Microencapsulation of Tomato (Solanum lycopersicum L.) Pomace Ethanolic Extract by Spray Drying: Optimization of Process Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

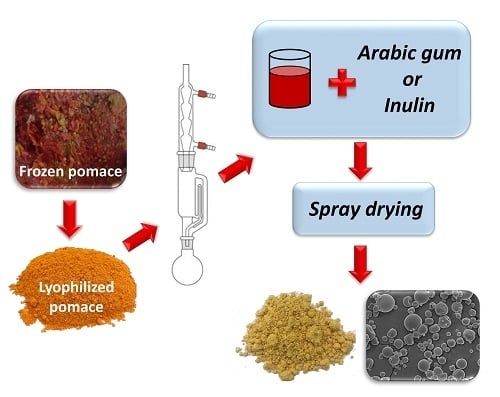

2.2. Tomato Pomace Extract Preparation

2.3. Preparation of Emulsions

2.4. Spray Drying Process

2.5. Experimental Design

2.6. Analytical Methods

2.6.1. Carotenoids Content in the Tomato Pomace Extract

2.6.2. Antioxidant Activity

2.7. Spray Drying and Microparticles’ Characterization

2.7.1. Drying Yield

2.7.2. Morphological Characterization of Microparticles

2.7.3. Loading Capacity and Encapsulation Efficiency

2.7.4. Antioxidant Activity of the Encapsulated Carotenoids

3. Results and Discussion

3.1. Characterization of Tomato Pomace Extract

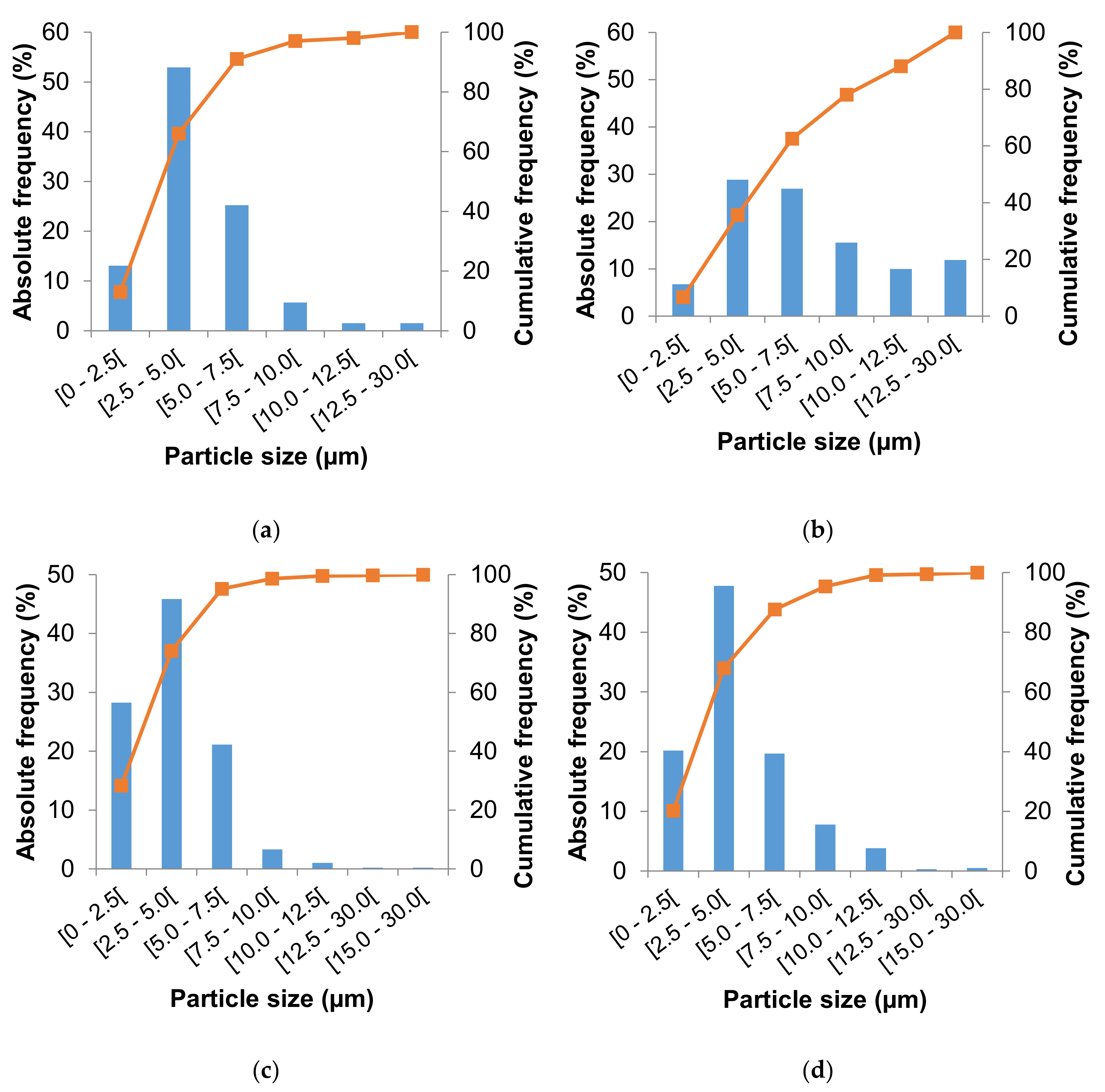

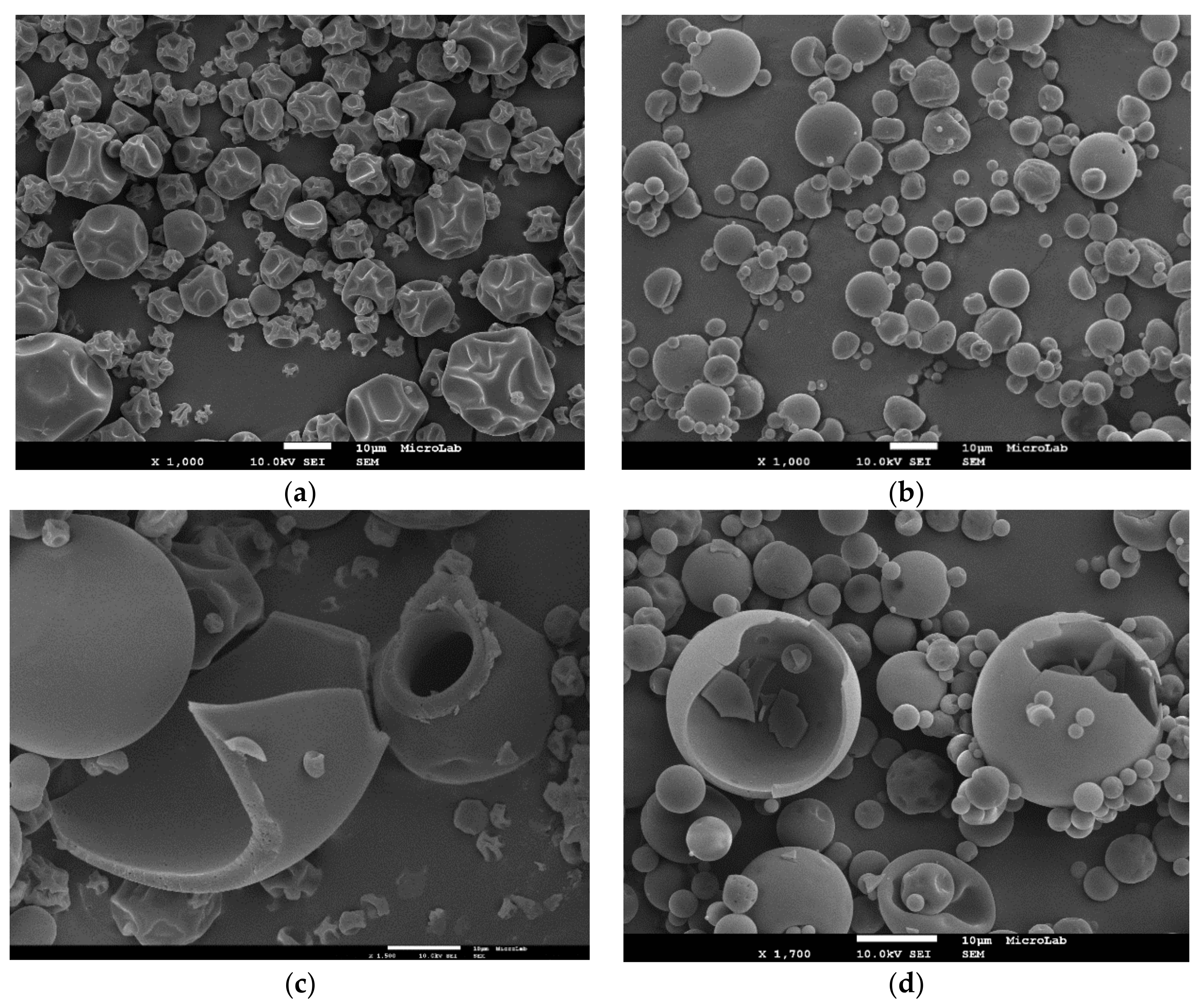

3.2. Microparticles’ Morphology

3.3. Response Variables of Experimental Design

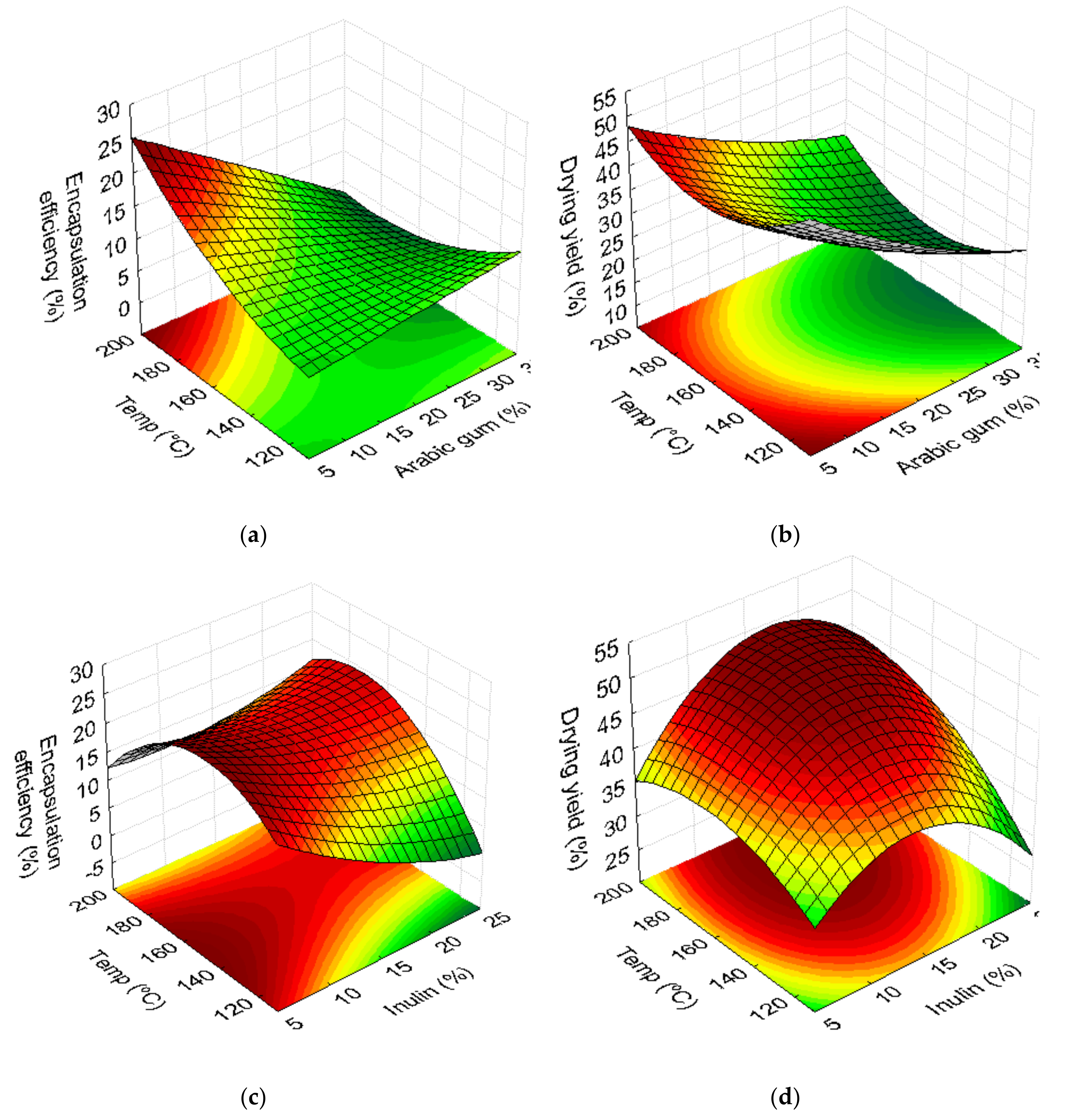

3.3.1. Encapsulation Efficiency and Loading Capacity

3.3.2. Drying Yield

3.3.3. Antioxidant Activity

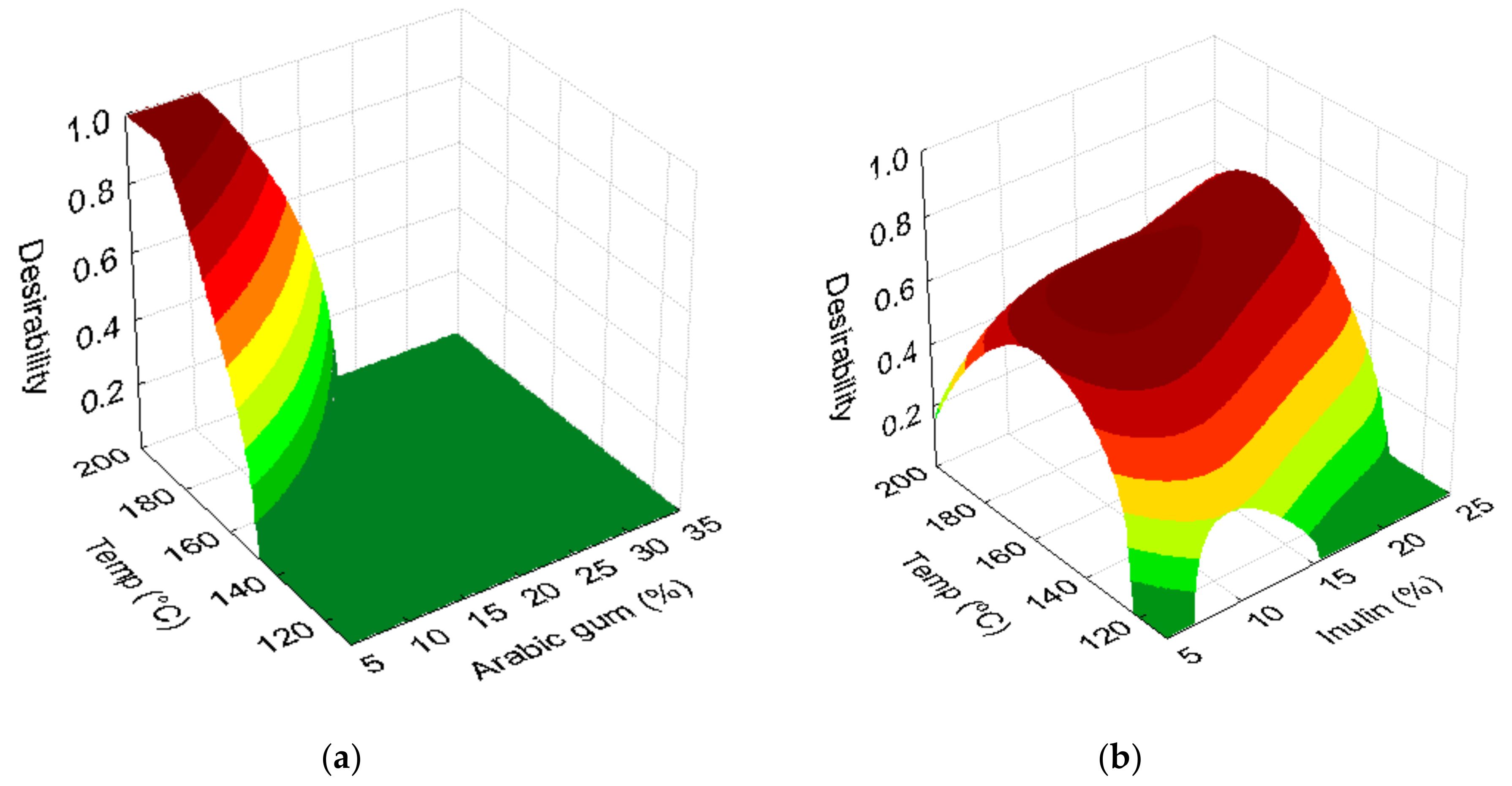

3.4. Spray Drying Process Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Torbica, A.; Belović, M.; Mastilović, J.; Kevrešan, Ž.; Pestorić, M.; Škrobot, D.; Dapčević Hadnađev, T. Nutritional, rheological, and sensory evaluation of tomato ketchup with increased content of natural fibres made from fresh tomato pomace. Food Bioprod. Process. 2016, 98, 299–309. [Google Scholar] [CrossRef]

- Viuda-Martos, M.; Sanchez-Zapata, E.; Sayas-Barberá, E.; Sendra, E.; Perez-Alvarez, J.; Fernandez-Lopez, J. Tomato and tomato byproducts. Human health benefits of lycopene and its application to meat products: A review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1032–1049. [Google Scholar] [CrossRef]

- García Herrera, P.; Sánchez-Mata, M.C.; Cámara, M. Nutritional characterization of tomato fiber as a useful ingredient for food industry. Innovative Food Sci. Emerg. Technol. 2010, 11, 707–711. [Google Scholar] [CrossRef]

- Belović, M.; Pajić-Lijaković, I.; Torbica, A.; Mastilović, J.; Pećinar, I. The influence of concentration and temperature on the viscoelastic properties of tomato pomace dispersions. Food Hydrocoll. 2016, 61, 617–624. [Google Scholar] [CrossRef]

- Eurostat. Agriculture, Forestry and Fishery Statistics. Publications Office of the European Union: Bruxelles, Belgium, 2016; 240. [Google Scholar]

- Shaaban, H.A.E.; El-Ghorab, A.H.; Shibamoto, T. Bioactivity of essential oils and their volatile aroma components: Review. J. Essent. Oil Res. 2012, 24, 203–212. [Google Scholar] [CrossRef]

- Rao, A.V.; Rao, L.G. Carotenoids and human health. Pharmacol. Res. 2007, 55, 207–216. [Google Scholar] [CrossRef]

- Chang, C.; Nickerson, M.T. Encapsulation of omega 3-6-9 fatty acids-rich oils using protein-based emulsions with spray drying. J. Food Sci. Technol. 2018, 55, 2850–2861. [Google Scholar] [CrossRef]

- Pires, F.C.S.; da Silva Pena, R. Optimization of spray drying process parameters for tucupi powder using the response surface methodology. J. Food Sci. Technol. 2017, 54, 3459–3472. [Google Scholar] [CrossRef]

- Singh, J.; Kaur, K.; Kumar, P. Optimizing microencapsulation of α-tocopherol with pectin and sodium alginate. J. Food Sci. Technol. 2018, 55, 3625–3631. [Google Scholar] [CrossRef]

- De Vos, P.; Faas, M.M.; Spasojevic, M.; Sikkema, J. Encapsulation for preservation of functionality and targeted delivery of bioactive food components. Int. Dairy J. 2010, 20, 292–302. [Google Scholar] [CrossRef]

- Kha, T.C.; Nguyen, M.H.; Roach, P.D.; Stathopoulos, C.E. Microencapsulation of Gac oil: Optimisation of spray drying conditions using response surface methodology. Powder Technol. 2014, 264, 298–309. [Google Scholar] [CrossRef]

- Murugesan, R.; Orsat, V. Spray Drying for the Production of Nutraceutical Ingredients—A Review. Food Bioproc. Technol. 2011, 5, 3–14. [Google Scholar] [CrossRef]

- Fernandes, R.V.d.B.; Borges, S.V.; Botrel, D.A. Gum arabic/starch/maltodextrin/inulin as wall materials on the microencapsulation of rosemary essential oil. Carbohydr. Polym. 2014, 101, 524–532. [Google Scholar] [CrossRef] [PubMed]

- Beirão-da-Costa, S.; Duarte, C.; Bourbon, A.I.; Pinheiro, A.C.; Januário, M.I.N.; Vicente, A.A.; Beirão-da-Costa, M.L.; Delgadillo, I. Inulin potential for encapsulation and controlled delivery of Oregano essential oil. Food Hydrocoll. 2013, 33, 199–206. [Google Scholar] [CrossRef]

- Niness, K.R. Inulin and oligofructose: What are they? J. Nutr. 1999, 129, 1402S–1406s. [Google Scholar] [CrossRef] [PubMed]

- Karimi, R.; Azizi, M.H.; Ghasemlou, M.; Vaziri, M. Application of inulin in cheese as prebiotic, fat replacer and texturizer: A review. Carbohydr. Polym. 2015, 119, 85–100. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, D.C. Design and Analysis of Experiments, 8 ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; p. 741. [Google Scholar]

- Rocha, G.A.; Fávaro-Trindade, C.S.; Grosso, C.R.F. Microencapsulation of lycopene by spray drying: Characterization, stability and application of microcapsules. Food Bioprod. Process. 2012, 90, 37–42. [Google Scholar] [CrossRef]

- Vági, E.; Simándi, B.; Vásárhelyiné, K.P.; Daood, H.; Kéry, Á.; Doleschall, F.; Nagy, B. Supercritical carbon dioxide extraction of carotenoids, tocopherols and sitosterols from industrial tomato by-products. J. Supercrit. Fluids 2007, 40, 218–226. [Google Scholar] [CrossRef]

- Machmudah, S.; Zakaria; Winardi, S.; Sasaki, M.; Goto, M.; Kusumoto, N.; Hayakawa, K. Lycopene extraction from tomato peel by-product containing tomato seed using supercritical carbon dioxide. J. Food Eng. 2012, 108, 290–296. [Google Scholar] [CrossRef]

- Reineccius, G.A. The spray drying of food flavors. Drying Technol. 2004, 22, 1289–1324. [Google Scholar] [CrossRef]

- Tontul, I.; Topuz, A. Spray-drying of fruit and vegetable juices: Effect of drying conditions on the product yield and physical properties. Trends Food Sci. Technol. 2017, 63, 91–102. [Google Scholar] [CrossRef]

- Corrêa-Filho, L.C.; Lourenço, M.M.; Moldão-Martins, M.; Alves, V.D. Microencapsulation of β-Carotene by Spray Drying: Effect of Wall Material Concentration and Drying Inlet Temperature. Int. J. Food Sci. 2019, 2019. [Google Scholar] [CrossRef]

- Ferrari, C.C.; Germer, S.P.M.; de Aguirre, J.M. Effects of Spray-Drying Conditions on the Physicochemical Properties of Blackberry Powder. Drying Technol. 2012, 30, 154–163. [Google Scholar] [CrossRef]

- Botrel, D.A.; de Barros Fernandes, R.V.; Borges, S.V.; Yoshida, M.I. Influence of wall matrix systems on the properties of spray-dried microparticles containing fish oil. Food Res. Int. 2014, 62, 344–352. [Google Scholar] [CrossRef]

- Wilkowska, A.; Czyżowska, A.; Ambroziak, W.; Adamiec, J. Structural, physicochemical and biological properties of spray-dried wine powders. Food Chem. 2017, 228, 77–84. [Google Scholar] [CrossRef] [PubMed]

- Aniesrani Delfiya, D.S.; Thangavel, K.; Natarajan, N.; Kasthuri, R.; Kailappan, R. Microencapsulation of Turmeric Oleoresin by Spray Drying and In Vitro Release Studies of Microcapsules. J. Food Process. Eng. 2015, 38, 37–48. [Google Scholar] [CrossRef]

- Torres, C.A.V.; Antunes, S.; Ricardo, A.R.; Grandfils, C.; Alves, V.D.; Freitas, F.; Reis, M.A.M. Study of the interactive effect of temperature and pH on exopolysaccharide production by Enterobacter A47 using multivariate statistical analysis. Bioresour. Technol. 2012, 119, 148–156. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, R.V.d.B.; Botrel, D.A.; Silva, E.K.; Borges, S.V.; Oliveira, C.R.d.; Yoshida, M.I.; Feitosa, J.P.d.A.; de Paula, R.C.M. Cashew gum and inulin: New alternative for ginger essential oil microencapsulation. Carbohydr. Polym. 2016, 153, 133–142. [Google Scholar] [CrossRef] [PubMed]

- Goula, A.M.; Adamopoulos, K.G. A new technique for spray-dried encapsulation of lycopene. Dry. Technol. 2012, 30, 641–652. [Google Scholar] [CrossRef]

- Shamaei, S.; Seiiedlou, S.S.; Aghbashlo, M.; Tsotsas, E.; Kharaghani, A. Microencapsulation of walnut oil by spray drying: Effects of wall material and drying conditions on physicochemical properties of microcapsules. Innov. Food Sci. Emerg. Technol. 2017, 39, 101–112. [Google Scholar] [CrossRef]

- Murali, S.; Kar, A.; Mohapatra, D.; Kalia, P. Encapsulation of black carrot juice using spray and freeze drying. Revista de Agaroquimica y Tecnologia de Alimentos 2015, 21, 604–612. [Google Scholar] [CrossRef]

- Kha, T.C.; Nguyen, M.H.; Roach, P.D. Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J. Food Eng. 2010, 98, 385–392. [Google Scholar] [CrossRef]

- Quek, S.Y.; Chok, N.K.; Swedlund, P. The physicochemical properties of spray-dried watermelon powders. Chem. Eng. Process. 2007, 46, 386–392. [Google Scholar] [CrossRef]

- Nunes, I.L.; Mercadante, A.Z. Encapsulation of lycopene using spray-drying and molecular inclusion processes. Braz. Arch. Biol. Technol. 2007, 50, 893–900. [Google Scholar] [CrossRef]

- Santana, A.A.; Kurozawa, L.E.; de Oliveira, R.A.; Park, K.J. Influence of process conditions on the physicochemical properties of pequi powder produced by spray drying. Dry. Technol. 2013, 31, 825–836. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Simon-Brown, K.; Solval, K.M.; Chotiko, A.; Alfaro, L.; Reyes, V.; Liu, C.; Dzandu, B.; Kyereh, E.; Goldson Barnaby, A.; Thompson, I.; et al. Microencapsulation of ginger (Zingiber officinale) extract by spray drying technology. LWT - Food Sci. Technol. 2016, 70, 119–125. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef]

- Tumwesigye, S.K.; Montañez, J.C.; Oliveira, J.C.; Sousa-Gallagher, M.J. Novel Intact Bitter Cassava: Sustainable Development and Desirability Optimisation of Packaging Films. Food Bioproc. Technol. 2016, 9, 801–812. [Google Scholar] [CrossRef]

| Arabic Gum | ||||||

| Drying Conditions | Response Variables | |||||

| Test | Arabic Gum (%) | T (°C) | LC | EE | AA | DY |

| 1 | 9.4 (−1) | 123.2 (−1) | 1.86 | 8.5 | 1.5 | 44.0 |

| 2 | 9.4 (−1) | 186.8 (+1) | 2.10 | 20.5 | 2.3 | 38.6 |

| 3 | 30.6 (+1) | 123.2 (−1) | 1.44 | 8.0 | 1.9 | 29.0 |

| 4 | 30.6 (+1) | 186.8 (+1) | 1.45 | 7.3 | 4.6 | 26.7 |

| 5 | 20 (0) | 155 (0) | 1.79 | 9.3 | 1.9 | 27.2 |

| 6 | 20 (0) | 155 (0) | 1.46 | 8.1 | 1.8 | 29.1 |

| 7 | 20 (0) | 155 (0) | 1.49 | 8.4 | 1.8 | 27.6 |

| 8 | 5 (−α) | 155 (0) | 1.51 | 12.0 | 4.5 | 43.4 |

| 9 | 35 (+α) | 155 (0) | 1.15 | 3.4 | 0.9 | 14.7 |

| 10 | 20 (0) | 110 (−α) | 1.48 | 9.8 | 1.7 | 34.6 |

| 11 | 20 (0) | 200(+α) | 1.74 | 11.8 | 4.4 | 35.7 |

| Inulin | ||||||

| Test | Inulin (%) | T (°C) | LC | EE | AA | DY |

| 1 | 7.9 (−1) | 123.2 (−1) | 2.73 | 19.7 | 2.5 | 37.5 |

| 2 | 7.9 (−1) | 186.8 (+1) | 1.78 | 15.2 | 1.0 | 45.2 |

| 3 | 22.1 (+1) | 123.2 (−1) | 1.16 | 7.8 | 1.6 | 34.9 |

| 4 | 22.1 (+1) | 186.8 (+1) | 1.63 | 14.8 | 3.4 | 49.5 |

| 5 | 15 (0) | 155 (0) | 2.37 | 20.2 | 2.5 | 48.9 |

| 6 | 15 (0) | 155 (0) | 1.93 | 17.4 | 2.6 | 47.3 |

| 7 | 15 (0) | 155 (0) | 2.20 | 19.2 | 3.0 | 48.8 |

| 8 | 5 (−α) | 155 (0) | 3.08 | 25.3 | 3.5 | 37.7 |

| 9 | 25 (+α) | 155 (0) | 2.54 | 19.3 | 2.1 | 39.7 |

| 10 | 15 (0) | 110 (−α) | 0.87 | 6.9 | 3.2 | 41.4 |

| 11 | 15 (0) | 200(+α) | 1.65 | 14.4 | 1.4 | 45.7 |

| Wall Material | Equation | R2 | RAdj2 |

|---|---|---|---|

| Arabic gum | EE = 13.830 + 1.15306AG* + 0.0001AG2 − 0.232T + 0.002T2* − 0.009AG.T* | 0.91 | 0.81 |

| DY = 158.789* − 1.564AG* + 0.01AG2 − 1.359T* + 0.004T2* + 0.002AG.T | 0.93 | 0.87 | |

| Inulin | EE = −59.613 − 3.029In* + 0.023In2 + 1.291T* − 0.005T2* + 0.0127In.T | 0.92 | 0.84 |

| DY = −25.960 + 1.682In* − 0.093In2* + 0.677T* − 0.002T2* + 0.008In.T | 0.87 | 0.74 | |

| LC = −4.715 − 0.448In* + 0.005In2 + 0.134T* − 0.001T2* + 0.002In.T | 0.86 | 0.72 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corrêa-Filho, L.C.; Lourenço, S.C.; Duarte, D.F.; Moldão-Martins, M.; Alves, V.D. Microencapsulation of Tomato (Solanum lycopersicum L.) Pomace Ethanolic Extract by Spray Drying: Optimization of Process Conditions. Appl. Sci. 2019, 9, 612. https://doi.org/10.3390/app9030612

Corrêa-Filho LC, Lourenço SC, Duarte DF, Moldão-Martins M, Alves VD. Microencapsulation of Tomato (Solanum lycopersicum L.) Pomace Ethanolic Extract by Spray Drying: Optimization of Process Conditions. Applied Sciences. 2019; 9(3):612. https://doi.org/10.3390/app9030612

Chicago/Turabian StyleCorrêa-Filho, Luiz C., Sofia C. Lourenço, Daniel F. Duarte, Margarida Moldão-Martins, and Vítor D. Alves. 2019. "Microencapsulation of Tomato (Solanum lycopersicum L.) Pomace Ethanolic Extract by Spray Drying: Optimization of Process Conditions" Applied Sciences 9, no. 3: 612. https://doi.org/10.3390/app9030612

APA StyleCorrêa-Filho, L. C., Lourenço, S. C., Duarte, D. F., Moldão-Martins, M., & Alves, V. D. (2019). Microencapsulation of Tomato (Solanum lycopersicum L.) Pomace Ethanolic Extract by Spray Drying: Optimization of Process Conditions. Applied Sciences, 9(3), 612. https://doi.org/10.3390/app9030612