An Orthogonal Model to Study the Effect of Electrospraying Parameters on the Morphology of poly (d,l)-lactide-co-glycolide (PLGA) Particles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polymer Materials

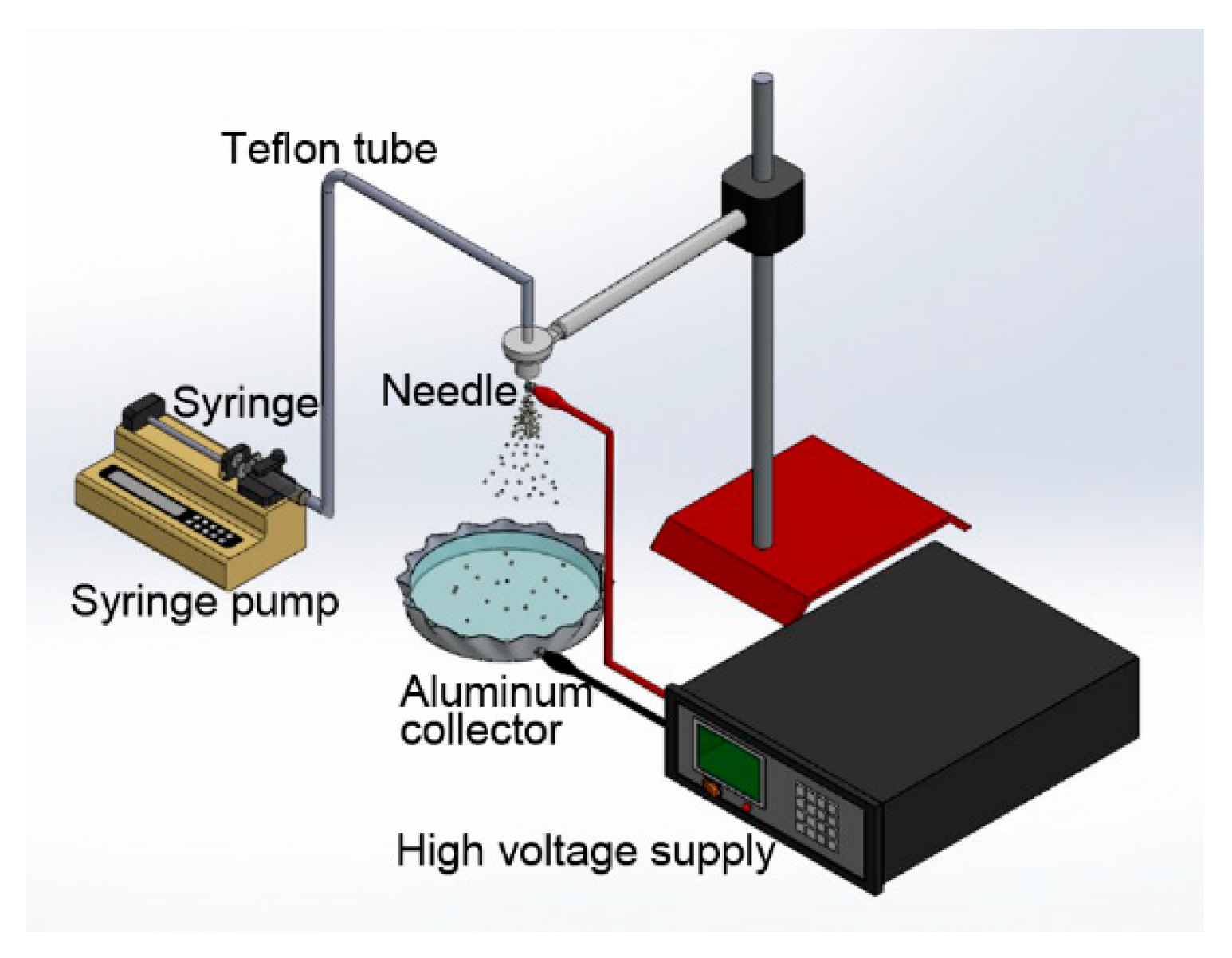

2.2. Experimental Setup

2.3. Empirical Factors and Orthogonal Design

3. Results and Discussions

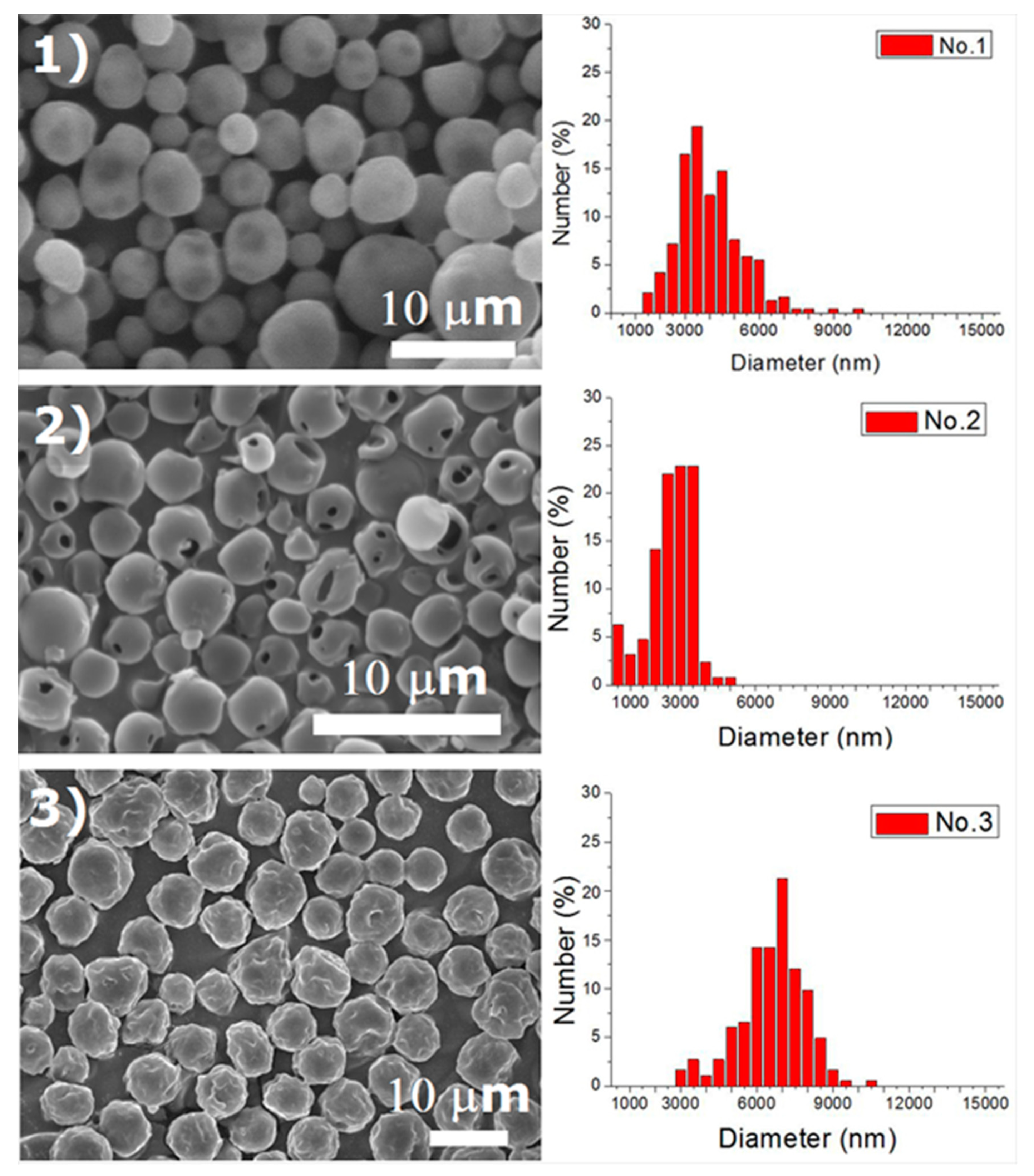

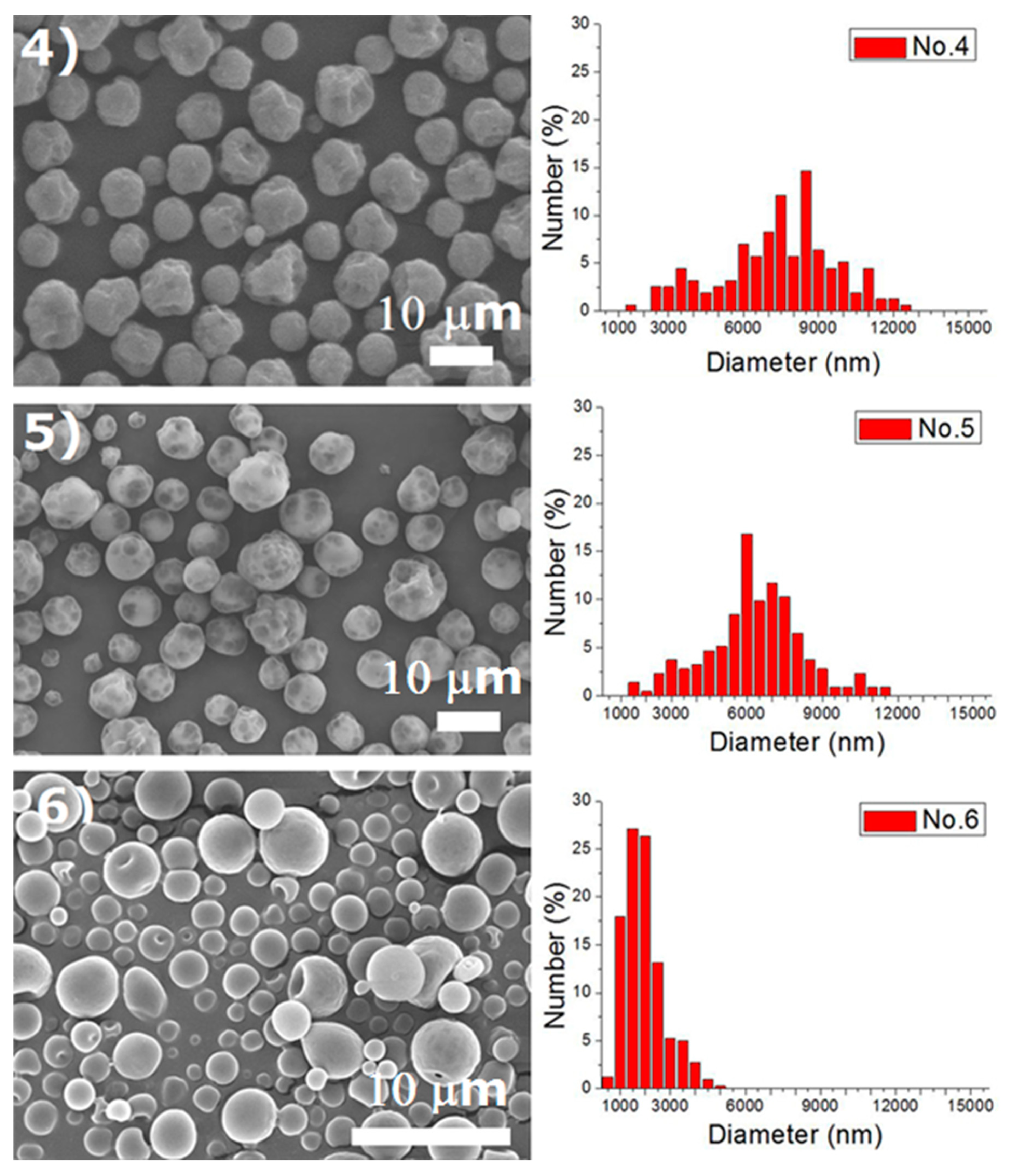

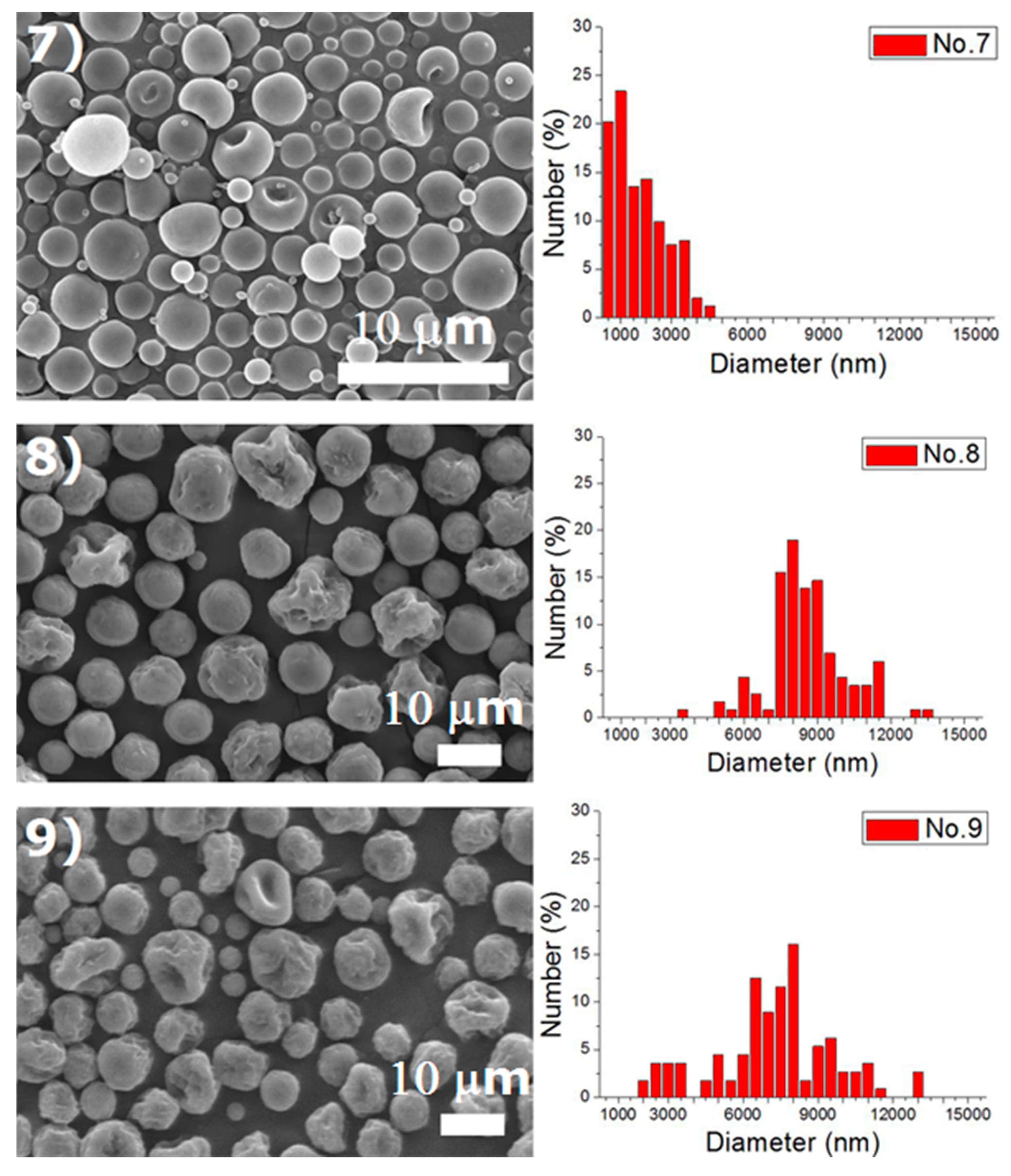

3.1. Optimization of Processing Parameters

3.2. Significance of Factors

4. Conclusions

- Orthogonal array design based on the Taguchi technique was adequate in minimizing the particle size of electrosprayed microspheres by optimizing the processing factors, despite the interaction among the chosen factors was ignored in the evaluation.

- For the factors selected in the experiments, the type of solvent used was discovered to be the principal factor affecting the particle size of electrosprayed microspheres. HFIP electrosprayed microparticles had the smallest diameter. However, hollowed particles could be seen among these microspheres.

- DCM was found to electrospray microspheres with a fairly spherical geometry, while TCM electrosprayed particles with relatively rougher surfaces.

- Particle size of sprayed microspheres decreases somewhat with the polymer concentration and the travel distance.

Author Contributions

Funding

Conflicts of Interest

References

- Gaskell, S.M. Electrospray: Principles and Practice. J. Mass Spectrom. 1997, 32, 677–688. [Google Scholar] [CrossRef]

- Jaworek, A. Micro- and nanoparticle production by electrospraying. Powder Technol. 2007, 176, 18–35. [Google Scholar] [CrossRef]

- Boda, S.K.; Li, X.; Xie, J. Electrospraying an enabling technology for pharmaceutical and biomedical applications: A review. J. Aerosol Sci. 2018. [Google Scholar] [CrossRef]

- Bock, N.; Woodruff, M.A.; Hutmacher, D.W.; Dargaville, T.R. Electrospraying, a reproducible method for production of polymeric microspheres for biomedical applications. Polymers 2011, 3, 131–149. [Google Scholar] [CrossRef]

- Enayati, M.; Chang, M.-W.; Bragman, F.; Edirisinghe, M.; Stride, E. Electrohydrodynamic preparation of particles, capsules and bubbles for biomedical engineering applications. Colloids Surf. A 2011, 382, 154–164. [Google Scholar] [CrossRef]

- Danhier, F.; Ansorena, E.; Silva, J.M.; Coco, R.; Breton, A.L.; Preat, V. PLGA-based nanoparticles: An overview of biomedical applications. J. Control Release 2012, 161, 505–522. [Google Scholar] [CrossRef]

- Nguyen, D.N.; Clasen, C.; Van den Mooter, G. Pharmaceutical applications of electrospraying. J. Pharm. Sci. 2016, 105, 2601–2620. [Google Scholar] [CrossRef]

- Sridhar, R.; Ramakrishna, S. Electrosprayed nanoparticles for drug delivery and pharmaceutical applications. Biomatter 2013, 3, e24281. [Google Scholar] [CrossRef]

- Peltonen, L.; Valo, H.; Kolakovic, R.; Laaksonen, T.; Hirvonen, J. Electrospraying, spray drying and related techniques for production and formulation of drug nanoparticles. Expert Opin. Drug Deliv. 2010, 7, 705–719. [Google Scholar] [CrossRef]

- Hao, S.; Wang, Y.; Wang, B.; Deng, J.; Liu, X.; Liu, J. Rapid preparation of pH-sensitive polymeric nanoparticle with high loading capacity using electrospray for oral drug delivery. Mater. Sci. Eng. C 2013, 33, 4562–4567. [Google Scholar] [CrossRef]

- Prabhakaran, M.P.; Zamani, M.; Felice, B.; Ramakrishna, S. Electrospraying technique for the fabrication of metronidazole contained PLGA particles and their release profile. Mater. Sci. Eng. C 2015, 56, 66–73. [Google Scholar] [CrossRef] [PubMed]

- Hao, S.; Wang, Y.; Wang, B.; Deng, J.; Zhu, L.; Cao, Y. Formulation of porous poly(lactic-co-glycolic acid) microparticles by electrospray deposition method for controlled drug release. Mater. Sci. Eng. C 2014, 39, 113–119. [Google Scholar] [CrossRef] [PubMed]

- Songsurang, K.; Praphairaksit, N.; Siraleartmukul, K.; Muangsin, N. Electrospray fabrication of doxorubicin-chitosan-tripolyphosphate nanoparticles for delivery of doxorubicin. Arch. Pharm. Res. 2011, 34, 583–592. [Google Scholar] [CrossRef] [PubMed]

- Malik, S.A.; Ng, W.H.; Bowen, J.; Tang, J.; Gomez, A.; Kenyon, A.J.; Richard, M.; Day, R.M. Electrospray synthesis and properties of hierarchically structured PLGA TIPS microspheres for use as controlled release technologies. J. Colloid Interface Sci. 2016, 467, 220–229. [Google Scholar] [CrossRef]

- Makadia, H.K.; Siegel, S.J. Poly lactic-co-glycolic acid (PLGA) as biodegradable controlled drug delivery carrier. Polymers 2011, 3, 1377–1397. [Google Scholar] [CrossRef]

- Sah, E.; Sah, H. Recent trends in preparation of poly(lactide-co-glycolide) nanoparticles by mixing polymeric organic solution with antisolvent. J. Nanomater. 2015, 16, e794601. [Google Scholar] [CrossRef]

- Roy, R.K. A Primer on the Taguchi Method; Society of Manufacturing Engineering: New York, NY, USA, 1990. [Google Scholar]

- Reichardt, C.; Welton, T. Solvents and Solvent Effects in Organic Chemistry, 4th ed.; Wiley-VCH Verlag: Weinheim, Germany, 2011. [Google Scholar]

- Mayol, L.; Borzacchiello, A.; Guarino, V.; Serri, C.; Biondi, M.; Ambrosio, L. Design of electrosprayed non-spherical poly (L-lactide-co-glicoide) microdevices for sustained drug delivery. J. Mater. Sci. Mater. Med. 2014, 25, 383–390. [Google Scholar] [CrossRef]

- Bock, N.; Dargaville, T.R.; Woodruff, M.A. Electrospraying of polymers with therapeutic molecules: State of the art. Prog. Polym. Sci. 2012, 37, 1510–1551. [Google Scholar] [CrossRef]

- Liu, S.J.; Kau, Y.C.; Chou, C.Y.; Chen, J.K.; Wu, R.C.; Yeh, W.L. Electrospun PLGA/collagen nanofibrous membrane as early-stage wound dressing. J. Membr. Sci. 2010, 355, 53–59. [Google Scholar] [CrossRef]

- Wu, Y.; Clark, R.L. Controllable porous polymer particles generated by electrospraying. J. Colloid Interface Sci. 2007, 310, 529–535. [Google Scholar] [CrossRef] [PubMed]

- Costa, L.M.M.; Bretas, R.E.S.; Gergorio, R., Jr. Effect of solution concentration on the electrospray/electrospinning transition and on the crystalline phase of PVDF. Mater. Sci. Appl. 2010, 1, 247–252. [Google Scholar] [CrossRef]

- Faramarzi, A.-R.; Barzin, J.; Mobedi, H. Effect of solution and apparatus parameters on the morphology and size of electrosprayed PLGA microparticles. Fiber Polym. 2016, 117, 1806–1819. [Google Scholar] [CrossRef]

| Factors | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| A: Polymer concentration (%, w/v) | 3 | 5 | 7 |

| B: Flow rate (mL/h) | 0.6 | 0.8 | 1.0 |

| C: Travel distance (cm) | 10 | 13 | 15 |

| D: Voltage (kV) | 11 | 14 | 17 |

| E: Size of needle (mm) | 0.64 | 0.51 | 0.40 |

| F: Solvent | DCM | HFIP | TCM |

| Run | A: Polymer Concentration (%, w/v) | B: Flow rate (mL/h) | C: Travel Distance (cm) | D: Voltage (kV) | E: Size of Needle (mm) | F: Solvent |

|---|---|---|---|---|---|---|

| 1 | 3% | 0.6 | 10 | 11 | 0.64 | DCM |

| 2 | 3% | 0.8 | 13 | 14 | 0.51 | HFIP |

| 3 | 3% | 1 | 15 | 17 | 0.40 | TCM |

| 4 | 5% | 0.6 | 10 | 14 | 0.51 | TCM |

| 5 | 5% | 0.8 | 13 | 17 | 0.40 | DCM |

| 6 | 5% | 1 | 15 | 11 | 0.64 | HFIP |

| 7 | 7% | 0.6 | 13 | 11 | 0.40 | HFIP |

| 8 | 7% | 0.8 | 15 | 14 | 0.64 | TCM |

| 9 | 7% | 1 | 10 | 17 | 0.51 | DCM |

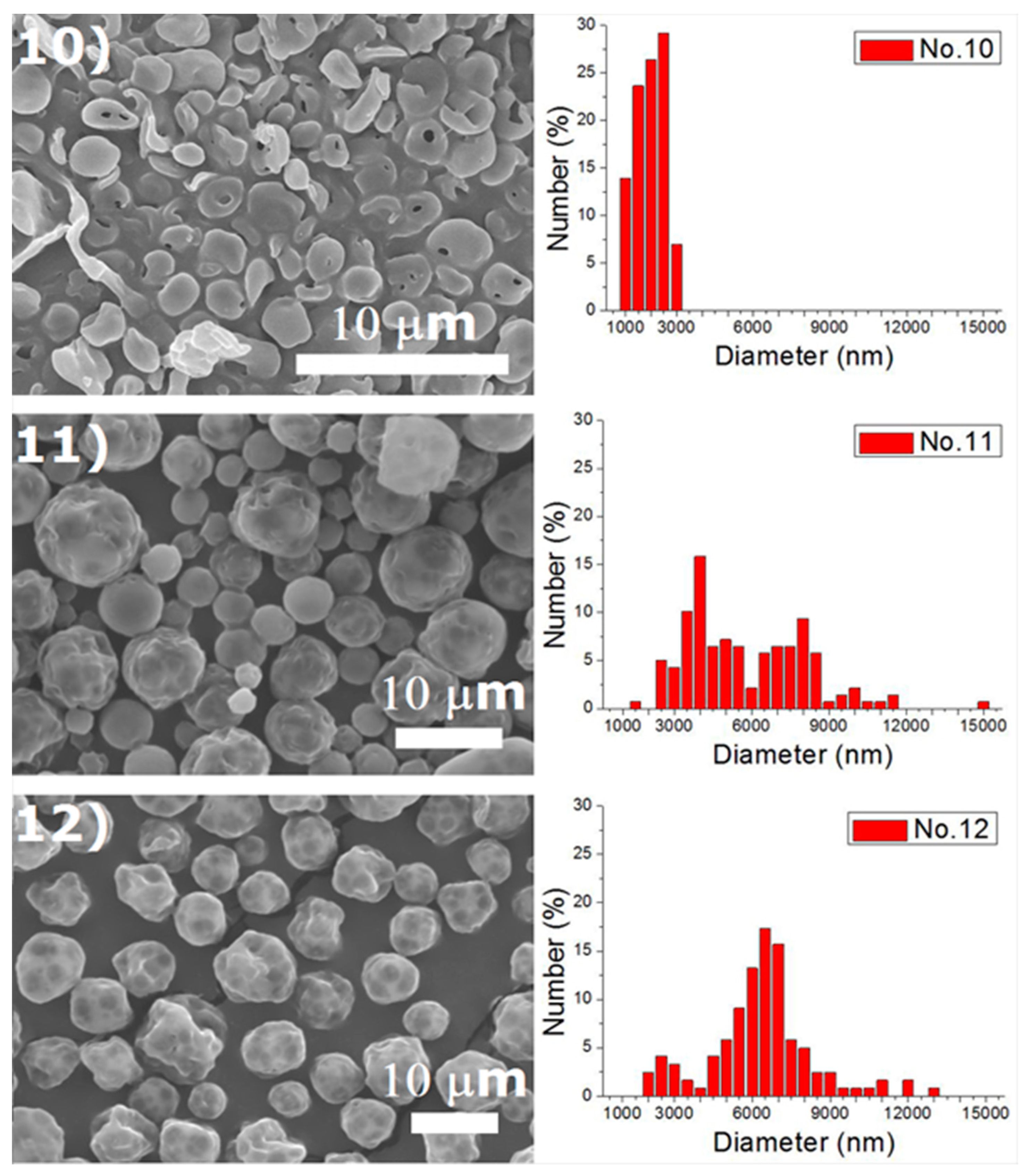

| 10 | 3% | 0.6 | 15 | 17 | 0.51 | HFIP |

| 11 | 3% | 0.8 | 10 | 11 | 0.40 | TCM |

| 12 | 3% | 1 | 13 | 14 | 0.64 | DCM |

| 13 | 5% | 0.6 | 13 | 17 | 0.64 | TCM |

| 14 | 5% | 0.8 | 15 | 11 | 0.51 | DCM |

| 15 | 5% | 1 | 10 | 14 | 0.40 | HFIP |

| 16 | 7% | 0.6 | 15 | 14 | 0.40 | DCM |

| 17 | 7% | 0.8 | 10 | 17 | 0.64 | HFIP |

| 18 | 7% | 1 | 13 | 11 | 0.51 | TCM |

| Run | Particle Size (µm) | S/N Ratio |

|---|---|---|

| 1 | 3.88 ± 1.30 | −12.25 |

| 2 | 2.38 ± 0.87 | −8.08 |

| 3 | 6.36 ± 1.30 | −16.24 |

| 4 | 7.15 ± 2.29 | −17.51 |

| 5 | 6.09 ± 1.93 | −16.11 |

| 6 | 1.71 ± 0.79 | −5.52 |

| 7 | 1.50 ± 1.00 | −5.14 |

| 8 | 8.34 ± 1.62 | −18.58 |

| 9 | 7.01 ± 2.37 | −17.38 |

| 10 | 1.71 ± 0.56 | −5.11 |

| 11 | 5.56 ± 2.33 | −15.61 |

| 12 | 6.08 ± 2.02 | −16.14 |

| 13 | 4.36 ± 1.36 | −13.20 |

| 14 | 8.15 ± 1.83 | −18.44 |

| 15 | 1.40 ± 0.57 | −3.63 |

| 16 | 6.59 ± 1.96 | −16.75 |

| 17 | 2.09 ± 1.10 | −7.49 |

| 18 | 6.12 ± 1.10 | −15.87 |

| Factor | Degree of Freedom | Sum of Squares | Mean Square | F |

|---|---|---|---|---|

| A-Polymer concentration (%) | 2 | 8.08 | 4.04 | 1.62 |

| B-Flow rate (mL/h) | 2 | 13.75 | 6.87 | 2.76 |

| C-Travel distance (cm) | 2 | 12.24 | 6.12 | 2.46 |

| D-Voltage (kV) | 2 | 7.43 | 3.71 | 1.49 |

| E-Needle size (mm) | 2 | 10.48 | 5.24 | 2.10 |

| F-Solvent type | 2 | 244.07 | 122.03 | 49.02 |

| Error | 36 | 89.61 | 2.48 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, M.-Y.; Feng, C.-H.; Liu, Y.-W.; Liu, S.-J. An Orthogonal Model to Study the Effect of Electrospraying Parameters on the Morphology of poly (d,l)-lactide-co-glycolide (PLGA) Particles. Appl. Sci. 2019, 9, 1077. https://doi.org/10.3390/app9061077

Hsu M-Y, Feng C-H, Liu Y-W, Liu S-J. An Orthogonal Model to Study the Effect of Electrospraying Parameters on the Morphology of poly (d,l)-lactide-co-glycolide (PLGA) Particles. Applied Sciences. 2019; 9(6):1077. https://doi.org/10.3390/app9061077

Chicago/Turabian StyleHsu, Ming-Yi, Chu-Han Feng, Yen-Wei Liu, and Shih-Jung Liu. 2019. "An Orthogonal Model to Study the Effect of Electrospraying Parameters on the Morphology of poly (d,l)-lactide-co-glycolide (PLGA) Particles" Applied Sciences 9, no. 6: 1077. https://doi.org/10.3390/app9061077

APA StyleHsu, M.-Y., Feng, C.-H., Liu, Y.-W., & Liu, S.-J. (2019). An Orthogonal Model to Study the Effect of Electrospraying Parameters on the Morphology of poly (d,l)-lactide-co-glycolide (PLGA) Particles. Applied Sciences, 9(6), 1077. https://doi.org/10.3390/app9061077