Wind Farm Power Production Assessment: Introduction of a New Actuator Disc Method and Comparison with Existing Models in the Context of a Case Study

Abstract

1. Introduction

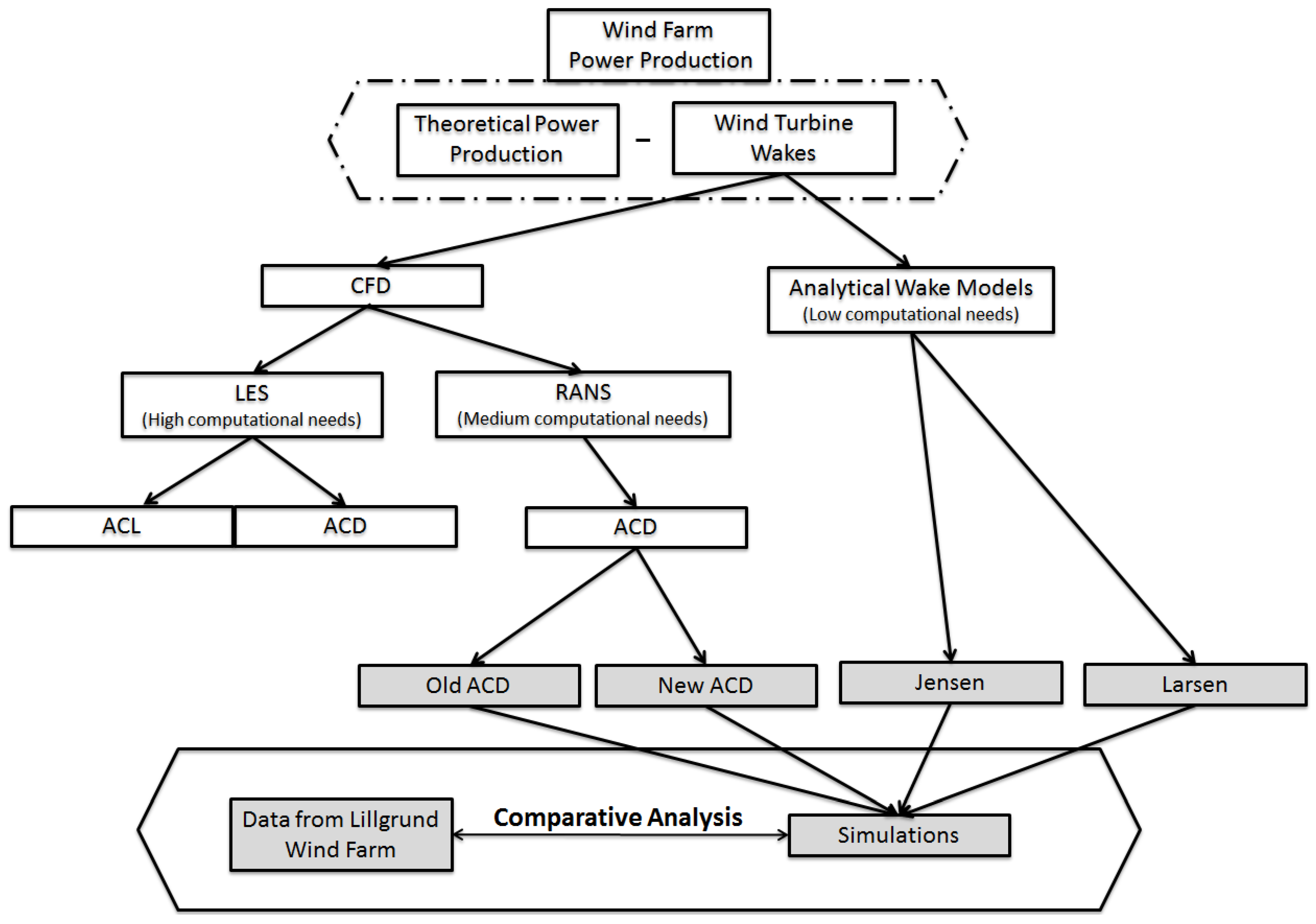

2. Methodological Framework

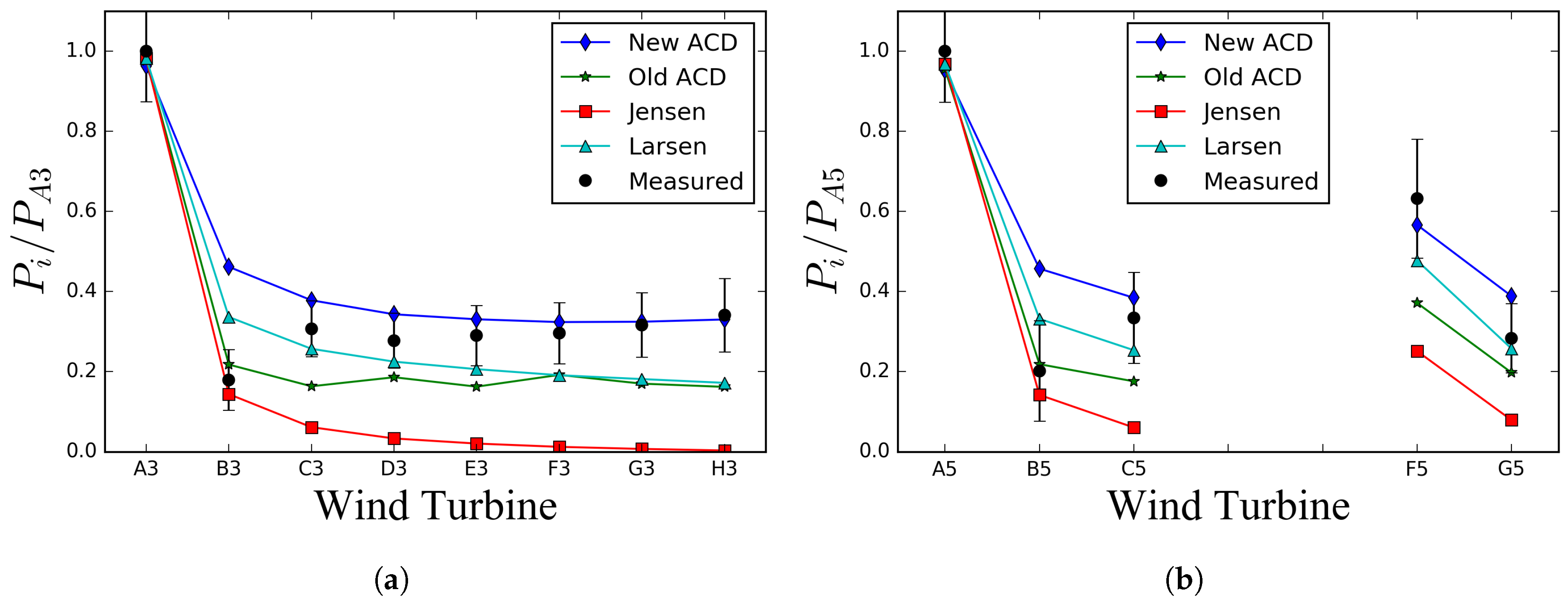

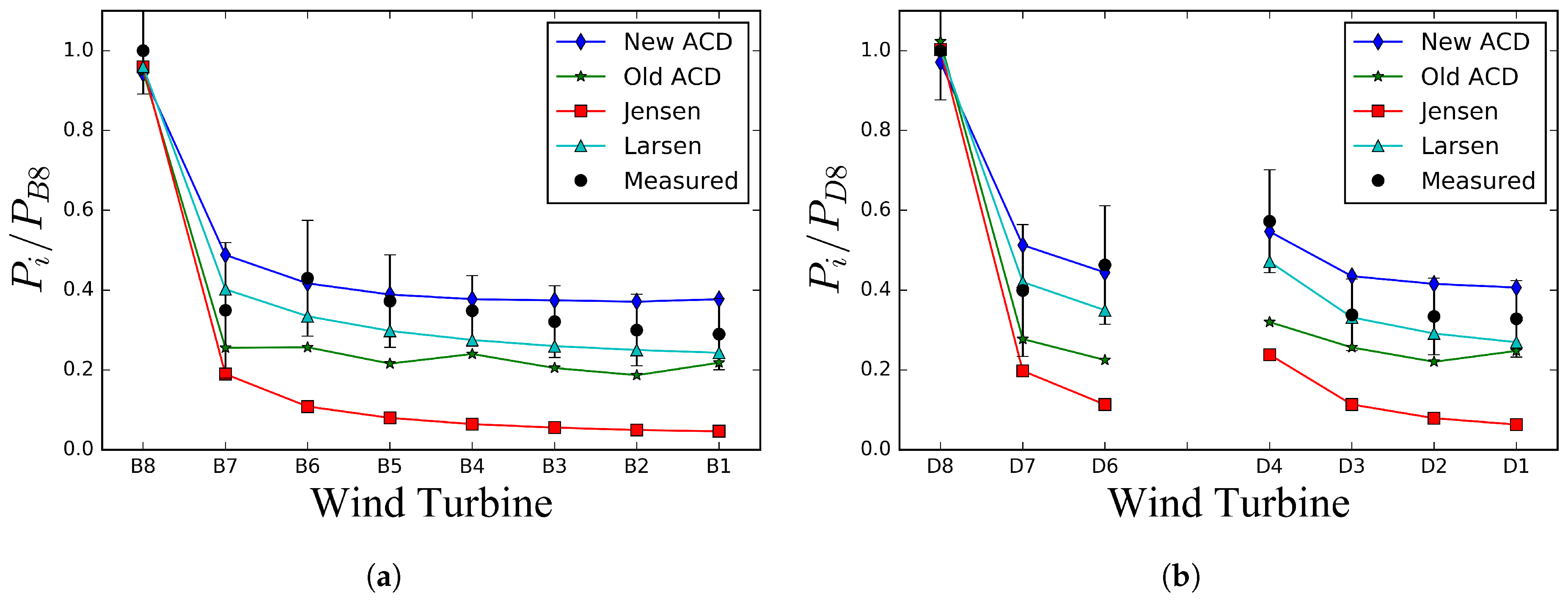

2.1. ACD Method

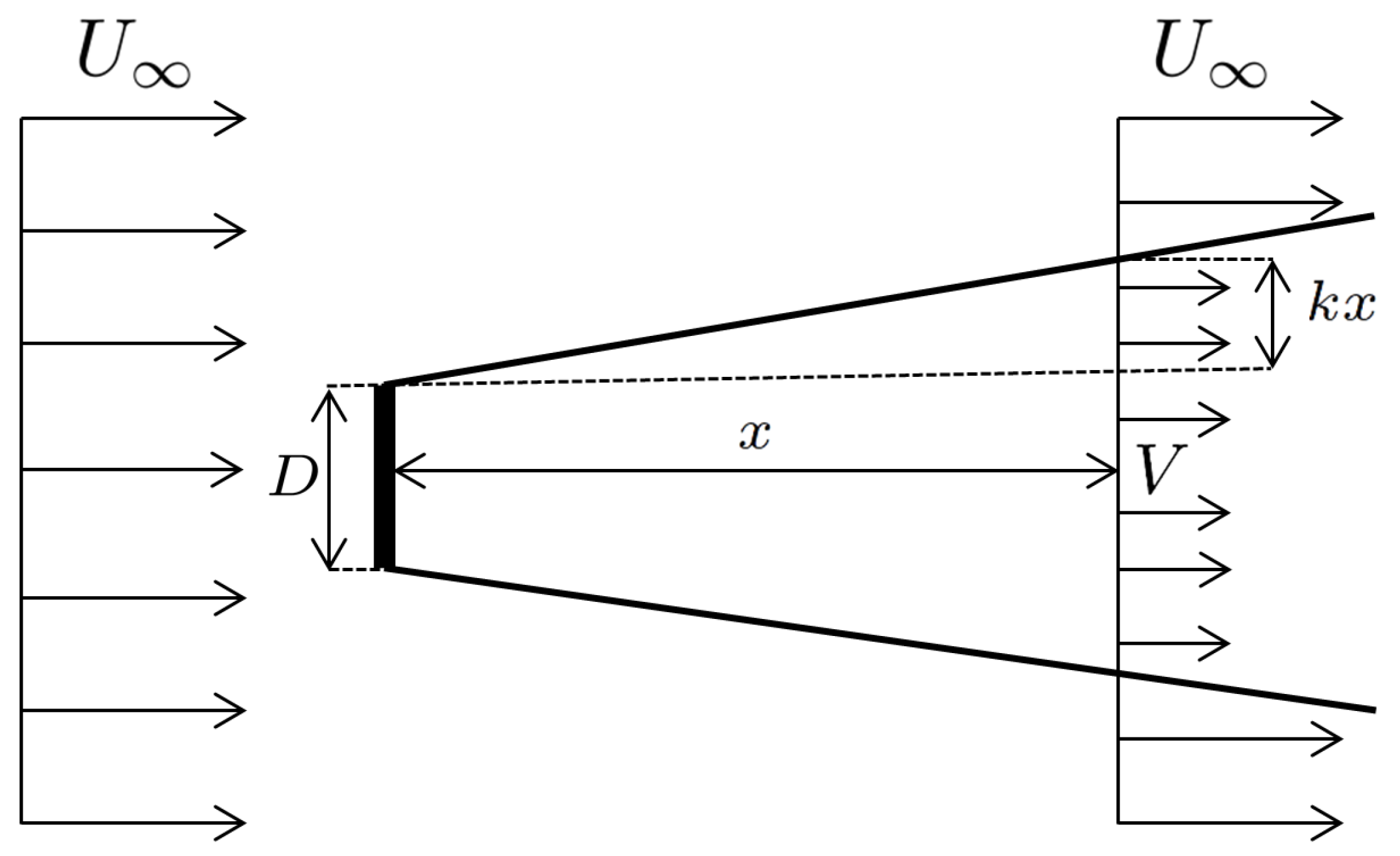

2.2. Analytical Wake Models

2.3. Boundary Conditions

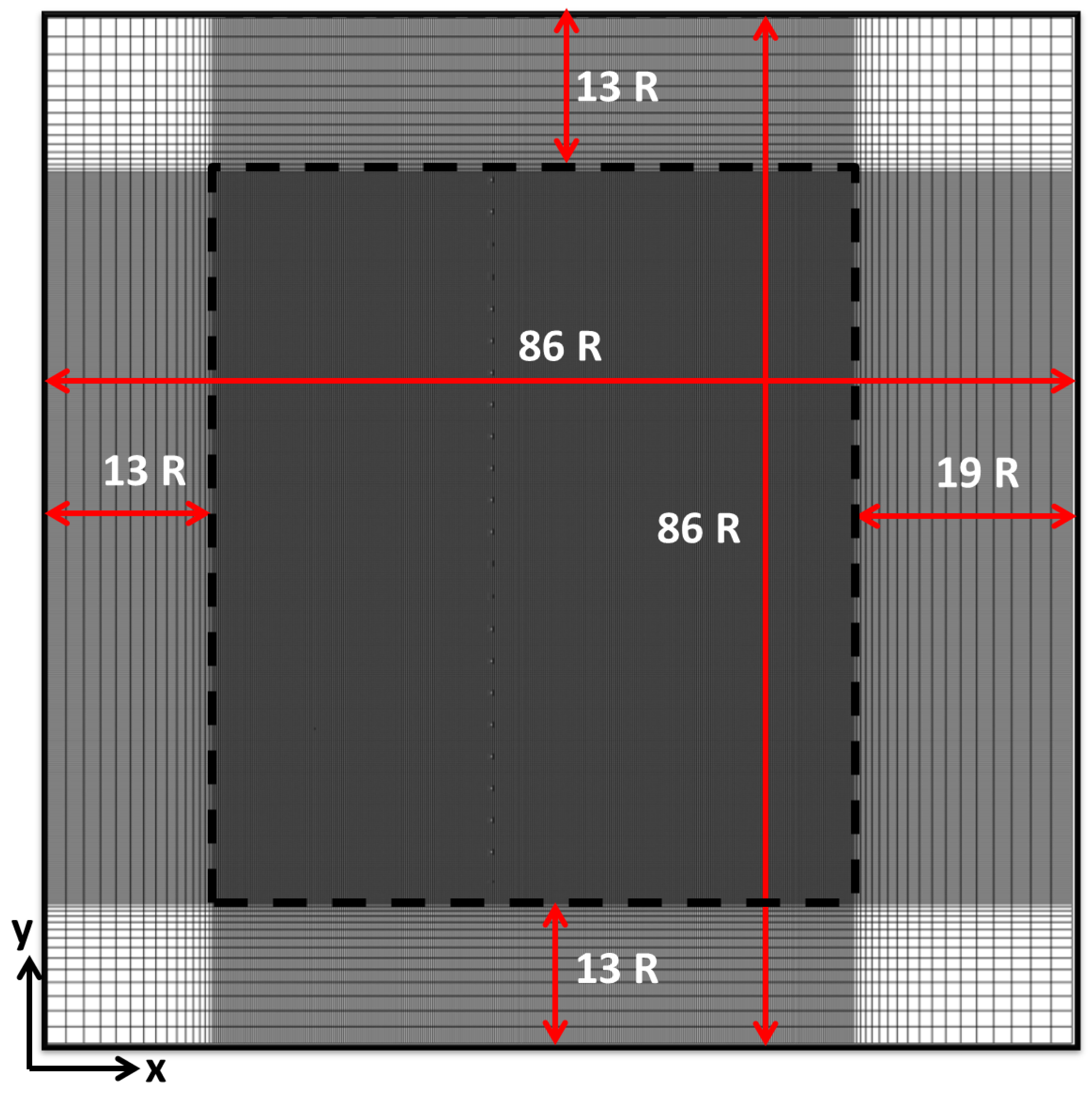

2.3.1. Body-Fitted Grid

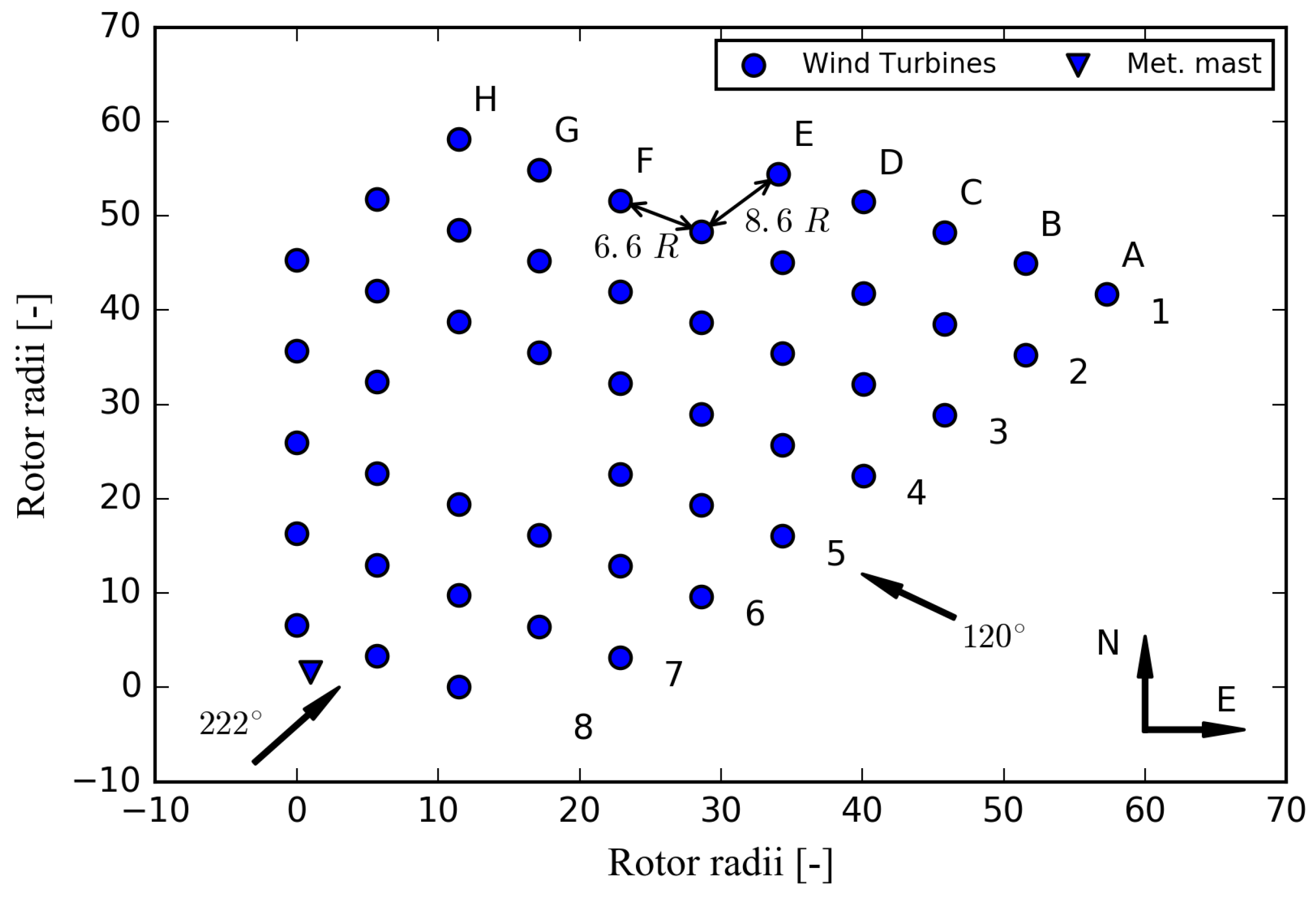

3. Lillgrund Offshore Wind Farm

4. Results and Discussion

- When presenting the results, the directional uncertainty as proposed by [48] has not been considered.

- Yaw misalignment errors are not considered.

- The data has not been filtered for stability.

- The study has been performed only for cases where the wind direction is in-line to the row of wind turbines.

- Only the turbulence model is used.

- In the simulations one power curve is used; in reality depending on the environmental conditions e.g., turbulence intensity or air density, wind turbines operate on a range of power curves.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ACD | Actuator Disc |

| ACL | Actuator Line |

| RANS | Reynolds Averaged Navier–Stokes |

| LES | Large Eddy Simulations |

| GCV | General Collocated Velocity |

| BFC | body-fitted Coordinate |

References

- Polatidis, H.; Ivanell, S. Micro-siting/positioning of wind turbines: Introducing a multi-criteria decision analysis framework. In Proceedings of the 7th International Multi-Conference on Engineering and Technological Innovation (IMETI 2014), Orlando, FL, USA, 15–18 July 2014; pp. 23–27. [Google Scholar]

- Barthelmie, R.J.; Hansen, K.; Frandsen, S.T.; Rathmann, O.; Schepers, J.; Schlez, W.; Phillips, J.; Rados, K.; Zervos, A.; Politis, E.; et al. Modelling and measuring flow and wind turbine wakes in large wind farms offshore. Wind Energy 2009, 12, 431–444. [Google Scholar] [CrossRef]

- Hou, P.; Hu, W.; Soltani, M.; Chen, C.; Chen, Z. Combined optimization for offshore wind turbine micro siting. Appl. Energy 2017, 189, 271–282. [Google Scholar] [CrossRef]

- Jensen, N.O. A Note on Wind Generator Interaction; Technical University of Denmark: Kongens Lyngby, Denmark, 1983. [Google Scholar]

- Larsen, G.C. A Simple Wake Calculation Procedure; Technical University of Denmark: Kongens Lyngby, Denmark, 1988. [Google Scholar]

- Katic, I.; Højstrup, J.; Jensen, N. A Simple Model for Cluster Efficiency. In Proceedings of the European Wind Energy Association Conference and Exhibition, Rome, Italy, 7–9 October 1986. [Google Scholar]

- Troldborg, N. Actuator Line Modeling of Wind Turbine Wakes; Technical University of Denmark: Kongens Lyngby, Denmark, 2009. [Google Scholar]

- Seim, F.; Gravdahl, A.R.; Adaramola, M.S. Validation of kinematic wind turbine wake models in complex terrain using actual windfarm production data. Energy 2017, 123, 742–753. [Google Scholar] [CrossRef]

- Larsen, G.C. A Simple Stationary Semi-Analytical Wake Model; Technical University of Denmark: Kongens Lyngby, Denmark, 2009. [Google Scholar]

- Ott, S.; Berg, J.; Nielsen, M. Linearised CFD Models for Wakes; Risø National Laboratory: Roskilde, Denmark, 2011.

- Gaumond, M.; Réthoré, P.E.; Bechmann, A.; Ott, S.; Larsen, G.C.; Pena Diaz, A.; Kurt, K. Benchmarking of wind turbine wake models in large offshore windfarms. In Proceedings of the Science of Making Torque from Wind 2012 Conference, Oldenburg, Germany, 9–11 Octorber 2012. [Google Scholar]

- Silicon Graphics International Corporation. OpenFOAM. Available online: http://www.openfoam.org (accessed on 13 December 2018).

- Rolf-Erik, K. Validation of the standalone implementation of the dynamic wake meandering model for power production. Wind Energy 2015, 18, 1579–1591. [Google Scholar]

- Churchfield, M.; Lee, S.; Moriarty, P.; Martinez, L.; Leonardi, S.; Vijayakumar, G.; Brasseur, J. A large-eddy simulations of wind-plant aerodynamics. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012; p. 537. [Google Scholar]

- Sørensen, J.N.; Shen, W.Z. Numerical modeling of wind turbine wakes. J. Fluids Eng. 2002, 124, 393–399. [Google Scholar] [CrossRef]

- Ivanell, S.; Sørensen, J.N.; Mikkelsen, R.; Henningson, D. Numerical analysis of the tip and root vortex position in the wake of a wind turbine. J. Phys. Conf. Ser. 2007, 75, 012035. [Google Scholar] [CrossRef]

- Nilsson, K.; Shen, W.Z.; Sørensen, J.N.; Breton, S.P.; Ivanell, S. Validation of the actuator line method using near wake measurements of the MEXICO rotor. Wind Energy 2015, 18, 499–514. [Google Scholar] [CrossRef]

- Sarmast, S.; Dadfar, R.; Mikkelsen, R.F.; Schlatter, P.; Ivanell, S.; Sørensen, J.N.; Henningson, D.S. Mutual inductance instability of the tip vortices behind a wind turbine. J. Fluid Mech. 2014, 755, 705–731. [Google Scholar] [CrossRef]

- Breton, S.P.; Nilsson, K.; Olivares-Espinosa, H.; Masson, C.; Dufresne, L.; Ivanell, S. Study of the influence of imposed turbulence on the asymptotic wake deficit in a very long line of wind turbines. Renew. Energy 2014, 70, 153–163. [Google Scholar] [CrossRef]

- Wu, Y.T.; Porté-Agel, F. Large-eddy simulation of wind-turbine wakes: Evaluation of turbine parametrisations. Bound. Layer Meteorol. 2011, 138, 345–366. [Google Scholar] [CrossRef]

- Olivares-Espinosa, H.; Breton, S.; Masson, C.; Dufresne, L. Turbulence characteristics in a free wake of an actuator disk: comparisons between a rotating and a non-rotating actuator disk in uniform inflow. J. Phys. 2014, 555, 012081. [Google Scholar] [CrossRef]

- Van der Laan, M.P.; Sørensen, N.N.; Réthoré, P.E.; Mann, J.; Kelly, M.C.; Troldborg, N.; Schepers, J.G.; Machefaux, E. An improved k-ε model applied to a wind turbine wake in atmospheric turbulence. Wind Energy 2015, 18, 889–907. [Google Scholar] [CrossRef]

- Nilsson, K.; Ivanell, S.; Hansen, K.S.; Mikkelsen, R.; Sørensen, J.N.; Breton, S.P.; Henningson, D. Large-eddy simulations of the Lillgrund wind farm. Wind Energy 2015, 18, 449–467. [Google Scholar] [CrossRef]

- Castellani, F.; Vignaroli, A. An application of the actuator disc model for wind turbine wakes calculations. Appl. Energy 2013, 101, 432–440. [Google Scholar] [CrossRef]

- Prospathopoulos, J.; Politis, E.; Rados, K.; Chaviaropoulos, P. Evaluation of the effects of turbulence model enhancements on wind turbine wake predictions. Wind Energy 2011, 14, 285–300. [Google Scholar] [CrossRef]

- El Kasmi, A.; Masson, C. An extended k–ε model for turbulent flow through horizontal-axis wind turbines. J. Wind Eng. Ind. Aerodyn. 2008, 96, 103–122. [Google Scholar] [CrossRef]

- Sumner, J.; Espana, G.; Masson, C.; Aubrun, S. Evaluation of RANS/actuator disk modelling of wind turbine wake flow using wind tunnel measurements. Int. J. Eng. Syst. Model. Simul. 2013, 5, 147–158. [Google Scholar] [CrossRef]

- Crasto, G.; Gravdahl, A.R. CFD wake modeling using a porous disc. In Proceedings of the European Wind Energy Conference & Exhibition 2008, Brussels, Belgium, 31 March–3 April 2008. [Google Scholar]

- WindSim AS. 2017. Available online: https://windsim.com (accessed on 14 December 2018).

- Simisiroglou, N.; Sarmast, S.; Breton, S.P.; Ivanell, S. Validation of the actuator disc approach in PHOENICS using small scale model wind turbines. J. Phys. 2016, 753, 032028. [Google Scholar] [CrossRef]

- Calaf, M.; Meneveau, C.; Meyers, J. Large eddy simulation study of fully developed wind-turbine array boundary layers. Phys. Fluids 2010, 22, 015110. [Google Scholar] [CrossRef]

- Hansen, K. Presentation of Lillgrund Offshore Wind Farm and the Siemens SWT-2.3-93 Wind Turbine; Siemens: Munich, Germany, 2013. [Google Scholar]

- Jeppsson, J.; Larsen, P.E.; Larsson, Å. Technical Description Lillgrund Wind Power Plant; Vattenfall Vindkraft: Stockholm, Sweden, 2008; 78p. [Google Scholar]

- Semin, V.; Spalding, D.; Zhubrin, S. Two novel algorithms for the simulation of flow around turbine blades. In IMechE Seminar “Latest Advances in the Aerodynamics of Turbomachinery with Special Emphasis on Unsteady Flows”; Professional Engineering Publishing: London, UK, 1996. [Google Scholar]

- Rhie, C.M. Numerical study of the flow past an isolated airfoil with separation. Diss. Abstr. Int. Part B Sci. Eng. 1982, 42, 3793. [Google Scholar]

- Rhie, C.; Chow, W.L. Numerical study of the turbulent flow past an airfoil with trailing edge separation. AIAA J. 1983, 21, 1525–1532. [Google Scholar] [CrossRef]

- Majumdar, S. Role of underrelaxation in momentum interpolation for calculation of flow with nonstaggered grids. Numer. Heat Transf. 1988, 13, 125–132. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Spalding, D. A novel finite difference formulation for differential expressions involving both first and second derivatives. Int. J. Numer. Methods Eng. 1972, 4, 551–559. [Google Scholar] [CrossRef]

- Launder, B.; Morse, A.; Rodi, W.; Spalding, D. Prediction of Free Shear Flows: A Comparison of the Performance of Six Turbulence Models; NASA: Washington, DC, USA, 1973.

- PHOENICS VR Reference Guide TR326. 2017. Available online: http://www.cham.co.uk/documentation/tr326.pdf (accessed on 14 December 2018).

- Dahlberg, J.A. Assessment of the Lillgrund Wind Farm: Power Performance Wake Effects. Available online: https://corporate.vattenfall.se/globalassets/sverige/om-vattenfall/om-oss/var-verksamhet/vindkraft/lillgrund/assessment.pdf (accessed on 14 December 2018).

- Bergström, H. Meteorological conditions at Lillgrund. Vattenfall Vindkraft AB 2009. Available online: https://corporate.vattenfall.se/globalassets/sverige/om-vattenfall/om-oss/var-verksamhet/vindkraft/lillgrund/meteorological_conditions.pdf (accessed on 14 December 2018).

- Van der Laan, M.P.; Sørensen, N.N.; Réthoré, P.E.; Mann, J.; Kelly, M.C.; Troldborg, N.; Hansen, K.S.; Murcia, J.P. The k-ε-fP model applied to wind farms. Wind Energy 2015, 18, 2065–2084. [Google Scholar] [CrossRef]

- Pena, A.; Réthoré, P.E.; Hasager, C.B.; Hansen, K.S. Results of Wake Simulations at the Horns Rev I and Lillgrund Wind Farms Using the Modified Park Model; Technical University of Denmark: Kongens Lyngby, Denmark, 2013. [Google Scholar]

- Creech, A.C.; Früh, W.G.; Maguire, A.E. High-resolution CFD modelling of Lillgrund Wind farm. In Proceedings of the International Conference on Renewable Energies and Power Quality, Bilbao, Spain, 20–22 March 2013. [Google Scholar]

- Réthoré, P.E. Wind Turbine Wake in Atmospheric Turbulence. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2009. [Google Scholar]

- Gaumond, M.; Réthoré, P.E.; Ott, S.; Peña, A.; Bechmann, A.; Hansen, K.S. Evaluation of the wind direction uncertainty and its impact on wake modeling at the Horns Rev offshore wind farm. Wind Energy 2014, 17, 1169–1178. [Google Scholar] [CrossRef]

- Van der Laan, M.P.; Sørensen, N.N.; Réthoré, P.E.; Mann, J.; Kelly, M.C.; Troldborg, N. The k-ε-fP model applied to double wind turbine wakes using different actuator disk force methods. Wind Energy 2015, 18, 2223–2240. [Google Scholar] [CrossRef]

- Barthelmie, R.J.; Frandsen, S.T.; Rathmann, O.; Hansen, K.S.; Politis, E.; Prospathopoulos, J.; Schepers, J.; Rados, K.; Cabezón, D.; Schlez, W.; et al. Flow and Wakes in Large Wind Farms: Final Report for UpWind WP8; Technical University of Denmark: Kongens Lyngby, Denmark, 2011. [Google Scholar]

| Description | Power Production Estimation | Thrust Coefficient | Thrust Distribution |

|---|---|---|---|

| ACD (2008) | Velocity at hub height | static | Uniform, Parabolic and Polynomial |

| ACD (2016) | Averaged value over the rotor | update at each iteration | Undistributed |

| Domain | Inner Equidistant Region | Total Number of Cells | |||||

|---|---|---|---|---|---|---|---|

| Cell Size | |||||||

| Description | Inflow Direction (Degrees) | Row/Column | Wind Velocity (m s) | Turbulence Intensity (%) |

|---|---|---|---|---|

| Southeast | 3, 5 | 5.5 | ||

| Southwest | B, D | 5.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simisiroglou, N.; Polatidis, H.; Ivanell, S. Wind Farm Power Production Assessment: Introduction of a New Actuator Disc Method and Comparison with Existing Models in the Context of a Case Study. Appl. Sci. 2019, 9, 431. https://doi.org/10.3390/app9030431

Simisiroglou N, Polatidis H, Ivanell S. Wind Farm Power Production Assessment: Introduction of a New Actuator Disc Method and Comparison with Existing Models in the Context of a Case Study. Applied Sciences. 2019; 9(3):431. https://doi.org/10.3390/app9030431

Chicago/Turabian StyleSimisiroglou, Nikolaos, Heracles Polatidis, and Stefan Ivanell. 2019. "Wind Farm Power Production Assessment: Introduction of a New Actuator Disc Method and Comparison with Existing Models in the Context of a Case Study" Applied Sciences 9, no. 3: 431. https://doi.org/10.3390/app9030431

APA StyleSimisiroglou, N., Polatidis, H., & Ivanell, S. (2019). Wind Farm Power Production Assessment: Introduction of a New Actuator Disc Method and Comparison with Existing Models in the Context of a Case Study. Applied Sciences, 9(3), 431. https://doi.org/10.3390/app9030431