Experimental Investigation on Contaminated Friction of Hydraulic Spool Valve

Abstract

:Featured Application

Abstract

1. Introduction

2. The Real-Time Experimental System of Contaminated Friction Measurement

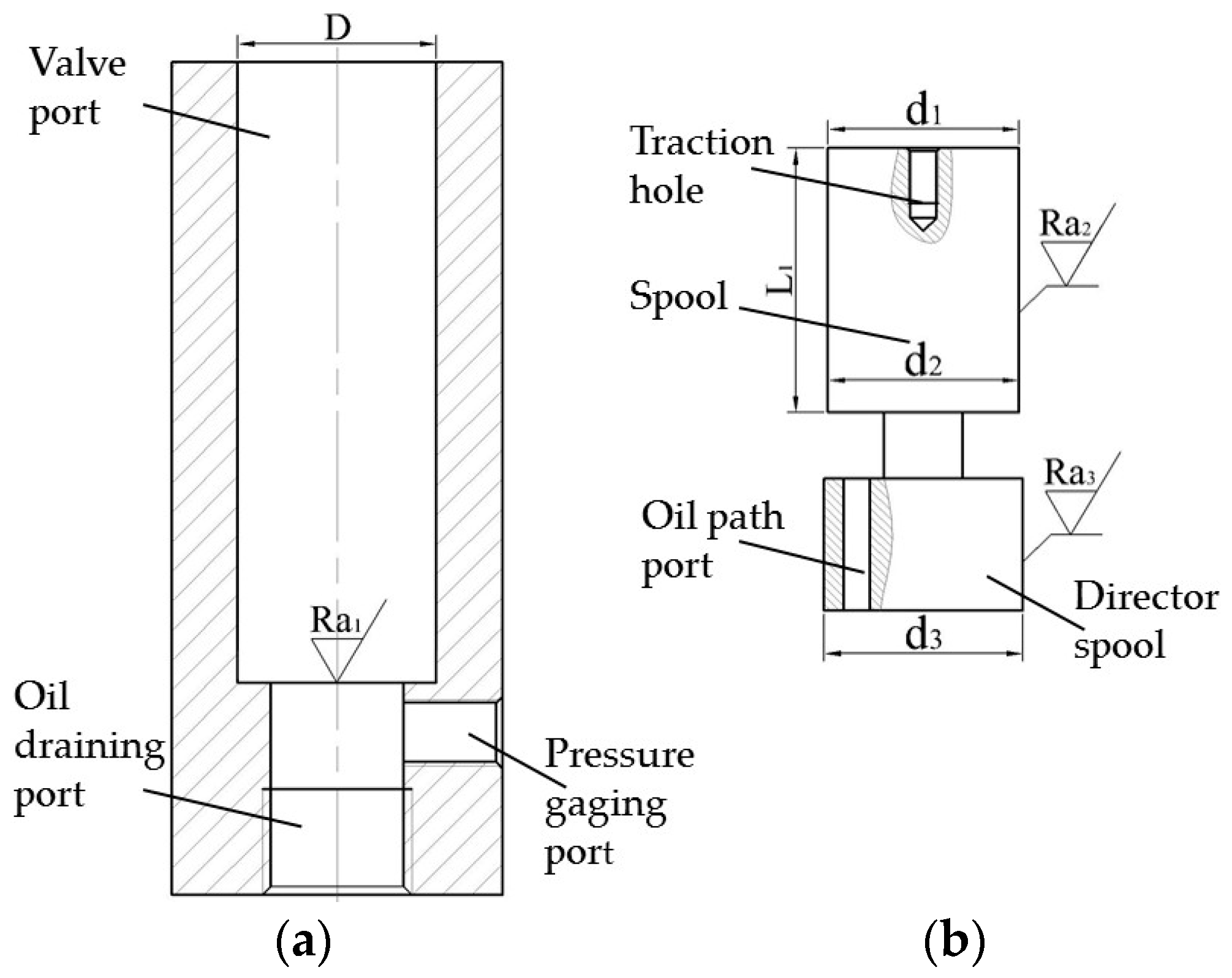

2.1. The Experimental Model of Spool

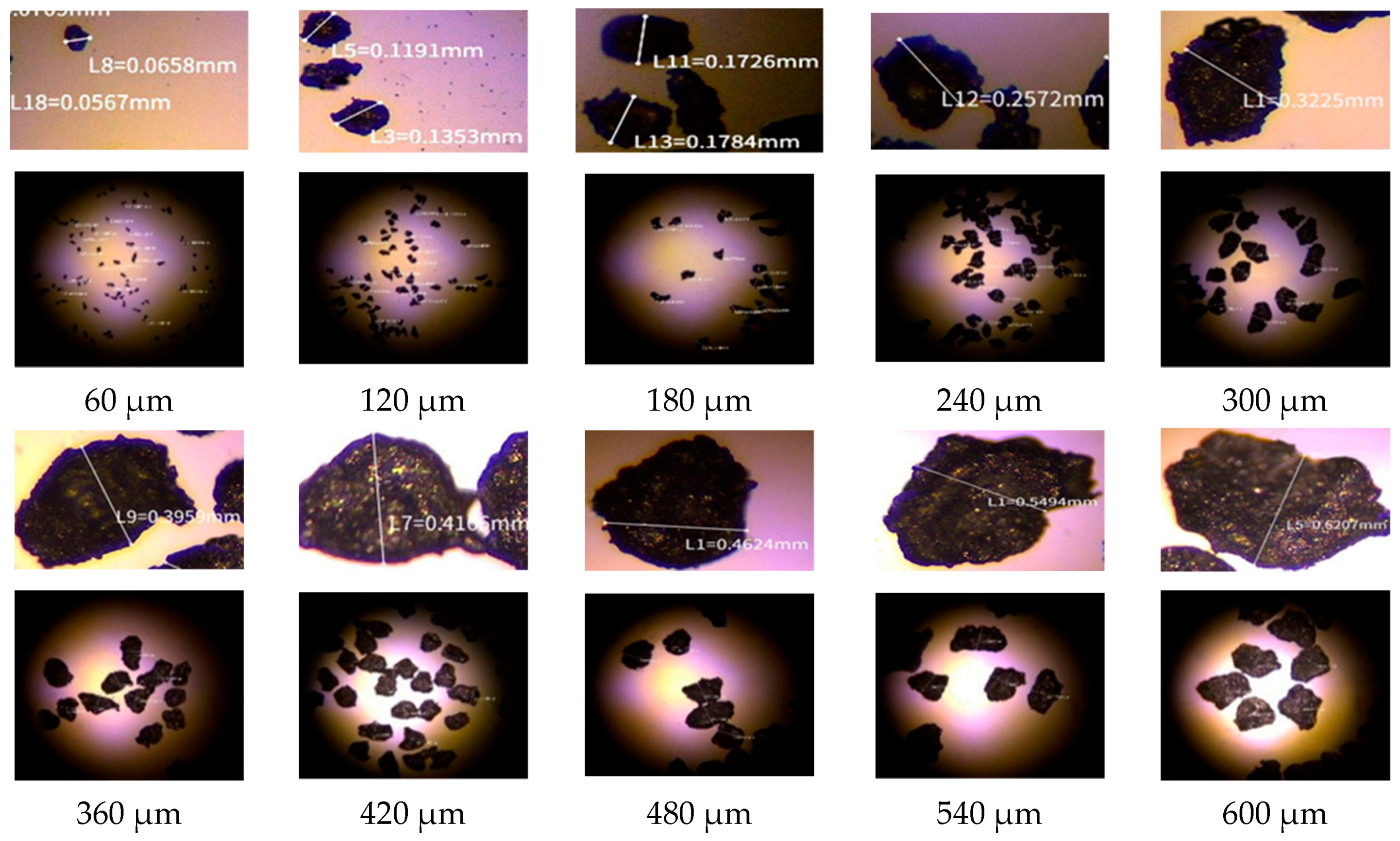

2.2. The Oil of Suspended Solid Particulates

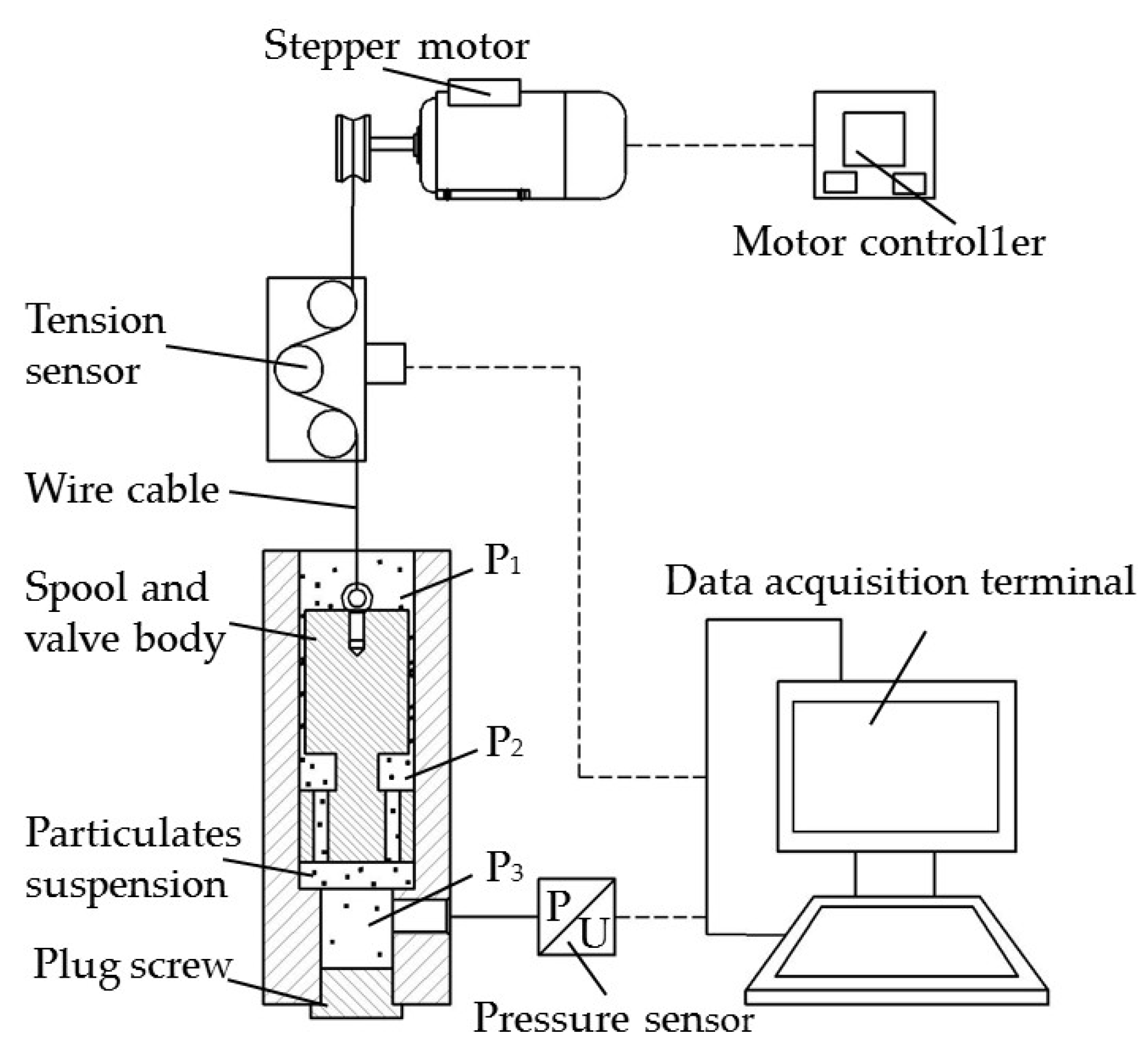

2.3. Experimental Principle

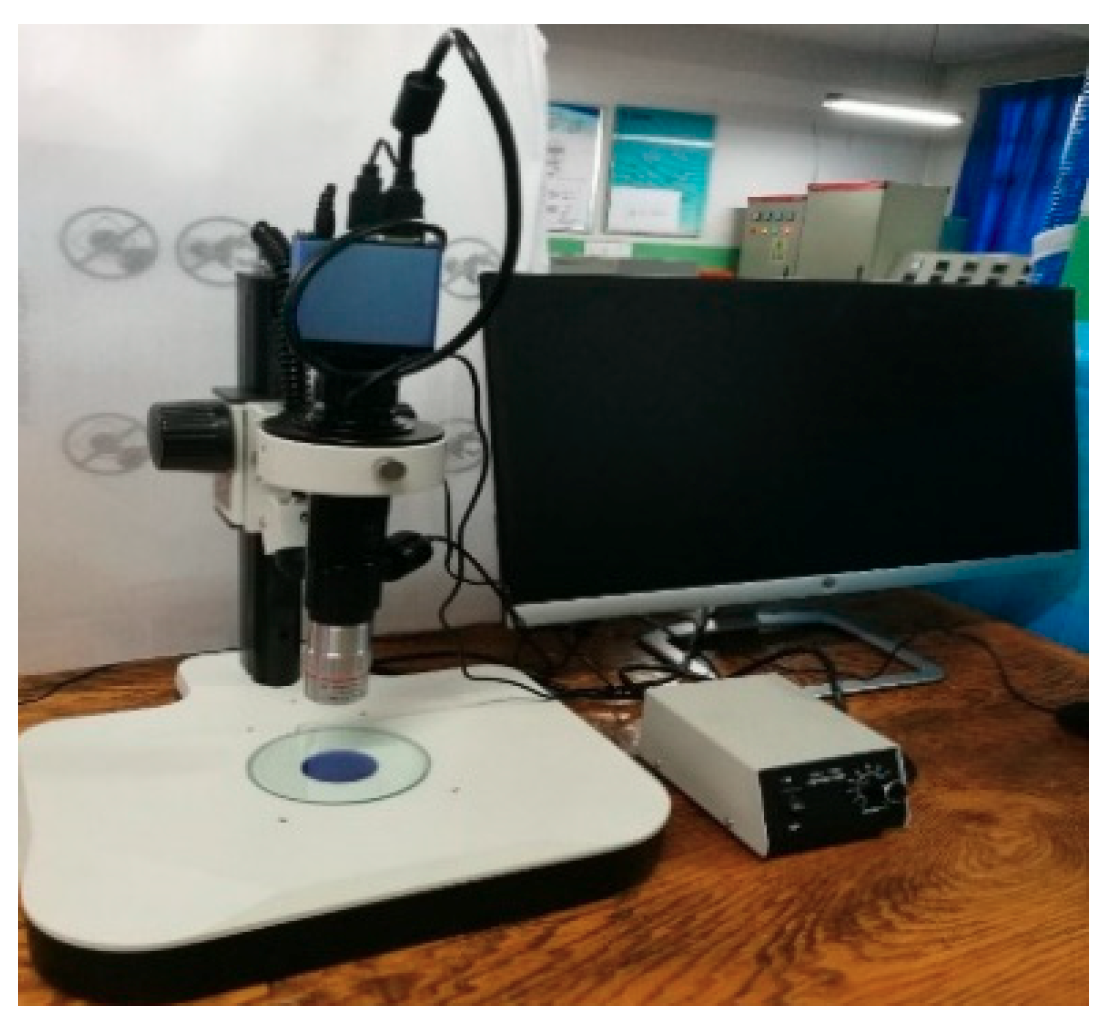

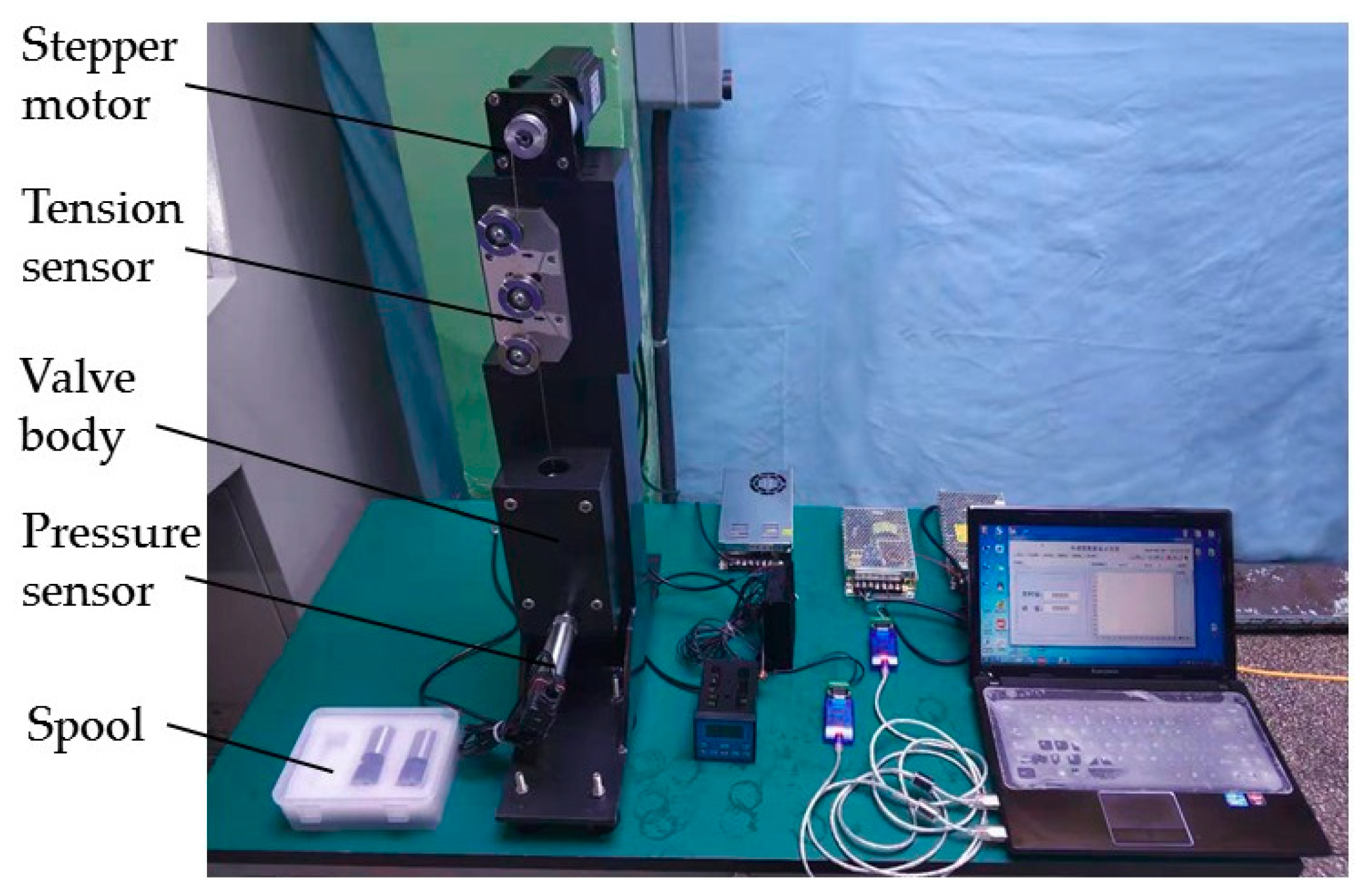

2.4. The Real-Time Experimental Test Bench for Measuring Contaminated Friction of Spool

- (1)

- Place the spools to the bottom of valve hole and injecting oil with particulates suspended of each size into the experimental model.

- (2)

- Start stepper motor and pull spools along the valve hole in a constant velocity.

- (3)

- The real-time traction force and oil pressure values are collected after the movement is stable.

- (4)

- The experimental data were substituted into Equations (2) and (4) for post-treatment. The real-time contaminated friction of spool with various morphologies in oil with particulates suspended of each size was obtained after processing.

2.5. Comprehensive Measuring Accuracy of the Experimental System

3. Contaminated Friction Experimental Analysis of the Spool with Standard Morphology

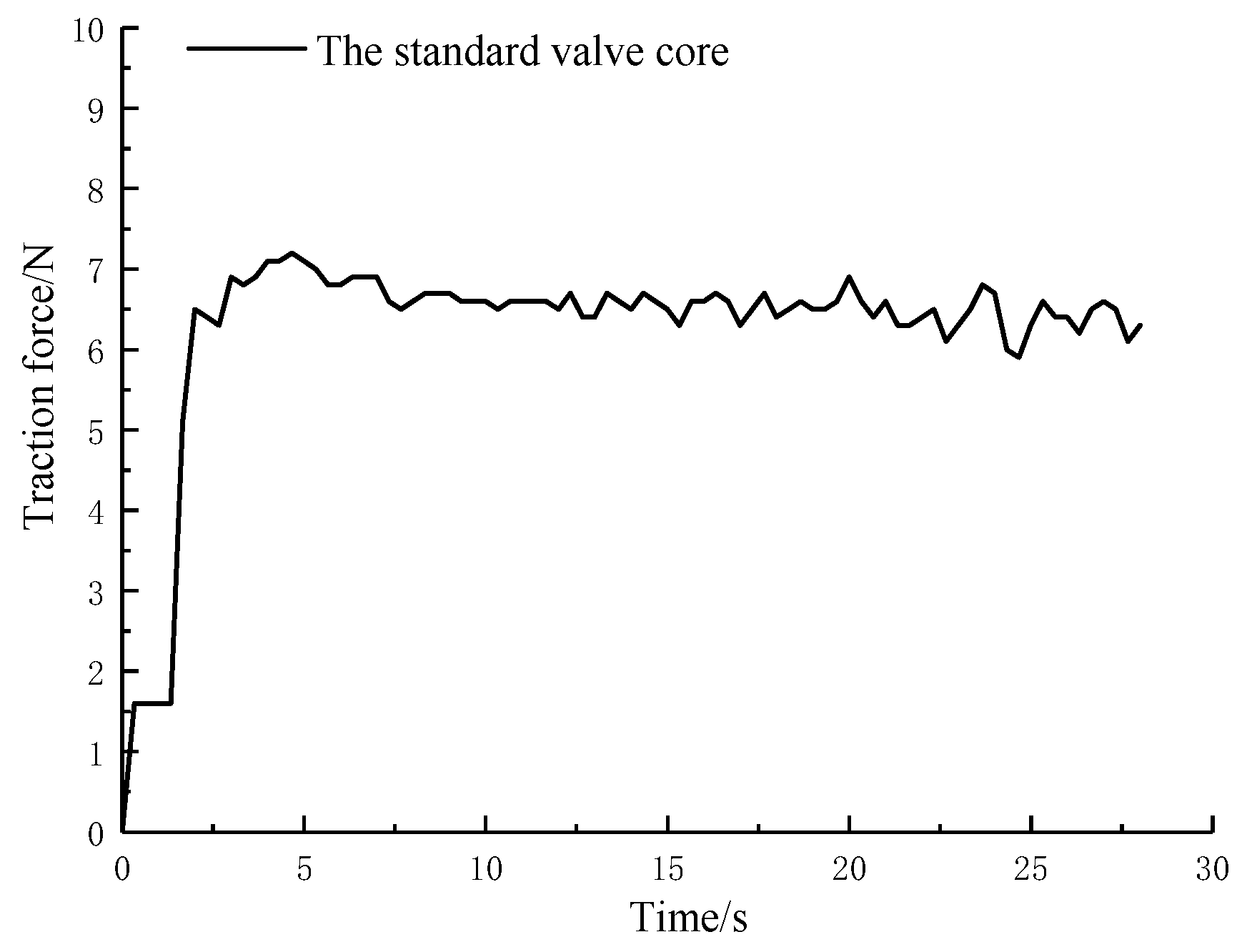

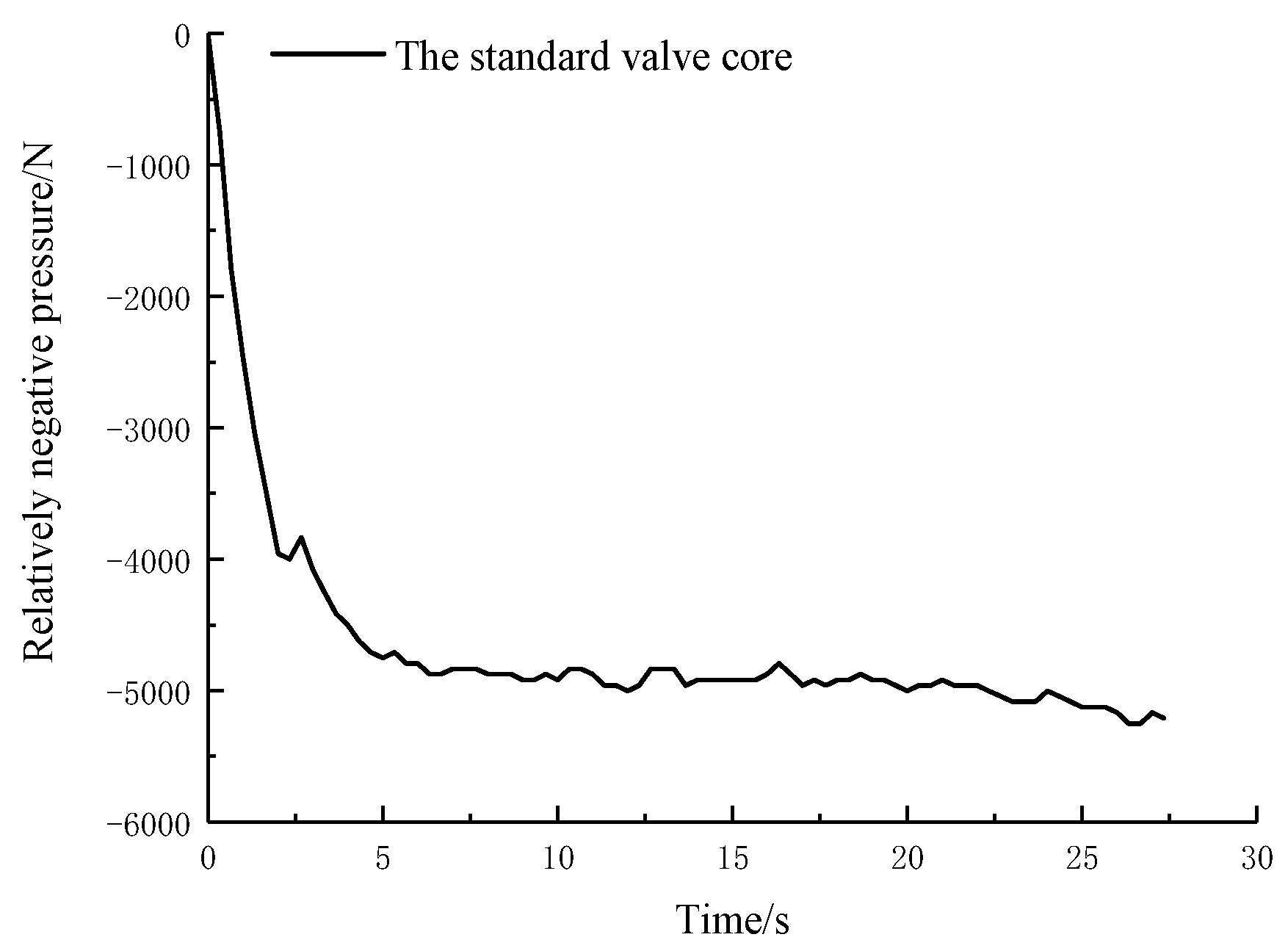

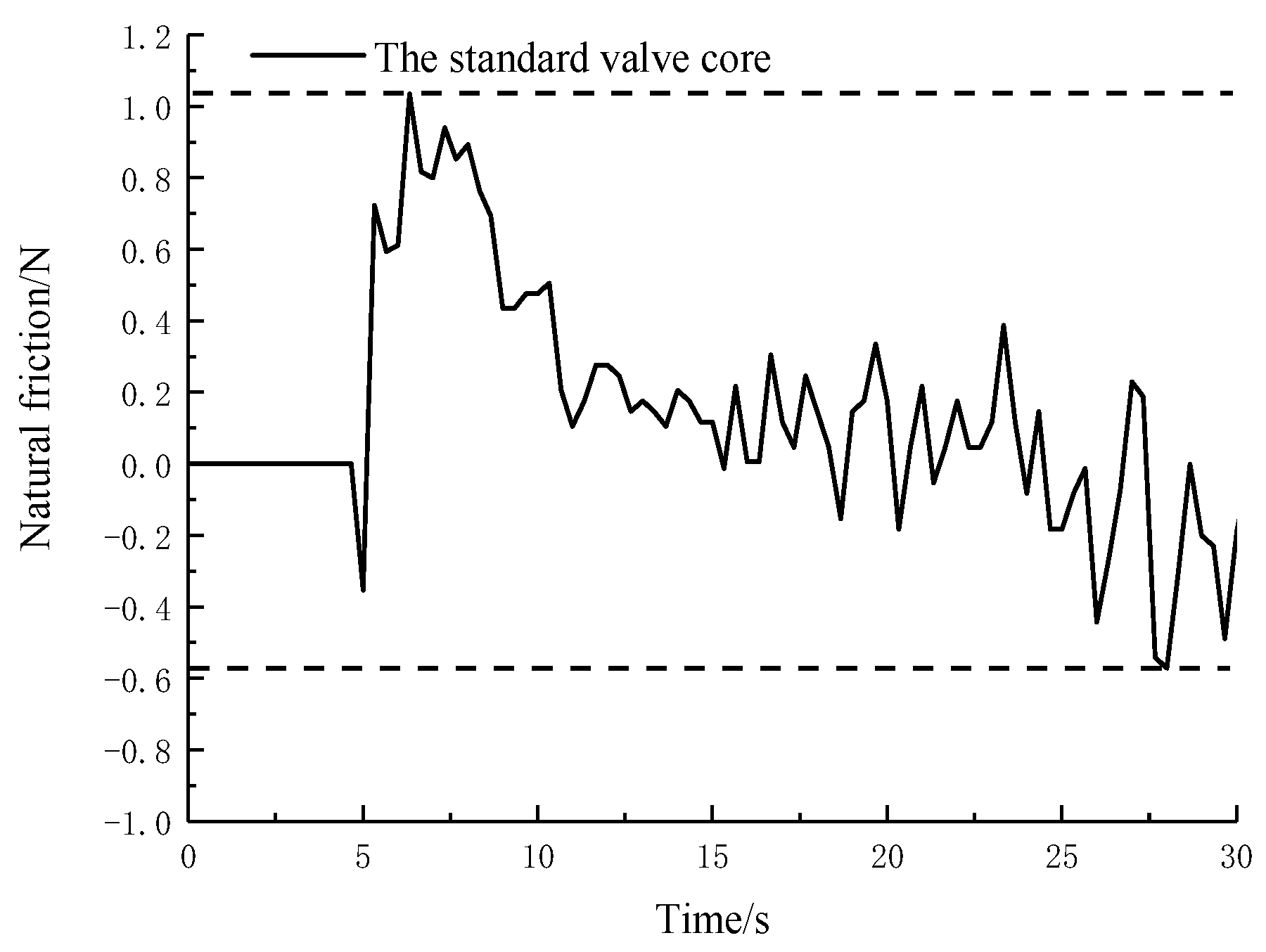

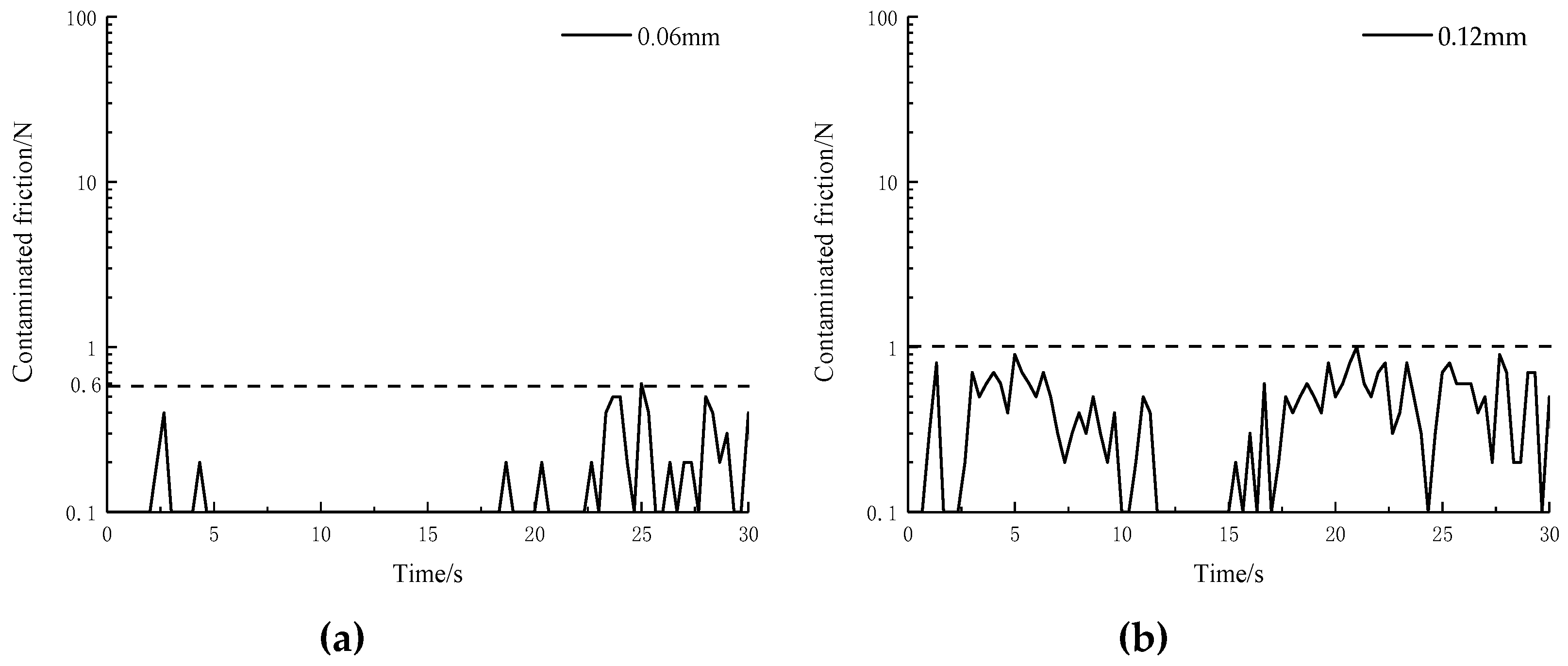

3.1. The Contaminated Friction Curve of the Spool

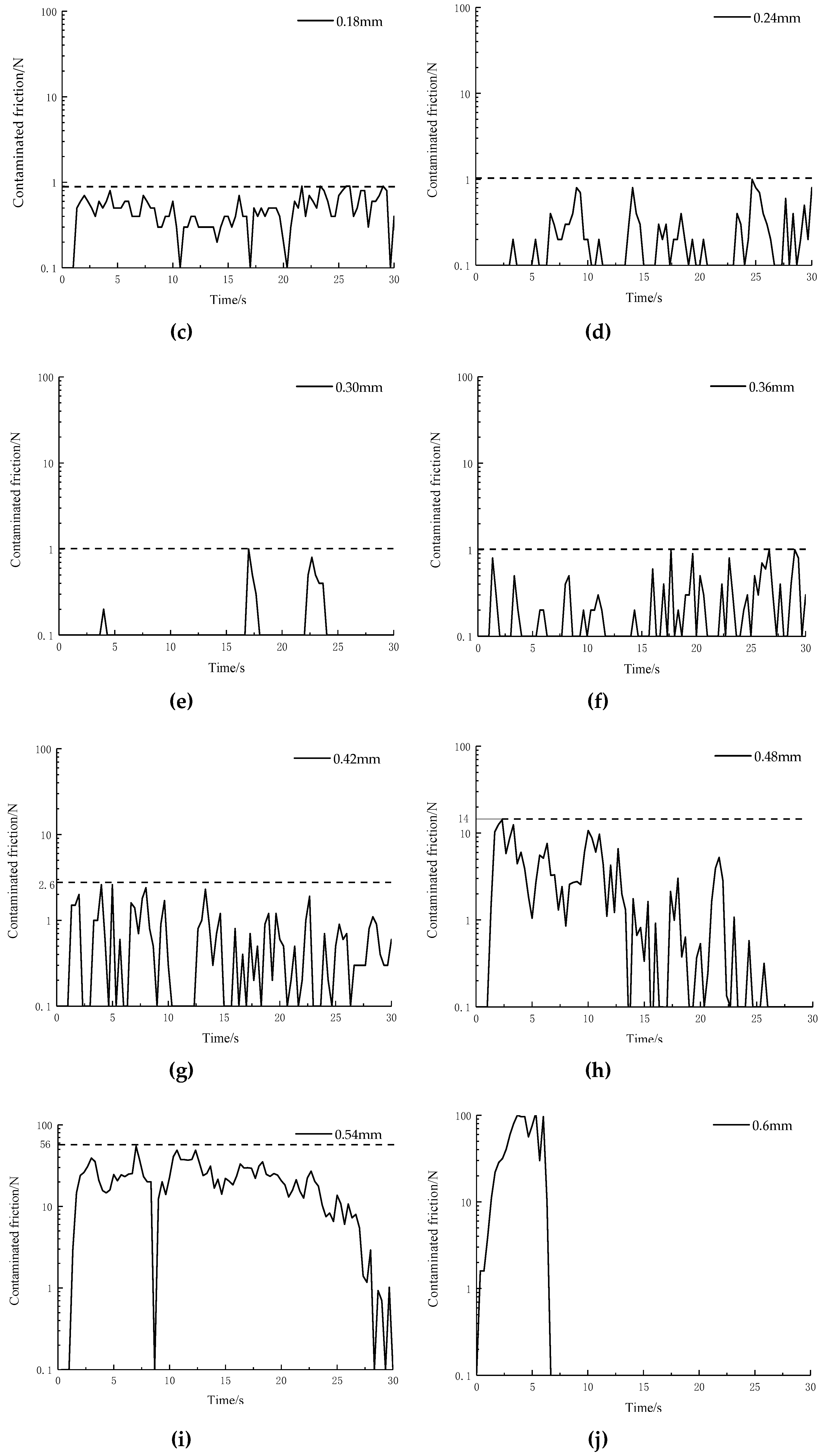

3.2. Stagnation-Sensitive Size

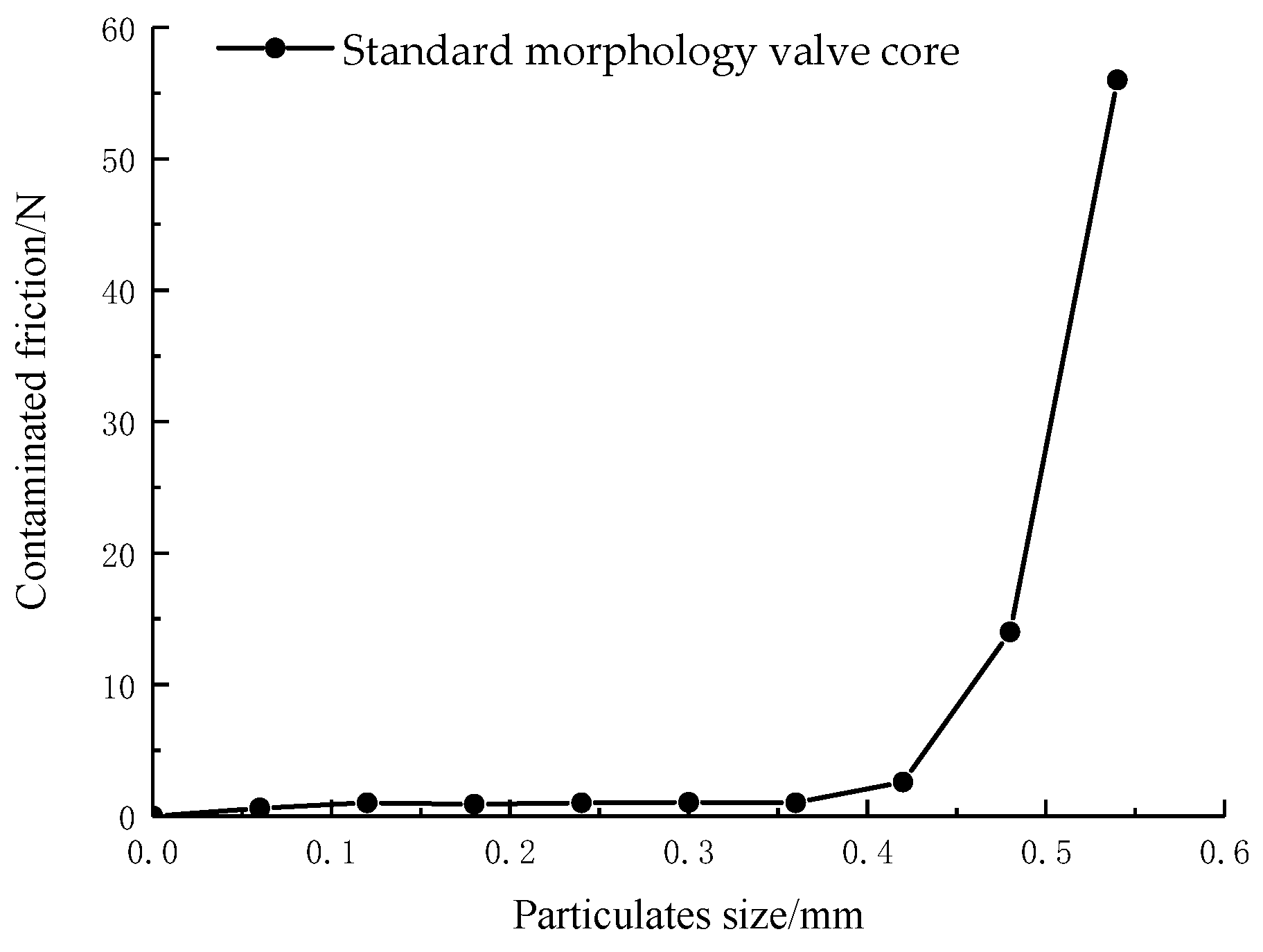

3.3. Contaminated Stagnation Model

4. The Experimental Analysis on Contaminated Friction of Spool with Different Morphologies

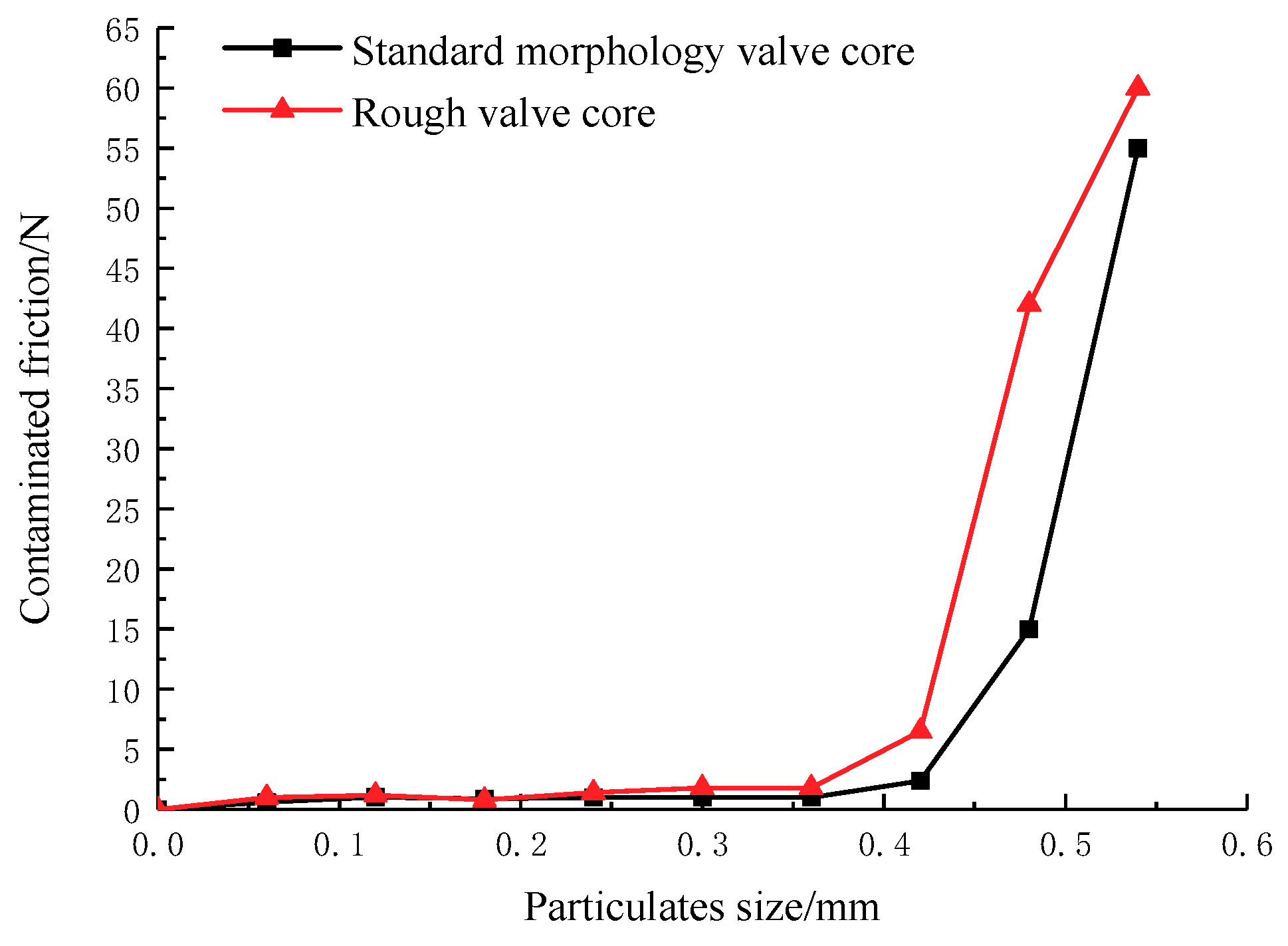

4.1. The Experimental Analysis on Contaminated Friction of the Rough Spool

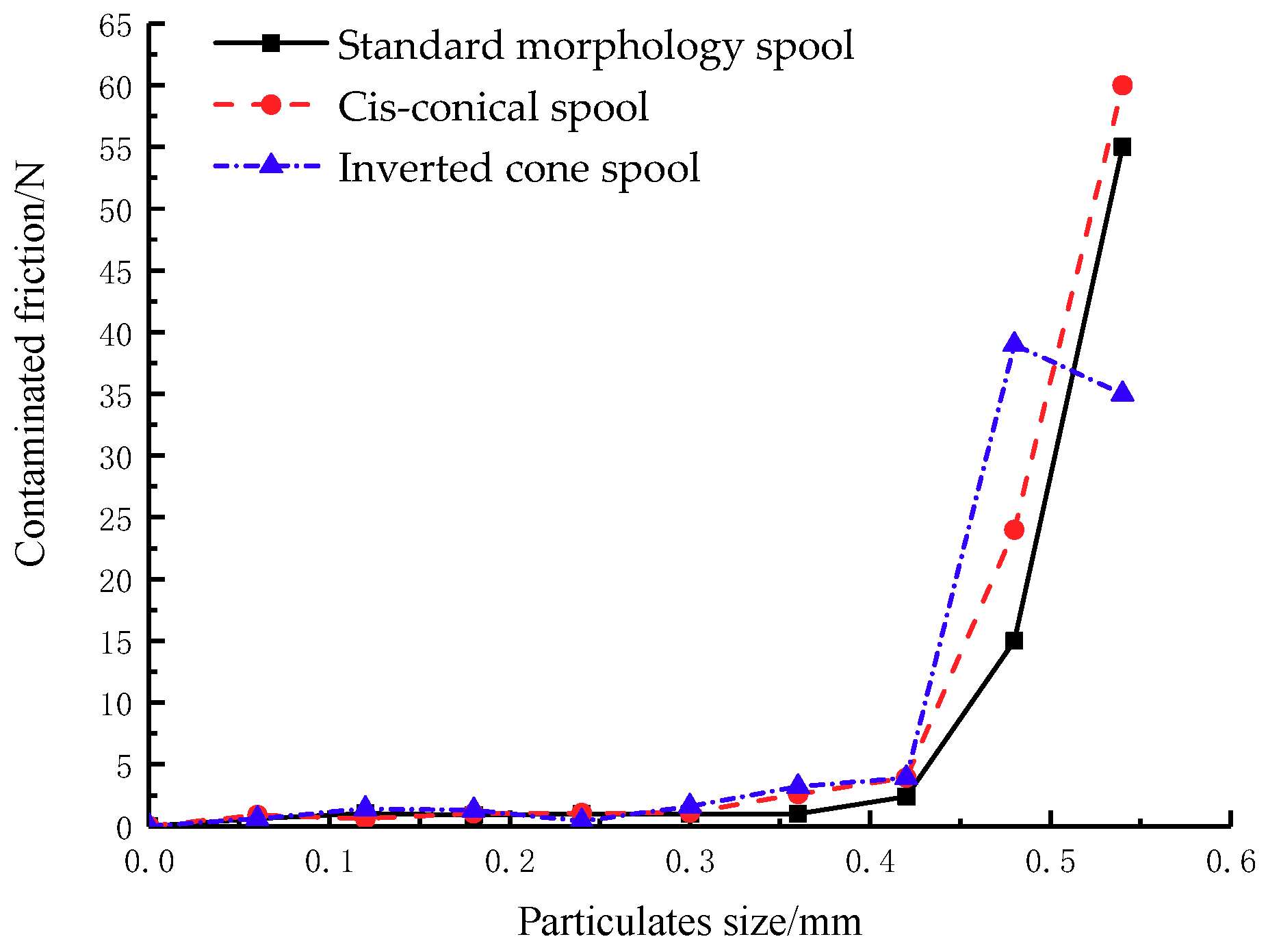

4.2. The Experimental Analysis on Contaminated Friction of the Conical Spool

5. Conclusions

- (1)

- The contaminated friction of spool has the characteristics of pulsation.

- (2)

- The sensitive size range for stagnation of solid particulates is 0.7 to 0.9 times the size of clearance.

- (3)

- Compared with the standard morphology of spool, the contaminated friction of rough spool has the same trend with particulates size, but the contaminated friction increases within the sensitive size range.

- (4)

- Compared with the standard morphology of spool, the lower limit of sensitive size range in the conical spools decreases, and the contaminated friction of cis-conical spool shows an increasing trend, whereas the contaminated friction of inverted cone spool shows a trend of increasing first and then decreasing

Author Contributions

Funding

Conflicts of Interest

References

- Wang, Z.L. Research and Analysis on Valve Element Clutch of Hydraulic Diverter Valve. Master’s Thesis, Jilin University, Changchun, China, 2005. [Google Scholar]

- Wang, A.L.; Dong, Y.N.; Zhou, P.J.; Wu, X.-F.; Zhou, C.-L. Robust design method for the seizure problem of hydraulic slide valve. J. Shanghai Jiaotong Univ. 2011, 45, 1637–1642. [Google Scholar]

- Kandlikar, S.G.; Schmitt, D.; Carrano, A.L.; Taylor, J.B. Characterization of surface roughness effects on pressure drop in single-phase flow in minichannels. Phys. Fluids 2005, 17, 100606. [Google Scholar] [CrossRef]

- Yaobao, Y.; Jiayang, Y.; Shengrong, G. Numerical study of solid particle erosion in hydraulic spools. Wear 2017, 392, 174–189. [Google Scholar] [CrossRef]

- Terrell, E.J.; Higgs, C.F., III. A modeling approach for predicting the abrasive particle motion during chemical mechanical polishing. J. Tribol. 2007, 129, 933–941. [Google Scholar] [CrossRef]

- Dharaiya, V.V.; Kandlikar, S.G. A numerical study on the effects of 2d structured sinusoidal elements on fluid flow and heat transfer at microscale. Int. J. Heat Mass Transf. 2013, 57, 190–201. [Google Scholar] [CrossRef]

- Weilin, Q.; Mala, G.M.; Dongqing, L. Pressure-driven water flows in trapezoidal silicon microchannels. Int. J. Heat Mass Transf. 2000, 43, 353–364. [Google Scholar] [CrossRef]

- Zheng, C.S.; Ge, P.F.; Li, Y.H. Contaminant Lock Force and Filter Cake Forming Mechanism of Hydraulic Spools Valves. Lubr. Eng. 2014, 39, 14–19. [Google Scholar]

- Ge, P.F.; Zheng, C.S.; Ma, B. Study on the Contamination Wear Failure of Hydraulic Valve and the Influencing Factors. Acta Armament. 2014, 35, 298–304. [Google Scholar]

- Xi, H.; Xu, H.Q.; Tang, R.M. Experimental study of the flow in the gap of needle valve. J. Tsinghua Univ. Sci. Tech. 2001, 41, 68–70. [Google Scholar]

- Feng, Y.B.; Sun, F.; Wang, H. Research on Particle Distribution in Valve Chamber and Clearance of Servo Spool. Lubr. Eng. 2016, 41, 60–64. [Google Scholar]

- Inoue, R. Contaminant Lock in Spool Type Directional Control Valves-Theory and Experimental Verification. BFPR J. 1980, 13, 167–171. [Google Scholar]

- Jiang, G.J.; Yin, C.B.; Jia, W.H. Study on the Effect of Spool’s Microscopic Surface on Micro-flow in Valve gap. Lubr. Eng. 2011, 36, 68–71. [Google Scholar]

- Feng, Z.-G.; Michaelides, E.E. Heat transfer in particulate flows with direct numerical simulation (DNS). Int. J. Heat Mass Transf. 2009, 52, 777–786. [Google Scholar] [CrossRef]

- Mittal, R.; Iaccarino, G. Immersed boundary methods. Annu. Rev. Fluid Mech. 2005, 37, 239–261. [Google Scholar] [CrossRef]

- Heltai, L.; Costanzo, F. Variational implementation of immersed finite element methods. Comput. Methods Appl. Mech. Eng. 2012, 229–232, 110–127. [Google Scholar] [CrossRef]

- Feng, Z.G.; Huh, H.; Joseph, D.D. Direct simulation of initial value problems for the motion of solid bodies in a Newtonian fluid Part 1. Sedimentation. J. Fluid Mech. 1994, 261, 95–134. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Khandaker, I.; Glavas, E.; Jones, G.R. A fibre-optic oil condition monitor based on chromatic modulation. Meas. Sci. Technol. 1993, 4, 608. [Google Scholar] [CrossRef]

- Kwon, K.O.; Kong, S.H.; Han, H.G.; Yoon, E.-S.; Myshkin, N.K.; Markova, L.V.; Semeniouk, M.S. On-Line Measurement of Contaminant Level in Lubricating Oil. U.S. Patent 6,151,108[P], 21 November 2000. [Google Scholar]

- Edmonds, J.; Resner, M.S.; Shkarlet, K. Detection of Precursor Wear Debris in Lubrication Systems. In Proceedings of the 2000 IEEE Aerospace Conference Proceedings (Cat No 00TH8484), Big Sky, MT, USA, 25 March 2000; IEEE: Anchorage, AK, USA, 2000; pp. 73–77. [Google Scholar]

- Chen, Q.; Ji, H.; Zhu, Y.; Yang, X. Proposal for optimization of spool valve flow force based on the MATLAB-AMESim-FLUENT joint simulation method. IEEE Access 2018, 6, 33148–33158. [Google Scholar]

- Singh, M.; Lathkar, G.S.; Basu, S.K. Failure Prevention of Hydraulic System Based on Oil Contamination. J. Inst. Eng. India Ser. C 2012, 93, 269–274. [Google Scholar] [CrossRef]

- Zhang, H.P.; Huang, W.; Zhang, Y.D.; Shen, Y.; Li, D.Q. Design of the Microfluidic Chip of Oil Detection. Appl. Mech. Mater. 2011, 117–119, 517–520. [Google Scholar] [CrossRef]

- Murali, S.; Xia, X.; Jagtiani, A.V.; Carletta, J.; Zhe, J. Capacitive Coulter Counting: Detection of Metal Wear Particles in Lubricant Using a Microfluidic Device. Smart Mater. Struct. 2009, 18, 037001. [Google Scholar] [CrossRef]

- Yang, X.J. Theoretical and Experimental Equipment Research on the Influence of Solid Particle Impurities on Piston Ring-Cylinder Liner Lubrication and Wear. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2005; pp. 21–50. [Google Scholar]

| Experiment Model | Structural Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| D/mm | d1/mm | d2/mm | d3/mm | L1/mm | Ra1 | Ra2 | Ra3 | m/Kg | |

| Standard morphology spool | / | 28.8 | 28.8 | 30 | 35 | / | 0.8 | 0.8 | 0.2983 |

| Rough spool | / | 28.8 | 28.8 | 30 | 35 | / | 12.5 | 0.8 | 0.3027 |

| Cis-conical spool | / | 28.7 | 28.9 | 30 | 35 | / | 0.8 | 0.8 | 0.3117 |

| Inverted cone spool | / | 28.9 | 28.7 | 30 | 35 | / | 0.8 | 0.8 | 0.3117 |

| Valve body | 30.01 | / | / | / | / | 0.8 | / | / | / |

| Parameters | Values |

|---|---|

| Oil density/(g/cm3) | 0.879 |

| Oil dynamic viscosity/(Pa·s) | 0.0364 |

| Components | Type | Parameters |

|---|---|---|

| Stepper motor | 57BYG250H-8 | pulse frequency 600 Hz rotational speed 2.12 r/min |

| Tension sensor | JZHL-T1 | range100N precision 0.5% |

| Pressure sensor | CYYZ11 | range-50 KPa precision 0.5% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, S.; Xu, R.; Ji, H.; Yang, S.; Yuan, Q. Experimental Investigation on Contaminated Friction of Hydraulic Spool Valve. Appl. Sci. 2019, 9, 5230. https://doi.org/10.3390/app9235230

Fan S, Xu R, Ji H, Yang S, Yuan Q. Experimental Investigation on Contaminated Friction of Hydraulic Spool Valve. Applied Sciences. 2019; 9(23):5230. https://doi.org/10.3390/app9235230

Chicago/Turabian StyleFan, Shuai, Rui Xu, Hong Ji, Shengqing Yang, and Qingyun Yuan. 2019. "Experimental Investigation on Contaminated Friction of Hydraulic Spool Valve" Applied Sciences 9, no. 23: 5230. https://doi.org/10.3390/app9235230

APA StyleFan, S., Xu, R., Ji, H., Yang, S., & Yuan, Q. (2019). Experimental Investigation on Contaminated Friction of Hydraulic Spool Valve. Applied Sciences, 9(23), 5230. https://doi.org/10.3390/app9235230