaris L) increases with bio-char additions. Biol. Fertil. Soils 2007, 43, 699–708. [Google Scholar] [CrossRef]

- Popp, J.; Lakner, Z.; Harangi-Rákos, M.; Fári, M. The effect of bioenergy expansion: Food, energy, and environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef]

- Lédé, J. Biomass pyrolysis: Comments on some sources of confusions in the definitions of temperatures and heating rates. Energies 2010, 3, 886–898. [Google Scholar] [CrossRef]

- Onay, O. Influence of pyrolysis temperature and heating rate on the production of bio-oil and char from safflower seed by pyrolysis, using a well-swept fixed-bed reactor. Fuel Process. Technol. 2007, 88, 523–531. [Google Scholar] [CrossRef]

- Sinha, S.; Jhalani, A.; Ravi, M.R.; Ray, A. Modelling of Pyrolysis in Wood: A Review. Sol. Energy Soc. India J. 2000, 10, 41–62. [Google Scholar]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels Production through Biomass Pyrolysis—A Technological Review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Van den Bergh, C. Biochar and waste law: A comparative analysis. Eur. Energy Environ. Law Rev. 2009, 18, 243–253. [Google Scholar]

- Montanarella, L.; Lugato, E. The application of biochar in the EU: Challenges and opportunities. Agron. J. 2013, 3, 462–473. [Google Scholar] [CrossRef]

- Vereš, J.; Koloničný, J.; Ochodek, T. Biochar status under international law and regulatory issues for the practical application. Chem. Eng. Trans. 2014, 37, 799–804. [Google Scholar]

- Van Laer, T.; De Smedt, P.; Ronsse, F.; Ruysschaert, G.; Boeckx, P.; Verstraete, W.; Buysse, J.; Lavrysen, L.J. Legal constraints and opportunities for biochar: A case analysis of EU law. GCB Bioenergy 2015, 7, 14–24. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: http://www.lex.pl/serial-akt/-/akt/dz-u-ue-l-2008-312-3 (accessed on 1 February 2019).

- Directive 2001/77/EC of the European Parliament and of the Council of 27 September 2001. Available online: http://orka.sejm.gov.pl/Drektywy.nsf/all/32001L0077/%24File/32001L0077.pdf (accessed on 1 February 2019).

- Ustawa z dnia 14 Grudnia 2012 o Odpadach [Waste Act of 14 December 2012]. Available online: http://isap.sejm.gov.pl/DetailsServlet?id=WDU20130000021 (accessed on 1 February 2019).

- Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH). Available online: http://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:036:0084:0084:PL:PDF (accessed on 1 February 2019).

- Regulation (EC) No 2003/2003 of the European Parliament and of the Council of 13 October 2003 Relating to Fertilisers. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32003R2003 PDF (accessed on 1 February 2019).

- EBC. European Biochar Certificate—Guidelines for Sustainable Production of Biochar; Version 6.2E; European Biochar Foundation (EBC): Arbraz, Switzerland, 2012. [Google Scholar]

- Biochar Quality Mandate (BQM) v.1.0. Available online: http://www.britishbiocharfoundation.org/wp-content/uploads/BQM-V1.0.pdf (accessed on 1 February 2019).

- Malińska, K.; Mełgieś, K. Current quality and legal requirements for biochar as a fertilizers and soil improver. Prace Inst. Ceram. Mater. Bud. 2016, 9, 82–95. [Google Scholar]

- Refertil Biochar EU Policy—Support Abstract Draft 2014. D 2.3. Biochar Policy Supporting Report, Concerning the Absence of Potential Risks for the Different Environmental Compartments, for the Plants and for Human Health through the Food Chain Resulting from the Use of These Materials in Agricultural Soils. Available online: http://www.refertil.info/sites/default/files/REFERTIL_289785_BIOCHAR_POLICY_abstract_draft_2014.pdf (accessed on 1 February 2019).

- Hibler, I.; Blum, F.; Leifeld, J.; Schmidt, H.P.; Bucheli, T.D. Quantitative determination of PAHs in biochar: A prerequisite to ensure its quality and safe application. J. Agric. Food Chem. 2012, 60, 3042–3050. [Google Scholar]

- Fabbri, D.; Rombolà, A.G.; Torri, C.; Spokas, K.A. Determination of polycyclic aromatic carbons in biochar and biochar amended soil. J. Anal. Appl. Pyrolysis 2013, 103, 60–67. [Google Scholar] [CrossRef]

- Quilliam, R.S.; Rangecroft, S.; Emmett, B.A.; Deluca, T.H.; Jones, D.L. Is biochar a source or sink for polycyclic aromatic hydrocarbons (PAH) compounds in agricultural soils? GCB Bioenergy 2013, 5, 96–103. [Google Scholar] [CrossRef]

- Regulation of the Minister of Agriculture and Rural Development, of 18 June 2008, on Implementation of Certain Provisions of the Act on Fertilizers and Fertilization. Available online: http://isap.sejm.gov.pl/DetailsServlet?id=WDU2008119 (accessed on 1 February 2019).

- Singh, B.P.; Cowie, A.L.; Smernik, R.J. Biochar carbon stability in a clayey soil as a function of feedstock and pyrolysis temperature. Environ. Sci. Technol. 2012, 46, 11770–11778. [Google Scholar] [CrossRef]

- Bis, Z. Biochar – return to the past, opportunity for the future. Available online: https://www.cire.pl/pliki/2/biowegiel.pdf (accessed on 1 February 2019).

- Matovic, D. Biochar as a viable carbon sequestration option: Global and Canadian perspective. Energy 2011, 36, 2011–2016. [Google Scholar] [CrossRef]

- Verheijen, F.; Jeffery, S.; Bastos, A.C.; Van der Velde, M.; Diafas, I. Biochar Application to Soils—A Critical Scientific Review of Effects on Soil Properties, Processes and Functions; European Commission: Ispra, Italy, 2010. [Google Scholar]

- Skreiberg, Ø.; Wang, L.; Khalil, R.; Gjølsjø, S.; Turn, S. Enabling the biocarbon value chains for energy and metallurgical industries. In Proceedings of the European Biomass Conference and Exhibition, Copenhagen, Denmark, 14–18 May 2018; pp. 1221–1228. [Google Scholar]

- Olszewski, M.; Kempegowda, R.S.; Skreiberg, Ø.; Wang, L.; Løvås, T. Techno-Economics of Biocarbon Production Processes under Norwegian Conditions. Energy Fuels 2017, 31, 14338–14356. [Google Scholar] [CrossRef]

- Bach, Q.V.; Tran, K.Q.; Skreiberg, Ø. Comparative study on the thermal degradation of dry- and wet-torrefied woods. Appl. Energy 2017, 185, 1051–1058. [Google Scholar] [CrossRef]

- McLaren, D.A. Comparative global assessment of potential negative emissions technologies. Process Saf. Environ. Prot. 2012, 90, 489–500. [Google Scholar] [CrossRef]

- Sukiran, M.A.; Kheang, L.S.; Baker, N.A.; May, C.Y. Production and characterization of biochar from the pyrolysis of empty fruit bunches. Am. J. Appl. Sci. 2011, 8, 984–988. [Google Scholar] [CrossRef]

- Gheorghe, C.; Marculescu, C.; Badea, A.; Dinca, C.; Apostol, T. Effect of pyrolysis conditions on bio-char production from biomass. Conference papers of 3rd WSEAS International Conference on Renewable Energy Sources. 2009. Available online: https://pdfs.semanticscholar.org/c47b/51964c1fc9ba5ca1bdb660b5fe31478532f4.pdf (accessed on 1 February 2019).

- Sun, K.; Ro, K.; Guo, M.; Novak, J.; Mashayekhi, H.; Xing, B. Sorption of bisphenol A, 17α-ethinyl estradiol and phenanthrene on thermally and hydrothermally produced biochars. Bioresour. Technol. 2011, 102, 5757–5763. [Google Scholar] [CrossRef] [PubMed]

- Tong, X.; Li, J.; Yuan, J.; Xu, R. Adsorption of Cu(II) by biochars generated from three crop straws. J. Chem. Eng. 2011, 172, 828–834. [Google Scholar] [CrossRef]

- Regmi, P.; Moscoso, J.L.G.; Kumar, S.; Cao, X.; Mao, J.; Scharfan, G. Removal of copper and cadmium from aqueous solutions using switchgrass biochar produced via hydrothermal carbonization proces. J. Environ. Manag. 2012, 109, 61–69. [Google Scholar] [CrossRef] [PubMed]

- Inyang, M.; Gao, B.; Yao, Y.; Xue, Y.; Zimmerman, A.R.; Pullammanappallil, P.; Cao, X. Removal of heavy metals from aqueous solution by biochars derived from anaerobically digested biomass. Bioresour. Technol. 2012, 110, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Mohan, D.; Rajput, S.; Singh, V.K.; Steele, P.H.; Pittman, C.U. Modelling and evaluation of chromium remediation from water using low cost bio-char, a green adsorbent. J. Hazard. Mater. 2011, 188, 319–333. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W.; Guo, M.; Chow, T.; Bennet, D.N.; Rajagopalan, N. Sorption properties of greenwaste biochar for two triazine pesticides. J. Hazard. Mater. 2010, 181, 121–126. [Google Scholar] [CrossRef]

- Zhang, P.; Sun, H.; Yu, L.; Sun, T. Adsorption and catalytic hydrolysis of carbaryl and antrazine on pig manure-derived biochars: impact of structural properties of biochars. J. Hazard. Mater. 2013, 244, 217–224. [Google Scholar] [CrossRef]

- Spokas, K.A.; Koskinen, W.C.; Baker, J.M.; Reicosky, D.C. Impacts of woodchip biochar additions on greenhouse gas production and sorption/degradation of two herbicides in a Minnesota soil. Chemosphere 2009, 77, 574–581. [Google Scholar] [CrossRef]

- Cao, X.; Ma, L.; Liang, Y.; Gao, B.; Harris, W. Simultaneous immobilization of lead and atrazine in contaminated soils using dairy-manure biochar. Environ. Sci. Technol. 2011, 45, 4884–4889. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Harris, W. Properties of dairy-manure-derived biochar pertinent to its potential use in remediation. Bioresour. Technol. 2010, 101, 5222–5228. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Lou, L.; Luo, L.; Cao, R.; Duan, D.; Chen, Y. Effect of bamboo biochar on pentachlorophenol leachability and bioavailability in agricultural soil. Sci. Total. Environ. 2012, 414, 727–731. [Google Scholar] [CrossRef] [PubMed]

- Teixido, M.; Pignatello, J.J.; Beltran, J.L.; Granados, M.; Peccia, J. Speciation of the ionizable antibiotic sulfamethazine on black carbon (biochar). Environ. Sci. Technol. 2011, 45, 10020–10027. [Google Scholar] [CrossRef] [PubMed]

- Jeong, C.Y.; Wang, J.J.; Dodla, S.K.; Eberhardt, T.L.; Groom, L. Effect of biochar amendment on tylosin adsorption-desorption and transport in two different soils. J. Environ. Qual. 2012, 41, 1185–1192. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Liu, W.J.; Jiang, H.; Chen, J.J.; Li, W.W.; Yu, H.Q. Modification of biochar derived from fast pyrolysis of biomass and its application in removal of tetracycline from aqueous solution. Bioresour. Technol. 2012, 121, 235–240. [Google Scholar] [CrossRef] [PubMed]

- Hale, S.E.; Hanley, K.; Lehmann, J.; Zimmerman, A.R.; Cornelissen, G. Effects of chemical, biological, and physical aging as well as soil addition on the sorption of pyrene to activated carbon and biochar. Environ. Sci. Technol. 2011, 45, 10445–10453. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, L.; Sun, H. Modifications of black carbons and their influence on pyrene sorption. Chemosphere 2011, 85, 1306–1311. [Google Scholar] [CrossRef]

- Ahmad, M.; Lee, S.S.; Dou, X.; Mohan, D.; Sung, J.K.; Yang, J.E.; Ok, Y.S. Effects of pyrolysis temperature on soybean stover-and peanut shell-derived biochar properties and TCE adsorption in water. Bioresour. Technol. 2012, 118, 536–544. [Google Scholar] [CrossRef]

- Chen, B.; Zhou, D.; Zhu, L. Transitional adsorption and partition on nonpolar and polar aromatic contaminants by biochars of pine needles with different pyrolytic temperatures. Environ. Sci. Technol. 2008, 42, 5137–5143. [Google Scholar] [CrossRef]

- Kim, W.K.; Shim, T.; Kim, Y.S.; Hyun, S.; Ryu, C.; Park, Y.K.; Jung, J. Characterization of cadmium removal from aqueous solution by biochar produced from a giant Miscanthus at different pyrolytic temperatures. Bioresour. Technol. 2013, 138, 266–270. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhang, F.S. Removal of lead from water using biochars prepared from hydrothermal liquefaction of biomass. J. Hazard. Mater. 2009, 167, 933–939. [Google Scholar] [CrossRef]

- Purnomo, C.W.; Castello, D.; Fiori, L. Granular Activated Carbon from Grape Seeds Hydrothermal Char. Appl. Sci. 2018, 8, 331. [Google Scholar] [CrossRef]

- Gurten, I.I.; Ozmak, M.; Yagmur, E.; Aktas, Z. Preparation and characterisation of activated carbon from waste tea using K2CO3. Biomass Bioenergy 2012, 37, 73–81. [Google Scholar] [CrossRef]

- Tamer, M.A.; Ismail, A.; Mohd, A.A.; Ahmad, A.F. Review: Production of activated carbon from agricultural byproducts via conventional and microwave heating. J. Chem. Technol. Biotechnol. 2013, 88, 1183–1190. [Google Scholar]

- Bedia, J.; Peñas-Garzón, M.; Gómez-Avilés, A.; Rodriguez, J.J.; Belver, C. A Review on the Synthesis and Characterization of Biomass-Derived Carbons for Adsorption of Emerging Contaminants from Water. J. Carbon Res. 2018, 4, 63. [Google Scholar] [CrossRef]

- Hagemann, N.; Spokas, K.; Schmidt, H.-P.; Kägi, R.; Böhler, M.A.; Bucheli, T.D. Activated Carbon, Biochar and Charcoal: Linkages and Synergies across Pyrogenic Carbon’s ABCs. Water 2018, 10, 182. [Google Scholar] [CrossRef]

- González-García, P. Activated carbon from lignocellulosics precursors: A review of the synthesis methods, characterization techniques and applications. Renew. Sustain. Energy Rev. 2018, 82, 1393–1414. [Google Scholar] [CrossRef]

- Amaya, A.; Medero, N.; Tancredi, N.; Silva, H.; Deiana, C. Activated carbon briquettes from biomass materials. Bioresour. Technol. 2007, 98, 1635–1641. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, W.; Lin, H.; Li, Y.; Lu, H.; Wang, Y. A green technology for the preparation of high capacitance rice husk-based activated carbon. J. Clean. Prod. 2015, 1–9. [Google Scholar] [CrossRef]

- Wilson, K.; Yang, H.; Seo, C.W.; Marshall, W.E. Select metal adsorption by activated carbon made from peanut shells. Bioresour. Technol. 2006, 97, 2266–2270. [Google Scholar] [CrossRef]

- Unur, E. Functional nanoporous carbons from hydrothermally treated biomass for environmental purification. Microporous Mesoporous Mater. 2013, 168, 92–101. [Google Scholar] [CrossRef]

- Lei, H.; Wang, Y.; Huo, J. Porous graphitic carbon materials prepared from cornstarch with the assistance of microwave irradiation. Microporous Mesoporous Mater. 2015, 210, 39–45. [Google Scholar] [CrossRef]

- Wang, D.; Geng, Z.; Li, B.; Zhang, C. High performance electrode materials for electric double-layer capacitors based on biomass-derived activated carbons. Electrochim. Acta 2015, 173, 377–384. [Google Scholar] [CrossRef]

- Sardella, F.; Gimenez, M.; Navas, C.; Morandi, C.; Deiana, C.; Sapag, K. Conversion of viticultural industry wastes into activated carbons for removal of lead and cadmium. J. Environ. Chem. Eng. 2014, 3, 253–260. [Google Scholar] [CrossRef]

- Ruiz, B.; Ruisánchez, E.; Gil, R.R.; Ferrera-Lorenzo, N.; Lozano, M.S.; Fuente, E. Sustainable porous carbons from lignocellulosic wastes obtained from the extraction of tannins. Microporous Mesoporous Mater. 2015, 209, 23–29. [Google Scholar] [CrossRef]

- Kilpimaa, S.; Runtti, H.; Kangas, T.; Lassi, U.; Kuokkanen, T. Physical activation of carbon residue from biomass gasification: Novel sorbent for the removal of phosphates and nitrates from aqueous solution. J. Ind. Eng. Chem. 2014, 21, 1354–1364. [Google Scholar] [CrossRef]

- Marco-Lozar, J.P.; Linares-Solano, A.; Cazorla-Amorós, D. Effect of the porous texture and surface chemistry of activated carbons on the adsorption of a germanium complex from dilute aqueous solutions. Carbon 2011, 49, 3325–3331. [Google Scholar] [CrossRef]

- Tsyntsarski, B.; Stoycheva, I.; Tsoncheva, T.; Genova, I.; Dimitrov, M.; Petrova, B.; Paneva, D.; Zheleva, Z.; Budinova, T.; Kolev, H.; et al. Activated carbons from waste biomass and low rank coals as catalyst supports for hydrogen production by methanol decomposition. Fuel Process. Technol. 2015, 137, 139–147. [Google Scholar] [CrossRef]

- Temdrara, L.; Khelifi, A.; Addoun, A.; Spahis, N. Study of the adsorption properties of lignocellulosic material activated chemically by gas adsorption and immersion calorimetry. Desalination 2008, 223, 274–282. [Google Scholar] [CrossRef]

- Román, S.; Valente-Nabais, J.M.; Ledesma, B.; González, J.F.; Laginhas, C.; Titirici, M.M. Production of low-cost adsorbents with tunable surface chemistry by conjunction of hydrothermal carbonization and activation processes. Microporous Mesoporous Mater. 2013, 165, 127–133. [Google Scholar]

- Jibril, B.; Houache, O.; Al-Maamari, R.; Al-Rashidi, B. Effects of H3PO4 and KOH in carbonization of lignocellulosic material. J. Anal. Appl. Pyrolysis 2008, 83, 151–156. [Google Scholar] [CrossRef]

- Nabais, J.M.V.; Laginhas, C.; Carrott, P.J.M.; Carrott, M.M.L.R. Thermal conversion of a novel biomass agricultural residue (vine shoots) into activated carbon using activation with CO2. J. Anal. Appl. Pyrolysis 2010, 87, 8–13. [Google Scholar] [CrossRef]

- Tan, X.-F.; Liu, S.-B.; Liu, Y.-G.; Gu, Y.-L.; Zeng, G.-M.; Hu, X.-J.; Wang, X.; Liu, S.-H.; Jiang, L.-H. Biochar as potential sustainable precursors for activated carbon production: Multiple applications in environmental protection and energy storage. Bioresour. Technol. 2017, 227, 359–372. [Google Scholar] [CrossRef] [PubMed]

- Hoegberg, L.C.; Groenlykke, T.B.; Abildtrup, U.; Angelo, H.R. Combined paracetamol and amitriptyline adsorption to activated charcoal. Clin. Toxicol. 2010, 48, 898–903. [Google Scholar] [CrossRef] [PubMed]

- Nanda, S.; Dalai, A.K.; Berruti, F.; Kozinski, J.A. Biochar as an experimental bioresource for energy, agronomy, carbon sequestration, activated carbon and specialty materials. Waste Biomass Valor. 2016, 7, 201–235. [Google Scholar] [CrossRef]

- Ozsoy, H.D.; van Leeuwen, J. Removal of color from fruit candy waste by activated carbon adsorption. J. Food Eng. 2010, 101, 106–112. [Google Scholar] [CrossRef]

- Bogusz, A.; Cejner, M. Biochar materials in adsorption of organic and inorganic contaminants. Inżynieria środowiska 2016, 22, 9–33. [Google Scholar]

- Sun, K.; Jin, J.; Keiluweit, M.; Kleber, M.; Wang, Z.; Pan, Z.; Xing, B. Polar and aliphatic domains regulate sorption of phthalic acid esters (PAEs) to biochars. Bioresour. Technol. 2012, 118, 120–127. [Google Scholar] [CrossRef]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Ok, Y.S. Biochar as a sorbent for contaminant management in soil and water: A review. Chemosphere 2014, 99, 19–33. [Google Scholar] [CrossRef]

- Tan, X.; Liu, Y.; Zeng, G.; Wang, X.; Hu, X.; Gu, Y.; Yang, Z. Application of biochar for the removal of pollutants from aqueous solutions. Chemosphere 2015, 125, 70–85. [Google Scholar] [CrossRef]

- Enders, A.; Hanley, K.; Whitman, T.; Joseph, S.; Lehmann, J. Characterization of biochars to evaluate recalcitrance and agronomic performance. Bioresour. Technol. 2012, 114, 644–653. [Google Scholar] [CrossRef]

- Bezerra, J.; Turnhout, E.; Vasquez, I.M.; Rittl, T.F.; Arts, B.; Kuyper, T.W. The promises of the Amazonian soil: Shifts in discourses of Terra Preta and biochar. J. Environ. Policy Plan. 2016, 46, 1–13. [Google Scholar] [CrossRef]

- Medyńska-Juraszek, A. Biochar as a soil amendment. Soil Sci. Annual. 2016, 67, 151–157. [Google Scholar] [CrossRef]

- Macdonald, L.; Farrell, M.; Van Zwieten, L.; Krull, E. Plant growth responses to biochar addition: An Australian soils perspective. Biol. Fertil. Soils 2014, 50, 1035–1045. [Google Scholar] [CrossRef]

- Beesley, L.; Moreno-Jiménez, E.; Gomez-Eyles, J.; Harris, E.; Robinson, B.; Sizmur, T. A review of biochars’ potential role in the remediation, revegetation and restoration of contaminated soils. Environ. Pollut. 2011, 159, 3269–3282. [Google Scholar] [CrossRef]

- Palansooriya, K.N.; Ok, Y.S.; Awad, Y.M.; Lee, S.S.; Sung, J.K.; Koutsospyros, A.; Moon, D.H. Impacts of biochar application on upland agriculture: A review. J. Environ. Manag. 2019, 234, 52–64. [Google Scholar] [CrossRef]

- Glaser, B.; Lehmann, J.; Zech, W. Ameliorating physical and chemical properties of highly weathered soils in the tropics with charcoal-a review. Biol Fertil. Soils 2002, 35, 1719–1730. [Google Scholar] [CrossRef]

- Chan, K.Y.; Van Zwieten, L.; Meszaros, I.; Downie, A.; Joseph, S. Using poultry litter biochars as soil amendments. Aust. J. Soil Res. 2008, 46, 437–444. [Google Scholar] [CrossRef]

- Genesio, L.; Miglietta, F.; Baronti, S.; Vaccari, F.P. Biochar increases vineyard productivity without affecting grape quality: Results from a four years field experiment in Tuscany. Agric. Ecosyst. Environ. 2015, 201, 20–25. [Google Scholar] [CrossRef]

- Uzoma, K.C.; Inoue, M.; Andry, H.; Fujimaki, H.; Zahoor, A.; Nishihara, E. Effect of cow manure biochar on maize productivity under sandy soil condition. Soil Use Manag. 2011, 27, 205–212. [Google Scholar] [CrossRef]

- Rogovska, N.; Laird, D.A.; Rathke, S.J.; Karlen, D.L. Biochar impact on Midwestern Mollisols and maize nutrient availability. Geoderma 2014, 230, 340–347. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Jing, Y.; Li, Q.; Zhang, J.; Huang, Q. Effects of biochar amendment on rapeseed and sweet potato yields and water stable aggregate in upland red soil. Catena 2014, 123, 45–51. [Google Scholar] [CrossRef]

- Cross, A.; Sohi, S. The priming potential of biochar products in relation to labile carbon contents and soil organic matter status. Soil Biol. Biochem. 2011, 43, 2127–2134. [Google Scholar] [CrossRef]

- Zhang, Q.; Du, Z.; Lou, Y.; He, X. A one-year short-term biochar application improved carbon accumulation in large macro aggregate fractions. Catena 2015, 127, 26–31. [Google Scholar] [CrossRef]

- Laird, D.A. The charcoal vision: A win-win-win scenario for simultaneously producing bioenergy, permanently sequestering carbon, while improving soil and water quality. Agron. J. 2008, 100, 178–181. [Google Scholar] [CrossRef]

- Woolf, D.; Amonette, J.E.; Street-Perrott, F.A.; Lehmann, J.; Joseph, S. Sustainable biochar to mitigate global climate change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef]

- Li, Z.; Delvaux, B.; Yans, J.; Dufour, N.; Houben, D.; Cornelis, J.T. Phytolith-rich biochar increases cotton biomass and silicon-mineralomass in a highly weathered soil. J. Plant Nutr. Soil Sci. 2018, 181, 537–546. [Google Scholar] [CrossRef]

- Yuan, J.; Xu, R.; Zhang, H. The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour. Technol. 2011, 102, 3488–3497. [Google Scholar] [CrossRef]

- Zong, Y.; Xiao, Q.; Lu, S. Acidity, water retention, and mechanical physical quality of a strongly acidic Ultisol amended with biochars derived from different feedstocks. J. Soil Sediments 2016, 16, 177–190. [Google Scholar] [CrossRef]

- Jien, S.; Wang, C. Effects of biochar on soil properties and erosion potential in a highly weathered soil. Catena 2014, 110, 225–233. [Google Scholar] [CrossRef]

- Agegnehu, G.; Bass, A.; Nelson, P.; Bird, M. Benefits of biochar, compost and biochar-compost for soil quality, maize yield and greenhouse gas emissions in a tropical agricultural soil. Sci. Total Environ. 2016, 543, 295–306. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A. The love-hate relationship of pyrolysis biochar and water: A perspective. Sci. Total Environ. 2015, 512/513, 682–685. [Google Scholar] [CrossRef]

- Cayuela, M.; Van Zwieten, L.; Singh, B.; Jeffery, S.; Roig, A.; Sanchez-Monedero, M.A. Biochar’s role in mitigating soil nitrous oxide emissions: A review and meta-analysis. Agric. Ecosyst. Environ. 2014, 191, 5–16. [Google Scholar] [CrossRef]

- Ameloot, N.; De Neve, S.; Jegajeevagan, K.; Yildiz, G.; Buchan, D.; Funkuin, Y.N.; Prins, W.; Bouckaert, L.; Sleutel, S. Short-term CO2 and N2O emissions and microbial properties of biochar amended sandy loam soils. Soil Biol. Biochem. 2013, 57, 401–410. [Google Scholar] [CrossRef]

- Ameloot, N.; Sleutel, S.; Das, K.C.; Kanagaratnam, J.; De Neve, S. Biochar amendment to soils with contrasting organic matter level: Effects on N mineralization and biological soil properties. GCB Bioenergy 2015, 7, 135–144. [Google Scholar] [CrossRef]

- Jones, D.L.; Rousk, J.; Edwards-Jones, G.; DeLuca, T.H.; Murphy, D.V. Biochar-mediated changes in soil quality and plant growth in a three year field trial. Soil Biol. Biochem. 2012, 45, 113–124. [Google Scholar] [CrossRef]

- Gomez, J.D.; Denef, K.; Stewart, C.E.; Zheng, J.; Cotrufo, M.F. Biochar addition rate influences soil microbial abundance and activity in temperate soils. Eur. J. Soil Sci. 2014, 65, 28–39. [Google Scholar] [CrossRef]

| Origin of Feedstocks | Type |

|---|---|

| Agriculture | Energy crops, corncob, rice husk, sunflower husk, post-fermentation oats, bamboo, bagasse, waste from olive oil production, straw, wheat husk, cattle manure, poultry litter |

| Forest | Conifer bark, pellets from sawdust, peat, moss, beech timber, |

| Waste | Waste from tea factories, paper, sewage sludge, municipal organic waste |

| Feedstock for Biochar Production | pH | C g kg−1 | N g kg−1 | C/N | P g kg−1 | K g kg−1 | Ash % | Temp. of Pyrolysis (°C) | References |

|---|---|---|---|---|---|---|---|---|---|

| Acacia bark | 7.4 | 398 | 10.4 | 38 | – | – | – | 260–360 | [36] |

| Coconut | – | 690 | 9.4 | 73 | – | – | 3.38 | 500 | [37] |

| Corn | – | 675 | 9.3 | 73 | – | 10.4 | – | 350 | [38] |

| Corn | – | 790 | 9.2 | 86 | – | 6.7 | – | 600 | |

| Green waste | 6.2 | 680 | 1.7 | 400 | 0.2 | 1 | – | 450 | [39] |

| Peanut shells | – | 499 | 11.0 | 45 | 0.6 | 6.2 | – | 400 | [40] |

| Pecan shells | 7.6 | 834 | 3.4 | 245 | – | – | 3.8 | 700 | [41] |

| Pecan shells | – | 880 | 4.0 | 220 | – | – | – | 700 | [42] |

| Rice straw | – | 490 | 13.2 | 37 | – | – | 9.54 | 500 | [37] |

| Sewage sludge | – | 470 | 64 | 7 | 56 | – | 35 | 450 | [43] |

| Sugarcane bagasse | – | 710 | 17.7 | 40 | – | – | 4.34 | 500 | [37] |

| Eucalyptus wood | 7.0 | 824 | 5.7 | 144 | 0.6 | – | 0.23 | 350 | [44] |

| Oak wood | – | 759 | 1.0 | 759 | – | 1.1 | – | 350 | [38] |

| Oak wood | – | 884 | 1.2 | 737 | – | 2.2 | – | 600 |

| Parameter (mg kg−1 of Dry Matter) | IBI | BQM | EBC | REFERTIL | ||

|---|---|---|---|---|---|---|

| Type of Biochar | ||||||

| High Grade | Standard | Premium | Basic | |||

| As | 13–100 | 10 | 100 | 13 | 13 | 10 |

| Cd | 1.4–39 | 3 | 39 | 1 | 1.5 | 1.5 |

| Cr | 93–1200 | 15 | 100 | 80 | 90 | 100 |

| Cu | 143–6000 | 40 | 1500 | 100 | 1000 | 200 |

| Hg | 1–17 | 1 | 17 | 1 | 1 | 1 |

| Ni | 47–420 | 10 | 600 | 30 | 50 | 50 |

| Pb | 121–300 | 60 | 500 | 120 | 150 | 120 |

| Zn | 416–7400 | 150 | 2800 | 400 | 400 | 600 |

| Se | 2–200 | 5 | 100 | – | – | – |

| Mo | 5–75 | 10 | 75 | – | – | – |

| F | – | – | – | – | – | – |

| WWA | 6–300 | 20 | 20 | 4 | 12 | 6 |

| PCB | 0.2–1 | 0.5 | 0.5 | 0.2 | 0.2 | 0.2 |

| Dioxins and furans (ng kg−1) | 20 | 20 | 20 | 20 | 20 | 20 |

| Fuel | Calorific Value (MJ kg−1) | Carbon | Ash | Volatiles |

|---|---|---|---|---|

| % | ||||

| Fossil fuels | ||||

| Natural gas | 48.0 | 75.0 | 0.0 | 100.0 |

| Lignite | 25.0 | 60.0 | 12.0 | 25.0 |

| Bituminous coal | 7.5–21.0 | 66.0–73.0 | 10.0–20.0 | 40.0–60.0 |

| Biomass | ||||

| Wood | 10.5 | 35.0 | 1.0 | 55.0 |

| Straw | 15.0 | 43.0 | 3.0 | 73.0 |

| Rapeseed | 15.3 | 44.7 | 7.3 | 78.7 |

| Sunflower | 15.7 | 17.2 | 8.3 | 74.5 |

| Biochar | ||||

| Biochar from rapeseed | 23.4 | 72.7 | 21.8 | 13.6 |

| Biochar from sunflower | 20.5 | 63.4 | 28.9 | 13.4 |

| Biochar from oil palm (residues) | 17.1 | 53.8 | 3.1 | 81.9 |

| Biochar from cherry wood | 27.7 | 59.5 | 9.1 | 22.2 |

| Contamination | Type of Biochar (Feedstock/Pyrolysis Temperature) | Type of Environment | References |

|---|---|---|---|

| Agricultural chemicals | |||

| Atrazine | Cattle manure (450 °C) | Soil | [85] |

| Cattle manure (200 °C) | Water | [86] | |

| Atrazine and simazine | Green waste (450 °C) | Water | [82] |

| Pentachlorophenol | Bamboo (600 °C) | Soil | [87] |

| Antibiotics | |||

| Sulfamethazine | Hardwood (600 °C) | Water | [88] |

| Sulfamethoxazole | Bamboo (450 and 600 °C) | Water | [28] |

| Tylosin | Hardwood (850 and 900 °C) | Water | [89] |

| Tetracycline | Rice husk (450–500 °C) | Water | [90] |

| Other hydrocarbons | |||

| Pyrene | Corncob (600 °C) | Water | [91] |

| Sawdust (400 i 700 °C) | [92] | ||

| Trichloroethylene | Peanut shell (300 and 700 °C) | Water | [93] |

| Naphthalene | Pine needles (100–700 °C) | Water | [94] |

| Heavy metals | |||

| Cadmium | Miscanthus sacchariflorus (300–600 °C) | Water | [95] |

| Aluminum | Rice straw (100–600 °C) | Water | [29] |

| Lead | Pine wood (300 °C) | Water | [96] |

| Physically Activated Carbons | Chemically Activated Carbons | ||||

|---|---|---|---|---|---|

| Initial Material | Activation Agent | Surface Aream2 g−1 | Initial Material | Activation Agent | Surface Aream2 g−1 |

| Rice [103] | Steam | 1122 | Rice [104] | KOH | 3263 |

| Peanut shells [105] | Steam | 757 | Hazelnut shells [106] | KOH | 1700 |

| Cornstarch [107] | Thermal | 686 | Corncob [108] | KOH | 3054 |

| Grape pomace, grape stalks [109] | Steam | 266 300 | Grape seeds [110] | KOH | 1860 |

| Finish wood [111] | CO2 | 590 | Eucalyptus wood, Beech wood [112] | KOH | 2120, 2460 |

| Olive Stone [113] | CO2 | 1355 | Olives stones [114] | ZnCl2 | 1860 |

| Sunflower stem [115] | CO2 | 438 | Stem of date palm [116] | KOH H3PO4 | 947 1100 |

| Vine shoots [117] | CO2 | 1173 | Waste tea [98] | K2CO3 | 1722 |

| Type of Biochar (Feedstock) | Dose (t ha−1) | Crop | Increase in Yield Compared to the Control % | References |

|---|---|---|---|---|

| Wood | 68 | Cowpea | 20 | [132] |

| 136.75 | 100 | |||

| 68 | Rice | 50 | ||

| Poultry litter | 10 | Radish | 42 | [39,133] |

| 50.5 | Radish | 96 | ||

| Woodchips from fruit trees | 22 | Grapes | 20 | [134] |

| Cattle manure | 15 | Maize | 150 | [135] |

| Hardwood | 19 | Maize | 10 | [136] |

| 38 | 17 | |||

| 58 | 48 | |||

| Wheat straw | 40 | Rapeseed | 36 | [137] |

| 40 | Sweet potatoes | 54 |

| Type of Biochar (Feedstock) | Impact on Soil Microorganisms | References |

|---|---|---|

| Willow wood and swine manure: slow pyrolysis at 350 °C slow pyrolysis at 700 °C | Increased microbial biomass in both cases: increased dehydrogenase activity decreased dehydrogenase activity | [149] |

| Poultry litter and pine woodchips (pyrolysis at 400 and 500 °C) | Increased microbial biomass | [150] |

| Leaves and fragmented branches | Increased rate of fungal and bacterial growth | [151] |

| Wood (fast pyrolysis) | Increased microbial count | [152] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saletnik, B.; Zaguła, G.; Bajcar, M.; Tarapatskyy, M.; Bobula, G.; Puchalski, C. Biochar as a Multifunctional Component of the Environment—A Review. Appl. Sci. 2019, 9, 1139. https://doi.org/10.3390/app9061139

Saletnik B, Zaguła G, Bajcar M, Tarapatskyy M, Bobula G, Puchalski C. Biochar as a Multifunctional Component of the Environment—A Review. Applied Sciences. 2019; 9(6):1139. https://doi.org/10.3390/app9061139

Chicago/Turabian StyleSaletnik, Bogdan, Grzegorz Zaguła, Marcin Bajcar, Maria Tarapatskyy, Gabriel Bobula, and Czesław Puchalski. 2019. "Biochar as a Multifunctional Component of the Environment—A Review" Applied Sciences 9, no. 6: 1139. https://doi.org/10.3390/app9061139

APA StyleSaletnik, B., Zaguła, G., Bajcar, M., Tarapatskyy, M., Bobula, G., & Puchalski, C. (2019). Biochar as a Multifunctional Component of the Environment—A Review. Applied Sciences, 9(6), 1139. https://doi.org/10.3390/app9061139