Viscoelastic Properties of Asphalt Mixtures with Different Modifiers at Different Temperatures Based on Static Creep Tests

Abstract

1. Introduction

2. Materials and Methods

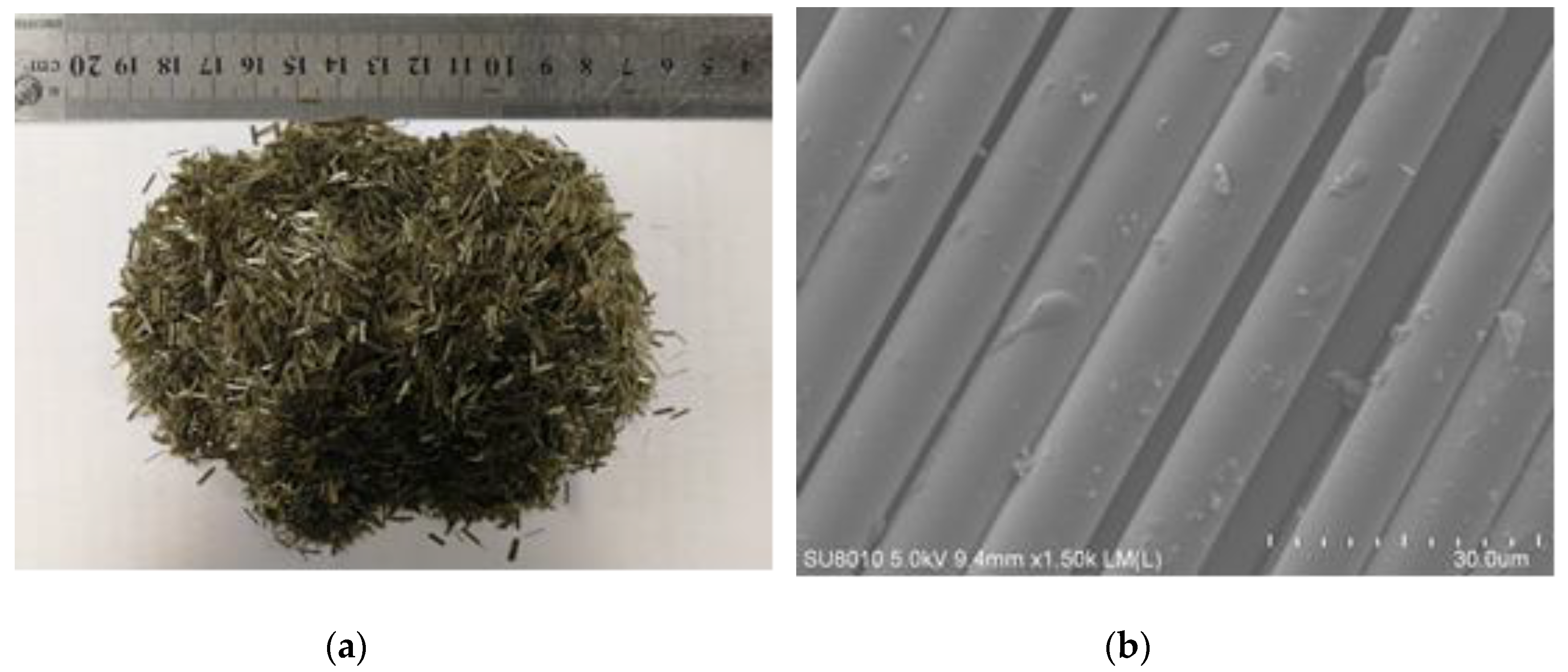

2.1. Materials

2.2. Experimental Method

2.3. Interconversion between Relaxation Modulus and Creep Compliance

3. Results and Discussion

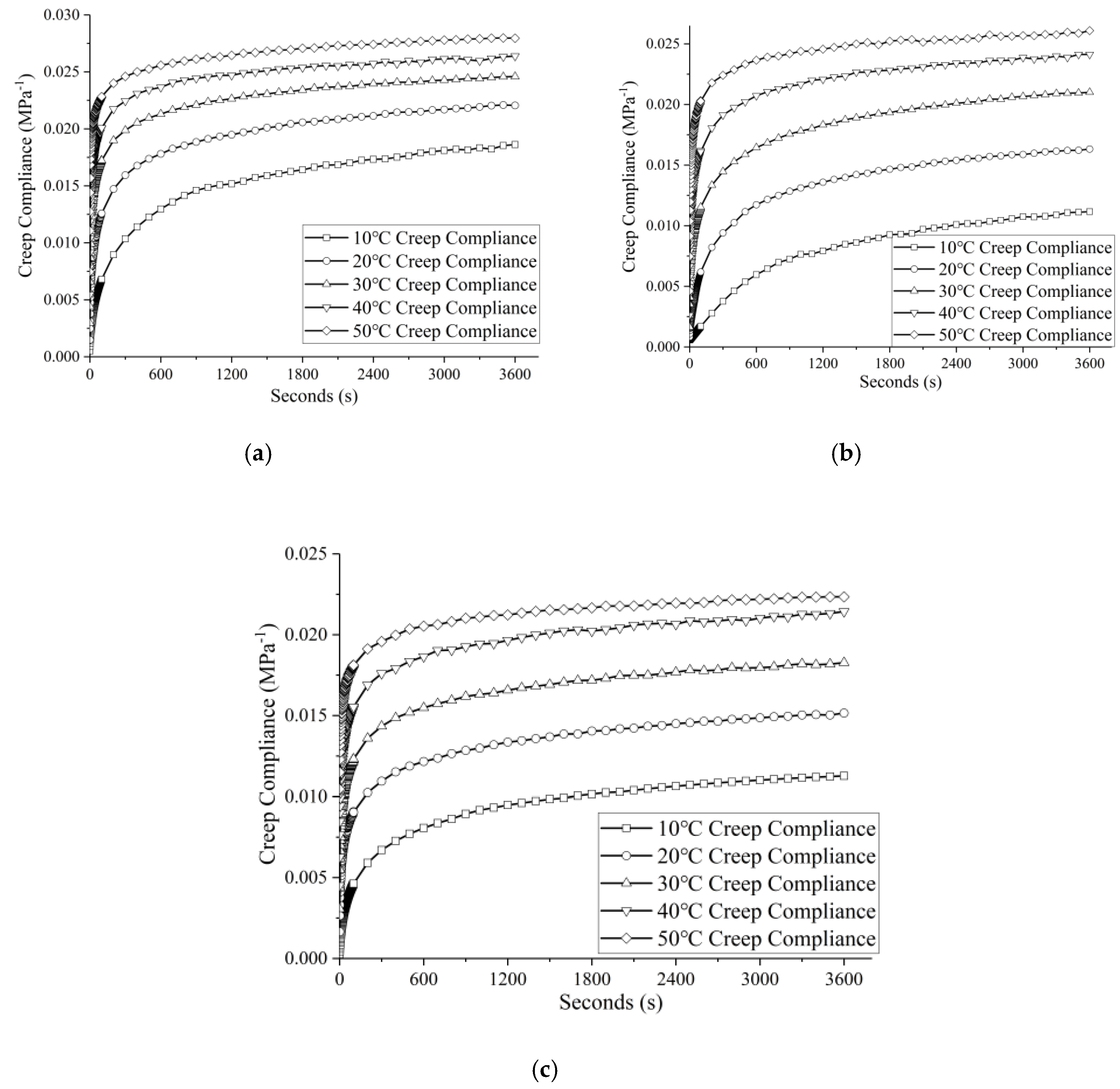

3.1. Creep Compliance of Asphalt Mixtures at Different Temperatures

3.2. Creep Characteristics of the Three Asphalt Mixtures

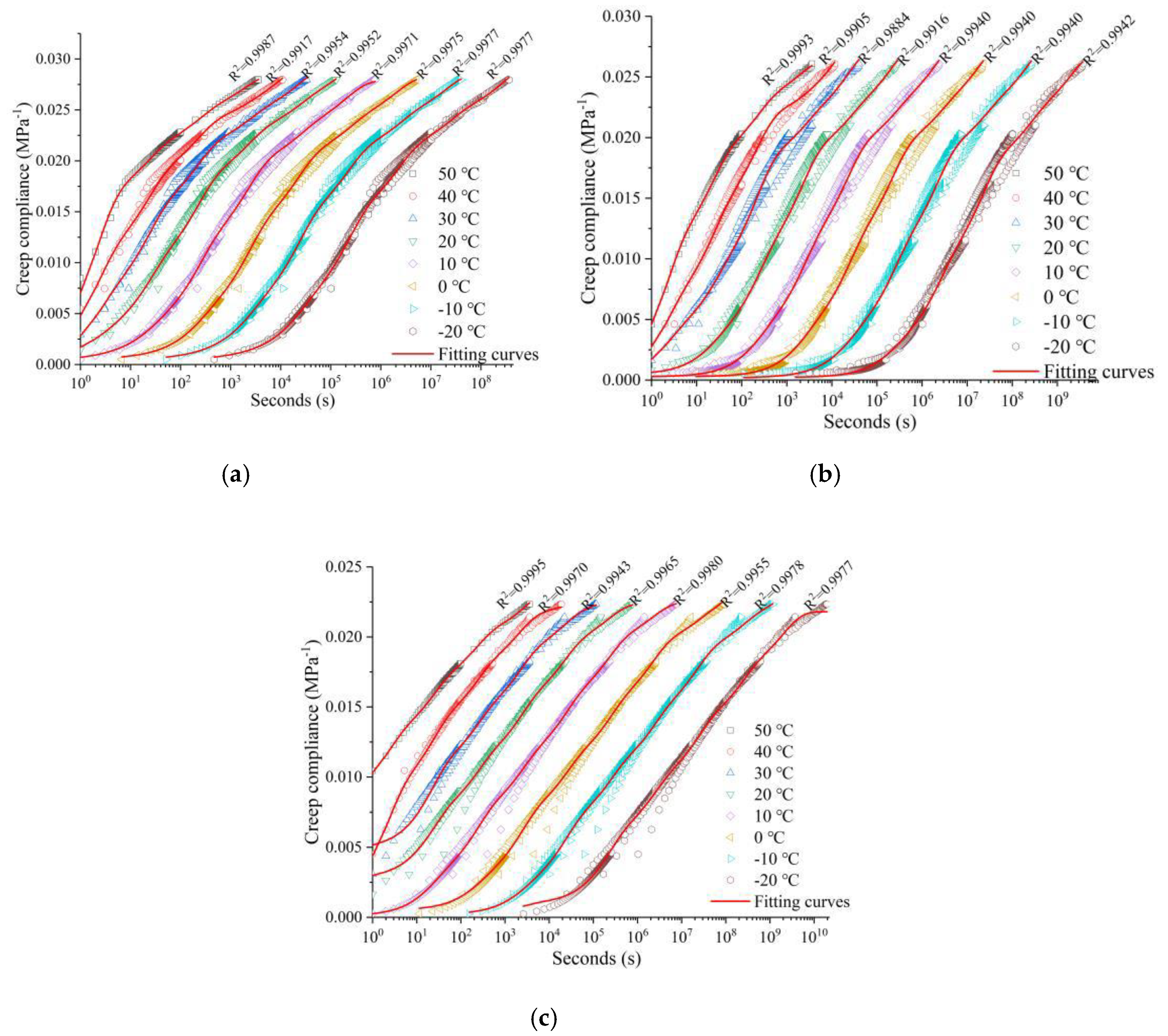

3.2.1. Fitting Analyses of Creep Compliance

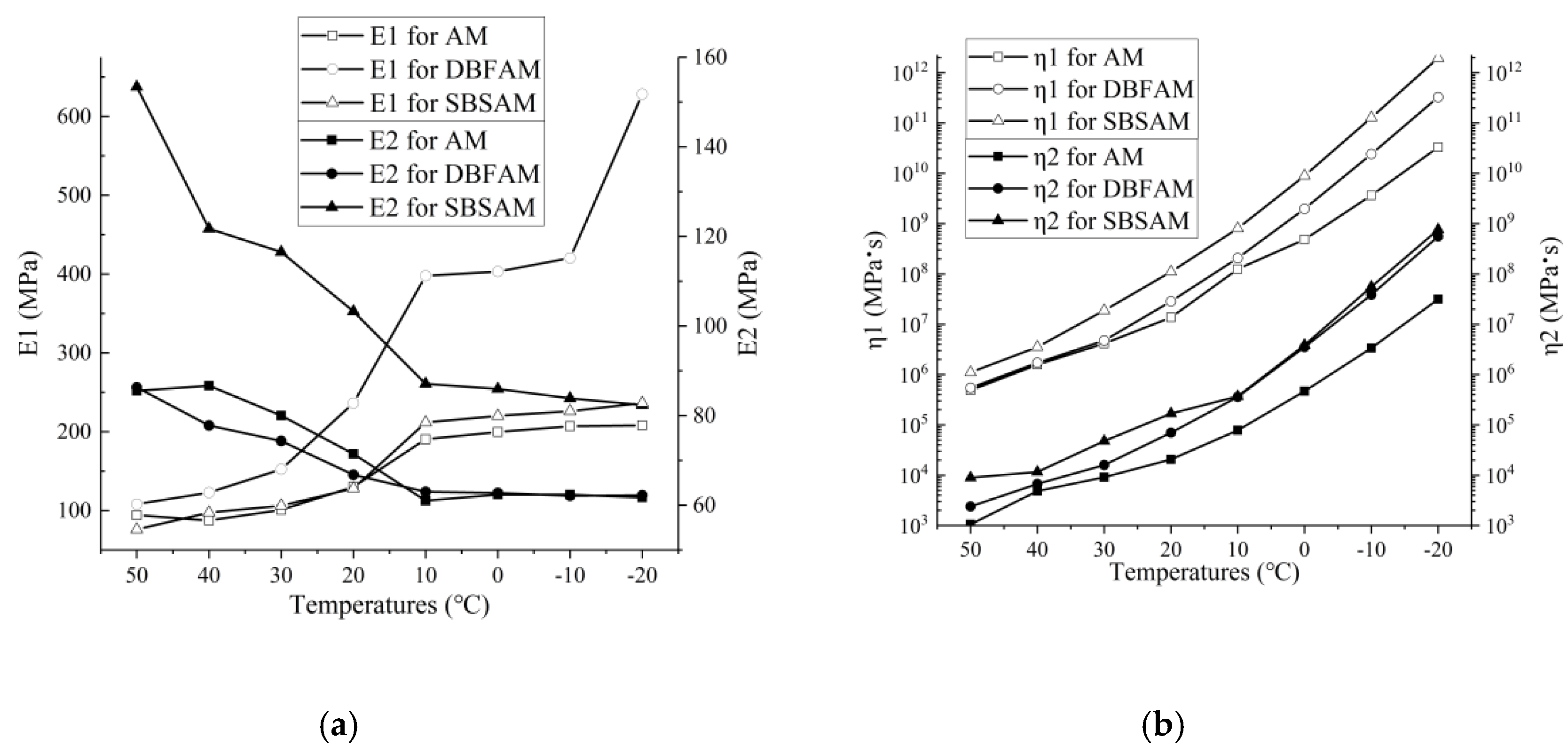

3.2.2. Elastic Parts and Viscous Parts of the Three Asphalt Mixtures

3.2.3. Viscoelasticity of the Three Asphalt Mixtures

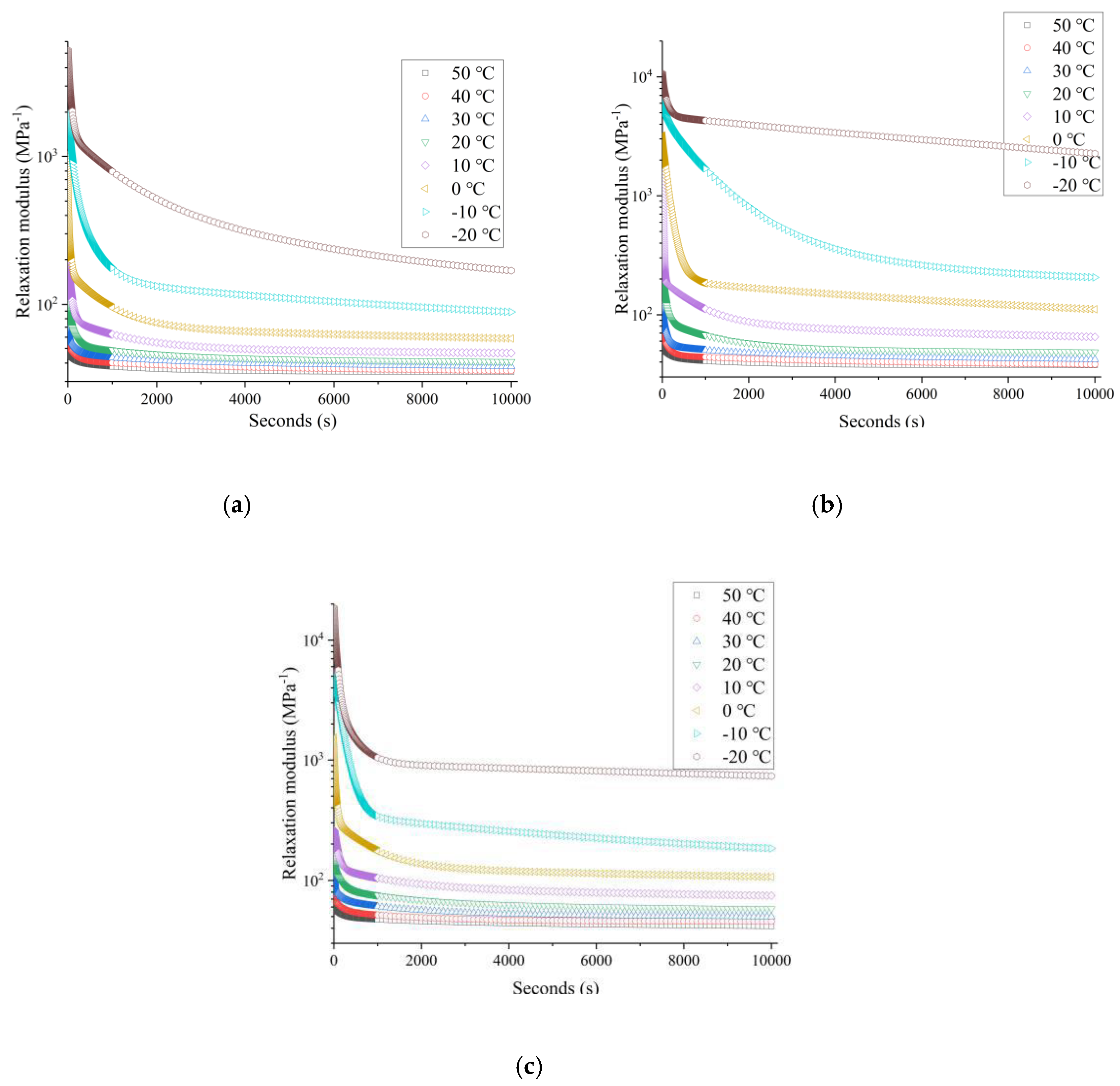

3.3. Relaxation Characteristics of the Three Asphalt Mixtures

3.3.1. Calculation of Relaxation Modulus of the Three Asphalt Mixtures

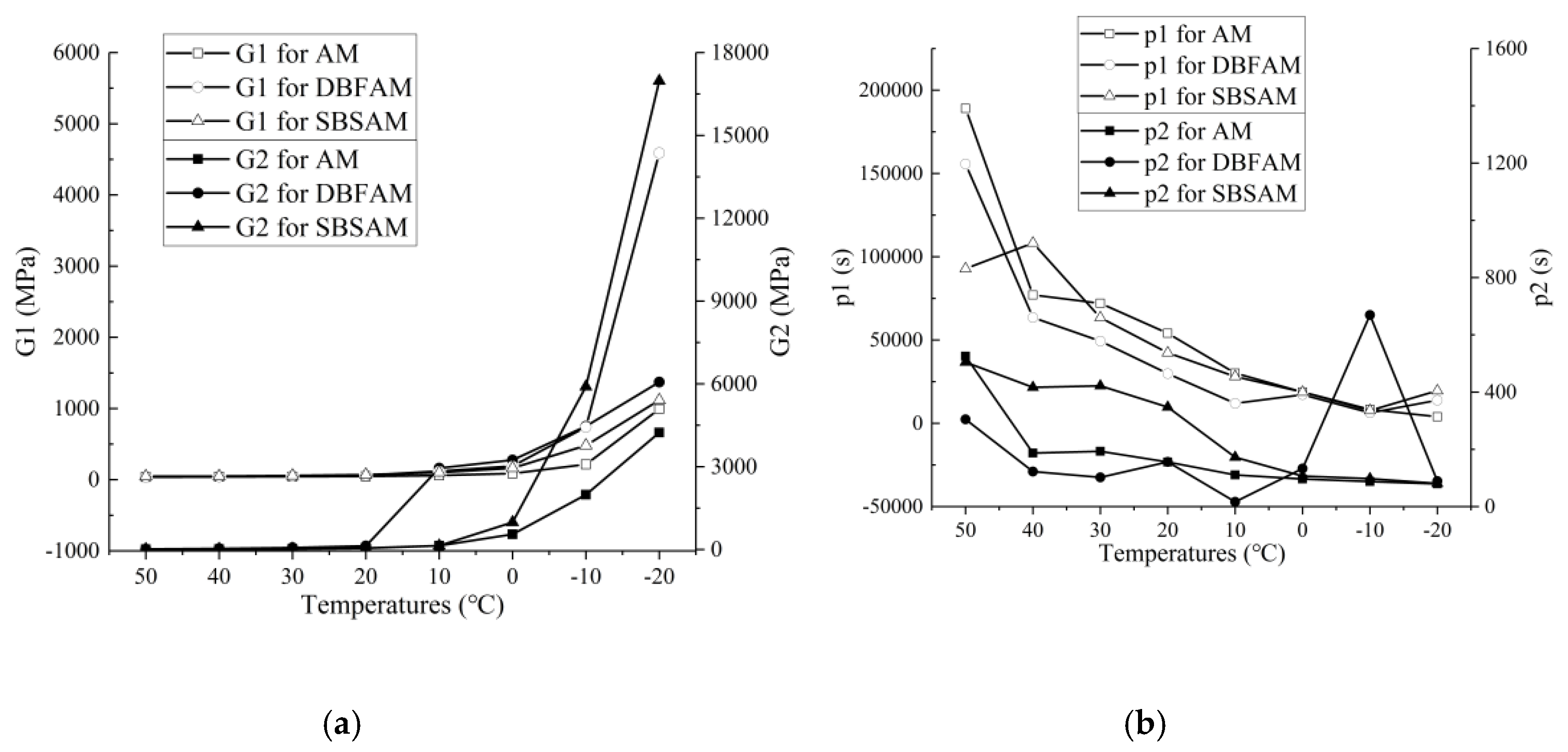

3.3.2. Fitting Analysis of Relaxation Modulus of the Three Asphalt Mixtures

3.3.3. Analysis of Relaxation Characteristics of Three Asphalt Mixtures

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ameri, M.; Reza Seif, M.; Abbasi, M.; Khavandi Khiavi, A. Viscoelastic fatigue resistance of asphalt binders modified with crumb rubber and styrene butadiene polymer. Pet. Sci. Technol. 2016, 35, 30–36. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Zhu, H.Z.; Wang, G.A.; Chen, T.J. Evaluation of Low Temperature Performance for Diatomite Modified Asphalt Mixture. Adv. Mater. Res. 2011, 413, 246–251. [Google Scholar] [CrossRef]

- Tan, Y.Q.; Zhang, L.; Zhang, X.Y. Investigation of low-temperature properties of diatomite-modified asphalt mixtures. Constr. Build. Mater. 2012, 36, 787–795. [Google Scholar]

- Celauro, C.; Pratico, F.G. Asphalt mixtures modified with basalt fibres for surface courses. Constr. Build. Mater. 2018, 170, 245–253. [Google Scholar] [CrossRef]

- Yang, C.; Xie, J.; Zhou, X.; Liu, Q.; Pang, L. Performance Evaluation and Improving Mechanisms of Diatomite-Modified Asphalt Mixture. Materials 2018, 11, 686. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.-S.; Liao, M.-C.; Shiah, M.-S. Asphalt Modified by Styrene-Butadiene-Styrene Triblock Copolymer: Morphology and Model. J. Mater. Civ. Eng. 2002, 14, 224–229. [Google Scholar] [CrossRef]

- Ho, S. The low temperature properties of conventional and modified asphalt binders evaluated by the failure energy and secant modulus from direct tension tests. Mater. Struct. 2004, 38, 137–143. [Google Scholar] [CrossRef]

- Vlachovicova, Z.; Wekumbura, C.; Stastna, J.; Zanzotto, L. Creep characteristics of asphalt modified by radial styrene–butadiene–styrene copolymer. Constr. Build. Mater. 2007, 21, 567–577. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Evaluation of the properties and microstructure of SBS and EVA polymer modified bitumen. Constr. Build. Mater. 2008, 22, 1897–1905. [Google Scholar] [CrossRef]

- Huang, W.; Tang, N. Characterizing SBS modified asphalt with sulfur using multiple stress creep recovery test. Constr. Build. Mater. 2015, 93, 514–521. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Liu, Z.; Li, S. Dynamic modulus test and master curve analysis of asphalt mix with trapezoid beam method. Road Mater. Pavement Des. 2017, 18, 281–291. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, M.; Shao, L.; Chen, Z. Effect of volcanic ash filler on thermal viscoelastic property of SBS modified asphalt mastic. Constr. Build. Mater. 2018, 190, 495–507. [Google Scholar] [CrossRef]

- Qin, X.; Shen, A.; Guo, Y.; Li, Z.; Lv, Z. Characterization of asphalt mastics reinforced with basalt fiber. Constr. Build. Mater. 2018, 159, 508–516. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, X.; Lv, J.; Zhu, Z.; Zou, X. Numerical analysis of the rheological behaviors of basalt fiber reinforced asphalt mortar using ABAQUS. Constr. Build. Mater. 2017, 157, 392–401. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, X.; Lv, J.; Zou, X. 3D numerical model to investigate the rheological properties of basalt fiber reinforced asphalt-like materials. Constr. Build. Mater. 2017, 138, 185–194. [Google Scholar] [CrossRef]

- Zheng, Y.; Cai, Y.; Zhang, G.; Fang, H. Fatigue property of basalt fiber-modified asphalt mixture under complicated environment. J. Wuhan Univ. Technol. 2014, 29, 996–1004. [Google Scholar] [CrossRef]

- Cheng, Y.; Yu, D.; Gong, Y.; Zhu, C.; Tao, J.; Wang, W. Laboratory Evaluation on Performance of Eco-Friendly Basalt Fiber and Diatomite Compound Modified Asphalt Mixture. Materials 2018, 11, 2400. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Zhu, C.; Tan, G.; Lv, Z.; Yang, J.; Ma, J. Laboratory Study on Properties of Diatomite and Basalt Fiber Compound Modified Asphalt Mastic. Adv. Mater. Sci. Eng. 2017, 2017, 1–10. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, L.; Zhou, P.; Zhang, Y.; Liu, H. Multi-objective optimization design and test of compound diatomite and basalt fiber asphalt mixture. Materials 2019, 12, 1461. [Google Scholar] [CrossRef]

- Davar, A.; Tanzadeh, J.; Fadaee, O. Experimental evaluation of the basalt fibers and diatomite powder compound on enhanced fatigue life and tensile strength of hot mix asphalt at low temperatures. Constr. Build. Mater. 2017, 153, 238–246. [Google Scholar] [CrossRef]

- Airey, G.D. Styrene butadiene styrene polymer modification of road bitumens. J. Mater. Sci. 2004, 39, 951–959. [Google Scholar] [CrossRef]

- Swamy, A.K.; Rongali, U.D.; Jain, P.K. Effect of HDPEH polymer on viscoelastic properties of SBS modified asphalt. Constr. Build. Mater. 2017, 136, 230–236. [Google Scholar] [CrossRef]

- Bai, F.; Yang, X.H.; Zeng, G.W. Stochastic Viscoelastic-Viscoplastic Response of Asphalt Mixture under Uniaxial Compression. J. Eng. Mech. 2017, 143. [Google Scholar] [CrossRef]

- Chen, S.Q.; Wang, D.S.; Yi, J.Y.; Feng, D.C. Implement the Laplace transform to convert viscoelastic functions of asphalt mixtures. Constr. Build. Mater. 2019, 203, 633–641. [Google Scholar] [CrossRef]

- Li, P.L.; Jiang, X.M.; Guo, K.; Xue, Y.; Dong, H. Analysis of viscoelastic response and creep deformation mechanism of asphalt mixture. Constr. Build. Mater. 2018, 171, 22–32. [Google Scholar] [CrossRef]

- Darabi, M.K.; Huang, C.-W.; Bazzaz, M.; Masad, E.A.; Little, D.N. Characterization and validation of the nonlinear viscoelastic-viscoplastic with hardening-relaxation constitutive relationship for asphalt mixtures. Constr. Build. Mater. 2019, 216, 648–660. [Google Scholar] [CrossRef]

- Bazzaz, M.; Darabi, M.K.; Little, D.N.; Garg, N. A Straightforward Procedure to Characterize Nonlinear Viscoelastic Response of Asphalt Concrete at High Temperatures. Transp. Res. Rec. 2018, 2672, 481–492. [Google Scholar] [CrossRef]

- Bazzaz, M. Experimental and Analytical Procedures to Characterize Mechanical Properties of Asphalt Concrete Materials for Airfield Pavement Applications. Ph.D. Thesis, University of Kansas, Lawrence, KS, USA, 2018. [Google Scholar]

- Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; Research Institute of Highway Ministry of Transport: Beijing, China, 2011. (In Chinese)

- Baghaee Moghaddam, T.; Soltani, M.; Karim, M.R. Experimental characterization of rutting performance of Polyethylene Terephthalate modified asphalt mixtures under static and dynamic loads. Constr. Build. Mater. 2014, 65, 487–494. [Google Scholar] [CrossRef]

- Singh, M.; Kumar, P.; Anupam, A.K. Effect of type of aggregate on permanent deformation of bituminous concrete mixes. Road Mater. Pavement Des. 2015, 17, 417–433. [Google Scholar] [CrossRef]

- Pattanaik, M.L.; Choudhary, R.; Kumar, B.; Kumar, A. Mechanical properties of open graded friction course mixtures with different contents of electric arc furnace steel slag as an alternative aggregate from steel industries. Road Mater. Pavement Des. 2019, 1–25. [Google Scholar] [CrossRef]

- Tapkin, S.; Cevik, A.; Ozcan, S. Utilising Neural Networks and Closed Form Solutions to Determine Static Creep Behaviour and Optimal Polypropylene Amount in Bituminous Mixtures. Mater. Res. 2012, 15, 865–883. [Google Scholar] [CrossRef]

- Park, S.W.; Kim, Y.R. Interconversion between relaxation modulus and creep compliance for viscoelastic solids. J. Mater. Civ. Eng. 1999, 11, 76–82. [Google Scholar] [CrossRef]

- Schapery, R.A.; Park, S.W. Methods of interconversion between linear viscoelastic material functions. Part II—an approximate analytical method. Int. J. Solids Struct. 1999, 36, 1677–1699. [Google Scholar] [CrossRef]

- Sorvari, J.; Malinen, M. Numerical interconversion between linear viscoelastic material functions with regularization. Int. J. Solids Struct. 2007, 44, 1291–1303. [Google Scholar] [CrossRef]

- Lachance-Tremblay, E.; Vaillancourt, M.; Perraton, D.; Di Benedetto, H. Linear viscoelastic (LVE) properties of asphalt mixtures with different glass aggregates and hydrated lime content. Int. J. Pavement Eng. 2018, 1–10. [Google Scholar] [CrossRef]

- Graziani, A.; Cardone, F.; Virgili, A. Characterization of the three-dimensional linear viscoelastic behavior of asphalt concrete mixtures. Constr. Build. Mater. 2016, 105, 356–364. [Google Scholar] [CrossRef]

- Gergesova, M.; Zupancic, B.; Saprunov, I.; Emri, I. The closed form t-T-P shifting (CFS) algorithm. J. Rheol. 2011, 55, 1–16. [Google Scholar] [CrossRef]

- Luo, R.; Lv, H.J.; Liu, H.Q. Development of Prony series models based on continuous relaxation spectrums for relaxation moduli determined using creep tests. Constr. Build. Mater. 2018, 168, 758–770. [Google Scholar] [CrossRef]

- Ho, C.H.; Martin Linares, C.P. Representation Functions to Predict Relaxation Modulus of Asphalt Mixtures Subject to the Action of Freeze-Thaw Cycles. J. Transp. Eng. Part B Pavements 2018, 144, 04018013. [Google Scholar] [CrossRef]

- Hajikarimi, P.; Nejad, F.M.; Aghdam, M.M. Implementing General Power Law to Interconvert Linear Viscoelastic Functions of Modified Asphalt Binders. J. Transp. Eng. Part B Pavements 2018, 144. [Google Scholar] [CrossRef]

- Park, S.W.; Schapery, R. Methods of interconversion between linear viscoelastic material functions. Part I—A numerical method based on Prony series. Int. J. Solids Struct. 1998, 36, 1653–1675. [Google Scholar] [CrossRef]

- Mainardi, F.; Spada, G. Creep, relaxation and viscosity properties for basic fractional models in rheology. Eur. Phys. J. Spec. Top. 2011, 193, 133–160. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, X.; Lv, J.; Zhu, Z.; Ni, F. Mechanism and behavior of fiber-reinforced asphalt mastic at high temperature. Int. J. Pavement Eng. 2018, 19, 407–415. [Google Scholar] [CrossRef]

- Sun, Y.; Gu, B.; Gao, L.; Li, L.; Guo, R.; Yue, Q.; Wang, J. Viscoelastic Mechanical Responses of HMAP under Moving Load. Materials 2018, 11, 2490. [Google Scholar] [CrossRef] [PubMed]

| Properties | A-90# Asphalt | SBS Modified Asphalt | ||

|---|---|---|---|---|

| Standard | Value | Standard | Value | |

| Density (15 °C, g/cm3) | — | 1.016 | — | 1.013 |

| Penetration (25 °C, 0.1 mm) | 80–100 | 91.6 | 60-80 | 65.1 |

| Softening point TR&B (°C) | ≥45 | 46.9 | ≥55 | 61.0 |

| Ductility (cm) | ≥100 (25 °C) | >150 | ≥30 (5 °C) | 68.5 (5 °C) |

| Elastic recovery | — | — | ≥65 | 88 |

| After TFOT | ||||

| Mass loss (%) | ≤±0.8 | 0.38 | ≤±1.0 | 0.22 |

| Residual penetration ratio (25 °C, %) | ≥57 | 73.3 | ≥60 | 66.9 |

| Ductility (cm) | ≥20 (15 °C) | >120 (15 °C) | ≥20 (5 °C) | 33.2 (5 °C) |

| Properties | Diameter (μm) | Length (mm) | Water Content (%) | Combustible Content (%) | Tensile Strength (MPa) | Tensile Modulus of Elasticity (GPa) | Elongation at Break (%) |

|---|---|---|---|---|---|---|---|

| Value | 10–13 | 6 | 0.030 | 0.56 | 2320 | 86.3 | 2.84 |

| Chemical Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | K2O |

|---|---|---|---|---|---|---|---|

| Proportion (%) | 85.60 | 4.50 | 1.50 | 0.52 | 0.45 | 0.30 | 0.67 |

| Sieve Size (mm) | 0.075 | 0.15 | 0.3 | 0.6 | 1.18 | 2.36 | 4.75 | 9.5 | 13.2 | 16 |

|---|---|---|---|---|---|---|---|---|---|---|

| Percent passing (%) | 6 | 10 | 13.5 | 19 | 26.5 | 37 | 53 | 76.5 | 95 | 100 |

| Comparison Temperature | log αT Based on Tests | log αT Based on Arrhenius Equation | |||||

|---|---|---|---|---|---|---|---|

| 40 °C | 30 °C | 20 °C | 10°C | 0 °C | −10 °C | −20 °C | |

| AM | 0.4816 | 0.9981 | 1.5865 | 2.3674 | 3.1927 | 4.0809 | 5.0393 |

| DBFAM | 0.5076 | 1.0451 | 1.8972 | 2.8168 | 3.7683 | 4.8294 | 5.9744 |

| SBSAM | 0.7208 | 1.5078 | 2.3363 | 3.3218 | 4.3393 | 5.4741 | 6.6984 |

| Types | A | E (kJ) | R2 | Equation |

|---|---|---|---|---|

| AM | 0.3768 | 122.22 | 0.99963 | αT = 0.3768 × exp[14701 × (1/T-1/323.15)] |

| DBFAM | 0.2804 | 146.01 | 0.99999 | αT = 0.2804 × exp[17562 × (1/T-1/323.15)] |

| SBSAM | 0.5238 | 156.14 | 0.99998 | αT = 0.5238 × exp[18781 × (1/T-1/323.15)] |

| Mixtures | Parameters | Temperatures (°C) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 50 | 40 | 30 | 20 | 10 | 0 | −10 | −20 | ||

| AM | E1 (MPa) | 94.06 | 87.51 | 100.74 | 130.1 | 190.4 | 199.6 | 206.9 | 208.03 |

| η1 (MPa∙s) | 4.86 × 105 | 1.57 × 106 | 4.13 × 106 | 1.36 × 107 | 1.25 × 108 | 4.84 × 108 | 3.65 × 109 | 3.39 × 1010 | |

| E2 (MPa) | 85.54 | 86.67 | 80.00 | 71.44 | 61.01 | 62.38 | 62.34 | 61.74 | |

| η2 (MPa∙s) | 1057 | 4817 | 9131 | 20599 | 78224 | 467705 | 3.36 × 106 | 3.15 × 107 | |

| R2 | 0.9258 | 0.9368 | 0.9373 | 0.9478 | 0.9461 | 0.9525 | 0.9523 | 0.9525 | |

| DBFAM | E1 (MPa) | 108.05 | 122.78 | 152.40 | 236.29 | 397.67 | 403.2 | 420.3 | 628.2 |

| η1 (MPa∙s) | 5.45 × 105 | 1.72 × 106 | 4.74 × 106 | 2.86 × 107 | 2.06 × 108 | 1.97 × 109 | 2.42 × 1010 | 3.26 × 1011 | |

| E2 (MPa) | 86.28 | 77.78 | 74.34 | 66.80 | 62.98 | 62.75 | 62.1 | 62.2 | |

| η2 (MPa∙s) | 2390 | 6696 | 15909 | 69888 | 3.59 × 105 | 3.52 × 106 | 3.85 × 107 | 5.56 × 108 | |

| R2 | 0.9491 | 0.9611 | 0.9631 | 0.9584 | 0.9559 | 0.9558 | 0.9556 | 0.9556 | |

| SBSAM | E1 (MPa) | 76.07 | 97.42 | 106.15 | 128.16 | 211.65 | 220.1 | 226.03 | 236.4 |

| η1 (MPa∙s) | 1.10 × 106 | 3.53 × 106 | 1.88 × 107 | 1.10 × 108 | 8.03 × 108 | 8.92 × 109 | 1.28 × 1011 | 1.95 × 1012 | |

| E2 (MPa) | 153.38 | 121.73 | 116.50 | 103.26 | 87.09 | 85.95 | 83.85 | 82.34 | |

| η2 (MPa∙s) | 8920 | 1.16 × 104 | 4.78 × 104 | 1.68 × 105 | 3.70 × 105 | 3.86 × 106 | 5.57 × 107 | 7.63 × 108 | |

| R2 | 0.9660 | 0.9230 | 0.9283 | 0.9260 | 0.9092 | 0.9090 | 0.9090 | 0.9082 | |

| Mixtures | Parameters | Temperatures (°C) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 50 | 40 | 30 | 20 | 10 | 0 | −10 | −20 | ||

| AM | G1 (MPa) | 36.42 | 39.92 | 42.77 | 47.71 | 60.20 | 88.64 | 213.49 | 992.58 |

| G2 (MPa) | 8.77 | 15.67 | 22.93 | 47.04 | 135.74 | 548.71 | 1983.5 | 4237.65 | |

| p1 (s) | 189,007 | 77,017 | 72,068 | 54,021 | 30,076 | 18,815 | 8341 | 3944.85 | |

| p2 (s) | 525.18 | 186.99 | 193.19 | 155.59 | 110.63 | 96.40 | 87.27 | 79.24 | |

| R2 | 0.9568 | 0.9654 | 0.9520 | 0.9475 | 0.9240 | 0.8449 | 0.9419 | 0.9674 | |

| DBFAM | G1 (MPa) | 39.68 | 44.08 | 49.95 | 63.17 | 119.80 | 190.40 | 740.97 | 4587.87 |

| G2 (MPa) | 13.60 | 31.38 | 65.85 | 127.98 | 2949.0 | 3241.65 | 4464.5 | 6063.54 | |

| p1 (s) | 155,709 | 63,491 | 49,404 | 29,792 | 11,959 | 17,147 | 6261 | 13,846.4 | |

| p2 (s) | 304.60 | 122.31 | 101.92 | 156.19 | 16.55 | 132.99 | 669.16 | 88.95 | |

| R2 | 0.9361 | 0.9723 | 0.9621 | 0.9302 | 0.9319 | 0.9998 | 0.9923 | 0.9984 | |

| SBSAM | G1 (MPa) | 46.16 | 49.14 | 56.91 | 70.89 | 100.51 | 162.02 | 481.07 | 1117.40 |

| G2 (MPa) | 10.19 | 19.23 | 29.69 | 51.24 | 137.85 | 986.01 | 5900.2 | 16,974.5 | |

| p1 (s) | 92,778 | 108,254 | 63,392 | 42,332 | 28,051 | 18,742 | 7687 | 19,530 | |

| p2 (s) | 504.40 | 416.27 | 421.64 | 347.35 | 172.40 | 106.43 | 97.51 | 80.74 | |

| R2 | 0.9605 | 0.9496 | 0.9463 | 0.9482 | 0.9525 | 0.9023 | 0.9472 | 0.9815 | |

| Parameters | Temperatures (°C) | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 40 | 30 | 20 | 10 | 0 | −10 | −20 | |

| Ee (MPa) | 34.729 | 11.163 | 25.575 | 15.168 | 40.868 | 56.266 | 3.089 | 182.22 |

| E1 (MPa) | 5137.1 | 6943.5 | 1,010,500 | 3563.9 | 67,882.5 | 5193.33 | 4489.88 | 157116 |

| E2 (MPa) | 2176.2 | 5963.7 | 855.84 | 3560.9 | 1527.0 | 1438.7 | 1530.7 | 2809.2 |

| E3 (MPa) | 33.01 | 453.61 | 328.53 | 3560.7 | 1487.1 | 1423.6 | 1354.8 | 2807.9 |

| E4 (MPa) | 11.25 | 23.61 | 33.33 | 58.69 | 206.01 | 1397.3 | 1345.5 | 2807.9 |

| E5 (MPa) | 6.13 | 8.45 | 13.69 | 26.50 | 54.71 | 126.3 | 1121.4 | 1493.1 |

| E6 (MPa) | 4.96 | 4.43 | 5.32 | 8.53 | 22.71 | 54.65 | 82.31 | 919.85 |

| E7 (MPa) | 0.020 | 4.43 | 5.31 | 5.41 | 1.08 | 0.544 | 53.46 | 0.0533 |

| E8 (MPa) | 0.013 | 4.43 | 4.167 | 4.974 | 1.044 | 0.544 | 51.52 | 0.0469 |

| E9 (MPa) | 0.013 | 4.42 | 2.235 | 4.763 | 1.037 | 0.544 | 2.91 | 0.0447 |

| E10 (MPa) | 0.010 | 4.42 | 1.000 | 4.729 | 1.028 | 0.334 | 2.437 | 0.0436 |

| E11 (MPa) | 0.010 | 4.42 | 0.999 | 4.656 | 1.014 | 0.298 | 0.537 | 0.0419 |

| E12 (MPa) | 0.010 | 4.42 | 0.953 | 3.564 | 0.989 | 0.279 | 0.247 | 0.0397 |

| R2 | 0.9992 | 0.9966 | 0.9955 | 0.9952 | 0.9901 | 0.9958 | 0.9971 | 0.9854 |

| Parameters | Temperatures (°C) | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 40 | 30 | 20 | 10 | 0 | −10 | −20 | |

| Ee (MPa) | 23.27 | 17.76 | 18.77 | 0.87 | 6.45 | 26.72 | 89.20 | 0.0973 |

| E1 (MPa) | 712,357 | 32,995.2 | 57,986.4 | 175.7 | 13,056.4 | 14,422.0 | 3977.79 | 38,069.22 |

| E2 (MPa) | 531,625 | 32,995.21 | 38,731.11 | 175.65 | 10,995.88 | 2304.55 | 3977.79 | 3977.78 |

| E3 (MPa) | 509.51 | 55.19 | 95.80 | 175.64 | 10,898.08 | 2304.55 | 2766.72 | 3977.69 |

| E4 (MPa) | 17.54 | 46.09 | 95.80 | 174.82 | 2118.32 | 2304.55 | 2766.60 | 3977.69 |

| E5 (MPa) | 10.93 | 14.13 | 27.08 | 73.08 | 66.70 | 2304.55 | 2766.60 | 1822.42 |

| E6 (MPa) | 3.08 | 5.31 | 7.45 | 20.88 | 66.33 | 28.68 | 2591.78 | 1822.42 |

| E7 (MPa) | 3.08 | 5.31 | 7.44 | 11.28 | 14.78 | 28.68 | 0.0152 | 1822.42 |

| E8 (MPa) | 3.06 | 5.31 | 7.12 | 11.27 | 14.68 | 28.68 | 0.0151 | 1510.65 |

| E9 (MPa) | 2.89 | 4.84 | 4.76 | 11.04 | 14.60 | 28.25 | 0.0100 | 0.0120 |

| E10 (MPa) | 2.83 | 2.62 | 3.59 | 8.40 | 14.54 | 9.20 | 0.0100 | 0.0108 |

| E11 (MPa) | 2.62 | 2.60 | 2.86 | 8.37 | 2.91 | 9.14 | 0.0100 | 0.0103 |

| E12 (MPa) | 0.99 | 2.59 | 0.96 | 1.21 | 2.57 | 8.09 | 0.0100 | 0.0101 |

| R2 | 0.9872 | 0.9857 | 0.9896 | 0.9864 | 0.9733 | 0.9823 | 0.9712 | 0.9525 |

| Parameters | Temperatures (°C) | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 40 | 30 | 20 | 10 | 0 | −10 | −20 | |

| Ee (MPa) | 12.76 | 29.27 | 35.32 | 22.50 | 1.40 | 84.99 | 15.74 | 0.0123 |

| E1 (MPa) | 950.05 | 7617.25 | 588.95 | 4469.53 | 6536.74 | 6702.77 | 3729.3 | 11,273.09 |

| E2 (MPa) | 22.69 | 215.31 | 457.14 | 421.28 | 4720.3 | 6584.8 | 3729. | 11,253.15 |

| E3 (MPa) | 19.05 | 55.51 | 366.38 | 308.55 | 172.35 | 2383.2 | 3689.25 | 11,252.86 |

| E4 (MPa) | 18.36 | 26.42 | 53.28 | 86.34 | 152.63 | 2088.36 | 3689.25 | 11,252.86 |

| E5 (MPa) | 7.95 | 14.99 | 18.94 | 33.28 | 82.24 | 337.61 | 3689.25 | 6374.06 |

| E6 (MPa) | 5.26 | 7.60 | 15.54 | 23.24 | 34.00 | 93.05 | 139.58 | 422.99 |

| E7 (MPa) | 5.26 | 3.54 | 2.85 | 7.02 | 16.07 | 4.11 | 139.54 | 422.99 |

| E8 (MPa) | 5.26 | 3.54 | 2.70 | 6.62 | 14.84 | 3.97 | 31.43 | 422.83 |

| E9 (MPa) | 5.26 | 3.54 | 2.59 | 6.40 | 13.03 | 3.96 | 31.34 | 0.0118 |

| E10 (MPa) | 5.26 | 3.51 | 2.54 | 6.23 | 12.41 | 3.93 | 23.34 | 0.0105 |

| E11 (MPa) | 5.26 | 2.67 | 2.53 | 6.21 | 12.25 | 3.93 | 5.77 | 0.0100 |

| E12 (MPa) | 4.92 | 0.67 | 2.53 | 6.21 | 12.13 | 3.92 | 4.63 | 0.0100 |

| R2 | 0.9975 | 0.9961 | 0.9983 | 0.9978 | 0.9907 | 0.9853 | 0.9912 | 0.9640 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Li, H.; Li, L.; Zhang, Y.; Wang, H.; Bai, Y. Viscoelastic Properties of Asphalt Mixtures with Different Modifiers at Different Temperatures Based on Static Creep Tests. Appl. Sci. 2019, 9, 4246. https://doi.org/10.3390/app9204246

Cheng Y, Li H, Li L, Zhang Y, Wang H, Bai Y. Viscoelastic Properties of Asphalt Mixtures with Different Modifiers at Different Temperatures Based on Static Creep Tests. Applied Sciences. 2019; 9(20):4246. https://doi.org/10.3390/app9204246

Chicago/Turabian StyleCheng, Yongchun, He Li, Liding Li, Yuwei Zhang, Haitao Wang, and Yunshuo Bai. 2019. "Viscoelastic Properties of Asphalt Mixtures with Different Modifiers at Different Temperatures Based on Static Creep Tests" Applied Sciences 9, no. 20: 4246. https://doi.org/10.3390/app9204246

APA StyleCheng, Y., Li, H., Li, L., Zhang, Y., Wang, H., & Bai, Y. (2019). Viscoelastic Properties of Asphalt Mixtures with Different Modifiers at Different Temperatures Based on Static Creep Tests. Applied Sciences, 9(20), 4246. https://doi.org/10.3390/app9204246