Multi-Criteria Analysis of Potential Applications of Waste from Rock Minerals Mining

Abstract

:Featured Application

Abstract

1. Introduction

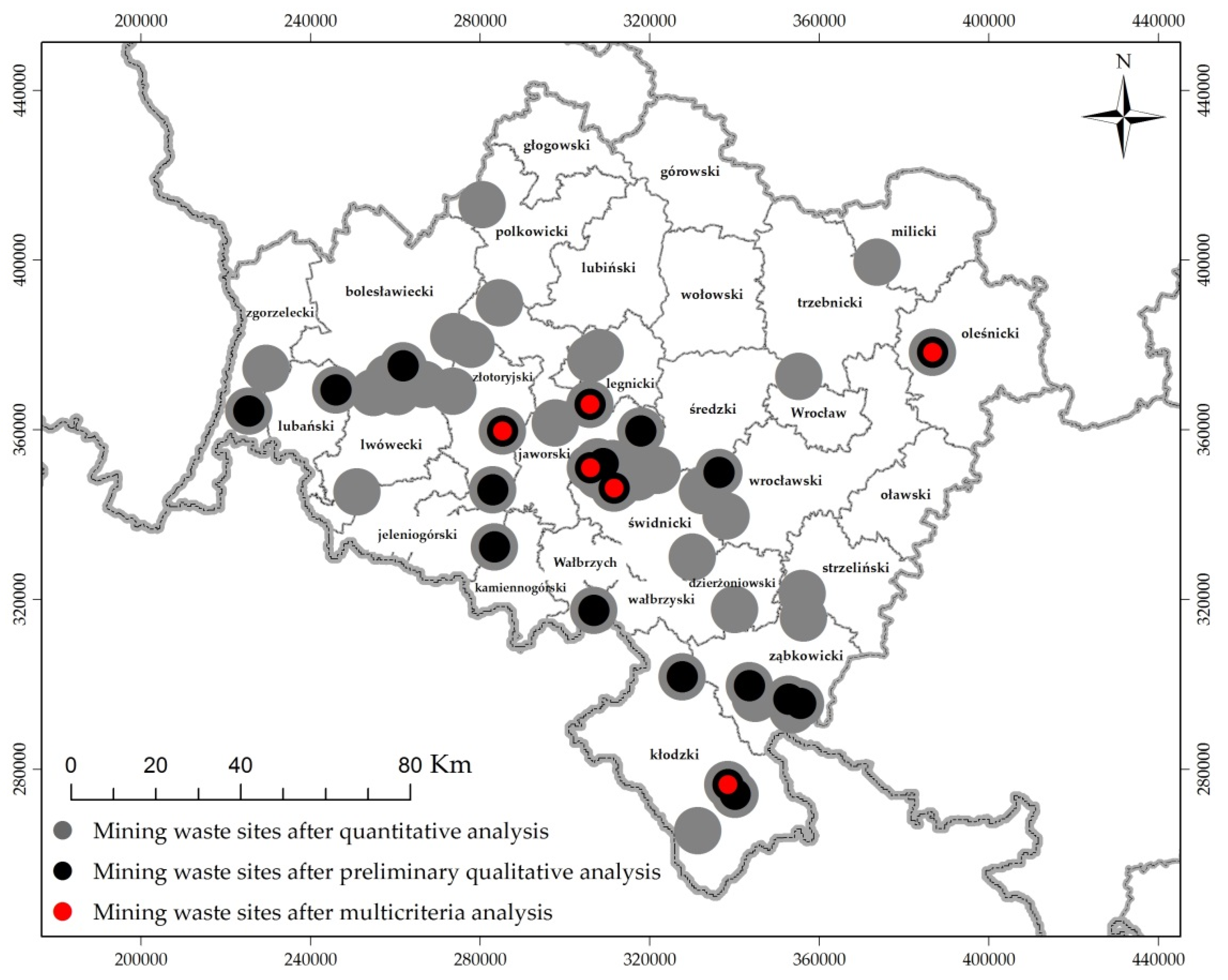

2. Preliminary Qualitative Analysis

- Industrial use of clays: the clays mainly consist of loamy minerals, such as kaolinite, illinite, montmorillonite, and other aluminosilicates, as well as other various components, e.g., quartz grains, apatite, granite, iron hydroxide, etc. The potential uses include: multifunctional sorbent-fertilizers designed for the reclamation of sands [19,20], feed additives, which constitute an important group of preparations in breeding, such as peat humus, zeolites, kaolins, bentonites, and others having a positive effect on production indicators [21,22], insecticides, and fungicides in order to increase the effectiveness of pesticides [23,24,25,26], food industry use of bentonite clay for storing fruit and vegetables in households [27], and environmental protection use of clay as an absorbent to remove heavy metal ions and purification of industrial and drinking water [23,28].

- Rock meals: basalt, granite and serpentine materials from mining waste can be used to produce rock meals, which are created from grinding of the rock. Such meals can be used to improve soil properties by enriching it with minerals, such as calcium, potassium, and magnesium. E.g., comprehensive “remineralisation” of the soil substrate with basalt meal [29]. Granite meals are useful on heavy soils as well as light, sandy soils, which are poor in loamy minerals because they increase the water capacity of soils, particularly in the humus layer and include many necessary macro-, micro-, and ultra-microelements, which are necessary for the proper growth of plants. In addition, these rock meal plays a sanitary role, preventing the spread of diseases and pests. The serpentinite meal can provide the soils with many microelements, among others iron and phosphorus [30,31].

- For the production of light, inferior. or hydro-technical aggregates: use of granite waste for the production of aggregates, which allowed to strengthen the strength of aggregates produced and eliminate flux and apply it to various structures (for example, stabilization of landslips and slopes, strengthening of underwater slopes, etc.) [32].

- As a granulate supporting cultivation of plants: granulate contains rock siliceous meal selected from the group of basalt, feldspar, or amphibolite meals. The granulate remains on the soil in unchanged form until atmospheric precipitation, and then it gradually disintegrates and returns to silty form and gradually penetrates into the soil structure [33].

- As fillers for thermoplastics: in the scope of this technology, the gabbro waste can be used as an attractive solution for obtaining inexpensive composites with good thermal and mechanical properties [34].

- Environmental criteria:

- Criterion K1—waste category—dangerous or inert,

- Criterion K2—location in protected natural areas and Main Underground Water Reservoirs,

- Economic criteria:

- Criterion K3—raw materials that are essential for the economy,

- Criterion K4—occurrence above 10 000 thousand Mg,

- Criterion K5—occurrence of loamy raw materials (use e.g., in agriculture or in the food industry),

- Criterion K6—occurrence of raw materials as a source of potassium—meals and small granite fractions,

- Criterion K7—occurrence of raw materials as a source of magnesium—serpentinite, basalt, syenite.

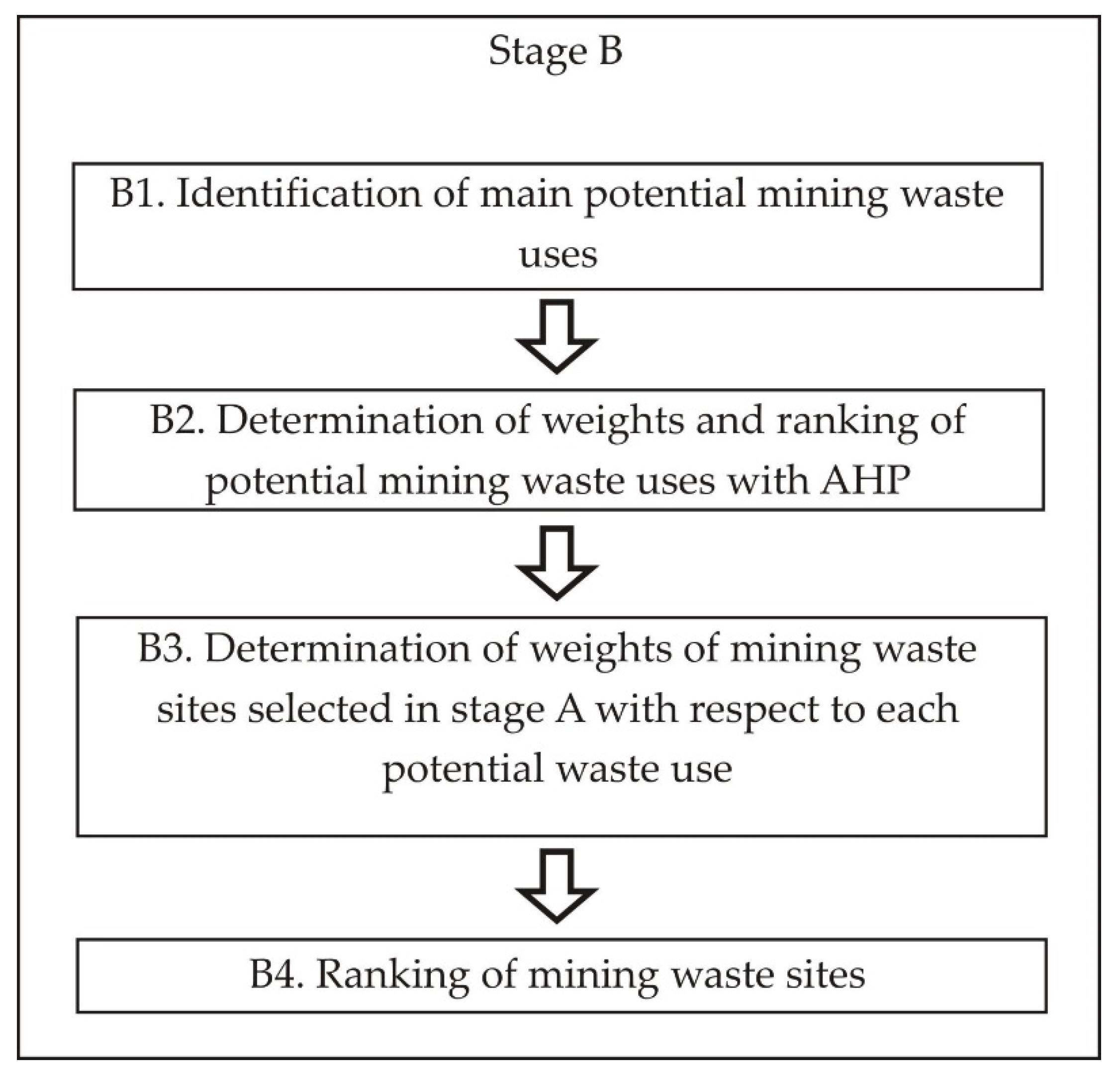

3. Methodology

- a)

- developing the model,

- b)

- deriving weights for the criteria,

- c)

- checking the consistency,

- d)

- deriving local preferences for the alternatives,

- e)

- deriving overall priorities and making the final judgement.

- to construct a n × n pairwise comparison matrix m for analysed criteria, where aij denotes entry in the i th row and the j th column of matrix m,

- aij states the preference score of criterion i to criterion j using the nine-integer value scale suggested by Saaty [37], where:

- ▪

- 1 denotes that criteria i and j are of equal importance,

- ▪

- 3 is moderate importance of i over j,

- ▪

- 5 is strong importance of i over j,

- ▪

- 7 is very strong importance of i over j,

- ▪

- 9 denotes that criterion i is extremely more important than criterion j, and

- ▪

- 2, 4, 6, and 8 are intermediate, optional, values.

- the entries of preference score aij and aji must satisfy the following constraint of Equation (1):

- to establish a normalized pairwise comparison matrix m, the sum of each column must be equal to 1. This can be obtained using Equation (2) to calculate for each entry of the matrix [38],

- to obtain the relative weights, the average across rows is computed using the Equation (3); for each element, the relative weight is within the range of 0 to 1 and a higher weight shows a greater influence of a given element (criterion) [37],

- calculate the eigenvector and the maximum eigenvalue for matrix m,

- next, calculate an approximation to the Consistency Index (CI) according to Equation (4):where

- λmax is the maximum eigenvalue of the comparison matrix,

- n is the number of criteria.

- RI is the random consistency index that varies according to the number of criteria in a comparison (n).

- Cwi is the criterion weight,

- Awi is the preference of alternative relative to that criterion,

- n is the number of criteria.

4. Results

- Use in road and railroad construction,

- Use in construction,

- Use in agriculture,

- Use for reclamation/development of post-mining areas,

- Use in the food industry,

- Storage of mining waste.

4.1. Results for Deriving Weights for the Criteria

4.2. Results for Deriving Local Preferences for the Alternatives

5. Discussion and Recommendations Resulting from the Performance of Multicriteria Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Generation of Waste by Economic Activity. Mining and Quarrying. EUROSTAT. Available online: https://ec.europa.eu/eurostat/tgm/table.do?tab=table&plugin=1&language=en&pcode=ten00106 (accessed on 11 October 2018).

- Duda, M. Circular economy—A contribution to in-depth discussion. Wsei Sci. J. Ser. Econ. 2017, 13–14, 45–57. [Google Scholar]

- Zhu, Y.; Dhu, D. A revised circular economy model and its application based on objectivity-process-subjectivity analysis. Shanghai Environ. Sci. 2007, 26, 14–18. [Google Scholar]

- Kaźmierczak, U. Impact of rock mining on the income of the commune budgets. Surf. Min. 2015, 56, 36–42. (In Polish) [Google Scholar]

- Blachowski, J.; Kaźmierczak, U.; Górniak Zimroz, J. Spatial and Quantitative Analysis of Waste from Rock Raw Minerals Mining: A Case Study of Lower Silesia Region in Poland. Sustainability 2018, 10, 4493. [Google Scholar] [CrossRef]

- Kaźmierczak, U.; Blachowski, J.; Górniak Zimroz, J.; Wirth, H. Quantitative and qualitative research on the wast from the mining of rock raw materials in Lower Silesia. Minerals 2018, 8, 375. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; Mcgraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Vaidya, O.S.; Kumar, S. Analytic hierarchy process: An overview of applications. Eur. J. Oper. Res. 2006, 169, 1–29. [Google Scholar] [CrossRef]

- Donevska, K.R.; Gorsevski, P.V.; Jovanovski, M.; Pesevski, I. Regional non-hazardous landfill site selection by integrating fuzzy logic, AHP and geographic information systems. Environ. Earth Sci. 2012, 67, 121–131. [Google Scholar] [CrossRef]

- Aydi, A.; Zairi, M.; Dhia, H.B. Minimization of environmental risk of landfill site using fuzzy logic, analytical hierarchy process, and weighted linear combination methodology in a geographic information system environment. Environ. Earth Sci. 2013, 68, 1375–1389. [Google Scholar] [CrossRef]

- Felicori, T.C.; Marques, E. Multicriteria decision analysis applied in the selection of suitable areas for disposal of solid waste in Zona da Mata, minas Gerais, Brazil. J. Solid Waste Technol. Manag. 2017, 43, 47–64. [Google Scholar] [CrossRef]

- Dimopoulou, E.; Tolidis, K.; Orfanoudakis, Y.; Adam, K. Spatial multi-criteria decision analysis for site selection of sustainable stone waste disposal. Fresenius Environ. Bull. 2013, 22. [Google Scholar]

- Shahba, S.; Arjmandi, R.; Monavari, M.; Ghodusi, J. Application of multi-attribute decision-making methods in SWOT analysis of mine waste management (case study: Sirjan’s Golgohar iron mine, Iran). Resour. Policy 2017, 51, 67–76. [Google Scholar] [CrossRef]

- Milentijevic, G.; Nedeljkovic, B.; Lekic, M.; Nikic, Z.; Ristovic, I.; Djokic, J. Application of a Method for Intelligent Multi-Criteria Analysis of the Environmental Impact of Tailing Ponds in Northern Kosovo and Metohija. Energies 2016, 9, 935. [Google Scholar] [CrossRef]

- Safari, M.; Ataei, M.; Khalokakaie, R.; Karamozian, M. Mineral processing plant location using the analytic hierarchy process—A case study: The Sangan iron ore mine (phase 1). Min. Sci. Technol. 2010, 20, 691–695. [Google Scholar] [CrossRef]

- Betrie, G.D.; Sadiq, R.; Morin, K.A.; Tesfamariam, S. Selection of remedial alternatives for mine sites: A multicriteria decision analysis approach. J. Environ. Manag. 2013, 119, 36–46. [Google Scholar] [CrossRef] [PubMed]

- Kozioł, W.; Piotrowski, Z.; Pomykała, R.; Machniak, Ł.; Baic, I.; Witkowska-Kita, B.; Lutyński, A.; Blaschke, W. Application of Analytic Hierarchy Process (AHP) for Multicriteria Assessment of the Technologies of Waste from Coal Mining Management Innovation. Annu. Set Environ. Prot. 2011, 13, 1619–1634, (In Polish with English Summary). [Google Scholar]

- Radwanek-Bąk, B.; Galos, K.; Nieć, M. Pivotal, strategic and critical mineral raw materials for the Polish economy. Geol. Overv. 2018, 66, 153–159. (In Polish) [Google Scholar]

- Bolewski, A.; Michałek, Z.; Skawina, T.; Kamieniecki, F.; Tymiński, S.; Polak, T.; Greszta, J. The Method of Reclamation of Post-Industrial Wastelands and Sand Dunes and Improvement of the Properties of Light and Peat Soils. PL Patent description No 53762, 10 November 1964. [Google Scholar]

- Bolewski, A.; Michałek, Z.; Skawina, T.; Kamieniecki, F.; Tymiński, S. The method of obtaining fertilizer with mineral sorbent. PL Patent description No 53142, 20 February 1965. [Google Scholar]

- Dobrzański, Z.; Górecki, H.; Kołacz, R.; Górecka, H.; Rudzik, R. Application of Certain Aluminosilicates in the Feed and Bedding in the Scope of Poultry Farming; Scientific Works; The Institute of Inorganic Technologies and Mineral Fertilizers, Wroclaw University of Technology: Wroclaw, Poland, 1994; pp. 143–148. (In Polish) [Google Scholar]

- Tronina, S.; Augustyn, D.; Dobrzański, Z.; Jamroz, D.; Kukla, S.; Mazurkiewicz, M. Feed Additive for Poultry, Especially for Broiler Chickens and Forest Hens. PL Patent 172908, 3 March 1994. (In Polish). [Google Scholar]

- Savic, I.; Stojiljkovic, S.; Savic, S.; Gajic, D. Industrial application of clays and clay minerals. In Clays and Clay Minerals: Geological Origin, Mechanical Properties and Industrial Applications; Wesley, L.R., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2014; pp. 379–402. [Google Scholar]

- Abd El-Aziz, S.E. Evaluation of particle films as a physical control method for controlling melon ladybird, Epilachna chrysomelina (F.) (Coleoptera: Coccinellidae) on cantaloupe plants. Bull. Entomol. Soc. Egypt 2003, 29, 21–34. [Google Scholar]

- Abd El-Aziz, S.E. Kaolin & Bentonite clays particle films as a new trend for suppression of chewing and sucking insects of cotton plants. Arab. Univ. J. Agric. Sci. 2003, 11, 373–385. [Google Scholar]

- Abd El-Aziz, S.E. Laboratory and field Evaluation of Kaolin and Bentonite particle films against onion thrips, Thrips tabaci (Lind.) (Thysanoptera: Thripidae) on onion plants. J. Appl. Sci. Res. 2013, 9, 3141–3145. [Google Scholar]

- Al-Arfaj, A.A.; Murugan, A.M.; Chinnathambi, A.; Al-Hazmi, M.I. Cost-effective bentonite clayed pyramid technologies for household fruits and vegetables siorage. J. Food Agric. Environ. 2013, 11, 175–180. [Google Scholar]

- Kłapyta, Z. Montmorillonite rocks of the upper silesian coal basin. In Mineral Polish Sorbents; Kłapyła, Z., Żabiński, W., Eds.; Uczelnianie Wydawnictwa Naukowo-Dydaktyczne: Kraków, Poland, 2008; pp. 20–30. ISBN 9788374641074. (In Polish) [Google Scholar]

- Zagożdżon, P.P. Basalt powder in agricultural use. Min. Sci. 2008, 123, 133–142. (In Polish) [Google Scholar]

- Heflik, W. On the possibilities of using serpentinites. Pol. Stone Mag. 2015, 4, 66–67. (In Polish) [Google Scholar]

- Bolewski, A.; Skawina, T. An Attempt to Use Montmorillonite Rocks for the Reclamation of Sands; Polish Academy of Sciences Branch in Krakow, Commission of Mineralogical Sciences, Geological Publishers: Warszawa, Poland, 1972; pp. 1–68. (In Polish) [Google Scholar]

- Kukielska, D.; Cebra, P. Development of granite waste. Min. Aggreg. 2018, 2, 93–97. (In Polish) [Google Scholar]

- Derkowska-Sitarz, M.; Zagozdzon, K. Granules Supporting the Cultivation of Plants and the Method of its Production. PL Patent 210673, 14 February 2011. (In Polish). [Google Scholar]

- Czycz, D.; Kędziora, G.; Steller, R.; Pigłowski, J.; Pawlaczyk, S.; Poderski, R.; Dębiński, K. Properties of thermoplastics filled with powder of igneous rock Gabro. In Proceedings of the European Advanced Materials Congress, Stockholm, Sweden, 22–24 August 2017; Proceedings and Abstracts Book. pp. 410–411. [Google Scholar]

- Goepel, K.D. Implementing the Analytic Hierarchy Process as a Standard Method for Multi-Criteria Decision Making In Corporate Enterprises—A New AHP Excel Template with Multiple Inputs. In Proceedings of the International Symposium on the Analytic Hierarchy Process, Kuala Lumpur, Malaysia, 23–26 June 2013. [Google Scholar]

- Mu, E.; Pereyra-Rojas, M. Practical Decision Making. Briefs in Operations Research; Springer: Berlin, Germany, 2017; pp. 1–120. [Google Scholar] [CrossRef]

- Saaty, T.L. Relative Measurement and its Generalization in Decision Making Why Pairwise Comparisons are Central in Mathematics for the Measurement of Intangible Factors the Analytic Hierarchy/Network Process. Rev. Real Acad. Cienc. Exactas Fis. 2008, 102, 251–318. [Google Scholar] [CrossRef]

- Dogan, H.A.; Dodd, F.J. A note on Saaty’s random indexes. Math. Comput. Model. 1991, 15, 135–137. [Google Scholar] [CrossRef]

| Rank | Mining Site | Mineral | Weighted Score |

|---|---|---|---|

| 1. | Krzeniów | basalt | 2.6542 |

| 2. | Lubień | basalt | 2.3808 |

| 3. | Grabina Śląska-Kam. 15/27 | granite | 2.0890 |

| 4. | Gniewków | granite | 1.9811 |

| 5. | Boguszyce | sands and gravels | 1.9298 |

| 6. | Romanowo Górne | marble | 1.9022 |

| 7. | Rogoźnica II | granite | 1.8732 |

| 8. | Byczeń I | sands and gravels | 1.8722 |

| 9 | Stróża Górna II | sands and gravels | 1.8722 |

| 10. | Sulików | basalt | 1.8640 |

| 11 | Słupiec-Dębówka | gabbro | 1.8640 |

| 12 | Janina I | sandstone | 1.7326 |

| 13 | Rybnica Leśna | melaphyre | 1.6864 |

| 14 | Doboszowice I | gneiss | 1.6564 |

| 15 | Radostów Średni II, III | sands and gravels | 1.6564 |

| 16 | Braszowice | gabbro | 1.6482 |

| 17 | Jenków | schist | 1.5209 |

| 18 | Nowy Waliszów – soczewka C | marble | 1.5168 |

| 19. | Połom | limestone | 1.5168 |

| 20. | Rędziny | dolomite | 1.4892 |

| Position | Criterion Name | Weight [%] |

|---|---|---|

| 1. | Use in road and railroad construction | 32.6 |

| 2. | Use in construction | 25.0 |

| 3. | Use in agriculture | 15.2 |

| 4. | Use for reclamation/development of post-mining areas | 15.0 |

| 5. | Use in the food industry | 9.2 |

| 6. | Storage of mining waste | 2.9 |

| Alternatives (Waste Sites) | Storage | Reclamation/Development | Agriculture | Food Industry | Road/R-Road Construction | Construction |

|---|---|---|---|---|---|---|

| Site 1. Krzenów | 0.058 | 0.097 | 0.242 | 0.025 | 0.211 | 0.149 |

| Site 2. Lubień | 0.197 | 0.136 | 0.093 | 0.260 | 0.067 | 0.080 |

| Site 3. Grabina Śl. | 0.143 | 0.262 | 0.258 | 0.111 | 0.308 | 0.309 |

| Site 4. Gniewków | 0.136 | 0.206 | 0.276 | 0.182 | 0.287 | 0.318 |

| Site 5. Boguszyce | 0.163 | 0.171 | 0.070 | 0.192 | 0.063 | 0.073 |

| Site 6. Romanowo | 0.303 | 0.128 | 0.061 | 0.230 | 0.064 | 0.072 |

| Position | Alternatives (Waste Sites) | Overall Priority [%] |

|---|---|---|

| 1. | Site 3. Grabina Śl. | 27.1 |

| 2. | Site 4. Gniewków | 26.7 |

| 3. | Site 1. Krzeniów | 16.1 |

| 4. | Site 2. Lubień | 10.6 |

| 5. | Site 5. Boguszyce | 9.8 |

| 6. | Site 6. Romanowo G. | 9.7 |

| Name of the Mining Plant | Waste | Hierarchy of Potential Use |

|---|---|---|

| Grabina Śl. | weathered granite | for the manufacture of hydro-technical stones for the manufacture of light aggregates for the manufacture of aggregates of the inferior quality granite rock meal—for improvement of soil properties |

| clay | sorbent-fertilizer of montmorillonite rocks for reclamation use of bentonite for soil fertilization use of kaolin as a feed additive use of bentonite clay in the food industry (for storing fruits and vegetables) | |

| Gniewków | granite saprolite | for the manufacture of light aggregates granite rock meal—for improvement of soil properties for the manufacture of light aggregates |

| clay | use of bentonite for soil fertilization use of kaolin as a feed additive sorbent-fertilizer of montmorillonite rocks for reclamation use of bentonite clay in the food industry (for storing fruits and vegetables) | |

| Krzeniów | gangue with overgrowths of weathered basalt basalt-fraction 0–8mm | rock (basalt meal) for improvement of soil properties |

| Lubień | clay | use of bentonite clay in the food industry (for storing fruits and vegetables) sorbent-fertilizer of montmorillonite rocks for reclamation use of bentonite for soil fertilization use of kaolin as a feed additive |

| Boguszyce | clay | use of bentonite clay in the food industry (for storing fruits and vegetables) sorbent-fertilizer of montmorillonite rocks for reclamation use of bentonite for soil fertilization use of kaolin as a feed additive |

| Romanowo Górne | overburden | use of bentonite clay in the food industry (for storing fruits and vegetables) sorbent-fertilizer of montmorillonite rocks for reclamation use of bentonite for soil fertilization use of kaolin as a feed additive |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaźmierczak, U.; Blachowski, J.; Górniak-Zimroz, J. Multi-Criteria Analysis of Potential Applications of Waste from Rock Minerals Mining. Appl. Sci. 2019, 9, 441. https://doi.org/10.3390/app9030441

Kaźmierczak U, Blachowski J, Górniak-Zimroz J. Multi-Criteria Analysis of Potential Applications of Waste from Rock Minerals Mining. Applied Sciences. 2019; 9(3):441. https://doi.org/10.3390/app9030441

Chicago/Turabian StyleKaźmierczak, Urszula, Jan Blachowski, and Justyna Górniak-Zimroz. 2019. "Multi-Criteria Analysis of Potential Applications of Waste from Rock Minerals Mining" Applied Sciences 9, no. 3: 441. https://doi.org/10.3390/app9030441

APA StyleKaźmierczak, U., Blachowski, J., & Górniak-Zimroz, J. (2019). Multi-Criteria Analysis of Potential Applications of Waste from Rock Minerals Mining. Applied Sciences, 9(3), 441. https://doi.org/10.3390/app9030441