1. Introduction

Skid resistance refers to the friction force that prevents the tire from slipping along the pavement surface [

1]. It had been shown that the traffic accident risk increased significantly when the skid resistance was below a certain threshold value [

2]. Therefore, skid resistance of the pavement is an important design parameter affecting driving safety.

Skid resistance/friction force consists of adhesion and hysteresis, mainly depending on the surface texture of the pavement [

3,

4,

5,

6]. The surface texture is classified according to wavelengths, including microtexture (0–0.5 mm), macrotexture (0.5–50 mm), megatexture (50–500 mm), and unevenness (500 mm to 50 m) [

7]. The skid resistance of the pavement mainly depends on its microtexture and macrotexture. It is generally considered that the microtexture characterized by the friction coefficient plays a major role in skid resistance at low speeds; that the macrotexture characterized by mean texture depth (MTD), mean profile depth (MPD) or sensor measured texture depth (SMTD) has a great influence on the skid resistance at high speeds [

8].

There are still no effective methods to accurately characterize microtexture until now. A number of studies used the British pendulum tester (BPN) to characterize microtexture and evaluate skid resistance at low speeds [

9,

10]. Liu et al. found that the friction coefficient measured by BPN was significantly affected by macrotexture. Hence, the general view that skid resistance of the pavement mainly depends on its microtexture is not always right [

11]. Additionally, a dynamic friction tester (DFT) and a grip tester were also used to evaluate skid resistance at low speeds [

12,

13].

As mentioned previously, a number of parameters were applied to characterize the macrotexture of the pavement surface. These parameters could be obtained by different methods. Flintsch et al. used the circular track meter (CTM), laser inertial road profiler, and a sand patch to measure the pavement texture, and used MPD and MTD to characterize the macrotexture of stone mastic asphalt (SMA) and open-graded friction course (OGFC). Then, the correlation of parameters obtained by different test methods was established [

14]. The stationary laser profilometer (SLP) was applied to obtain the texture elevation of the pavement surface and the texture spectral characteristics by digital signal processing. Simultaneously, the formulas of texture indicators with different wavelength ranges were proposed [

15]. The texture elevation of the pavement surface could be also obtained by laser texture scanners (LTS), and geometrical indicators were used to characterize macrotexture, including MPD, average roughness, leveling depth, mean depth, surface roughness depth, and peak to valley height [

16]. However, CTM, SLP, and LTS are quite expensive.

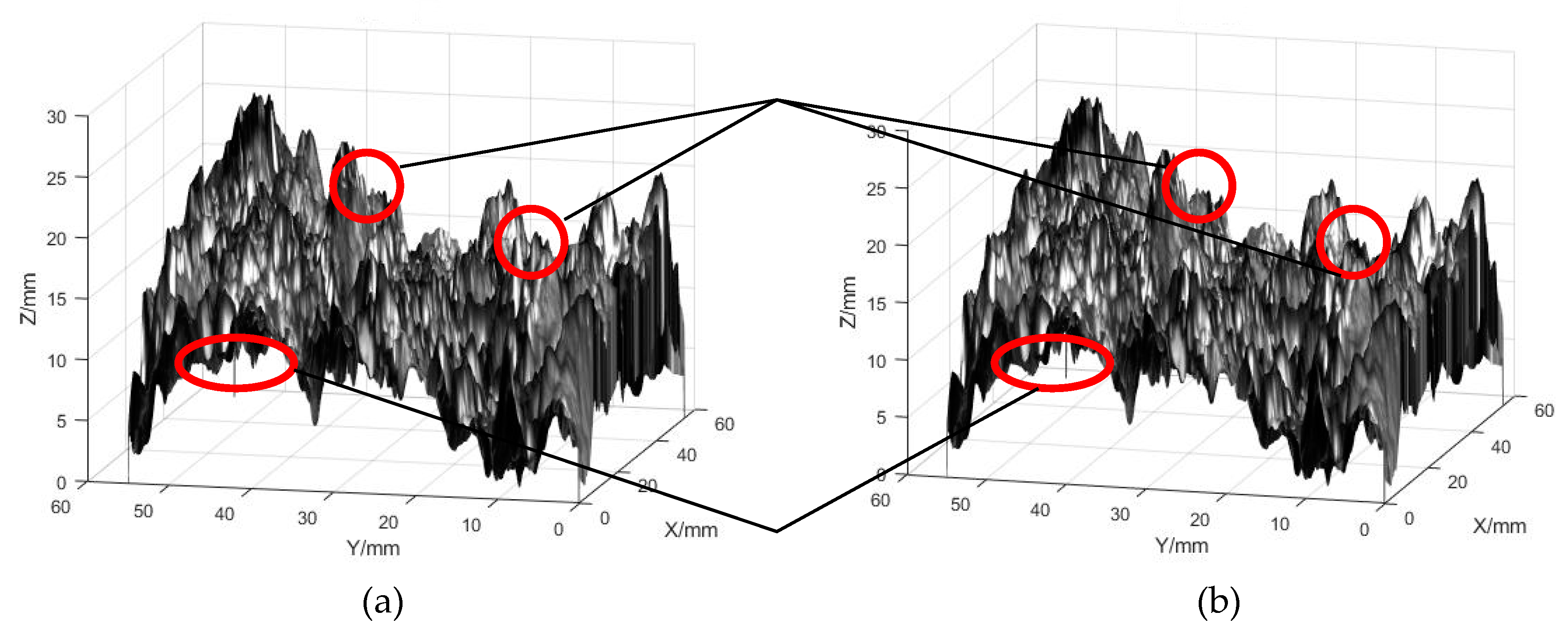

In light of expensive devices measuring pavement texture, three dimensional (3D) measurements by stereophotogrammetry or microscopy were considered to characterize macrotexture of pavement surface [

17,

18,

19,

20]. Compared with using two-dimensional (2D) line profiles, measurements in 3D can accurately characterize the roughness of the pavement surface. Firstly, a large amount of data from multiple images can be collected; secondly, 3D models of the pavement surface were established by some software, such as Digital Surf MountainsMap, 3D flow Zephyr, etc; finally, roughness parameters (arithmetic mean skewness, kurtosis, height, etc) were calculated. These parameters could be used to evaluate microtexture, macrotexture, and megatexture.

Asphalt pavement consists of asphalt and aggregates with different sizes [

21,

22,

23,

24,

25,

26,

27,

28]. Its texture is affected by many factors, such as aggregates type, aggregates sizes, mixture type, etc. Previous studies focused on how to characterize pavement surface texture and the influence of different factors (coarse aggregates type, mixture type, etc) on skid resistance. However, few studies were carried out to analyze the influence of mixture design parameters on skid resistance of pavement with constant coarse aggregates and mixture type. For a certain project, material source and mixture type are constant. Therefore, the skid resistance of pavement mainly depends on design parameters, such as gradation, asphalt content, etc. Although it is well known that the SMA pavement has good skid resistance, the skid resistance is not satisfactory, or its durability is poor when the mixture design is unreasonable [

20].

This paper seeks to analyze the influence of mixture design parameters on the skid resistance of SMA pavement. The mixtures were designed with an orthogonal experiment. There were five factors, namely the percentage of aggregates passing the maximum size (PNMSA), the percentage of aggregates passing the sieve size which is only one smaller than the maximum size (PNMSA-1), the percentage of aggregates passing the control sieve size (PCS), the percentage of aggregates passing the sieve size which is only one smaller than the control sieve size (PCS-1), and asphalt content (AC), and each factor had four levels. The skid-resistance index (SI) obtained by the 3D measurement was used to evaluate skid resistance.

3. Results

SI was used to evaluate skid resistance. As mentioned before,

ki represents mean values of SI for each factor at a certain level

i (

i = 1, 2, 3, 4), and

R reflects the effect order of different factors. The above three parameters could be calculated by the corresponding formula.

Table 10,

Table 11,

Table 12 and

Table 13 show the calculation results.

Table 10,

Table 11,

Table 12 and

Table 13 show the skid resistance of SMA-16, SMA-13, SMA-10, and SMA-5 respectively. The following conclusions can be drawn from these tables.

For different SMA types, the effect order of the three factors (PNMSA, PCS, and AC) is constant. Among them, PNMSA has the greatest impact on the skid resistance, AC is the second, and the impact of PCS on skid resistance is the smallest. Moreover, the three parameters have higher impact on skid resistance than the other two parameters in general. It is obvious that the three parameters are the key parameters to improve skid resistance.

The effect order of PNMSA-1 and PCS-1 with different SMA types is various. For SMA-16, PNMSA-1 has a greater impact on skid resistance than PCS-1, but the conclusion is the opposite for SMA-13.

For PNMSA-1, SMA pavements with different mixture types have the best skid resistance at the level (i = 1). For other design parameters, the corresponding levels (i) with different mixture types are significantly different when the skid resistance is best.

Taking SMA-13 as an example, AC (5.6%) is lower than OAC (6.3%) when the skid resistance is best. It is possible that the surface texture of SMA pavement with lower AC is richer, resulting in better skid resistance. It is noticed that the pavement may have excellent skid resistance but poor pavement performance when AC is 5.6%. Therefore, the determination of the best design parameters should be considered both skid resistance and pavement performance.

The influence of each factor on the skid resistance of SMA pavement could be intuitively determined by the trend of ki with different levels. For each factor, the value increased with levels.

3.1. The Influence of NMAS on Skid Resistance

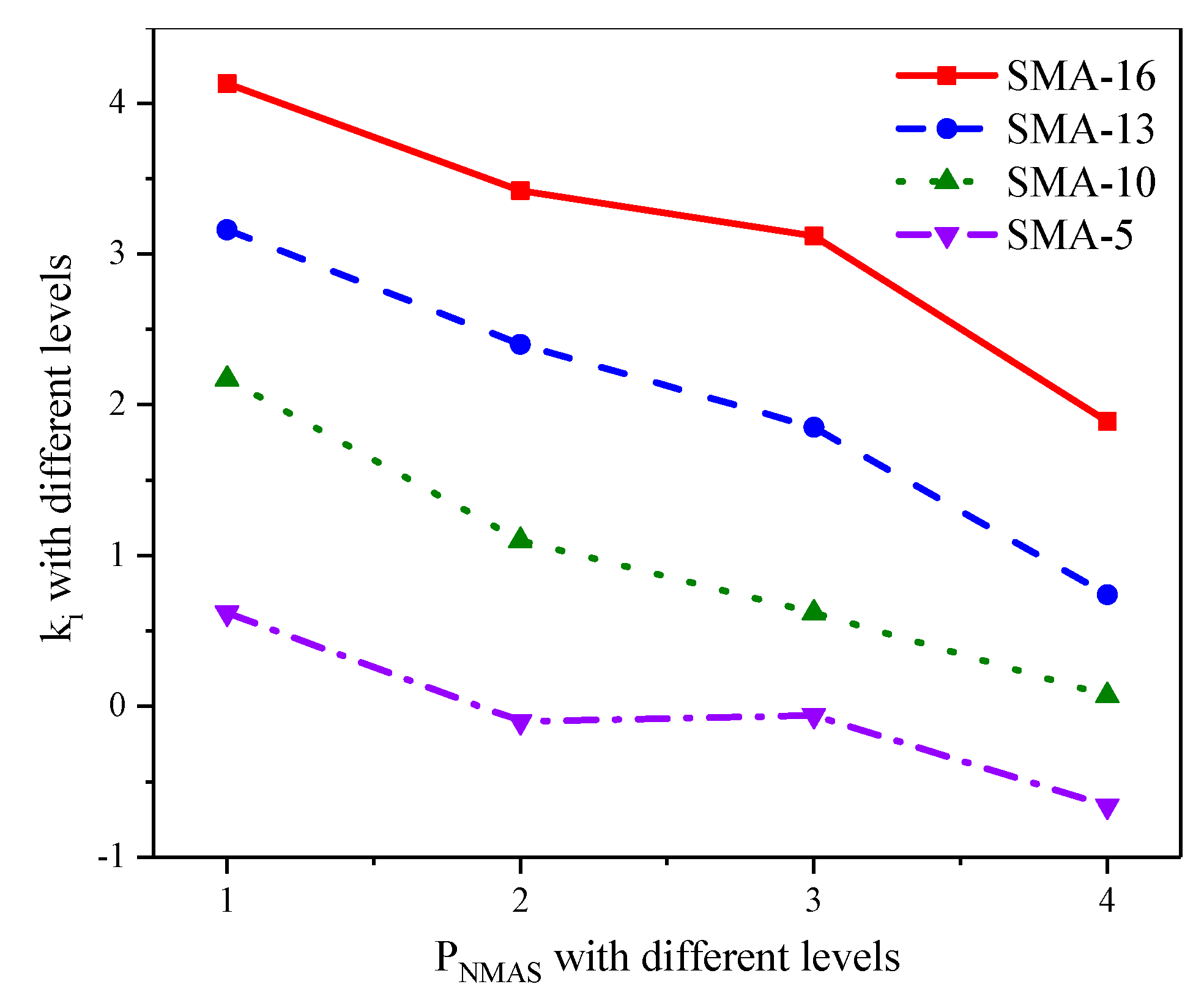

Figure 2 shows the relationship between P

NMAS and the skid resistance of SMA pavement. It can be seen that the skid resistance gradually reduces with the increasing of P

NMAS. P

NMAS refers to percentage of aggregates passing of the maximum size. Lower P

NMAS means more aggregates remaining on the sieve. The macrotexture of asphalt pavement is mainly contributed by the coarse aggregate. The content of aggregates with the size larger than nominal maximum size leads to richer macrotexture, resulting in better skid resistance.

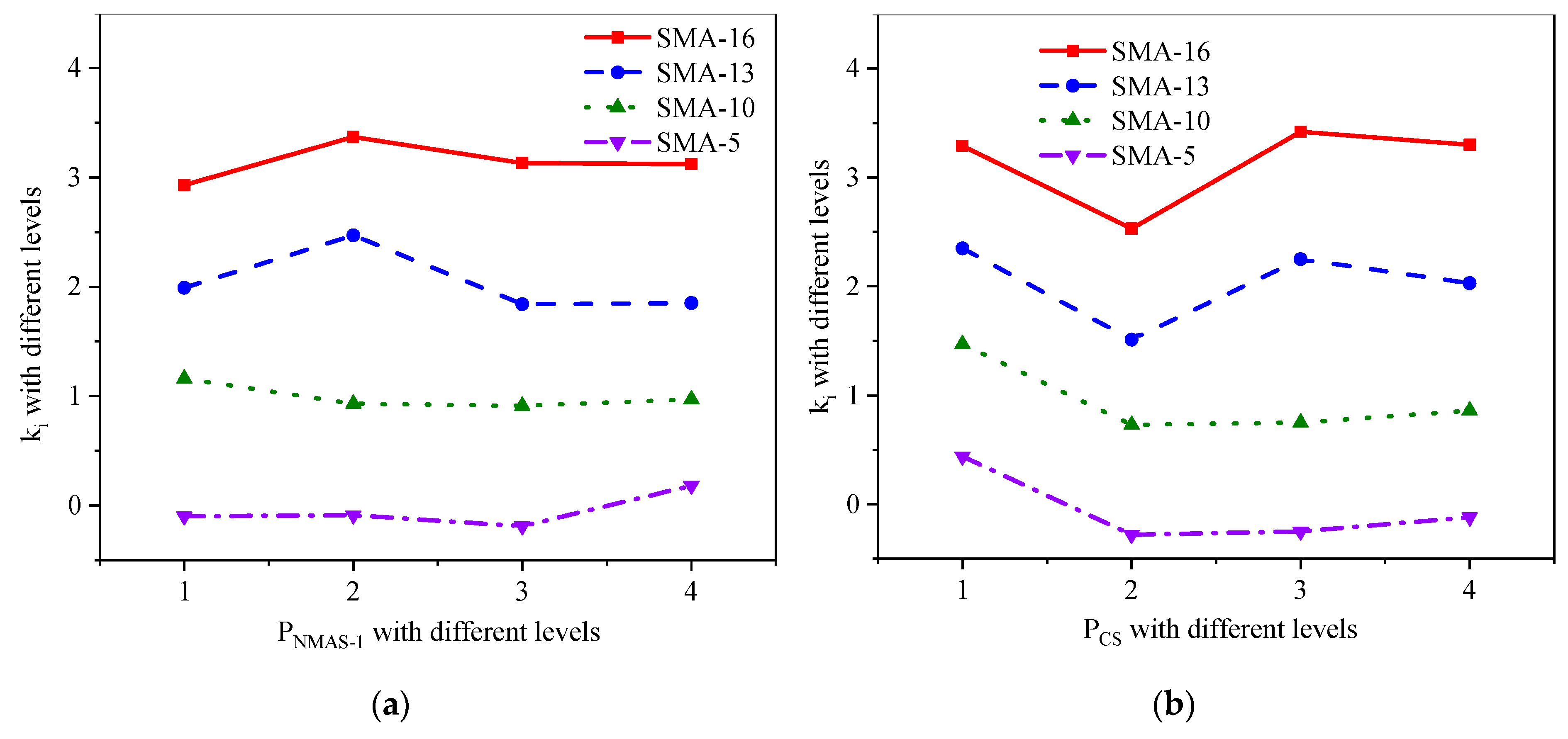

3.2. The Influence of Control Sieve Percent on Skid Resistance

Figure 3 shows the relationship between the percentage passing several control sieves and skid resistance of SMA pavement. With increasing P

CS, the trend of

ki with different mixture types stays the same, which first decreases and then increases. It means that the skid resistance of SMA pavement first decreases and then increases with increasing P

CS. For P

NMAS-1 and P

CS-1,

ki with different mixture types and levels of factors is various. However, the value of

ki does not change much, indicating that P

NMAS-1 and P

CS-1 have an insignificant effect on skid resistance of SMA pavement.

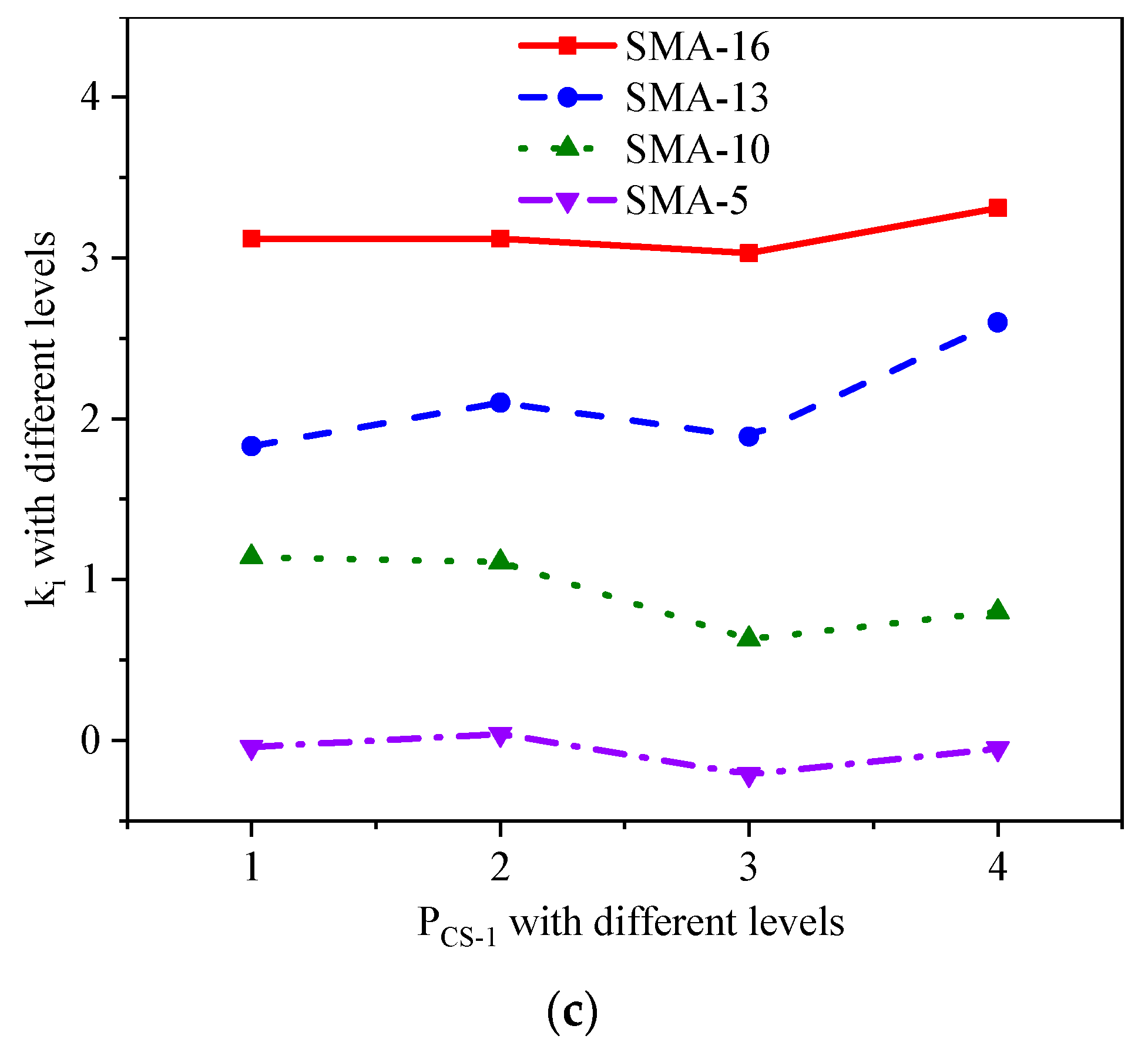

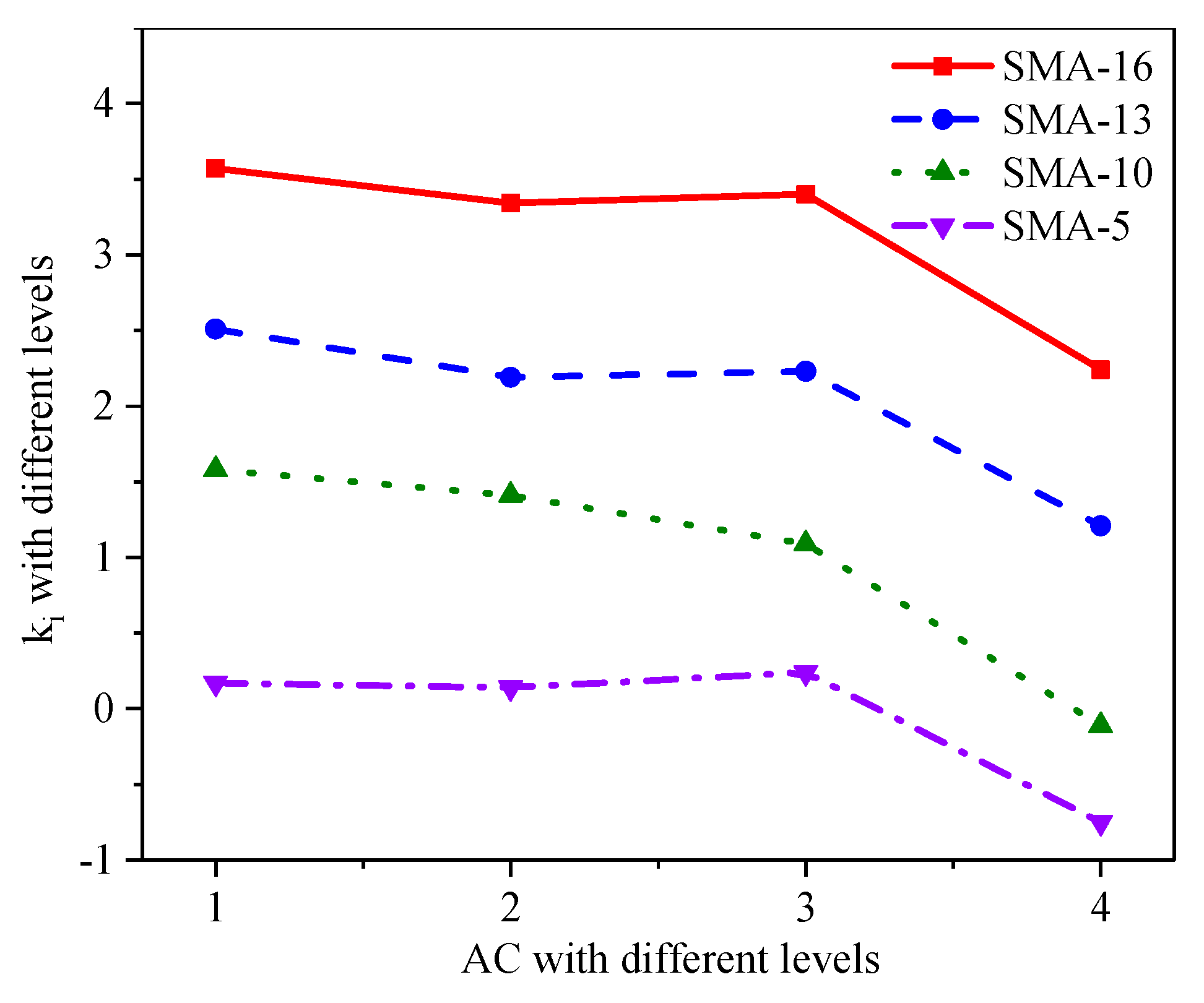

3.3. The Influence of AC on Skid Resistance

Figure 4 shows the relationship between AC and the skid resistance of SMA pavement.

It can be seen that the trend of ki is consistent for different mixture types in general with increasing AC. ki gradually decreases as AC increases, indicating that the skid resistance decreases. This is mainly due to the fact that when AC increases, the asphalt film is thicker, resulting in a smaller macrotexture, which leads to weaker skid resistance. It is noticed that the trend of ki of SMA-5 is significantly different from the other SMA types. ki first increases and then decreases with increasing AC. When the aggregates sizes are small enough, the compaction work during the specimen process may lead to rearrangement of aggregates, resulting in an abnormality in the gradation. It may have an impact on skid resistance.