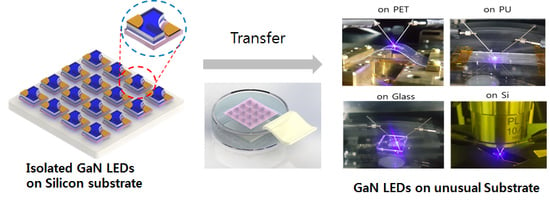

Mass Transfer of Microscale Light-Emitting Diodes to Unusual Substrates by Spontaneously Formed Vertical Tethers During Chemical Lift-Off

Abstract

:1. Introduction

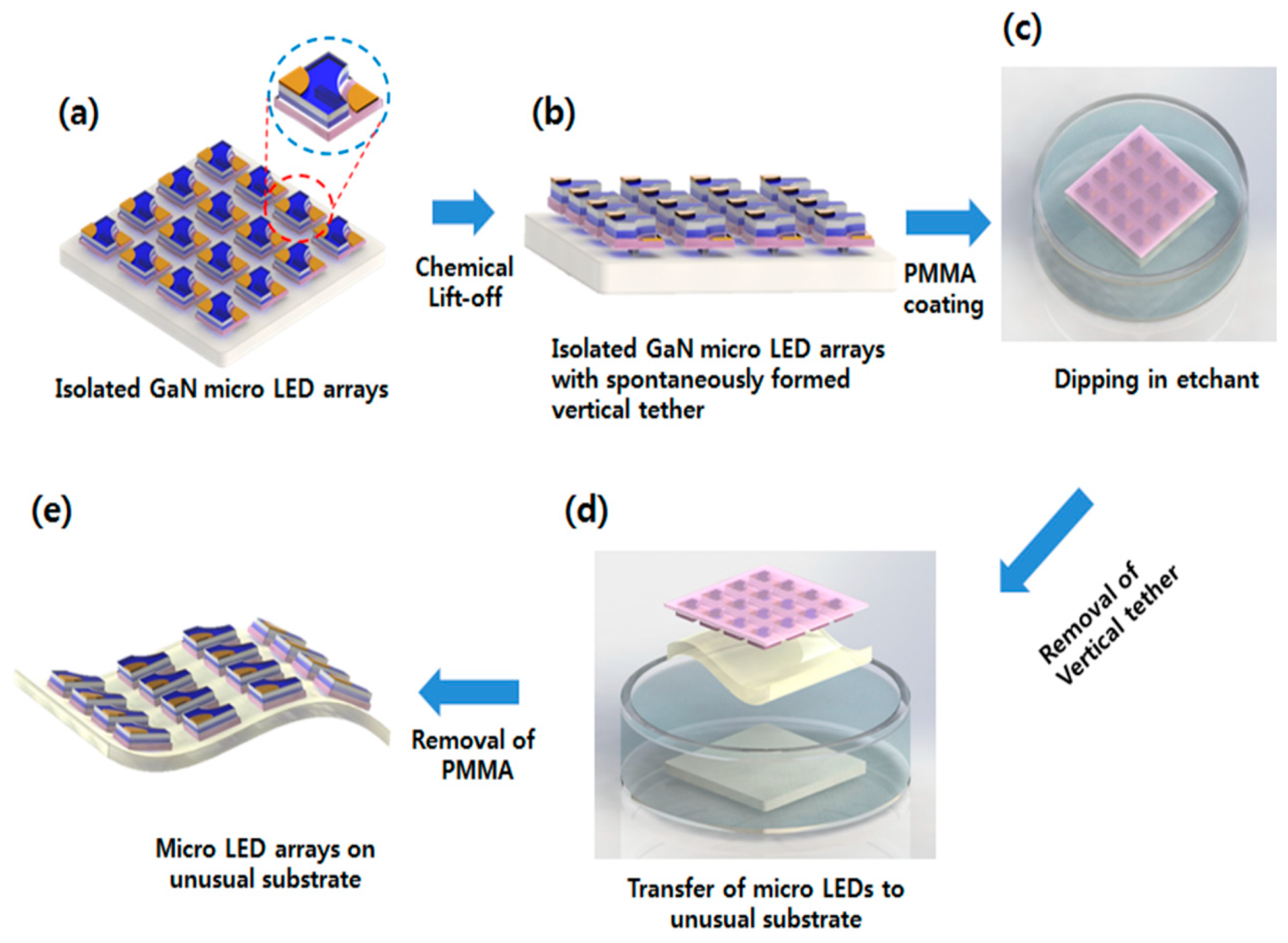

2. Experimental

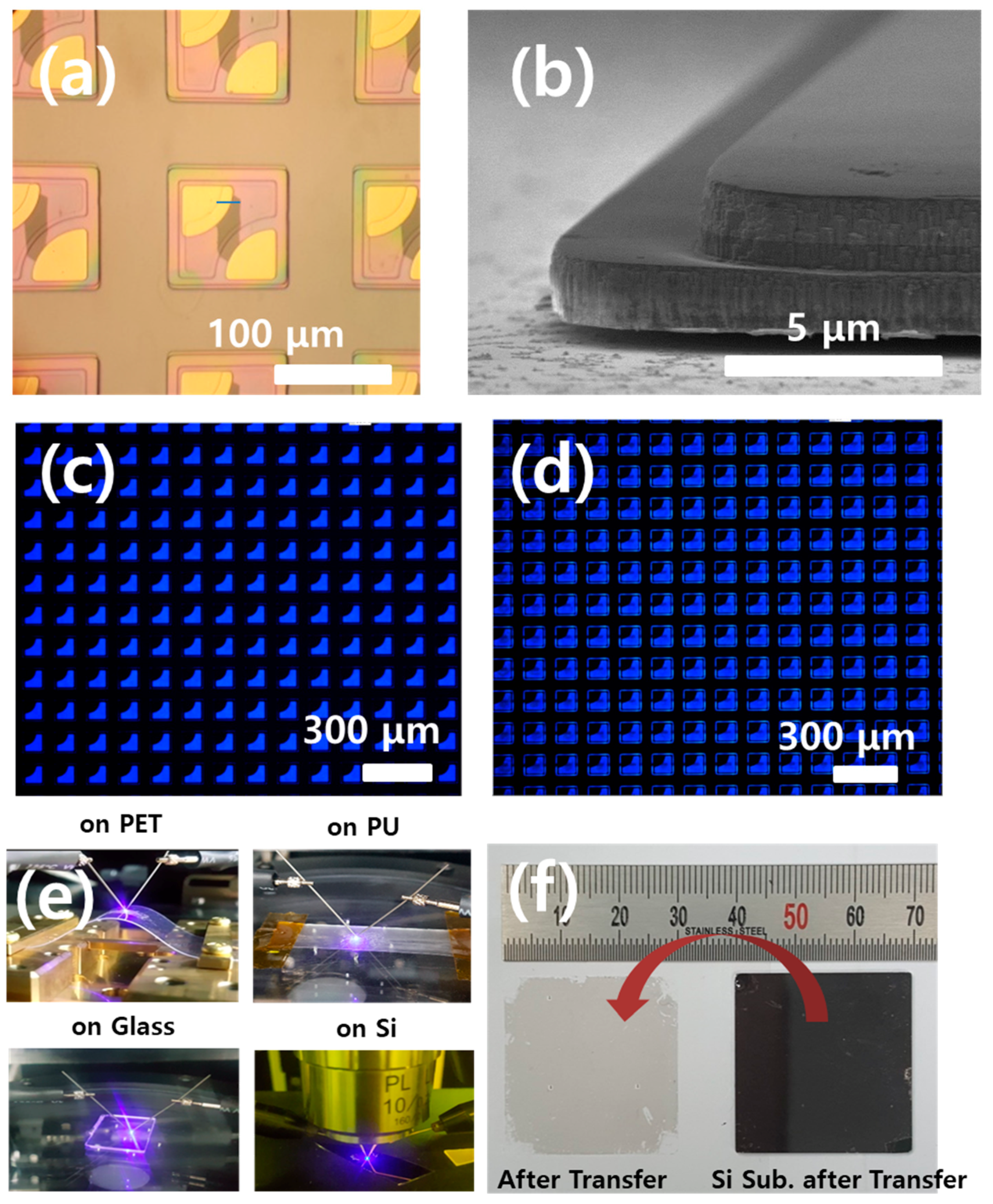

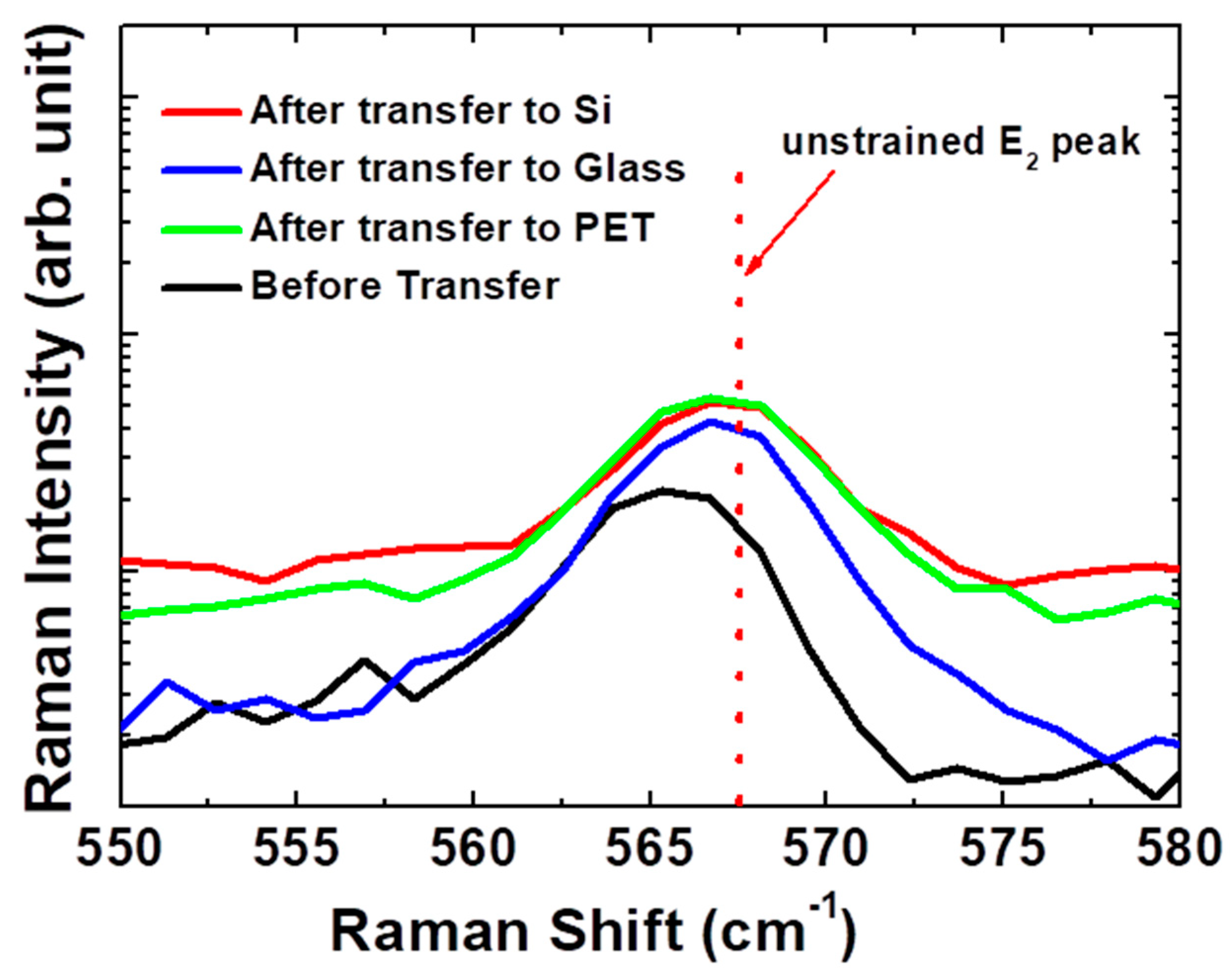

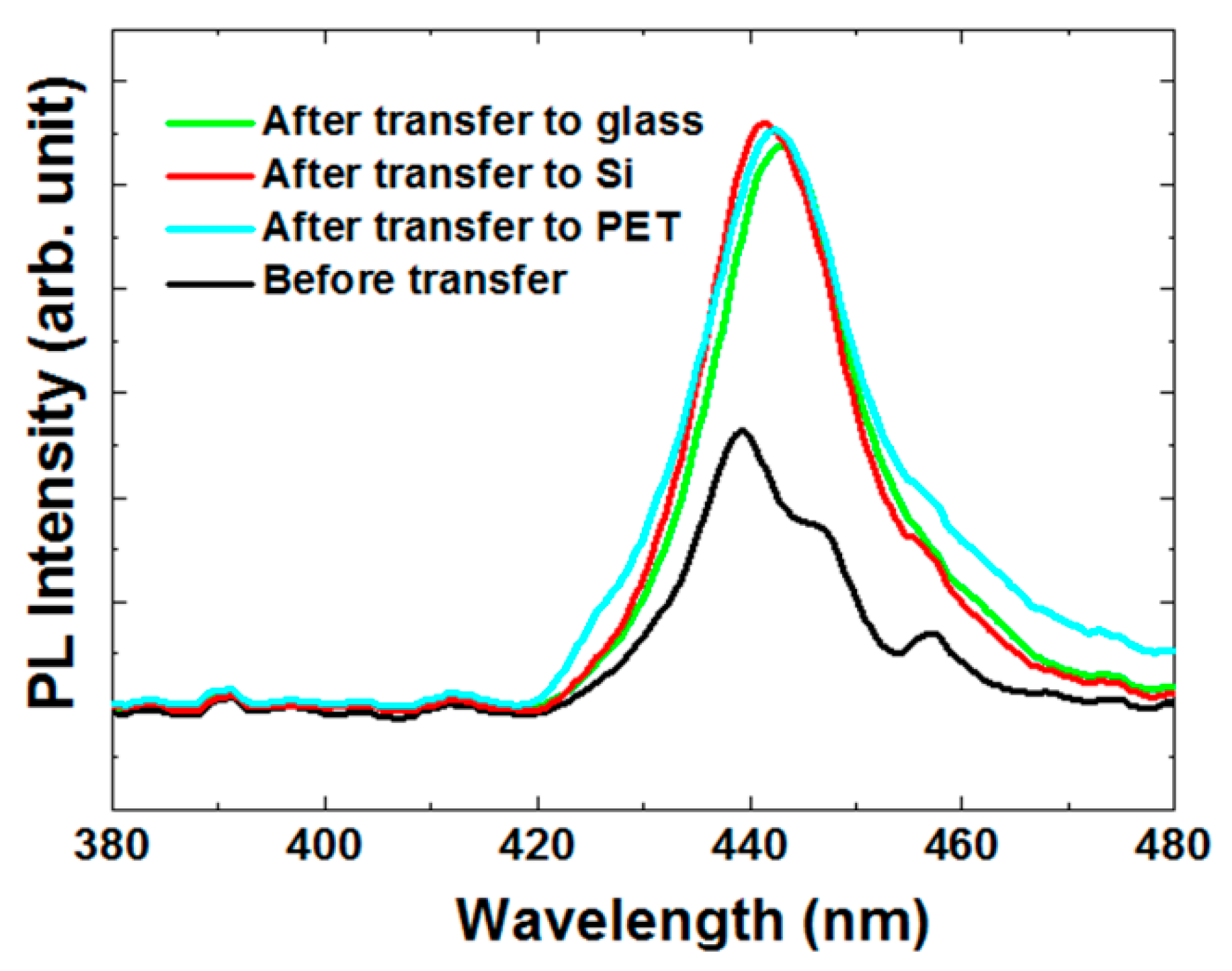

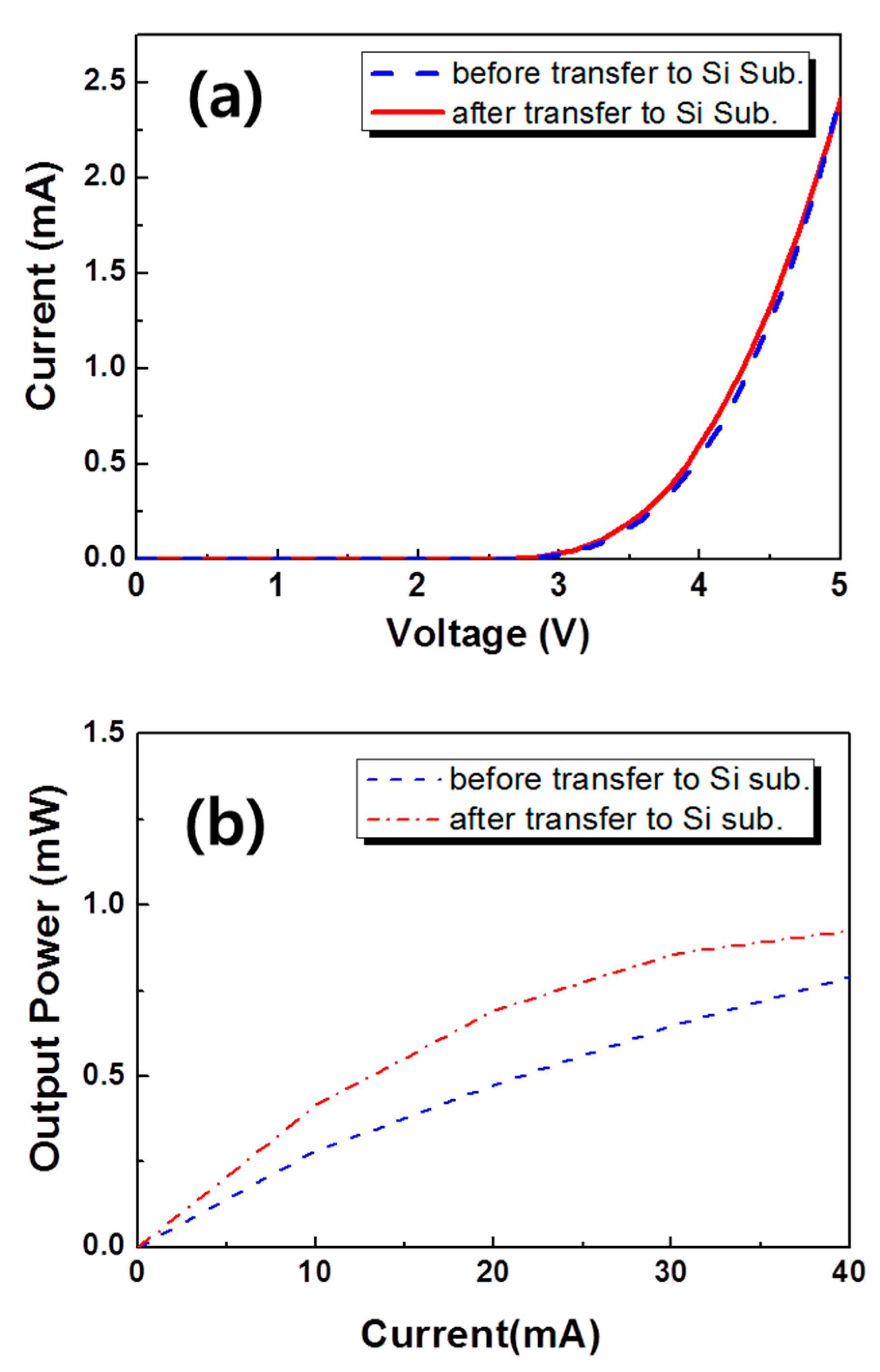

3. Results and Discussion

4. Summary

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Deol, R.S.; Choi, H.W.; Singh, M.; Jabbour, G.E. Printable displays and light sources for sensor applications: A review. IEEE Sens. J. 2015, 15, 3186. [Google Scholar] [CrossRef]

- Jeong, C.K.; Park, K.I.; Son, J.H.; Hwang, G.T.; Lee, S.H.; Park, D.Y.; Lee, H.E.; Lee, H.K.; Byun, M.; Lee, K.J. Self-powered fully-flexible light-emitting system enabled by flexible energy harvester. Energy. Environ. Sci. 2014, 7, 4035. [Google Scholar] [CrossRef]

- Huang, Y.; Tan, G.; Gou, F.; Li, M.; Lee, S.; Wu, S. Prospects and challenges of mini-LED and micro-LED displays. J. Soc. Inf. Disp. 2019, 27, 387. [Google Scholar] [CrossRef]

- Gou, F.; Hsiang, E.; Tan, G.; Chou, P.; Li, Y.; Lan, Y.; Wu, S. Angular color shift of micro-LED displays. Opt. Express 2019, 27, A746. [Google Scholar] [CrossRef] [PubMed]

- Wong, W.S.; Sands, T.; Cheung, N.W.; Kneissl, M.; Bour, D.P.; Mei, P.; Romano, L.T.; Johnson, N.M. Fabrication of thin-film InGaN light-emitting diode membranes by laser lift-off. Appl. Phys. Lett. 1999, 75, 1360. [Google Scholar] [CrossRef]

- Kim, T.I.; Jung, Y.H.; Song, J.Z.; Kim, D.; Li, Y.H.; Kim, H.S.; Song, I.S.; Wierer, J.J.; Pao, H.A.; Huang, Y.G.; et al. High-efficiency, microscale GaN light-emitting diodes and their thermal properties on unusual substrates. Small 2012, 8, 1643. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.H.; Li, J.; Lee, J.; Gong, S.Q.; Lin, J.Y.; Jiang, H.X.; Ma, Z.Q. A simplified method of making flexible blue LEDs on a plastic substrate. IEEE Photonics J. 2015, 7, 8200207. [Google Scholar] [CrossRef]

- Choi, W.S.; Park, H.J.; Park, S.H.; Jeong, T. Flexible InGaN LEDs on a polyimide substrate fabricated using a simple direct-transfer method. IEEE Photonics. Technol. Lett. 2014, 26, 2115. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Liu, W.J.; Chen, M.; Hu, X.L.; Lv, X.Q.; Ying, L.Y.; Zhang, B.P. Performance enhancement of GaN-based light emitting diodes by transfer from sapphire to silicon substrate using double-transfer technique. Nanoscale Res. Lett. 2012, 7, 244. [Google Scholar] [CrossRef] [PubMed]

- Hsu, S.C.; Pong, B.J.; Li, W.H.; Beechem, E.T.; Graham, S.; Liu, C.Y. Stress relaxation in GaN by transfer bonding on Si substrates. Appl. Phys. Lett. 2007, 91, 251114. [Google Scholar] [CrossRef] [Green Version]

- Trindade, A.J.; Guilhabert, B.; Massoubre, D.; Zhu, D.; Laurand, N.; Gu, E.; Watson, I.M.; Humphreys, C.J.; Dawson, M.D. Nanoscale-accuracy transfer printing of ultra-thin AlInGaN light-emitting diodes onto mechanically flexible substrates. Appl. Phys. Lett. 2013, 103, 253302. [Google Scholar] [CrossRef] [Green Version]

- Hahn, B.; Galler, B.; Engl, K. Development of high-efficiency and high-power vertical light emitting diodes. Jpn. J. Appl. Phys. 2014, 53, 100208. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.F.; Seng, H.L.; Teng, J.H.; Chua, S.J.; Chi, D.Z. Effects of lift-off and strain relaxation on optical properties of InGaN/GaN blue LED grown on 150 mm diameter Si (111) substrate. J. Cryst. Growth 2014, 402, 155. [Google Scholar] [CrossRef]

- Tripathy, S.; Chua, S.J.; Chen, P.; Miao, Z.L. Micro-Raman investigation of strain in GaN and AlxGa1−xN/GaN heterostructures grown on Si(111). J. Appl. Phys. 2002, 92, 3503–3510. [Google Scholar] [CrossRef]

- Hsu, C.W.; Chen, Y.F.; Su, Y.K. Quality improvement of GaN on Si substrate for ultraviolet photodetector application. IEEE J. Quantum Electron. 2014, 50, 35. [Google Scholar] [CrossRef]

- Zhao, H.P.; Liu, G.Y.; Zhang, J.; Poplawsky, J.D.; Dierolf, V.; Tansu, N. Approaches for high internal quantum efficiency green InGaN light-emitting diodes with large overlap quantum wells. Opt. Express 2011, 19, A991–A1007. [Google Scholar] [CrossRef] [PubMed] [Green Version]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-Y.; Cho, Y.-H.; Park, H.-S.; Ryou, J.-H.; Kwon, M.-K. Mass Transfer of Microscale Light-Emitting Diodes to Unusual Substrates by Spontaneously Formed Vertical Tethers During Chemical Lift-Off. Appl. Sci. 2019, 9, 4243. https://doi.org/10.3390/app9204243

Kim J-Y, Cho Y-H, Park H-S, Ryou J-H, Kwon M-K. Mass Transfer of Microscale Light-Emitting Diodes to Unusual Substrates by Spontaneously Formed Vertical Tethers During Chemical Lift-Off. Applied Sciences. 2019; 9(20):4243. https://doi.org/10.3390/app9204243

Chicago/Turabian StyleKim, Ja-Yeon, Yoo-Hyun Cho, Hyun-Sun Park, Jae-Hyun Ryou, and Min-Ki Kwon. 2019. "Mass Transfer of Microscale Light-Emitting Diodes to Unusual Substrates by Spontaneously Formed Vertical Tethers During Chemical Lift-Off" Applied Sciences 9, no. 20: 4243. https://doi.org/10.3390/app9204243

APA StyleKim, J.-Y., Cho, Y.-H., Park, H.-S., Ryou, J.-H., & Kwon, M.-K. (2019). Mass Transfer of Microscale Light-Emitting Diodes to Unusual Substrates by Spontaneously Formed Vertical Tethers During Chemical Lift-Off. Applied Sciences, 9(20), 4243. https://doi.org/10.3390/app9204243