Using Post-Harvest Waste to Improve Shearing Behaviour of Loess and Its Validation by Multiscale Direct Shear Tests

Abstract

Featured Application

Abstract

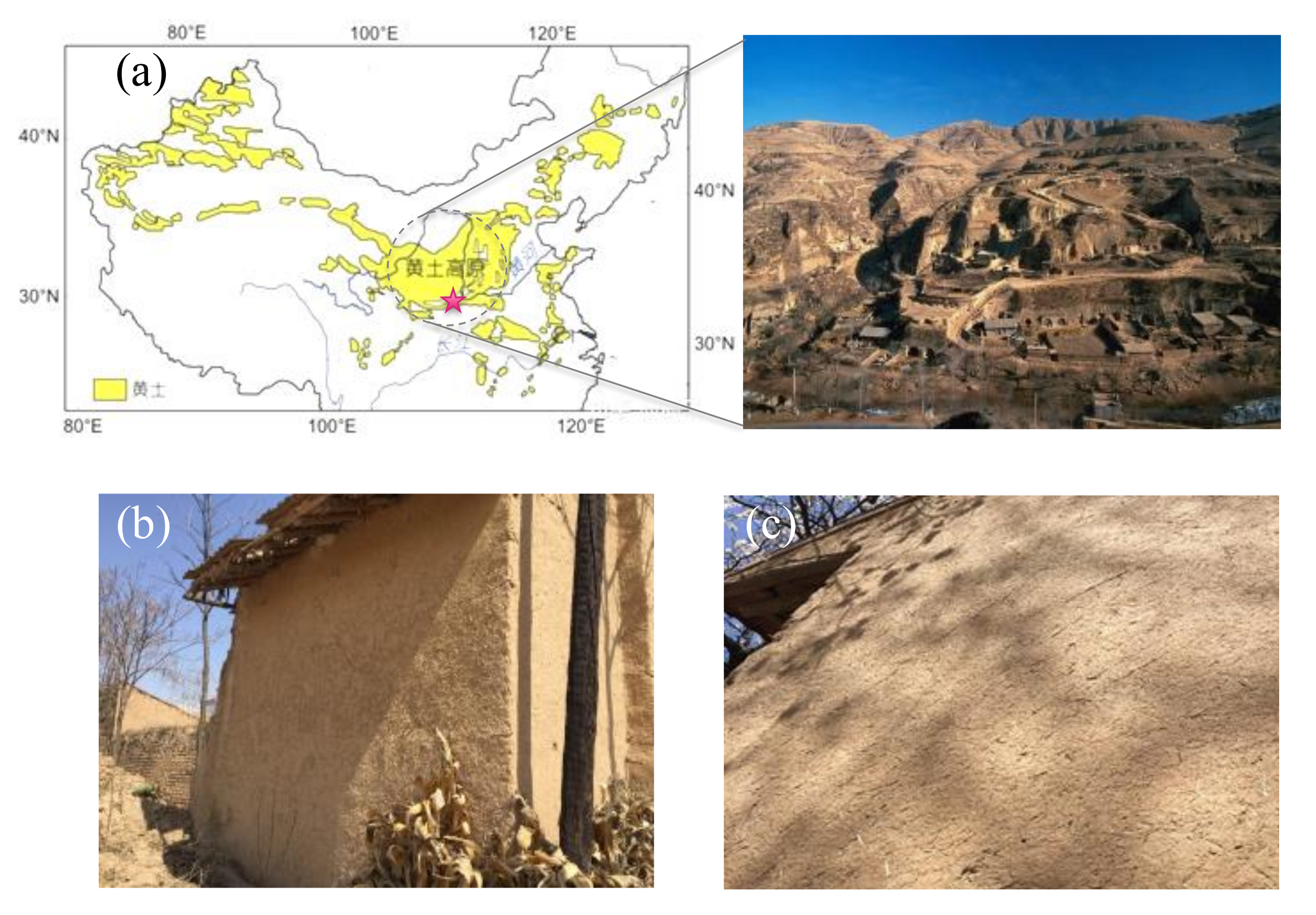

1. Introduction

2. Materials and Methods

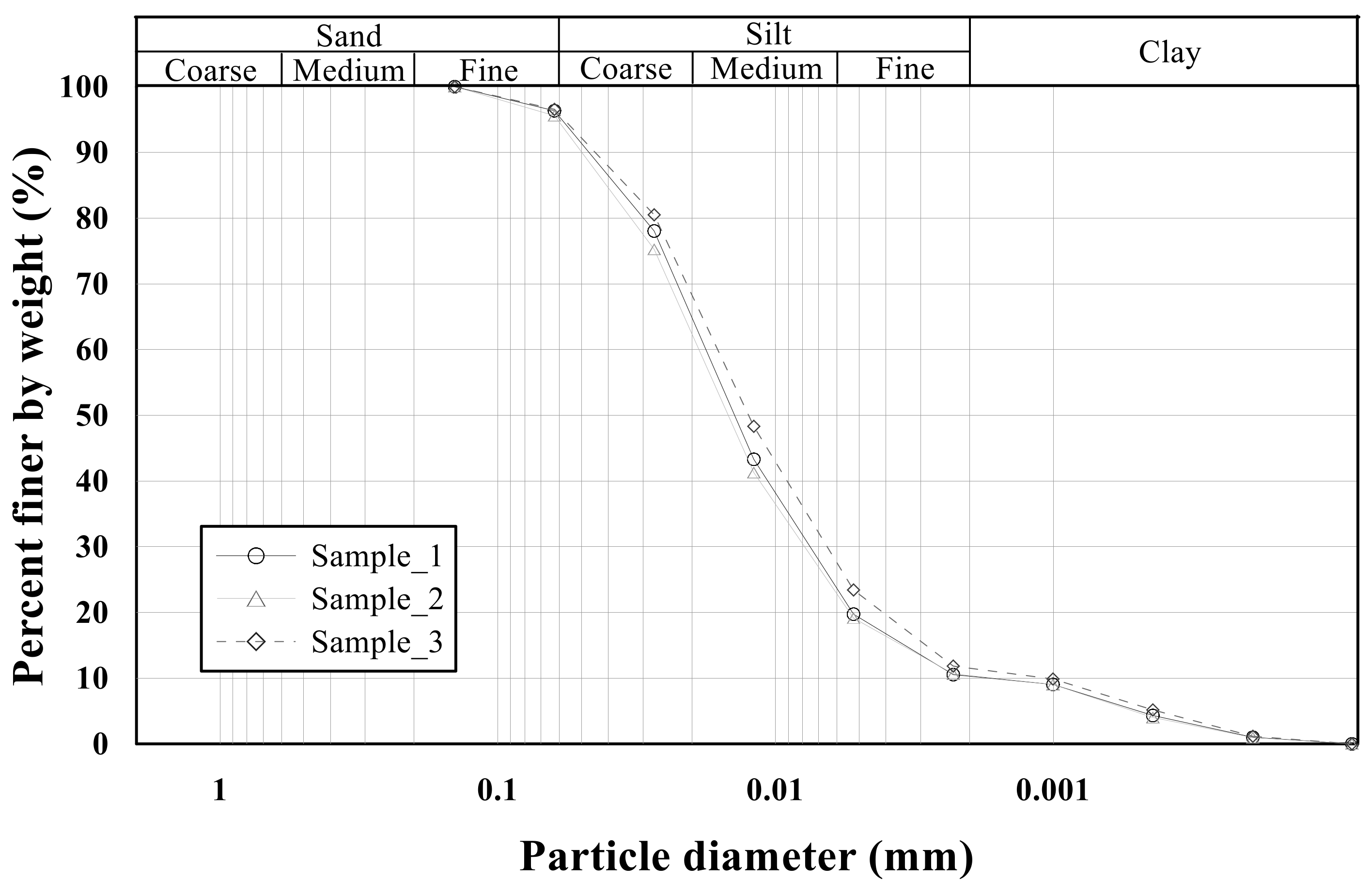

2.1. Loess-Post-Harvest Waste (PHW) Mixture Specimens

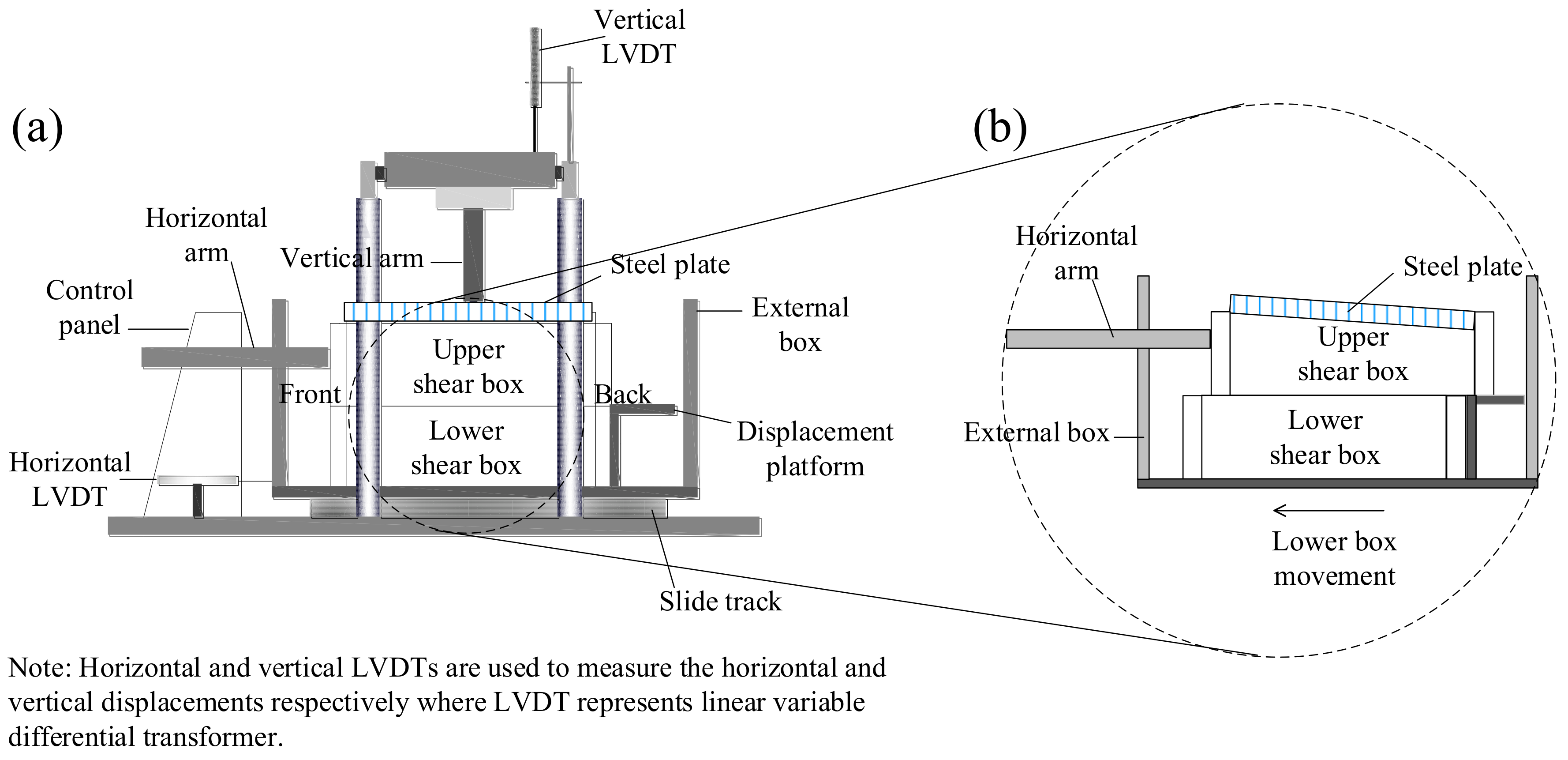

2.2. Small-Scale Direct Shear Tests

2.3. Large-Scale Direct Shear Tests

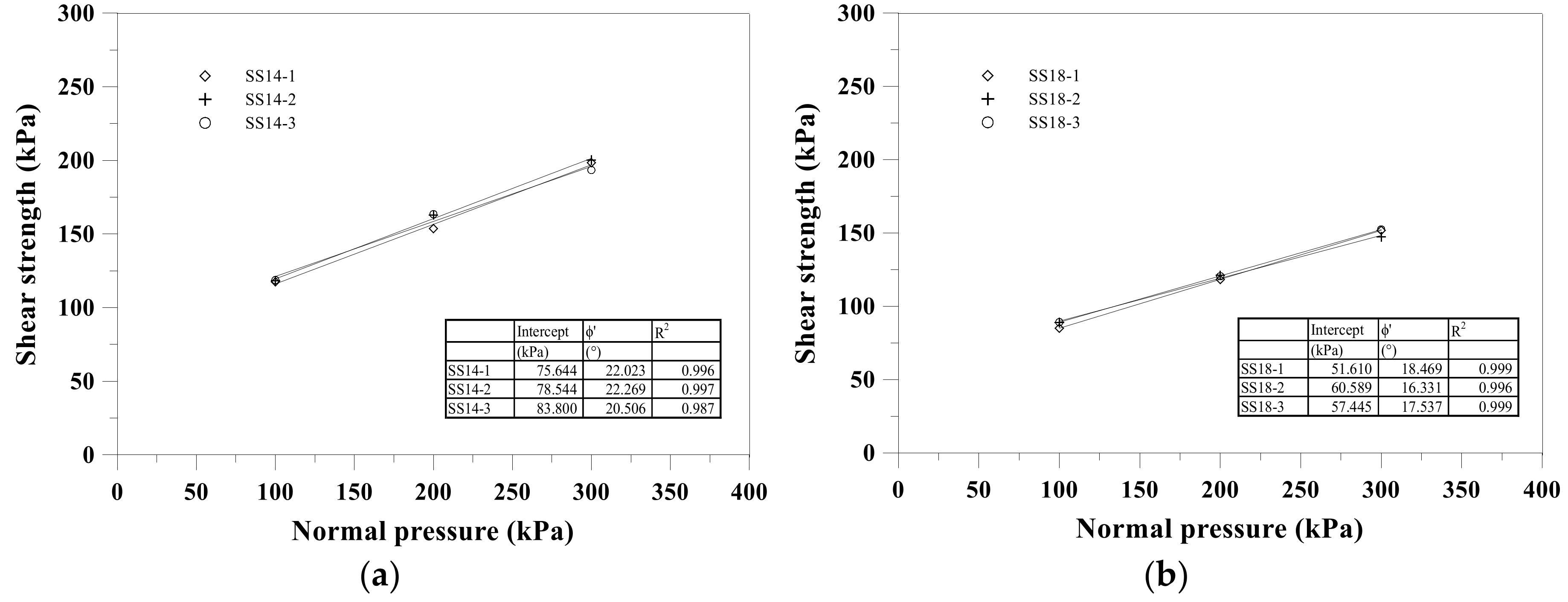

2.4. Repeatability of Direct Shear Methods

3. Results and Discussion

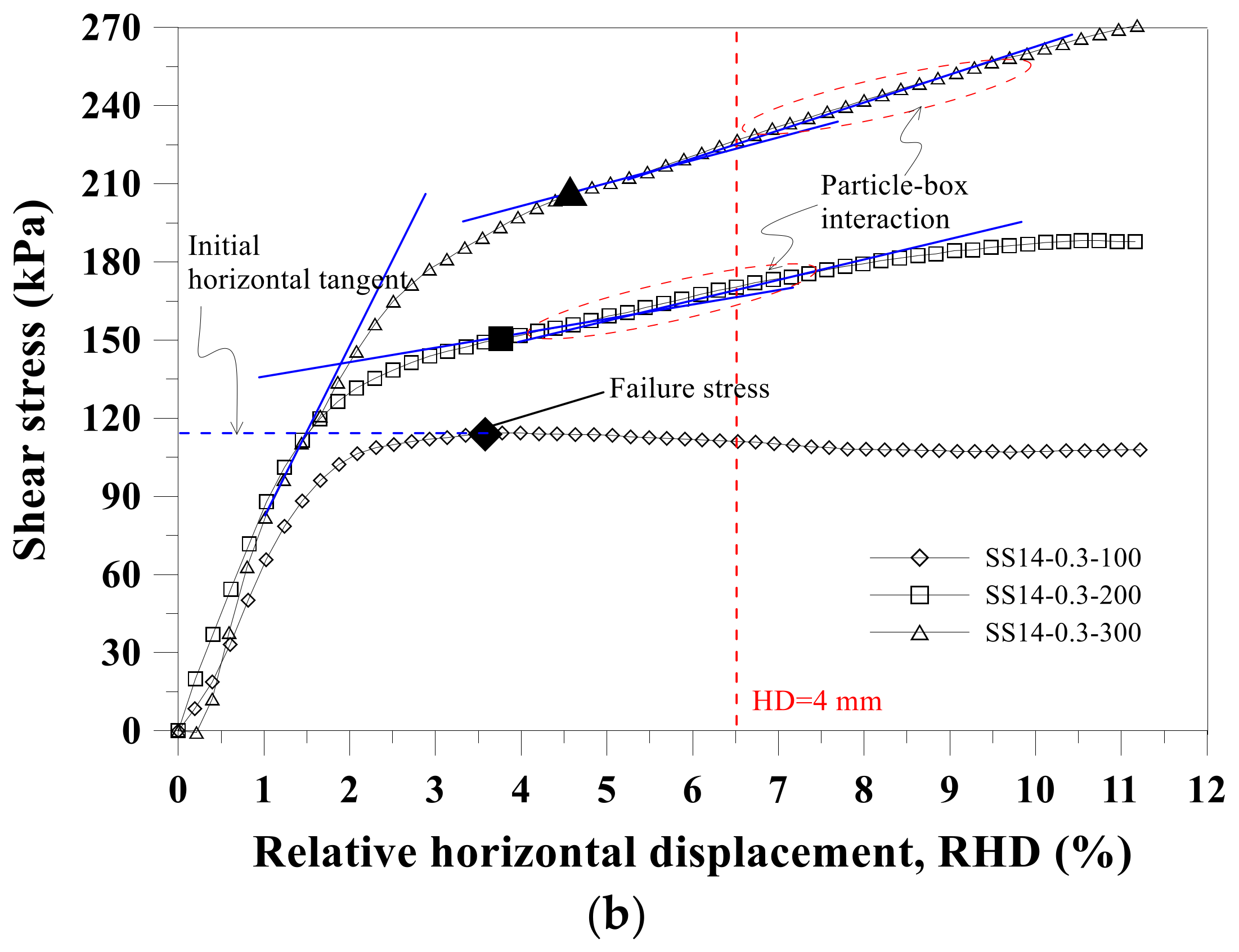

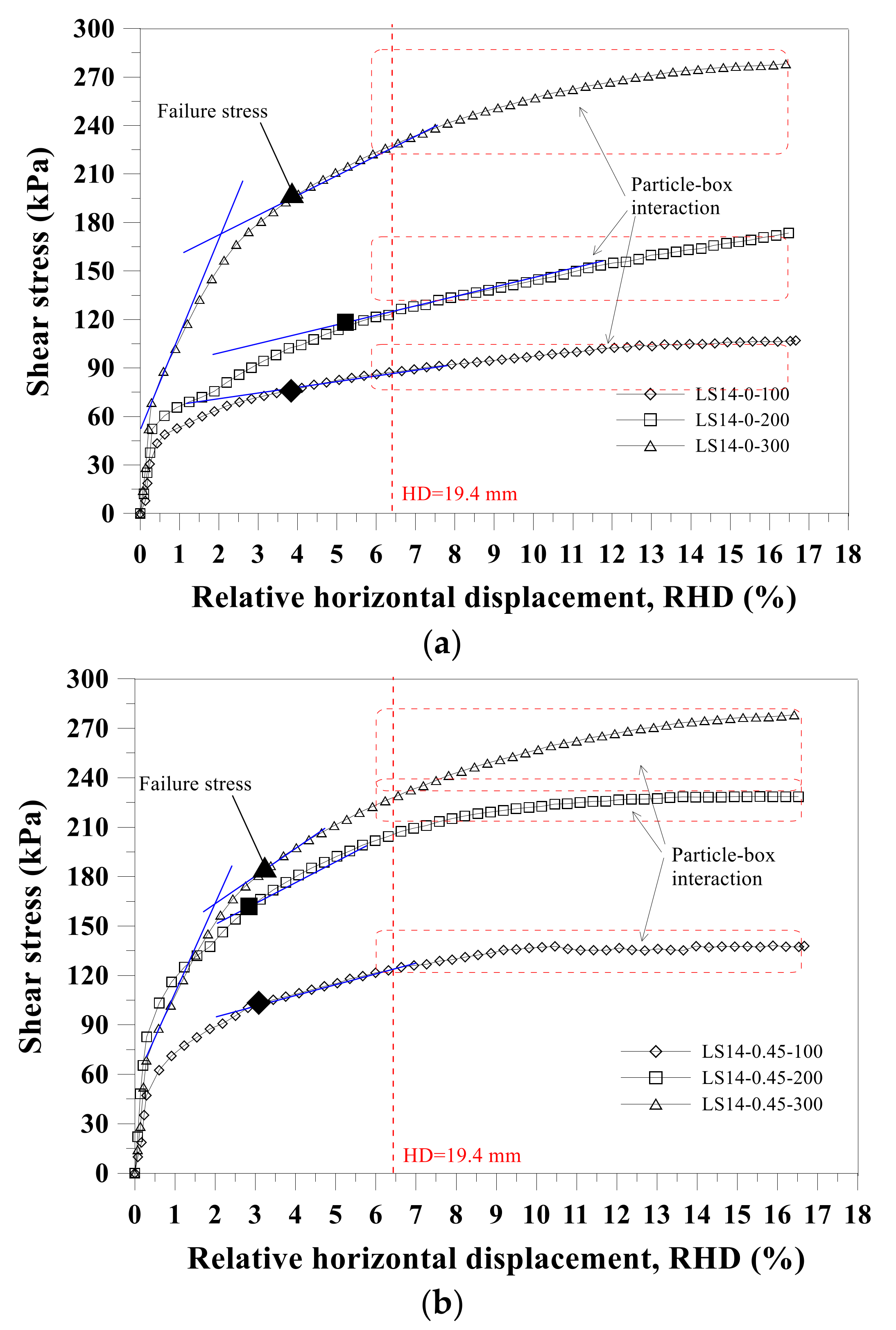

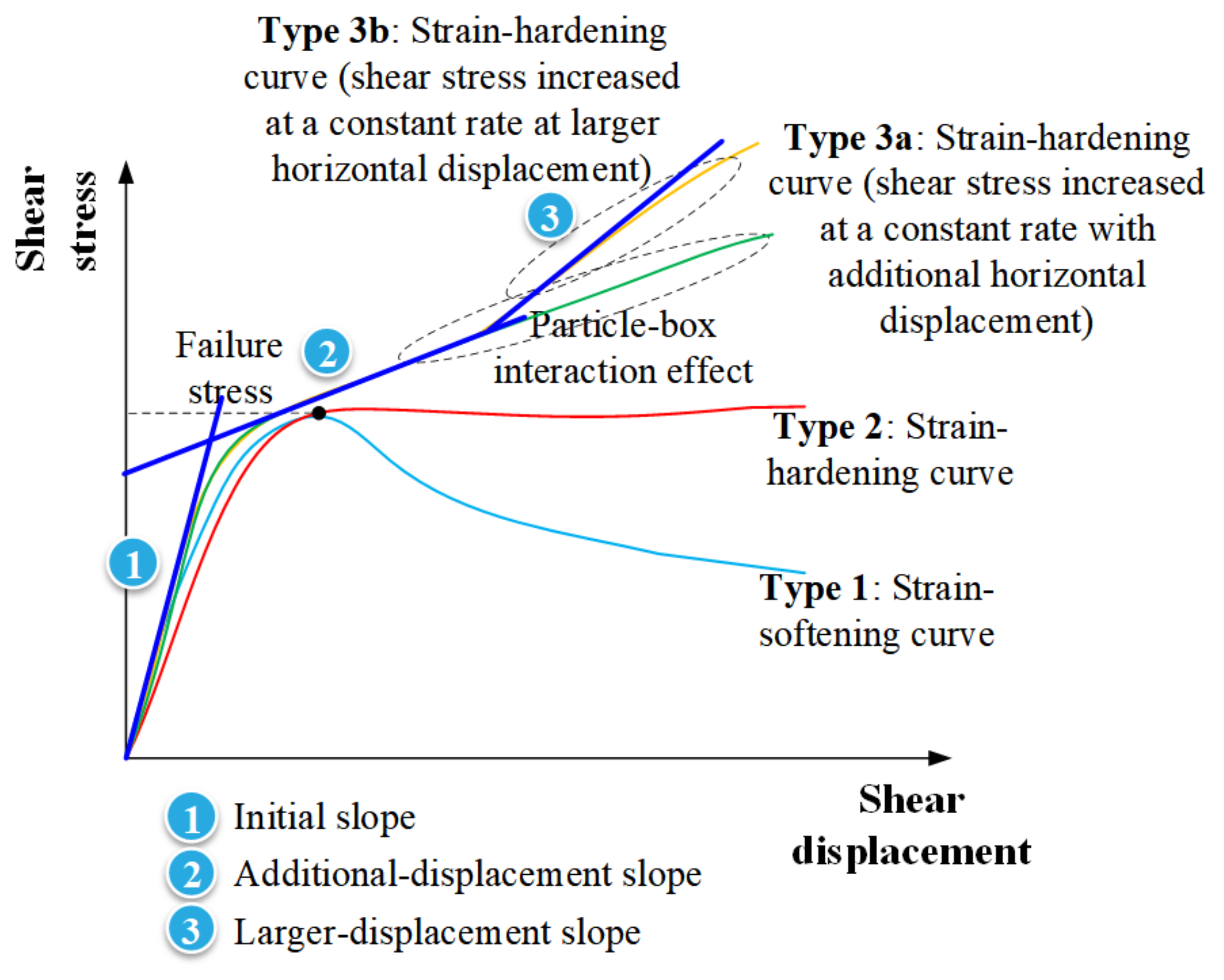

3.1. Definition of Failure

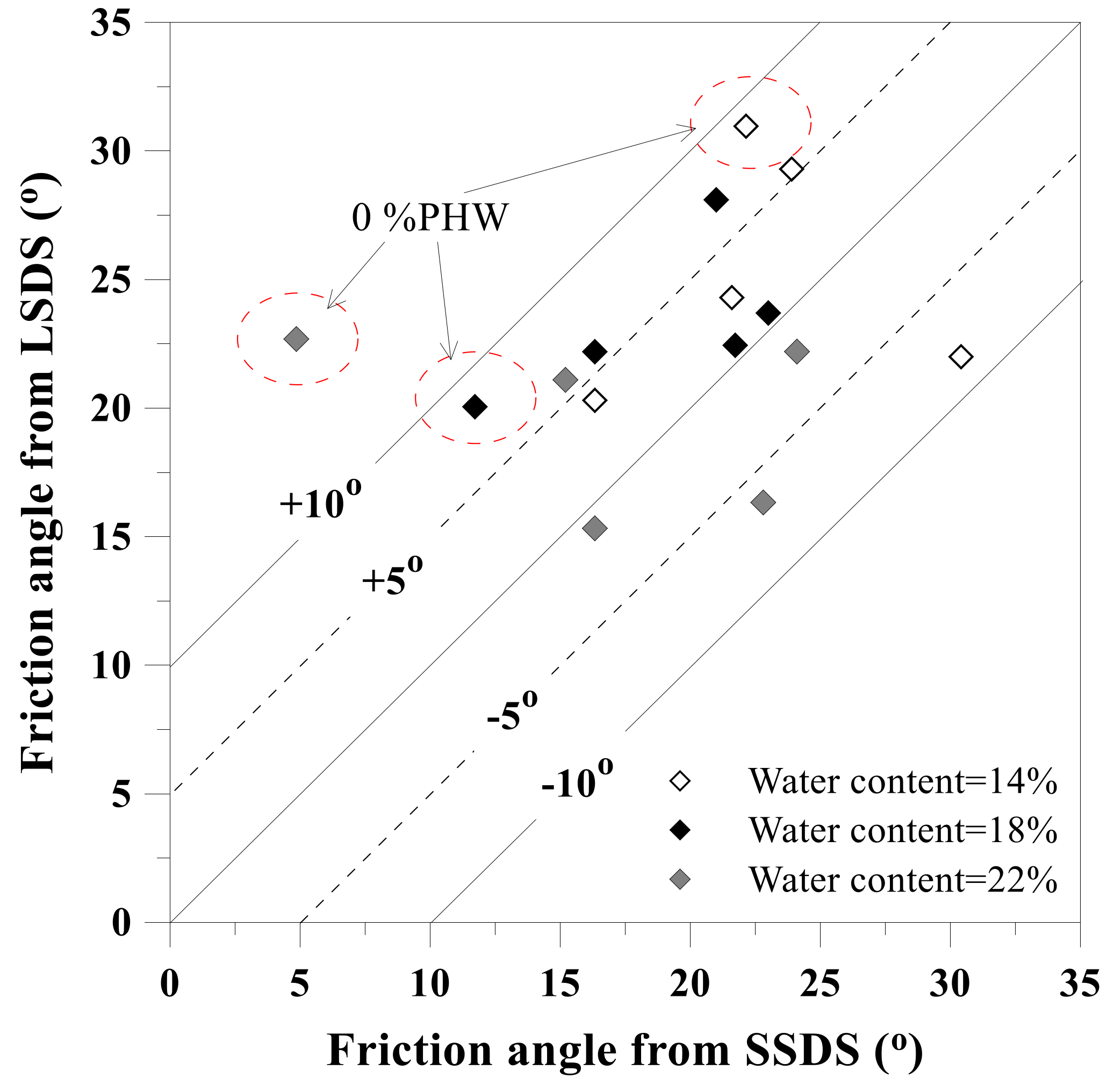

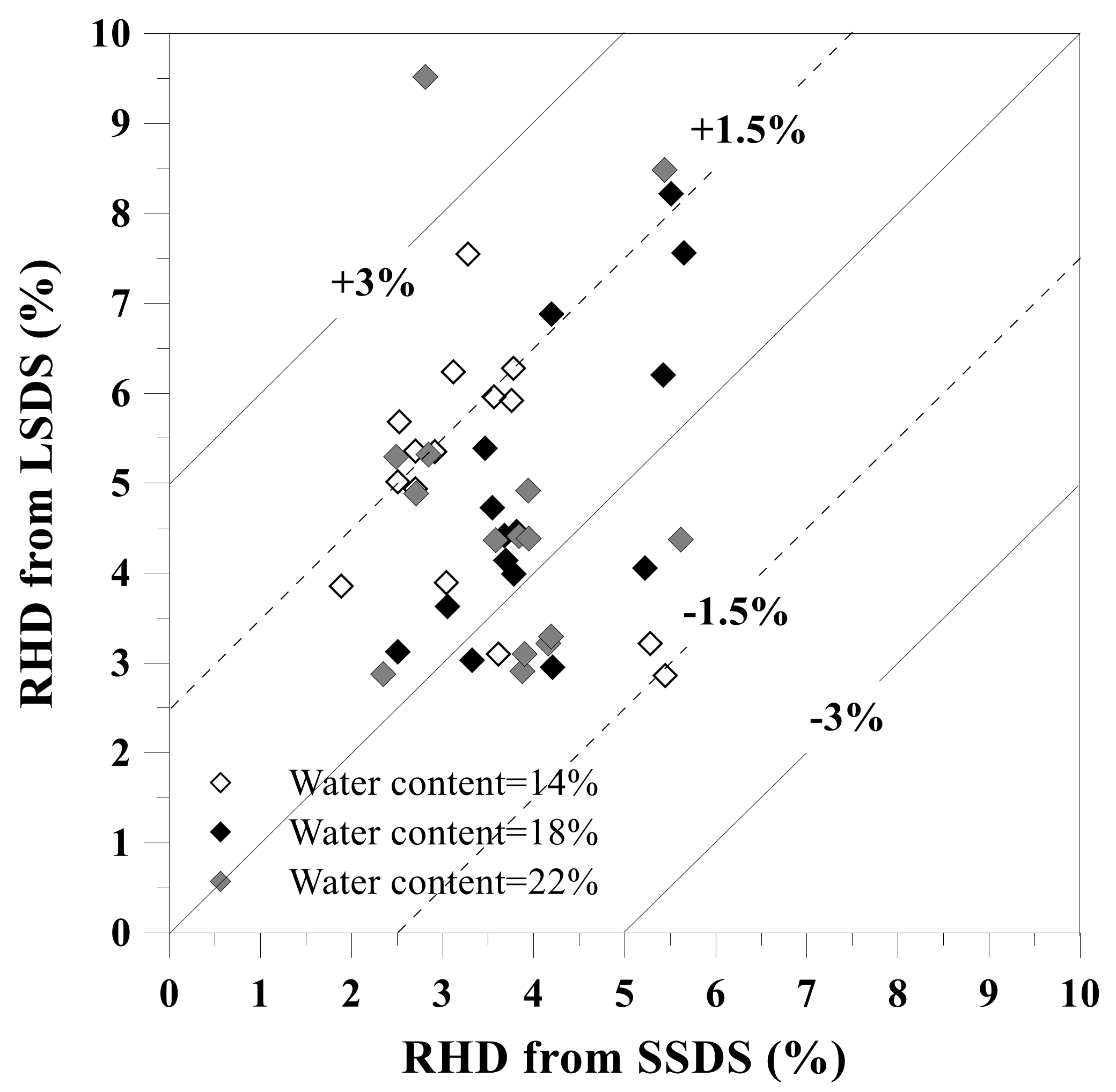

3.2. Comparison of Shear Strength between Small-Scale Direct Shear and Large-Scale Direct Shear

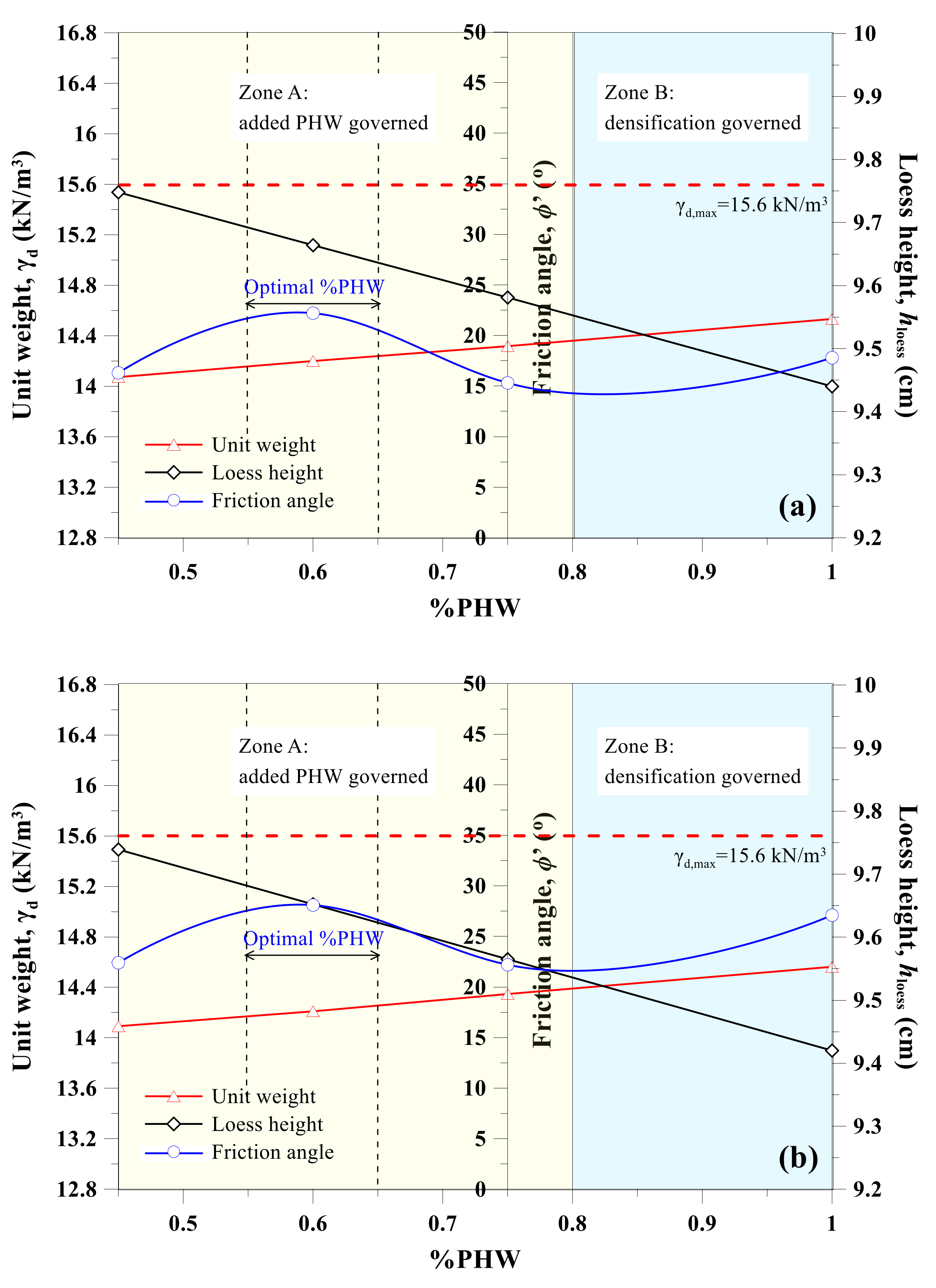

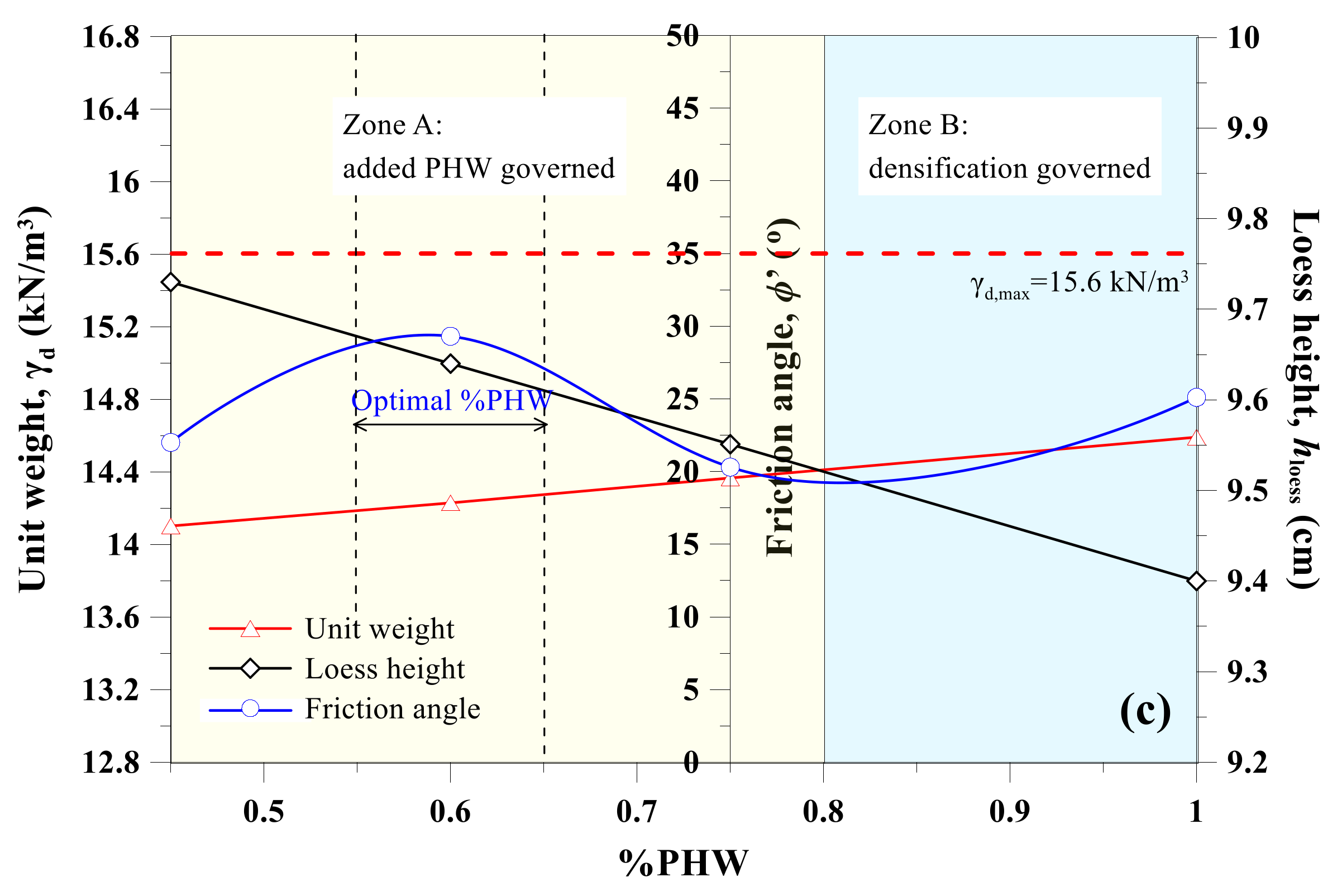

3.3. Determination of Optimal PHW Dosage

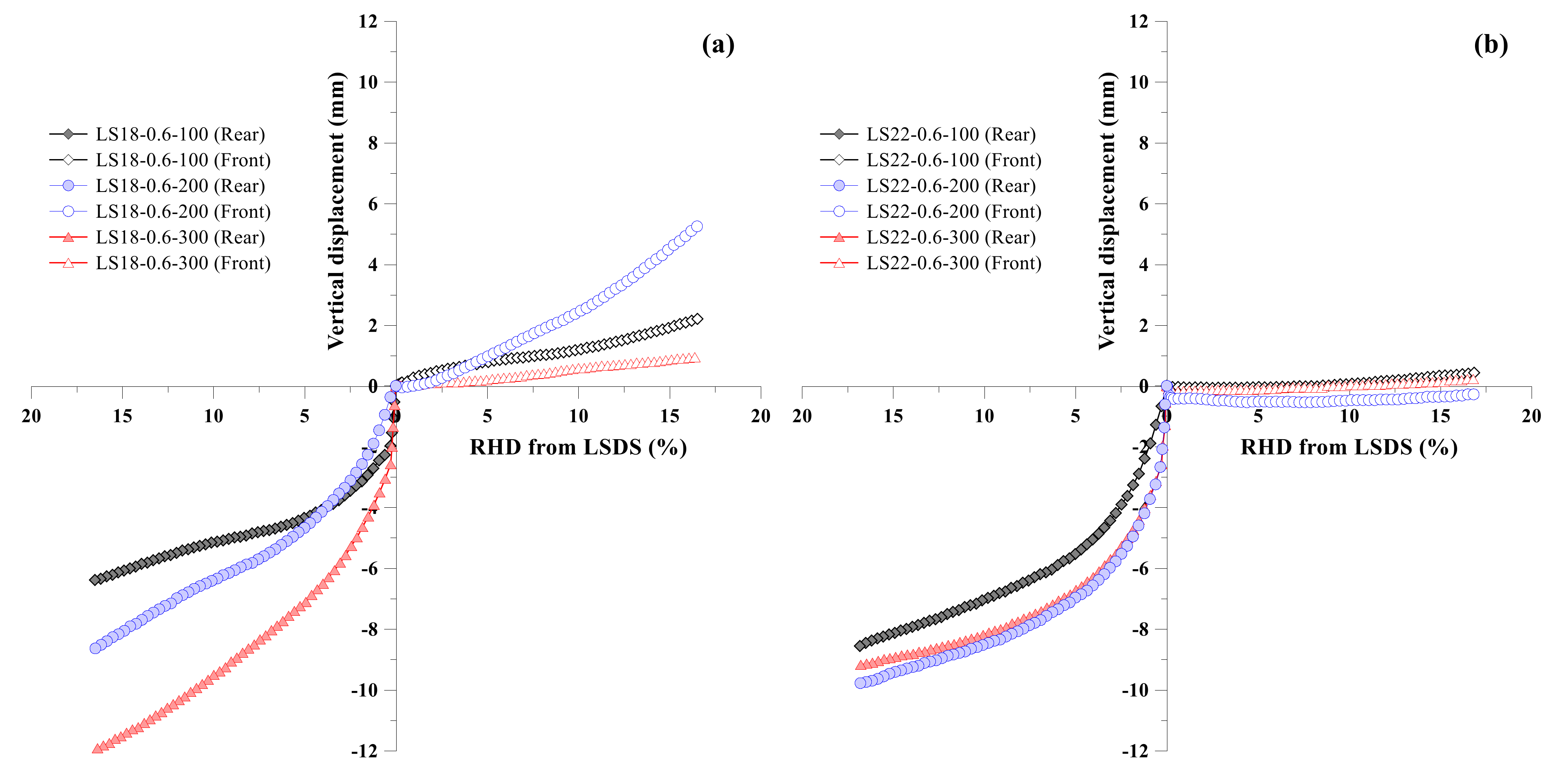

3.4. Effect of Particle–Box Interaction

3.5. Mechanism Leading to Improved Shearing Behaviour

4. Conclusions

- (1)

- The test results showed that the difference in the ϕ’ value between SSDS and LSDS was typically between 0.7–8.8°, and that the RHD at failure was generally limited to <1.5%, with an average of 1.2%. The improved shearing behaviour of the loess-PHW mixture was attributed to the effect of particle inter-locking and this effect took effect as the water content reached a threshold, i.e., >14%, that facilitates particle rearrangement. The improvement highlighted the great potential of application of loess-PHW mixtures to loess erosion control and slope stabilisation.

- (2)

- The ϕ’ value was the highest as the %PHW was equal to 0.6. The observed higher ϕ’ value, while the %PHW being equal to 0.8–1.0, was most likely because of the densification effect. The optimal PHW dosage derived this study was considered to be 0.55–0.65, taking into account specimen homogenisation and testing reliability.

- (3)

- In the LSDS tests, the vertical displacement, while shearing, was observed at front and rear of the shear box. This movement was more distinct at rear than at front. Additionally, the vertical displacement was increased with the increasing normal pressure. This phenomenon was deemed as the main cause leading to the gradual increase in shear stress following the curve inflection point.

Author Contributions

Funding

Acknowledgments

Data Availability

Conflicts of Interest

References

- Cheng, W.C.; Ni, J.C.; Arulrajah, A.; Huang, H.W. A simple approach for characterising tunnel bore conditions based upon pipe-jacking data. Tunn. Undergr. Space Technol. 2018, 71, 494–504. [Google Scholar] [CrossRef]

- Cheng, W.C.; Song, Z.P.; Tian, W.; Wang, Z.F. Shield tunnel uplift and deformation characterisation: A case study from Zhangzhou Metro. Tunn. Undergr. Space Technol. 2018, 79, 83–95. [Google Scholar] [CrossRef]

- Lyu, H.M.; Xu, Y.S.; Cheng, W.C.; Arulrajah, A. Flooding hazards across southern China and perspective sustainability measures. Sustainability 2018, 10, 1682. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Wang, Z.F.; Cheng, W.C. A review on land subsidence caused by groundwater withdrawal in Xi’an, China. Bull. Eng. Geol. Environ. 2018, 78, 2851–2863. [Google Scholar] [CrossRef]

- Wang, Z.F.; Cheng, W.C.; Wang, Y.Q. Investigation into geohazards during urbanization process of Xi’an, China. Nat. Hazards 2018, 92, 1937–1953. [Google Scholar] [CrossRef]

- Elbaz, K.; Shen, S.L.; Tan, Y.; Cheng, W.C. Investigation into performance of deep excavation in sand covered karst: A case report. Soil Found. 2018, 58, 1042–1058. [Google Scholar] [CrossRef]

- Cheng, W.C.; Wang, L.; Xue, Z.F.; Ni, J.C.; Rahman, M.; Arulrajah, A. Lubrication performance of pipejacking in alluvial deposits. Tunn. Undergr. Space Technol. 2019, 91, 102991. [Google Scholar] [CrossRef]

- Babu Sivakumar, G.L.; Vasudevan, A.K. Strength and stiffness response of coir reinforced tropical soils. J. Mater. Civ. Eng. 2008, 20, 571–577. [Google Scholar] [CrossRef]

- Shen, S.L.; Wang, Z.F.; Cheng, W.C. Estimation of lateral displacement induced by jet grouting in clayey soils. Geotechnique 2017, 67, 1–10. [Google Scholar] [CrossRef]

- Cheng, W.C.; Ni, J.C.; Shen, S.L.; Wang, Z.F. Modeling of permeation and fracturing grouting in sand: Laboratory investigations. J. Test. Eval. 2018, 46, 2067–2082. [Google Scholar] [CrossRef]

- Wang, Z.F.; Shen, J.S.; Cheng, W.C. Simple method to predict ground displacements caused by installing horizontal jet-grouting columns. Math. Probl. Eng. 2018, 2018, 1897394. [Google Scholar] [CrossRef]

- Ge, L.; Wang, C.C.; Hung, C.W.; Liao, W.C.; Zhao, H. Assessment of strength development of slag cement stabilized kaolinite. Constr. Build. Mater. 2018, 184, 492–501. [Google Scholar] [CrossRef]

- Kua, T.A.; Arulrajah, A.; Mohammadinia, A.; Horpibulsuk, S.; Mirzababaei, M. Stiffness and deformation properties of spent coffee grounds based geopolymers. Constr. Build. Mater. 2017, 138, 79–87. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Kua, T.A.; Arulrajah, A.; Maghool, F.; Horpibulsuk, S. Strength and microstructure properties of spent coffee grounds stabilized with rice husk ash and slag geopolymers. Constr. Build. Mater. 2017, 146, 312–320. [Google Scholar] [CrossRef]

- Arulrajah, A.; Kua, T.A.; Suksiripattanapong, C.; Horpibulsuk, S.; Shen, J.S. Compressive strength and microstructure properties of spent coffee grounds-bagasse ash based geopolymers with slag supplements. J. Clean. Prod. 2017, 162, 1491–1501. [Google Scholar] [CrossRef]

- Belhadj, B.; Bederina, M.; Makhloufi, Z.; Dheilly, R.M.; Montrelay, N.; Quéneudéc, M. Contribution to the development of a sand concrete lightened by the addition of barley straws. Constr. Build. Mater. 2016, 113, 513–522. [Google Scholar] [CrossRef]

- Bederina, M.; Belhadj, B.; Ammari, M.S.; Gouilleux, A.; Makhloufi, Z.; Montrelay, N.; Quéneudéc, M. Improvement of the properties of a sand concrete containing barley straws—Treatment of the barley straws. Constr. Build. Mater. 2016, 115, 464–477. [Google Scholar] [CrossRef]

- Lu, J.; Wang, T.H.; Cheng, W.C.; Yang, T.; Luo, Y. Permeability anisotropy of loess under influence of dry density and freeze-thaw cycles. Int. J. Geomech. 2019, 19, 04019103. [Google Scholar] [CrossRef]

- Tabarsa, A.; Latifi, N.; Meehan, C.L.; Manahiloh, K.N. Laboratory investigation and field evaluation of loess improvement using nanoclay—A sustainable material for construction. Constr. Build. Mater. 2018, 158, 454–463. [Google Scholar] [CrossRef]

- Dijkstra, T.A.; Rogers, C.D.F.; Smalley, I.J.; Derbyshire, E.; Li, Y.J.; Meng, X.M. The loess of north-central China: Geotechnical properties and their relation to slope stability. Eng. Geol. 1994, 36, 153–171. [Google Scholar] [CrossRef]

- Duan, Z.; Cheng, W.C.; Peng, J.B.; Wang, Q.Y.; Chen, W. Investigation into triggering mechanism of loess landslides in south Jingyang platform, Shaanxi province. Bull. Eng. Geol. Environ. 2019. [Google Scholar] [CrossRef]

- Jin, X.; Wang, T.T.; Cheng, W.C.; Luo, Y.; Zhou, A. A simple method for settlement evaluation of loess-pile foundation. Can. Geotech. J. 2019. [Google Scholar] [CrossRef]

- Juang, C.H.; Dijkstra, T.; Wasowski, J.; Meng, X.M. Loess geohazards research in China: Advances and challenges for mega engineering projects. Eng. Geol. 2019, 251, 1–10. [Google Scholar] [CrossRef]

- Yuan, W.N.; Fan, W.; Jiang, C.C.; Peng, X.L. Experimental study on the shear behavior of loess and paleosol based on ring shear tests. Eng. Geol. 2019, 250, 11–20. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, X.C.; Pei, X.J.; Wang, S.Y.; Huang, R.Q.; Xu, Q.; Wang, Z.L. Model test study on the hydrological mechanisms and early warning thresholds for loess fill slope failure induced by rainfall. Eng. Geol. 2019, 258, 105135. [Google Scholar] [CrossRef]

- Chen, L.; Wei, W.; Fu, B.; Lü, Y. Soil and water conservation on the Loess Plateau in China: Review and perspective. Prog. Phys. Geogr. Earth Environ. 2007, 31, 389–403. [Google Scholar] [CrossRef]

- Qiu, H.; Cui, P.; Regmi, A.D.; Hu, S.; Wang, X.; Zhang, Y.; He, Y. Influence of topography and volume on mobility of loess slides within different slip surfaces. Catena 2017, 157, 180–188. [Google Scholar] [CrossRef]

- Wu, L.; Jiang, J.; Li, G.X.; Ma, X.Y. Characteristics of pulsed runoff-erosion events under typical rainstorms in a small watershed on the Loess Plateau of China. Sci. Rep. 2018, 8, 3672. [Google Scholar] [CrossRef]

- Yates, K.; Fenton, C.H.; Bell, D.H. A review of the geotechnical characteristics of loess and loess-derived soils from Canterbury, South Island, New Zealand. Eng. Geol. 2018, 236, 11–21. [Google Scholar] [CrossRef]

- Larsen, I.J.; Montgomery, D.R.; Korup, O. Landslide erosion controlled by hillslope material. Nat. Geosci. 2010, 3, 247–251. [Google Scholar] [CrossRef]

- Fattet, M.; Fu, Y.; Ghestem, M.; Ma, W.; Foulonneau, M.; Nespoulous, J.; Le Bissonnais, Y.; Stokes, A. Effects of vegetation type on soil resistance to erosion: Relationship between aggregate stability and shear strength. Catena 2011, 87, 60–69. [Google Scholar] [CrossRef]

- Pradhan, B.; Chaudhari, A.; Adinarayana, J.; Buchroithner, M.F. Soil erosion assessment and its correlation with landslide events using remote sensing data and GIS: A case study at Penang Island, Malaysia. Environ. Monit. Assess. 2012, 184, 715–727. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, M.; Phillips, C.; Marden, M.; McIvor, I.R.; Douglas, G.B.; Watson, A. Modelling of root reinforcement and erosion control by ‘Veronese’ poplar on pastoral hill country in New Zealand. N. Z. J. For. Sci. 2016, 46, 4. [Google Scholar] [CrossRef]

- Osman, N.; Barakbah, S.S. Parameters to predict slope stability—Soil water and root profiles. Ecol. Eng. 2006, 28, 90–95. [Google Scholar] [CrossRef]

- Comino, E.; Druetta, A. The effect of Poaceae roots on the shear strength of soils in the Italian alpine environment. Soil Tillage Res. 2010, 106, 194–201. [Google Scholar] [CrossRef]

- Schwarz, M.; Preti, F.; Giadrossich, F.; Lehmann, P.; Or, D. Quantifying the role of vegetation in slope stability: A case study in Tuscany (Italy). Ecol. Eng. 2010, 36, 285–291. [Google Scholar] [CrossRef]

- Peng, H.; Jia, Y.W.; Qiu, Y.Q.; Niu, C.W.; Ding, X.Y. Assessing climate change impacts on the ecohydrology of the Jinghe River basin in the Loess Plateau, China. Hydrol. Sci. J. 2013, 58, 651–670. [Google Scholar] [CrossRef]

- Cerato, A.B.; Lutenegger, A.J. Specimen size and scale effects of direct shear box tests of sands. Geotech. Test. J. 2006, 29, 507–516. [Google Scholar]

- Wu, P.; Matsushima, K.; Tatsuoka, F. Effects of specimen size and some other factors on the strength and deformation of granular soil in direct shear tests. Geotech. Test. J. 2008, 31, 45–64. [Google Scholar]

- Bareither, C.A.; Benson, C.H.; Edil, T.B. Comparison of shear strength of sand backfills measured in small-scale and large-scale direct shear tests. Can. Geotech. J. 2008, 45, 1224–1236. [Google Scholar] [CrossRef]

- Zhang, M.; Cheng, G.; Feng, H.; Sun, B.H.; Zhao, Y.; Chen, H.X.; Chen, J.; Dyek, M.; Wang, X.D.; Zhang, J.G.; et al. Effects of straw and biochar amendments on aggregate stability, soil organic carbon, and enzyme activities in the Loess Plateau, China. Environ. Sci. Pollut. Res. 2017, 24, 10108–10120. [Google Scholar] [CrossRef]

- Zhang, A.F.; Cheng, G.; Hussain, Q.; Zhang, M.; Feng, H.; Dyck, M.; Sun, B.H.; Zhao, Y.; Chen, H.X.; Chen, J.; et al. Contrasting effects of straw and straw-derived biochar application on net global warming potential in the Loess Plateau of China. Field Crops Res. 2017, 205, 45–54. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. Standard Method of Test for Direct Shear Test of Soil under Consolidated Drained Conditions. T 236–92; AASHTO: Washington, DC, USA, 2001. [Google Scholar]

- Nanjing Hydraulic Research Institute. Test Code for Soil—Direct Shear Test. SL 237–021; China Water Power Press: Beijing, China, 1999. [Google Scholar]

- Cheng, W.C.; Xue, Z.F.; Wang, L.; Liu, N.; Xu, J.; Horpibulsuk, S. Recent massive incidents for subway construction in soft alluvial deposits of Taiwan: A review. Tunn. Undergr. Space Technol. 2020, 96, 103178. [Google Scholar] [CrossRef]

- Chen, F.; Wang, L.; Zhang, W. Reliability assessment on stability of tunneling perpendicularly beneath an existing tunnel considering spatial variabilities of rock mass properties. Tunn. Undergr. Space Technol. 2019, 88, 276–289. [Google Scholar] [CrossRef]

- Xiang, Y.; Liu, H.; Zhang, W.; Chu, J.; Zhou, D.; Xiao, Y. Application of transparent soil model test and DEM simulation in study of tunnel failure mechanism. Tunn. Undergr. Space Technol. 2018, 74, 178–184. [Google Scholar] [CrossRef]

| Sample | Uniformity Coefficient Cu | Coefficient of Gradation Cc | % Silt and Clay | % Sand | % Gravel | Unit Weight γd (kN/m3) | USCS Symbol |

|---|---|---|---|---|---|---|---|

| S1a | 9.26 | 1.94 | 74.46 | 6.57 | 0 | 13.72 | ML |

| S1b | 10.48 | 2.13 | 73.79 | 7.88 | 0 | 13.60 | ML |

| S1c | 15.26 | 2.79 | 71.68 | 5.95 | 0 | 13.83 | ML |

| Specimenno. | Cohesion c′ (kPa) | Friction Angle ϕ′ (°) | Coefficient of Determination R2 |

|---|---|---|---|

| SS14-1 | 75.64 | 22.0 | 0.996 |

| SS14-2 | 78.54 | 22.3 | 0.997 |

| SS14-3 | 83.80 | 20.5 | 0.987 |

| SS18-1 | 51.61 | 18.5 | 0.999 |

| SS18-2 | 60.59 | 16.3 | 0.996 |

| SS18-3 | 57.45 | 17.5 | 0.999 |

| Average | 67.94 | 19.5 | 0.996 |

| Standard deviation | 11.93 | 2.2 | 0.004 |

| Specimen no. | SSDS | Specimen no. | LSDS | ||||

|---|---|---|---|---|---|---|---|

| c (kPa) | ϕ′ (°) | R2 | c (kPa) | ϕ′ (°) | R2 | ||

| SS14-0 | 79.4 | 22.1 | 0.997 | LS14-0 | 48.5 | 18.4 | 0.965 |

| SS14-0.3 | 73.6 | 21.6 | 0.998 | LS14-0.30 | 59.6 | 24.3 | 0.995 |

| SS14-0.45 | 59.6 | 30.4 | 0.972 | LS14-0.45 | 68.5 | 22.0 | 0.942 |

| SS14-0.6 | 73.2 | 23.9 | 0.914 | LS14-0.60 | 44.8 | 29.3 | 0.999 |

| SS14-0.75 | 60.9 | 16.3 | 0.986 | LS14-0.75 | 65.8 | 20.3 | 0.961 |

| SS18-0 | 66.1 | 11.7 | 0.974 | LS18-0 | 40.7 | 20.1 | 0.977 |

| SS18-0.3 | 46.3 | 23.0 | 0.962 | LS18-0.30 | 54.3 | 23.7 | 0.999 |

| SS18-0.45 | 60.7 | 21.7 | 0.936 | LS18-0.45 | 36.9 | 22.4 | 0.906 |

| SS18-0.6 | 63.0 | 21.0 | 0.968 | LS18-0.60 | 40.3 | 28.1 | 0.966 |

| SS18-0.75 | 60.9 | 16.3 | 0.986 | LS18-0.75 | 28.2 | 22.2 | 0.976 |

| SS22-0 | 79.7 | 4.9 | 0.997 | LS22-0 | 16.4 | 21.4 | 0.987 |

| SS22-0.3 | 41.2 | 15.2 | 0.968 | LS22-0.30 | 39.8 | 21.1 | 0.986 |

| SS22-0.45 | 27.4 | 22.8 | 0.999 | LS22-0.45 | 39.2 | 16.3 | 0.930 |

| SS22-0.6 | 43.4 | 24.1 | 0.997 | LS22-0.60 | 30.2 | 22.2 | 0.999 |

| SS22-0.75 | 60.9 | 16.3 | 0.986 | LS22-0.75 | 31.7 | 15.3 | 0.990 |

| Specimen no. | LSDS | ||

|---|---|---|---|

| ϕ′ (°) | R2 | γd (kN/m3) | |

| LS14-0 | 31.0 | 0.965 | 13.72 |

| LS14-0.45 | 22.0 | 0.942 | 14.07 |

| LS14-0.6 | 29.3 | 0.999 | 14.20 |

| LS14-0.75 | 20.3 | 0.961 | 14.32 |

| LS14-1 | 25.1 | 0.995 | 14.53 |

| LS18-0 | 20.1 | 0.977 | 13.72 |

| LS18-0.45 | 22.4 | 0.906 | 14.09 |

| LS18-0.6 | 28.1 | 0.966 | 14.21 |

| LS18-0.75 | 22.2 | 0.976 | 14.35 |

| LS18-1 | 27.1 | 0.995 | 14.56 |

| LS22-0 | 22.7 | 0.987 | 13.72 |

| LS22-0.45 | 16.3 | 0.930 | 14.10 |

| LS22-0.6 | 22.2 | 0.999 | 14.23 |

| LS22-0.75 | 15.3 | 0.990 | 14.37 |

| LS22-1 | 17.8 | 0.807 | 14.59 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, W.-C.; Xue, Z.-F.; Wang, L.; Xu, J. Using Post-Harvest Waste to Improve Shearing Behaviour of Loess and Its Validation by Multiscale Direct Shear Tests. Appl. Sci. 2019, 9, 5206. https://doi.org/10.3390/app9235206

Cheng W-C, Xue Z-F, Wang L, Xu J. Using Post-Harvest Waste to Improve Shearing Behaviour of Loess and Its Validation by Multiscale Direct Shear Tests. Applied Sciences. 2019; 9(23):5206. https://doi.org/10.3390/app9235206

Chicago/Turabian StyleCheng, Wen-Chieh, Zhong-Fei Xue, Lin Wang, and Jian Xu. 2019. "Using Post-Harvest Waste to Improve Shearing Behaviour of Loess and Its Validation by Multiscale Direct Shear Tests" Applied Sciences 9, no. 23: 5206. https://doi.org/10.3390/app9235206

APA StyleCheng, W.-C., Xue, Z.-F., Wang, L., & Xu, J. (2019). Using Post-Harvest Waste to Improve Shearing Behaviour of Loess and Its Validation by Multiscale Direct Shear Tests. Applied Sciences, 9(23), 5206. https://doi.org/10.3390/app9235206