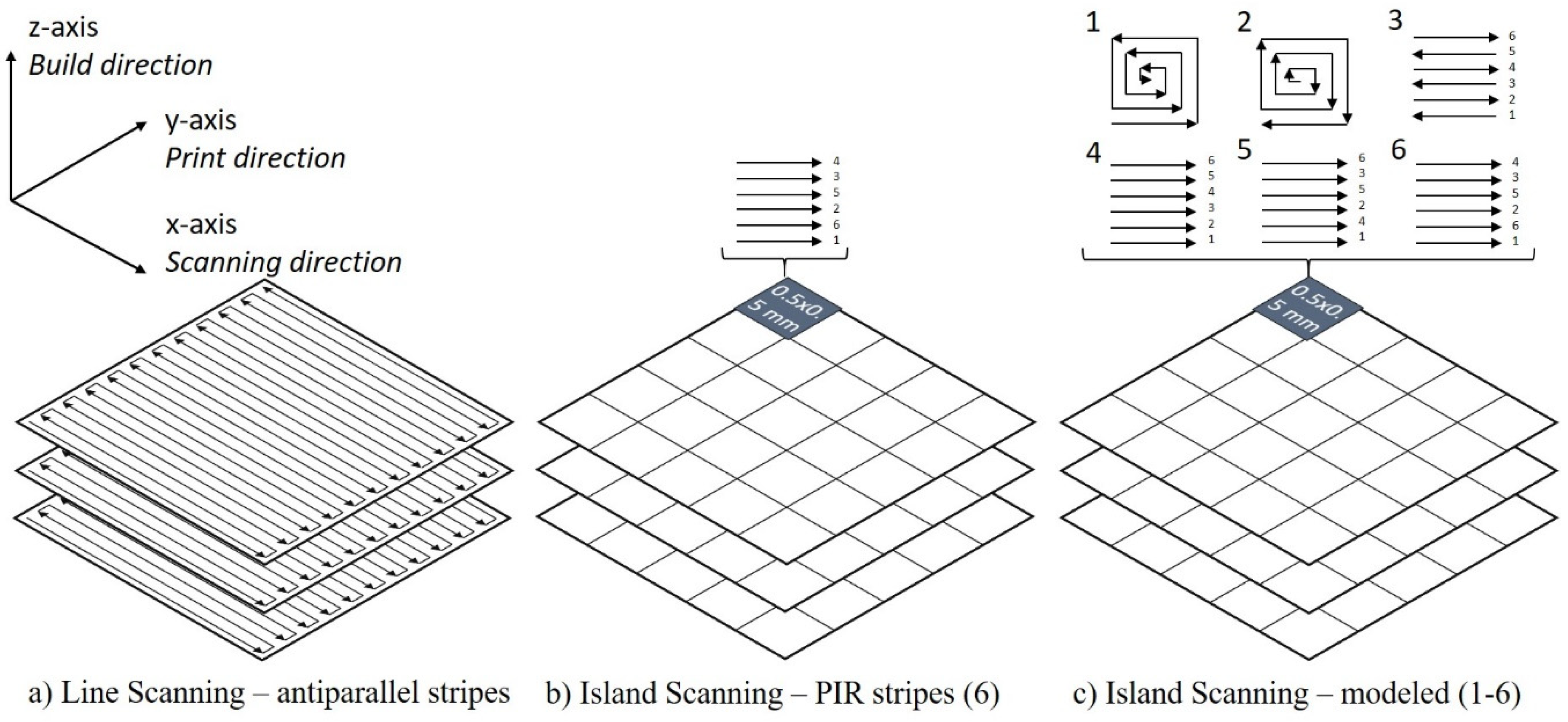

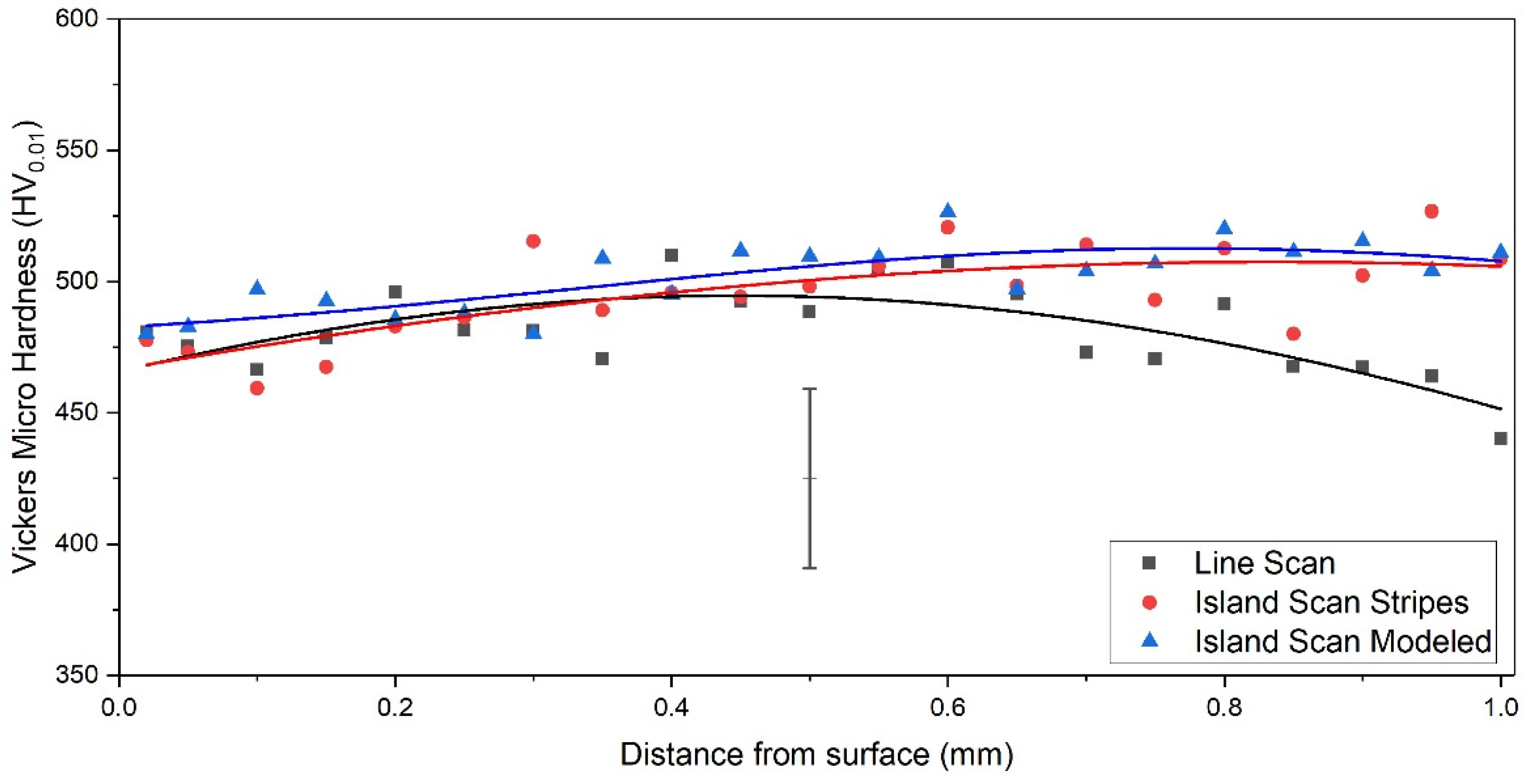

3.1. Macroscopical Features of the Line Scan Specimen

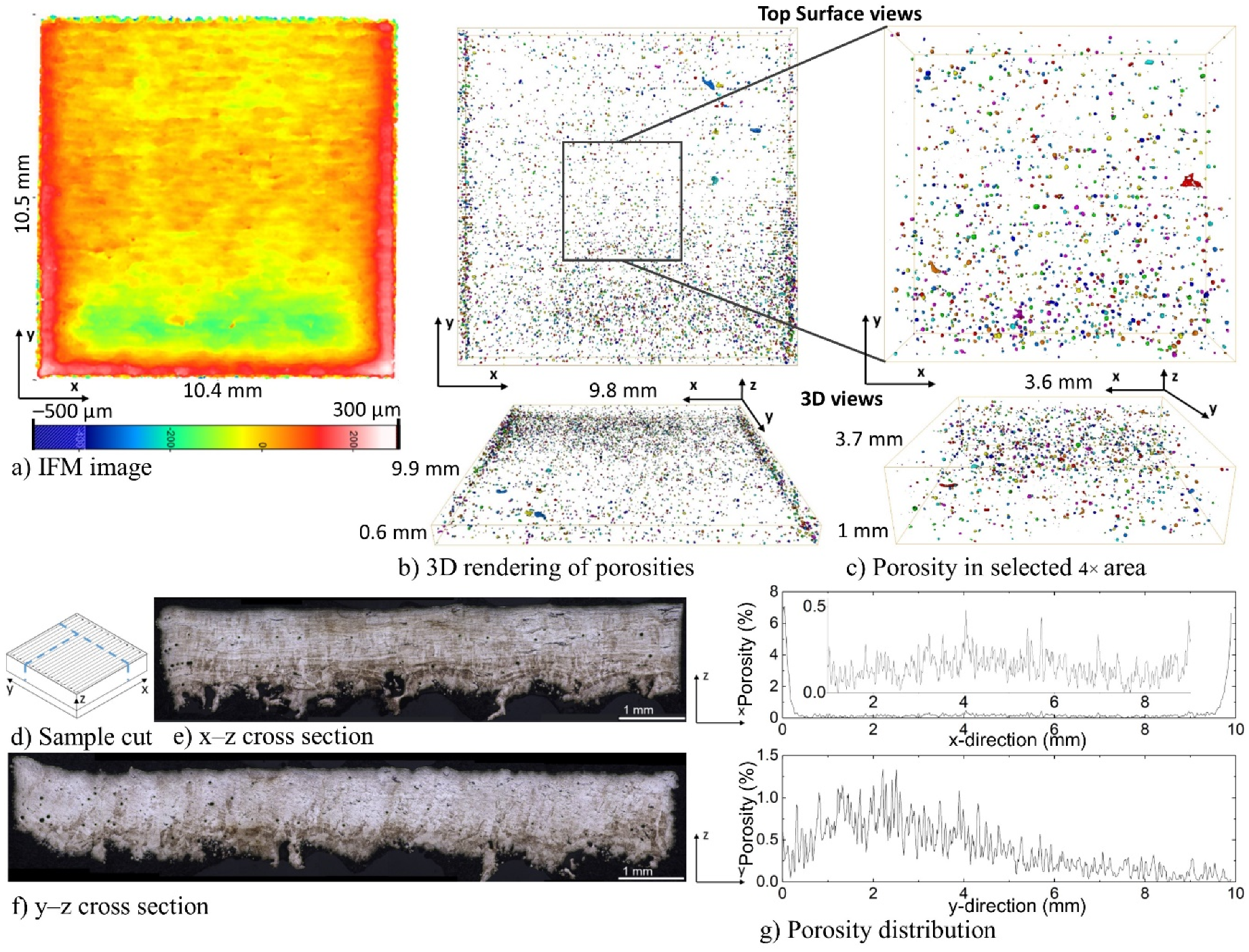

A collage of the macroscopic features of the line scan specimen, including surface topography, porosity analysis, and macrographs of x–z and y–z cross sections, is given in

Figure 2. Generally, the specimen is higher along the edges, apart from the last scanned side at the top (

Figure 2a). The macrographs in

Figure 2d–f show that the higher edge along the scan direction is related to distortion of the first scanned corner (to the left). The increased height along the edges in the print direction (y-axis) is not due to deformation, but caused by material build-up (i.e., an edge-effect) as identified in the macrograph in

Figure 2e. The build-up happens when a scan line is adjacent to the specimen’s border, where the melt pool is surrounded by powder on 3–4 sides as compared to 2 sides for scan lines inside the specimen. The lower thermal conductivity and lower density of the powder relative to solidified material lead to a shape change of the melt pool, which leads to incorporation of more of the residing powder, hereby increasing the melt pool size [

23]. In addition, the first melt in the powder sinks down into the powder, leading to an inclined solidified deposit [

24], similar to that observed to the left in

Figure 2f.

The height increase at the edges decreases slightly along the print direction (y-axis). Similarly, the height increase along the scan direction (x-axis) is most pronounced in the corners. Contour scans during fabrication of the specimens can decrease the deformation, but were not applied, because they can lead to even higher edges [

23]. Focusing on the specimen surface away from the edges, a green-colored valley is observed over about the first fifth in the print direction, while the remaining surface is uniform in height. The (antiparallel) stripes can be recognized parallel to the x-direction in the surface topography.

Computed tomography (CT) results are shown in

Figure 2b,c. In order to exclude the surface defects and focus on internal pores, data treatment was performed on a cropped area; see measures in

Figure 2b,c. The identified porosities are visualized by 3D renderings in

Figure 2b (LFOV) and 2c (4× zoom). It is noted that 3D projections of pores give an exaggerated impression of the degree of porosity. The pores are mainly spherical and vary in size. Some pores are aligned along the x-direction, positioning them along the scan lines during the SLM process (

Figure 2c, top surface view). The pores are unevenly distributed over the specimen: enhanced pore densities are observed along the edges in the y-direction and in the “green valley” observed in

Figure 2a. The trend is quantified in

Figure 2g, showing the pore distribution as a function of x- and y-directions in the cropped area of the line scan specimen. In the x-direction (i.e., integrated over the y- and z-direction of the specimen), in addition to the obvious high pore density near the edges, the inserted graph shows an increased number of pores over a distance of 3 mm in the center of the specimen (from 3 to 6 mm). In the y-direction (i.e., integrated over the x- and z-direction of the specimen) the higher density of pores in the “green valley” is very distinct. In general, no trend in porosity along the build direction (z-direction) is observed.

The macrographs of the line scan specimen in

Figure 2e,f show darker etchings near the bottom of the cross sections and the directions of the elongated prior β grains become apparent, both of which will be discussed later. Additionally, a ragged morphology in the bottom of the cross sections is present. This is due to building on a support structure and will not be discussed further.

3.2. Macroscopical Features of the Island Scan Stripes Specimen

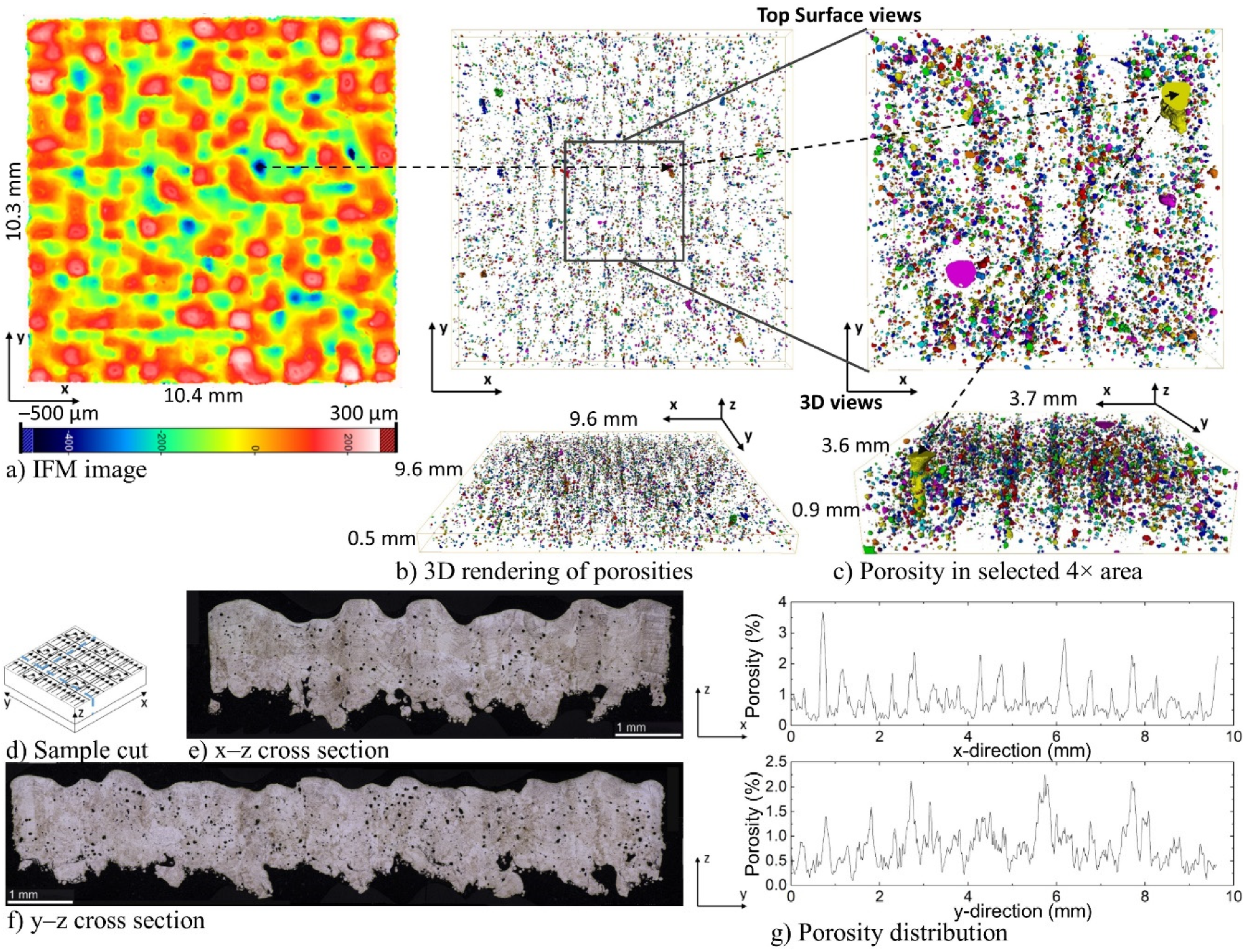

The surface topography of the island scan stripes specimen clearly shows a pattern of height differences reflecting the 20 × 20 island pattern (

Figure 3a). All islands are higher in the first scanned corner, consistent with the same scan strategy for all islands (parallel-interlaced-reversed (PIR)). In general, the “green valleys” in

Figure 3a were scanned later than the “red ridges”. The degree and shape of the increase vary, which relates to the order in which the islands were scanned. This order was unchanged during building in the z-direction.

The macrographs of the cross sections in

Figure 3e,f show that most of the islands have a surface inclination towards the left-hand side (e.g., −x and −y), which is preserved in the build direction. This indicates that the height differences are introduced in an early stage of the build and are retained (and possibly aggravated) on continued building. This phenomenon is directly related to the scanning of individual islands, while they are completely surrounded by powder and have no immediate neighboring island that was scanned earlier. As convincingly demonstrated by Leung et al. [

24], the first melt track that is formed in a deep powder bed (first layer) sinks towards the bottom of the powder bed as the track proceeds, and undergoes bending during cooling, leaving the first scanned corner at a higher level than the part that is later melted and the solidified part. This is hereafter termed “bending deflection”. In this respect, the first line of each island behaves similar to the line scan specimen in

Figure 2, albeit on a smaller scale. It is noted that parallel line scanning applies for the islands in

Figure 3, while antiparallel scanning applies for the lines in

Figure 2. As a consequence, bending deflections in both x- and y-directions occur for the islands (the specimen bottoms in

Figure 2f and

Figure 3e). In addition, the surface topography depends on the presence of completed neighboring islands in the same layer. If an island is scanned after an island to its right (+x) was completed earlier and, consequently, has already deflected slightly upwards on the left-hand side (−x), the island being scanned will be fused to the island on its right (+x) at a slightly lower position. If, on the other hand, an island is already present to the left (−x), the difference in surface height at fusion is not as prominent, because deflection is most prominent at the left-hand side (−x, first scanned). According to the same reasoning, the number of neighboring islands (up to 4) affects the surface topography. The same phenomenon means that scanning above (i.e., in the y-direction) an already scanned island leads to a smaller height difference than scanning below an already solidified island (−y), leading to the direction pattern of the deflections seen in the island scan stripes specimen (

Figure 3a).

Some islands have more material near the edges of the islands, showing that the edge effect is significant for this method. The first scanned island includes powder from the adjacent (non-scanned) islands, implying that the first scanned island has higher edges, and leaves less powder for melting at the borders for later scanned adjacent islands. As a consequence, pronounced fusion defects arise in-between the islands. This is clearly reflected in the porosity distributions shown in

Figure 3b,c and the macrographs in

Figure 3e,f, showing lack-of-fusion defects, identified by their irregular shapes, in-between many of the columns. These lack-of-fusion defects are located along rows parallel to the y-direction. The severity of the lack-of-fusion defects is not the same everywhere (

Figure 3b,c), which is most certainly related to the order in which the islands were scanned, just as the surface topography. In addition, spherical porosity is also observed. The spherical pores are concentrated to the right (i.e., in the x-direction) of the lack-of-fusion defects (

Figure 3c,e). Spherical porosities appear more evenly distributed along the y-direction, although high concentrations occur close to some lack of fusion defects.

Figure 3g illustrates how the porosity is distributed along the x- and y-directions of the island scan stripes specimen. From this it is clear how the lack-of-fusion defects account for the periodic peaks in the x-direction (integrated over the y- and z-direction of the specimen) at 0.5 mm intervals (i.e., the island width). The right-hand shoulders to these peaks are caused by the spherical porosities concentrated to the right of the lack-of-fusion defects. In the y-direction (integrated over the x- and z-direction of the specimen), the porosity appears again periodically distributed, with a periodicity reflecting island width, albeit not as clear as for the x-direction. This is because the porosity is mainly concentrated along the island boundaries parallel to the x-direction, and the porosity distribution in the y-direction is therefore mainly dependent on the number of lack-of-fusion defects between islands in the x-direction. Secondly, the lack-of-fusion boundaries appear to be concentrated between the boundaries parallel to the y-direction, while the periodic valleys correlate with the island boundaries in the y-direction.

3.3. Macroscopical Features of the Island Scan Modeled Specimen

As a consequence of applying six different scan strategies, the surface topography of the Island scan modeled specimen (

Figure 4a) shows no clear direction of deformation patterns, as in previous cases. Nevertheless, similar to the island scan stripes specimen in

Figure 3a, a pattern of peaks and valleys reflecting the periodicity of the islands is observed. As compared to

Figure 3a, an irregular shape of the island topographies is observed, which is caused by combining the different scan strategies in the islands with the order of scanning of the islands, leading to different deformations and edge-effects in the individual islands as well as different locations and extents of the melt-pool digging [

24]. Islands with near-circular topographical shapes can be recognized in

Figure 4a. They are clearest for the highest and lowest islands as reflected by the circular white rings and the blue circles, and developed because scanning followed either an (1) out–in spiral or (2) in–out spiral scan type, as described by Cheng et al. [

18].

Porosity for the island scan modeled specimen is shown in

Figure 4b,c. In general, a high content of spherical porosities is observed. Lack-of-fusion defects appear less pronounced than for the island scan stripes in

Figure 3, implying that the islands are fused better together. This is confirmed by

Figure 4e–g. Most islands are completely fused, while some have a relatively high degree of spherical porosities or lack-of-fusion defects (

Figure 4b,c). Again, lines of spherical porosities distributed along the y-direction are present, located at or close to the island borders along the x-direction (

Figure 4g). However, this time they do not extend through the full length of the specimen, due to the use of the variation in scan strategy. Instead, high concentrations of spherical porosities are observed inside many islands; several islands show depressions (appearing blue in

Figure 4a), combined with few spherical porosities. Some of these have developed into funnel-like defects, for example the large yellow pore in

Figure 4c. These deep defects are observed in islands that were filled in after their surrounding islands were completed (see

Figure S1, where island 354 is where the yellow pore in

Figure 4c was created).

The pore distributions in

Figure 4g show that periodic behavior with a periodicity reflecting the island width occurs in the x-direction, albeit less pronounced as in

Figure 3g, because of the use of different scan strategies within the islands. Consistently, the heights of the peaks are significantly lower than in

Figure 3g, due to fewer lack-of-fusion defects. The periodic behavior in the y-direction (

Figure 4g) is also less pronounced than in

Figure 3g. An explanation for the occurrence of a pattern in the porosity distribution in both the x- and y-direction, despite the use of different scan strategies, is that the direction of scan types 3–6 are still parallel to the x-direction, implying that lack-of-fusion defects could still occur, albeit less pronounced than in the island scanning stripes specimen. Secondly, it appears that the use of different scan strategies is not sufficient to avoid overlap between islands; even though the frequency of lack-of-fusion defects is reduced, more trapped-gas porosities appear at the borders.

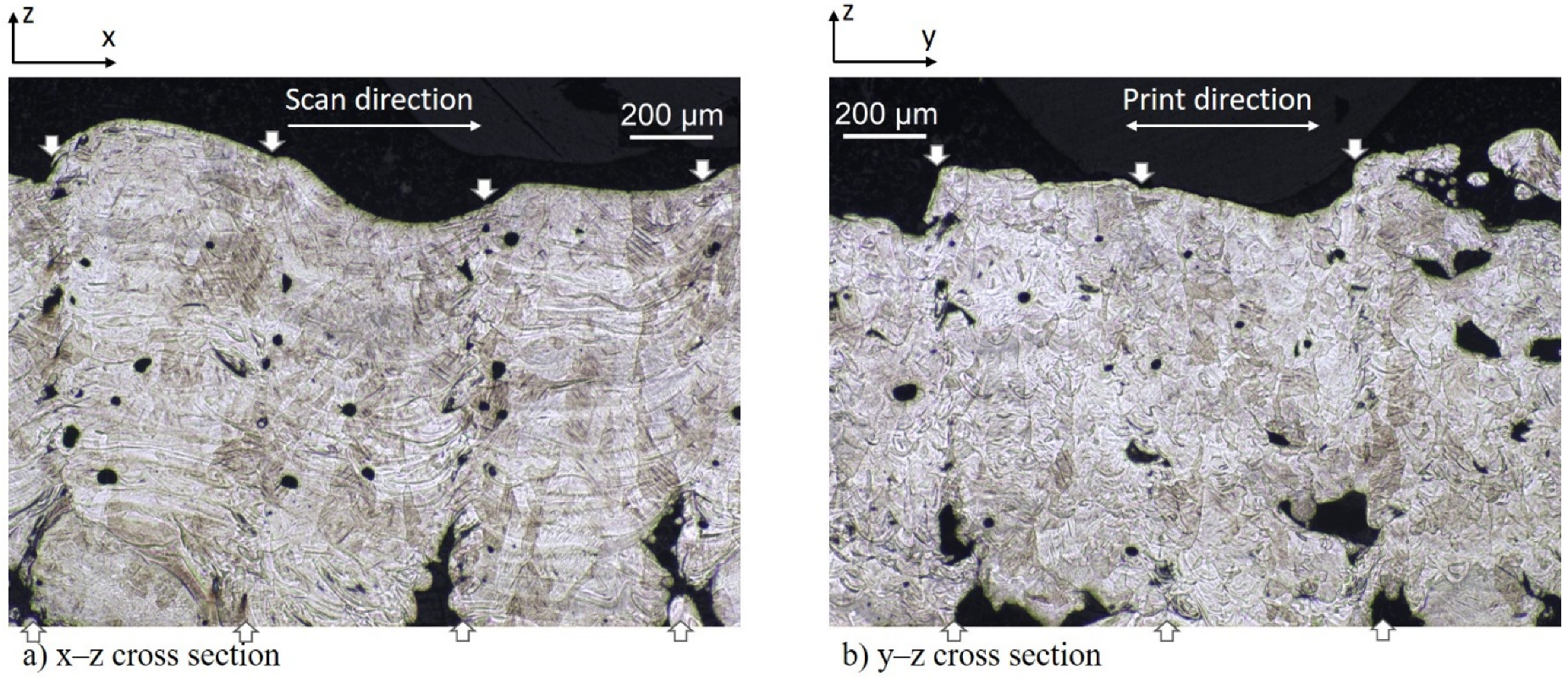

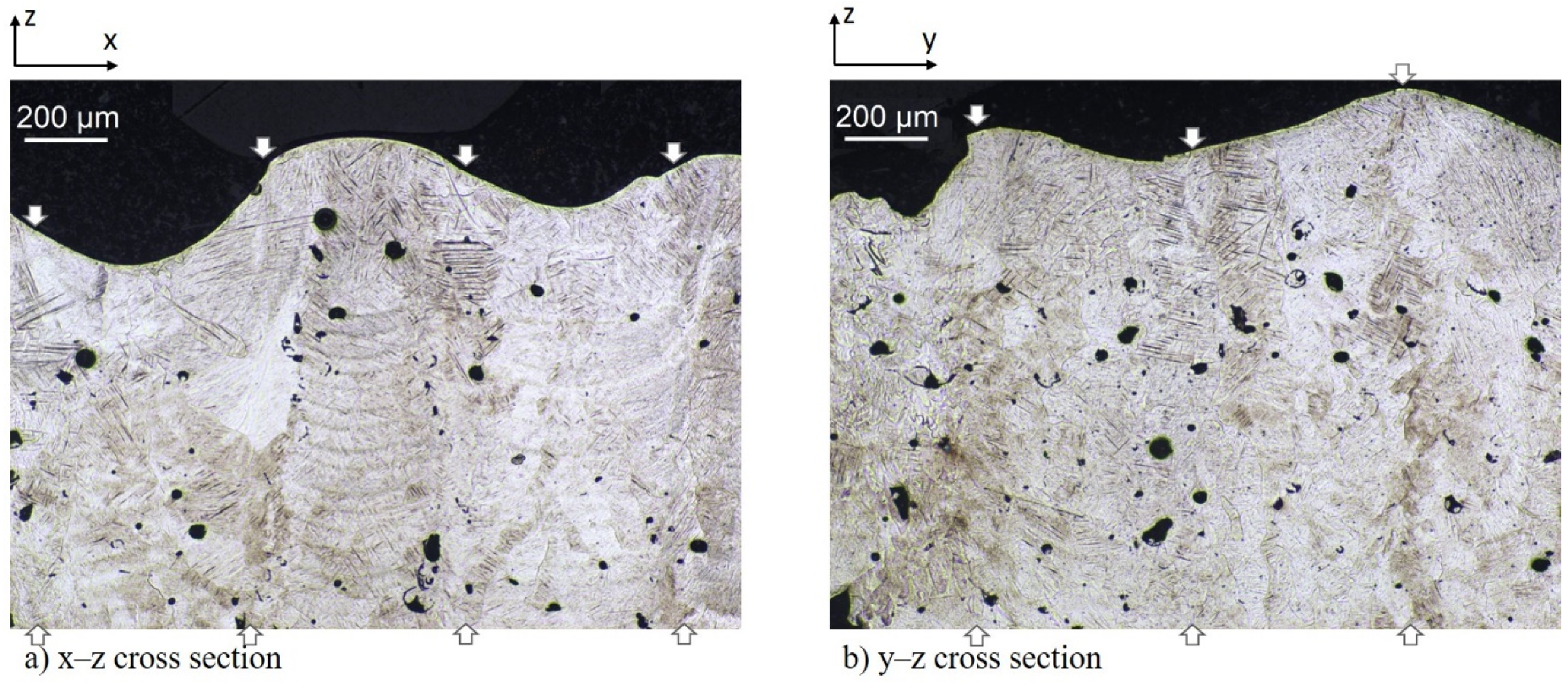

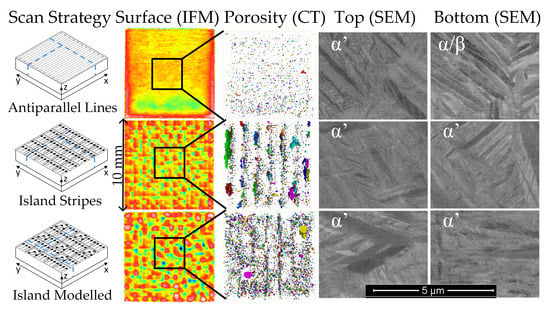

3.4. Microstructure

Selective laser melting exposes the metal to complex thermal cycles and associated temperature gradients, resulting in complex microstructures [

9,

10]. The following features can be distinguished: pores, phase distribution (α’ to α/β transformation), solidification structure (prior β grains), melt pool shapes (fusion-boundaries), and banding. For the line scan specimen, micrographs in the x–z and y–z cross sections show a heterogeneous microstructure (

Figure 5).

Elongated prior β grains are visible in both cross sections. The β phase forming during solidification of the melt grows homo-epitaxially on the β phase in the previously deposited layer, which is partly remelted. This is a consequence of a steep thermal gradient during SLM, which, despite a large partitioning coefficient of Ti-6Al-4V, leads to a planar solidification front and inhibits nucleation in the melt [

8].

The elongated prior β grains are oriented perpendicular to the surface in the scan direction (

Figure 2e and

Figure 5a). In the print direction (

Figure 2f and

Figure 5b), the prior β grains are still elongated perpendicular to the surface but tilt towards the print direction (y-axis) in the last scanned half. The inclination indicates higher thermal gradients in the melt pool towards the y-direction, which are the same for every consecutive layer because the scan direction is the same for every new layer. Kim et al. showed that the temperature at the side of the melt pool where it bounded by unmelted powder is significantly higher than on the side where it bounds to the solidified material, due to the higher conductivity of dense material as compared to powder [

25].

Etching resulted in darker areas near the bottom of the specimen, indicating a different microstructure with more compositional inhomogeneity. It is suggested that this is a result of different cooling conditions with shallower temperature gradients, because this part is closer to the open structure of the support. Also, dark banded lines parallel to the surface are visible due to preferential etching.

Apart from the dark bands, elongated reflections are visible in the micrograph of the x–z cross section (white arrows in

Figure 5a), roughly following the banded structure and consisting of several elongated and overlapping lines. Most likely, these features originate from selective polishing and etching of the fusion-boundaries developing when the laser moves roughly along the x-direction in the x–z plane. This could be caused by the dissolution of oxygen in the melt. Alternatively, it could mark the difference between remelted and non-remelted areas of the coherent elongated β grains. The bowl-shaped reflections in the y–z cross section of the line scan specimen (

Figure 5b) correspond to the fusion boundaries for each scan line (corresponding to the laser moving in and out of the y–z plane). A few dark bands are visible in the bottom of the y–z cross section. Along with the variation in thickness through the specimen, this indicates that the dark bands depend on the thermal history.

Banding is also observed in the island scan stripes specimen in

Figure 6. In contrast to the observations for in the line scan specimen, the preferential etching appears to be present to an equal extent throughout the build direction (see macrographs in

Figure 3b,c). This means that the cooling conditions were similar throughout the build, which could be a consequence of the high degree of porosity along the island boundaries (see below).

In the micrograph of the island scan stripes specimen, the elongated former β grains are visible in the x–z cross section (

Figure 4e,f) and have the same width in the line scan specimen. The lengths of these grains sometimes reach the full height of the specimen. As opposed to the line scan specimen, where β grains are inclined in the y-direction (i.e., the y–z cross section), the elongated prior β grains are oriented vertically and do not continue in the neighboring island (

Figure 6b). This is a result of the high degree of porosity in-between the islands, causing the steepest thermal gradient to be along the thickness direction of the island. In the scan direction (

Figure 6a) the prior β grains are slightly tilted inward to the center of the islands, indicating a small contribution of the thermal gradient along the x-axis, associated with the order of the parallel stripes scanning of the islands (

Figure 1b). The bowl shaped fusion boundaries are visible, elongated along the scan direction, and rounded off in the print direction (y-axis).

In the micrographs of the island scan modeled specimen (

Figure 7), the microstructure at the connections between islands is observed to consist of prior β grain interfaces. Some are wavy, looking like intertwined 50–100 µm waves, while others are less distinguishable. The macrostructure is very chaotic, due to the different scan strategies, resulting in more erratic prior β grains. The prior β grains are elongated, roughly along the build direction, but differ significantly in width, both within the islands and among islands with different scan strategies. An example is the spiral scans, creating prior β grains tilted either to the center of the island (out-in) or from the center and to the edges of the island (in-out). The contrast resulting from fusion boundaries is less pronounced than for the island scan modeled specimen, while banding structures from selective etching are abundantly present. Some islands show clear layering, while others have none.

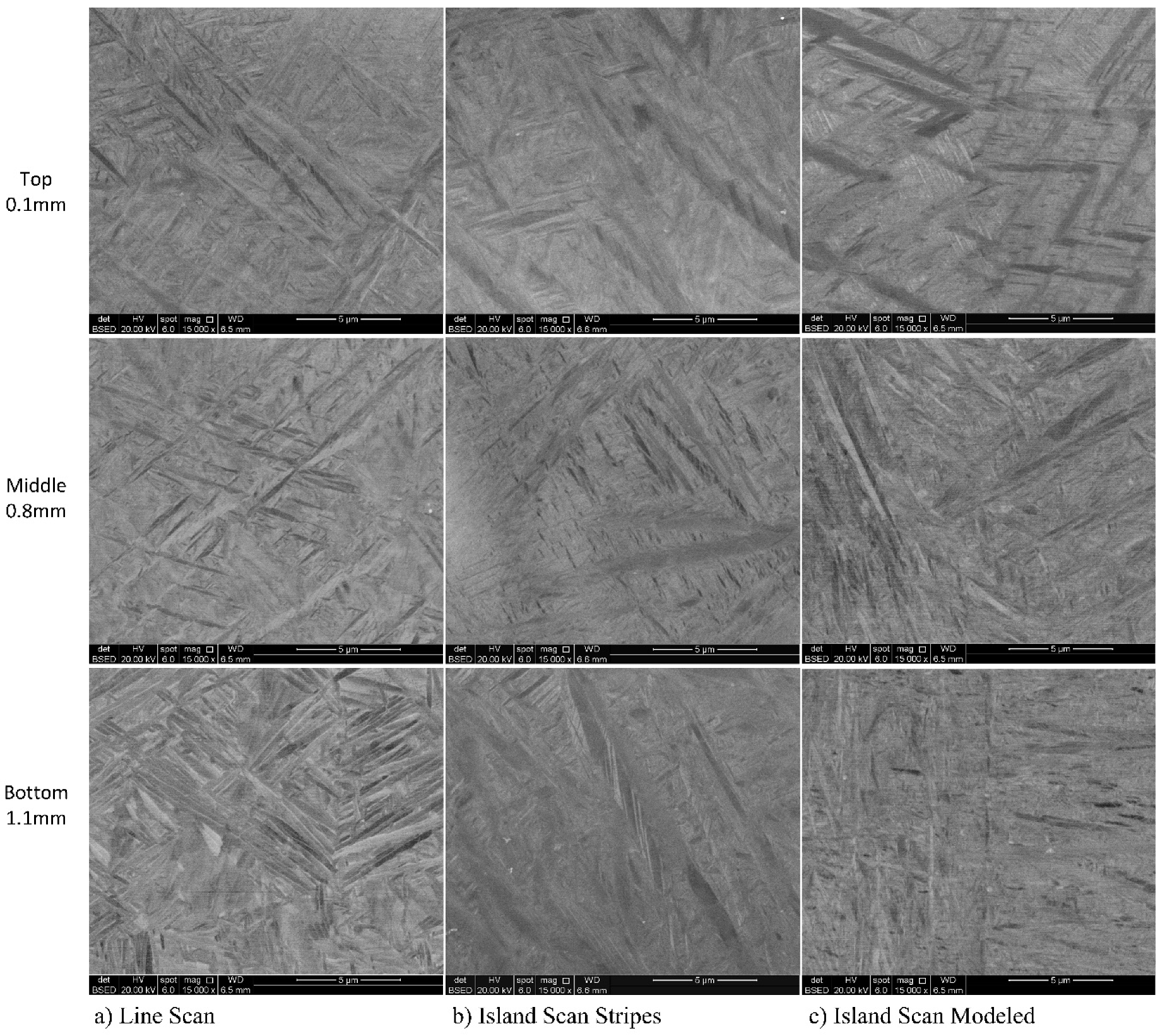

The microstructures as revealed by SEM are presented in

Figure 8 for the three specimens at three different locations (bottom, middle, and top). The microstructure in the top and middle of the SLM specimens is acicular α’ martensite, with twinned primary and secondary α’ plates.

Mostly the martensite in the SLM specimens shows acicular α’ structure with primary, secondary, tertiary, and quartic α’ martensite, as described by Yang et al. [

13]. This is clearly observed for the line scan specimen at the top and in the middle (

Figure 8a). In the bottom of the line scan specimen, the microstructure is mainly ultrafine lamellar as revealed by partitioning observed in backscatter imaging, indicating that decomposition of α’ into α + β had occurred [

14]. The lamellar α and β forms from the α’ martensite by partitioning of Al and V [

26]. The lamellar α + β may also have formed indirectly from α’; where α’ martensite is transformed into β during reheating, from which α and β lamellar form during cooling, if the cooling after reheating is sufficiently slow.

No such α’ to α + β transformation was observed in the island scan specimens, where hierarchical α’ martensite was the only microstructure constituent observed, as no partitioning was visible (

Figure 8b). The different microstructures in the bottom parts of the specimens confirm that the etching response in the top and bottom, as observed in

Figure 2 and

Figure 5 for the line scan strategy, are a consequence of different microstructures and local composition variations (see above).

The inhomogeneous structure of the island scan modeled specimen is also visible in the martensitic microstructure, showing different lath morphologies in the lateral and vertical location. The microstructure in the top, middle, and bottom images of

Figure 8c is therefore not covering the full morphology of the specimen at the ascribed height, but merely examples. At the top, a morphology of zig-zag α’ plates with thinner acicular α’ in-between the zig-zag plates was observed. In the bottom ultra-fine martensite is observed, around primary α’ plates starting at the prior β grain boundary (

Figure 8c, bottom).