Electrospun Nanomaterials for Energy Applications: Recent Advances

Abstract

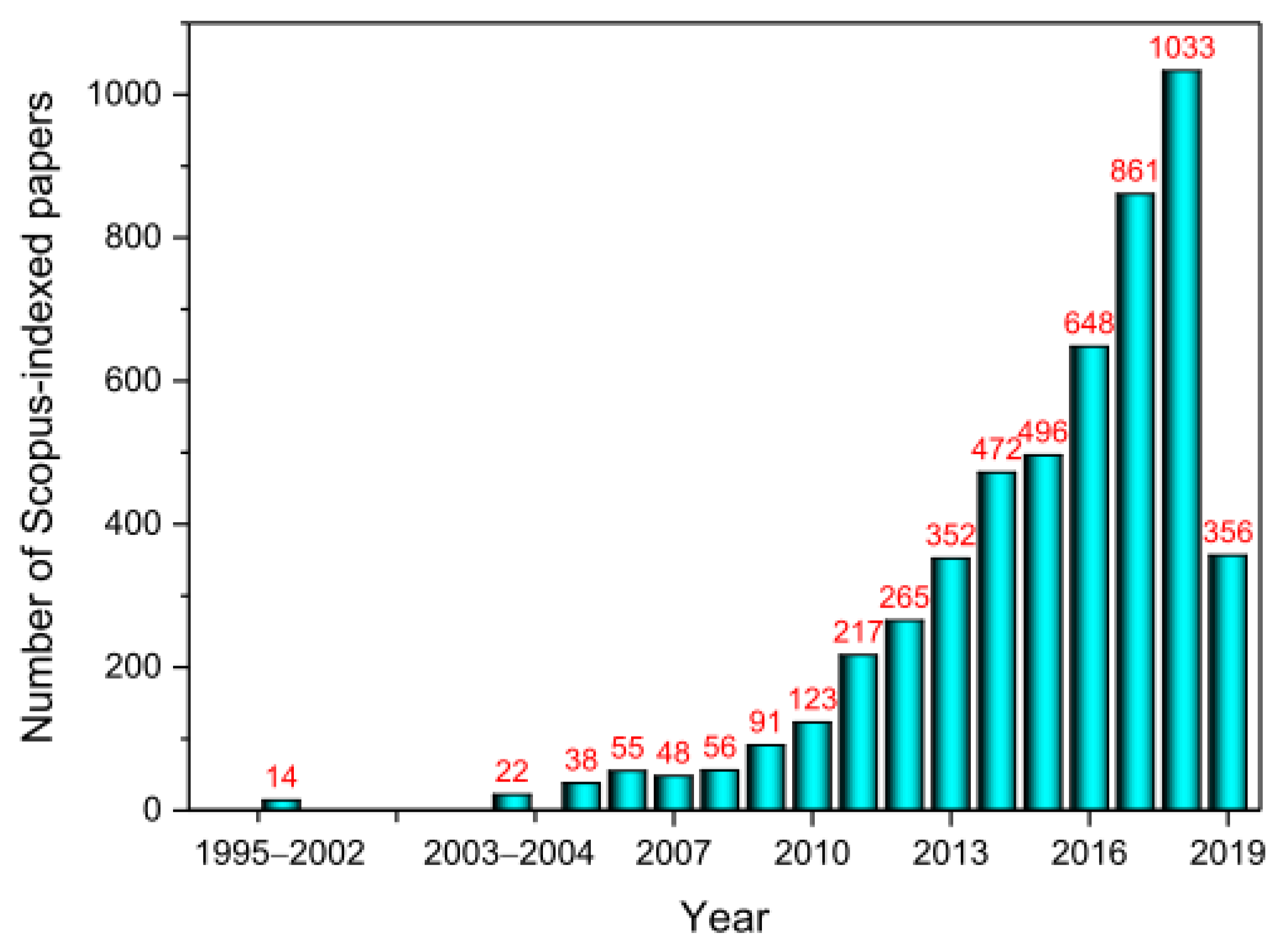

1. Introduction

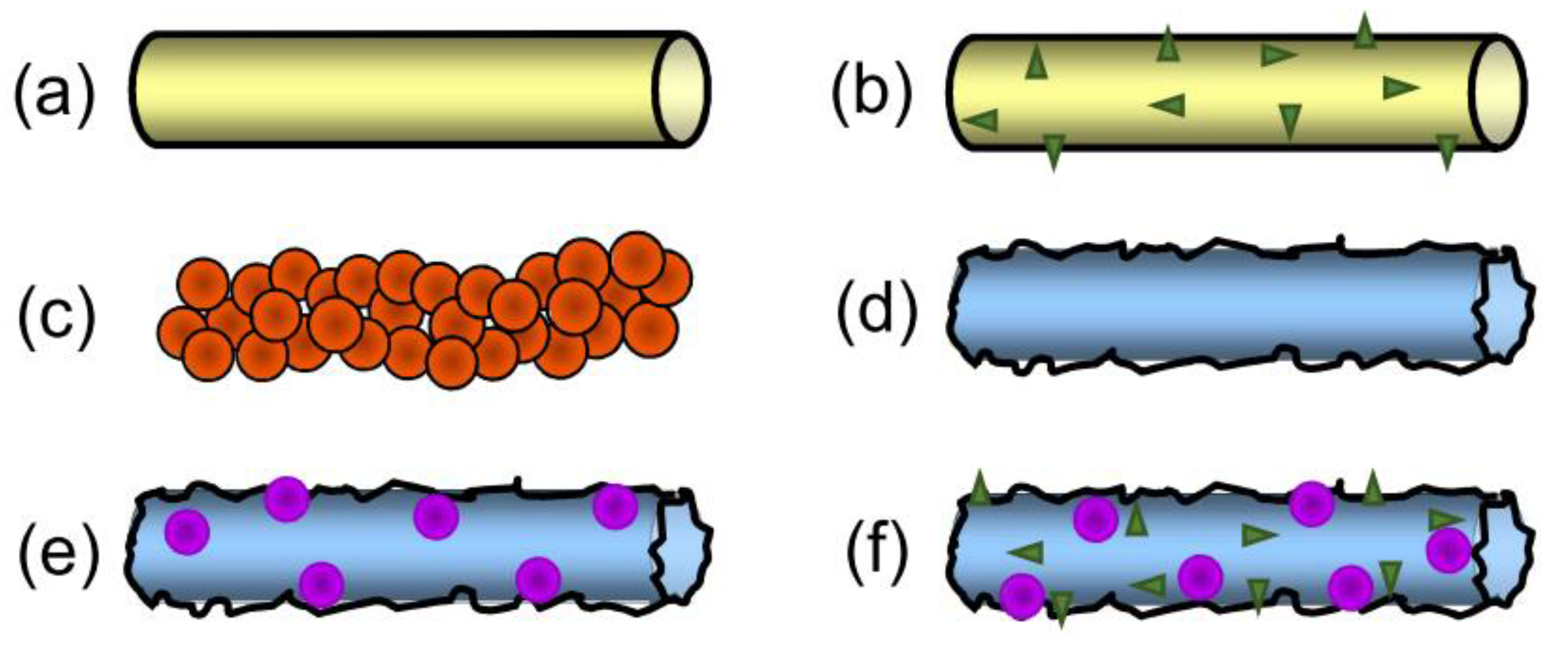

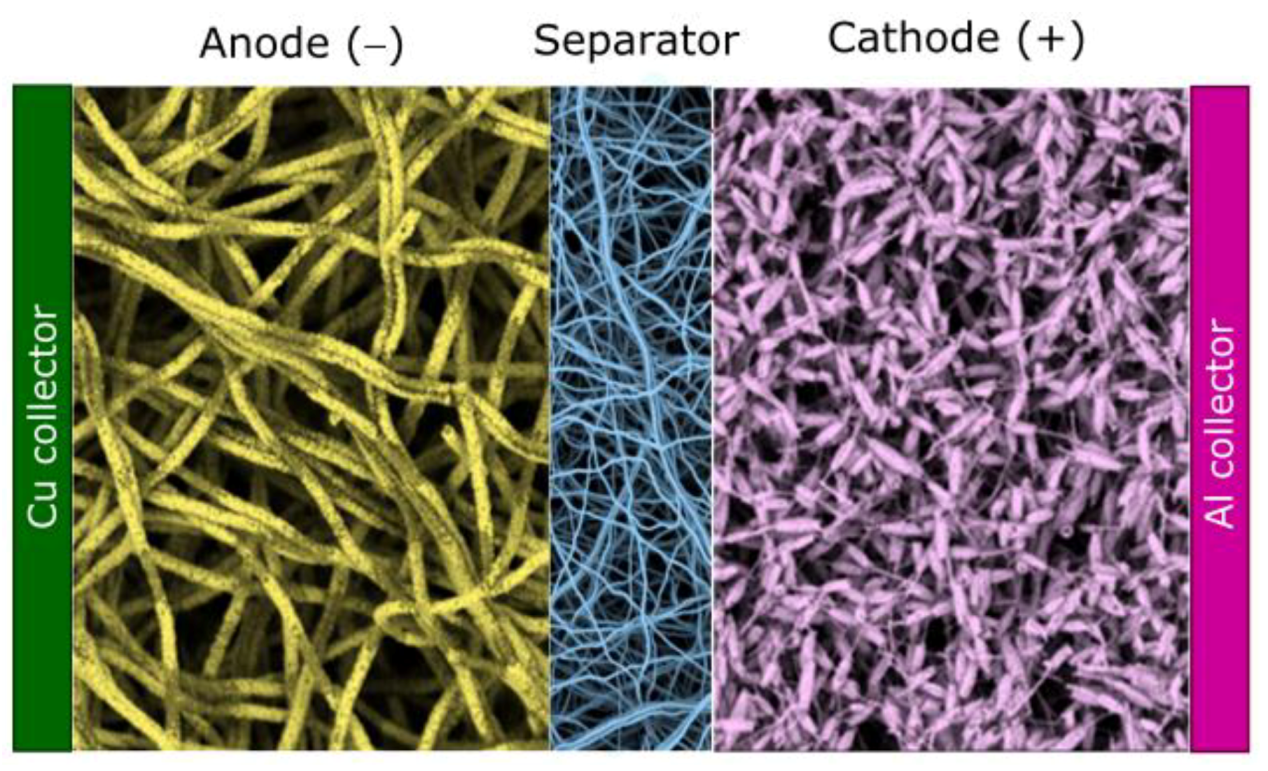

2. Principle of Electrospinning, Experimental Setup, and Production of Fibrous Nanomaterials

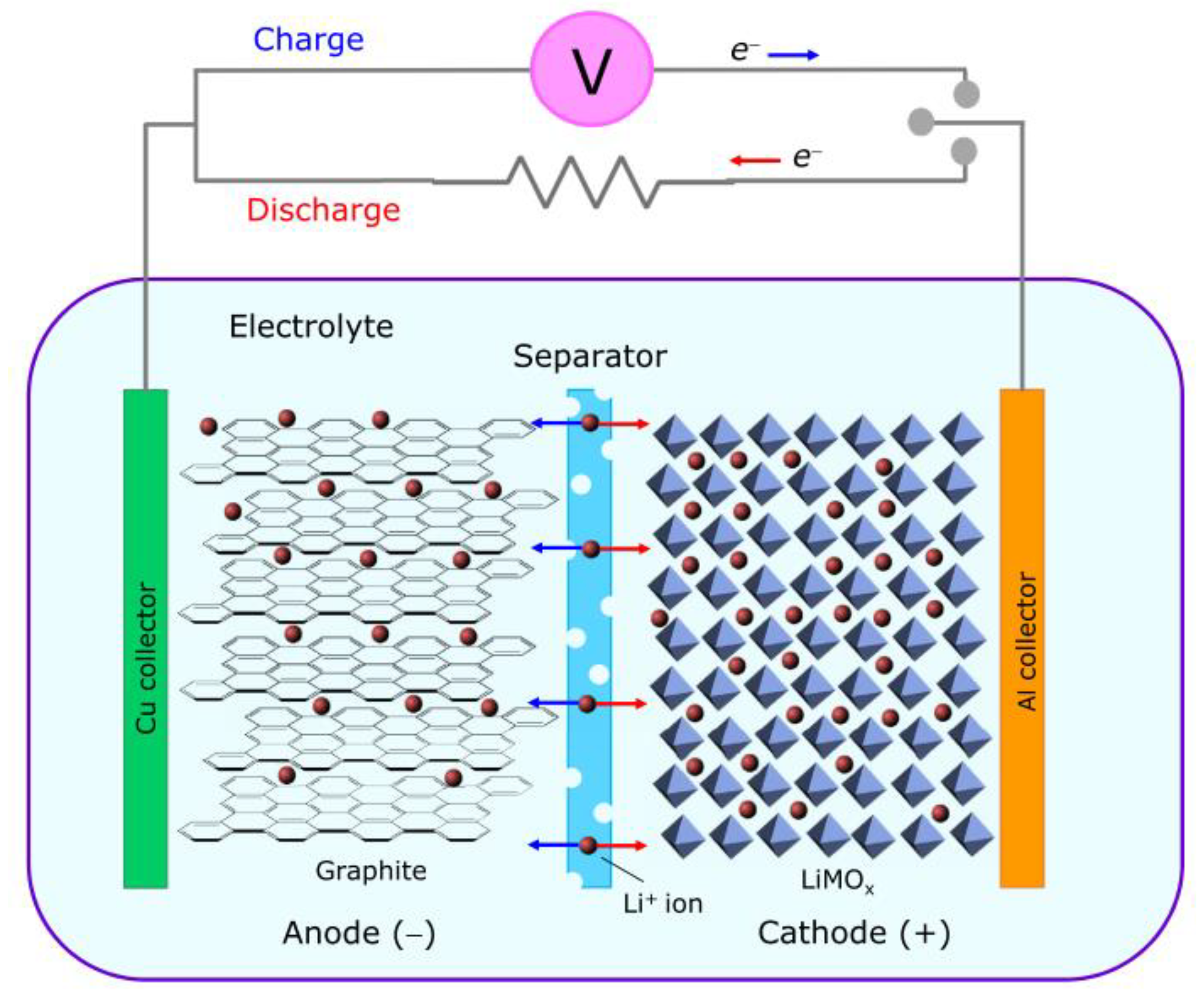

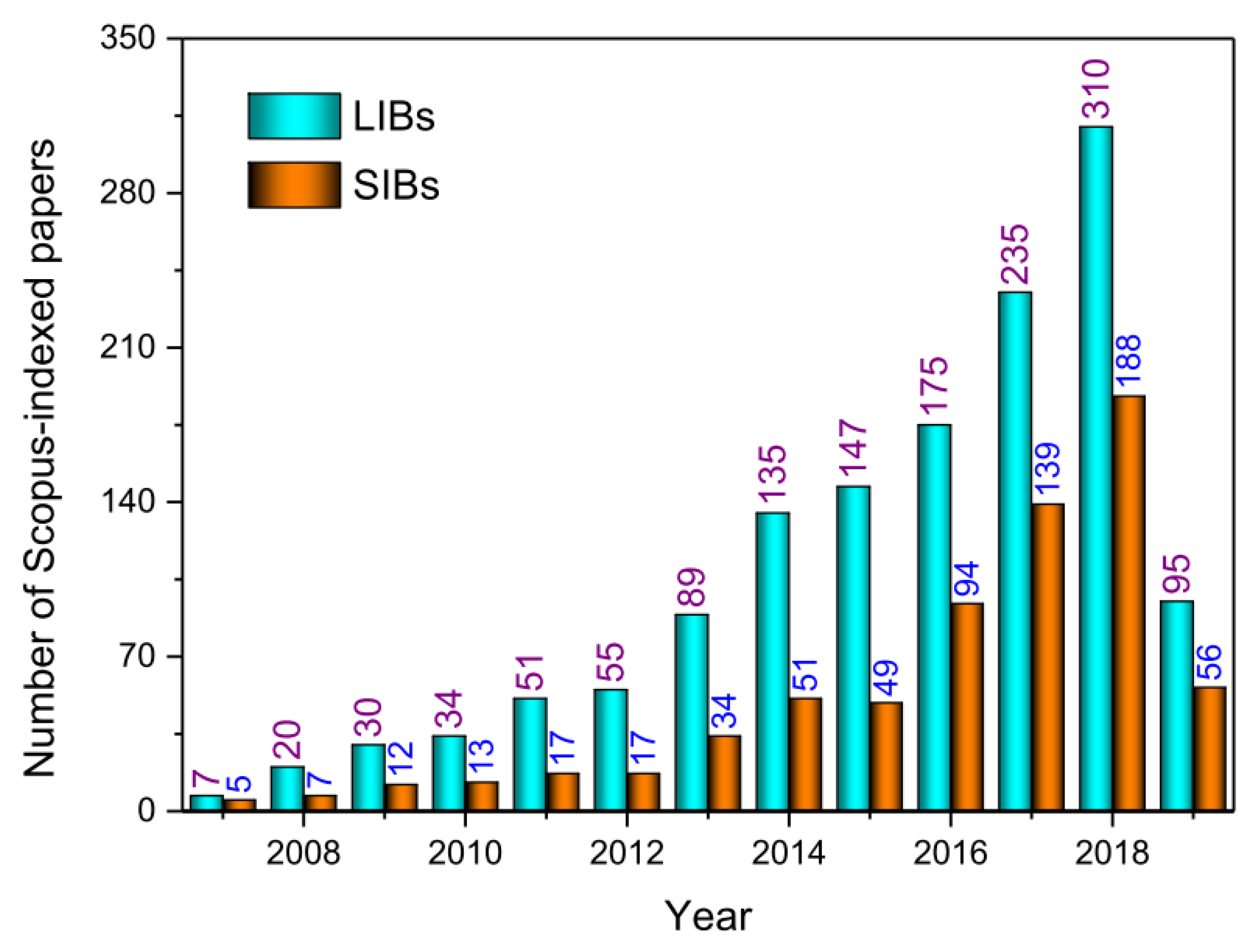

3. Rechargeable Lithium-Ion and Sodium-Ion Batteries

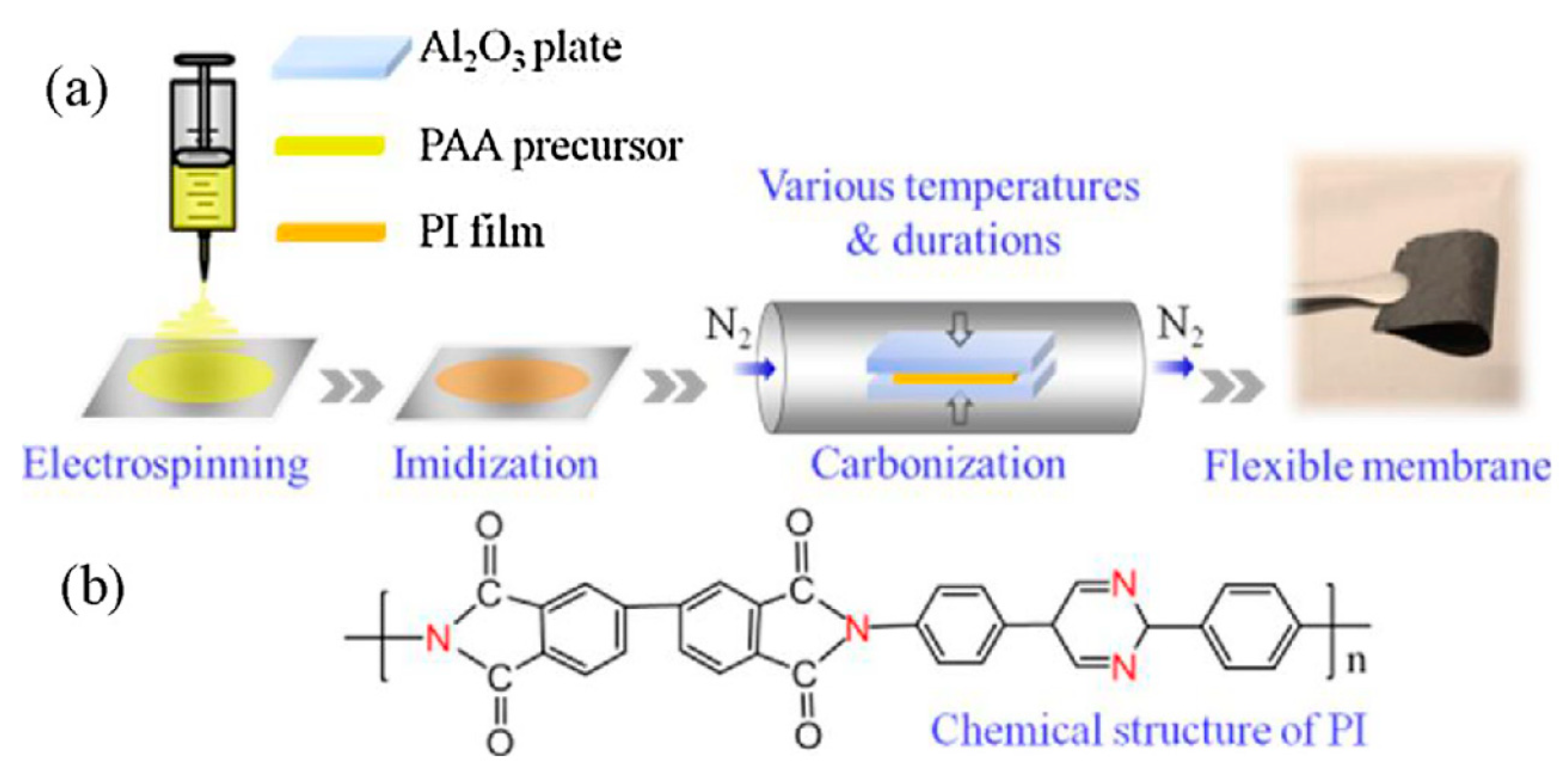

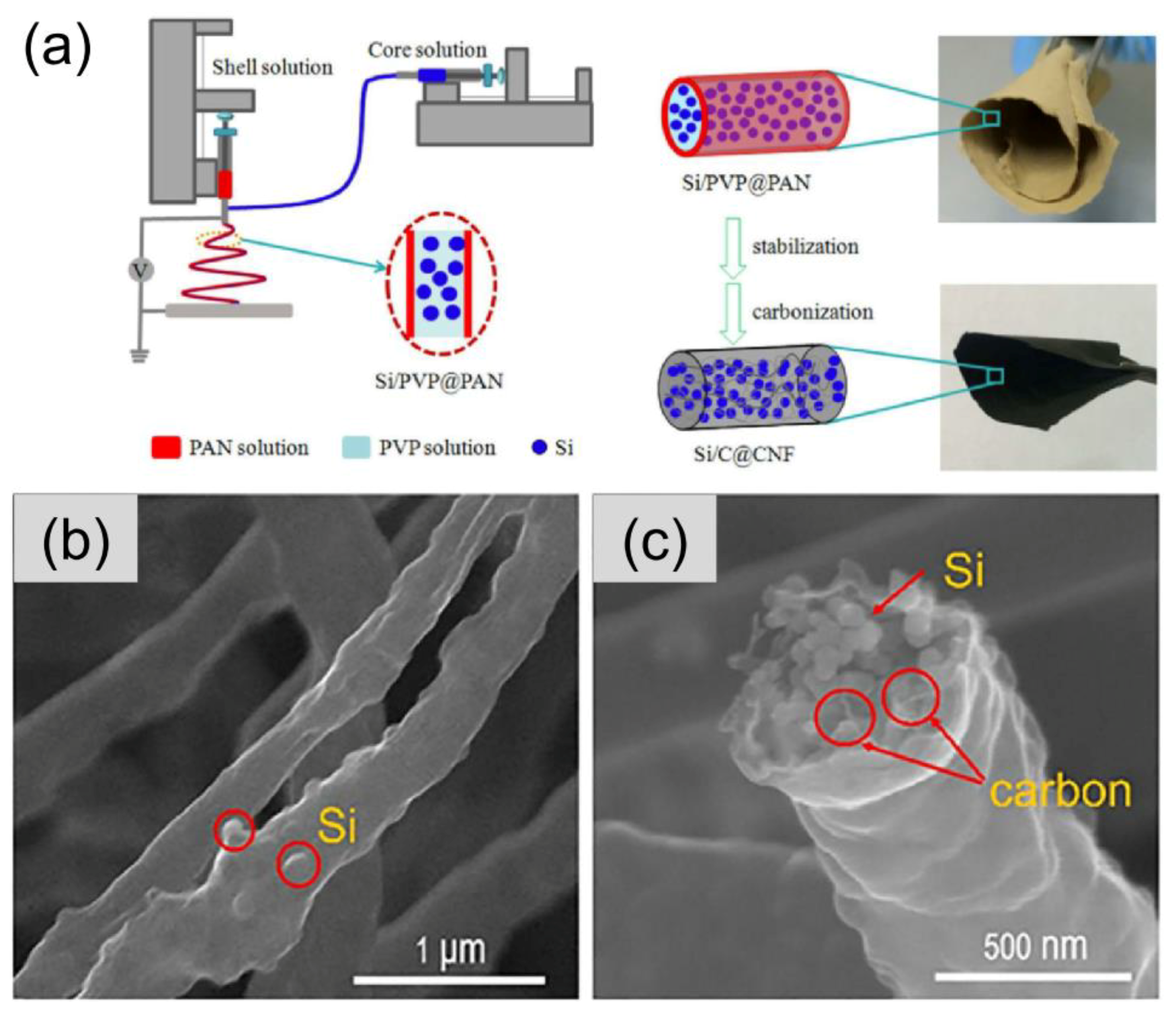

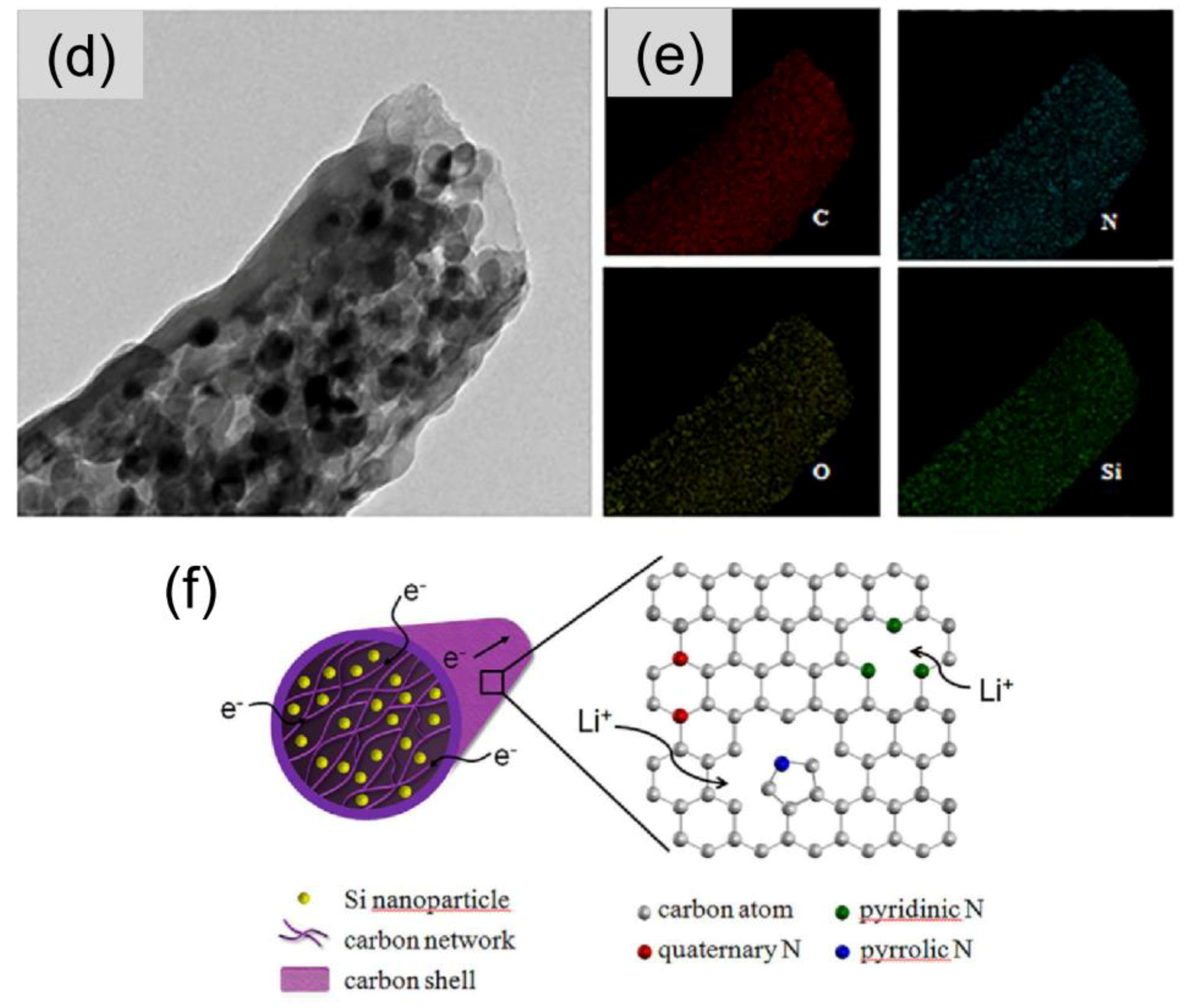

3.1. Lithium-Ion Batteries

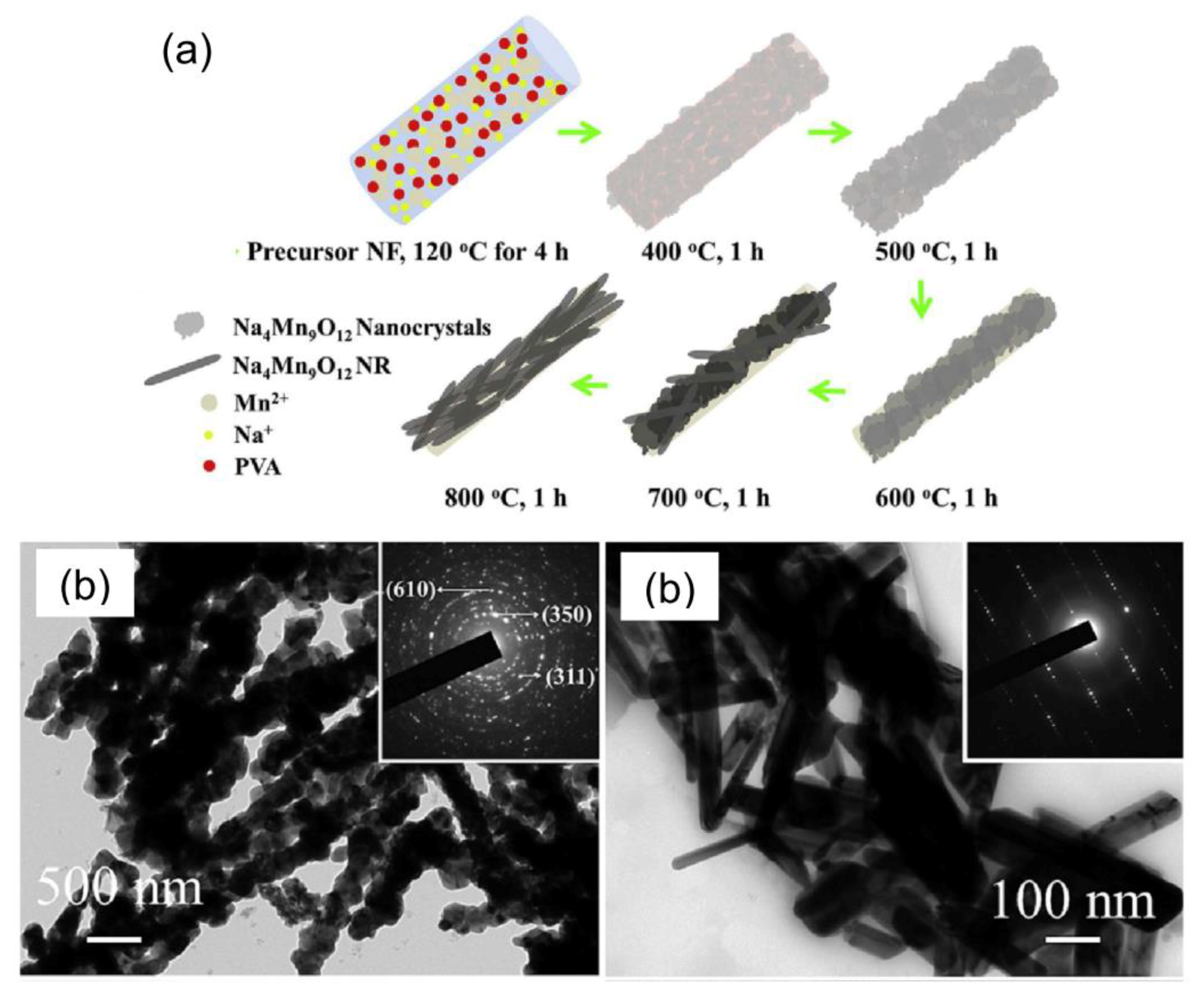

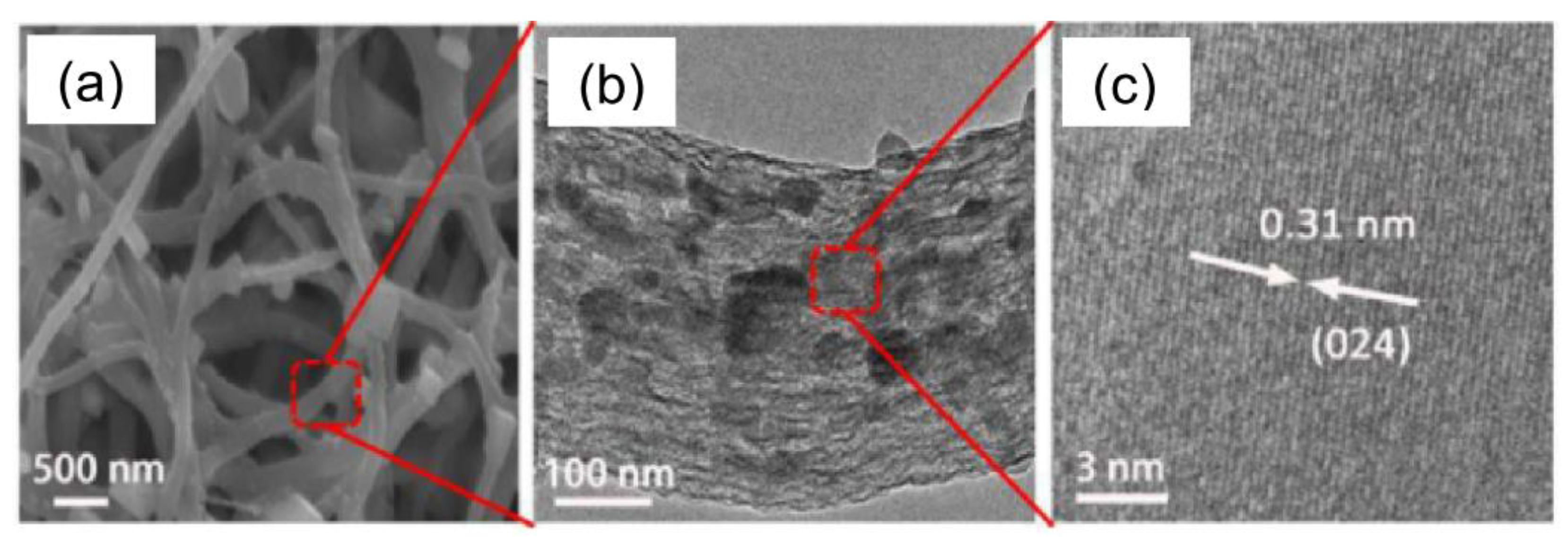

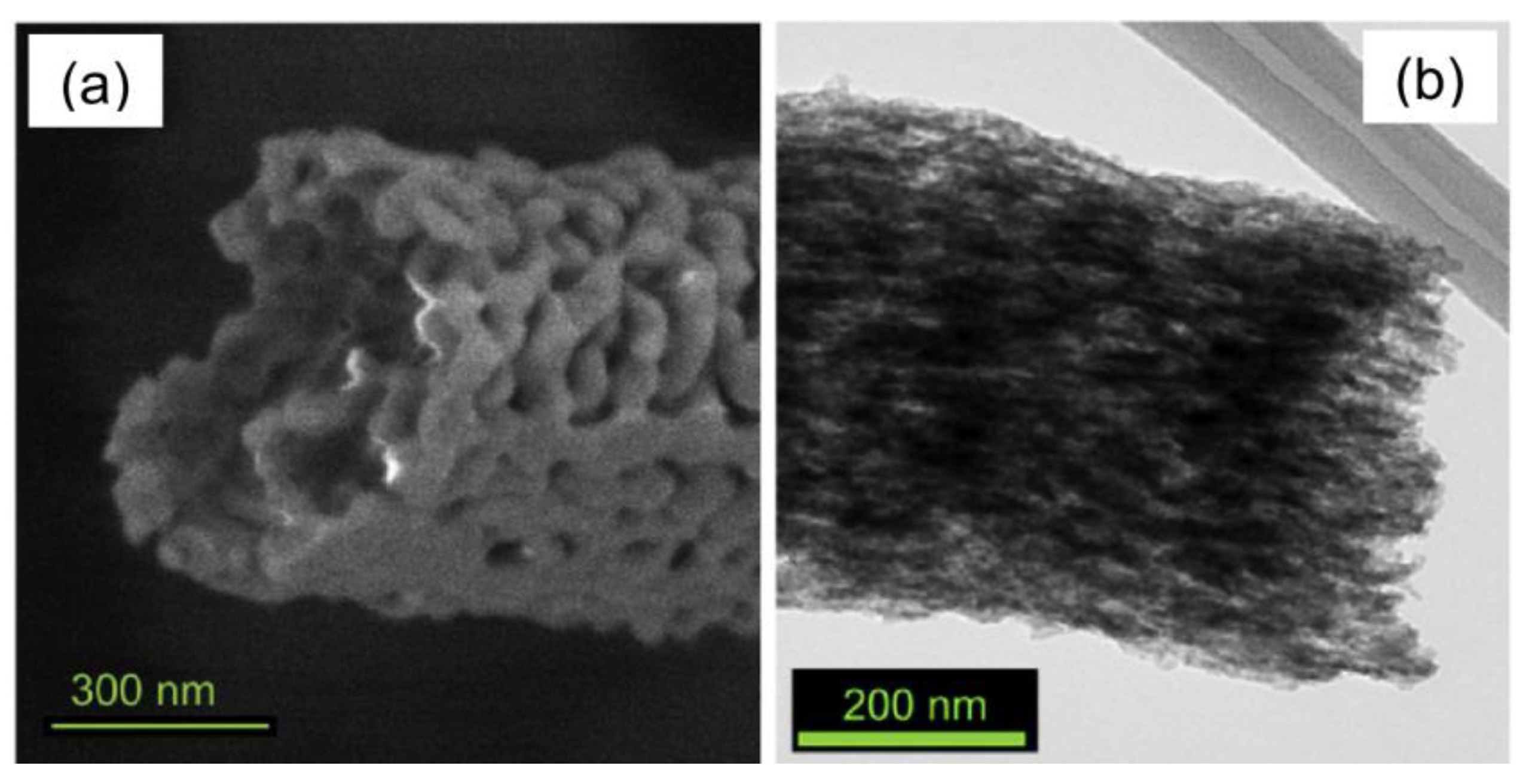

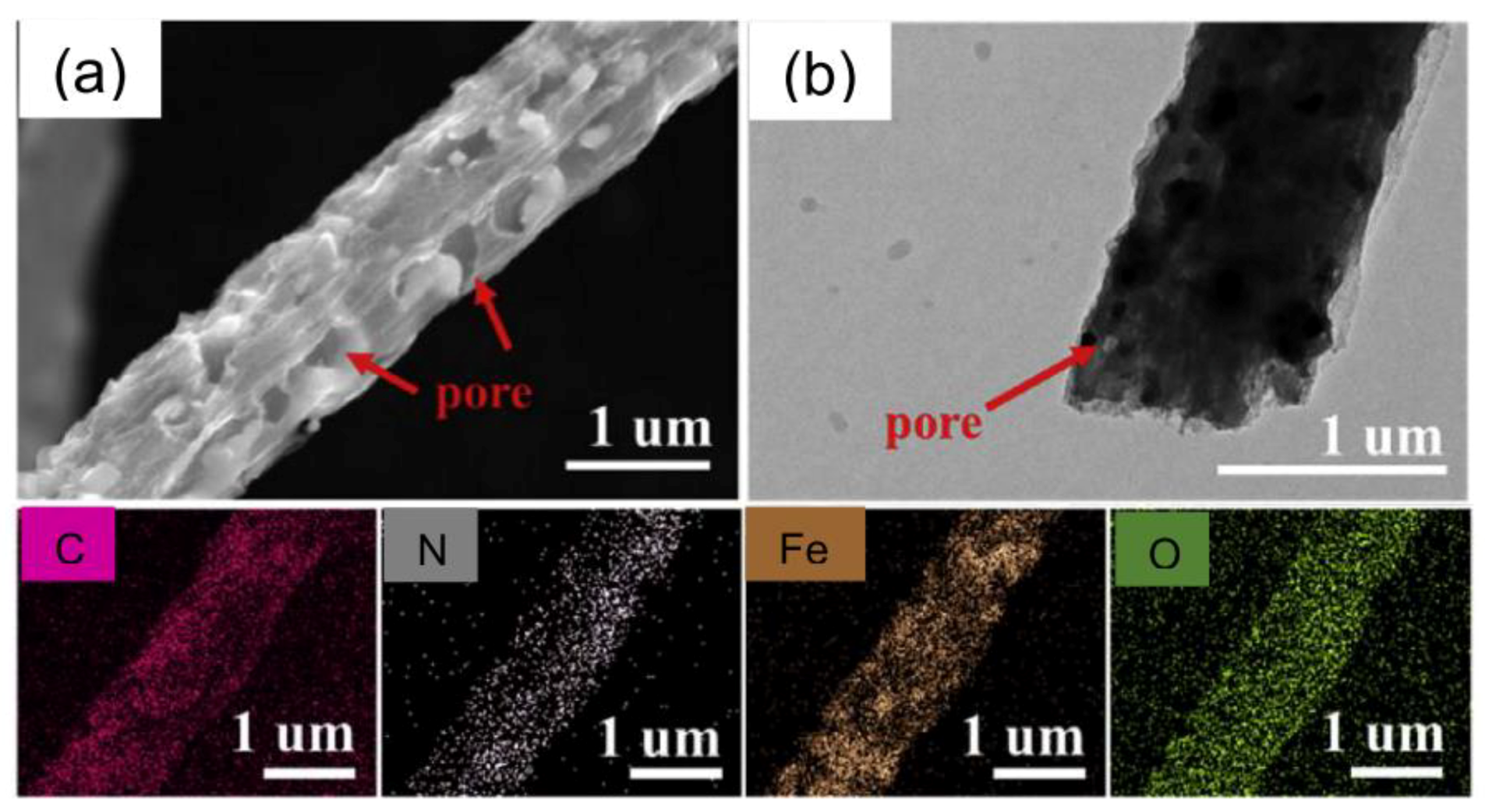

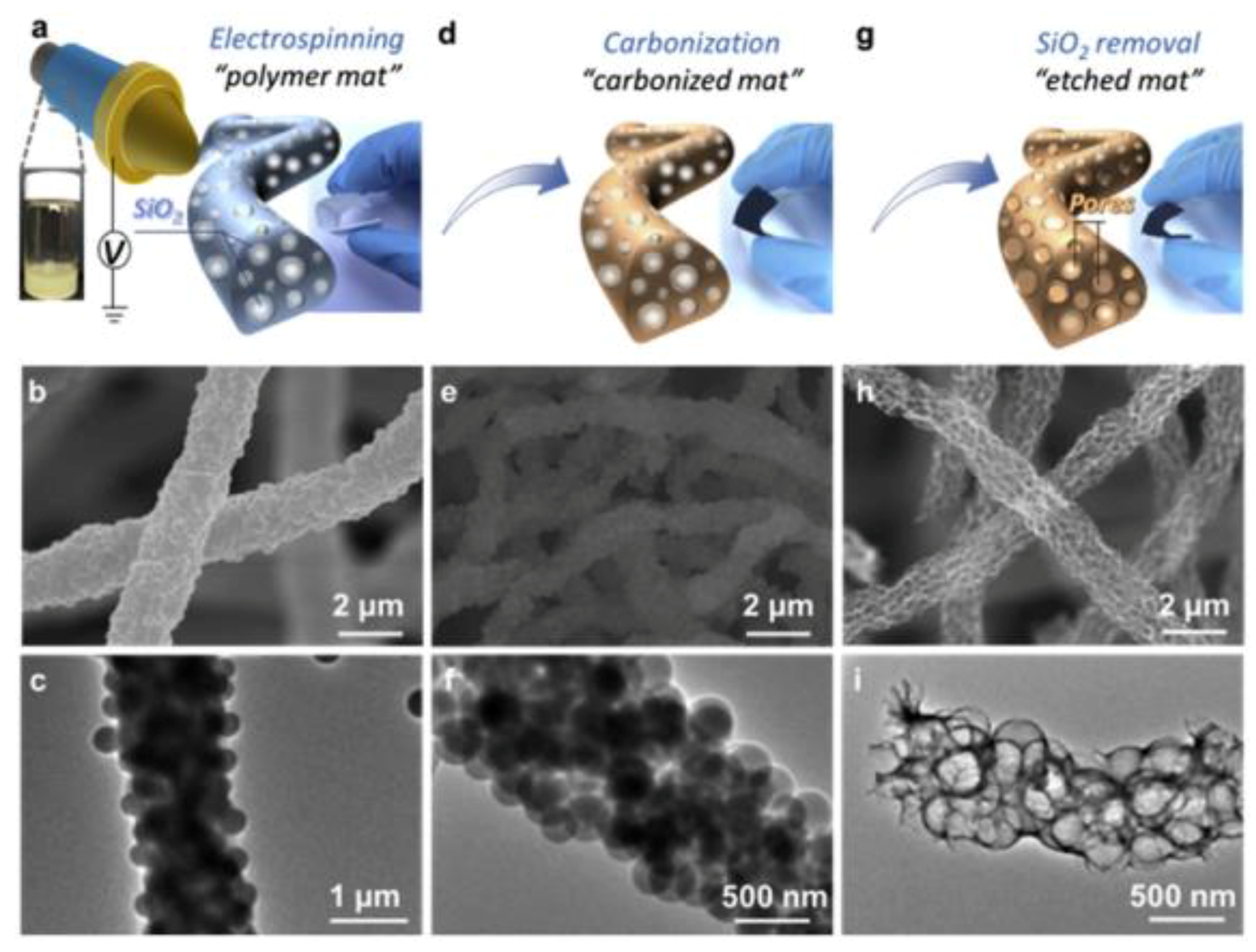

3.2. Sodium-Ion Batteries

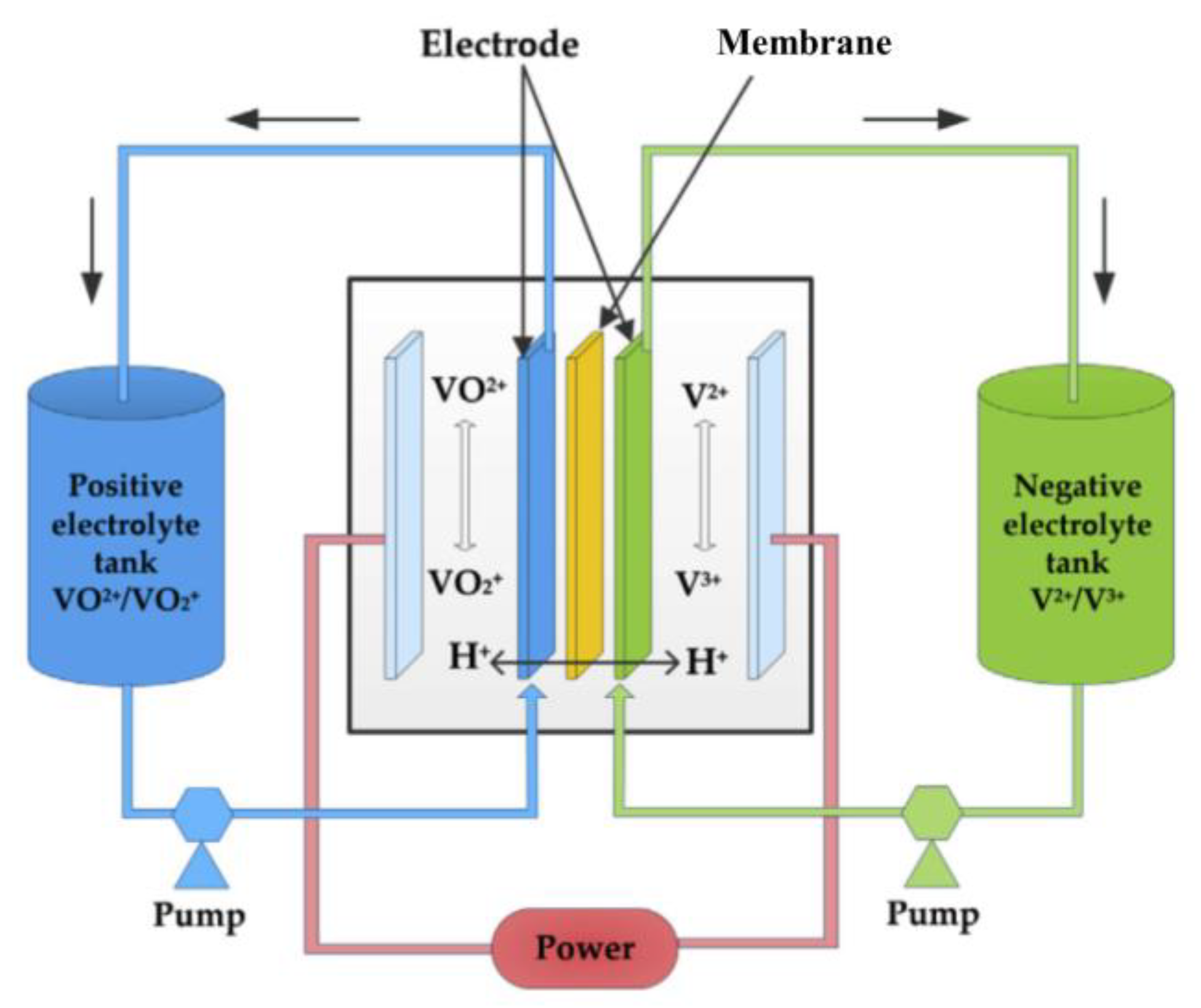

4. Secondary Redox Flow Batteries

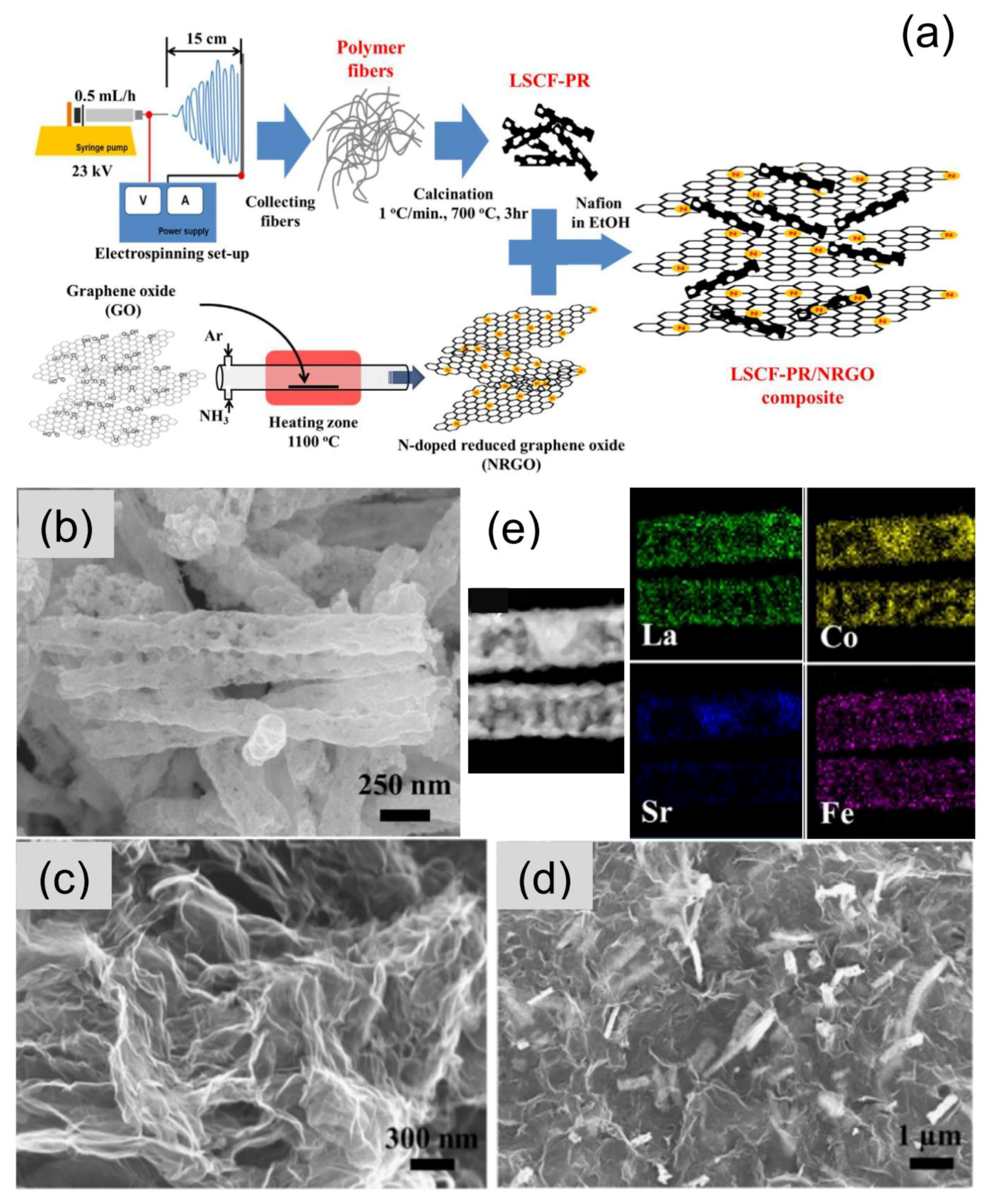

5. Metal-Air Batteries

6. Supercapacitors

7. Capacitive Deionization of Water

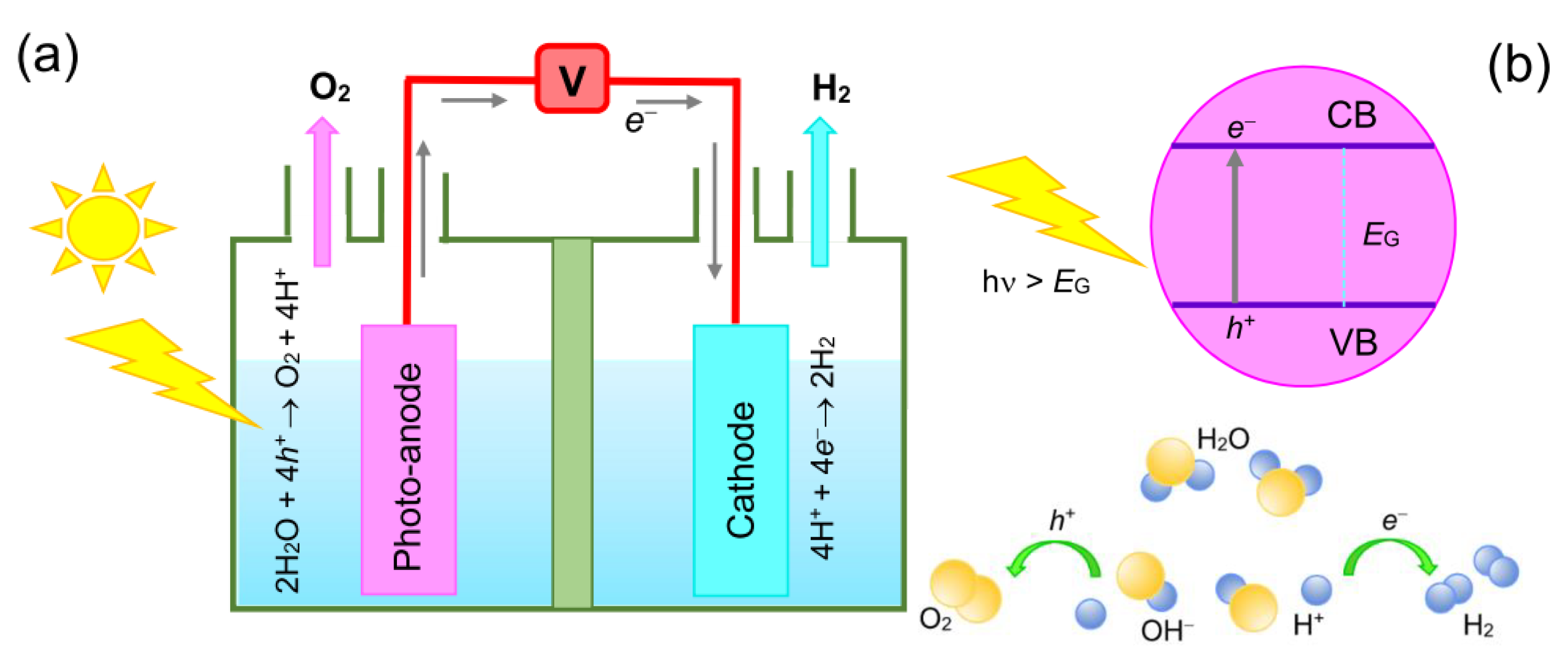

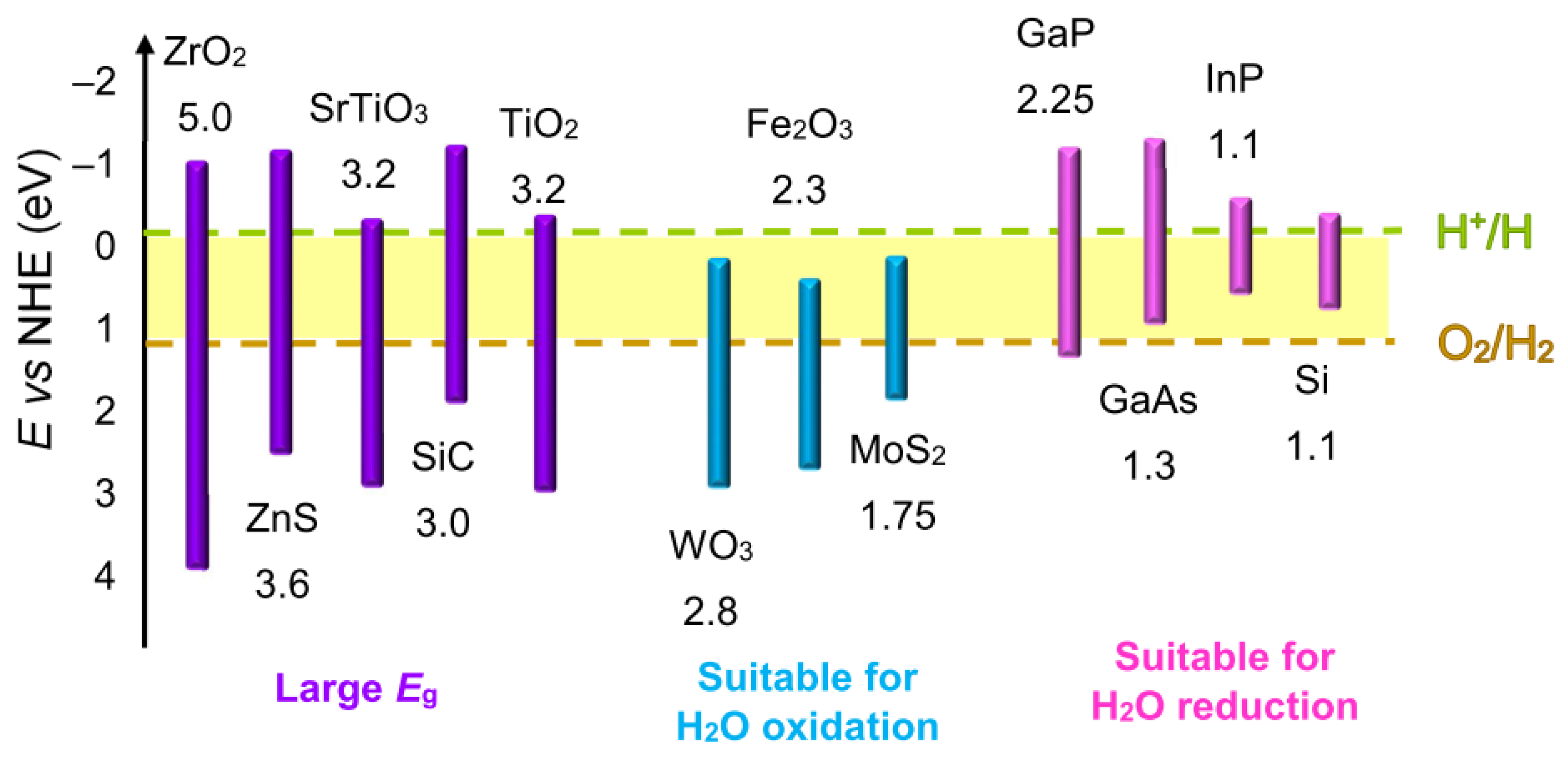

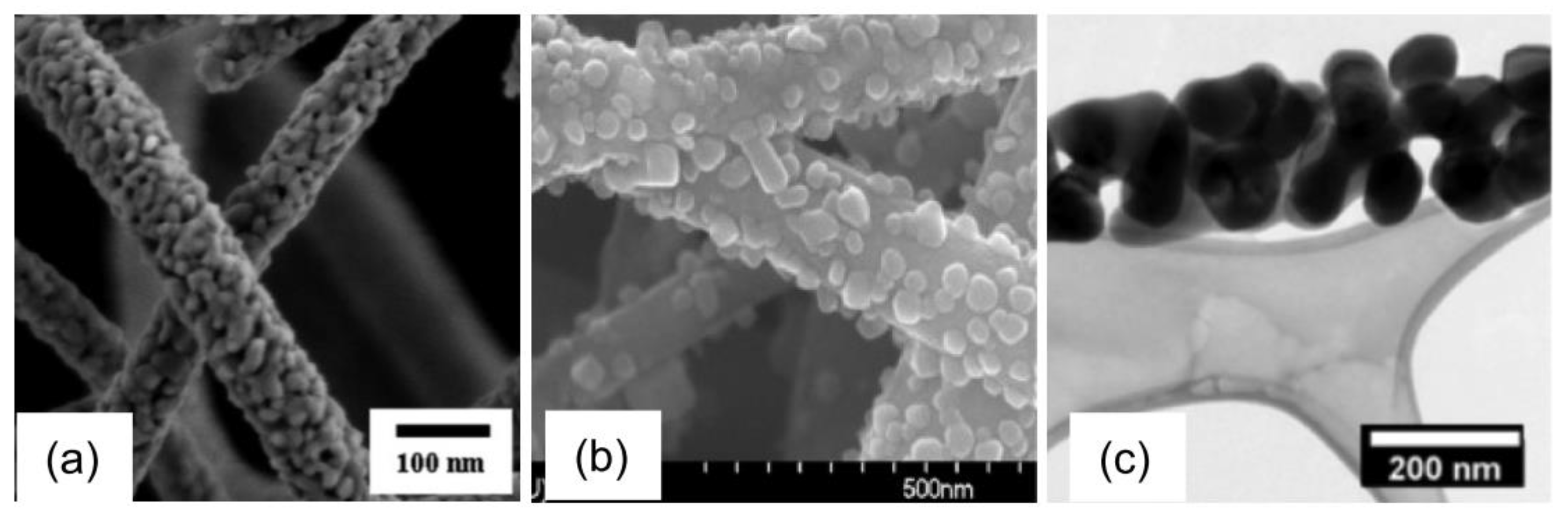

8. Hydrogen Production by Photo-Assisted Electro-Chemical Water Splitting

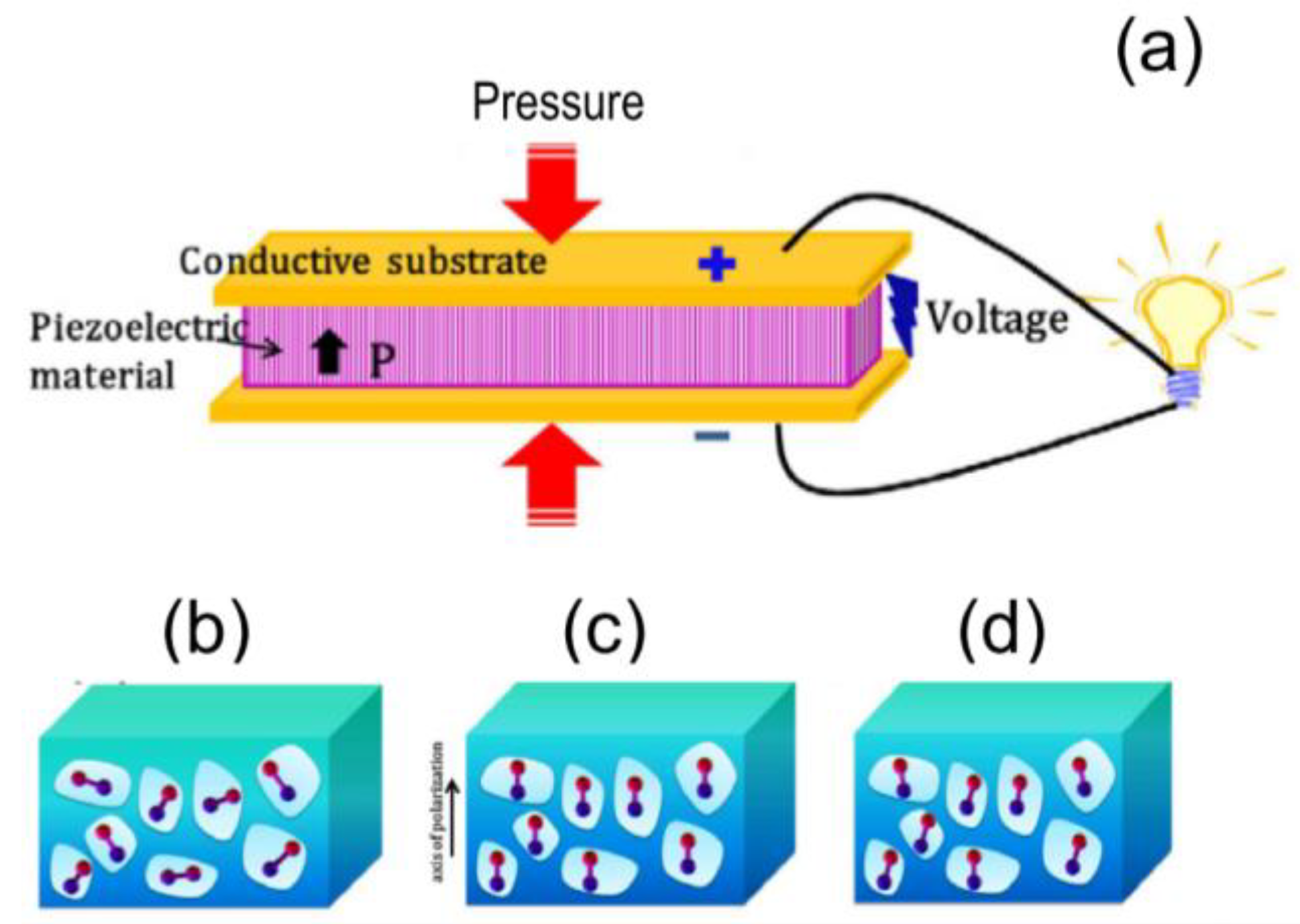

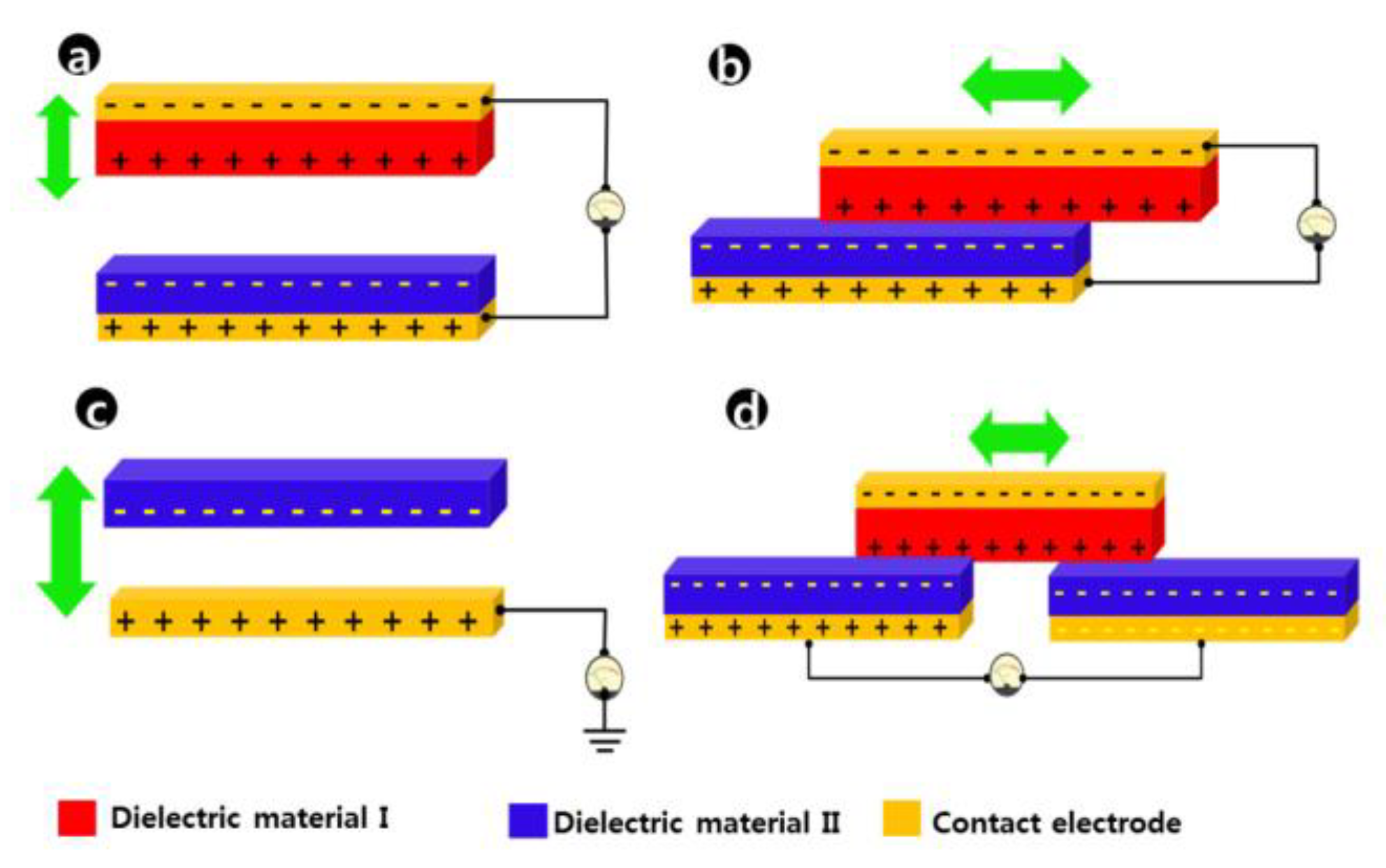

9. Nanogenerators for Energy Harvesting

10. Textiles for Energy Saving through Personal Thermal Management

11. Conclusions

- Search for safer polymer/solvent combinations and abundant, non-toxic precursors to limit the impact of the fiber production on human health as well as the environment.

- Development of ceramic fibers with improved mechanical strength for the production of flexible mats to be used as free-standing electrodes.

- For the composite fibers, improvement of the existing approaches to contrast the tendency towards the aggregation of the very small-sized nanoparticles embedded into the carbon matrix.

- Search for new additives and development of new fiber surface-modification methods to generate electrospun nanomaterials endowed with new functionalities.

- Introduction of new methodologies for the full control of the fiber diameter to be able to produce ultrathin fibers, as well as of the fiber pore size and distribution to enable the fine tunability of their (even hierarchical) porosity.

- Design of new (e.g., suitably patterned) collectors to realize fibrous mats endowed with specific shapes and fiber orientations.

- Invention of new spinning geometries allowing for the integration of different functionalities in a single-layered multi-component fibrous mat.

Supplementary Materials

Funding

Acknowledgments

Conflicts of Interest

References

- Cho, H.; Min, S.Y.; Lee, T.W. Electrospun organic nanofiber electronics and photonics. Macromol. Mater. Eng. 2013, 298, 475–486. [Google Scholar] [CrossRef]

- Fang, J.; Shao, H.; Niu, H.; Lin, T. Applications of electrospun nanofibers for electronic devices. In Handbook of Smart Textiles; Tao, X., Ed.; Springer: Singapore, 2015; pp. 617–652. [Google Scholar] [CrossRef]

- Xue, J.; Xie, J.; Liu, W.; Xia, Y. Electrospun nanofibers: New concepts, materials, and applications. Acc. Chem. Res. 2017, 50, 1976–1987. [Google Scholar] [CrossRef]

- Lim, C.T. Nanofiber technology: Current status and emerging developments. Prog. Polym. Sci. 2017, 70, 1–17. [Google Scholar] [CrossRef]

- Thenmozhi, S.; Dharmaraj, N.; Kadirvelu, K.; Kim, H.Y. Electrospun nanofibers: New generation materials for advanced applications. Mater. Sci. Eng. B 2017, 217, 36–48. [Google Scholar] [CrossRef]

- Ghafoor, B.; Aleem, A.; Ali, M.N.; Mir, M. Review of the fabrication techniques and applications of polymeric electrospun nanofibers for drug delivery systems. J. Drug Deliv. Sci. Technol. 2018, 48, 82–87. [Google Scholar] [CrossRef]

- Esfahani, M.R.; Aktij, S.A.; Dabaghian, Z.; Firouzjaei, M.D.; Rahimpour, A.; Eke, J.; Esboar, I.C.; Abolhassani, M.; Greenlee, L.F.; Esfahani, A.R.; et al. Nanocomposite membranes for water separation and purification: Fabrication, modification, and applications. Separ. Purific. Technol. 2018, 213, 465–499. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, C.; Jia, Y.; Wu, J.; Huang, Y.; Wang, L. Review on electrospun ultrafine phase change fibers (PCFs) for thermal energy storage. Appl. Energy 2018, 210, 167–181. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, J.; Li, J.; Li, D.; Xiao, C.; Xiao, H.; Yang, H.; Zhuang, X.; Chen, X. Electrospun polymer biomaterials. Prog. Polym. Sci. 2019. [Google Scholar] [CrossRef]

- Jung, J.W.; Lee, C.L.; Yu, S.; Kim, I.D. Electrospun nanofibers as a platform for advanced secondary batteries: A comprehensive review. J. Mater. Chem. A 2016, 4, 703–751. [Google Scholar] [CrossRef]

- Cavaliere, S.; Subianto, S.; Savych, I.; Jones, D.J.; Roziere, J. Electrospinning: Designed architectures for energy conversion and storage devices. Energy Environ. Sci. 2011, 4, 4761–4786. [Google Scholar] [CrossRef]

- Zhang, X.; Ji, L.; Toprakci, O.; Liang, Y.; Alcoutlabi, M. Electrospun Nanofiber-based anodes, cathodes, and separators for advanced lithium-ion batteries. Polym. Rev. 2011, 51, 239–264. [Google Scholar] [CrossRef]

- Mao, X.; Hatton, T.A.; Rutledge, G.C. A review of Electrospun Carbon Fibers as Electrode Materials for Energy Storage. Curr. Org. Chem. 2013, 17, 1390–1401. [Google Scholar] [CrossRef]

- Pampal, E.S.; Stojanovska, E.; Simon, B.; Kilic, A. A Review of nanofibrous structures in lithium ion batteries. J. Power Sources 2015, 300, 199–215. [Google Scholar] [CrossRef]

- Aravindan, V.; Sundaramurthy, J.; Kumar, P.S.; Lee, Y.S.; Ramakrishna, S.; Madhavi, S. Electrospun nanofibers: A prospective electro-active material for constructing high performance Li-ion batteries. Chem. Commun. 2015, 51, 2225–2235. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y.; Huang, H.; Mai, Y.W.; Zhou, L. Electrospun carbon-based nanostructured electrodes for advanced energy storage—A review. Energy Storage Mater. 2016, 5, 58–92. [Google Scholar] [CrossRef]

- Armer, C.F.; Yeoh, J.S.; Li, X.; Lowe, A. Electrospun vanadium-based oxides as electrode materials. J. Power Sources 2018, 395, 414–429. [Google Scholar] [CrossRef]

- Li, L.; Peng, S.; Lee, J.K.Y.; Ji, D.; Srinivasan, M.; Ramakrishna, S. Electrospun hollow nanofibers for advanced secondary batteries. Nano Energy 2017, 39, 111–139. [Google Scholar] [CrossRef]

- Cooley, J.F. Apparatus for Electrically Dispersing Fluids. U.S. Patent 692631, 4 February 1902. [Google Scholar]

- Morton, W.J. Method of Dispersing Fluid. U.S. Patent 705691, 29 July 1902. [Google Scholar]

- Formhals, A.; Gastell, S.R. Process and apparatus for preparing artificial threads. U.S. Patent 1975504, 2 October 1934. [Google Scholar]

- Formhals, A. Electrical Spinning of Fibers from Solutions. U.S. Patent 2123992, 19 July 1938. [Google Scholar]

- Formhals, A. Electrical Spinning of Fibers Such as Those Produced from Cellulose Acetate. U.S. Patent 2116942, 19 July 1938. [Google Scholar]

- Formhals, Production of Artificial Fibers. U.S. Patent 2077373, 1 April 1937.

- Formhals, A. Method and Apparatus for Spinning. U.S. Patent 2160962, 1 July 1939. [Google Scholar]

- Formhals, A. Artificial Thread and Method of Producing Same Field. U.S. Patent 2187306, 16 January 1940. [Google Scholar]

- Formhals, A. Producing of Artifical Fibres from Fibre Forming Liquids. U.S. Patent 2323025, 29 January 1943. [Google Scholar]

- Formhals, A. Method and Apparatus for Spinning. U.S. Patent 2349950, 30 May 1944. [Google Scholar]

- Zeleny, J. The electrical discharge from liquid points, and a hydrostatic method of measuring the electric intensity at their surfaces. Phys. Rev. 1914, 3, 69. [Google Scholar] [CrossRef]

- Taylor, G.I. Disintegration of water droplets in an electric field. Proc. R. Soc. Lond. A 1964, 280, 383–397. [Google Scholar] [CrossRef]

- Taylor, G.I.; Van Dyke, M.D. The force exerted by an electric field on a long cylindrical conductor. Proc. R. Soc. Lond. A 1966, 291, 145–158. [Google Scholar] [CrossRef]

- Taylor, G.I.; Van Dyke, M.D. Electrically driven jets. Proc. R. Soc. Lond. A 1969, 313, 453–475. [Google Scholar] [CrossRef]

- Baumgarten, P.K. Electrostatic spinning of acrylic microfibers. J. Colloid Interf. Sci. 1971, 36, 71–79. [Google Scholar] [CrossRef]

- Fong, H.; Chun, I.; Reneker, D. Beaded nanofibers formed during electrospinning. Polymer 1999, 40, 4585–4592. [Google Scholar] [CrossRef]

- Doshi, J.; Reneker, D.H. Electrospinning process and applications of electrospun fibers. J. Electrost. 1995, 35, 151–160. [Google Scholar] [CrossRef]

- Reneker, D.H.; Chun, I. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 1996, 7, 216. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L.; Fong, H.; Koombhongse, S. Bending instability of electrically charged liquid jets of polymer solutions in electrospinning. J. Appl. Phys. 2000, 87, 4531–4547. [Google Scholar] [CrossRef]

- Koombhongse, S.; Liu, W.; Reneker, D.H. Flat polymer ribbons and other shapes by electrospinning. J. Polym. Sci. B 2001, 39, 2598–2606. [Google Scholar] [CrossRef]

- Yarin, A.L.; Koombhongse, S.; Reneker, D.H. Bending instability in Electrospinning of nanofibers. J. Appl. Phys. 2001, 89, 3018–3026. [Google Scholar] [CrossRef]

- Hohman, M.M.; Shin, M.; Rutledge, G.; Brenner, M.P. Electrospinning and electrically forced jets. I. Stability theory. Phys. Fluids 2001, 13, 2201–2220. [Google Scholar] [CrossRef]

- Hohman, M.M.; Shin, M.; Rutledge, G.; Brenner, M.P. Electrospinning and electrically forced jets. II. Applications. Phys. Fluids 2001, 13, 2221–2236. [Google Scholar] [CrossRef]

- Shin, Y.M.; Hohman, M.M.; Brenner, M.P.; Rutledge, G.C. Experimental characterization of electrospinning: The electrically forced jet and instabilities. Polymer 2001, 42, 09955–09967. [Google Scholar] [CrossRef]

- Shin, Y.M.; Hohman, M.M.; Brenner, M.P.; Rutledge, G.C. Electrospinning: A whipping fluid jet generates submicron polymer fibers. Appl. Phys. Lett. 2001, 78, 1149–1151. [Google Scholar] [CrossRef]

- Fridrikh, S.V.; Yu, J.H.; Brenner, M.P.; Rutledge, G.C. Controlling the fiber diameter during electrospinning. Phys. Rev. Lett. 2003, 90, 144502. [Google Scholar] [CrossRef]

- Liu, Q.; Zhu, J.; Zhang, L.; Qiu, Y. Recent advances in energy materials by electrospinning. Renew. Sustain. Energy Rev. 2018, 81, 1825–1858. [Google Scholar] [CrossRef]

- Simotwo, S.K.; Del Re, C.; Kalra, V. Supercapacitor Electrodes Based on High-Purity Electrospun Polyaniline and Polyaniline–Carbon Nanotube Nanofibers. ACS Appl. Mater. Interfaces 2016, 8, 21261–21269. [Google Scholar] [CrossRef]

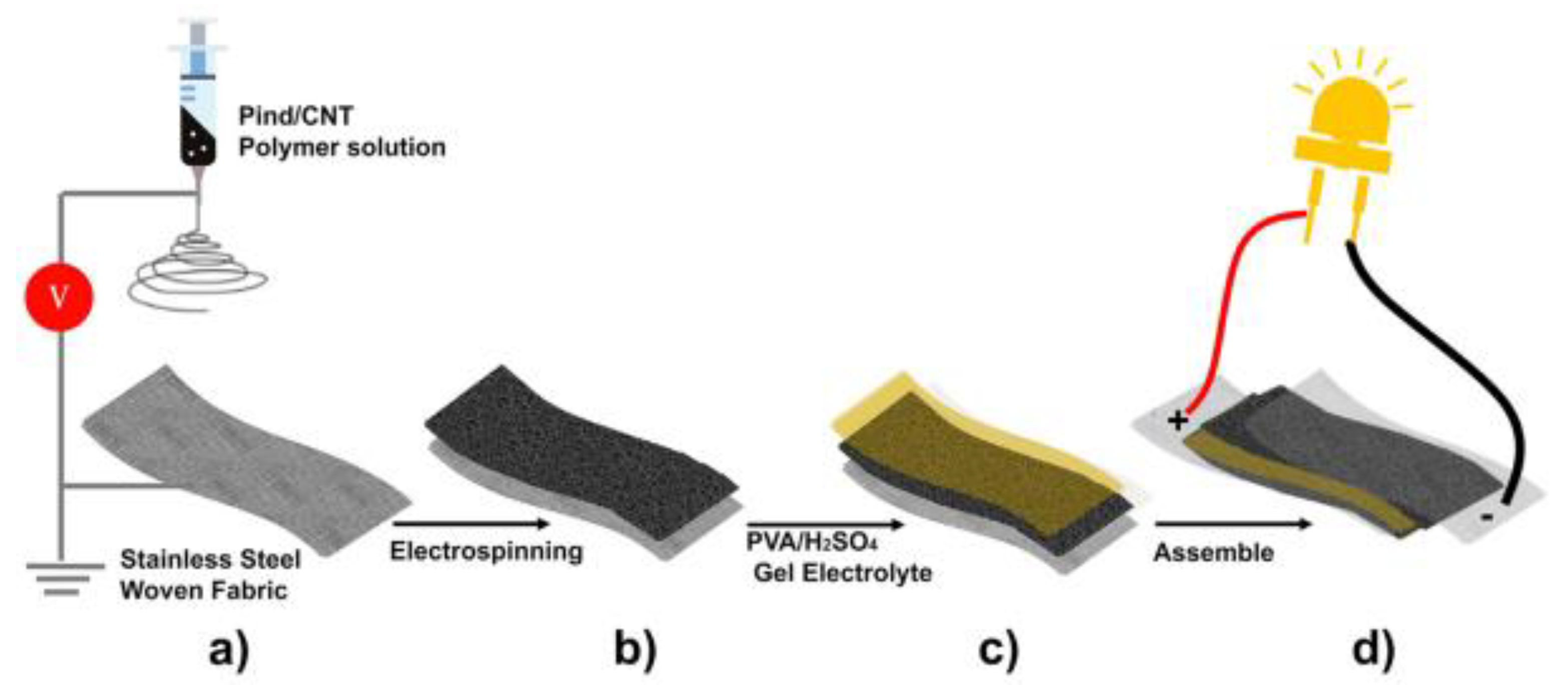

- Tebyetekerwa, M.; Yang, S.; Peng, S.; Xu, Z.; Shao, W.; Pan, D.; Ramakrishna, S.; Zhu, M. Unveiling polyindole: Freestanding as-electrospun polyindole nanofibers and polyindole/carbon nanotubes composites as enhanced electrodes for flexible all-solid-state supercapacitors. Electrochim. Acta 2017, 247, 400–409. [Google Scholar] [CrossRef]

- Wee, G.; Soh, H.Z.; Cheah, Y.L.; Mhaisalkar, S.G.; Srinivasan, M. Synthesis and electrochemical properties of electrospun V2O5 nanofibers as supercapacitor electrodes. J. Mater. Chem. 2010, 20, 6720–6725. [Google Scholar] [CrossRef]

- Faggio, G.; Modafferi, V.; Panzera, G.; Alfieri, D.; Santangelo, S. Micro-Raman and photoluminescence analysis of composite vanadium oxide/poly-vinyl acetate fibres synthesized by electrospinning. J. Raman Spectr. 2012, 43, 761–768. [Google Scholar] [CrossRef]

- Leonardi, S.G.; Mirzaei, A.; Bonavita, A.; Santangelo, S.; Frontera, P.; Pantò, F.; Antonucci, P.L.; Neri, G. A comparison of ethanol sensing properties of α-iron oxide nanostructures prepared via sol-gel and electrospinning technics. Nanotechnology 2016, 27, 75502–75511. [Google Scholar] [CrossRef]

- Santangelo, S.; Patanè, S.; Frontera, P.; Pantò, F.; Triolo, C.; Stelitano, S.; Antonucci, P.L. Effect of calcium- and/or aluminum-incorporation on morphological, structural and photoluminescence properties of electro-spun zinc oxide fibers. Mater. Res. Bull. 2017, 92, 9–18. [Google Scholar] [CrossRef]

- He, T.; Fu, Y.; Meng, X.; Yu, X.; Wang, X. A novel strategy for the high performance supercapacitor based on polyacrylonitrile-derived porous nanofibers as electrode and separator in ionic liquid electrolyte. Electrochim. Acta 2018, 282, 97–104. [Google Scholar] [CrossRef]

- Niu, H.; Zhang, J.; Xie, Z.; Wang, X.; Lin, T. Preparation, structure and supercapacitance of bonded carbon nanofiber electrode materials. Carbon 2011, 49, 2380–2388. [Google Scholar] [CrossRef]

- Li, X.; Zhao, Y.; Bai, Y.; Zhao, X.; Wang, R.; Huang, Y.; Liang, Q.; Huang, Z. A non-woven network of porous nitrogen-doping carbon nanofibers as a binder-free electrode for supercapacitors. Electrochim. Acta 2017, 230, 445–453. [Google Scholar] [CrossRef]

- Belaustegui, Y.; Zorita, S.; Fernández-Carretero, F.; García-Luis, A.; Pantò, F.; Stelitano, S.; Frontera, P.; Antonucci, P.; Santangelo, S. Electrospun graphene-enriched nitrogen-doped carbon fibres for electrochemical water desalination. Desalination 2018, 428, 40–49. [Google Scholar] [CrossRef]

- Pantò, F.; Fan, Y.; Frontera, P.; Stelitano, S.; Fazio, E.; Patanè, S.; Marelli, M.; Antonucci, P.L.; Neri, F.; Pinna, N.; et al. Are electrospun carbon/metal oxide composite fibres relevant electrode materials for Li-ion batteries? J. Electrochem. Soc. 2016, 163, A2930–A2937. [Google Scholar] [CrossRef]

- Pantò, F.; Fan, Y.; Stelitano, S.; Fazio, E.; Frontera, P.; Patanè, S.; Antonucci, P.L.; Pinna, N.; Santangelo, S. Electrospun C/GeO2 paper-like electrodes for flexible Li-ion batteries. Int. J. Hydrog. Energy 2017, 42, 28102–28112. [Google Scholar] [CrossRef]

- Pantò, F.; Fan, Y.; Stelitano, S.; Fazio, E.; Frontera, P.; Patanè, S.; Antonucci, P.L.; Pinna, N.; Santangelo, S. Are electro-spun fibrous membranes relevant electrode materials for Li-ion batteries? The case of the composite C/GeO2 fibres. Adv. Funct. Mater. 2018, 28, 1800938–1800951. [Google Scholar] [CrossRef]

- Fan, L.; Yang, L.; Ni, X.; Han, J.; Guo, R.; Zhang, C.J. Nitrogen-enriched meso-macroporous carbon fiber network as a binder-free flexible electrode for supercapacitors. Carbon 2016, 107, 629–637. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, J.; Kintner-Meyer, M.C.; Lu, X.; Choi, D.; Lemmon, J.P.; Liu, J. Electrochemical energy storage for green grid. Chem. Rev. 2011, 111, 3577–3613. [Google Scholar] [CrossRef]

- Office of Electricity Delivery and Energy Reliability—United States Department of Energy (DOE), Global Energy Storage Database. 2018. Available online: www.energystorageexange.org (accessed on 1 December 2018).

- Linden, D.; Reddy, T.B. Handbook of Batteries; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Thackeray, M.M.; David, W.I.F.; Bruce, P.G.; Goodenough, J.B. Lithium insertion into manganese spinels. Mater. Res. Bull. 1983, 18, 461–472. [Google Scholar] [CrossRef]

- Ritchie, A.G.; Giwa, C.O.; Lee, J.C.; Bowles, P.; Gilmour, A.; Allan, J.; Rice, D.A.; Brady, F.; Tsang, S.C.E. Future cathode materials for lithium rechargeable batteries. J. Power Sources 1999, 80, 98–102. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, F.; Liu, S.W.; Tan, A.Y.S.; Song, H.; Sun, X.W.; Yang, H.Y. Onion-like carbon matrix supported Co3O4 nanocomposites: A highly reversible anode material for lithium ion batteries with excellent cycling stability. J. Mater. Chem. A 2013, 1, 5212–5216. [Google Scholar] [CrossRef]

- Zhang, M.; Uchaker, E.; Hu, S.; Zhang, Q.; Wang, T.; Cao, G.; Li, J. CoO-carbon nanofiber networks prepared by electrospinning as binder-free anode materials for lithium-ion batteries with enhanced properties. Nanoscale 2013, 5, 12342–12349. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, H.; Petnikota, S.; Ramakrishna, S.; Fan, H.J. Electrospun Fe2O3-carbon composite nanofibers as durable anode materials for lithium ion batteries. J. Mater. Chem. A 2014, 2, 10835–10841. [Google Scholar] [CrossRef]

- Wang, H.G.; Zhou, Y.; Shen, Y.; Li, Y.; Zuo, Q.; Duan, Q. Fabrication, formation mechanism and the application in lithium-ion battery of porous Fe2O3 nanotubes via single-spinneret electrospinning. Electrochim. Acta 2015, 158, 105–112. [Google Scholar] [CrossRef]

- Chan, C.K.; Peng, H.; Liu, G.; McIlwrath, K.; Zhang, X.F.; Huggins, R.A.; Cui, Y. High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 2008, 3, 31–35. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, Y.; Liu, Y.; Wang, C. Electrochemical performance of porous carbon/tin composite anodes for sodium-ion and lithium-ion batteries. Adv. Energy Mater. 2013, 3, 128–133. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, S.; Zhang, C.; Cui, G. High performance germanium-based anode materials. Coord. Chem. Rev. 2016, 326, 34–85. [Google Scholar] [CrossRef]

- Ngo, D.T.; Le, H.T.T.; Kalubarme, R.S.; Lee, J.Y.; Park, C.N.; Park, C.J. Uniform GeO2 dispersed in nitrogen-doped porous carbon core–shell architecture: An anode material for lithium ion batteries. J. Mater. Chem. A 2015, 3, 21722–21732. [Google Scholar] [CrossRef]

- Li, M.; Zhou, D.; Song, W.L.; Li, X.; Fan, L.Z. Highly stable GeOx@C core–shell fibrous anodes for improved capacity in lithium-ion batteries. J. Mater. Chem. A 2015, 3, 19907–19912. [Google Scholar] [CrossRef]

- Lee, Y.W.; Kim, D.M.; Kim, S.J.; Kim, M.C.; Choe, H.S.; Lee, K.H.; Sohn, J.I.; Cha, S.N.; Kim, J.M.; Park, K.W. In situ synthesis and characterization of Ge embedded electrospun carbon nanostructures as high performance anode material for lithium-ion batteries. ACS Appl. Mater. Interfaces 2016, 8, 7022–7029. [Google Scholar] [CrossRef] [PubMed]

- Fergus, J.W. Recent developments in cathode materials for lithium ion batteries. J. Power Sources 2010, 195, 939–954. [Google Scholar] [CrossRef]

- Zhu, N.; Liu, W.; Xue, M.; Xie, Z.; Zhao, D.; Zhang, M.; Chen, J.; Cao, T. Graphene as a conductive additive to enhance the high-rate capabilities of electrospun Li4Ti5O12 for lithium-ion batteries. Electrochim. Acta 2010, 55, 5813–5818. [Google Scholar] [CrossRef]

- Li, W.; Yang, Z.; Cheng, J.; Zhong, X.; Gu, L.; Yu, Y. Germanium nanoparticles encapsulated in flexible carbon nanofibers as self-supported electrodes for high performance lithium-ion batteries. Nanoscale 2014, 6, 4532–4537. [Google Scholar] [CrossRef] [PubMed]

- Dufficy, M.K.; Khan, S.A.; Fedkiw, P.S. Hierarchical graphene-containing carbon nanofibers for lithium-ion battery anodes. ACS Appl. Mater. Interfaces 2016, 8, 1327–1336. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Fan, X.; Suo, L.; Luo, C.; Gao, T.; Wang, C. Electrospun FeS2@carbon fiber electrode as a high energy density cathode for rechargeable lithium batteries. ACS Nano 2016, 10, 1529–1538. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Zhao, X.; Peng, B.; Gan, F.; Yao, M.; Tan, W.; Dong, J.; Zhang, Q. Polyimide-derived carbon nanofiber membranes as anodes for high-performance flexible lithium ion batteries. Chin. Chem. Lett. 2018, 29, 1692–1697. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, Y.; Li, K.; Xu, F.; Zhang, P.; Ding, Y. Electrospun free-standing N-doped C@SnO2 anode paper for flexible Li-ion batteries. Mater. Res. Bull. 2019, 109, 41–48. [Google Scholar] [CrossRef]

- Xu, Y.; Yuan, T.; Bian, Z.; Sun, H.; Pang, Y.; Peng, C.; Yang, J.; Zheng, S. Electrospun flexible Si/C@CNF nonwoven anode for high capacity and durable lithium-ion battery. Compos. Commun. 2019, 11, 1–5. [Google Scholar] [CrossRef]

- Kim, J.K.; Manuel, J.; Lee, M.H.; Scheers, J.; Lim, D.H.; Johansson, P.; Ahn, J.H.; Matic, A.; Jacobsson, P. Towards flexible secondary lithium batteries: Polypyrrole-LiFePO4 thin electrodes with polymer electrolytes. J. Mater. Chem. 2012, 22, 15045–15049. [Google Scholar] [CrossRef]

- Liang, Y.; Li, N.; Li, F.; Xu, Z.; Hu, Y.; Jing, M.; Teng, K.; Yan, X.; Shi, J. Controllable nitrogen doping and specific surface from freestanding TiO2@carbon nanofibers as anode for lithium ion battery. Electrochim. Acta 2019, 297, 1063–1070. [Google Scholar] [CrossRef]

- Wang, W.; Xiao, Y.; Wang, X.; Liu, B.; Cao, M. In situ encapsulation of germanium clusters in carbon nanofibers: High-performance anodes for lithium-ion batteries. ChemSusChem 2014, 7, 2914–2922. [Google Scholar] [CrossRef]

- Mei, L.; Mao, M.; Chou, S.; Liu, H.; Dou, S.; Ng, D.H.L.; Ma, J. Nitrogen-doped carbon nanofibers with effectively encapsulated GeO2 nanocrystals for highly reversible lithium storage. J. Mater. Chem. A 2015, 3, 21699. [Google Scholar] [CrossRef]

- Wang, W.; Liang, Y.; Kang, Y.; Liu, L.; Xu, Z.; Tian, X.; Mai, W.; Fu, H.; Lv, H.; Teng, K.; et al. Carbon-coated SnO2@carbon nanofibers produced by electrospinning-electrospraying method for anode materials of lithium-ion batteries. Mater. Chem. Phys. 2019, 223, 762–770. [Google Scholar] [CrossRef]

- Yuan, Z.; Dong, L.; Gao, Q.; Huang, Z.; Wang, L.; Wang, G.; Yu, X. SnSb alloy nanoparticles embedded in N-doped porous carbon nanofibers as a high-capacity anode material for lithium-ion batteries. J. Alloys Compd. 2019, 777, 775–783. [Google Scholar] [CrossRef]

- Li, L.; Ding, Y.; Yu, D.; Li, L.; Ramakrishna, S.; Peng, S. Electrospun NiCo2O4 nanotubes as anode for Li- and Na-ion batteries. J. Alloys Compd. 2019, 777, 1286–1293. [Google Scholar] [CrossRef]

- Zheng, G.; Chen, M.; Zhang, H.; Zhang, J.; Liang, X.; Qi, M.; Yin, J. Zn-MOFs derived porous carbon nanofiber for high performance lithium-ion batteries. Surf. Coat. Technol. 2019, 359, 384–389. [Google Scholar] [CrossRef]

- Zeng, S.; Zhao, R.; Li, A.; Xue, S.; Lv, D.; Luo, Q.; Shu, D.; Chen, H. MnO/carbon fibers prepared by an electrospinning method and their properties used as anodes for lithium ion batteries. Appl. Surf. Sci. 2019, 463, 211–216. [Google Scholar] [CrossRef]

- Mai, L.; Xu, L.; Han, C.; Xu, X.; Luo, Y.; Zhao, S.; Zhao, Y. Electrospun ultralong hierarchical vanadium oxide nanowires with high performance for lithium ion batteries. Nano Lett. 2010, 10, 4750–4755. [Google Scholar] [CrossRef]

- Kalluri, S.; Seng, K.H.; Guo, Z.; Liu, H.K.; Dou, S.X. Electrospun lithium metal oxide cathode materials for lithium-ion batteries. RSC Adv. 2013, 3, 25576–25601. [Google Scholar] [CrossRef]

- Liu, Y.; Guan, D.; Gao, G.; Liang, X.; Sun, W.; Zhang, K.; Bi, W.; Wu, G. Enhanced electrochemical performance of electrospun V2O5 nanotubes as cathodes for lithium ion batteries. J. Alloys Compd. 2017, 726, 922–929. [Google Scholar] [CrossRef]

- Bachtin, K.; Kramer, D.; Chakravadhanula, V.S.K.; Mu, X.; Trouillet, V.; Kaus, M.; Indris, S.; Ehrenberg, H.; Roth, C. Activation and degradation of electrospun LiFePO4 battery cathodes. J. Power Sources 2018, 396, 386–394. [Google Scholar] [CrossRef]

- Wang, S.H.; Kuo, P.L.; Hsieh, C.T.; Teng, H. Design of Poly(Acrylonitrile)-based gel electrolytes for high performance lithium ion batteries. ACS Appl. Mater. Interfaces 2014, 6, 19360–19370. [Google Scholar] [CrossRef]

- Huang, X.; Zeng, S.; Liu, J.; He, T.; Sun, L.; Xu, D.; Yu, X.; Luo, Y.; Zhou, W.; Wu, J. High-performance electrospun poly(vinylidene fluoride)/poly(propylene carbonate) gel polymer electrolyte for lithium-ion batteries. J. Phys. Chem. C 2015, 119, 27882–27891. [Google Scholar] [CrossRef]

- Gao, M.; Wang, C.; Zhu, L.; Cheng, Q.; Xu, X.; Xu, G.; Huang, Y.; Bao, J. Composite polymer electrolytes based on electrospun thermoplastic polyurethane membrane and polyethylene oxide for all-solid-state lithium batteries. Polym. Int. 2018. [Google Scholar] [CrossRef]

- Wang, L.; Deng, N.; Fan, L.; Wang, L.; Wang, G.; Kang, W.; Cheng, B. A novel hot-pressed electrospun polymide separator for lithium-sulfur batteries. Mater. Lett. 2018, 233, 224–227. [Google Scholar] [CrossRef]

- Liu, X.; Song, K.; Lu, C.; Huang, Y.; Duan, X.; Li, S.; Ding, Y. Electrospun PU@GO separators for advanced lithium ion batteries. J. Membr. Sci. 2018, 555, 1–6. [Google Scholar] [CrossRef]

- Zhao, B.; Ran, R.; Liu, M.; Shao, Z. A comprehensive review of Li4Ti5O12-based electrodes for lithium-ion batteries: The latest advancements and future perspectives. Mater. Sci. Eng. R 2015, 98, 1–71. [Google Scholar] [CrossRef]

- Rahaman, M.S.A.; Ismail, A.F.; Mustafa, A. A review of heat treatment on polyacrylonitrile fiber. Polym. Degrad. Stab. 2007, 92, 1421–1432. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodities Summaries; U.S. Geological Survey: Reston, VA, USA, 2017; 202p. [CrossRef]

- Chung, D.; Elgqvist, E.; Santhanagopalan, S. Automotive Lithium-Ion Battery Supply Chain and US Competitiveness Considerations (No. NREL/PR-6A50-63354); Clean Energy Manufacturing Analysis Center (CEMAC): Golden, CO, USA, 2015. [Google Scholar]

- Hwang, J.Y.; Myung, S.T.; Sun, Y.K. Sodium-ion batteries: Present and future. Chem. Soc. Rev. 2017, 46, 3529–3614. [Google Scholar] [CrossRef]

- Skundin, A.M.; Kulova, T.L.; Yaroslavtsev, A.B. Sodium-ion batteries (a review). Russ. J. Electrochem. 2018, 54, 113–152. [Google Scholar] [CrossRef]

- Li, L.; Zheng, Y.; Zhang, S.; Yang, J.; Shao, Z.; Guo, Z. Recent progress on sodium ion batteries: Potential high-performance anodes. Energy Environ. Sci. 2018, 11, 2310–2340. [Google Scholar] [CrossRef]

- Chen, L.; Fiore, M.; Wang, J.E.; Ruffo, R.; Kim, D.K.; Longoni, G. Readiness level of sodium-ion battery technology: A materials review. Adv. Sustain. Syst. 2018, 2, 1700153. [Google Scholar] [CrossRef]

- Yina, D.; Chenb, Z.; Zhang, M. Sn-interspersed MoS2/C nanosheets with high capacity for Na+/K+ storage. J. Phys. Chem. Solids 2019, 126, 72–77. [Google Scholar] [CrossRef]

- Liu, W.; Zhi, H.; Yu, X. Recent progress in phosphorus based anode materials for lithium/sodium ion batteries. Energy Storage Mater. 2019, 16, 290–322. [Google Scholar] [CrossRef]

- Vaalma, C.; Buchholz, D.; Passerini, S. Non-aqueous potassium-ion batteries: A review. Curr. Opin. Electrochem. 2018, 9, 41–48. [Google Scholar] [CrossRef]

- Zhu, Y.H.; Yang, X.; Bao, D.; Bie, X.F.; Sun, T.; Wang, S.; Jiang, Y.S.; Zhang, X.B.; Yan, J.M.; Jiang, Q. High-energy-density flexible potassium-ion battery based on patterned electrodes. Joule 2018, 2, 736–746. [Google Scholar] [CrossRef]

- Masese, T.; Yoshii, K.; Yamaguchi, Y.; Okumura, T.; Huang, Z.D.; Kato, M.; Kubota, K.; Furutani, J.; Orisaka, Y.; Senoh, H.; et al. Rechargeable potassium-ion batteries with honeycomb-layered tellurates as high voltage cathodes and fast potassium-ion conductors. Nat. Commun. 2018, 9, 3823. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Wu, Y.; Hu, S.; Xu, R.; Wang, J.; Peng, Z.; Zhang, Q. Boosting potassium-ion battery performance by encapsulating red phosphorus in free-standing nitrogen-doped porous hollow carbon nanofibers. Nano Lett. 2019. [Google Scholar] [CrossRef]

- Jin, J.; Shi, Z.Q.; & Wang, C.Y. Electrochemical performance of electrospun carbon nanofibers as free-standing and binder-free anodes for sodium-ion and lithium-ion batteries. Electrochim. Acta 2014, 141, 302–310. [Google Scholar] [CrossRef]

- Peters, J.; Buchholz, D.; Passerini, S.; Weil, M. Life cycle assessment of sodium-ion batteries. Energy Environ. Sci. 2016, 9, 1744–1751. [Google Scholar] [CrossRef]

- Su, H.; Jaffer, S.; Yu, H. Transition metal oxides for sodium-ion batteries. Energy Storage Mater. 2016, 5, 116–131. [Google Scholar] [CrossRef]

- Dai, Z.; Mani, U.; Tan, H.T.; Yan, Q. Advanced cathode materials for sodium-ion batteries: What determines our choices? Small Methods 2017, 1, 1700098. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, P.F.; Guo, J.Z.; Chen, Z.M.; Pang, W.L.; Huang, K.C.; Guo, Y.G.; Wu, X.L.; Zhang, J.P. Advanced P2-Na2/3Ni1/3Mn7/12Fe1/12O2 cathode material with suppressed P2–O2 phase transition toward high-performance sodium-ion battery. ACS Appl. Mater. Interfaces 2018, 10, 34272–34282. [Google Scholar] [CrossRef] [PubMed]

- Kalluri, S.; Seng, H.K.; Pang, W.K.; Guo, Z.; Chen, Z.; Liu, H.K.; Dou, S.X. Electrospun P2-type Na2/3(Fe1/2Mn1/2)O2 hierarchical nanofibers as cathode material for sodium-ion batteries. ACS Appl. Mater. Interfaces 2014, 6, 8953–8958. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Bai, Y.; Wu, F.; Li, Y.; Wu, C. Budding willow branches shaped Na3V2(PO4)3/C nanofibers synthesized via an electrospinning technique and used as cathode material for sodium ion batteries. J. Power Sources 2015, 273, 784–792. [Google Scholar] [CrossRef]

- Liang, L.; Sun, X.; Denis, D.K.; Zhang, J.; Hou, L.; Liu, Y.; Yuan, C. Ultralong layered NaCrO2 nanowires: A competitive wide temperature-operating cathode for extraordinary high-rate sodium-ion batteries. ACS Appl. Mater. Interfaces 2019. [Google Scholar] [CrossRef] [PubMed]

- Jin, T.; Liu, Y.; Li, Y.; Cao, K.; Wang, X.; Jiao, L. Electrospun NaVPO4F/C nanofibers as self-standing cathode material for ultralong cycle life Na-ion batteries. Adv. Energy Mater. 2017, 7, 1700087. [Google Scholar] [CrossRef]

- Fu, B.; Zhou, X.; Wang, Y. High-rate performance electrospun Na0.44MnO2 nanofibers as cathode material for sodium-ion batteries. J. Power Sources 2016, 310, 102–108. [Google Scholar] [CrossRef]

- Tolosa, A.; Fleischmann, S.; Grobelsek, I.; Presser, V. Electrospun hybrid vanadium oxide/carbon fiber mats for lithium-and sodium-ion battery electrodes. ACS Appl. Energy Mater. 2018, 1, 3790–3801. [Google Scholar] [CrossRef]

- Liu, J.; Tang, K.; Song, K.; van Aken, P.A.; Yu, Y.; Maier, J. Electrospun Na3V2(PO4)3/C nanofibers as stable cathode materials for sodium-ion batteries. Nanoscale 2014, 6, 5081–5086. [Google Scholar] [CrossRef]

- Yang, L.; Wang, W.; Hu, M.; Shao, J.; Lv, R. Ultrahigh rate binder-free Na3V2(PO4)3/carbon cathode for sodium-ion battery. J. Energy Chem. 2018, 27, 1439–1445. [Google Scholar] [CrossRef]

- Cui, J.; Yao, S.; Kim, J.K. Recent progress in rational design of anode materials for high-performance Na-ion batteries. Energy Storage Mater. 2017, 7, 64–114. [Google Scholar] [CrossRef]

- Jiang, Y.; Hu, M.; Zhang, D.; Yuan, T.; Sun, W.; Xu, B.; Yan, M. Transition metal oxides for high performance sodium ion battery anodes. Nano Energy 2014, 5, 60–66. [Google Scholar] [CrossRef]

- Zhao, P.Y.; Zhang, J.; Li, Q.; Wang, C.Y. Electrochemical performance of fulvic acid-based electrospun hard carbon nanofibers as promising anodes for sodium-ion batteries. J. Power Sources 2016, 334, 170–178. [Google Scholar] [CrossRef]

- Wang, W.; Li, W.; Wang, S.; Miao, Z.; Liu, H.K.; Chou, S. Structural design of anode materials for sodium-ion batteries. J. Mater. Chem. A 2018, 6, 6183–6205. [Google Scholar] [CrossRef]

- Longoni, G.; Fiore, M.; Kim, J.H.; Jung, Y.H.; Kim, D.K.; Mari, C.M.; Ruffo, R. Co3O4 negative electrode material for rechargeable sodium ion batteries: An investigation of conversion reaction mechanism and morphology-performances correlations. J. Power Sources 2016, 332, 42–50. [Google Scholar] [CrossRef]

- Santangelo, S.; Fiore, M.; Pantò, F.; Stelitano, S.; Marelli, M.; Frontera, P.; Antonucci, P.; Longoni, G.; Ruffo, R. Electro-spun Co3O4 anode material for Na-ion rechargeable batteries. Solid State Ion. 2017, 309, 41–47. [Google Scholar] [CrossRef]

- Xiong, Y.; Qian, J.; Cao, Y.; Ai, X.; Yang, H. Electrospun TiO2/C nanofibers as a high-capacity and cycle-stable anode for sodium-ion batteries. ACS Appl. Mater. Interfaces 2016, 8, 16684–16689. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, N.; Yu, C.; Jiao, L.; Chen, J. MnFe2O4@C nanofibers as high-performance anode for sodium-ion batteries. Nano Lett. 2016, 16, 3321–3328. [Google Scholar] [CrossRef]

- Chen, Y.; Yuan, X.; Yang, C.; Lian, Y.; Razzaq, A.A.; Shah, R.; Shah, R.; Guo, J.; Zhao, X.; Peng, Y.; et al. γ-Fe2O3 nanoparticles embedded in porous carbon fibers as binder-free anodes for high-performance lithium and sodium ion batteries. J. Alloys Comp. 2019, 777, 127–134. [Google Scholar] [CrossRef]

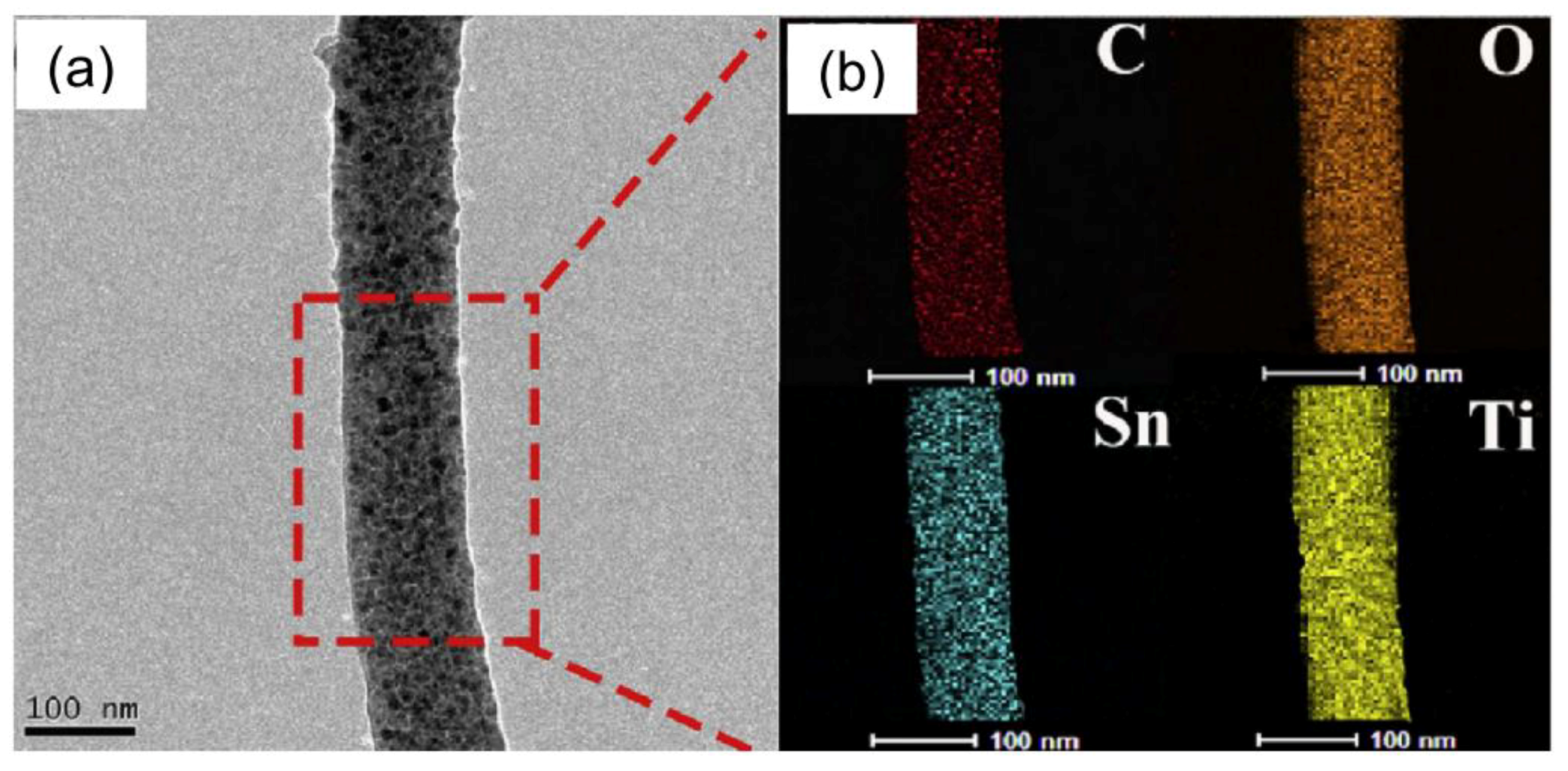

- Nie, S.; Liu, L.; Liu, J.; Xia, J.; Zhang, Y.; Xie, J.; Li, M.; Wang, X. TiO2-Sn/C composite nanofibers with high-capacity and long-cycle life as anode materials for sodium ion batteries. J. Alloys Comp. 2019, 772, 314–323. [Google Scholar] [CrossRef]

- Xia, J.; Liu, L.; Jamil, S.; Xie, J.; Yan, H.; Yuan, Y.; Zhang, Y.; Nie, S.; Pan, J.; Wang, X.; et al. Free-standing SnS/C nanofiber anodes for ultralong cycle-life lithium-ion batteries and sodium-ion batteries. Energy Storage Mater. 2019. [Google Scholar] [CrossRef]

- Xia, J.; Jiang, K.; Xie, J.; Guo, S.; Liu, L.; Zhang, Y.; Ne, S.; Yuan, Y.; Yan, H.; Wang, X. Tin disulfide embedded in N-, S-doped carbon nanofibers as anode material for sodium-ion batteries. Chem. Eng. J. 2019, 359, 1244–1251. [Google Scholar] [CrossRef]

- Fiore, M.; Longoni, G.; Santangelo, S.; Pantò, F.; Stelitano, S.; Frontera, P.; Antonucci, P.L.; Ruffo, R. Electrochemical characterization of highly abundant, low cost iron(III) oxide as anode material for sodium-ion rechargeable batteries. Electrochim. Acta 2018, 269, 367–377. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, N.; Jiao, L.; Chen, J. Tin nanodots encapsulated in porous nitrogen-doped carbon nanofibers as a free-standing anode for advanced sodium-ion batteries. Adv. Mater. 2015, 27, 6702–6707. [Google Scholar] [CrossRef]

- Shi, Y.; Eze, C.; Xiong, B.; He, W.; Zhang, H.; Lim, T.M.; Ukil, A.; Zhao, J. Recent development of membrane for vanadium redox flow battery applications: A review. Appl. Energy 2019, 238, 202–224. [Google Scholar] [CrossRef]

- Skyllas-Kazacos, M.; Rychick, M.; Robins, R. All-Vanadium Redox Battery. U.S. Patent No. 4,786,567, 22 November 1988. [Google Scholar]

- He, Z.; Li, M.; Li, Y.; Zhu, J.; Jiang, Y.; Meng, W.; Zhou, H.; Wang, L.; Dai, L. Flexible electrospun carbon nanofiber embedded with TiO2 as excellent negative electrode for vanadium redox flow battery. Electrochim. Acta 2018, 281, 601–610. [Google Scholar] [CrossRef]

- He, Z.; Li, M.; Li, Y.; Wang, L.; Zhu, J.; Meng, W.; Li, C.; Zhou, H.; Dai, L. Electrospun nitrogen-doped carbon nanofiber as negative electrode for vanadium redox flow battery. Appl. Surf. Sci. 2019, 469, 423–430. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.; Ding, Y.; Peng, S.; Guo, X.; Zhao, Y.; He, G.; Yu, G. Progress and prospects of next-generation redox flow batteries. Energy Storage Mater. 2018, 15, 324–350. [Google Scholar] [CrossRef]

- He, Z.; Jiang, Y.; Zhou, H.; Cheng, G.; Meng, W.; Wang, L.; Dai, L. Graphite felt electrode modified by square wave potential pulse for vanadium redox flow battery. Int. J. Energy Res. 2017, 41, 439–447. [Google Scholar] [CrossRef]

- Wei, G.; Fan, X.; Liu, J.; Yan, C. Investigation of the electrospun carbon web as the catalyst layer for vanadium redox flow battery. J. Power Sources 2014, 270, 634–645. [Google Scholar] [CrossRef]

- Wei, G.; Fan, X.; Liu, J.; Yan, C. Electrospun carbon nanofibers/electrocatalyst hybrids as asymmetric electrode for vanadium redox flow battery. J. Power Sources 2015, 281, 1–6. [Google Scholar] [CrossRef]

- Fetyan, A.; Derr, I.; Kayarkatte, M.K.; Langner, J.; Bernsmeier, D.; Kraehnert, R.; Roth, C. Electrospun based carbon nano-fibers as alternative electrode materials for vanadium redox flow batteries. ChemElectroChem 2015, 2, 2055–2060. [Google Scholar] [CrossRef]

- Bang, H.S.; Kim, D.; Hwang, S.S.; Won, J. Surface-modified porous membranes with electrospun Nafion/PVA fibres for non-aqueous redox flow battery. J. Membr. Sci. 2016, 514, 186–194. [Google Scholar] [CrossRef]

- Xu, C.; Li, X.; Liu, T.; Zhang, H. Design and synthesis of a free-standing carbon nano-fibrous web electrode with ultra large pores for high-performance vanadium flow batteries. RSC Adv. 2017, 7, 45932–45937. [Google Scholar] [CrossRef]

- Sun, J.; Zeng, L.; Jiang, H.R.; Chao, C.Y.H.; Zhao, T.S. Formation of electrodes by self-assembling porous carbon fibers into bundles for vanadium redox flow batteries. J. Power Sources 2018, 405, 106–113. [Google Scholar] [CrossRef]

- Di Blasi, A.; Busacca, C.; Di Blasi, O.; Briguglio, N.; Antonucci, V. Synthesis and characterization of electrospun nickel-carbon nanofibers as electrodes for vanadium redox flow battery. J. Electrochem. Soc. 2018, 165, A1478–A1485. [Google Scholar] [CrossRef]

- Busacca, C.; Di Blasi, O.; Briguglio, N.; Ferraro, M.; Antonucci, V.; Di Blasi, A. Electrochemical performance investigation of electrospun urchin-like V2O3-CNF composite nanostructure for vanadium redox flow battery. Electrochim. Acta 2017, 230, 174–180. [Google Scholar] [CrossRef]

- Di Blasi, A.; Busacca, C.; Di Blasi, O.; Briguglio, N.; Squadrito, G.; Antonucci, V. Synthesis of flexible electrodes based on electrospun carbon nanofibers with Mn3O4 nanoparticles for vanadium redox flow battery application. Appl. Energy 2017, 190, 165–171. [Google Scholar] [CrossRef]

- Ghoniem, A.F. Needs, resources and climate change: Clean and efficient conversion technologies. Prog. Energy Combust. Sci. 2011, 37, 15–51. [Google Scholar] [CrossRef]

- Christensen, J.; Albertus, P.; Sanchez-Carrera, R.S.; Lohmann, T.; Kozinsky, B.; Liedtke, R.; Ahmed, J.; Kojic, A. A critical review of Li/air batteries. J. Electrochem. Soc. 2011, 159, R1–R30. [Google Scholar] [CrossRef]

- Harting, K.; Kunz, U.; Turek, T. Zinc-air batteries: Prospects and challenges for future improvement. Z. Phys. Chem. 2012, 226, 151–166. [Google Scholar] [CrossRef]

- Rahman, M.A.; Wang, X.; Wen, C. High energy density metal-air batteries: A review. J. Electrochem. Soc. 2013, 160, A1759–A1771. [Google Scholar] [CrossRef]

- Park, H.W.; Lee, D.U.; Zamani, P.; Seo, M.H.; Nazar, L.F.; Chen, Z. Electrospun porous nanorod perovskite oxide/nitrogen-doped graphene composite as a bi-functional catalyst for metal air batteries. Nano Energy 2014, 10, 192–200. [Google Scholar] [CrossRef]

- Sun, B.; Wang, B.; Su, D.; Xiao, L.; Ahn, H.; Wang, G. Graphene nanosheets as cathode catalysts for lithium-air batteries with an enhanced electrochemical performance. Carbon 2012, 50, 727–733. [Google Scholar] [CrossRef]

- Cao, R.; Lee, J.S.; Liu, M.; Cho, J. Recent progress in non-precious catalysts for metal-air batteries. Adv. Energy Mater. 2012, 2, 816–829. [Google Scholar] [CrossRef]

- Takeguchi, T.; Yamanaka, T.; Takahashi, H.; Watanabe, H.; Kuroki, T.; Nakanishi, H.; Orikasa, Y.; Uchimoto, Y.; Takano, H.; Ohguri, N.; et al. Layered perovskite oxide: A reversible air electrode for oxygen evolution/reduction in rechargeable metal-air batteries. J. Am. Chem. Soc. 2013, 135, 11125–11130. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, M.; Zhang, L.; Dai, L.; Xia, Z. Design principles for heteroatom-doped carbon nanomaterials as highly efficient catalysts for fuel cells and metal–air batteries. Adv. Mater. 2015, 27, 6834–6840. [Google Scholar] [CrossRef]

- Park, G.S.; Lee, J.S.; Kim, S.T.; Park, S.; Cho, J. Porous nitrogen doped carbon fiber with churros morphology derived from electrospun bicomponent polymer as highly efficient electrocatalyst for Zn-air batteries. J. Power Sources 2013, 243, 267–273. [Google Scholar] [CrossRef]

- Song, M.J.; Kim, I.T.; Kim, Y.B.; Shin, M.W. Self-standing, binder-free electrospun Co3O4/carbon nanofiber composites for non-aqueous Li-air batteries. Electrochim. Acta 2015, 182, 289–296. [Google Scholar] [CrossRef]

- Prabu, M.; Ramakrishnan, P.; Ganesan, P.; Manthiram, A.; Shanmugam, S. LaTi0.65Fe0.35O3 –δ nanoparticle-decorated nitrogen-doped carbon nanorods as an advanced hierarchical air electrode for rechargeable metal-air batteries. Nano Energy 2015, 15, 92–103. [Google Scholar] [CrossRef]

- Li, B.; Ge, X.; Goh, F.T.; Hor, T.A.; Geng, D.; Du, G.; Liu, Z.; Zhang, J.; Zong, Y. Co3O4 nanoparticles decorated carbon nanofiber mat as binder-free air-cathode for high performance rechargeable zinc-air batteries. Nanoscale 2015, 7, 1830–1838. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Y.; Dai, L.; Yao, J. Scalable fabrication of nanoporous carbon fiber films as bifunctional catalytic electrodes for flexible Zn-air batteries. Adv. Mater. 2016, 28, 3000–3006. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Jin, T.; Meng, J.; Jiao, L.; Zhu, M.; Chen, J. Electrospun thin-walled CuCo2O4@C nanotubes as bifunctional oxygen electrocatalysts for rechargeable Zn–air batteries. Nano Lett. 2017, 17, 7989–7994. [Google Scholar] [CrossRef]

- Alegre, C.; Modica, E.; Di Blasi, A.; Di Blasi, O.; Busacca, C.; Ferraro, M.; Aricò, A.S.; Antonucci, V.; Baglio, V. NiCo-loaded carbon nanofibers obtained by electrospinning: Bifunctional behavior as air electrodes. Renew. Energy 2018, 125, 250–259. [Google Scholar] [CrossRef]

- Alegre, C.; Busacca, C.; Di Blasi, O.; Antonucci, V.; Aricò, A.S.; Di Blasi, A.M.; Baglio, V. A combination of CoO and Co nanoparticles supported on electrospun carbon nanofibers as highly stable air electrodes. J. Power Sources 2017, 364, 101–109. [Google Scholar] [CrossRef]

- Hossain, A.; Bandyopadhyay, P.; Guin, P.S.; Roy, S. Recent developed different structural nanomaterials and their performance for supercapacitor application. Appl. Mater. Today 2017, 9, 300–313. [Google Scholar] [CrossRef]

- Shi, X.; Zheng, S.; Wu, Z.S.; Bao, X. Recent advances of graphene-based materials for high-performance and new-concept supercapacitors. J. Energy Chem. 2018, 27, 25–42. [Google Scholar] [CrossRef]

- Li, Q.; Zheng, S.; Xu, Y.; Xue, H.; Pang, H. Ruthenium based materials as electrode materials for supercapacitors. Chem. Eng. J. 2018, 333, 505–518. [Google Scholar] [CrossRef]

- Bai, X.; Tong, X.; Gao, Y.; Zhu, W.; Fu, C.; Ma, J.; Tan, T.; Wang, C.; Luo, Y.; Sun, H. Hierarchical multidimensional MnO2 via hydrothermal synthesis for high performance supercapacitors. Electrochim. Acta 2018, 281, 525–533. [Google Scholar] [CrossRef]

- Li, X.; Wang, G.; Wang, X.; Li, X.; Ji, J. Flexible supercapacitor based on MnO2 nanoparticles via electrospinning. J. Mater. Chem. A 2013, 1, 10103–10106. [Google Scholar] [CrossRef]

- Kong, D.; Xiao, Z.; Gao, Y.; Zhang, X.; Guo, R.; Huang, X.; Li, X.; Zhi, L. Sp2-carbon dominant carbonaceous materials for energy conversion and storage. Mater. Sci. Eng. R 2019, 137, 1–37. [Google Scholar] [CrossRef]

- Yoon, J.; Lee, J.; Hur, J. Stretchable supercapacitors based on carbon nanotubes-deposited rubber polymer nanofibers electrode with high tolerance against strain. Nanomaterials 2018, 8, 541. [Google Scholar] [CrossRef]

- Kim, C.; Yang, K.S. Electrochemical properties of carbon nanofiber web as an electrode for supercapacitor prepared by electrospinning. Appl. Phys. Lett. 2003, 83, 1216–1218. [Google Scholar] [CrossRef]

- Kim, C.; Ngoc, B.T.N.; Yang, K.S.; Kojima, M.; Kim, Y.A.; Kim, Y.J.; Endo, M.; Yang, S.C. Self-sustained thin webs consisting of porous carbon nanofibers for supercapacitors via the electrospinning of polyacrylonitrile solutions containing zinc chloride. Adv. Mater. 2007, 19, 2341–2346. [Google Scholar] [CrossRef]

- Nan, W.; Zhao, Y.; Ding, Y.; Shende, A.R.; Fong, H.; Shende, R. Mechanically flexible electrospun carbon nanofiber mats derived from biochar and polyacrylonitrile. Mater. Lett. 2017, 205, 206–210. [Google Scholar] [CrossRef]

- Chee, W.K.; Lim, H.N.; Zainal, Z.; Harrison, I.; Andou, Y.; Huang, N.M.; Altarawneh, M.; Jiang, Z.T. Electrospun graphene nanoplatelets-reinforced carbon nanofibers as potential supercapacitor electrode. Mater. Lett. 2017, 199, 200–203. [Google Scholar] [CrossRef]

- Agyemang, F.O.; Tomboc, G.M.; Kwofie, S.; Kim, H. Electrospun carbon nanofiber-carbon nanotubes coated polyaniline composites with improved electrochemical properties for supercapacitors. Electrochim. Acta 2018, 259, 1110–1119. [Google Scholar] [CrossRef]

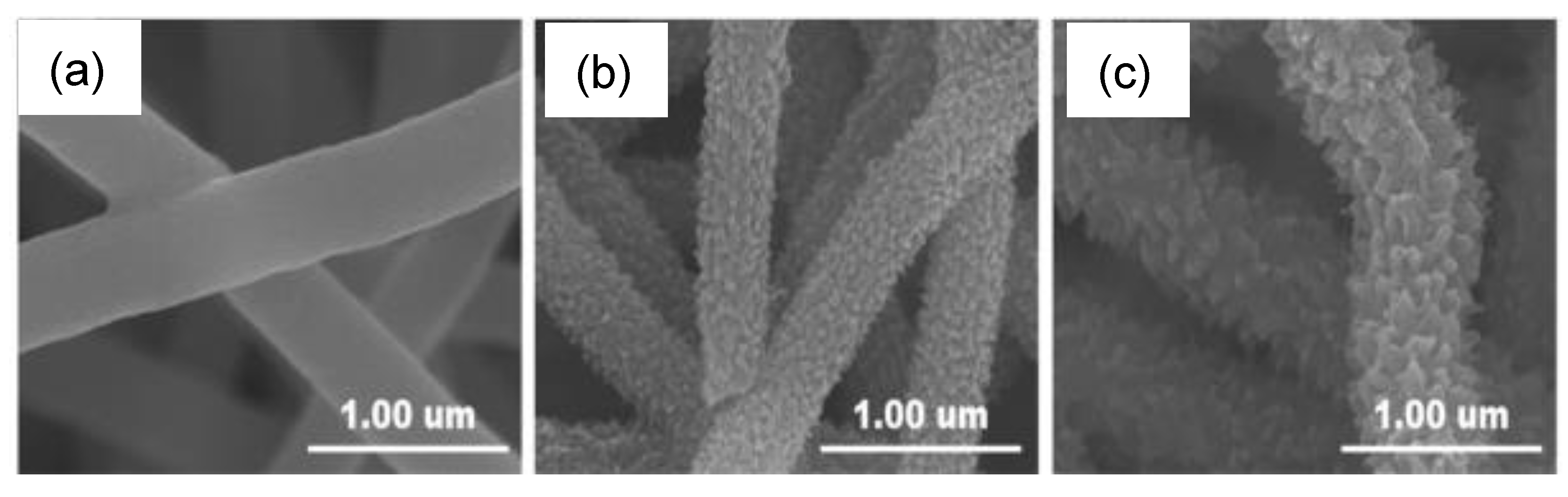

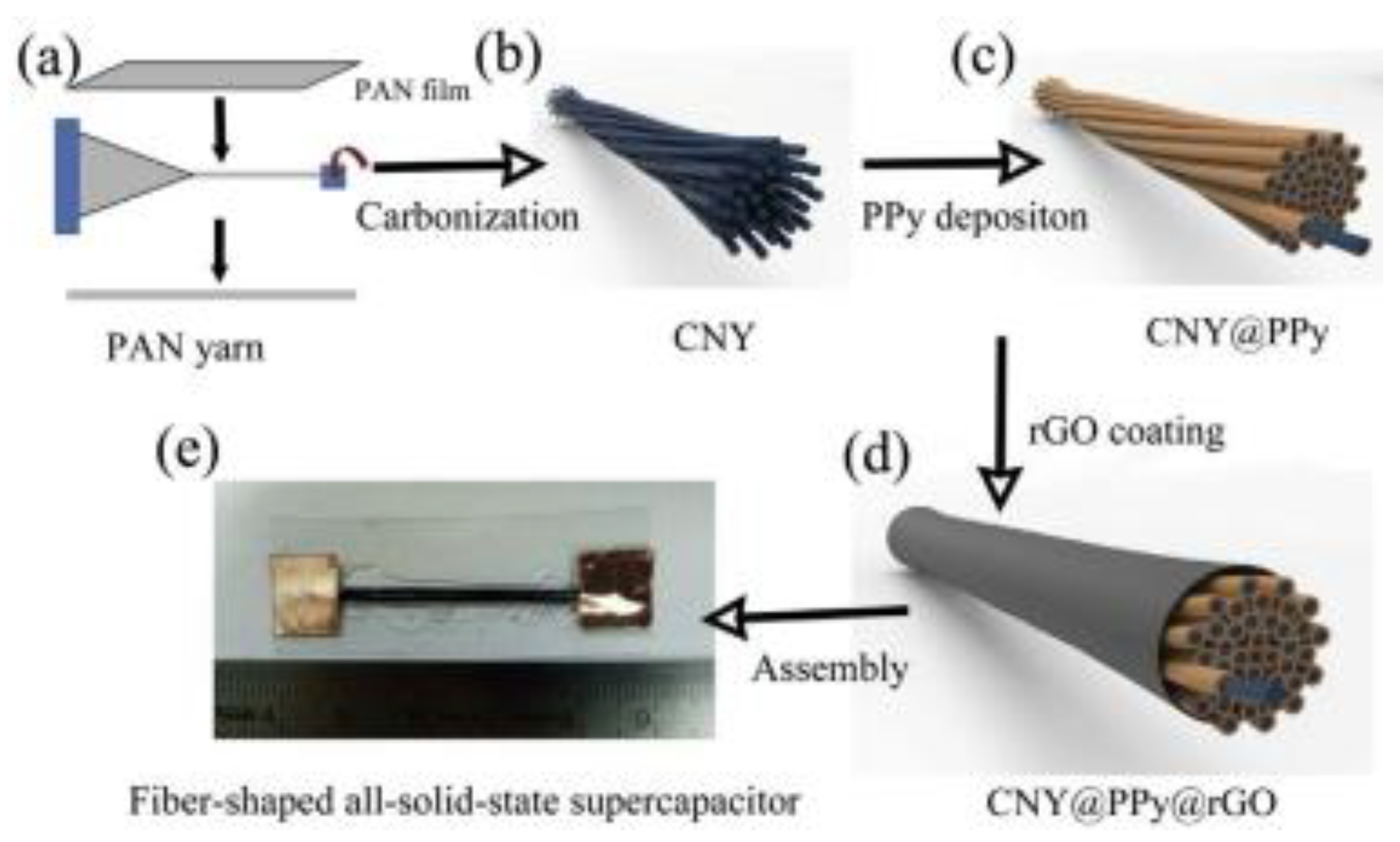

- Chen, L.; Li, D.; Chen, L.; Si, P.; Feng, J.; Zhang, L.; Li, Y.; Lou, J.; Ci, L. Core-shell structured carbon nanofibers yarn@polypyrrole@graphene for high performance all-solid-state fiber supercapacitors. Carbon 2018, 138, 264–270. [Google Scholar] [CrossRef]

- Liu, X.; Marlow, M.N.; Cooper, S.J.; Song, B.; Chen, X.; Brandon, N.P.; Wu, B. Flexible all-fiber electrospun supercapacitor. J. Power Sources 2018, 384, 264–269. [Google Scholar] [CrossRef]

- Kim, C. Electrochemical characterization of electrospun activated carbon nanofibres as an electrode in supercapacitors. J. Power Sources 2005, 142, 382–388. [Google Scholar] [CrossRef]

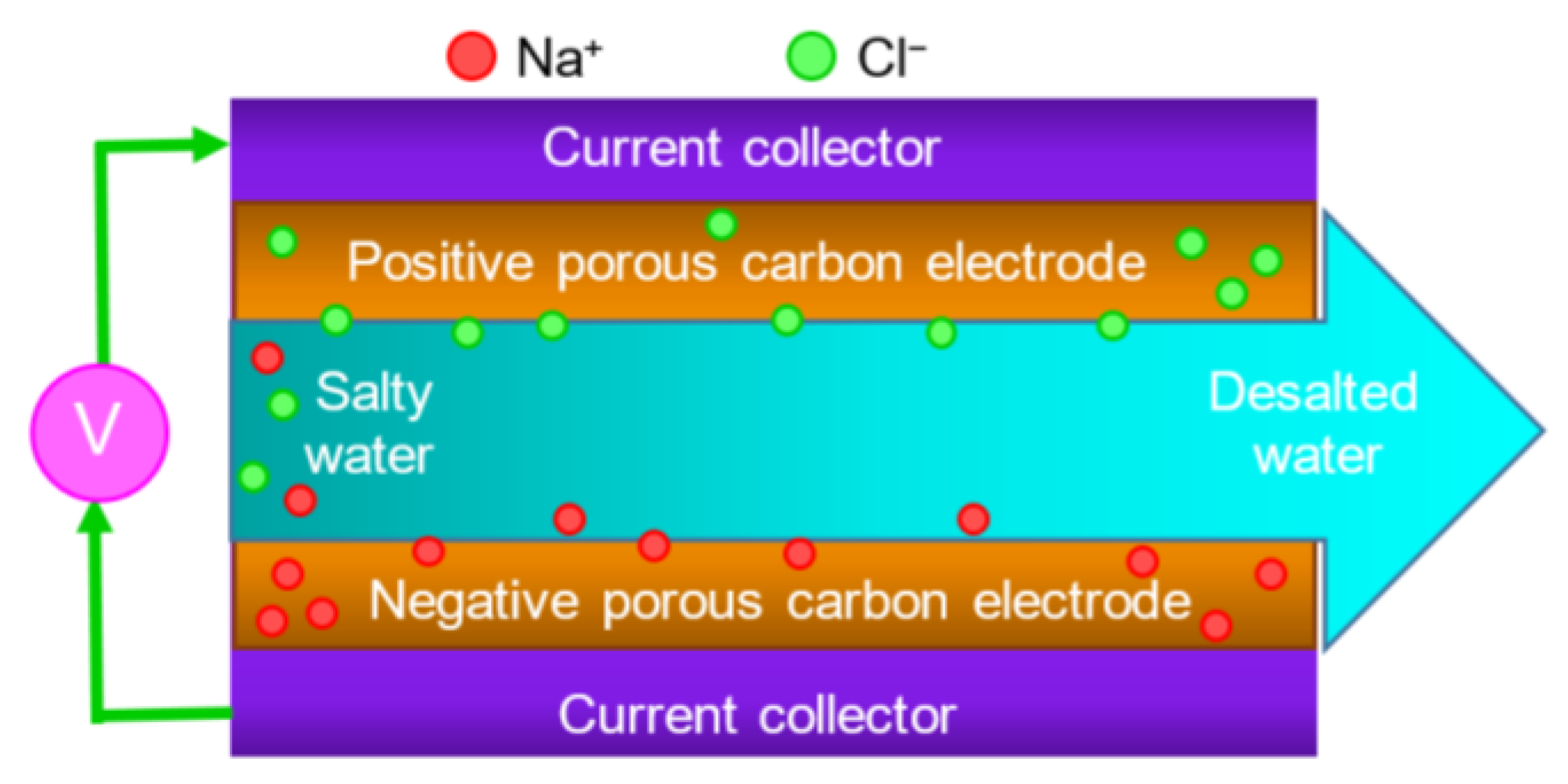

- Ahmed, M.A.; Tewari, S. Capacitive deionization: Processes, materials and state of the technology. J. Electroanal. Chem. 2018, 813, 178–192. [Google Scholar] [CrossRef]

- Teow, Y.H.; Mohammad, A.W. New generation nanomaterials for water desalination: A review. Desalination 2019, 451, 2–17. [Google Scholar] [CrossRef]

- Ratajczak, P.; Suss, M.E.; Kaasik, F.; Béguin, F. Carbon electrodes for capacitive technologies. Energy Storage Mater. 2019, 16, 126–145. [Google Scholar] [CrossRef]

- Oren, Y. Capacitive deionization (CDI) for desalination and water treatment—Past, present and future (a review). Desalination 2008, 22, 10–29. [Google Scholar] [CrossRef]

- Porada, S.; Zhao, R.; van der Wal, A.; Presser, V.; Biesheuvel, P.M. Review on the science and technology of water desalination by capacitive deionization. Prog. Mater. Sci. 2013, 58, 1388–1442. [Google Scholar] [CrossRef]

- Yin, H.; Zhao, S.; Wan, J.; Tang, H.; Chang, L.; He, L.; Zhao, H.; Gao, Y.; Tang, Z. Three-dimensional graphene/metal oxide nanoparticle hybrids for high-performance capacitive deionization of saline water. Adv. Mater. 2013, 25, 6270–6276. [Google Scholar] [CrossRef]

- Wang, Z.; Yan, T.; Fang, J.; Shi, L.; Zhang, D. Nitrogen-doped porous carbon derived from a bimetallic metal—Organic framework as highly efficient electrodes for flow-through deionization capacitors. J. Mater. Chem. A 2016, 4, 10858–10868. [Google Scholar] [CrossRef]

- Gabelich, C.J.; Tran, T.D.; Suffet, I.H. Electrosorption of inorganic salts from aqueous solution using carbon aerogels. Environ. Sci. Technol. 2002, 36, 3010–3019. [Google Scholar] [CrossRef]

- Xu, P.; Drewes, J.E.; Heil, D.; Wang, G. Treatment of brackish produced water using carbon aerogel-based capacitive deionization technology. Water Res. 2008, 42, 2605–2617. [Google Scholar] [CrossRef]

- Zou, L.; Morris, G.; Qi, D. Using activated carbon electrode in electrosorptive deionisation of brackish water. Desalination 2008, 225, 329–340. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, L.; Fang, J.; Dai, K. Influence of diameter of carbon nanotubes mounted in flow-through capacitors on removal of NaCl from salt water. J. Mater. Sci. 2006, 42, 2471–2475. [Google Scholar] [CrossRef]

- Nie, C.; Pan, L.; Li, H.; Chen, T.; Lu, T.; Sun, Z. Electrophoretic deposition of carbon nanotubes film electrodes for capacitive deionization. J. Electroanal. Chem. 2012, 666, 85–88. [Google Scholar] [CrossRef]

- Xu, X.; Sun, Z.; Chua, D.H.C.; Pan, L. Novel nitrogen doped graphene sponge with ultrahigh capacitive deionization performance. Sci. Rep. 2015, 5, 11225. [Google Scholar] [CrossRef] [PubMed]

- Dong, Q.; Wang, G.; Qian, B.; Hu, C.; Wang, Y.; Qiu, J. Electrospun composites made of reduced graphene oxide and activated carbon nanofibers for capacitive deionization. Electrochim. Acta 2014, 137, 388–394. [Google Scholar] [CrossRef]

- Wang, G.; Pan, C.; Wang, L.; Dong, Q.; Yu, C.; Zhao, Z.; Qiu, J. Activated carbon nanofiber webs made by electrospinning for capacitive deionization. Electrochim. Acta 2012, 69, 65–70. [Google Scholar] [CrossRef]

- Wang, G.; Dong, Q.; Ling, Z.; Pan, C.; Yu, C.; Qiu, J. Hierarchical activated carbon nanofiber webs with tuned structure fabricated by electrospinning for capacitive deionization. J. Mater. Chem. A 2012, 22, 21819–21823. [Google Scholar] [CrossRef]

- Subramanian, S.; Seeram, R. New directions in nanofiltration applications—Are nanofibers the right materials as membranes in desalination? Desalination 2013, 308, 198–208. [Google Scholar] [CrossRef]

- Dong, Q.; Wang, G.; Wu, T.; Peng, S.; Qiu, J. Enhancing capacitive deionization performance of electrospun activated carbon nanofibers by coupling with carbon nanotubes. J. Colloid Interface Sci. 2015, 446, 373–378. [Google Scholar] [CrossRef]

- Wang, M.; Huang, Z.H.; Wang, L.; Wang, M.X.; Kang, F.; Hou, H. Electrospun ultrafine carbon fiber webs for electrochemical capacitive desalination. New J. Chem. 2010, 34, 1843–1845. [Google Scholar] [CrossRef]

- Yasin, A.S.; Mohamed, I.M.A.; Park, C.H.; Kim, C. Design of novel electrode for capacitive deionization using electrospun composite titania/zirconia nanofibers doped-activated carbon. Mater. Lett. 2018, 213, 62–66. [Google Scholar] [CrossRef]

- Liu, J.; Xiong, Z.; Wang, S.; Cai, W.; Yang, J.; Zhang, H. Structure and electrochemistry comparison of electrospun porous carbon nanofibers for capacitive deionization. Electrochim. Acta 2016, 210, 171–180. [Google Scholar] [CrossRef]

- Liu, J.; Wang, S.; Yang, J.; Liao, J.; Lu, M.; Pan, H.; An, L. ZnCl2 activated electrospun carbon nanofiber for capacitive desalination. Desalination 2014, 344, 446–453. [Google Scholar] [CrossRef]

- Luo, G.; Wang, Y.; Gao, L.; Zhang, D.; Lin, T. Graphene bonded carbon nanofiber aerogels with high capacitive deionization capability. Electrochim. Acta 2018, 260, 656–663. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, Y.; Bao, S.; Song, S. Desalination by capacitive deionization with carbon-based materials as electrode: A review. Surf. Rev. Lett. 2013, 20, 1330003. [Google Scholar] [CrossRef]

- Singh, R.; Dutta, S. A review on H2 production through photocatalytic reactions using TiO2/TiO2-assisted catalysts. Fuel 2018, 220, 607–620. [Google Scholar] [CrossRef]

- Bora, D.K.; Braun, A.; Constable, E.C. “In rust we trust”. Hematite the prospective inorganic backbone for artificial photosynthesis. Energy Environ. Sci. 2013, 6, 407–425. [Google Scholar] [CrossRef]

- Ruth, J.D.; Hayes, L.M.; Martin, D.R.; Hatipoglu, K. An overview of photoelectrochemical cells (PEC): Mimicking nature to produce hydrogen for fuel cells. In Proceedings of the SoutheastCon 2017, Charlotte, NC, USA, 30 March–2 April 2017. [Google Scholar] [CrossRef]

- Gan, J.; Lu, X.; Tong, Y. Towards highly efficient photoanodes: Boosting sunlight-driven semiconductor nanomaterials for water oxidation. Nanoscale 2014, 6, 7142–7164. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Liu, Y.N.; Shen, C.C.; Xu, A.W. Nanoheterostructured photocatalysts for improving photocatalytic hydrogen production. Chin. J. Catal. 2017, 38, 1295–1306. [Google Scholar] [CrossRef]

- Tamirat, A.G.; Rick, J.; Dubale, A.A.; Su, W.N.; Hwang, B.J. Using hematite for photoelectrochemical water splitting: A review of current progress and challenges. Nanoscale Horiz. 2016, 1, 243–267. [Google Scholar] [CrossRef]

- Li, X.; Yu, J.; Low, J.; Fang, Y.; Xiao, J.; Chen, X. Engineering heterogeneous semiconductors for solar water splitting. J. Mater. Chem. A 2015, 3, 2485–2534. [Google Scholar] [CrossRef]

- Fujishima, A.; Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef]

- Shankara, S.S.; Hwang, J.Y.; Seo, H. Facile fabrication of bitter-gourd-shaped copper (II) tungstate thin films for improved photocatalytic water splitting. J. Catal. 2017, 350, 197–202. [Google Scholar] [CrossRef]

- Eftekhari, A.; Babu, V.J.; Ramakrishna, S. Photoelectrode nanomaterials for photoelectrochemical water splitting. Int. J. Hydrog. Energy 2017, 42, 11078–11109. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; Song, W.; Zhou, P.; Ji, H.; Ma, W.; Chen, C.; Zhao, J. Nonmetal P-doped hematite photoanode with enhanced electron mobility and high water oxidation activity. Energy Environ. Sci. 2015, 8, 1231–1236. [Google Scholar] [CrossRef]

- Liu, J.; Liang, C.; Xu, G.; Tian, Z.; Shao, G.; Zhang, L. Ge-doped hematite nanosheets with tunable doping level, structure and improved photoelectrochemical performance. Nano Energy 2013, 2, 328–336. [Google Scholar] [CrossRef]

- Lee, M.H.; Park, J.H.; Han, H.S.; Song, H.J.; Cho, I.S.; Noh, J.H.; Hong, K.S. Nanostructured Ti-doped hematite (α-Fe2O3) photoanodes for efficient photoelectrochemical water oxidation. Int. J. Hydrog. Energy 2014, 39, 17501–17507. [Google Scholar] [CrossRef]

- Dias, P.; Vilanova, A.; Lopes, T.; Andrade, L.; Mendes, A. Extremely stable bare hematite photoanode for solar water splitting. Nano Energy 2016, 23, 70–79. [Google Scholar] [CrossRef]

- Deshmukh, P.R.; Sohn, Y.; Shin, W.G. Chemical synthesis of ZnO nanorods: Investigations of electrochemical performance and photo-electrochemical water splitting applications. J. Alloys Compd. 2017, 711, 573–580. [Google Scholar] [CrossRef]

- Chuangchote, S.; Jitputti, J.; Sagawa, T.; Yoshikawa, S. Photocatalytic activity for hydrogen evolution of electrospun TiO2 nanofibers. ACS Appl. Mater. Interfaces 2009, 1, 1140–1143. [Google Scholar] [CrossRef]

- Lee, S.S.; Bai, H.; Liu, Z.; Sun, D.D. Novel-structured electrospun TiO2/CuO composite nanofibers for high efficient photocatalytic cogeneration of clean water and energy from dye wastewater. Water Res. 2013, 47, 4059–4073. [Google Scholar] [CrossRef]

- Lee, S.S.; Bai, H.; Liu, Z.; Sun, D.D. Electrospun TiO2/SnO2 nanofibers with innovative structure and chemical properties for highly efficient photocatalytic H2 generation. Int. J. Hydrog. Energy 2012, 37, 10575–10584. [Google Scholar] [CrossRef]

- Mali, M.G.; An, S.; Liou, M.; Al-Deyab, S.S.; Yoon, S.S. Photoelectrochemical solar water splitting using electrospun TiO2 nanofibers. Appl. Surf. Sci. 2015, 328, 109–114. [Google Scholar] [CrossRef]

- Babu, V.J.; Kumar, M.K.; Nair, A.S.; Kheng, T.L.; Allakhverdiev, S.I.; Ramakrishna, S. Visible light photocatalytic water splitting for hydrogen production from N-TiO2 rice grain shaped electrospun nanostructures. Int. J. Hydrog. Energy 2012, 37, 8897–8904. [Google Scholar] [CrossRef]

- Regonini, D.; Teloeken, A.C.; Alves, A.K.; Berutti, F.A.; Gajda-Schrantz, K.; Bergmann, C.P.; Graule, T.; Clemens, F. Electrospun TiO2 fiber composite photoelectrodes for water splitting. ACS Appl. Mater. Interfaces 2013, 5, 11747–11755. [Google Scholar] [CrossRef]

- Al-Enizi, A.M.; Brooks, R.M.; Abutaleb, A.; El-Halwany, M.M.; El-Newehy, M.H.; Yousef, A. Electrospun carbon nanofibers containing Co-TiC nanoparticles-like superficial protrusions as a catalyst for H2 gas production from ammonia borane complex. Ceram. Int. 2017, 43, 15735–15742. [Google Scholar] [CrossRef]

- Veluru, J.B.; Manippady, K.K.; Rajendiren, M.; Mya, K.M.; Rayavarapu, P.R.; Appukuttan, S.N.; Seeram, R. Photocatalytic hydrogen generation by splitting of water from electrospun hybrid nanostructures. Int. J. Hydrog. Energy 2013, 38, 4324–4333. [Google Scholar] [CrossRef]

- Hu, J.; Wang, L.; Zhang, P.; Liang, C.; Shao, G. Construction of solid-state Z-scheme carbon-modified TiO2/WO3 nanofibers with enhanced photocatalytic hydrogen production. J. Power Sources 2016, 328, 28–36. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, P.; Zhao, J.; Zhang, Y.; Hu, J.; Shao, G. Plasmon enhancement on photocatalytic hydrogen production over the Z-scheme photosynthetic heterojunction system. Appl. Catal. B 2017, 210, 297–305. [Google Scholar] [CrossRef]

- Saveh-Shemshakia, N.; Latifia, M.; Bagherzadehb, R.; Malekshahi Byranvandc, M.; Naserid, N.; Dabirian, A. Synthesis of mesoporous functional hematite nanofibrous photoanodes by electrospinning. Polym. Adv. Technol. 2016, 27, 358–365. [Google Scholar] [CrossRef]

- Pantò, F.; Leonardi, S.G.; Fazio, E.; Frontera, P.; Bonavita, A.; Neri, G.; Antonucci, P.L.; Neri, F.; Santangelo, S. CO2 sensing properties of electro-spun Ca-doped ZnO fibres. Nanotechnology 2018, 29, 305501–305512. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Liu, Z.; Yang, Y.; Geng, M.; Zou, Y.; Shahzad, M.B.; Dai, Y.; Qi, Y. Photocatalytic properties of Fe-doped ZnO electrospun nanofibers. Ceram. Int. 2018, 44, 19998–20005. [Google Scholar] [CrossRef]

- Santangelo, S.; Frontera, P.; Pantò, F.; Stelitano, S.; Marelli, M.; Patanè, S.; Malara, F.; Dal Santo, V.; Antonucci, P. Effect of Ti-or Si-doping on nanostructure and photo-electro-chemical activity of electro-spun iron oxide fibres. Int. J. Hydrog. Energy 2017, 42, 28070–28081. [Google Scholar] [CrossRef]

- Saremi-Yarahmadi, S.; Upul Wijayantha, K.G.; Tahir, A.A.; Vaidhyanathan, B. Nanostructured α-Fe2O3 electrodes for solar driven water splitting: Effect of doping agents on preparation and performance. J. Phys. Chem. C 2009, 113, 4768–4778. [Google Scholar] [CrossRef]

- Rauf, M.; Wang, J.W.; Zhang, P.; Iqbal, W.; Qu, J.; Li, Y. Non-precious nanostructured materials by electrospinning and their applications for oxygen reduction in polymer electrolyte membrane fuel cells. J. Power Sources 2018, 408, 17–27. [Google Scholar] [CrossRef]

- Aruna, S.T.; Balaji, L.S.; Kumar, S.S.; Prakash, B.S. Electrospinning in solid oxide fuel cells—A review. Renew. Sustain. Energy Rev. 2017, 67, 673–682. [Google Scholar] [CrossRef]

- Sood, R.; Cavaliere, S.; Jones, D.J.; Rozière, J. Electrospun nanofibre composite polymer electrolyte fuel cell and electrolysis membranes. Nano Energy 2016, 26, 729–745. [Google Scholar] [CrossRef]

- Junoh, H.; Jaafar, J.; Norddin, M.N.A.M.; Ismail, A.F.; Othman, M.H.D.; Rahman, M.A.; Yusof, N.; Salleh, W.N.W.; Ilbeygi, H. A review on the fabrication of electrospun polymer electrolyte membrane for direct methanol fuel cell. J. Nanomater. 2015, 4, 690965. [Google Scholar] [CrossRef]

- Joshi, P.; Zhang, L.; Chen, Q.; Galipeau, D.; Fong, H.; Qiao, Q. Electrospun carbon nanofibers as low-cost counter electrode for dye-sensitized solar cells. ACS Appl. Mater. Interfaces 2010, 2, 3572–3577. [Google Scholar] [CrossRef]

- Dharani, S.; Mulmudi, H.K.; Yantara, N.; Trang, P.T.T.; Park, N.G.; Graetzel, M.; Mhaisalkar, S.; Mathews, N.; Boix, P.P. High efficiency electrospun TiO2 nanofiber based hybrid organic–inorganic perovskite solar cell. Nanoscale 2014, 6, 1675–1679. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Xiao, J.; Sui, H.; Yang, X.; Zhang, W.; Li, X.; Hagfeldt, A.; Wu, M. Highly effective Co3S4/electrospun-carbon-nanofibers composite counter electrode synthesized with electrospun technique for cobalt redox electrolyte based on dye-sensitized solar cells. J. Power Sources 2016, 326, 6–13. [Google Scholar] [CrossRef]

- Zhao, K.; Zhang, X.; Wang, M.; Zhang, W.; Li, X.; Wang, H.; Li, L. Electrospun carbon nanofibers decorated with Pt-Ni2P nanoparticles as high efficiency counter electrode for dye-sensitized solar cells. J. Alloys Compd. 2019, 786, 50–55. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Bowen, C.; Roscow, J.; Zhang, Y.; Dang, D.K.; Kim, E.J.; Misra, R.D.K.; Deng, L.; Hur, S.H. Micro-scale to nano-scale generators for energy harvesting: Self powered piezoelectric, triboelectric and hybrid devices. Phys. Rep. 2019, 792, 1–33. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Z.L. Reviving vibration energy harvesting and self-powered sensing by a triboelectric nanogenerator. Joule 2017, 1, 480–521. [Google Scholar] [CrossRef]

- Zhu, G.; Peng, B.; Chen, J.; Jing, Q.; Wang, Z.L. Triboelectric nanogenerators as a new energy technology: From fundamentals, devices, to applications. Nano Energy 2015, 14, 126–138. [Google Scholar] [CrossRef]

- Tiwari, S.; Gaur, A.; Kumar, C.; Maiti, P. Enhanced piezoelectric response in nanoclay induced electrospun PVDF nanofibers for energy harvesting. Energy 2019, 171, 485–492. [Google Scholar] [CrossRef]

- Lin, Z.; Chen, J.; Jang, J. Recent progress in triboelectric nanogenerators as a renewable and sustainable power source. J. Mater. Res. 2016, 2016, 5651613. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Y.; Zhang, N.; Zou, H.; Liu, R.; Tao, C.; Fan, X.; Wang, Z.L. Micro-cable structured textile for simultaneously harvesting solar and mechanical energy. Nat. Energy 2016, 1, 16138. [Google Scholar] [CrossRef]

- Zhang, N.; Tao, C.; Fan, X.; Chen, J. Progress in triboelectric nanogenerators as self-powered smart sensors. J. Mater. Res. 2017, 32, 1628–1646. [Google Scholar] [CrossRef]

- Lin, Z.; Yang, J.; Li, X.; Wu, Y.; Wei, W.; Liu, J.; Chen, J.; Yang, J. Large-scale and washable smart textiles based on triboelectric nanogenerator arrays for self-powered sleeping monitoring. Adv. Funct. Mater. 2018, 28, 1704112. [Google Scholar] [CrossRef]

- Shi, K.; Sun, B.; Huang, X.; Jiang, P. Synergistic effect of graphene nanosheet and BaTiO3 nanoparticles on performance enhancement of electrospun PVDF nanofiber mat for flexible piezoelectric nanogenerators. Nano Energy 2018, 52, 153–162. [Google Scholar] [CrossRef]

- Li, Z.; Shen, J.; Abdalla, I.; Yu, J.; Ding, B. Nanofibrous membrane constructed wearable triboelectric nanogenerator for high performance biomechanical energy harvesting. Nano Energy 2017, 36, 341–348. [Google Scholar] [CrossRef]

- Shen, J.; Li, Z.; Yu, J.; Ding, B. Humidity-resisting triboelectric nanogenerator for high performance biomechanical energy harvesting. Nano Energy 2017, 40, 282–288. [Google Scholar] [CrossRef]

- Zhang, R.; Hummelgård, M.; Örtegren, J.; Olsen, M.; Andersson, H.; Olin, H. Interaction of the human body with triboelectric nanogenerators. Nano Energy 2019, 57, 279–292. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.H.; Lee, J.; Yamauchi, Y.; Choi, C.H.; Kim, J.H. Research update: Hybrid energy devices combining nanogenerators and energy storage systems for self-charging capability. Apl Mater. 2017, 5, 073804. [Google Scholar] [CrossRef]

- Sun, N.; Wen, Z.; Zhao, F.; Yang, Y.; Shao, H.; Zhou, C.; Shen, Q.; Feng, K.; Peng, M.; Li, Y.; et al. All flexible electrospun papers based self-charging power system. Nano Energy 2017, 38, 210–217. [Google Scholar] [CrossRef]

- Peng, Y.; Chen, J.; Song, A.Y.; Catrysse, P.B.; Hsu, P.C.; Cai, L.; Liu, B.; Zhu, Y.; Zhou, G.; Wu, D.S.; et al. Nanoporous polyethylene microfibres for large-scale radiative cooling fabric. Nat. Sustain. 2018, 1, 105. [Google Scholar] [CrossRef]

- Hsu, P.C.; Liu, X.; Liu, C.; Xie, X.; Lee, H.R.; Welch, A.J.; Zhao, T.; Cui, Y. Personal thermal management by metallic nanowire-coated textile. Nano Lett. 2015, 15, 365–371. [Google Scholar] [CrossRef]

- Hsu, P.C.; Song, A.Y.; Catrysse, P.B.; Liu, C.; Peng, Y.; Xie, J.; Fan, S.; Cui, Y. Radiative human body cooling by nanoporous polyethylene textile. Science 2016, 353, 1019–1023. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Song, A.Y.; Wu, P.; Hsu, P.C.; Peng, Y.; Chen, J.; Liu, C.; Catrysse, P.B.; Liu, Y.; Yang, A.; et al. Warming up human body by nanoporous metallized polyethylene textile. Nat. Commun. 2017, 8, 496. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Song, A.Y.; Li, W.; Hsu, P.C.; Lin, D.; Catrysse, P.B.; Liu, Y.; Peng, Y.; Chen, J.; Wang, H.; et al. Spectrally selective nanocomposite textile for outdoor personal cooling. Adv. Mater. 2018, 30, 1802152. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Wang, L.; Huang, Y. Electrospun phase change fibers based on polyethylene glycol/cellulose acetate blends. Appl. Energy 2011, 88, 3133–3139. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Y.; Liu, W. Electrospun polyethylene glycol/cellulose acetate phase change fibers with core-sheath structure for thermal energy storage. Renew. Energy 2013, 60, 222–225. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, X.; Fu, J.; Huan, C.; Qi, S.; Zhan, Y.; Zhu, Y.; Xu, G. Novel smart textile with phase change materials encapsulated core-sheath structure fabricated by coaxial electrospinning. Chem. Eng. J. 2019, 355, 532–539. [Google Scholar] [CrossRef]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santangelo, S. Electrospun Nanomaterials for Energy Applications: Recent Advances. Appl. Sci. 2019, 9, 1049. https://doi.org/10.3390/app9061049

Santangelo S. Electrospun Nanomaterials for Energy Applications: Recent Advances. Applied Sciences. 2019; 9(6):1049. https://doi.org/10.3390/app9061049

Chicago/Turabian StyleSantangelo, Saveria. 2019. "Electrospun Nanomaterials for Energy Applications: Recent Advances" Applied Sciences 9, no. 6: 1049. https://doi.org/10.3390/app9061049

APA StyleSantangelo, S. (2019). Electrospun Nanomaterials for Energy Applications: Recent Advances. Applied Sciences, 9(6), 1049. https://doi.org/10.3390/app9061049