Abstract

The present article investigates in laboratory conditions the effect of cyclic freezing and thawing (CFT) on characteristics of the neat bitumen and bitumens modified with different polymers, as well as stone mastic asphalt concretes prepared with the use of the neat and the modified bitumens. Maximal and minimal temperature in cycles of freezing and thawing (FT) is accepted equal to +20 °C and −18 ± 2 °C respectively. Characteristics of low temperature resistance of bitumens (stiffness S and m-value) have been determined on bending beam rheometer at the temperatures of −24 °C, −30 °C, and −36 °C. Strength at direct tension of the stone mastic asphalt concretes has been evaluated in the device TRAVIS (Infratest Ltd., Brackenheim, Germany) at the temperatures of 0 °C, −10 °C, −20 °C, and −30 °C. Resistance of stone mastic asphalt concretes to rutting has been determined on a Hamburg wheel tracking machine. The characteristics of the bitumens have been determined in the initial condition and after 25 and 50 cycles of FT, and the characteristics of stone mastic asphalt concretes, in the initial condition and after 50 cycles of FT. The results obtained experimentally have shown that CFT impacts essentially on the investigated characteristics of bitumens and stone mastic asphalt concretes. Modification with polymers improves the mechanical characteristics of the bitumens and decreases the effect of CFT. It is also found out that when selecting a bitumen for specific climatic conditions it is necessary to take into account both the number of cycles of FT and the characteristic low temperature.

1. Introduction

In many climatic conditions in late autumn, winter, and early spring seasons frequent cyclic transitions occur for air temperature, and for the temperature of the surface and upper part of asphalt concrete layers of highways, respectively, through 0 °C. According to some data the number of such transitions for air temperature through 0 °C is 100 and more in the south of Kazakhstan annually. The specified phenomenon is also a characteristic one for climatic conditions of many countries in the world including European ones. For example, index of freezing–thawing (FT) was 650 degree-days in Paris in the worst winter season of 1962–1963, and it was 240 degree-days in the south of France [1]. Mauduit et al. reported about the fact that pavement of Western Europe is subjected to 500–1200 freezing-thawing cycles for 12–15 years of service life [2]. It is known that cyclic freezing and thawing (CFT) decreases the asphalt concrete strength and results in failure of the asphalt concrete pavement [3]. It was only in 1940 when N.M. Raspopov stated that (CFT) resulted in irreversible failures of asphalt concrete pavements after 8–10 years of operation [4].

Therefore, impact assessment of CFT on properties of bitumens and asphalt concretes is an important one. For example, Ozgan et al. [5] give the results of laboratory experimental study for the effect of CFT on the characteristics of the asphalt concrete. It was found that CFT impacts greatly on the characteristics of the asphalt concrete. Specifically, it has been shown that already after six cycles Marshall stability is decreased by 56.6%, and after 24 cycles it is decreased by 77%.

The effect of CFT on stiffness at 60 s and other characteristics of six types for fine aggregate matrixes (FAM) have been investigated by Gong et al. [6]. Stiffness of the mixtures has been determined on bending beam rheometer (BBR). The obtained results have shown that CFT in all cases decreases the stiffness of mixtures and the stiffness decreasing becomes stronger with the increasing of cycles number for freezing and thawing. For example, after CFT the stiffness can be decreased till 27%.

Tarefder et al. [7] evaluated the effect of CFT on the fatigue life of hot mix asphalt and bitumen stiffness. The samples of asphalt concrete and bitumen have been subjected to 5, 10, 15, and 20 CFT. It is found out that the investigated characteristics of the asphalt concrete and bitumen are decreased with the number increase for cycles of FT. Meanwhile, after 20 cycles of FT the fatigue strength of the asphalt concrete and bitumen stiffness have been decreased for 37% and 41% respectively.

Stiffness decrease (deformability increase) and recoverability of creep strain decrease for neat bitumen and bitumen modified with ethylene vinyl acetate has been reported in the works [8] and [9] respectively.

Essential decrease of dynamic modulus for an asphalt concrete after CFT occurring within one winter season in conditions of southern Ontario (Canada) has been reported in the article [10].

Wei et al. [11], based on the results of laboratory tests, show also the effect of CFT on strength and resilient modulus of the asphalt concrete at compression. After 14 cycles of FT the strength and elasticity modulus are decreased for 14% and 20% respectively.

The results of laboratory experimental investigations for three types of asphalt concrete (a stone mastic asphalt mixture, a conventional dense graded asphalt mixture and an open graded asphalt mixture) have shown that CFT impacts greatly on permeability of asphalt concretes [12]. CFT increases the sizes of the existing pores and causes the occurrence of the new ones in an asphalt concrete. With increase of the cycle number of FT the hydraulic conductivity is essentially increased and with big values of hydraulic gradient the regime of water flow in the asphalt concrete does not follow the Darcy’s law, i.e., it is not a laminar regime, but a turbulent one [12].

The essential effect of compaction level on viscoelastic behavior of the asphalt concrete has been experimentally studied by Badeli et al. [13]. Specifically, it has been reported that CFT decreases complex modulus and increases phase angle of the asphalt concrete. After saturation before CFT the asphalt concrete modulus is increased at low temperatures, which is explained by transition of water into ice.

The effect of cyclic FT on other important characteristics of asphalt concretes have been studied in the works [14,15,16].

Literature review performed above shows that the impact of CFT on characteristics of bitumens and asphalt concretes has been intensively investigated in recent years. We consider that this article will make the updates of the known works as it contains the results of experimental investigation for the impact of CFT on the important characteristics of eight neat and modified bitumens and six stone mastic asphalt concretes.

2. Materials

2.1. Neat Bitumens

In this paper neat bitumens of grades 100/130 and 130/200, satisfying the requirements of Kazakhstan standard ST RK 1373 [17] have been used. Bitumens have been produced by the Pavlodar petrochemical plant from crude oil of Western Siberia (Russia) by the method of direct oxidation. Main standard indicators for the bitumens, determined in the laboratory of Kazakhstan Highway Research Institute (KazdorNII), are represented in Table 1.

Table 1.

Main standard indicators of neat bitumens.

2.2. Bitumens Modified with Polymers

Bitumens modified with polymers have been also examined. Neat bitumen of grade 130/200 has been used for modification, as well as the following polymers: Kraton, Calprene 501, Butonal NS198, Elvaloy 4170, SBS, Zydex, and Titan. The quantity of the polymers added to the bitumen of grade 130/200 is given in Table 2.

Table 2.

Quantity of the polymers added to the bitumen of grade 130/200.

The bitumens modified with the polymers satisfy the requirements of Kazakhstan standard ST RK 2534 [18] and their main indicators are shown in Table 3. Data comparison of Table 1 and Table 3 shows that in most cases bitumen modification with polymers reduces penetration and ductility considerably, considerably increases softening point, and increases Fraas point.

Table 3.

Main standard indicators of the modified bitumens.

2.3. Stone Mastic Asphalt Concretes

Using the neat bitumen of grade 100/130 and the modified bitumens (the bitumen of grade 130/200+polymers) the stone mastic asphalt concretes of grade SMA-20 which satisfy the requirements of standard [19] have been produced in laboratory conditions. The following fractions of crushed stone have been used for production of the asphalt concretes: 5–10 mm (9%), 10–15 mm (24%), and 15–20 mm (40%). Crushed stone has been supplied from the rock pit “Ozentas” (Almaty region, Kazakhstan). Sand of fraction 0–5 mm (16%) has been supplied from the plant “Asfaltobeton-1” (Almaty city, Kazakhstan) and activated mineral powder (11%) has been supplied from the rock pit “Zhartas” (Zhambyl region, Kazakhstan).

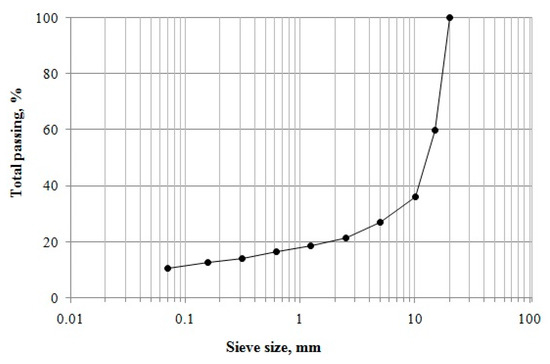

Content of the neat bitumen of grade 100/130 and the bitumens modified with the polymers in composition of all types of the stone mastic asphalt concretes was the same and equal to 4.8% by weight of dry mineral material (crushed stone+sand). Granulometric composition of the mineral part has been also accepted as the same one for all types of the asphalt concretes (Figure 1). Mix design characteristics of the asphalt concretes are represented in Table 4. As it is seen, density of asphalt concretes is practically the same (2.39–2.41 g/cm3), air voids content, voids in mineral aggregate, and water saturation vary within the following limits: 2.6–4.1%; 15.7–18.1%; 1.5–3.5% respectively.

Figure 1.

Granulometric curve of mineral part of the stone mastic asphalts.

Table 4.

Mix design characteristics of the stone mastic concretes.

3. Methods

3.1. Preparation of Modified Bitumens

Mixer of model IKA EUROSTAR 20 DIGITAL (Figure 2) was used for preparation of modified bitumens in laboratory conditions. Frequency of shaft rotation for this mixing device is regulated automatically by microprocessor within the interval of 30 and 2000 rotations per minute. Shaft rotation frequency has been regularly compared with the target one and it is automatically corrected at deviation. This ensures constant rotation rate even at binder viscosity variation.

Figure 2.

Laboratory mixing device.

Preparing of the modified bitumens by the mixing device was performed in the following sequence:

- The neat bitumen was heated up to the temperature of 175–180 °C in the mixing device.

- A polymer was gradually added in bitumen during mixing.

- Full mixing time was 2 h.

- Bitumens modified with polymer Elvaloy after mixing (duration for 2 h) were kept at the mixing temperature (175–180 °C) for 12 h.

3.2. Short-Term Aging

Short-term aging of the bituminous binders in the vertical rolling thin film oven has been performed under the standard of AASHTO T 240-13 [20], which models the bitumen aging during preparing of an asphalt concrete mix, its transportation, laying, and compaction. The samples of the bituminous binders were in the oven at the temperature of 150 °C for 75 min.

3.3. Long-Term Aging

Long-term aging of the bituminous binders in the special pressure aging vessel has been performed under the standard of ASTM D 6521-08 [21], which models the bituminous binder aging during operation of the asphalt concrete pavement. The samples of the bituminous binders, after the short-term aging, were in the vessel under the pressure of 2070 kPa and at the temperature of 100 °C for 20 h.

3.4. Preparation of Asphalt Concrete Mixes

A preparing of asphalt concrete mixes was performed in a laboratory mixer (Figure 3) of the company InfraTest (Brackenheim, Germany). The mixer with a capacity of 30 L has a constant shaft rotation rate, equal to 60 rotations per minute. Opening and closing of the upper cover of the mixer occurs automatically by an electric engine. The cover has an observation window, which allows observing of the process for mixing. The vessel of the mixer can bend forward by an electric engine to unload the prepared asphalt concrete mix.

Figure 3.

Laboratory mixing device for preparing of asphalt concrete mixes.

Preparing of asphalt concrete mixes (both with neat bitumen and with modified bitumens) has been performed in the following sequence:

- Stone material (crushed stone and sand) was heated in a drying oven up to the temperature of 180 °C.

- The laboratory mixing device was heated up to the temperature of 190 °C and the heated stone material was added in it.

- Mineral powder and bitumen (neat or modified) were gradually added in the stone material.

- Temperature of the prepared asphalt concrete mix was 150–155 °C under the requirements of the standard ST RK 1225 [22].

3.5. Production of Asphalt Concrete Samples

Asphalt concrete samples in the shape of a rectangular prism with dimensions of 5 × 5×50 mm (Figure 4, right) have been prepared in the following way. First, asphalt concrete samples, using the sector compactor (model CRT-RC2S, Cooper, Nottingham, UK) (Figure 5), have been prepared in the shape of a rectangular slab (Figure 4, left) under standard EN 12697-33 [23]. Then asphalt concrete samples have been cut from them in the shape of rectangular prisms.

Figure 4.

Asphalt concrete samples: in the shape of a square slab with dimensions 305 × 305 × 50 mm (left); in the shape of a rectangular prism with dimensions 5 × 5 × 50 mm (right).

Figure 5.

Sector compactor.

3.6. Cyclic Freezing and Thawing

The process of CFT for bituminous binder samples was performed in the following way. Bituminous binder samples having dimensions 6.25 × 12.5 × 125 mm have been placed into a freezing chamber with the temperature of −18 ± 2 °C, and the temperature in the freezing chamber was decreased to −18 ± 2 °C. The samples were kept at the temperature of −18 ± 2 °C for 4 h. Then the samples were taken out of the freezing chamber and thawed in the open air in room conditions (≈20 °C) for the next 4 h. The first set of bituminous binder samples was subjected to 25 cycles of FT, the second one to 50 cycles.

CFT of the asphalt concretes have been performed in the same way, except for the fact that the asphalt concrete samples have been saturated before, and their thawing has been performed in a bath with water at the temperature of +18 ± 2 °C [24]. Asphalt concrete samples were subjected to 50 cycles of FT.

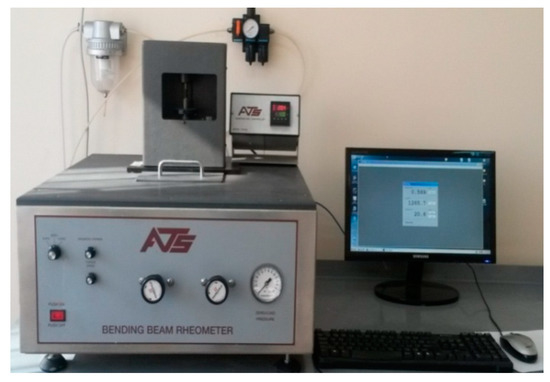

3.7. Bending Beam Rheometer

Testing of the bituminous binders at low temperatures has been performed by bending beam rheometer (BBR) (Figure 6) under the standard of AASHTO T 313-08 [25] after double (short-term and long-term) aging. The samples of the bituminous binders for the tests had the shape of a beam with dimensions of 6.25 × 12.5 × 125 mm. Before testing the samples have been kept at the tested temperature for 60 min. In the beginning of the test the load, equal to 980 mN, is applied automatically for 1 s and it has been kept as the constant one for the following 240 s. The maximum deflection of the middle of the beam has been measured automatically.

Figure 6.

Rheometer with bending beam (BBR).

Maximum stress on the bottom surface of the bituminous beam in its middle has been calculated under the formula:

where is a load, mN; , , are height, width, and length of the beam respectively, mm.

Maximum strain of the bottom surface of the bituminous beam in its middle at the time moment t has been calculated under the formula:

where is the maximum deflection of the middle of the bituminous beam, mm.

The stiffness modulus of the bitumen at the load duration of t has been calculated under the formula:

Bitumen m-value, characterizing stress relaxation rate, has been calculated under formula [26]:

Testing of the bitumens has been performed at the temperatures of −24 °C, −30 °C, and −36 °C. Such temperatures are characteristic for winter climate in many countries including Kazakhstan [27,28,29,30,31].

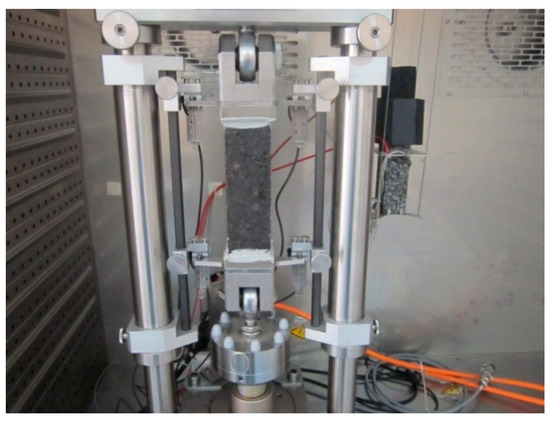

3.8. Tensile Strength of Asphalt Concretes

Testing of asphalt concretes at low temperatures (0 °C, −10 °C, −20 °C, and −30 °C) has been performed under standard [32] in a special device called TRAVIS produced by the company InfraTest (Brackenheim, Germany). Device TRAVIS (Figure 7) represents by itself a thermal chamber with the fixed equipment inside which allows performing the asphalt concrete sample test at direct tension (Figure 8).

Figure 7.

General view of the device for test at direct tension TRAVIS.

Figure 8.

Equipment for testing of asphalt concrete sample at direct tension.

An asphalt concrete sample is deformed with constant rate (1 mm/min) till its failure. A computer fixes stress and strain at the moment of the sample failure.

3.9. Rutting Resistance of Asphalt Concretes

Resistance of the stone mastic asphalt concretes to rutting has been evaluated on Hamburg wheel tracking machine (Cooper, Nottingham, UK) (Figure 9) according to the standard [33]. Asphalt concrete samples had the form of square plate with dimensions 305 × 305 × 50 mm (Figure 4, left). The test temperature was +60 °C and maximal number of wheel passes was 10,000.

Figure 9.

Hamburg wheel tracking machine.

4. Results and Discussion

4.1. Low Temperature Characteristics of Bitumens

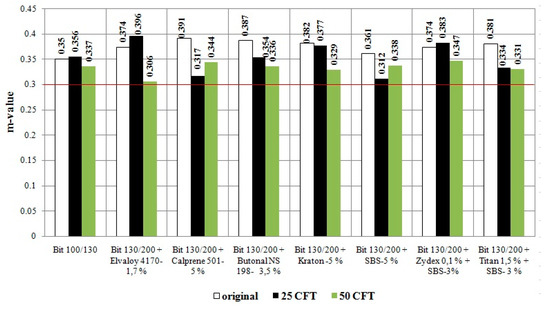

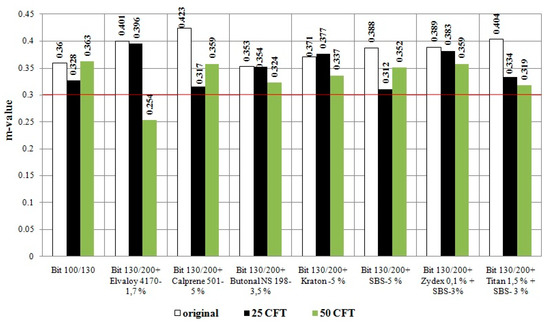

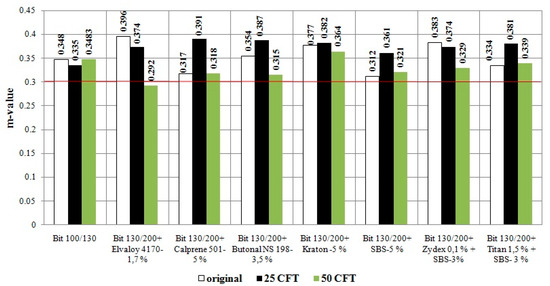

Indicators of low temperature resistance of bitumens stiffness S and m-value at load duration of 60 s, determined on BBR at the temperatures of −24 °C, −30 °C, and −36 °C, are represented in Figure 10, Figure 11, Figure 12, Figure 13, Figure 14 and Figure 15. The Superpave technical specifications require that bituminous binder stiffness at calculated minimal temperature and at load duration of 60 s should not exceed 300 MPa and m-value should not exceed 0.3 [10].

Figure 10.

Bitumens m-value at the temperature of −24 °C.

Figure 11.

Bitumens m-value at the temperature of –30 °C.

Figure 12.

Bitumens m-value at the temperature of –36 °C.

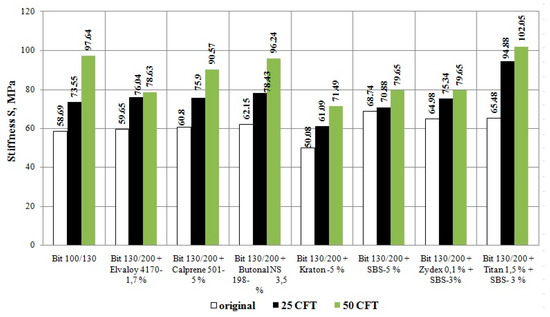

Figure 13.

Bitumens stiffness at the temperature of –24 °C.

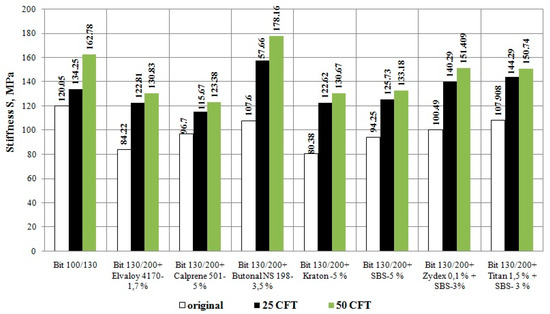

Figure 14.

Bitumens stiffness at the temperature of –30 °C.

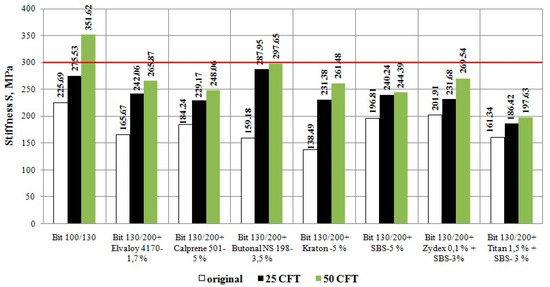

Figure 15.

Bitumens stiffness at the temperature of –36 °C.

It is seen from Figure 10, Figure 11 and Figure 12 that except for the bitumen with polymer Elvaloy after 50 cycles of FT at the temperatures of −30 °C and −36 °C all the considered bitumens satisfy the Superpave requirements. The decrease of bitumen m-value is observed with the number increase of FT cycles. However, noticeable change for the bitumens m-value was not found out depending on a temperature within the considered range of temperature.

Stiffness for all the considered bitumens is considerably increased with the temperature decrease and increase of number for FT cycles (Figure 13, Figure 14 and Figure 15). Only neat bitumen does not satisfy Superpave requirements after 50 cycles of FT at the temperature of −36 °C, all other bitumens have stiffness lower than 300 MPa at all the considered temperatures.

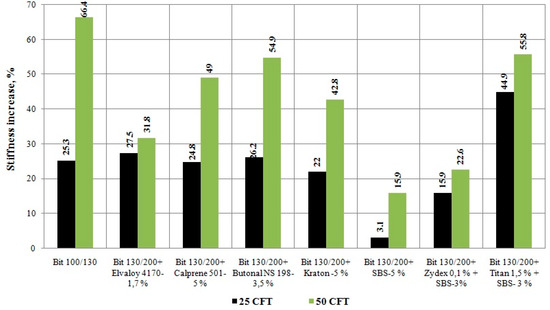

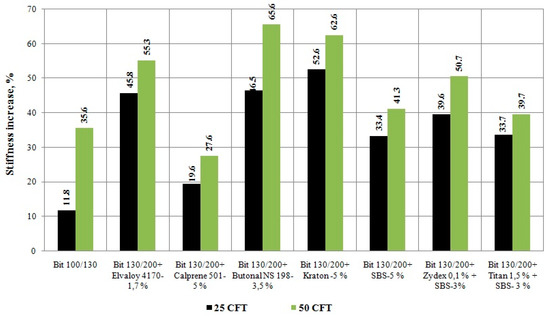

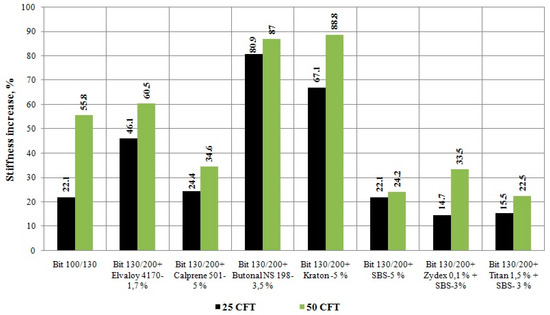

It is clear that an important characteristic for bitumens is the value for its stiffness increase at different negative temperatures after various cycles of FT. Bar charts showing the values of stiffness increase for the considered bitumens are represented in Figure 16, Figure 17 and Figure 18. It is seen that the stiffness of the neat bitumen, the bitumens with polymers Butonal and Titan+SBS has increased after 50 cycles of FT and at the temperature of −24 °C for 66.4%, 54.9%, and 55.8% respectively, and stiffness increase for the bitumens with polymers Butonal and Kraton at the temperature of −36 °C was 87.0% and 88.8% respectively.

Figure 16.

Bitumens stiffness increase after 25 and 50 cycles of FT at the temperature of −24°C.

Figure 17.

Bitumens stiffness increase after 25 and 50 cycles of FT at the temperature of –30 °C.

Figure 18.

Bitumens stiffness increase after 25 and 50 cycles of FT at the temperature of –36 °C.

The following binders are found as the most resistant to cyclic FT: bitumen with polymer SBS at the temperature of −24 °C (stiffness increase is 3.1% and 15.9% respectively); bitumen with polymer Calprene at the temperature of −30 °C (19.6% and 27.6% respectively); bitumen with polymers Calprene, SBS, Zydex+ SBS, and Titan+SBS at the temperature of −36 °C (from 14.7% to 34.6%).

Thus, when selecting a suitable bituminous binder considering climatic conditions it is necessary to take into account as the number of FT cycles as well as a characteristic low temperature.

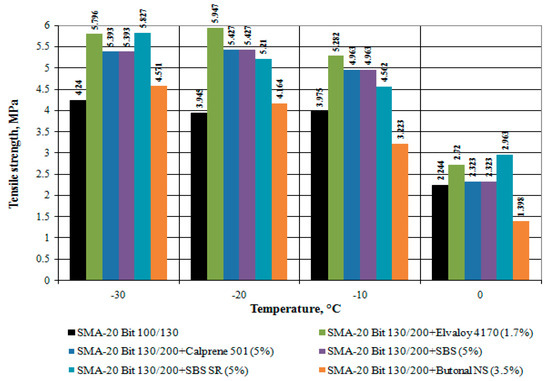

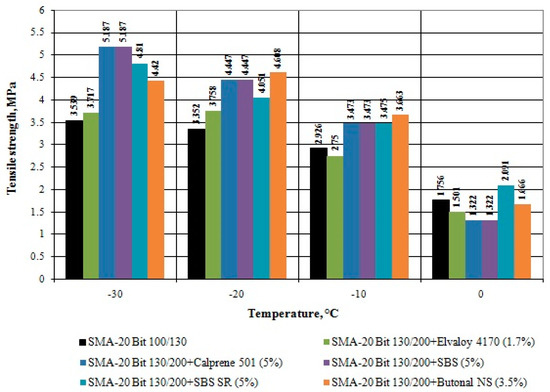

4.2. Low Temperature Strength of Asphalt Concretes

Figure 19 and Figure 20 represent bar charts showing the asphalt concrete strength at the temperatures of 0 °C, −10 °C, −20 °C, and −30 °C in the initial condition and after 50 cycles of FT. Comparison of bar charts shows that the strength is decreased practically for all the asphalt concretes at all the considered temperatures after 50 cycles of FT. The value of strength decrease can reach 48%.

Figure 19.

Strength of the stone mastic asphalt concretes in initial condition at low temperatures.

Figure 20.

Strength of the stone mastic asphalt concretes after 50 cycles of freezing and thawing at low temperatures.

It is also clearly seen that modification with polymers increases essentially the asphalt concrete strength as in the initial condition as well as after FT, especially at considerably low temperatures (−20 °C, −30 °C). For example, the strength of the asphalt concrete with polymer Elvaloy at the temperature of −20 °C is more for 50.6% compared with the asphalt concrete with neat bitumen in the initial condition, and after 50 cycles of FT the strength of the asphalt concrete with polymer Calprene at the temperature of −30 °C is more than 46.6%.

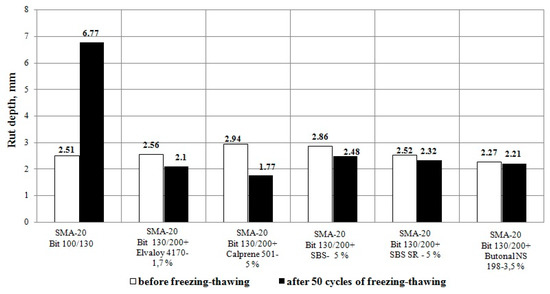

4.3. Rutting Resistance

Rut depths formed on the surface of the asphalt concrete samples after 10,000 wheel passes are represented in Figure 21. It is seen that cyclic FT decreases essentially the rutting resistance of the asphalt concrete with neat bitumen: after 50 cycles of FT the rut value has been increased nearly three times (269.7%) after 10,000 wheel passes. Modification with polymers gives a large positive effect: all types of the stone mastic asphalt concretes modified with polymers after 50 cycles of FT showed rutting resistance more than the relevant asphalt concretes in the initial condition (before FT).

Figure 21.

Rut depth on the samples of stone mastic asphalt concretes after 10,000 wheel passes.

5. Conclusions

1. Cyclic freezing and thawing decreases the relaxing ability of all the considered bitumens (both the neat bitumen and the modified bitumens). For example, the authors observed that after 50 cycles of FT, all binders satisfied the Superpave specification requirement at −24, −30, and −36 degrees by having m-value greater than 0.3. The Elvaloy polymer modified binder was the only exception as its m-value at −30 and −36 fell below the 0.3 limit.

2. Stiffness S of all the considered bitumens is essentially increased with the temperature decrease and the increase of FT cycles number. For example, the stiffness of the neat bitumen, the bitumens with polymers Butonal and Titan+SBS has increased after 50 cycles of FT and at the temperature of −24 °C for 66.4%, 54.9%, and 55.8% respectively, and stiffness increase for the bitumens with polymers Butonal and Kraton at the temperature of −36 °C was 87.0% and 88.8% respectively. The following binders have been found out as the most resistant to cyclic FT: at the temperature of –24 °C—bitumen with SBS polymer (stiffness increase after 25 and 50 cycles for 3.1% and 15.9% respectively); at the temperature of –30 °C—bitumen with Calprene polymer (19.6% and 27.6% respectively); at the temperature of –36 °C—bitumen with polymers Calprene, SBS, Zydex+ SBS and Titan+SBS (from 14.7% to 34.6%).

Thus, when selecting a suitable bituminous binder taking into account the climatic conditions it is necessary to consider both FT cycles number and the characteristic low temperature.

3. Practically all asphalt concretes (both with the use of the neat bitumen and the modified bitumens) at all the considered temperatures after 50 cycles of FT tensile strength is decreased. The strength is decreased by 48% for specific types of asphalt concretes.

Modification with polymers increases essentially the asphalt concrete strength both in the initial condition and after FT, especially at the considerably low temperatures (−20 °C, −30 °C). For example, addition of polymer Elvaloy increases the strength of the asphalt concrete for 50.6% at the temperature of −20 °C in the initial condition (before CFT). And the addition of polymer Calprene increases strength of the asphalt concrete for 46.6% at the temperature of –30 °C after 50 cycles of FT.

4. Cyclic FT decreases essentially the ability of the asphalt concrete with rutting resistance: In the original binder the rut depth increased after 50 cycles almost three times (269.7%) after 10,000 wheel passes. Modification with polymers gives a large positive effect: all types of stone mastic asphalt concretes modified with polymers after 50 cycles of FT have shown the rutting resistance more than the relevant asphalt concretes in the initial condition (before FT).

Author Contributions

B.T., C.R., G.I. and E.A. conceived and designed the experiments; B.T., C.R., G.I. and E.A. performed the experiments; B.T., C.R., G.I. and E.A. analysed the data; B.T., C.R., G.I. and E.A. contributed reagents/materials/analysis tools; B.T., C.R., G.I. and E.A. wrote the paper.

Funding

This research was funded by the Road Committee of the Ministry for Investments and Development of the Republic of Kazakhstan (Agreement No. 36 dated July 21, 2016).

Acknowledgments

This research is supported by the Road Committee of the Ministry for Investments and Development of the Republic of Kazakhstan (Agreement No. 36 dated July 21, 2016).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Berthier, J. La route face au problem dugel et du degel. Laboratoire Central des Ponts et Chaussees. Bulletin de Liaison 1970, 43, 55–68. [Google Scholar]

- Mauduit, V. Degration precessus des couches de roullement bitumineuses a sortie des hivers. RGRA 2007, 859, 99–104. [Google Scholar]

- MS-4. The Asphalt Handbook, 7th ed.; Asphalt Institute: Lexington, MA, USA, 2008. [Google Scholar]

- Raspopov, N.M. Investigation of frost stability of asphalt concrete pavement. In Proceedings of Highway Research Institute; SoyuzdorNII: Moscow, Russia, 1940; pp. 134–158. [Google Scholar]

- Ozgan, E.; Serin, S. Investigation of certain characteristics of asphalt concrete exposed to freeze-thaw cycles. Cold Reg. Sci. Technol. 2013, 85, 131–136. [Google Scholar] [CrossRef]

- Gong, X.; Romero, P.; Dong, Z.; Sudbury, D.S. The effect of freeze-thaw cycle on the low-temperature properties of asphalt fine aggregate matrix utilizing bending beam rheometer. Cold Reg. Sci. Technol. 2016, 125, 101–107. [Google Scholar] [CrossRef]

- Tarefder, R.; Faisal, H.; Barlas, G. Freeze-thaw effects on fatigue life of hot mix asphalt and stiffness of asphalt binder. Cold Reg. Sci. Technol. 2018, 153, 197–204. [Google Scholar] [CrossRef]

- Merbouh, M. Effect of thermal cycling on the creep-recovery behavior of road bitumen. Energy Procedia 2012, 18, 1106–1114. [Google Scholar] [CrossRef]

- Glaoui, B.; van de Ven, M.; Merbouh, M.; Chailleux, E.; Youcefi, A. Thermal fatigue with freeze-thaw cycles of polymer modified bitumen. J. Appl. Sci. 2011, 11, 1012–1018. [Google Scholar] [CrossRef]

- El-Hakim, M.; Tighe, S.L. Impact of freeze-thaw cycles on mechanical properties of asphalt mixtures. Transp. Res. Rec. 2014, 2444, 20–27. [Google Scholar] [CrossRef]

- Wei, S.; Ning, L.; Biao, M.; Junping, R.; Hainian, W.; Jian, H. Impact of freeze-thaw cycles on compressive characteristics of asphalt mixture in cold regions. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2015, 30, 703–709. [Google Scholar]

- Xu, H.; Guo, W.; Tan, Y. Permeability of asphalt mixtures exposed to freeze-thaw cycles. Cold Reg. Sci. Technol. 2016, 123, 99–106. [Google Scholar] [CrossRef]

- Badeli, S.; Carter, A.; Dore, G. Effect of laboratory compaction on the viscoelastic characteristics of an asphalt mix before and after rapid freeze-thaw cycles. Cold Reg. Sci. Technol. 2018, 146, 98–109. [Google Scholar] [CrossRef]

- Lamothe, S.; Perraton, D.; Di Benedetto, H. Contraction and expansion of partially saturated hot mix asphalt samples exposed to Freeze-Thaw cycles. Road Mater. Pavement Des. 2015, 16, 277–299. [Google Scholar] [CrossRef]

- Badeli, S.; Carter, A.; Doré, G. The importance of asphalt mixture air voids on the damage evolution during freeze-thaw cycles. In Proceedings of the Conference: Canadian Technical Asphalt Association, Banff, AB, USA, 13–16 November 2016. [Google Scholar]

- Badeli, S.; Carter, A.; Doré, G.; Saliani, S. Evaluation of the durability and the performance of an asphalt mix involving Aramid Pulp Fiber (APF): Complex modulus before and after freeze-thaw cycles, fatigue, and TSRST tests. Constr. Build. Mater. 2018, 174, 60–71. [Google Scholar] [CrossRef]

- ST RK 1373-2013. Bitumens and Bituminous Binders. Oil Road Viscous Bitumens; Technical Specifications. Astana, Kazakhstan, 2013. Available online: http://infozhol.kad.org.kz/ (accessed on 29 January 2019).

- ST RK 2534-2014. Bitumens and Bituminous Binders. Oil Modified Road Bitumens; Technical Specifications. Astana, Kazakhstan, 2014. Available online: http://infozhol.kad.org.kz/ (accessed on 29 January 2019).

- GOST 31015-2002. Asphalt Concrete Mixes and Stone Mastic Asphalt Concretes; Technical Specifications. Moscow, Russia, 2002. Available online: http://infozhol.kad.org.kz/ (accessed on 29 January 2019).

- AASHTO T. 240-13. Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film oven Test); Washington, DC, USA, 2013.

- ASTM D. 6521-08. Standard Practice for Accelerated Aging of Asphalt Binder Using Pressurized Aging Vessel (PAV); Washington, DC, USA, 2008.

- ST RK 1225-2013. Hot Mix Asphalt for Roads and Airfields. Technical Specifications; Astana, Kazakhstan, 2013. Available online: http://infozhol.kad.org.kz/ (accessed on 29 January 2019).

- European Committee for Standardization. EN 12697-33. Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Part 33: Specimen Prepared by Roller Compactor; European Committee for Standardization: Brussels, Belgium, 2003. [Google Scholar]

- ST RK 1218-2003. Materials Based on Organic Binders for Road and Airfield Construction; Test Methods. Astana, Kazakhstan, 2003. Available online: http://infozhol.kad.org.kz/ (accessed on 29 January 2019).

- AASHTO T. 313-08. Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). 2008.

- Asphalt Institute. Superpave Series No. 1. 2003. Performance Graded Asphalt Binder Specification and Testing; Asphalt Institute: Lexington, MA, USA, 2003. [Google Scholar]

- Teltayev, B.; Kaganovich, E. Bitumen and asphalt concrete requirements improvement for the climatic conditions of the Republic of Kazakhstan. In Proceedings of the 24th World Road Congress, Mexico City, Mexico, 26–30 September 2011; pp. 1–9. [Google Scholar]

- R. RK 218-96-2013. Zoning of Kazakhstan Territory According to Characteristic Temperatures of Asphalt Concrete Pavements; Astana, Kazakhstan, 2013. Available online: http://infozhol.kad.org.kz/ (accessed on 29 January 2019).

- Teltayev, B.; Radovskiy, B. Low Temperature Cracking Problem for Asphalt Pavements in Kazakhstan. In Proceedings of the 8th RILEM International Conference on Mechanisms of Cracking and Debonding in Pavements, Paris, France, 7–9 June 2016; Volume 1, pp. 139–145. [Google Scholar]

- Teltayev, B.; Radovskiy, B. Predicting thermal cracking of asphalt pavements from bitumen and mix properties. Road Mater. Pavement Des. 2017, 1832–1847. [Google Scholar] [CrossRef]

- Radovskiy, B.; Teltayev, B. Viscoelastic Properties of Asphalts Based on Penetration and Softening Point; Springer International Publishing AG: Cham, Switzerland, 2018. [Google Scholar]

- EN 12697-46 Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Part 46: Low Temperature Cracking and Properties by Uniaxial Tension Tests. 2004.

- ST RK EN 12697-22 Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Part22. Determining of Forming Rut Depth on Asphalt Concrete Samples. Astana, Kazakhstan, 2012.

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).