1. Introduction

In municipal infrastructures, it is usually necessary to construct a small, temporary, shallow shaft, such as a working shaft, for pipe jacking and pipe maintenance [

1,

2]. These temporary shafts are generally supported by reinforced concrete structures, which include reinforced concrete caissons, diaphragm walls, row piles, shotcrete and steel arch frame supports [

3,

4,

5,

6,

7]. The disadvantages of these methods include a long duration for concrete curing [

8,

9], high costs, complicated construction procedures, environmental pollution [

10], and resource waste [

11,

12], due to unrecyclable components. Zheng et al. [

13] proposed that sustainable and consumption reduction construction technology is an important development direction for the future.

In recent years, recyclable and prefabricated supporting structures and technologies have been proposed to solve these problems. Steel sheet piles and jet-grouted columns with H steel piles have been widely applied to foundation pits [

14,

15,

16,

17]. Steel sheet piles and soil mixing walls can solve the problem of construction pollution and material recovery to some extent, but there are still some limitations in engineering applications [

18]. For example, the large machinery needed for sinking and the loud noise and water pollution caused by cement means that it is not suitable for construction in high-density city areas that require strict environmental protection and small sites [

19,

20]. Additionally, some researchers [

21,

22] have provided several suggestions for supporting small shafts. Yang et al. [

21] designed a spiral supporting structure, which was prefabricated in a factory and assembled on site within the shaft. Guan et al. [

22] developed a spiral supporting structure and proposed a design approach. These authors verified the convenience, reliability, recyclability and effectiveness of this new supporting structure through field tests. Excavation and support are carried out simultaneously with this technology, which is suitable for urban construction, due to its low noise. However, this structure utilizes the passive stress structure method, which plays a role after soil deformation. This passive support method can induce the further development of deformation in surrounding soil [

23,

24], especially in soft soil, where the deformation is greater. Therefore, these structures are inapplicable to the conditions of soft soil, loose soil, and areas where deformation control is very strict. Prestressed supporting structures, such as prestressed anchor cables and prestressed internal supports, can satisfactorily solve these problems. However, this supporting structure’s prestress is applied at discrete points, which unevenly distributes the stress along the supporting structure.

To overcome such drawbacks, in this study, a novel prestressed supporting structure was designed to support small shafts. The construction of this structure was carried out via on-site assembly. Field tests were carried out to study the support effect of the novel structure. Field measurements of earth pressure, structure stress, and lateral displacement were collected to study the variation characteristics of the prestress during the construction process.

2. Prefabricated Prestressed Support Technology

2.1. Prefabricated Prestressed Supporting Structure Introduction

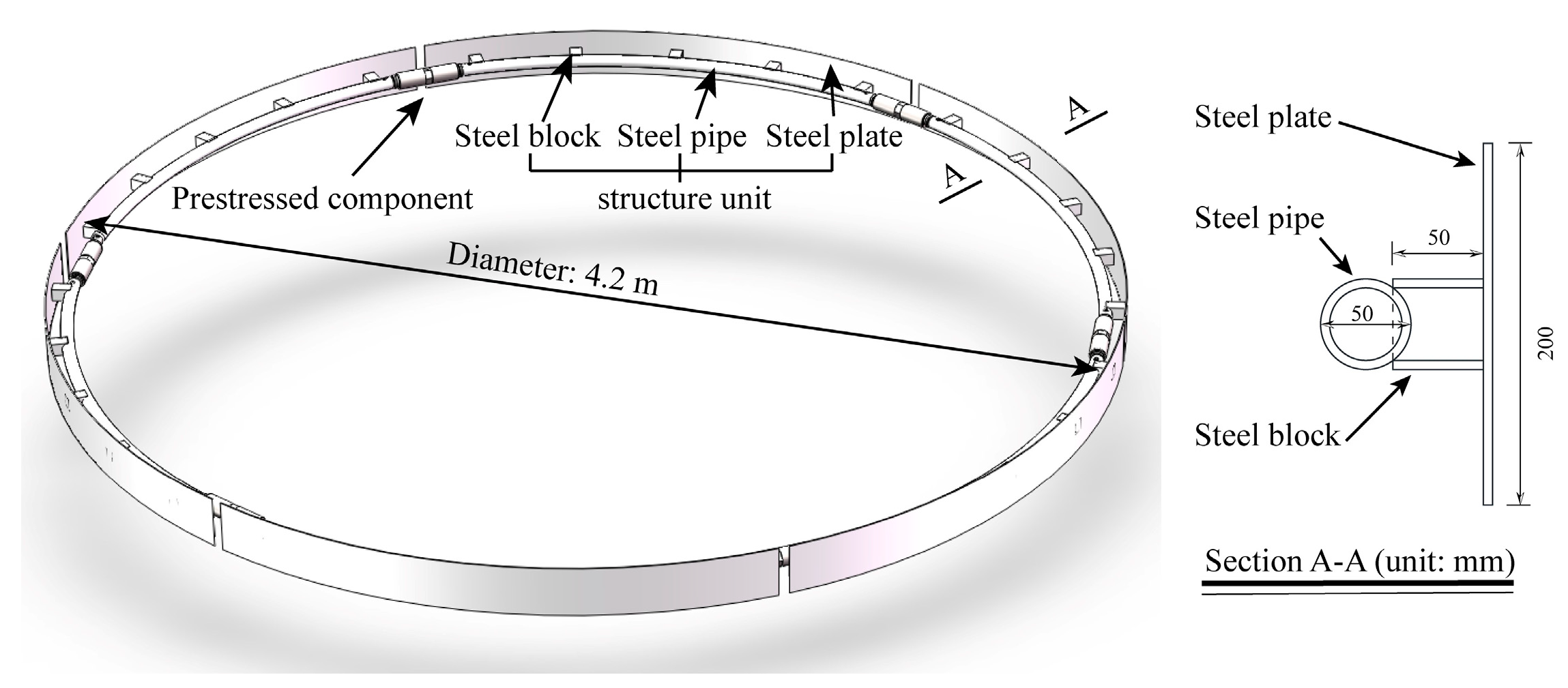

The overall prefabricated prestressed supporting structure is composed of many supporting structure layers, which are assembled into a cylindrical supporting system. The individual supporting structure layer has a height of 0.2 m and a diameter of 4.2 m. Each supporting structure layer consists of six steel structure units and six prestressed components, which are assembled into a roughly circular structure (see

Figure 1).

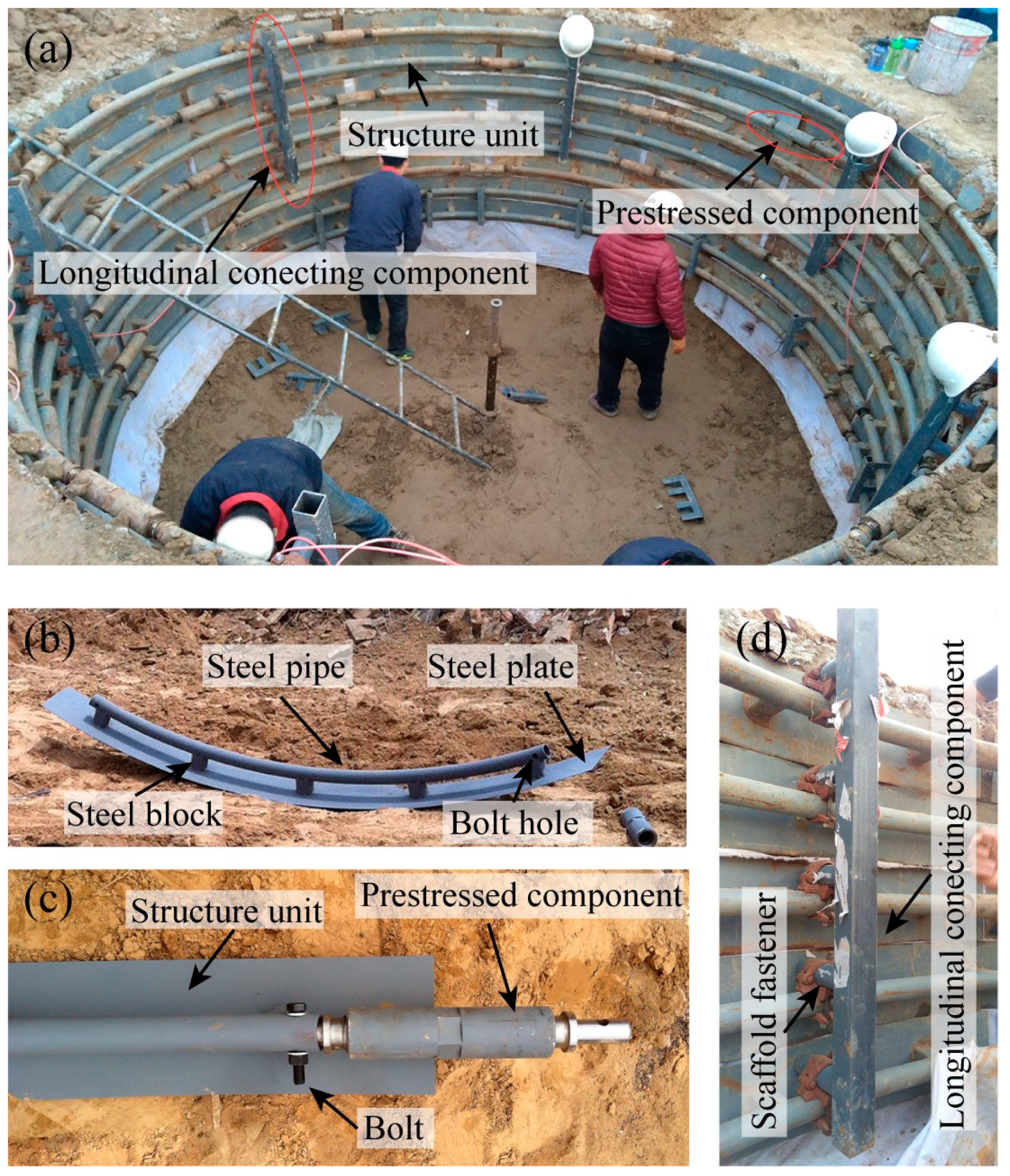

In

Figure 2a,d, the adjacent supporting structure layer is connected by a longitudinal connecting component, which can strengthen the integrity of the supporting structure. The supporting structure unit and longitudinal connecting components are connected by a scaffold fastener.

In

Figure 1 and

Figure 2b, each supporting structure unit consists of a steel plate and a steel pipe with two bolt holes at both ends; these components are welded together through steel blocks.

In

Figure 2c, the prestressed component consists of a medial sleeve with two screws on both ends, which are attached by a thread connection. The prestressed component and supporting structure unit are connected by a bolt. The prestressed component can expand or shrink by rotating the sleeve.

The steel plate is in close contact with the shaft wall when the structure is prestressed. The earth pressure passes from the steel plate to the steel pipe, and the steel pipe is the main member that bears the load. The supporting structure is in the active force state by applying prestress, similar to the anchor cable or the prestressed internal support.

2.2. Construction Procedure

The overall construction sequence is as follows:

Step 1: A circular trench is excavated with a design diameter and a depth of 0.2 m. The trench wall should be as flat as possible.

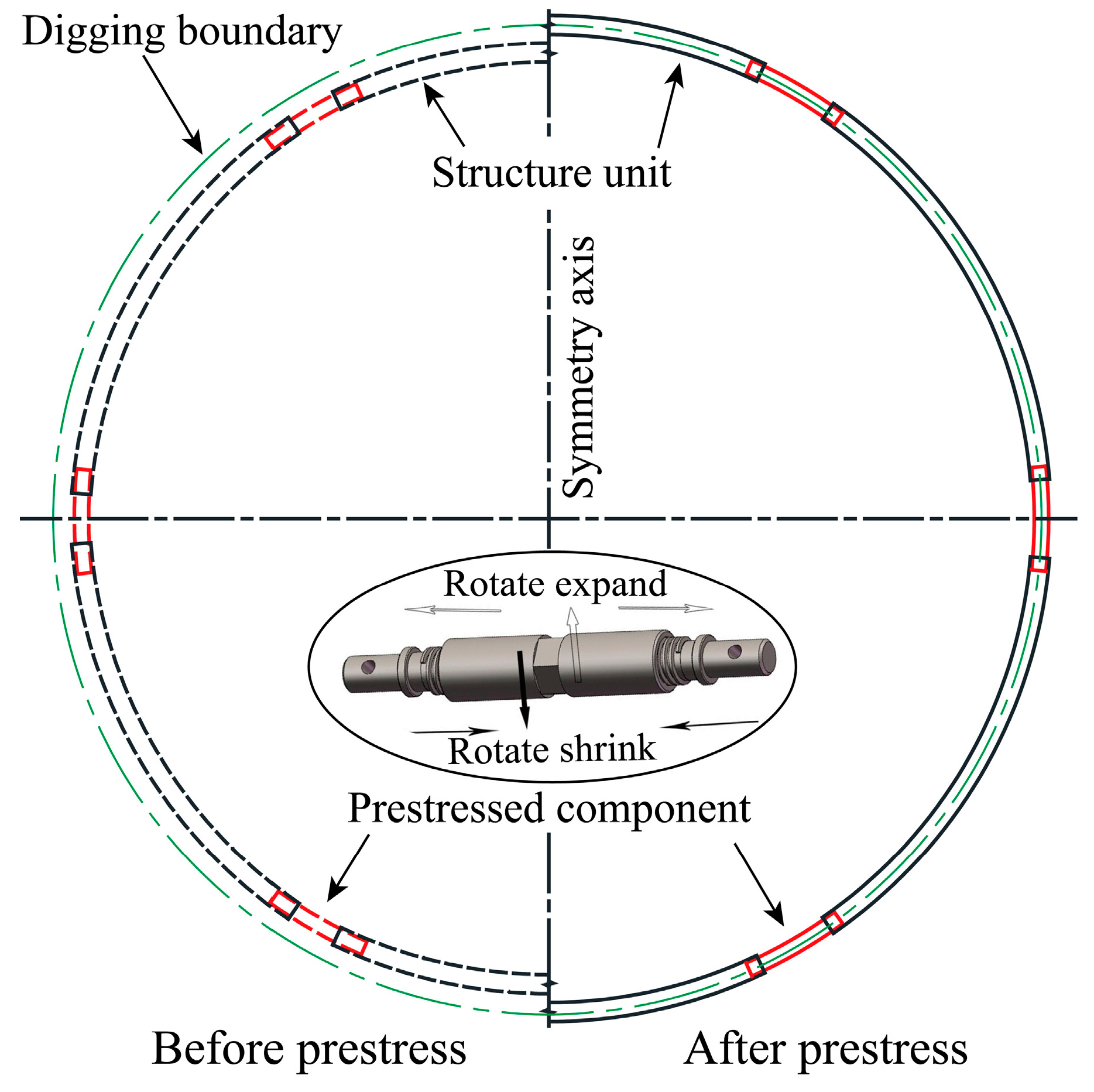

Step 2: The first supporting structure layer is assembled. The initial installation radius of the supporting structure layer is less than the excavation radius of the shaft. There is a gap between the structure and the soil before prestressing (see

Figure 3). The distance between the adjacent structure units becomes larger by rotating the sleeve of the prestressed component. Consequently, the structure radius is enlarged, and the supporting structure and soil are affixed to realize the application of prestress. The structure layer should also be adjusted to ensure that it is horizontal.

Step 3: The shaft is excavated with an excavation footage of 0.5 m. The shaft is manually excavated, and the excavated soil is lifted by a small crane. Then, second and third supporting structures are assembled to cling to the first structure. Notably, the assembled seams of the adjacent supporting structure layers need to be staggered. The physical map of the prefabricated supporting structure in the excavation progress is shown in

Figure 2a.

Step 4: Excavation and assembly are repeated until the shaft reaches the designed depth. In this process, a longitudinal connecting component needs to be installed every five supporting structure layers. Six longitudinal connecting components are uniformly installed in the circumference (see

Figure 2a).

Step 5: The supporting structure is recycled, and the shaft is backfilled. When the supporting structure is dismantled, the distance between the adjacent structure units decreases by rotating the sleeve of the prestressed component. Consequently, the structure radius is reduced, and the supporting structure detaches from the soil. The dismantling of the structure and the backfill of the shaft are carried out consecutively, and the number of layers of a single dismantling step needs to be controlled according to the stratum condition.

3. Field Tests

3.1. Site and Ground Conditions

The field test area is located in the Daxing district of Beijing, China. The diameter of the shaft is 4.2 m, and the excavation depth is 6.5 m. There are no buildings within 30 m.

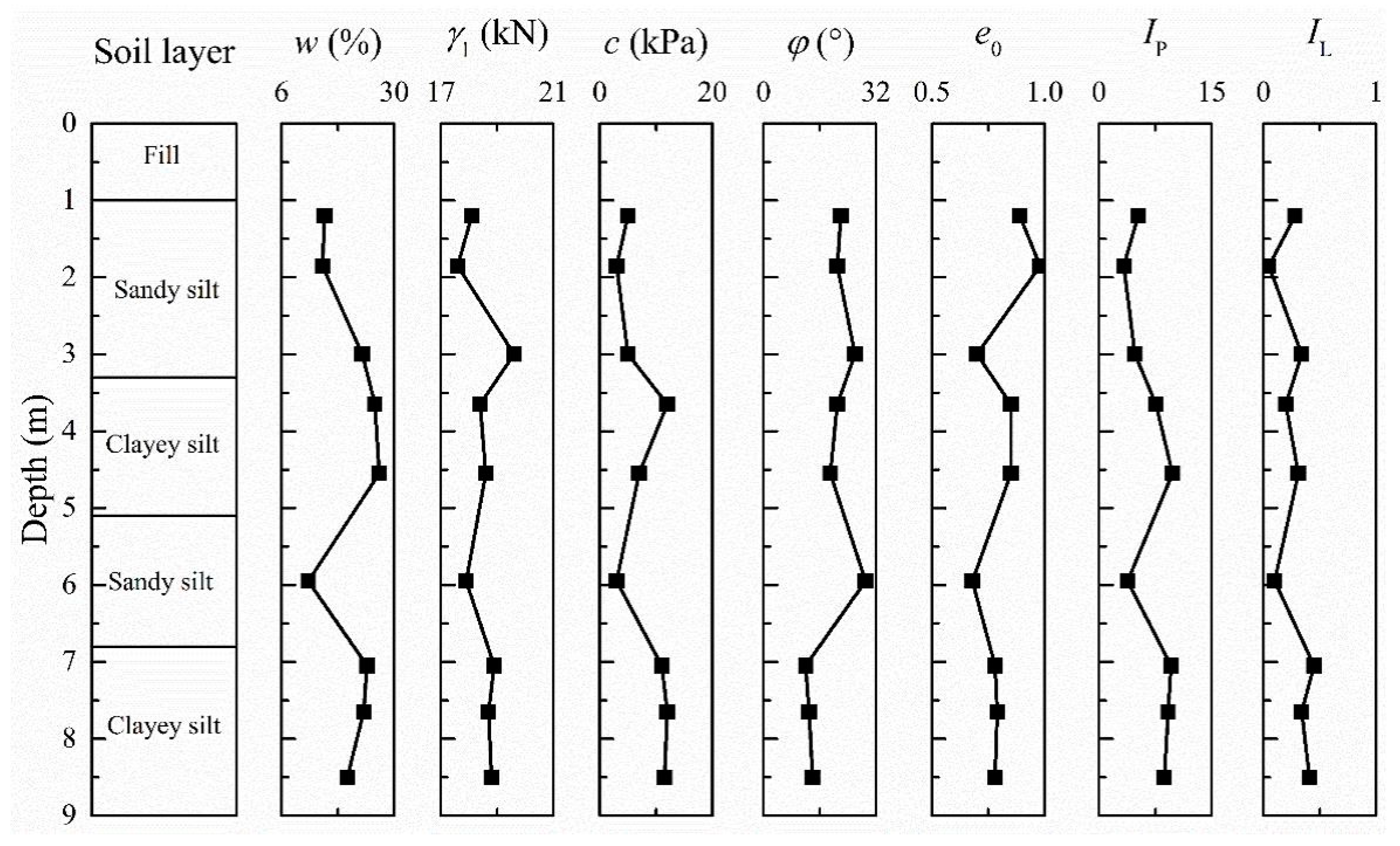

The field geology investigation and soil test have been carried out.

Figure 4 shows the detailed physical properties and geotechnical parameters of the soil. There are five layers of soil with a total depth up to 9 m. The top layer is filled with a depth of 1 m. The stratum of 1.0–3.3 m is sandy silt with a high void ratio. The stratum of 3.3–5.2 m is clayey silt with higher moisture content and plasticity index. The stratum of 5.2–6.8 m is also sandy silt, but has a lower void ratio. Below this stratum is also clayey silt. The ground water is 14 m underground.

3.2. Field Instrumentation

To verify the effectiveness and observe the performance of the proposed method, the supporting structure and surrounding ground were monitored during excavation and after construction.

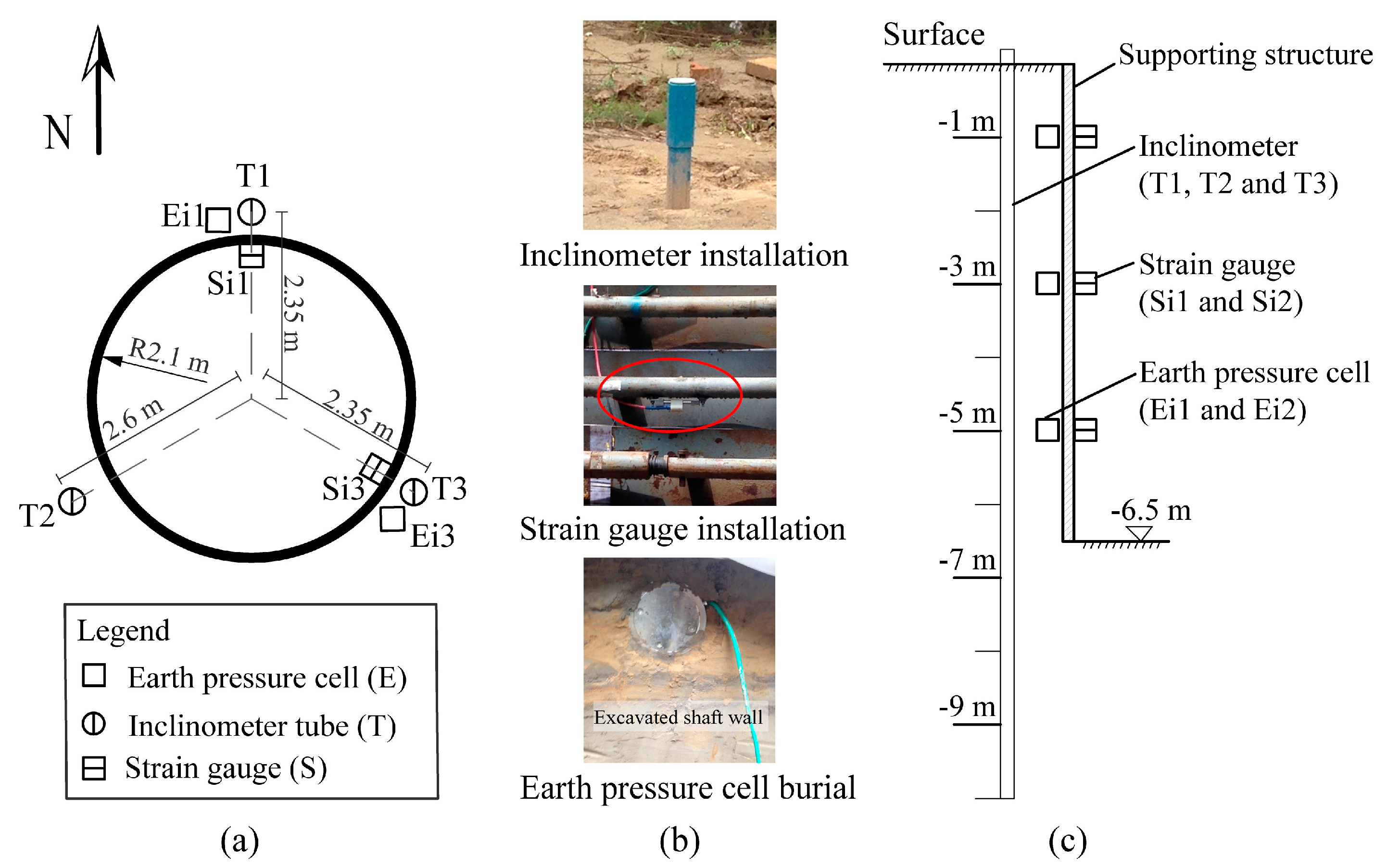

The field monitoring items included the following: (i) A buried earth pressure cell to obtain the load acting on the structure; (ii) a strain gauge installed in the structure unit to measure the stress state of the structure; and (iii) an inclinometer tube to monitor the lateral displacement of the surrounding soil. The distribution and installation of the instruments are shown in

Figure 5.

(1) Distribution and installation of earth pressure cell

Lateral earth pressure was observed using earth pressure cells. The measuring range of this instrument is from 0 to 200 kPa. As shown in

Figure 5, the earth pressure cells were buried 1 m, 3 m, and 5 m underground, respectively. Two monitoring points were distributed along the circumference at each depth; they were labeled Ei1, and Ei3, respectively. The letter, ‘i’ represents the depth of the earth pressure cell. There are six lateral earth pressure monitoring points in total.

The earth pressure cells were buried after excavating to the projected depth, and then the supporting structures were assembled with prestress. The holes were dug in the shaft wall, and subsequently, the cells were buried. The axis of the cylindrical earth pressure cell is perpendicular to the excavated shaft wall (see

Figure 5b).

(2) Distribution and installation of strain gauge

The stress in the structures was observed using strain gauges. The strain gauges were installed 1 m, 3 m, and 5 m underground, respectively. Two monitoring points were distributed along the circumference at each depth; they were labeled Si1and Si3, respectively. The letter, ‘i’ represents the depth of the strain gauge, as shown in

Figure 5. There are six stress monitoring points in total.

The strain gauges were installed in the middle of the steel pipe in advance. The supporting structures with strain gauges were assembled after excavating to the preset depth.

(3) Distribution and installation of the inclinometer

The lateral displacement was observed using inclinometers. Three inclinometer tubes were installed before excavation and were uniformly distributed along the circumference; they were labeled T1, T2, and T3, respectively. T1 and T3 were 0.25 m from the shaft wall. There is 0.5 m between T2 and the shaft wall. The detailed distribution is shown in

Figure 5.

4. Measurement Results Analysis and Discussion

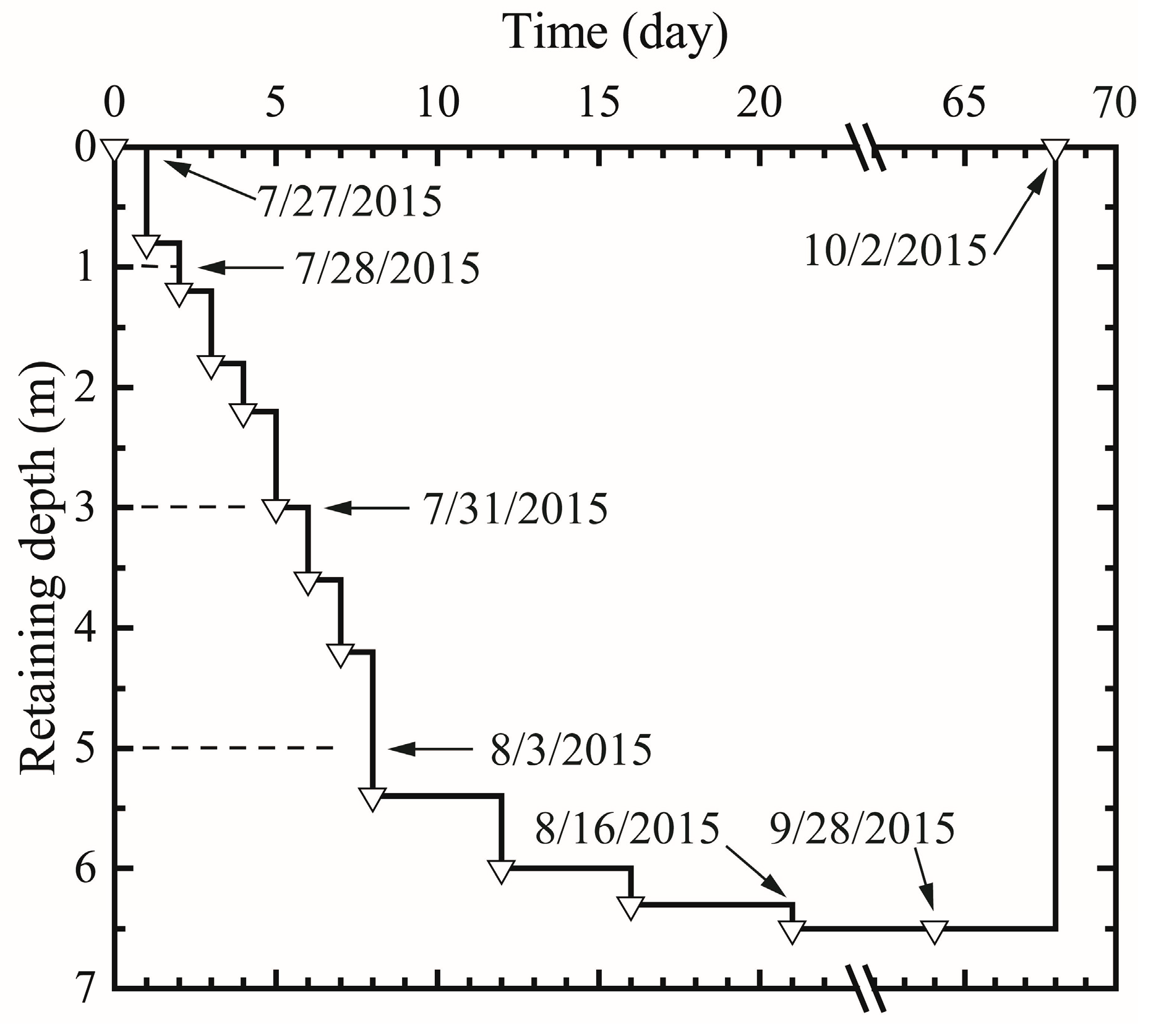

Figure 6 shows the schedule of the construction progress. The shaft had not been excavated until 27 July 2015. On 16 August 2015, the shaft was excavated to 6.5 m; it took 21 days to achieve the design excavation depth. The measurements began on the first day of construction and lasted 64 days (monitoring was completed on 28 September 2015). The supporting structure was recycled, and the shaft was backfilled on 2 October 2015.

To obtain the measurement data, the construction speed was deliberately slowed. The experience of field construction shows that the proposed technology avoids the steel bar binding and shotcrete needed for the traditional reinforced concrete support. The construction speed of the proposed technology can be increased by more than 1/3 compared with the traditional shotcrete approach under normal construction conditions.

The dismantling and backfill construction of the shaft were completed in one day. The supporting structure can be reused after being dismantled and recycled. Compared with the traditional reinforced concrete supporting structure, the new supporting structure does not need to break the concrete when the shaft is backfilled. Thus, the new supporting structure is more convenient, environmentally friendly and recyclable.

4.1. Lateral Earth Pressure

The attenuance of the lateral earth pressure (AOP) is introduced to characterize the attenuation characteristics of the soil pressure behind the structure. AOP is defined as the ratio of the attenuation of the earth pressure to the initially measured pressure.

Here,

is the attenuation amount of the soil pressure and

is the initial measured soil pressure.

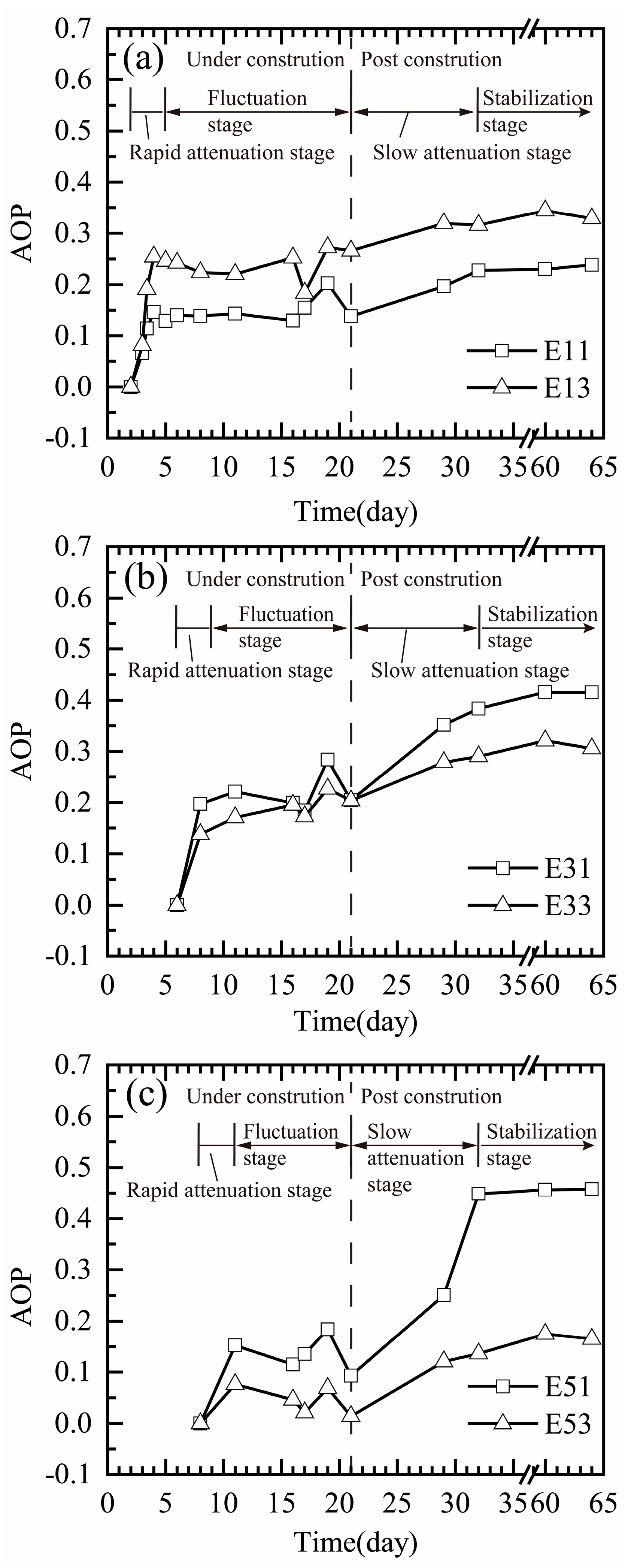

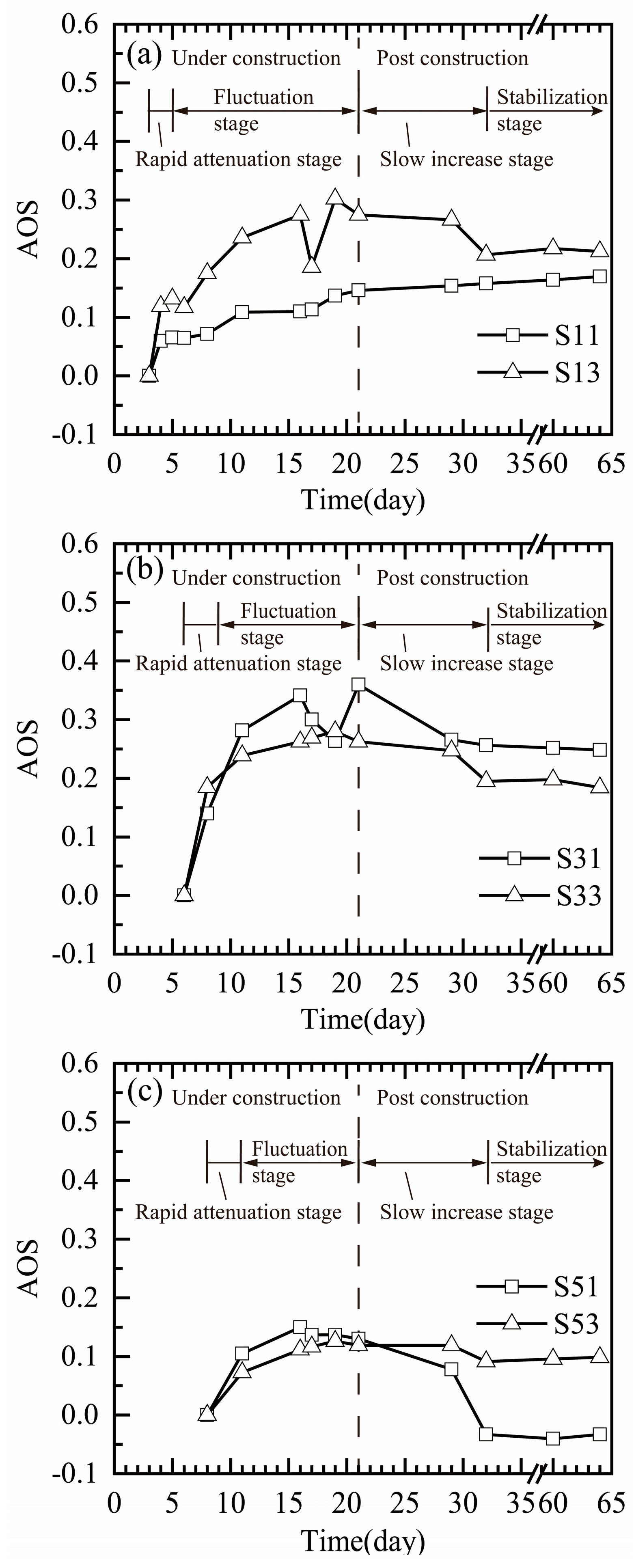

Figure 7 shows the variation in AOP with time. The greater the change in AOP (in units of time), the faster the earth pressure attenuates. During this period, the lateral earth pressure was measured 18 times. The variation of the lateral earth pressure with time was obtained.

The earth pressure behind the prestressed supporting structure was greatest after the initial installation was complete. In

Figure 7, the change in the earth pressure at each depth can be divided into four stages. The first stage was the rapid attenuation stage, which occurred within three days of the prestress application. The second stage was the fluctuation stage, which occurred between the third day after the prestress application and the completion of shaft excavation. The third stage was the slow attenuation stage, which occurred within ten days of the completion of shaft excavation. During the last stage, the earth pressure hardly changed and was stable. Combined with the practical situation on site, it is concluded that the earth pressure increases rapidly by applying prestress (before it could dissipate) and then gradually dissipates as time progresses.

In

Figure 7, AOP is not consistent at the two monitoring points at the same depth. In addition, there are differences in AOP at different depths. The most stable AOPs were 0.32, 0.39 and 0.45 at depths of 1 m, 3 m and 5 m, respectively. By analyzing the geologic conditions, the plasticity index (

Ip) at a depth of 5 m is larger than that at 1 m and 3 m. We conclude that AOP is related to soil conditions, and the more easily soil deforms, the more earth pressure is lost.

Table 1 shows the ratio of the AOP after rapid attenuation to the AOP of the stabilization stage. When the rapid attenuation stage is completed, the attenuation of earth pressure has been completed by 50% or more. This finding indicates that a higher residual prestress can be obtained by improving the initial prestress to enhance the supporting force.

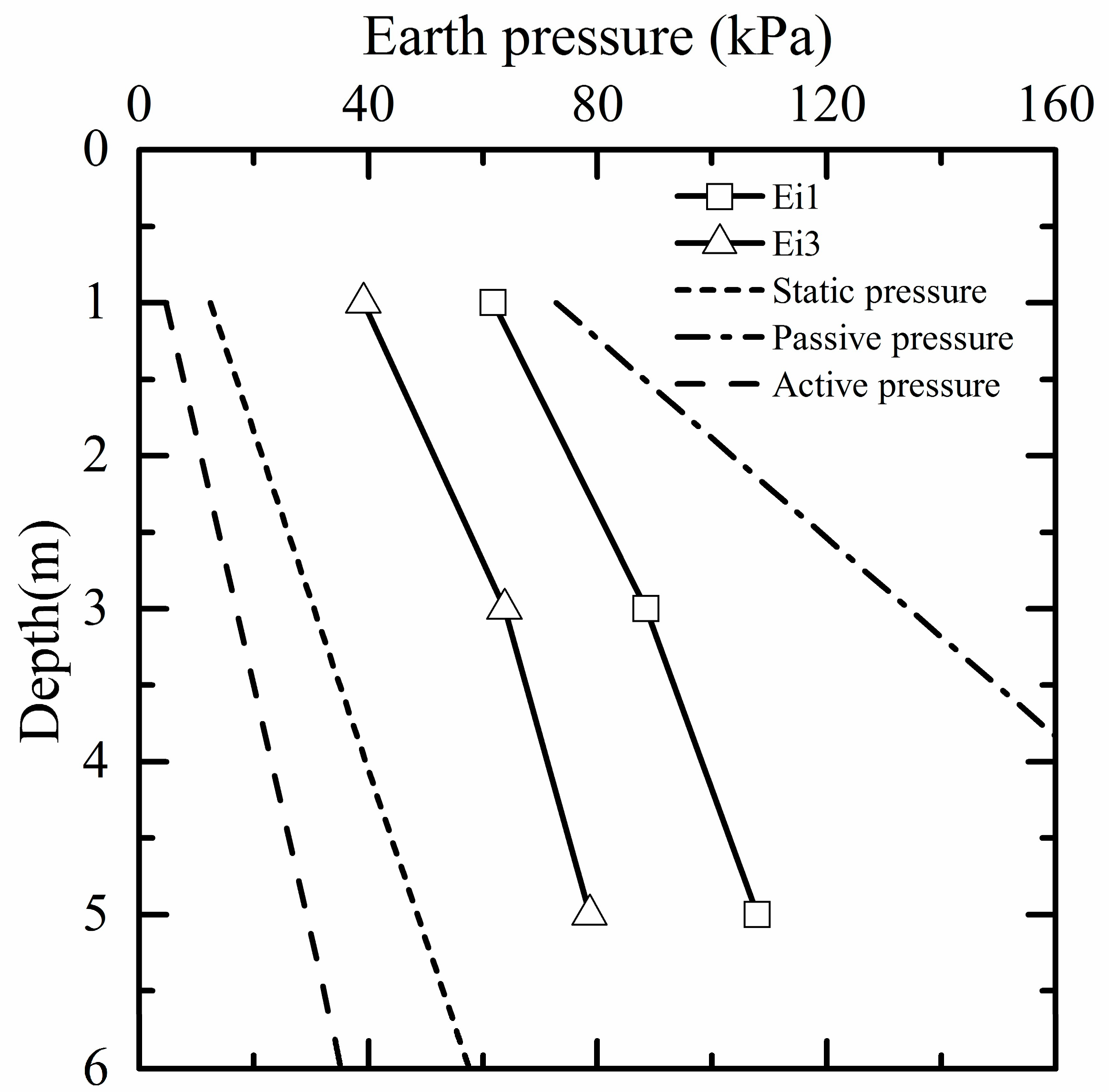

The measured stable earth pressure and calculated Rankine earth pressure are presented in

Figure 8, and the results show that the measured earth pressure values of both Ei1 and Ei3 increase with depth and are 108 kPa and 79 kPa at a depth of 5 m, respectively.

In

Figure 8, the measured pressure is located between the earth pressure at rest and the passive earth pressure. This result indicates that the prefabricated prestressed supporting structure applies prestress to the soil and has an active support effect. The earth pressure at different locations has a disparate value at the same depth. This phenomenon shows that the prestress applied by the prefabricated prestressed supporting structure was not uniform. Combined with the field tests, a conclusion is drawn that the single supporting structure layer asymmetrically expands while applying prestress, which leads to different pressures at the same depth.

4.2. Structure Stress

The attenuance of the structure stress (AOS) is introduced to characterize the attenuation characteristics of the structure stress. AOS is defined as the ratio of the attenuation of the structure stress to the initially measured stress.

Here,

is the attenuation amount of the structure stress and

is the initial measured stress.

Figure 9 shows the variation in AOS with time. The greater the change in AOS (in units of time), the faster the structure stress attenuates. During this period, the structure stress was measured 16 times. The variation of the structure stress with time was obtained.

The structure stress was the greatest when the initial installation was completed. In

Figure 9, the change in the structure stress at each depth can also be divided into four stages, similar to the change in the earth pressure. However, the change in AOS shows a slow increase stage within ten days after the completion of shaft excavation, which is different from the change in AOP.

Combined with the practical situation on site, this phenomenon can be explained as follows: (i) The structure internal stress rapidly increases, due to the applied prestress; (ii) then, the stress attenuates as the soil is gradually compressed; (iii) and finally, the soil behind the structure is gradually consolidated, which gives rise to an increase in AOS. It is concluded that the stress attenuation of the prefabricated supporting structure is different from the phenomenon of the prestressed anchor cable [

25].

In

Figure 9, the AOS is not consistent at the two monitoring points at the same depth. In addition, there are differences in AOS at different depths. The highest stable AOSs were 0.21, 0.26 and 0.09 at depths of 1 m, 3 m and 5 m, respectively. AOS is less than AOP, because AOS has a slow increase stage after the completion of shaft excavation.

Table 2 shows the ratio of the AOS after rapid attenuation to the AOS of the stabilization stage. When the rapid attenuation stage is completed, the attenuation of the structure stress has been completed by 50% or more.

The AOS of the stabilization stage at S51 is negative, which shows that the stress in the stabilization stage increases rather than attenuates when compared to the initial stress. This is considered to be due to the insufficient initial prestress at the S51 monitoring point. The prestress is applied by six prestressed components (see

Figure 3), which may result in a small prestress at the S51 monitoring point, due to the uneven prestress. Since the stress at the S51 monitoring point is smaller than that of other positions, the stress at the S51 monitoring point gradually increases with the stress redistribution after the completion of construction; thus, the AOS of the stabilization stage at the S51 measuring point is negative.

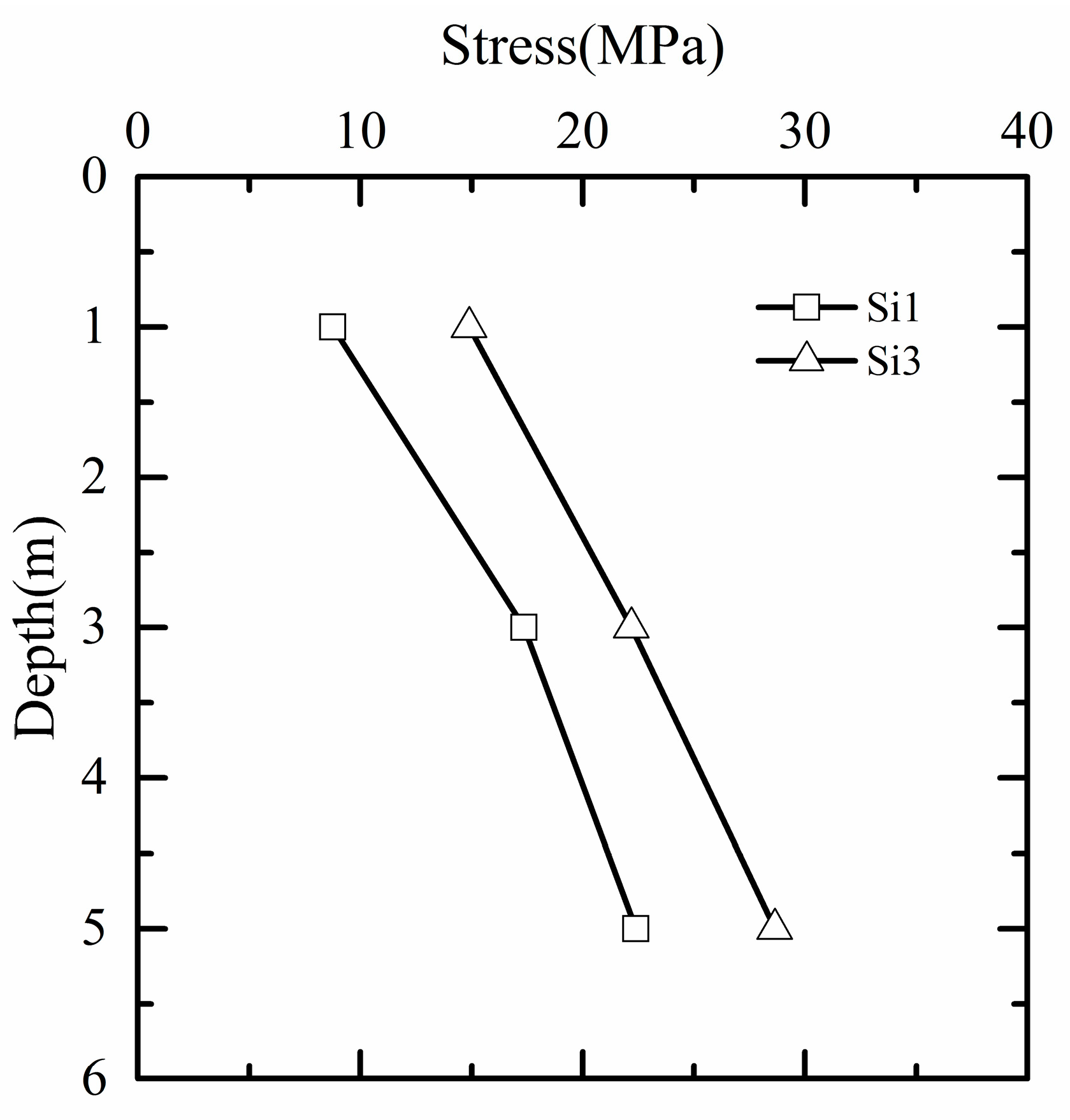

Figure 10 shows the variation in the measured stable structure stress with depth. Si1 and Si3 represent the measured stable structure stress. In

Figure 10, the structure stress values of both Si1 and Si3 increase with depth, and they are 22.4 MPa and 28.6 MPa at a depth of 5 m, respectively. The stress values of the monitoring points do not exceed the alarm value (235 MPa), which indicates that the prefabricated supporting structure in this work has good overall stability.

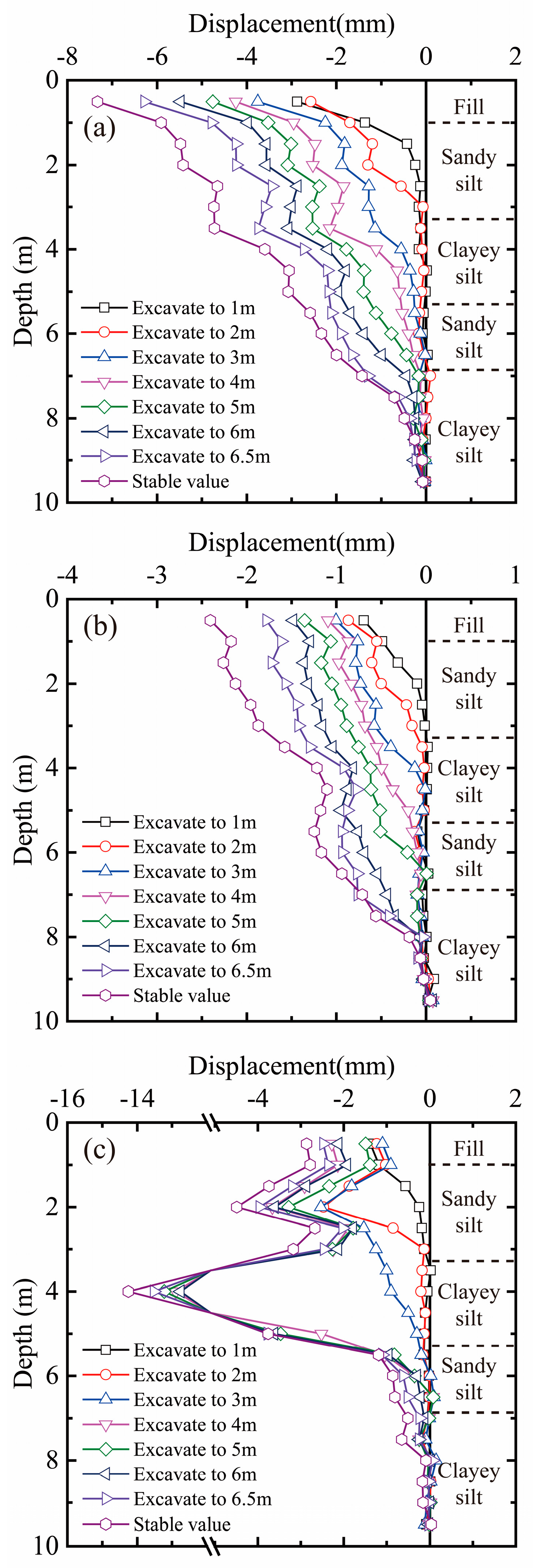

4.3. Lateral Displacement

Figure 11 shows the variation in the lateral soil displacement of the shaft with depth and construction schedule. The negative lateral displacement shows that the soil has moved out from the shaft. In

Figure 11a, the distribution of the lateral displacement was triangular. The lateral displacement of the surface was the maximum displacement (8.4 mm). The minimum lateral displacement was at the bottom of the shaft. The lateral displacement of T2 was, overall, smaller than the displacement in the other two directions (see

Figure 11b). The maximal displacement was 2.9 mm on the surface. This result indicates that the prefabricated supporting structure exhibits good performance with respect to deformation control. The lateral displacement of T3 was basically the same as that of T2 on the surface (see

Figure 11c). The displacement increased sharply at a depth of 4 m, reaching 14.25 mm. Based on the observation of the stratum conditions on site, we found that it was the clayey silt with a high moisture content (25.9%) and a low compression modulus (8.9 MPa) that underwent a rather large deformation under prestress conditions.

In

Figure 11, the following features of the lateral displacement can be concluded.

The lateral displacement of all monitoring points moved toward the outside of the shaft within the excavation depth. This finding is consistent with the result of the measured earth pressure between the static earth pressure and the passive earth pressure. This result is obviously different from the soil displacement models of traditional passive supports [

26].

At the depth of each excavation step, the lateral displacements are larger than the last measured results after prestress support, and a displacement inflection develops. This inflection is caused by soil compaction under prestress conditions.

The lateral displacement generally increased with increasing depth of excavation and supporting. The lateral displacement increase is a process of soil compaction, which causes prestress attenuation until equilibrium is reached. This phenomenon coincides with an attenuation in the earth pressure.

The lateral displacement of the three directions was not equal. This displacement is related to the asymmetrical prestress. The lateral displacement of T2 is smaller than that of T1 and T3. This value indicates that the farther the distance from the shaft is, the smaller the lateral horizontal deformation will be.

The stable value of the lateral displacement was larger than the value that was measured at the end of construction. This finding means that the soil is still slowly compacting under prestressing conditions after construction before finally stabilizing.

The lateral displacement of the three directions shows the change trend of a large deformation at the top and a small deformation at the bottom. The reason for this variation is that the soil has poor compactness at the top and is more easily compacted by prestress.

5. Conclusions

In this study, a prefabricated prestressed supporting structure was used in a field prototype test in Beijing, China. The performance of the new structure was investigated by monitoring the lateral earth pressure, the lateral displacement in the surrounding soil, and the stress of the supporting structure. The following conclusions may be drawn:

(1) The change in the earth pressure and structure stress can be divided into four stages during construction: Rapid attenuation, fluctuation, slow change, and stabilization. Both the earth pressure and structure stress completed the major attenuation within three days of the applied prestress and eventually stabilized. The values of the stable attenuance were 0.32–0.45 and 0.09–0.26 for earth pressure and structure stress, respectively.

(2) The surrounding soil at the supporting position apparently moves toward the outside of the shaft with the supporting structure construction. This behavior indicates that the new prestressed structure can realize active support and has a significant effect on controlling shaft deformation.

(3) The displacement value is connected with the prestressing value and the physical properties of the soil. The larger the prestress is and the softer the soil is, the larger the lateral displacement will be. The lateral displacement will increase with the prestress attenuation, and both tend to be stable when the lateral displacement and prestress achieve balance.

(4) The monitoring data of the field prototype tests show that both the stress and deformation are less than the warning value. It can also be concluded from the shaft construction that the new supporting structure is safe, convenient, environmentally friendly and recyclable. The mutative rules of prestress loss and soil deformation provide guidance for the construction of the new prefabricated prestressed structure.

Author Contributions

Conceptualization, G.Z. and Y.Y.; Data curation, G.Z. and C.G.; Formal analysis, S.M.; Investigation, C.G. and Y.Y.; Methodology, G.Z., S.M. and Y.Y.; Project administration, C.G. and Y.Y.; Writing—original draft, G.Z. and S.M.; Writing—review and editing, G.Z. and Y.Y.

Funding

This research was funded by the National Key Research and Development Program of China, grant number 2017YFC0805008 and the National Nature Science Foundation of China (NSFC), grant number 41472278.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

References

- Yuan, Y. Challenges in underground construction. Proc. Inst. Civ. Eng. Munic. Eng. 2008, 161, 25–34. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, B.S.; Zeng, C.; Xie, H.M.; Li, X.; Wang, D.W. Key techniques for the largest curved pipe jacking roof to date, A case study of Gongbei tunnel. Tunn. Undergr. Space Technol. 2016, 59, 134–145. [Google Scholar] [CrossRef]

- Peng, F.L.; Wang, H.L.; Tan, Y.; Xu, Z.L.; Li, Y.L. Field measurements and FEM simulation of a tunnel shaft constructed by pneumatic caisson method in Shanghai soft ground. J. Geotech. Geoenviron. Eng. 2011, 137, 516–524. [Google Scholar] [CrossRef]

- Sun, Y.; Su, J.B.; Xia, X.H.; Xu, Z.L. Numerical analysis of soil deformation behind the reaction wall of an open caisson induced by horizontal parallel pipe-jacking construction. Can. Geotech. J. 2015, 52, 2008–2016. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, D.L. Structural behaviors of large underground earth-retaining systems in shanghai i: Unpropped circular diaphragm wall. J. Perform. Constr. Facil. 2015, 29, 04014058. [Google Scholar] [CrossRef]

- Ali, J.; Khan, A.Q. Behaviour of anchored pile wall excavations in clays. Proc. Inst. Civ. Eng. Geotech. Eng. 2017, 170, 1–10. [Google Scholar] [CrossRef]

- Azzam, W.R.; Elwakil, A.Z. Performance of axially loaded-piled retaining wall: Experimental and numerical analysis. Int. J. Geomech. 2017, 17, 04016049. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Phojan, W.; Suddeepong, A.; Chinkulkijniwat, A.; Liu, M.D. Strength development in blended cement admixed saline clay. Appl. Clay Sci. 2012, 55, 44–52. [Google Scholar] [CrossRef]

- Sukmak, P.; Horpibulsuk, S.; Shen, S.L. Strength development in clay–fly ash geopolymer. Constr. Build. Mater. 2013, 40, 566–574. [Google Scholar] [CrossRef]

- Sakulich, A.R. Reinforced geopolymer composites for enhanced material greenness and durability. Sustain. Cities Soc. 2011, 1, 195–210. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Xiao, J.X.; Ding, T. Research on recycled concrete and its utilization in building structures in China. Front. Struct. Civ. Eng. 2013, 7, 215–226. [Google Scholar] [CrossRef]

- Zheng, G.; Zhu, H.H.; Liu, X.R.; Yang, G.H. Control of safety of deep excavations and underground engineering and its impact on surrounding environment. China Civ. Eng. J. 2016, 49, 1–24. (In Chinese) [Google Scholar]

- Shen, S.L.; Han, J.; Zhu, H.H.; Hong, Z.S. Evaluation of a dike damaged by pile driving in soft clay. J. Perform. Constr. Facil. 2005, 19, 300–307. [Google Scholar] [CrossRef]

- Bilgin, O. Lateral Earth Pressure Coefficients for Anchored Sheet Pile Walls. Int. J. Geomech. 2012, 12, 584–595. [Google Scholar] [CrossRef]

- Wang, Z.P.; Shen, S.L.; Ho, C.E.; Kim, Y.H. Investigation of field-installation effects of horizontal twin-jet grouting in Shanghai soft soil deposits. Can. Geotech. J. 2013, 50, 288–297. [Google Scholar] [CrossRef]

- Bolton, M.D.; Lam, S.Y.; Vardanega, P.J.; Ng, C.W.W.; Ma, X. Ground movements due to deep excavations in Shanghai: Design charts. Front. Struct. Civ. Eng. 2014, 8, 201–236. [Google Scholar] [CrossRef]

- Denisov, G.V.; Lalin, V.V.; Abramov, D.S. Preservation of Lock Joints in Steel Sheet Piling During Vibratory Driving. Soil Mech. Found. Eng. 2014, 51, 29–35. [Google Scholar] [CrossRef]

- Ding, L.Y.; Zhong, B.T.; Wu, S.; Luo, H.B. Construction risk knowledge management in BIM using ontology and semantic web technology. Saf. Sci. 2016, 87, 202–213. [Google Scholar] [CrossRef]

- Stahlhut, O.; Borchert, K.M.; Voigt, R.E. Design and execution of a trough excavation pit in the Hamburg city center considering complex structural conditions. Bautechnik 2018, 95, 62–71. [Google Scholar] [CrossRef]

- Yang, Y.Y.; Lv, J.G.; Huang, X.G.; Tu, X.M. Sensor monitoring of a newly designed foundation pit supporting structure. J. Cent. South. Univ. 2013, 20, 1064–1070. [Google Scholar] [CrossRef]

- Guan, C.L.; Yang, Y.Y.; Wang, C.B. Rapid excavation with a newly developed retaining system: Spiral assembly steel structure. J. Cent. South Univ. 2015, 22, 2719–2729. [Google Scholar] [CrossRef]

- Wei, Y.; Wang, Y.Q.; Gao, X. Effect of internal curing on moisture gradient distribution and deformation of a concrete pavement slab containing prewetted lightweight fine aggregates. Dry. Technol. 2015, 33, 355–364. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Xin, Y.X.; Xie, Y.L.; Li, J.; Wang, Z.F. Investigation of mechanical performance of prestressed steel arch in tunnel. Front. Struct. Civ. Eng. 2017, 11, 360–367. [Google Scholar] [CrossRef]

- Puigvert, F.; Gil, L.; Escrig, C.; Bernat, E. Stress relaxation analysis of adhesively bonded anchorages for CFRP tendons. Constr. Build. Mater. 2014, 66, 313–322. [Google Scholar] [CrossRef]

- Roboski, J.; Finno, R.J. Distributions of ground movements parallel to deep excavations in clay. Can. Geotech. J. 2006, 43, 43–58. [Google Scholar] [CrossRef]

Figure 1.

Schematic diagram of the assembled circular supporting structure layer.

Figure 1.

Schematic diagram of the assembled circular supporting structure layer.

Figure 2.

Physical map of the prestressed supporting structure: (a) Construction picture of the prefabricated supporting structure; (b) the structure unit shown in (a); (c) connection of the structure unit and prestressed component; and (d) connection of the structure unit and longitudinal connecting component.

Figure 2.

Physical map of the prestressed supporting structure: (a) Construction picture of the prefabricated supporting structure; (b) the structure unit shown in (a); (c) connection of the structure unit and prestressed component; and (d) connection of the structure unit and longitudinal connecting component.

Figure 3.

Schematic diagram of the prestress construction.

Figure 3.

Schematic diagram of the prestress construction.

Figure 4.

In situ geotechnical profile and soil properties (from left to right: Soil layer, moisture content (w), bulk density (γl), cohesion (c), angle of internal friction (φ), void ratio (e0), plasticity index (Ip) and liquid index (IL) varying with depth).

Figure 4.

In situ geotechnical profile and soil properties (from left to right: Soil layer, moisture content (w), bulk density (γl), cohesion (c), angle of internal friction (φ), void ratio (e0), plasticity index (Ip) and liquid index (IL) varying with depth).

Figure 5.

Distribution and installation of instruments: (a) Plan layout of the monitoring points; (b) photo of the instrument installation; and (c) cross-sectional view of the monitoring points. (The letter, ‘i’ represents the depth of the instruments).

Figure 5.

Distribution and installation of instruments: (a) Plan layout of the monitoring points; (b) photo of the instrument installation; and (c) cross-sectional view of the monitoring points. (The letter, ‘i’ represents the depth of the instruments).

Figure 6.

The schedule of the construction progress.

Figure 6.

The schedule of the construction progress.

Figure 7.

Time series of the lateral earth pressure attenuance at two monitoring points: (a) Below the surface at 1 m; (b) below the surface at 3 m; and (c) below the surface at 5 m.

Figure 7.

Time series of the lateral earth pressure attenuance at two monitoring points: (a) Below the surface at 1 m; (b) below the surface at 3 m; and (c) below the surface at 5 m.

Figure 8.

Measured stable earth pressure and calculated Rankine earth pressure versus depth.

Figure 8.

Measured stable earth pressure and calculated Rankine earth pressure versus depth.

Figure 9.

Time series of the structure stress attenuance at two monitoring points: (a) Below the surface at 1 m; (b) below the surface at 3 m; and (c) below the surface at 5 m.

Figure 9.

Time series of the structure stress attenuance at two monitoring points: (a) Below the surface at 1 m; (b) below the surface at 3 m; and (c) below the surface at 5 m.

Figure 10.

Measured stable structure stress.

Figure 10.

Measured stable structure stress.

Figure 11.

Measured lateral displacement: (a) T1; (b) T2; and (c) T3.

Figure 11.

Measured lateral displacement: (a) T1; (b) T2; and (c) T3.

Table 1.

The ratio of the attenuance of the lateral earth pressure (AOP) after rapid attenuation to the AOP of the stabilization stage.

Table 1.

The ratio of the attenuance of the lateral earth pressure (AOP) after rapid attenuation to the AOP of the stabilization stage.

| Name | AOP after Rapid Attenuation (AOPr) | AOP of Stabilization Stage (AOPs) | AOPr/AOPs |

|---|

| E11 | 0.15 | 0.23 | 0.65 |

| E13 | 0.25 | 0.32 | 0.78 |

| E31 | 0.20 | 0.39 | 0.51 |

| E33 | 0.14 | 0.29 | 0.48 |

| E51 | 0.15 | 0.45 | 0.33 |

| E53 | 0.08 | 0.14 | 0.57 |

Table 2.

The residual rate of the structure stress.

Table 2.

The residual rate of the structure stress.

| Name | AOS after Rapid Attenuation (AOSr) | AOS of Stabilization Stage (AOSs) | AOSr/AOSs |

|---|

| S11 | 0.06 | 0.16 | 0.38 |

| S13 | 0.12 | 0.21 | 0.57 |

| S31 | 0.14 | 0.26 | 0.54 |

| S33 | 0.18 | 0.19 | 0.95 |

| S51 | 0.10 | −0.03 | −3.33 |

| S53 | 0.07 | 0.09 | 0.78 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).