Filament Extrusion and Its 3D Printing of Poly(Lactic Acid)/Poly(Styrene-co-Methyl Methacrylate) Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Melt Blending

2.3. Filament Extrusion

2.4. 3D Printing

2.5. Characterization

2.5.1. Mechanical Properties

2.5.2. Rheological Properties

2.5.3. Differential Scanning Calorimetry Analysis

2.5.4. Thermogravimetric Analysis

3. Results and Discussion

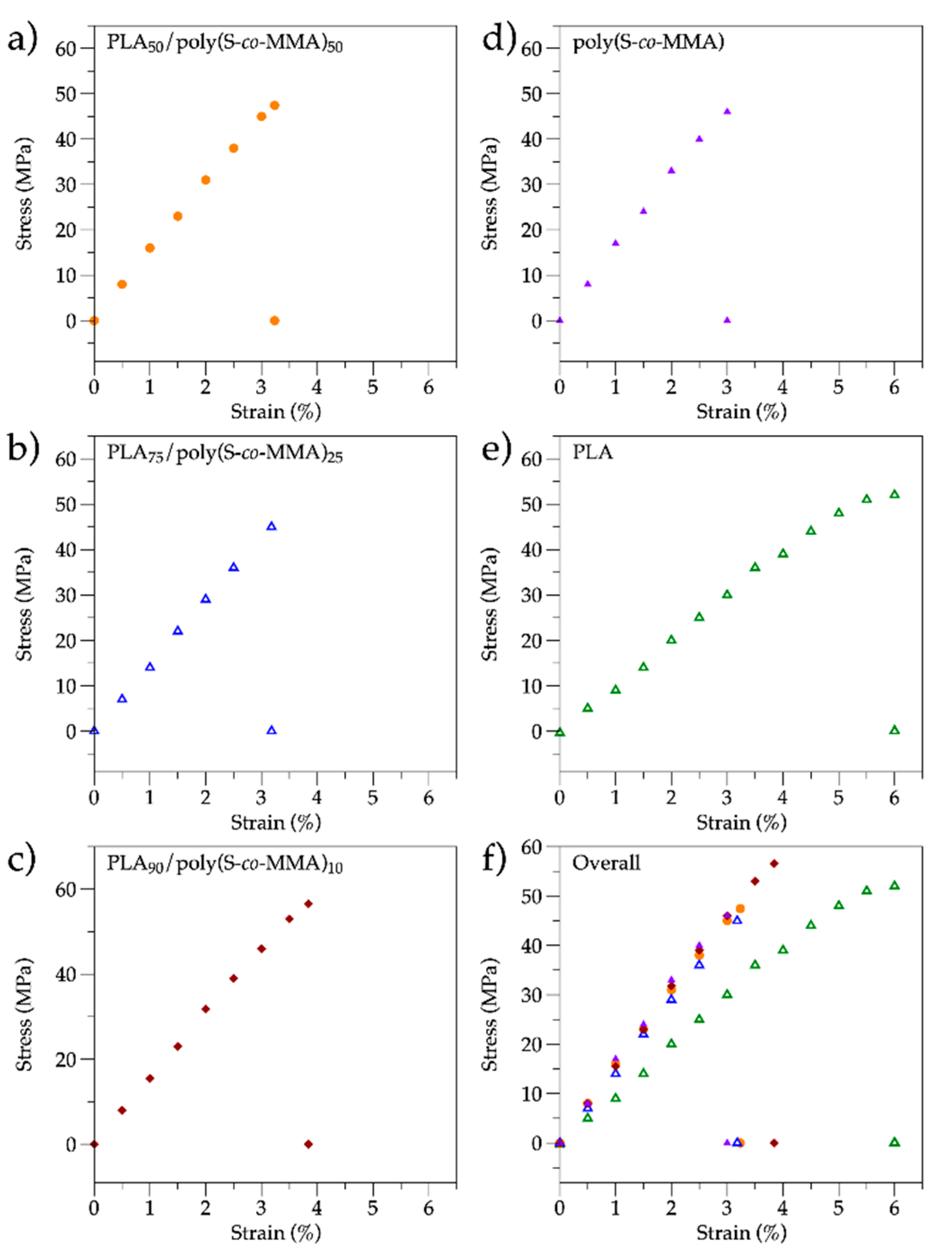

3.1. Mechanical Properties

3.1.1. Young’s Modulus

3.1.2. Elongation at Break (%)

3.1.3. Ultimate Tensile Strength

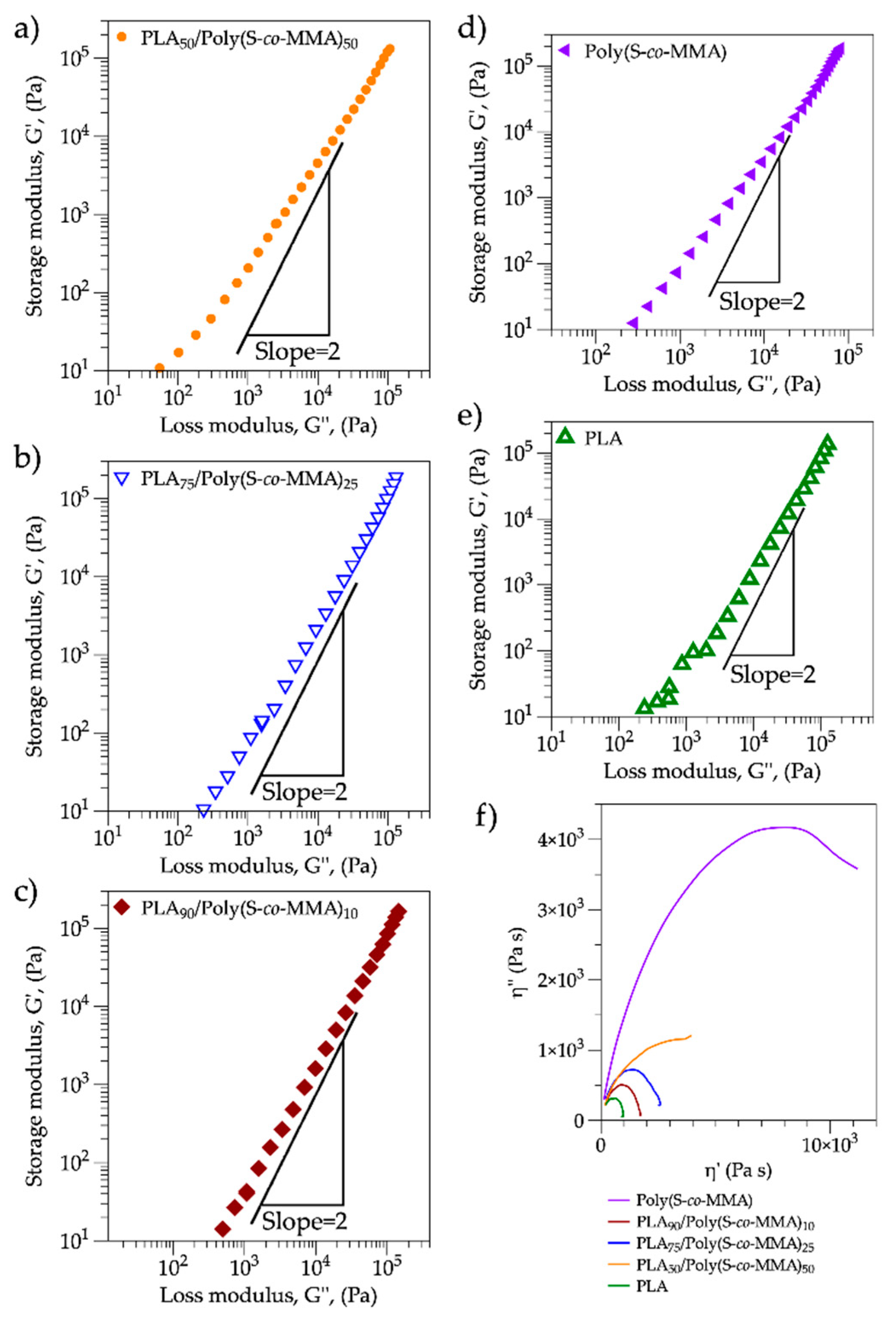

3.2. Rheological Properties

3.3. Thermal Analysis

3.3.1. Differential Scanning Calorimetry

3.3.2. Thermogravimetric Analysis

3.3.3. Filament Extrusion and 3D Printing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, S.; Daelemans, L.; Fiorio, R.; Gou, M.; D’hooge, D.R.; De Clerck, K.; Cardon, L. Improving mechanical properties for extrusion-based additive manufacturing of poly(lactic acid) by annealing and blending. Polymers 2019, 11, 1529. [Google Scholar] [CrossRef] [PubMed]

- Terekhina, S.; Skornyakov, I.; Tarasova, T.; Egorov, S. Effects of the infill density on the mechanical properties of nylon specimens made by filament fused fabrication. Technologies 2019, 7, 57. [Google Scholar] [CrossRef]

- Henkel, J.; Woodruff, M.A.; Epari, D.R.; Steck, R.; Glatt, V.; Dickinson, I.C.; Choong, P.F.M.; Schuetz, M.A.; Hutmacher, D.W. Bone regeneration based on tissue engineering conceptions—A 21st century perspective. Bone Res. 2013, 1, 216–248. [Google Scholar] [CrossRef]

- Liu, J.; Sun, L.; Xu, W.; Wang, Q.; Yu, S.; Sun, J. Current advances and future perspectives of 3D printing natural-derived biopolymers. Carbohydr. Polym. 2019, 207, 297–316. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Alhnan, M.A.; Okwuosa, T.C.; Sadia, M.; Wan, K.-W.; Ahmed, W.; Arafat, B. Emergence of 3D printed dosage forms: Opportunities and challenges. Pharm. Res. 2016, 33, 1817–1832. [Google Scholar] [CrossRef]

- Gregor-Svetec, D.; Leskovšek, M.; Brodnjak, U.V.; Elesini, U.S.; Muck, D.; Urbas, R. Characteristics of HDPE/cardboard dust 3D printable composite filaments. J. Mater. Process. Technol. 2020, 276. in press. [Google Scholar] [CrossRef]

- Mirón, V.; Ferrándiz, S.; Juárez, D.; Mengual, A. Manufacturing and characterization of 3D printer filament using tailoring materials. Procedia Manuf. 2017, 13, 888–894. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Domingos, M.; Gloria, A.; Coelho, J.; Bartolo, P.; Ciurana, J. Three-dimensional printed bone scaffolds: The role of nano/micro-hydroxyapatite particles on the adhesion and differentiation of human mesenchymal stem cells. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2017, 231, 555–564. [Google Scholar] [CrossRef]

- De Santis, R.; D’Amora, U.; Russo, T.; Ronca, A.; Gloria, A.; Ambrosio, L. 3D fibre deposition and stereolithography techniques for the design of multifunctional nanocomposite magnetic scaffolds. J. Mater. Sci. Mater. Med. 2015, 26, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Singh, G.; Singh, J.; Kumar, R. Investigations for tensile, compressive and morphological properties of 3D printed functional prototypes of PLA-PEKK-HAp-CS. J. Thermoplast. Compos. Mater. 2019, in press. [Google Scholar] [CrossRef]

- Lee, J.; Lee, H.; Cheon, K.-H.; Park, C.; Jang, T.-S.; Kim, H.-E.; Jung, H.-D. Fabrication of poly(lactic acid)/Ti composite scaffolds with enhanced mechanical properties and biocompatibility via fused filament fabrication (FFF)–based 3D printing. Addit. Manuf. 2019, 30. in press. [Google Scholar] [CrossRef]

- Prasad, E.; Islam, M.T.; Goodwin, D.J.; Megarry, A.J.; Halbert, G.W.; Florence, A.J.; Robertson, J. Development of a hot-melt extrusion (HME) process to produce drug loaded AffinisolTM 15LV filaments for fused filament fabrication (FFF) 3D printing. Addit. Manuf. 2019, 29. in press. [Google Scholar] [CrossRef]

- Pucci, J.U.; Christophe, B.R.; Sisti, J.A.; Connolly, E.S. Three-dimensional printing: technologies, applications, and limitations in neurosurgery. Biotechnol. Adv. 2017, 35, 521–529. [Google Scholar] [CrossRef]

- Zuniga, J.M. 3D printed antibacterial prostheses. Appl. Sci. 2018, 8, 1651. [Google Scholar] [CrossRef]

- Narayanan, G.; Vernekar, V.N.; Kuyinu, E.L.; Laurencin, C.T. Poly(lactic acid)-based biomaterials for orthopaedic regenerative engineering. Adv. Drug Deliv. Rev. 2016, 107, 247–276. [Google Scholar] [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Hu, G.F.; Liao, W.H. Large deformations of soft metamaterials fabricated by 3D printing. Mater. Des. 2017, 131, 81–91. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- An, J.; Teoh, J.E.M.; Suntornnond, R.; Chua, C.K. Design and 3D printing of scaffolds and tissues. Engineering 2015, 1, 261–268. [Google Scholar] [CrossRef]

- Senatov, F.S.; Niaza, K.V.; Zadorozhnyy, M.Y.; Maksimkin, A.V.; Kaloshkin, S.D.; Estrin, Y.Z. Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 2016, 57, 139–148. [Google Scholar] [CrossRef] [PubMed]

- Nagrath, M.; Sikora, A.; Graca, J.; Chinnici, J.L.; Rahman, S.U.; Reddy, S.G.; Ponnusamy, S.; Maddi, A.; Arany, P.R. Functionalized prosthetic interfaces using 3D printing: Generating infection-neutralizing prosthesis in dentistry. Mater. Today Commun. 2018, 15, 114–119. [Google Scholar] [CrossRef]

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.-C. Poly(lactic acid) blends: Processing, properties and applications. Int. J. Biol. Macromol. 2018, 125, 307–360. [Google Scholar] [CrossRef]

- Kaur, M.; Yun, T.G.; Han, S.M.; Thomas, E.L.; Kim, W.S. 3D printed stretching-dominated micro-trusses. Mater. Des. 2017, 134, 272–280. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications - A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Russias, J.; Saiz, E.; Nalla, R.K.; Gryn, K.; Ritchie, R.O.; Tomsia, A.P. Fabrication and mechanical properties of PLA/HA composites: A study of in vitro degradation. Mater. Sci. Eng. C 2006, 26, 1289–1295. [Google Scholar] [CrossRef]

- Heidari, B.S.; Oliaei, E.; Shayesteh, H.; Davachi, S.M.; Hejazi, I.; Seyfi, J.; Bahrami, M.; Rashedi, H. Simulation of mechanical behavior and optimization of simulated injection molding process for PLA based antibacterial composite and nanocomposite bone screws using central composite design. J. Mech. Behav. Biomed. Mater. 2017, 65, 160–176. [Google Scholar] [CrossRef]

- Michael, F.M.; Khalid, M.; Walvekar, R.; Ratnam, C.T.; Ramarad, S.; Siddiqui, H.; Hoque, M.E. Effect of nanofillers on the physico-mechanical properties of load bearing bone implants. Mater. Sci. Eng. C 2016, 67, 792–806. [Google Scholar] [CrossRef]

- Balk, M.; Behl, M.; Wischke, C.; Zotzmann, J.; Lendlein, A. Recent advances in degradable lactide-based shape-memory polymers. Adv. Drug Deliv. Rev. 2016, 107, 136–152. [Google Scholar] [CrossRef]

- Hao, X.; Kaschta, J.; Pan, Y.; Liu, X.; Schubert, D.W. Intermolecular cooperativity and entanglement network in a miscible PLA/PMMA blend in the presence of nanosilica. Polymer 2016, 82, 57–65. [Google Scholar] [CrossRef]

- Middleton, J.C.; Tipton, A.J. Synthetic biodegradable polymers as orthopedic devices. Biomaterials 2000, 21, 2335–2346. [Google Scholar] [CrossRef]

- He, Z.; Zhai, Q.; Hu, M.; Cao, C.; Wang, J.; Yang, H.; Li, B. Bone cements for percutaneous vertebroplasty and balloon kyphoplasty: Current status and future developments. J. Orthop. Transl. 2015, 3, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Chuai, C.Z.; Almdal, K.; Lyngaae-Jørgensen, J. Phase continuity and inversion in polystyrene/poly(methyl methacrylate) blends. Polymer 2003, 44, 481–493. [Google Scholar] [CrossRef]

- Bouzid, L.; Hiadsi, S.; Bensaid, M.O.; Foudad, F.Z. Molecular dynamics simulation studies of the miscibility and thermal properties of PMMA/PS polymer blend. Chinese J. Phys. 2018, 56, 3012–3019. [Google Scholar] [CrossRef]

- Tüzüner, Ş.; Demir, M.M. Dispersion of organophilic Ag nanoparticles in PS-PMMA blends. Mater. Chem. Phys. 2015, 162, 692–699. [Google Scholar] [CrossRef][Green Version]

- Yun, M.; Jung, N.; Yim, C.; Jeon, S. Nanomechanical thermal analysis of the effects of physical aging on glass transitions in PS/PMMA blend and PS-PMMA diblock copolymers. Polymer 2011, 52, 4136–4140. [Google Scholar] [CrossRef]

- Cochran, T.W. Polymer Compositions Based on SMMA. EP 3068834 B1, 19 July 2017. [Google Scholar]

- Quitadamo, A.; Massardier, V.; Santulli, C.; Valente, M. Optimization of thermoplastic blend matrix HDPE/PLA with different types and levels of coupling agents. Materials 2018, 11, 2527. [Google Scholar] [CrossRef]

- Balakrishnan, H.; Hassan, A.; Wahit, M.U. Mechanical, thermal, and morphological properties of polylactic acid/linear low density polyethylene blends. J. Elastomers Plast. 2010, 42, 223–239. [Google Scholar] [CrossRef]

- Montana, J.S.; Roland, S.; Richaud, E.; Miquelard-Garnier, G. Nanostructuration effect on the mechanical properties of PMMA toughened by a triblock acrylate copolymer using multilayer coextrusion. Polymer 2018, 149, 124–133. [Google Scholar] [CrossRef]

- Nofar, M.; Tabatabaei, A.; Sojoudiasli, H.; Park, C.B.; Carreau, P.J.; Heuzey, M.C.; Kamal, M.R. Mechanical and bead foaming behavior of PLA-PBAT and PLA-PBSA blends with different morphologies. Eur. Polym. J. 2017, 90, 231–244. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F.; Ko, Y.G. Mechanical properties and compatibility of polylactic acid/polystyrene polymer blend. Mater. Lett. 2016, 164, 409–412. [Google Scholar] [CrossRef]

- Li, K.; Huang, J.; Xu, D.; Zhong, Y.; Zhang, L.; Cai, J. Mechanically strong polystyrene nanocomposites by peroxide-induced grafting of styrene monomers within nanoporous cellulose gels. Carbohydr. Polym. 2018, 199, 473–481. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Yu, W.; Zhou, C. Phase behavior and its viscoelastic responses of poly(methyl methacrylate) and poly(styrene-co-maleic anhydride) blend systems. Polym. Bull. 2006, 56, 455–466. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, S.; Li, G.; Chen, D. Effect of fillers on the phase stability of binary polymer blends: A dynamic shear rheology study. Acta Materialia 2005, 53, 5117–5124. [Google Scholar] [CrossRef]

- Chopra, D.; Kontopoulou, M.; Vlassopoulos, D.; Hatzikiriakos, S.G. Effect of maleic anhydride content on the rheology and phase behavior of poly(styrene-co-maleic anhydride)/poly(methyl methacrylate) blends. Rheol. Acta 2003, 41, 10–24. [Google Scholar]

- Mohammadi, M.; Yousefi, A.A.; Ehsani, M. Thermorheological analysis of blend of high-and low-density polyethylenes. J. Polym. Res. 2012, 19, 24–29. [Google Scholar] [CrossRef]

- Vicente-Alique, E.; Vega, J.F.; Robledo, N.; Nieto, J.; Martínez-Salazar, J. Study of the effect of the molecular architecture of the components on the melt rheological properties of polyethylene blends. J. Polym. Res. 2015, 22, 62–73. [Google Scholar] [CrossRef]

- Ding, Y.; Feng, W.; Huang, D.; Lu, B.; Wang, P.; Wang, G. Compatibilization of immiscible PLA-based biodegradable polymer blends using amphiphilic di-block copolymers. Eur. Polym. J. 2019, 118, 45–52. [Google Scholar] [CrossRef]

- Singla, R.K.; Zafar, M.T.; Maiti, S.N.; Ghosh, A.K. Physical blends of PLA with high vinyl acetate containing EVA and their rheological, thermo-mechanical and morphological responses. Polym. Test. 2017, 63, 398–406. [Google Scholar] [CrossRef]

- Maroufkhani, M.; Katbab, A.A.; Liu, W.; Zhang, J. Polylactide (PLA) and acrylonitrile butadiene rubber (NBR) blends: The effect of ACN content on morphology, compatibility and mechanical properties. Polymer 2017, 115, 37–44. [Google Scholar] [CrossRef]

- Adrar, S.; Habi, A.; Ajji, A.; Grohens, Y. Synergistic effects in epoxy functionalized graphene and modified organo-montmorillonite PLA/PBAT blends. Appl. Clay Sci. 2018, 157, 65–75. [Google Scholar] [CrossRef]

- Nasti, G.; Gentile, G.; Cerruti, P.; Carfagna, C.; Ambrogi, V. Double percolation of multiwalled carbon nanotubes in polystyrene/polylactic acid blends. Polymer 2016, 99, 193–203. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, X.; Liu, H.; Wang, Y.; Guo, Z.; Liu, C. Multi-walled carbon nanotube in a miscible PEO/PMMA blend: Thermal and rheological behavior. Polym. Test. 2019, 75, 367–372. [Google Scholar] [CrossRef]

- Chiu, F.C.; Yeh, S.C. Comparison of PVDF/MWNT, PMMA/MWNT, and PVDF/PMMA/MWNT nanocomposites: MWNT dispersibility and thermal and rheological properties. Polym. Test. 2015, 45, 114–123. [Google Scholar] [CrossRef]

- Mao, Z.; Zhang, X.; Jiang, G.; Zhang, J. Fabricating sea-island structure and co-continuous structure in PMMA/ASA and PMMA/CPE blends: Correlation between impact property and phase morphology. Polym. Test. 2019, 73, 21–30. [Google Scholar] [CrossRef]

- Suresh, S.S.; Mohanty, S.; Nayak, S.K. Effect of nitrile rubber on mechanical, thermal, rheological and flammability properties of recycled blend. Process Saf. Environ. Prot. 2019, 123, 370–378. [Google Scholar] [CrossRef]

- Mezger, T.G. The Rheology Handbook, 4th ed.; Vincentz Network: Hanover, Germany, 2014; pp. 97–106. [Google Scholar]

- Prado, B.R.; Bartoli, J.R. Synthesis and characterization of PMMA and organic modified montmorilonites nanocomposites via in situ polymerization assisted by sonication. Appl. Clay Sci. 2018, 160, 132–143. [Google Scholar] [CrossRef]

- Potanin, A. Rheology of silica dispersions stabilized by polymers. Colloids Surfaces A Physicochem. Eng. Asp. 2019, 562, 54–60. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, C.; Song, Y.; Zheng, Q. Rheology of fumed silica/polypropylene glycol dispersions. Polymer 2018, 148, 400–406. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J.; Shenguo, W.; Shen, D. Miscibility and phase structure of binary blends of polylactide and poly(methyl methacrylate). J. Appl. Polym. Sci. Part B Polym. Phys. 2003, 41, 23–30. [Google Scholar] [CrossRef]

- Canetti, M.; Cacciamani, A.; Bertini, F. Miscible blends of polylactide and poly(methyl methacrylate): Morphology, structure, and thermal behavior. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 1168–1177. [Google Scholar] [CrossRef]

- Repka, M.A.; Shah, S.; Lu, J.; Maddineni, S.; Morott, J.; Patwardhan, K.; Mohammed, N.N. Melt extrusion: Process to product. Expert Opin. Drug Deliv. 2012, 9, 105–125. [Google Scholar] [CrossRef] [PubMed]

- Elsawy, M.A.; Kim, K.H.; Park, J.W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- Chow, W.S.; Lok, S.K. Thermal properties of poly(lactic acid)/organo-mont-morillonite nanocomposites. J. Therm. Anal. Calorim. 2009, 95, 627–632. [Google Scholar] [CrossRef]

- Witkowski, A.; Stec, A.A.; Hull, R.T. Thermal decomposition of polymeric materials. In SFPE Handbook of Fire Protection Engineering, 5th ed.; Hurley, M.J., Gottuk, D., Hall, J.R., Harada, K., Kuligowski, E., Puchovsky, M., Torero, J., Watts, J.M., Jr., Wieczorek, C., Eds.; Springer: New York, NY, USA, 2016; pp. 53–65. [Google Scholar]

- Arshad, M.; Masud, K.; Saeed, A. AlBr3 impact on the thermal degradation of P(S-co-MMA): A study performed by contemporary techniques. Iran Polym. J. 2012, 21, 143–155. [Google Scholar] [CrossRef]

- Buruga, K.; Kalathi, J.T. Synthesis of poly(styrene-co-methyl methacrylate) nanospheres by ultrasound-mediated pickering nanoemulsion polymerization. J. Polym. Res. 2019, 26. in press. [Google Scholar] [CrossRef]

- Mohamed, A.; Gordon, S.H.; Biresaw, G. Poly(lactic acid)/polystyrene bioblends characterized by thermogravimetric analysis, differential scanning calorimetry, and photoacoustic infrared spectroscopy. J. Appl. Polym. Sci. 2007, 106, 1689–1696. [Google Scholar] [CrossRef]

- Teoh, E.L.; Mariatti, M.; Chow, W.S. Thermal and flame resistant properties of poly (lactic acid)/poly (methyl methacrylate) blends containing halogen-free flame retardant. Procedia Chem. 2016, 19, 795–802. [Google Scholar] [CrossRef]

- Mangin, R.; Vahabi, H.; Sonnier, R.; Chivas-Joly, C.; Lopez-Cuesta, J.M.; Cochez, M. Improving the resistance to hydrothermal ageing of flame-retarded PLA by incorporating miscible PMMA. Polym. Degrad. Stab. 2018, 155, 52–66. [Google Scholar] [CrossRef]

- Anakabe, J.; Zaldua Huici, A.M.; Eceiza, A.; Arbelaiz, A. The effect of the addition of poly(styrene-co-glycidyl methacrylate) copolymer on the properties of polylactide/poly(methyl methacrylate) blend. J. Appl. Polym. Sci. 2016, 133, 1–10. [Google Scholar] [CrossRef]

- Cuadri, A.A.; Martín-Alfonso, J.E. Thermal, thermo-oxidative and thermomechanical degradation of PLA: A comparative study based on rheological, chemical and thermal properties. Polym. Degrad. Stab. 2018, 150, 37–45. [Google Scholar] [CrossRef]

- Zubair, M.; Shehzad, F.; Al-Harthi, M.A. Impact of modified graphene and microwave irradiation on thermal stability and degradation mechanism of poly (styrene-co-methyl meth acrylate). Thermochim. Acta 2016, 633, 48–55. [Google Scholar] [CrossRef]

- León-Cabezas, M.A.; Martínez-García, A.; Varela-Gandía, F.J. Innovative functionalized monofilaments for 3D printing using fused deposition modeling for the toy industry. Procedia Manuf. 2017, 13, 738–745. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

| Samples | PLAx/poly(S-co-MMA)y (wt.%) | |

|---|---|---|

| x | y | |

| Neat PLA | 100 | 0 |

| Neat poly(S-co-MMA) | 0 | 100 |

| PLA50/poly(S-co-MMA)50 | 50 | 50 |

| PLA75/poly(S-co-MMA)25 | 75 | 25 |

| PLA90/poly(S-co-MMA)10 | 90 | 10 |

| Parameter | Value | Units |

|---|---|---|

| Object infill (%) | 10 | % |

| Layer Height (mm) | 0.25 | mm |

| Number of shells | 3 | |

| Feed rate (mm/s) | 40 | mm/s |

| Travel feed rate | 35 | |

| Print temperature (°C) | 195 | °C |

| Sample | Young’s Modulus (GPa) | Elongation at Break (%) | Ultimate Tensile Strength (MPa) |

|---|---|---|---|

| Neat PLA | 1.16 | 6.00 | 52 |

| PLA50/poly(S-co-MMA)50 | 1.57 | 3.23 | 48 |

| PLA75/poly(S-co-MMA)25 | 1.58 | 3.17 | 45 |

| PLA90/poly(S-co-MMA)10 | 1.60 | 3.84 | 56 |

| Neat poly(S-co-MMA) | 1.68 | 3.00 | 46 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solorio-Rodríguez, L.E.; Vega-Rios, A. Filament Extrusion and Its 3D Printing of Poly(Lactic Acid)/Poly(Styrene-co-Methyl Methacrylate) Blends. Appl. Sci. 2019, 9, 5153. https://doi.org/10.3390/app9235153

Solorio-Rodríguez LE, Vega-Rios A. Filament Extrusion and Its 3D Printing of Poly(Lactic Acid)/Poly(Styrene-co-Methyl Methacrylate) Blends. Applied Sciences. 2019; 9(23):5153. https://doi.org/10.3390/app9235153

Chicago/Turabian StyleSolorio-Rodríguez, Luis Enrique, and Alejandro Vega-Rios. 2019. "Filament Extrusion and Its 3D Printing of Poly(Lactic Acid)/Poly(Styrene-co-Methyl Methacrylate) Blends" Applied Sciences 9, no. 23: 5153. https://doi.org/10.3390/app9235153

APA StyleSolorio-Rodríguez, L. E., & Vega-Rios, A. (2019). Filament Extrusion and Its 3D Printing of Poly(Lactic Acid)/Poly(Styrene-co-Methyl Methacrylate) Blends. Applied Sciences, 9(23), 5153. https://doi.org/10.3390/app9235153