A User-Specific Approach for Comfortable Application of Advanced 3D CAD/CAM Technique in Dental Environments Using the Harmonic Series Noise Model

Abstract

1. Introduction

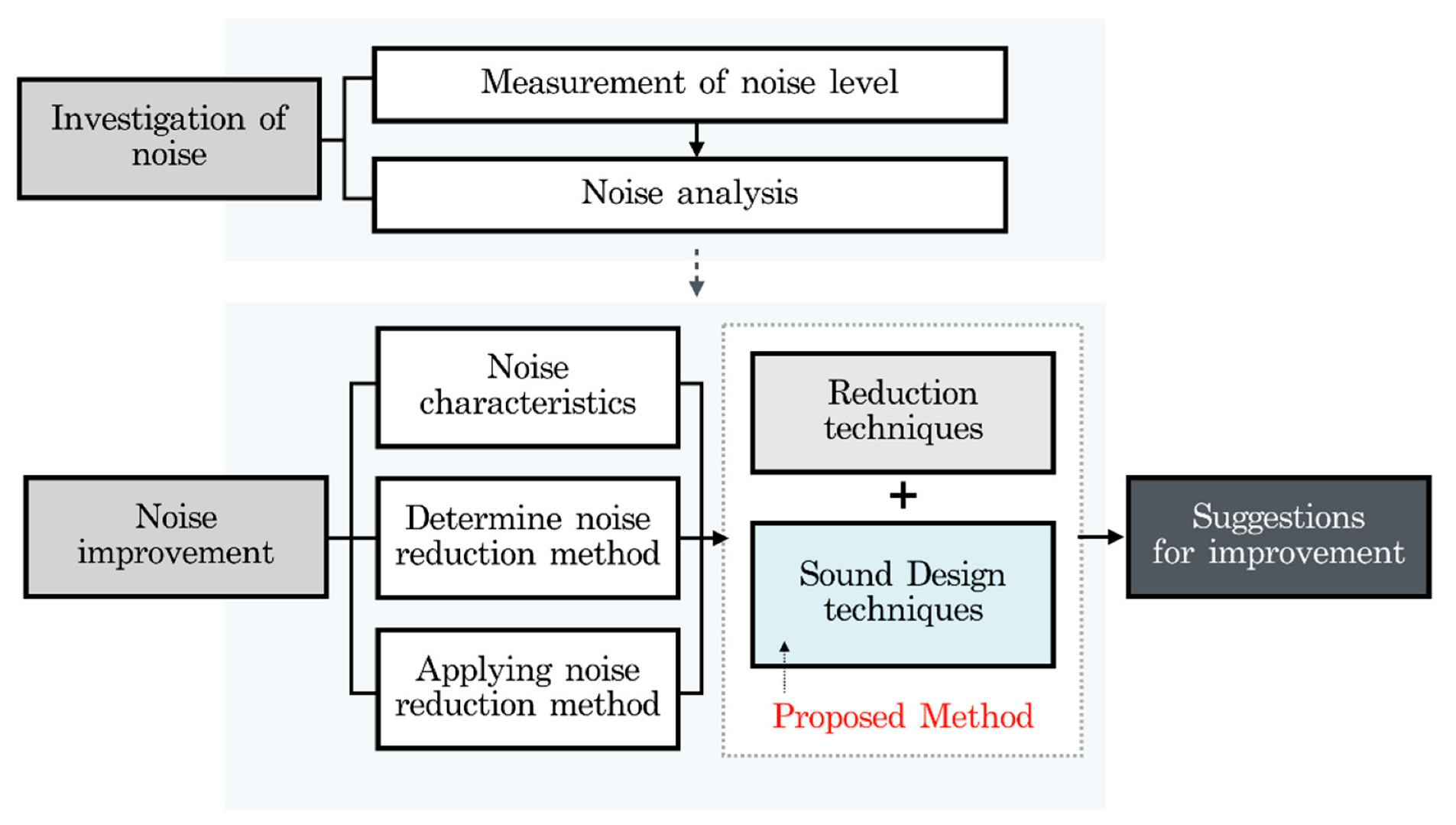

2. Materials and Methods

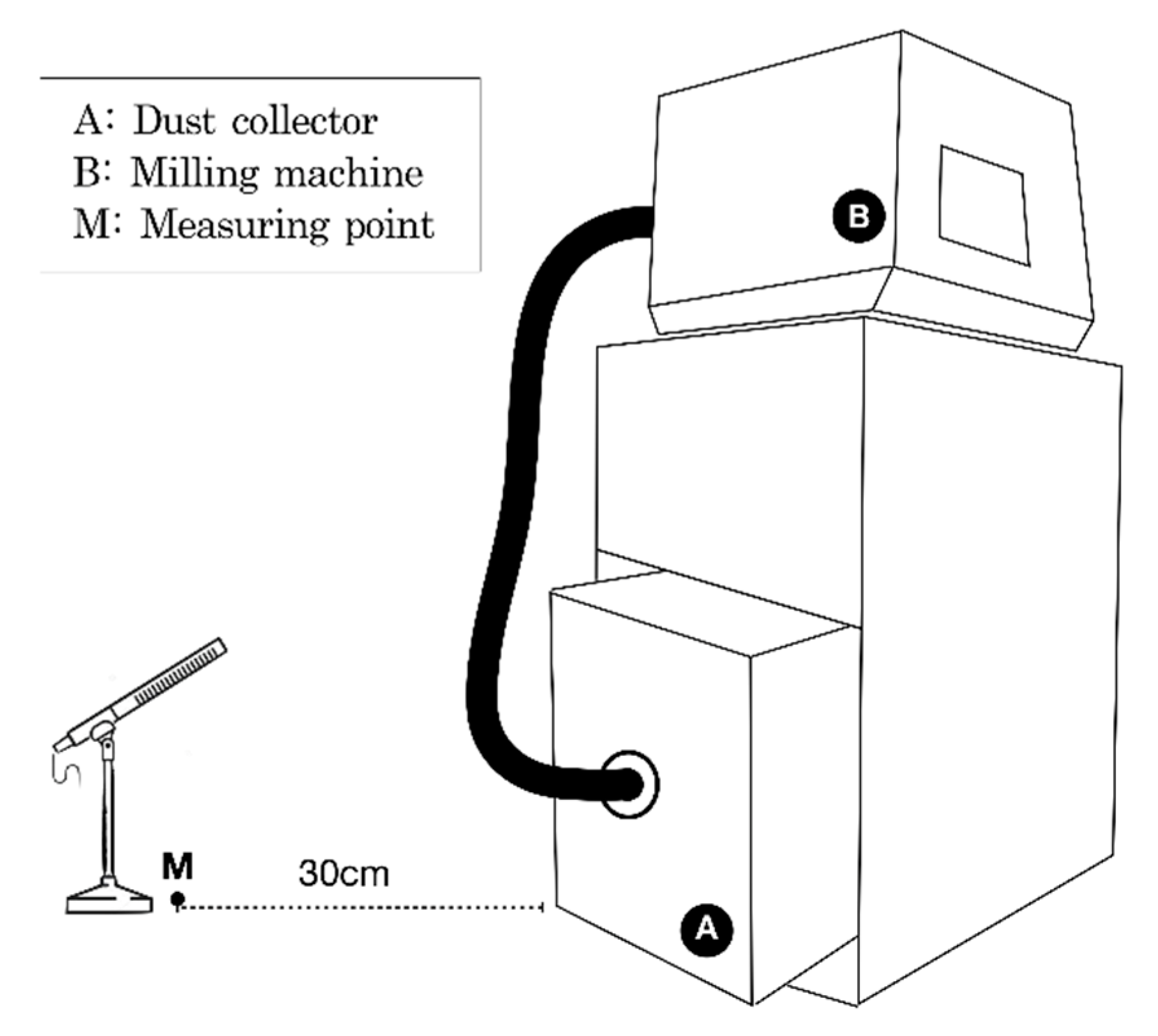

2.1. Measurement of Noise

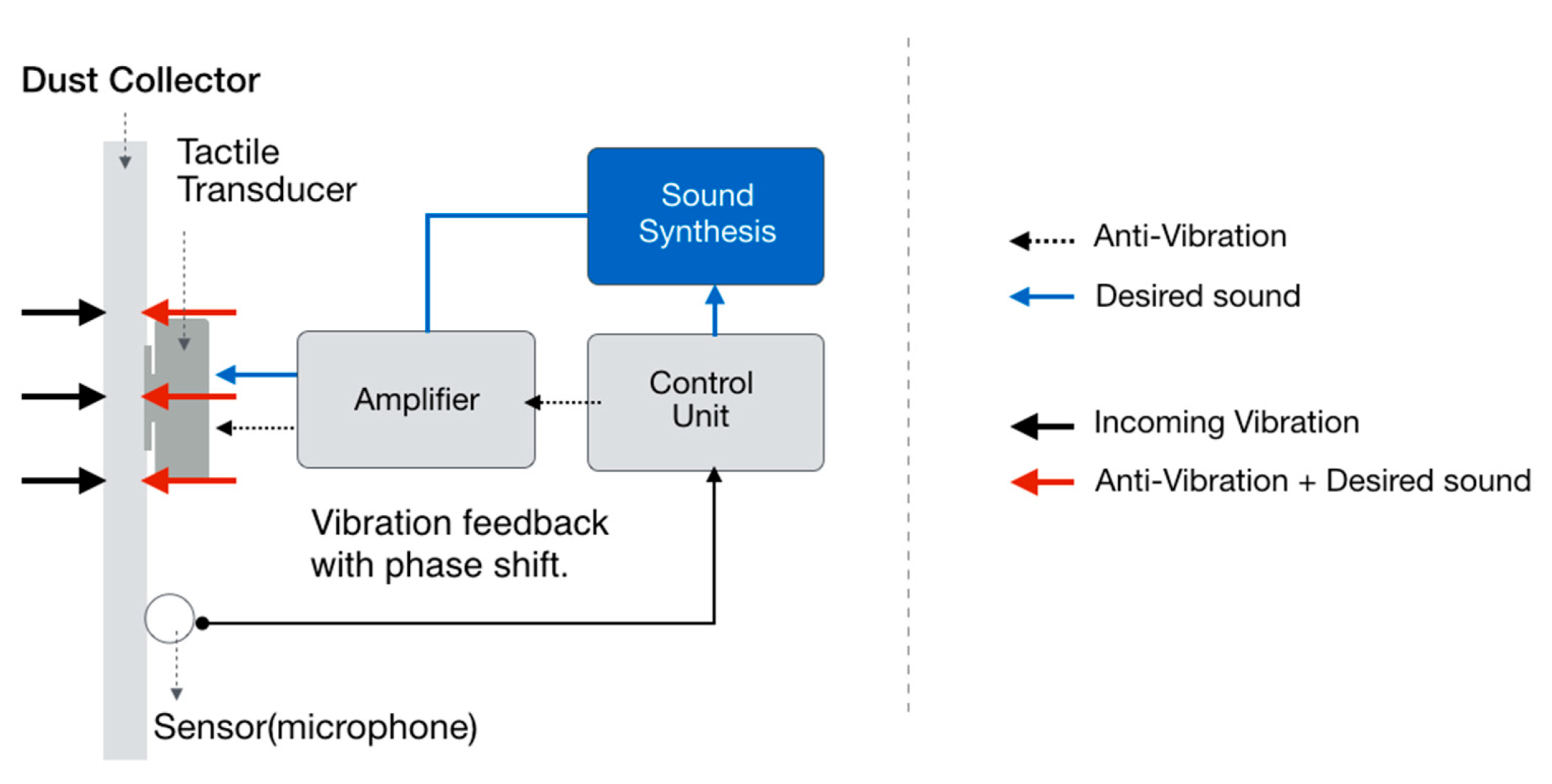

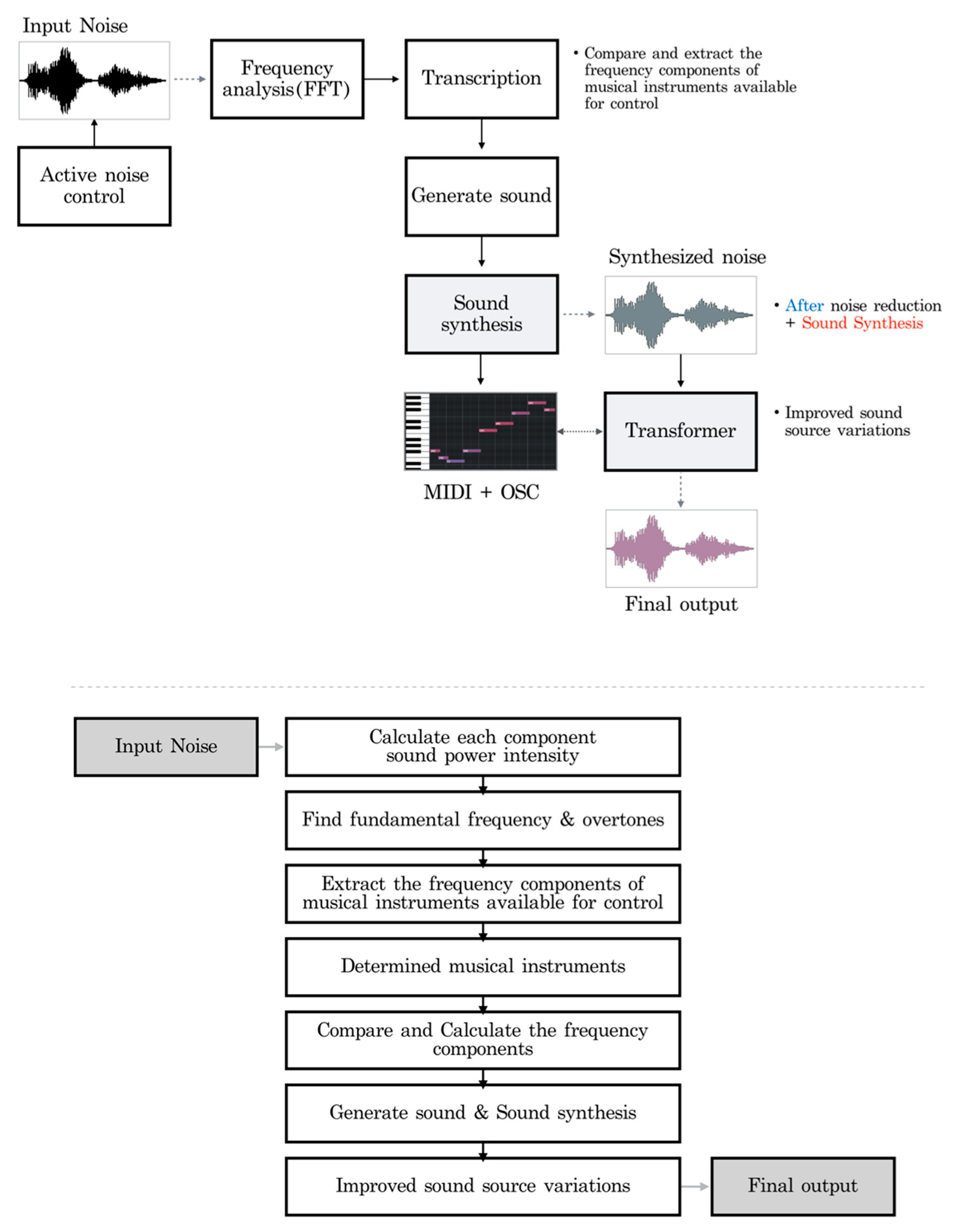

2.2. Sound Synthesis

3. Noise Improvement Plan

3.1. Analysis of Noise

3.2. Sound Design

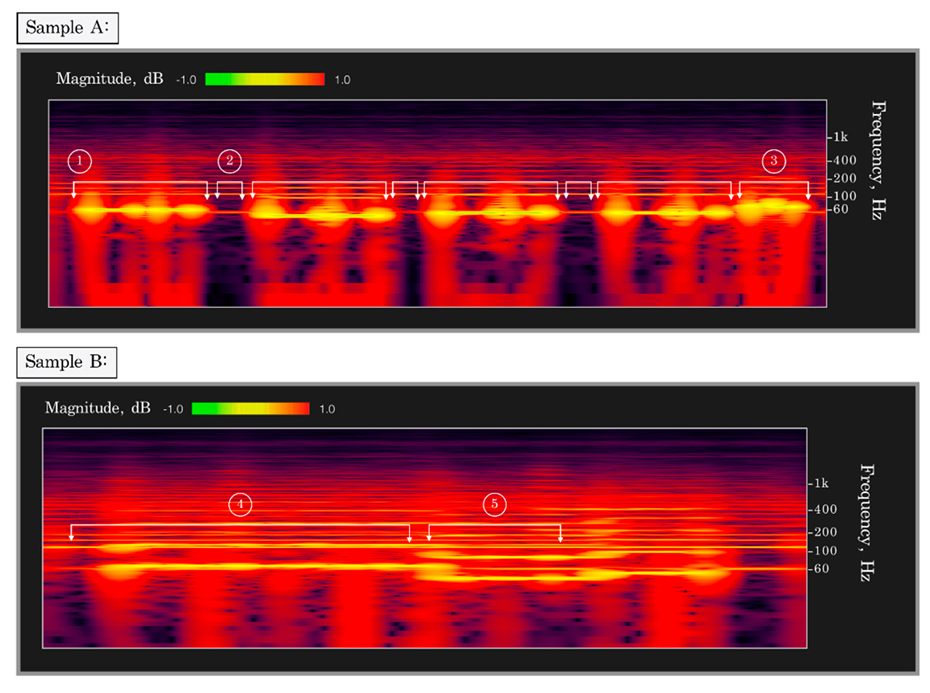

3.2.1. Experimental Method

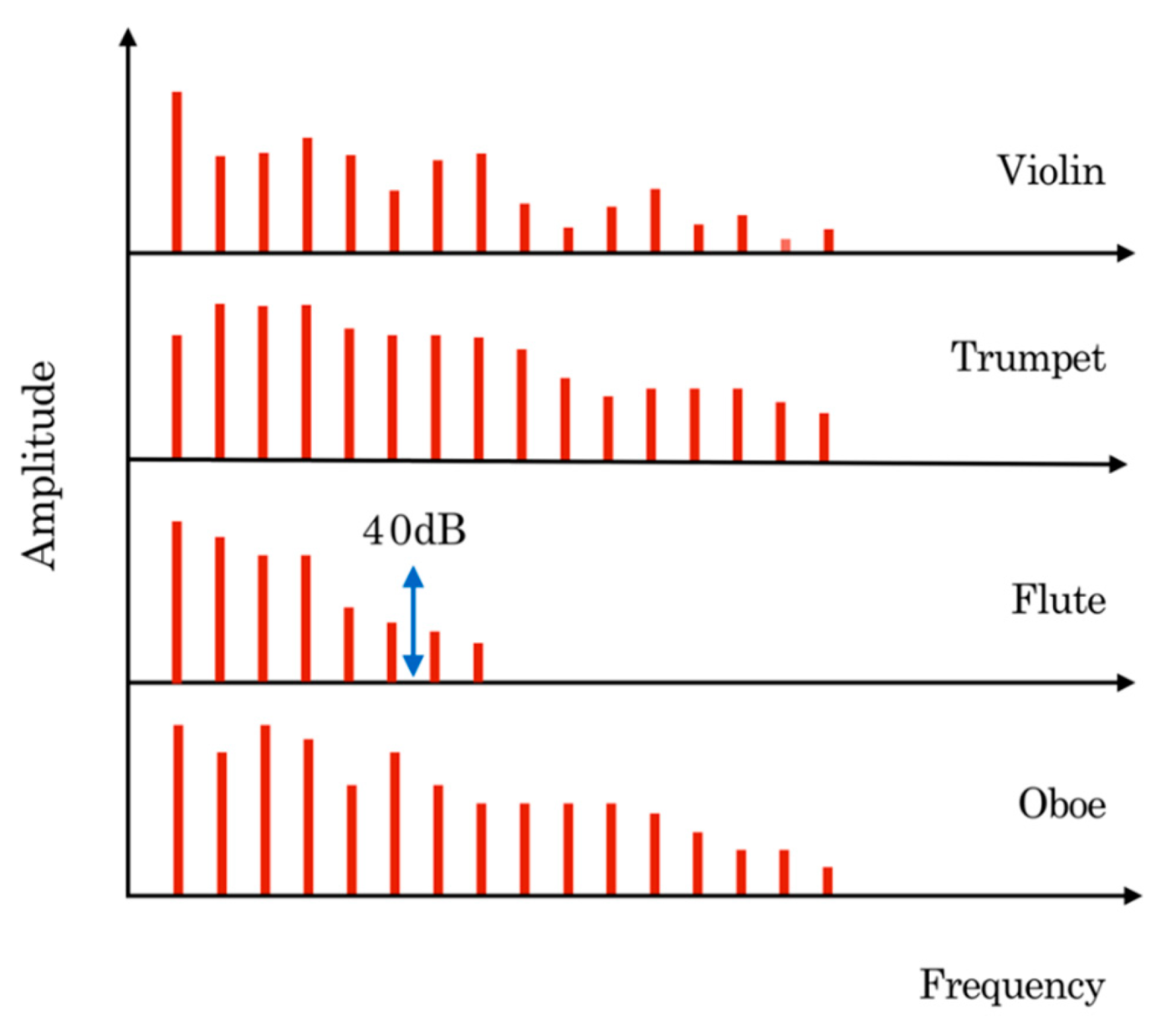

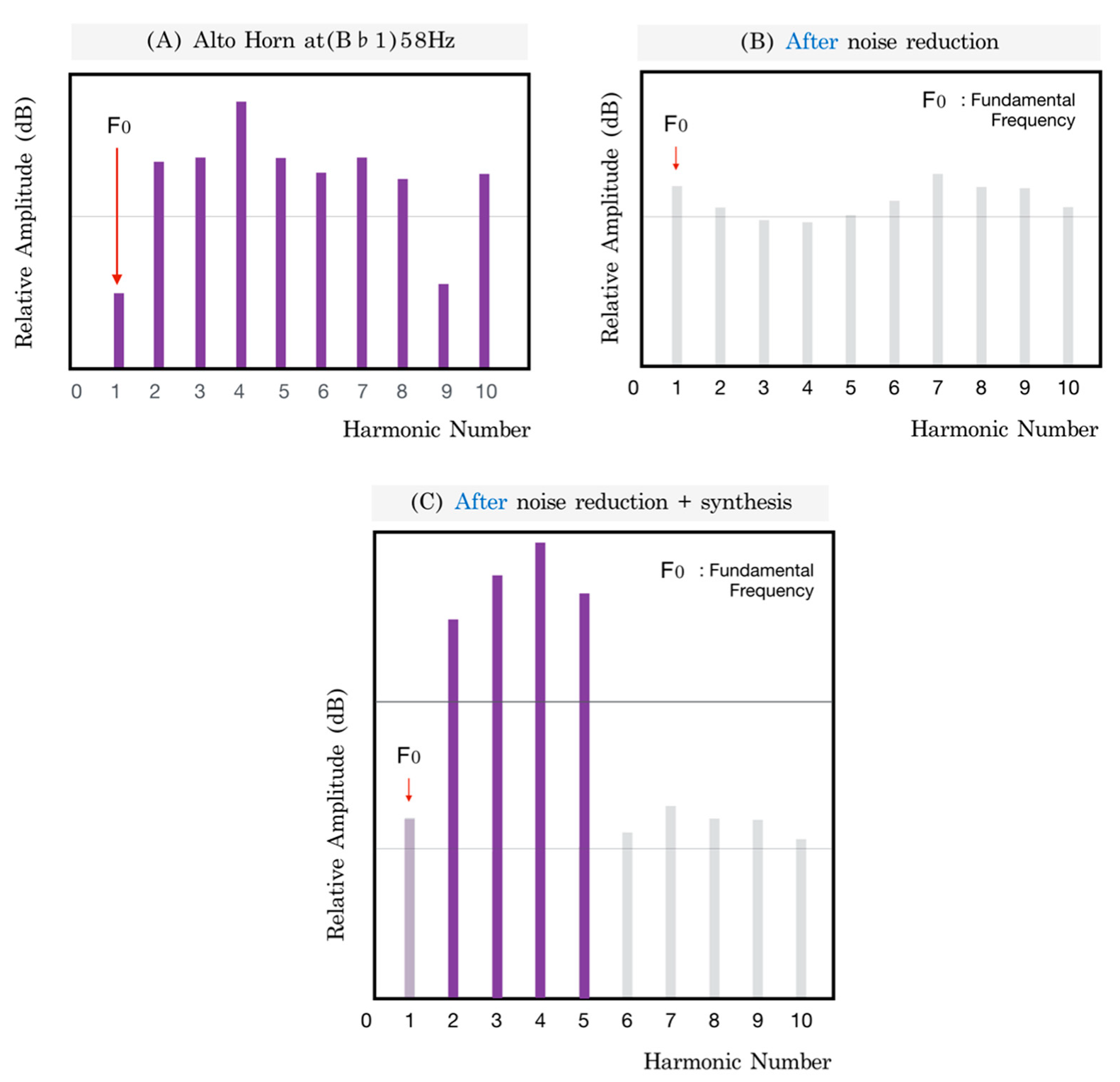

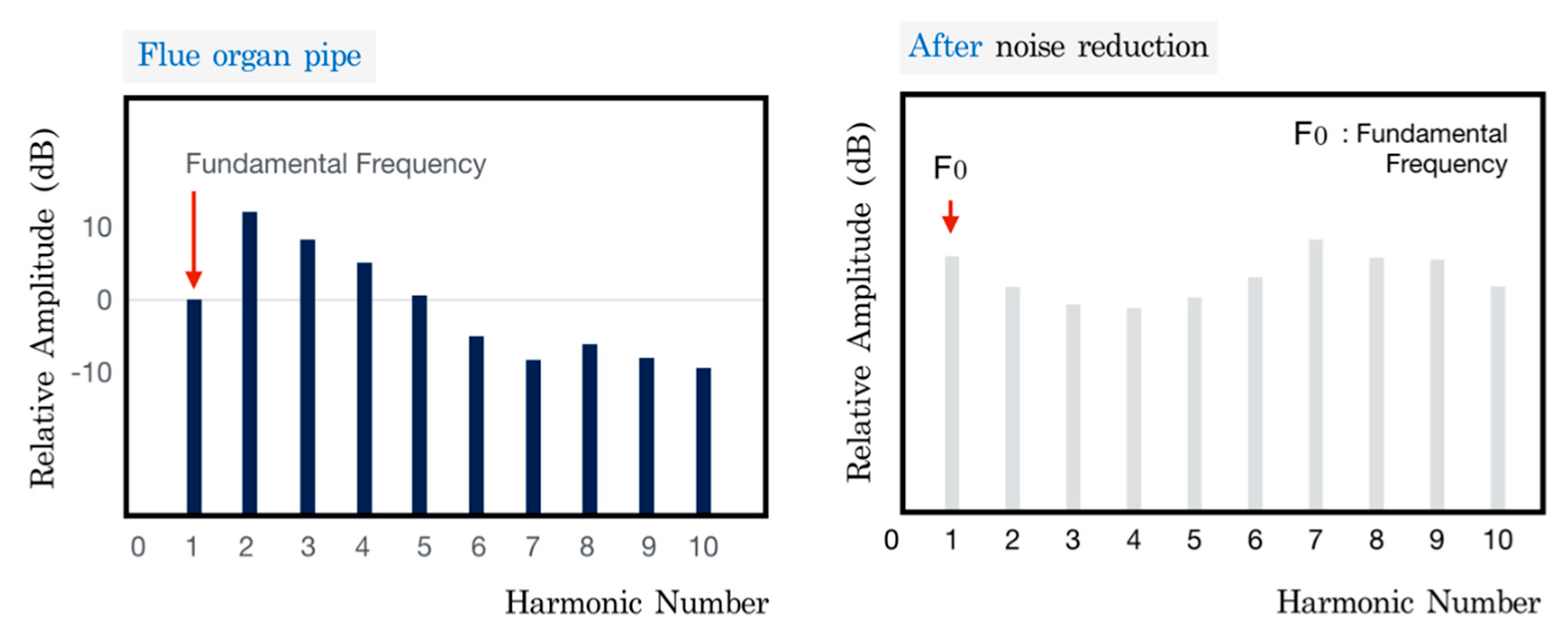

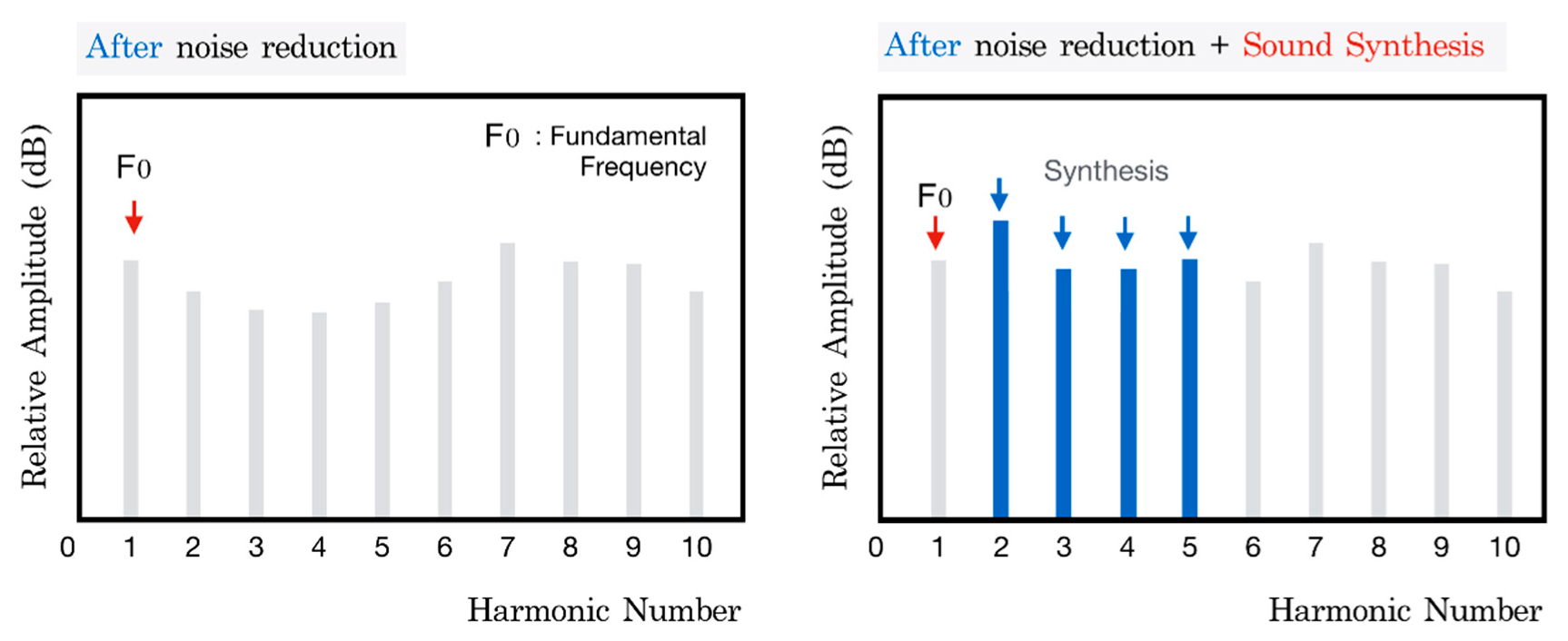

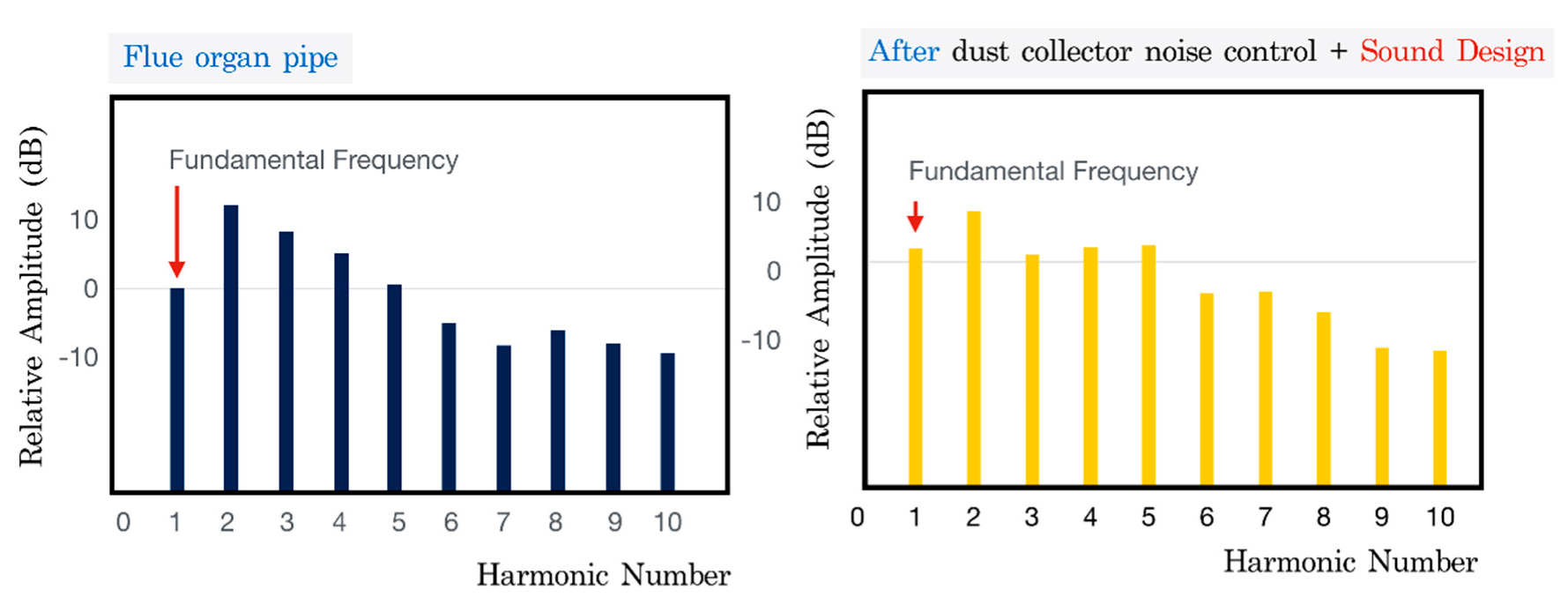

3.2.2. Harmonic Series Noise Model

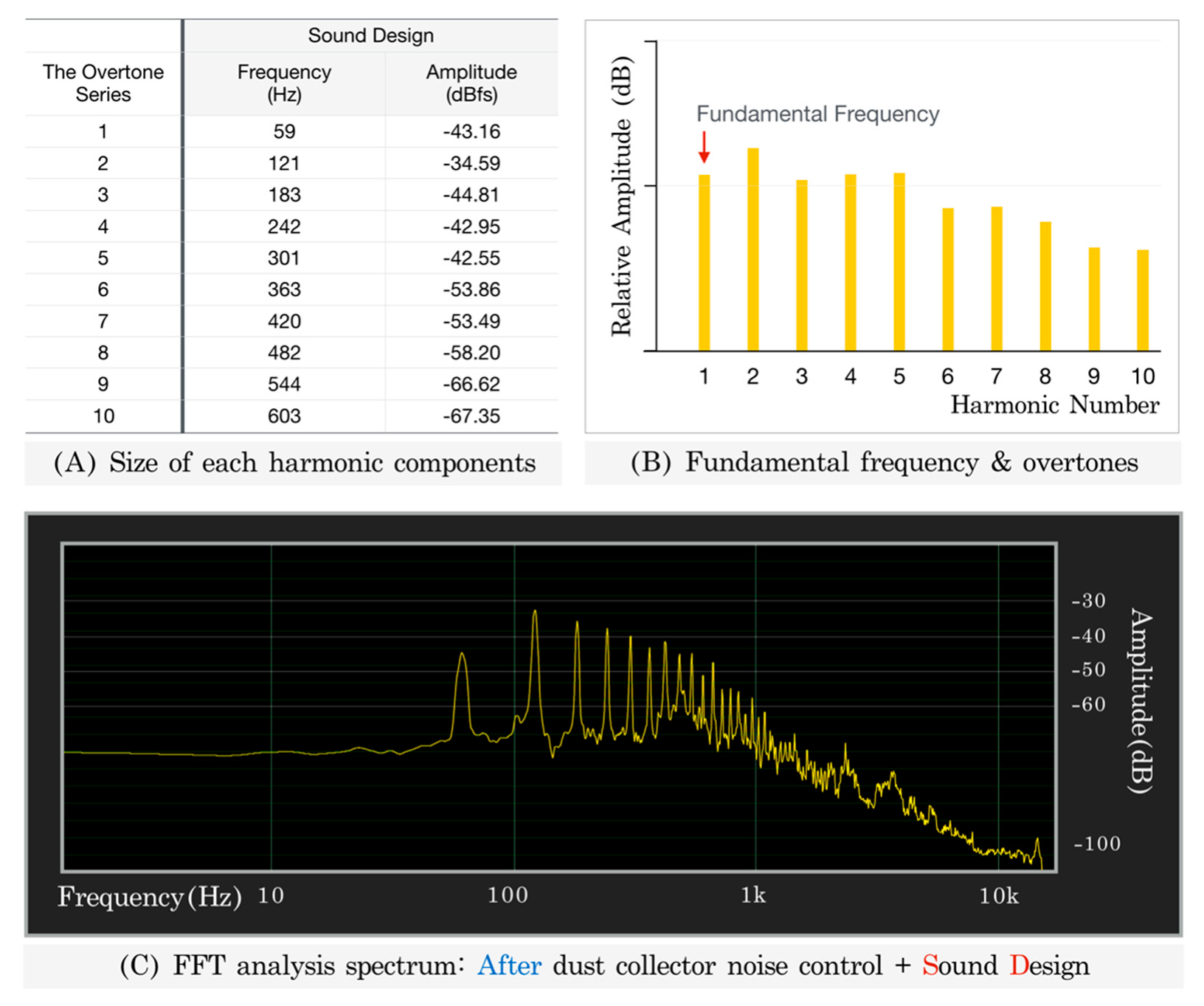

3.2.3. Determination of Sound Design

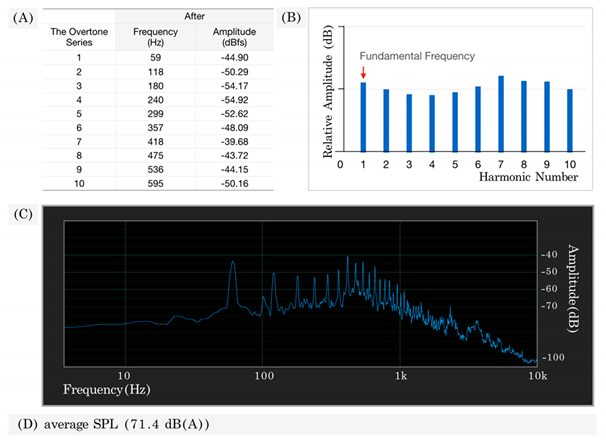

4. Result

5. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Imani, M.; Ghoreishi, S.F.; Braga-Neto, U.M. Bayesian control of large MDPs with unknown dynamics in data-poor environments. In Proceedings of the Advances in Neural Information Processing Systems, Montréal, Canada, 2–8 December 2018; pp. 8146–8156. [Google Scholar]

- Imani, M.; Ghoreishi, S.F.; Allaire, D.; Braga-Neto, U.M. MFBO-SSM: Multi-fidelity Bayesian optimization for fast inference in state-space models. In Proceedings of the AAAI Conference on Artificial Intelligence, Patiala (AAAI-19), Honolulu, HI, USA, 27 January–1 February 2019; pp. 7858–7865. [Google Scholar]

- Schwarz, I.; Kovačević, S. Textile Application: From Need to Imagination. In Textiles for Advanced Applications; IntechOpen: London, UK, 2017. [Google Scholar]

- Davidowitz, G.; Kotick, P.G. The use of CAD/CAM in dentistry. Dent. Clin. 2011, 55, 559–570. [Google Scholar] [CrossRef] [PubMed]

- Gijbels, F.; Jacobs, R.; Princen, K.; Nackaerts, O.; Debruyne, F. Potential occupational health problems for dentists in Flanders, Belgium. Clin. Oral Investig. 2006, 10, 8–17. [Google Scholar] [CrossRef] [PubMed]

- Messano, G.A.; Petti, S. General dental practitioners and hearing impairment. J. Dent. 2012, 40, 821–828. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, H.O.; Ali, W.J. Noise levels, noise annoyance, and hearing-related problems in a dental college. Arch. Environ. Occup. Health 2017, 72, 159–165. [Google Scholar]

- Song, E.S.; Lim, Y.J.; Kim, B.; Mun, M.S. Noise Reduction Using Active Vibration Control Methods in CAD/CAM Dental Milling Machines. Appl. Sci. 2019, 9, 1516. [Google Scholar] [CrossRef]

- Beranek, L.L. Noise and Vibration Control Engineering: Principles and Applications, 2nd ed.; Wiley: New York, NY, USA, 2005; pp. 721–855. [Google Scholar]

- Lemaitre, G.; Susini, P. Timbre, Sound Quality, and Sound Design. In Timbre: Acoustics, Perception, and Cognition; Springer: Cham, Switzerland, 2019; pp. 245–272. [Google Scholar]

- Genuit, K. Sound quality aspects for environmental noise. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Dearborn, MI, USA, 19–21 August 2002; Institute of Noise Control Engineering: Dearborn, MI, USA, 2002. [Google Scholar]

- Luigi, R. The art of noises: Futurist manifesto, In Cox, Christoph; Warner, Daniel. In Audio Culture: Readings in Modern Music; Continuum: New York, NY, USA, 2004; p. 10. [Google Scholar]

- Kuo, S.M.; Chen, Y.R.; Chang, C.Y.; Lai, C.W. Development and Evaluation of Light-Weight Active Noise Cancellation Earphones. Appl. Sci. 2018, 8, 1178. [Google Scholar] [CrossRef]

- Colman, A.M. A Dictionary of Psychology, 3rd ed.; Oxford University Press: Oxford, UK, 2008. [Google Scholar]

- Samarasinghe, P.N.; Zhang, W.; Abhayapala, T.D. Recent advances in active noise control inside automobile cabins: Toward quieter cars. IEEE Signal Process. Mag. 2016, 33, 61–73. [Google Scholar] [CrossRef]

- Harris, C. Handbook of Acoustical Measurements and Noise Control; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Västfjäll, D. Affect as a Component of Perceived Sound and Vibration Quality in Aircraft. Ph.D. Thesis, Chalmers TH, Göteborg, Sweden, 2003. [Google Scholar]

- Berglund, B.; Berglund, U.; Lindvall, T. Scaling Loudness, Noisiness and Annoyance of Aircraft Noise. J. Acoust. Soc. Am. 1975, 57, 930–934. [Google Scholar] [CrossRef] [PubMed]

- Tajadura-Jiménez, A.; Väljamäe, A.; Asutay, E.; Västfjäll, D. Embodied Auditory Perception: The Emotional Impact of Approaching and Receding Sound Sources. Emotion 2010, 3, 216–229. [Google Scholar] [CrossRef] [PubMed]

- Asutay, E.; Västfjäll, D. Perception of loudness is influenced by emotion. PLoS ONE 2012, 7, e38660. [Google Scholar] [CrossRef] [PubMed]

- Fastl, H.; Zwicker, E. Psycho-Acoustics; Facts and Models, 3rd ed.; Springer: Berlin, Germany, 1991. [Google Scholar]

- Acoustics-Method for Calculating Loudness Level; ISO 532 B; International Organization for Standardization: Geneva, Switzerland, 1975.

- Park, S.G.; Park, J.T.; Seo, K.W.; Lee, G.B. Comparison of the Sound Quality Characteristics for the Outdoor Unit according to the Compressor Model. In Proceedings of the International Compressor Engineering Conference at Purdue, West Lafayette, IN, USA, 16–19 July 2012; p. 2229. [Google Scholar]

- Menon, V.; Levitin, D.J.; Smith, B.K.; Lembke, A.; Krasnow, B.D.; Glazer, D.; McAdams, S. Neural correlates of timbre change in harmonic sounds. Neuroimage 2002, 17, 1742–1754. [Google Scholar] [CrossRef] [PubMed]

- Harriman, J. Feedback lapsteel: Exploring tactile transducers as string actuators. In Proceedings of the International Conference on New Interfaces for Musical Expression (NIME), Baton Rouge, LA, USA, 31 May –3 June 2015; pp. 178–179. [Google Scholar]

- Plomp, R.; Levelt, W.J.M. Tonal Consonance and Critical Bandwidth. J. Acoust. Soc. Am. 1965, 38, 548–560. [Google Scholar] [CrossRef] [PubMed]

- Howard, D.M.; Angus, J. Acoustics and Psychoacoustics, 4th ed.; Focal Press: Waltham, MA, USA, 2016; p. 125. [Google Scholar]

- Angster, J.; Rucz, P.; Miklós, A. Acoustics of Organ Pipes and Future Trends in the Research. Acoust. Today 2017, 13, 10–18. [Google Scholar]

- Spring, G.; Hutcheson, J. Musical form and Analysis: Time, Pattern, Proportion; Waveland Press: Long Grove, IL, USA, 2013. [Google Scholar]

- Yang, S.; Gao, B.; Jiang, L.; Jin, J.; Gao, Z.; Ma, X.; Woo, W.L. IoT Structured Long-Term Wearable Social Sensing for Mental Wellbeing. IEEE Internet Things J. 2018, 6, 3652–3662. [Google Scholar] [CrossRef]

- Jiang, L.; Gao, B.; Gu, J.; Chen, Y.; Gao, Z.; Ma, X.; Woo, W.L. Wearable long-term social sensing for mental wellbeing. IEEE Sens. J. 2018, 19, 8532–8542. [Google Scholar] [CrossRef]

- Bhalke, D.G.; Rao, C.R.; Bormane, D.S. Automatic musical instrument classification using fractional fourier transform based-MFCC features and counter propagation neural network. J. Intell. Inf. Syst. 2016, 46, 425–446. [Google Scholar] [CrossRef]

| Before applying active vibration control |  |

| After applying active vibration control |  |

| Average | Before Synthesis | After Synthesis |

|---|---|---|

| SPL (dB(A)) | 78.3 | 79.62 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, E.-S.; Lim, Y.-J.; Kim, B. A User-Specific Approach for Comfortable Application of Advanced 3D CAD/CAM Technique in Dental Environments Using the Harmonic Series Noise Model. Appl. Sci. 2019, 9, 4307. https://doi.org/10.3390/app9204307

Song E-S, Lim Y-J, Kim B. A User-Specific Approach for Comfortable Application of Advanced 3D CAD/CAM Technique in Dental Environments Using the Harmonic Series Noise Model. Applied Sciences. 2019; 9(20):4307. https://doi.org/10.3390/app9204307

Chicago/Turabian StyleSong, Eun-Sung, Young-Jun Lim, and Bongju Kim. 2019. "A User-Specific Approach for Comfortable Application of Advanced 3D CAD/CAM Technique in Dental Environments Using the Harmonic Series Noise Model" Applied Sciences 9, no. 20: 4307. https://doi.org/10.3390/app9204307

APA StyleSong, E.-S., Lim, Y.-J., & Kim, B. (2019). A User-Specific Approach for Comfortable Application of Advanced 3D CAD/CAM Technique in Dental Environments Using the Harmonic Series Noise Model. Applied Sciences, 9(20), 4307. https://doi.org/10.3390/app9204307