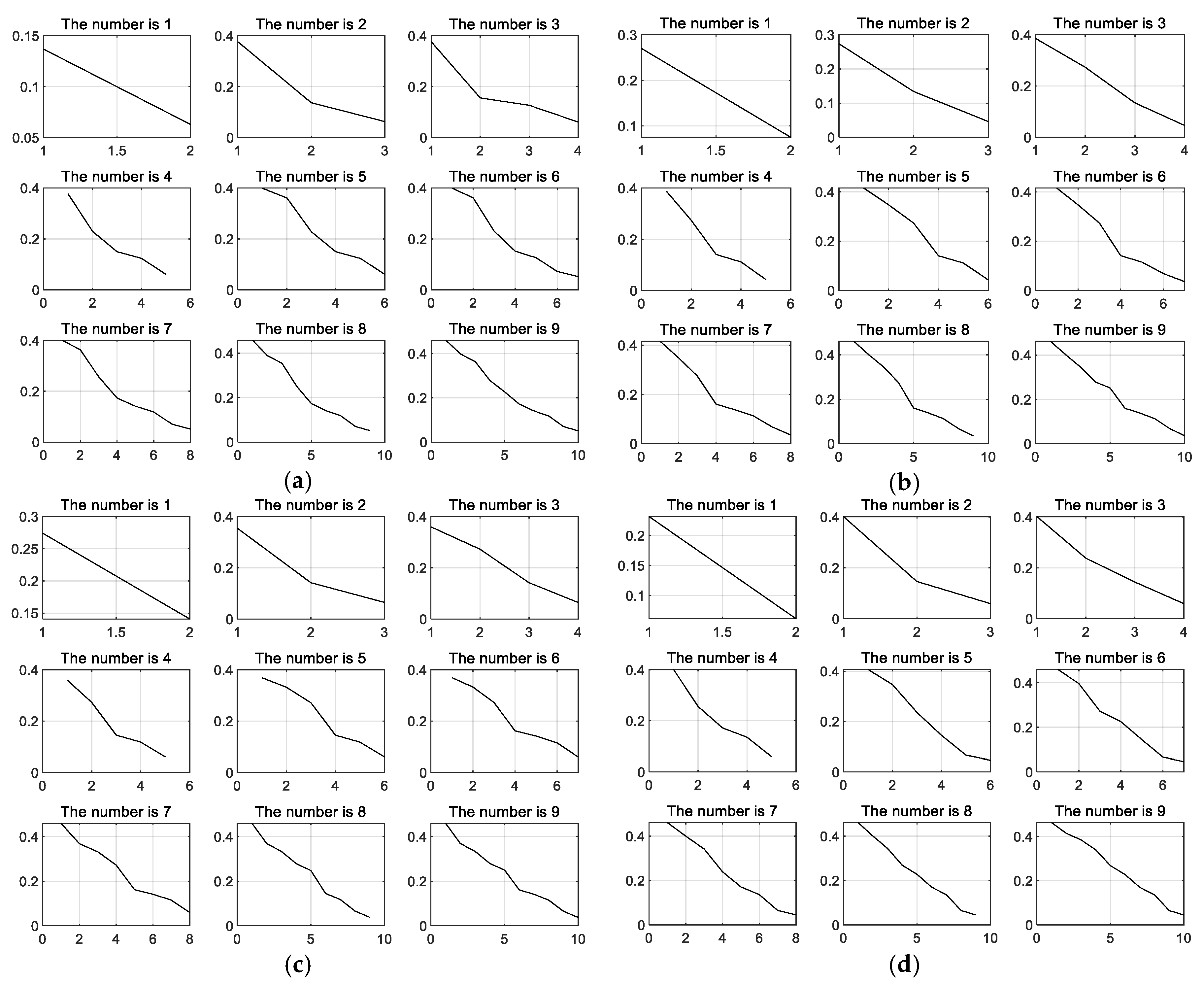

The standard component kurtosis values are selected for training. The sample number 1 and sample number 2 of the normal gear data set, the sample number 5 and the sample number 6 of the gear with tooth wear data set, the sample number 9 and the sample number 10 of the gear with tooth crack data set, and the sample number 13 and sample number 14 of the gear with tooth break data set are selected to form a training sample matrix input into the SOM neural network for training. After the training of SOM neural network, the remaining 8 sets of samples were input into the standard SOM neural network for gear fault diagnosis as the unknown gear fault test sample matrix.

Fault Diagnosis and Result Analysis

Eight sets of data were extracted from 16 sets of sample data, including one set for each gear states. The remaining 8 sets of data were tested as test data sets. The kurtosis value normalization matrix was input into SOM neural network for classification and identification, and the following results were the training times of 100.

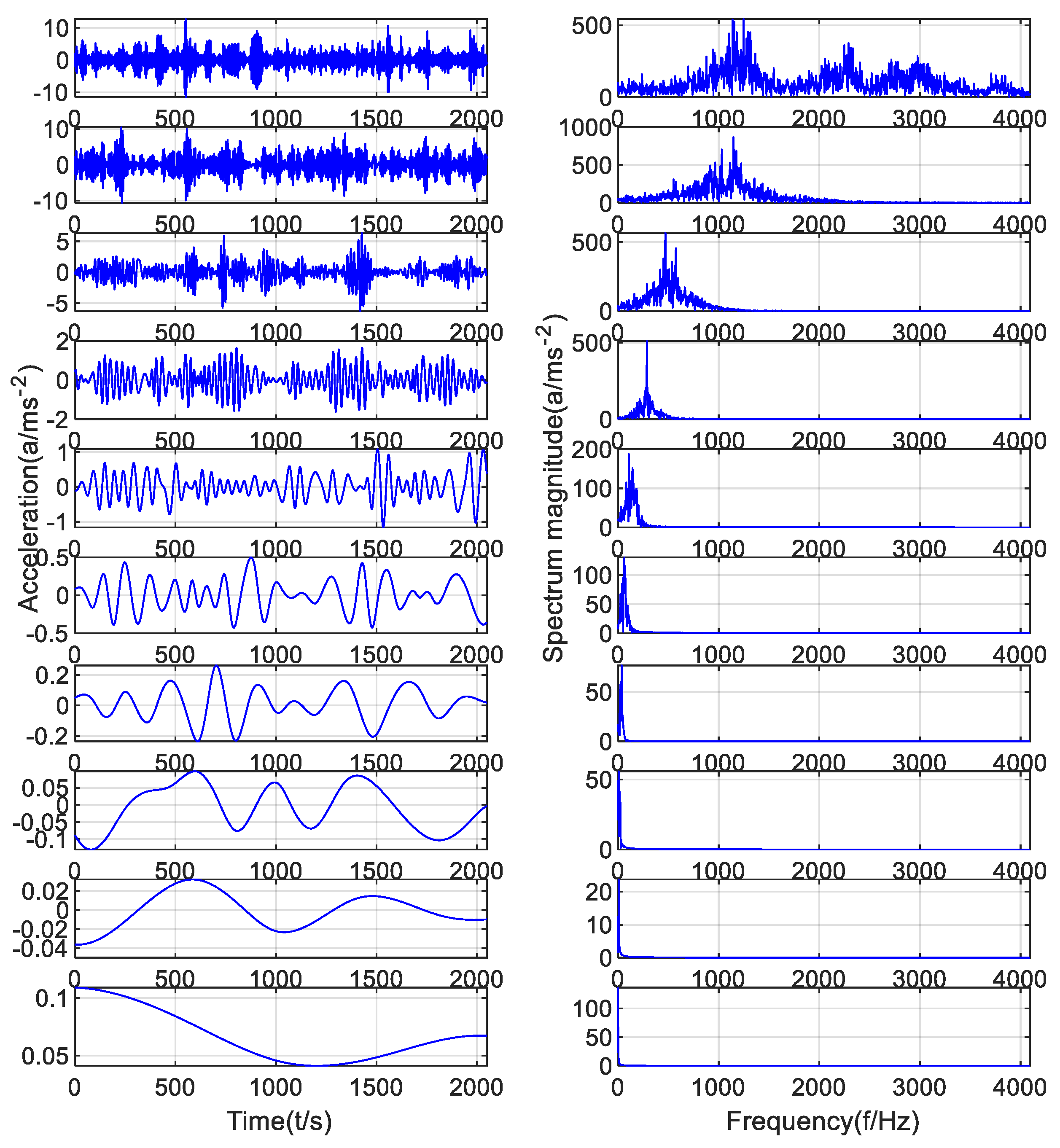

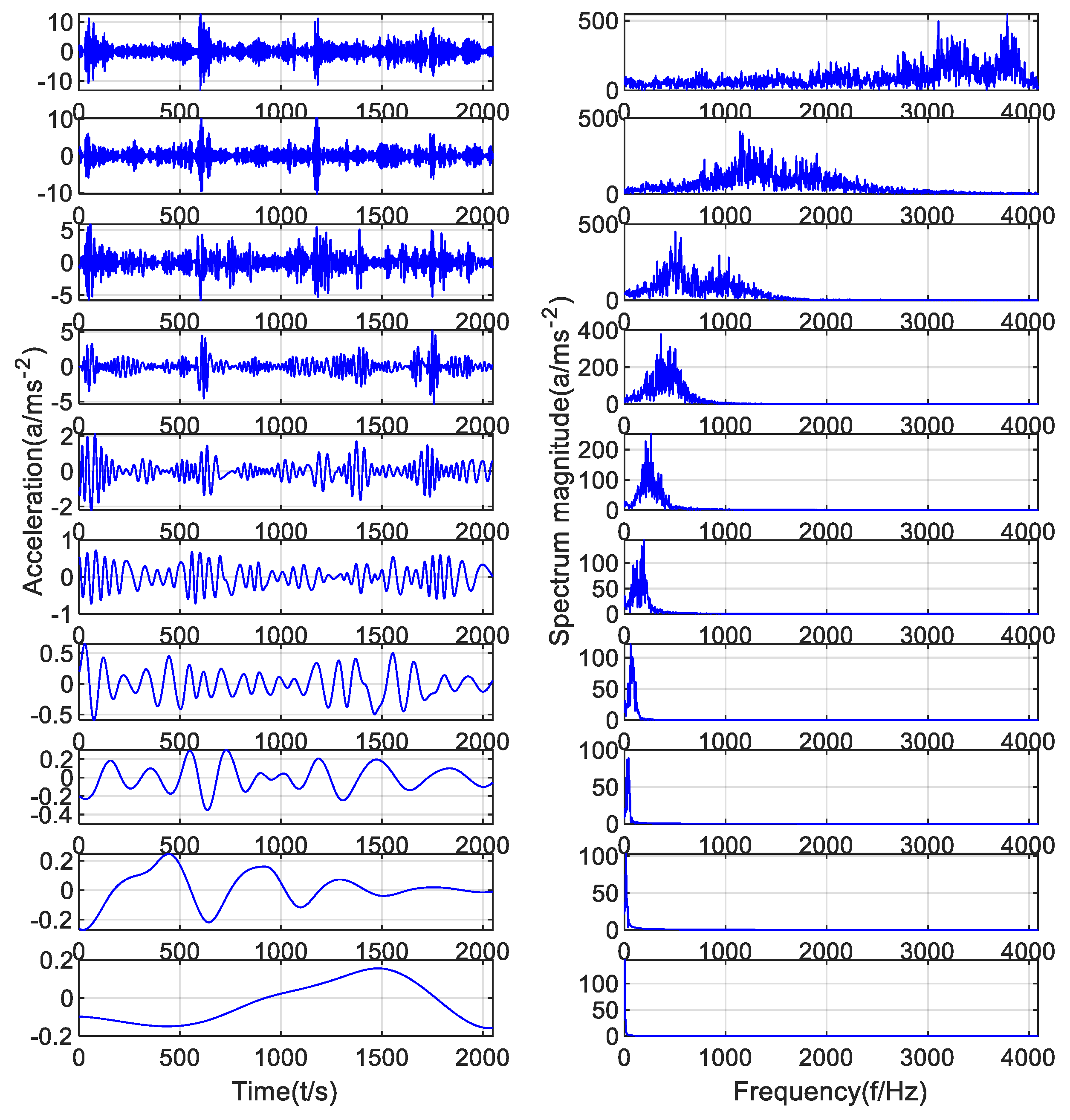

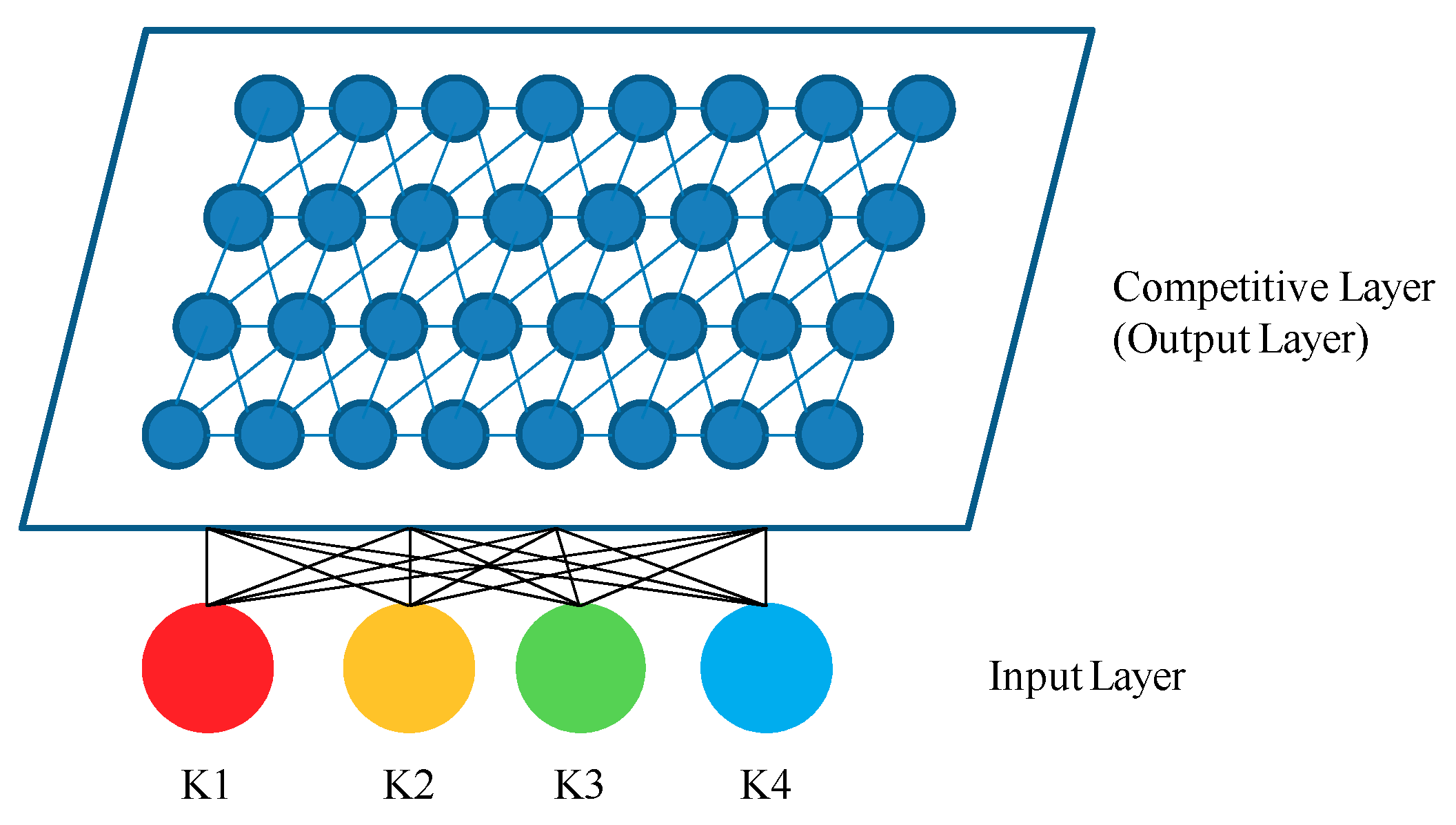

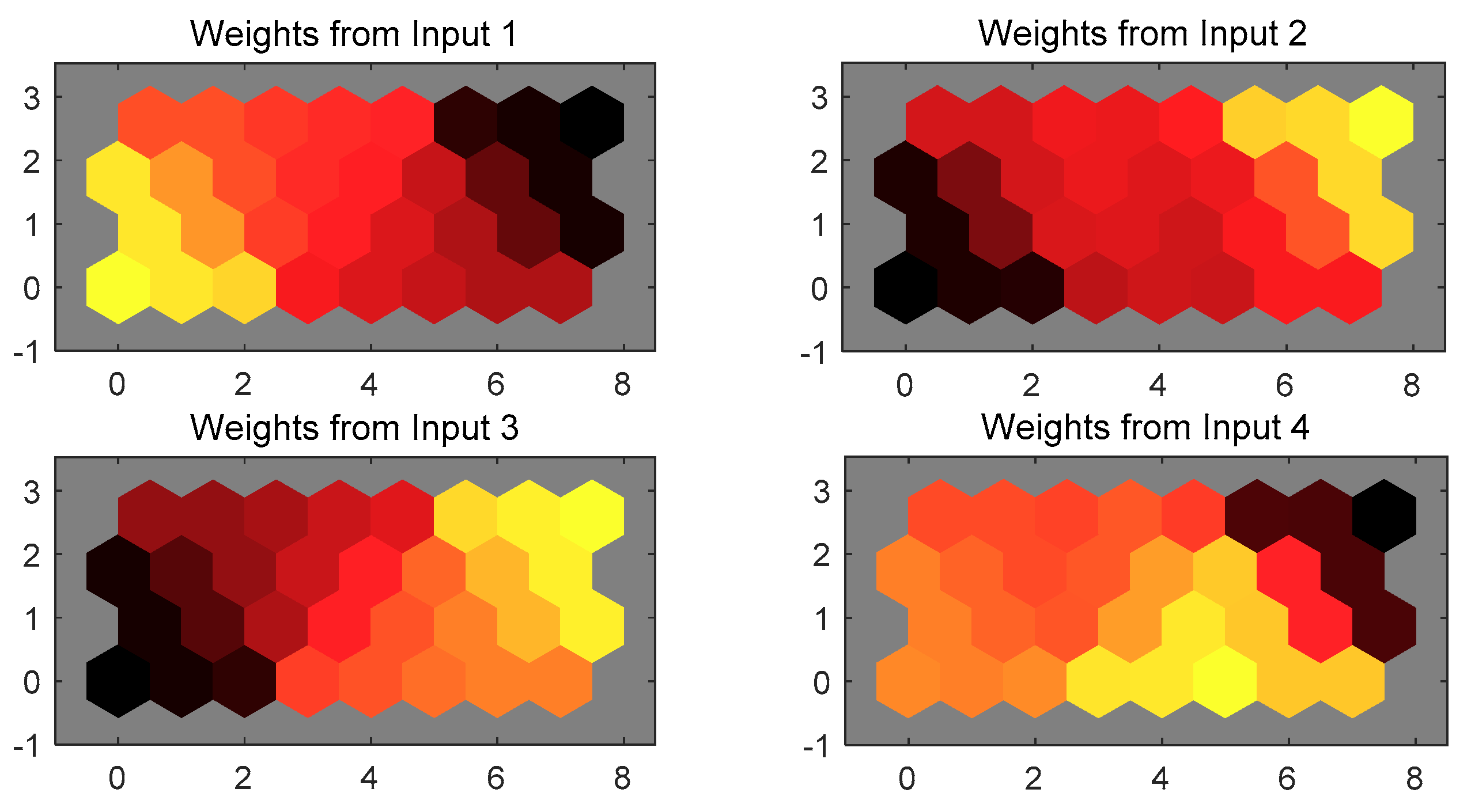

The kurtosis value normalization matrix in

Table 2 is used as training data to train the SOM neural network.As the number of training steps increases, theweight vector is constantly adjusted and the magnitude of theweight vector is also changed.Where, the weight connection between the input sample and the competition layer neuronsare shown in

Figure 17, where the lightest color hexagon weight value is the smallest, and the black hexagon weight value is usually 0.

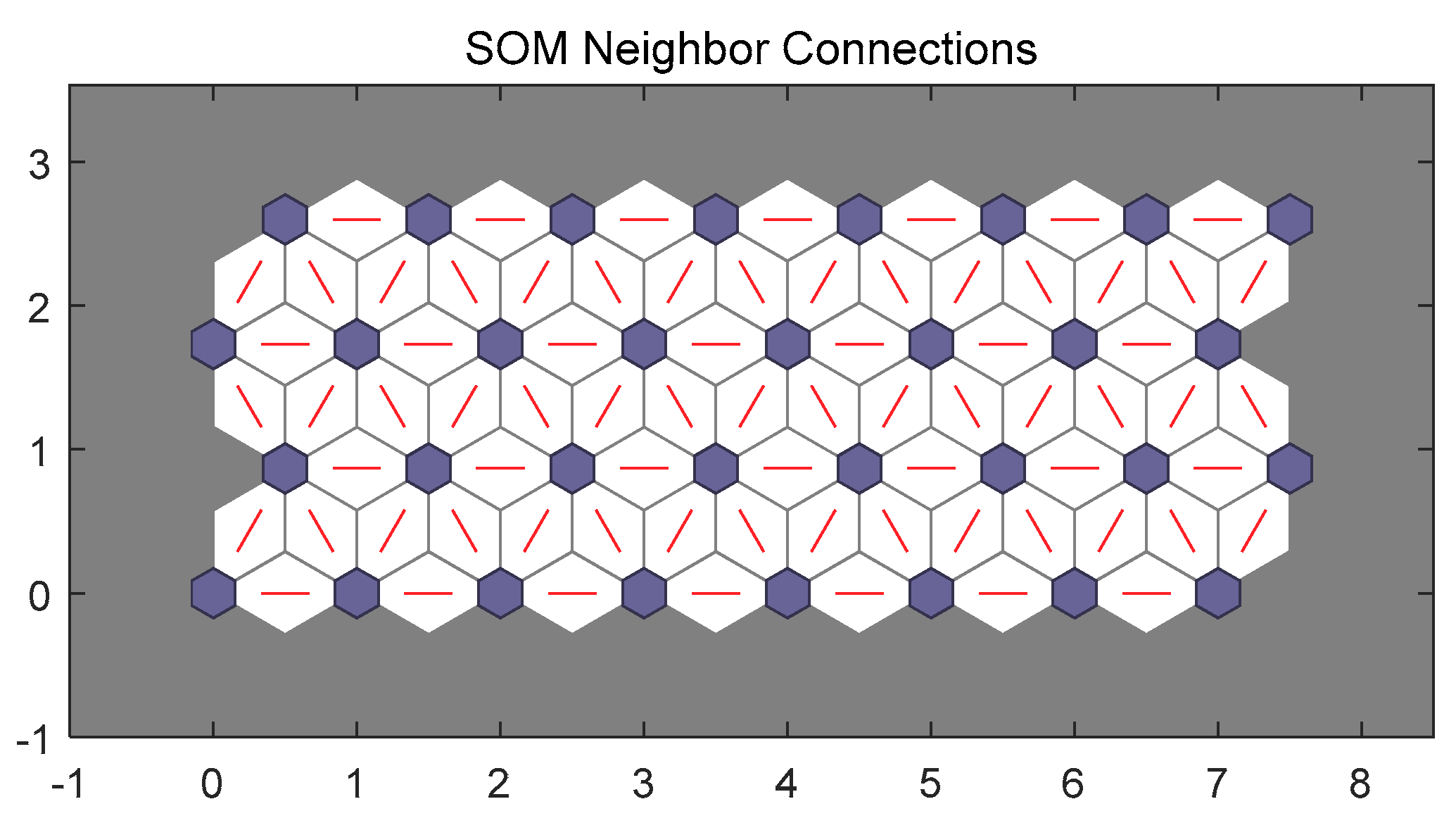

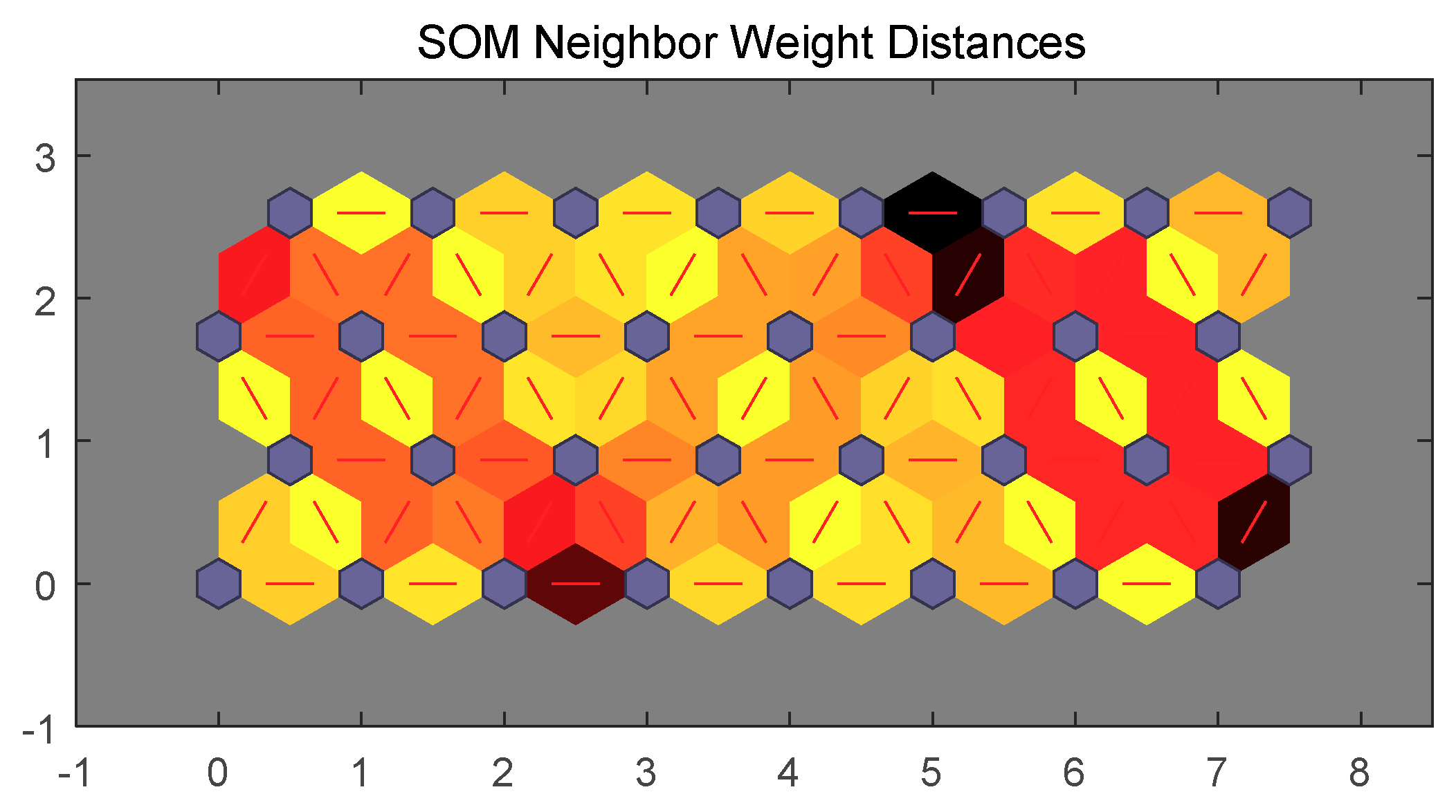

As shown in

Figure 18, the hexagon represents a neuron on the competition layer, the node of the neuron is represented by 32 equal-sized hexagons, and the short line between the hexagons represents the interconnection between the neurons.The difference in color between the diamond blocks located around the neurons indicates the difference in distance between the neurons. The SOM neural network forms clusters based on the distance between the neurons, and there is no clear boundary between the clustering results. From the color (light to dark) of the diamond block, the darker the color that the block is, the farther the distance between the neurons.

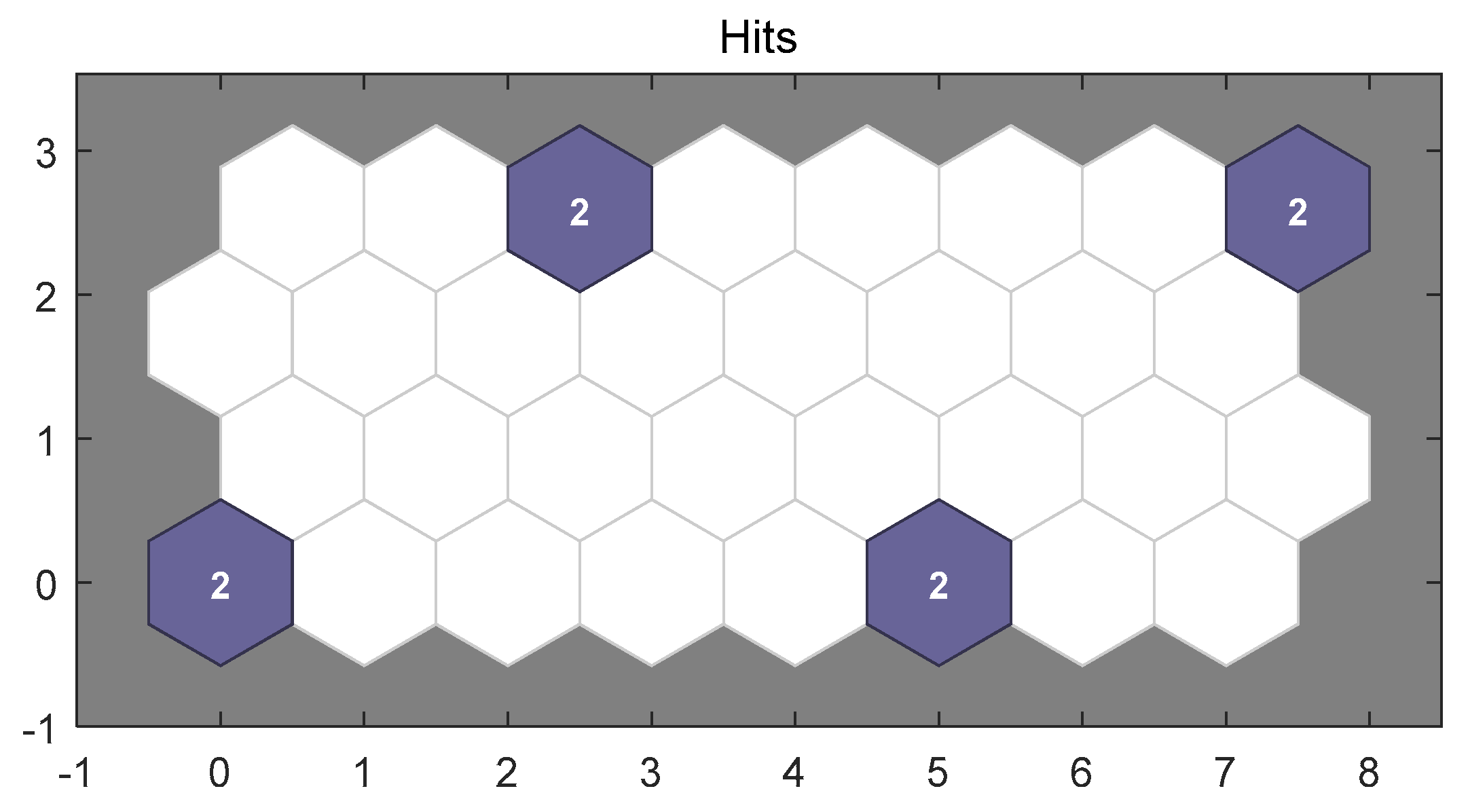

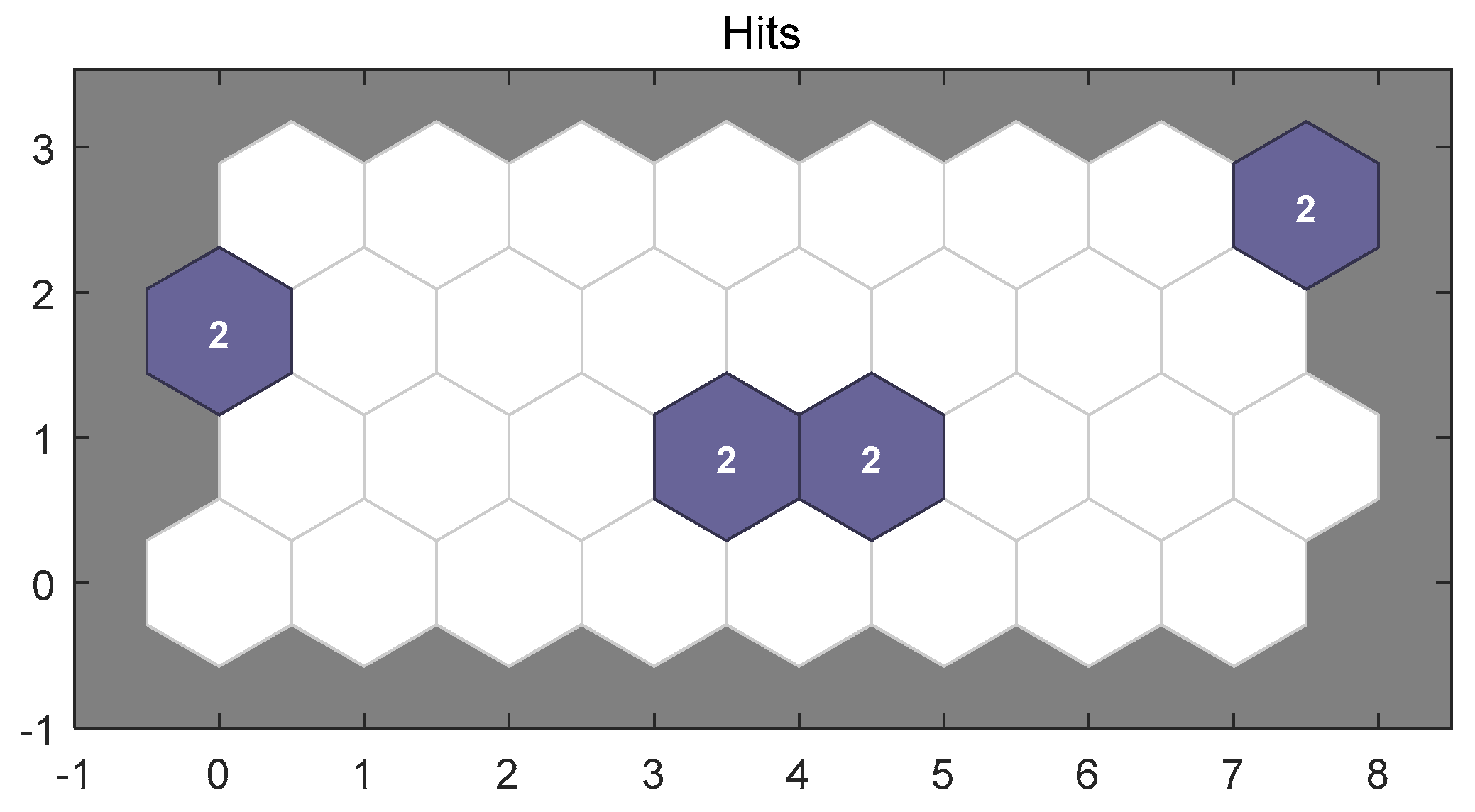

Figure 19 is the recognition result of training times of 100:

According to the clustering results of SOM neural network, adjacent neurons can be regarded as the same species, while neurons with more distant neighbors can be regarded as different species. In

Table 3, the numerical values of the classification results indicate the location number of SOM neural network neurons, and the adjacent number indicates the adjacent neurons, which are regarded as the same species. As shown in

Figure 12, the four fault types of gear fault, normal gear, gear with tooth wear, gear with tooth crack, and gear with tooth break are effectively distinguished. The accuracy of gear fault of SOM neural network is 100% when the number of trainings is 100. Among them,

Table 3 shows the classification results of the training samples numbered 1, 2, 5, 6, 9, 10, 13, and 14, which were input into the SOM neural network as the training sample matrix and the training times were 100.

Table 4 shows the classification results of the samples numbered 3, 4, 7, 8, 11, 12, 15, and 16, which were input into the SOM neural network as the test samples matrices after 100 times of training. By comparing the classification results in

Table 3, it can be seen that all test samples have been correctly classified into the corresponding fault categories, and the fault diagnosis recognition rate is 100%.

Figure 17,

Figure 18 and

Figure 19 show that when the training times are 100 times, 8 test samples of SOM neural network fault diagnosis model classifier correspond with the training samples of standard SOM neural network, and its fault diagnosis accuracy is up to 100%. It effectively proves the effectiveness of SOM neural network in the classification and identification of gear fault diagnosis.

In order to obtain the identification effect advantage of the SOM neural network when the training times are 100 times and the training times are 10, 50, 500, and 1000 times, the gear failure accuracy is compared, respectively, in

Figure 20,

Figure 21,

Figure 22 and

Figure 23.

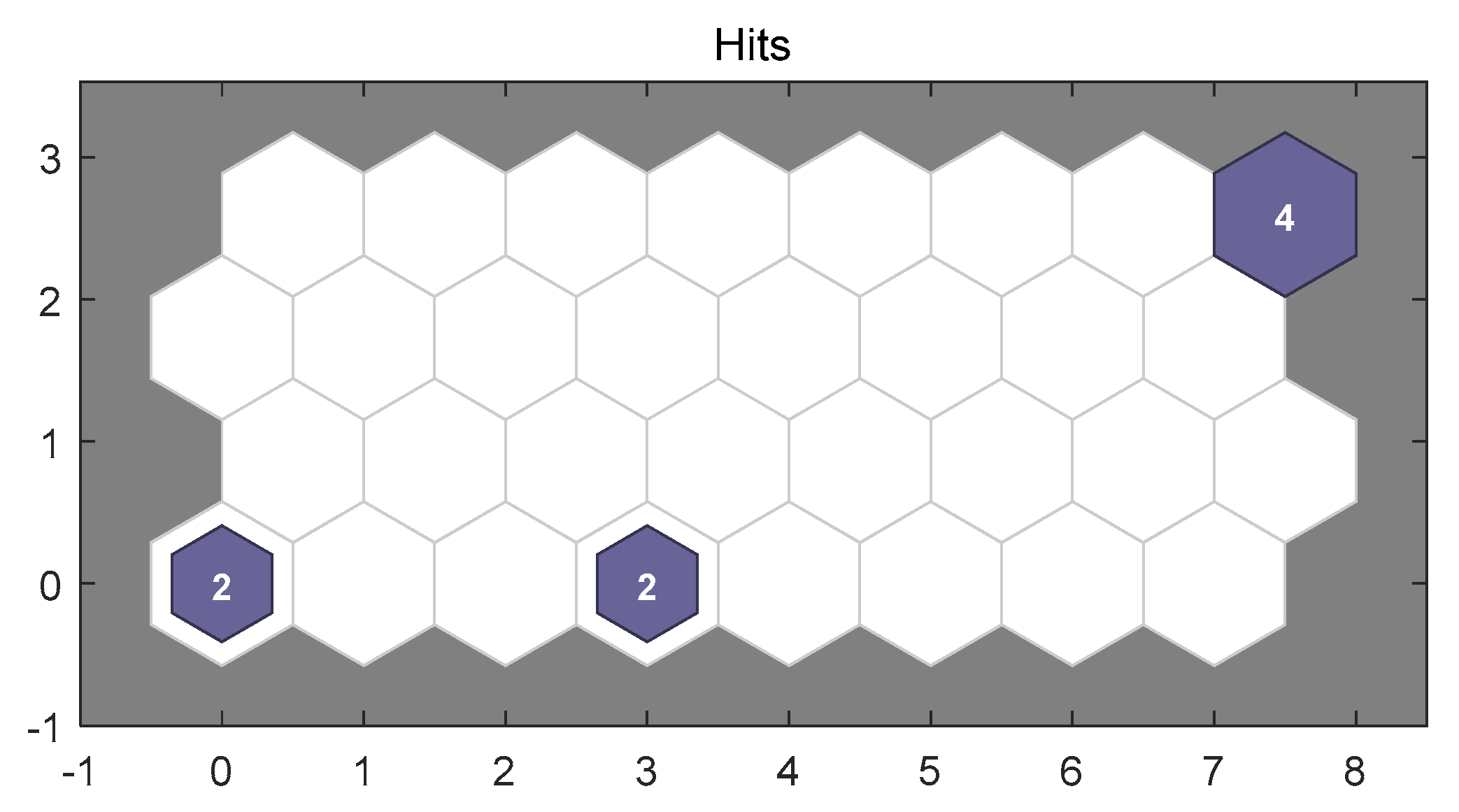

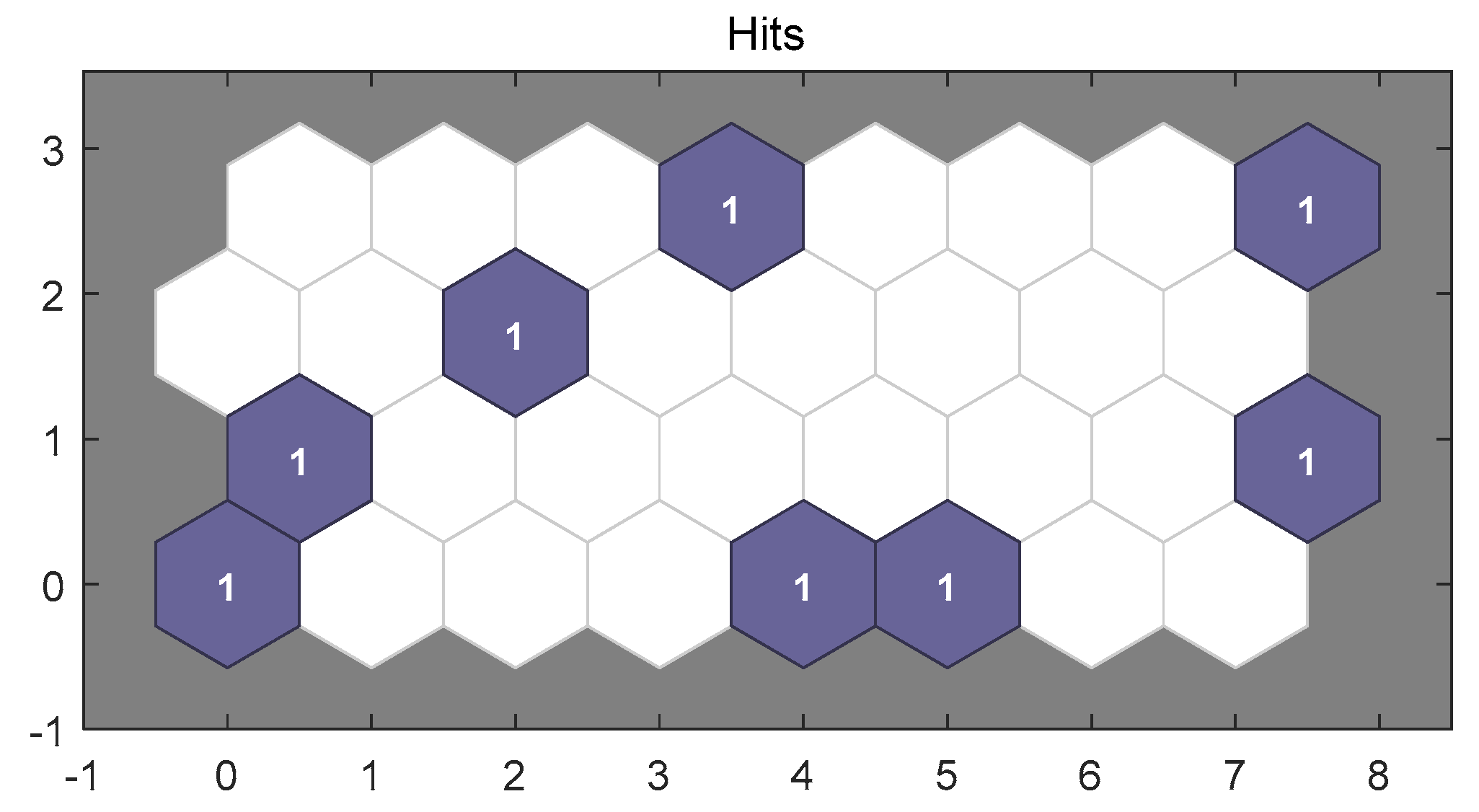

Figure 20 shows the recognition result of the training number 10:

As can be seen from the identification results in

Figure 20, the four fault types of gear, normal gear, gear with tooth wear, gear with tooth crack, and gear with tooth break were classified into three fault states and onegear fault state was not identified. From the identification results in

Table 5 and

Table 6, it can be concluded that normal gear and gear with tooth wear are identified into the same category. This is the classification result of SOM neural network with 10 times of training, and

Table 5 is the classification result of SOM neural network with 10 times of training as the training sample matrix with sample numbers 1, 2, 5, 6, 9, 10, 13, and 14.

Table 6 shows the classification results of the sample numbered 3, 4, 7, 8, 11, 12, 15, and 16, which were input into the SOM neural network as the test sample matrices after 10 training times. By comparing the classification results in

Table 5, it can be seen that the classification results of the test samples from the fault training samples are not good, in which there is an identification error in the fault state of gear with tooth wear and gear with tooth break respectively, resulting in a fault diagnosis identification rate of 75%.

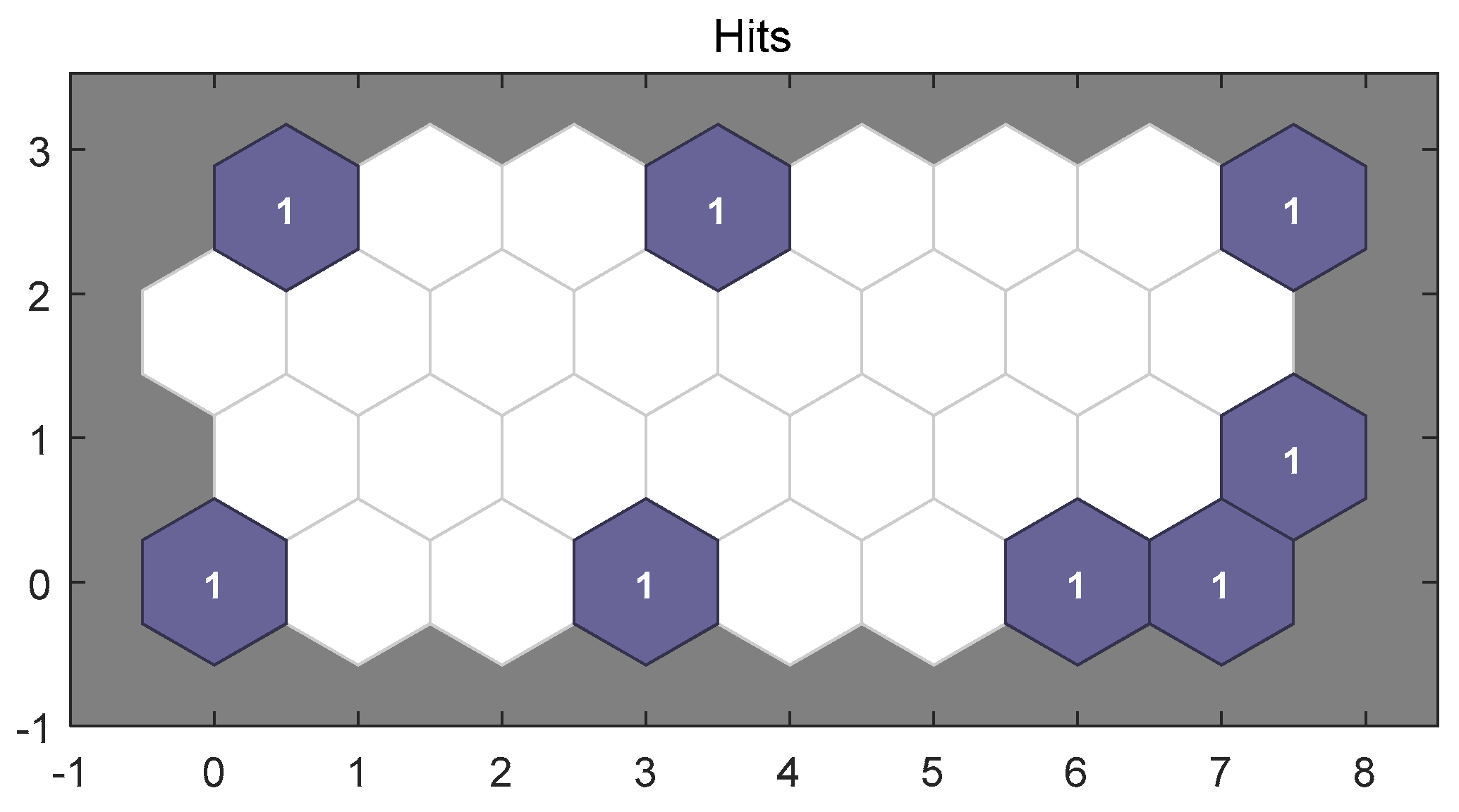

Figure 21 shows the recognition result of the training number 50:

As can be seen from the identification results in

Figure 21, the four fault types of gear, normal gear, gear with tooth wear, gear with tooth crack, and gear with tooth break, were classified into three fault states, and also onegear fault state was not identified. From the identification results in

Table 7 and

Table 8, it can be concluded that gear with tooth wear and gear with tooth crack are identified into the same category. This is the classification result of SOM neural network with 50 times of training, and

Table 7 is the classification result of SOM neural network with 50 times of training as the training sample matrix with sample numbers 1, 2, 5, 6, 9, 10, 13, and 14.

Table 8 shows the classification results of the sample numbered 3, 4, 7, 8, 11, 12, 15, and 16, which were input into the SOM neural network as the test sample matrices after 50 training times. By comparing the classification results in

Table 7, it can be seen that the classification results of the test samples from the fault training samples are not good, in which there is an identification error in the fault state of gear with tooth wear and gear with tooth break, respectively, resulting in a fault diagnosis identification rate of 75%.

Figure 22 shows the recognition result of the training number 500:

As can be seen from the identification results in

Figure 22, the four fault types of gear, normal gear, gear with tooth wear, gear with tooth crack, and gear with tooth break were classified into six fault states and two unknown fault states emerged. This is the classification result of SOM neural network with 500 times of training, and

Table 9 is the classification result of SOM neural network with 500 times of training as the training sample matrix with sample numbers 1, 2, 5, 6, 9, 10, 13, and 14.

Table 10 shows the classification results of the sample numbered 3, 4, 7, 8, 11, 12, 15, and 16, which were input into the SOM neural network as the test sample matrices after 500 training times. By comparing the classification results in

Table 9, it can be seen that the classification results of the test samples from the fault training samples are not good, in which there is an identification error in the fault state of gear with tooth wear and gear with tooth break respectively, resulting in a fault diagnosis identification rate of 75%.

Figure 23 shows the recognition result of the training number 1000:

As shown in

Figure 23, the four fault types of gear fault, normal gear, gear with tooth wear, gear with tooth crack, and gear with tooth break were classified into eight fault states and four unknown fault states emerged. When the number of training sessions of SOM neural network is 1000,

Table 11 shows the classification results of the training samples numbered 1, 2, 5, 6, 9, 10, 13, and 14 as training samples matrix input to SOM neural network when the number of training sessions is 1000.

Table 12 shows the classification results of samples numbered 3, 4, 7, 8, 11, 12, 15, and 16, which were input into the SOM neural network as the test sample matrices after 1000 times of training. By comparing the classification results in

Table 11, it can be seen that the classification results of test samples from fault training samples are not good, in which there is one identification error in the fault state of gear with tooth crack and gear with tooth break respectively, and two identification errors in the fault state of gear with tooth wear, resulting in a fault diagnosis identification rate of 50%.

Figure 19,

Figure 20,

Figure 21,

Figure 22 and

Figure 23 shows that when the training times are 100 times, 8 test samples of SOM neural network fault diagnosis model classifier correspond with the training samples of standard SOM neural network, and its fault diagnosis accuracy is up to 100%. It effectively proves the effectiveness of SOM neural network in the classification and identification of gear fault diagnosis. However, when the training times were 10 times and 50 times, the 8 test samples of SOM neural network model classifier showed onegear fault state was not identified. And when the training times were 500 times and 1000 times, the 8 test samples of SOM neural network model classifier showed unrecognized types. This is not an identification error, which means that as the number of training sessions increases it is the same for each sample, but it is not divided into categories, and there is an unrecognizable type. At this time, if you increase the number of training, there is no practical significance.

From the comparison of the accuracy of gear fault recognition of the SOM neural network in different training times in

Table 13, it can be obtained that the gear fault recognition accuracy of the SOM neural network is the highest when the training times are 100 times. So the training times of the SOM neural network are 100times.

From the above results, it can be concluded that the effect of SOM neural network is the best when the training times are 100times. The EMD algorithm mentioned in the article will have adverse effects such as mode mixing in the gear fault signal decomposition. Here, the EMD algorithm is combined with the SOM neural network to identify the gear fault states, and then compared with the VMD algorithm and the SOM neural network recognition results.

First, the gear fault signal was decomposed by EMD algorithm, then the kurtosis value was extracted, and then it was normalized as the input vector of SOM neural network. According to the above results, the gear fault identification rate of SOM neural network was the highest when the training times were 100times.Therefore, the training times of SOM neural network are 100 times. The following

Figure 24 shows the recognition diagram of gear fault signal by EMD algorithm is combined with the SOM neural network with 100 training times.

As shown in

Figure 24, the four fault types of gear fault, normal gear, gear with tooth wear, gear with tooth crack, and gear with tooth break were classified into six fault states and two unknown fault states emerged. When the number of training sessions of SOM neural network is 100,

Table 14 shows the classification results of the training samples numbered 1, 2, 5, 6, 9, 10, 13, and 14 as training samples matrix input to SOM neural network when the number of training sessions is 100.

Table 15 shows the classification results of samples numbered 3, 4, 7, 8, 11, 12, 15, and 16, which were input into the SOM neural network as the test sample matrices after 100 times of training. By comparing the classification results in

Table 14, it can be seen that the classification results of test samples from fault training samples are not good, in which there is one identification error in the fault state of gear with tooth crack and gear with tooth break respectively, and two identification errors in the fault state of gear with tooth wear, resulting in a fault diagnosis identification rate of 50%.

As can be seen from the comparison results in

Table 14 and

Table 15, the EMD algorithm will not only generate mode mixing in the process of gear signal decomposition, but also reduce the accuracy of gear fault identification.

According to the comparison results of

Table 3 and

Table 4 with

Table 14 and

Table 15, the advantages of VMD algorithm over EMD algorithm can be obtained, and the optimal training times of SOM can also be obtained. However, there are many classification algorithms. So how do we evaluate the advantages of SOM neural network over other classification algorithms? Here, the SVM algorithm is used for gear fault classification instead of SOM neural network, and the calculation results are shown in

Table 16.

According to the comparison of fault diagnosis accuracy in

Table 16, compared with the EMD algorithm, the VMD algorithm can avoid mode mixing and other shortcomings in the EMD algorithm in terms of decomposition effect. In terms of the accuracy of gear fault diagnosis, the VMD algorithm has a higher accuracy than the EMD algorithm. As for the classification algorithm recognition rate of the SOM neural network, the overall fault diagnosis accuracy of the SOM neural network is much higher than that of the SVM algorithm whether it is matched with the EMD algorithm or the VMD algorithm.Therefore, the algorithm of VMD combined with SOM neural network has better advantages and better application prospects in gear fault diagnosis.