Damage Analyses of Replaceable Links in Eccentrically Braced Frame (EBF) Subject to Cyclic Loading

Abstract

Featured Application

Abstract

1. Introduction

2. Experimental Study

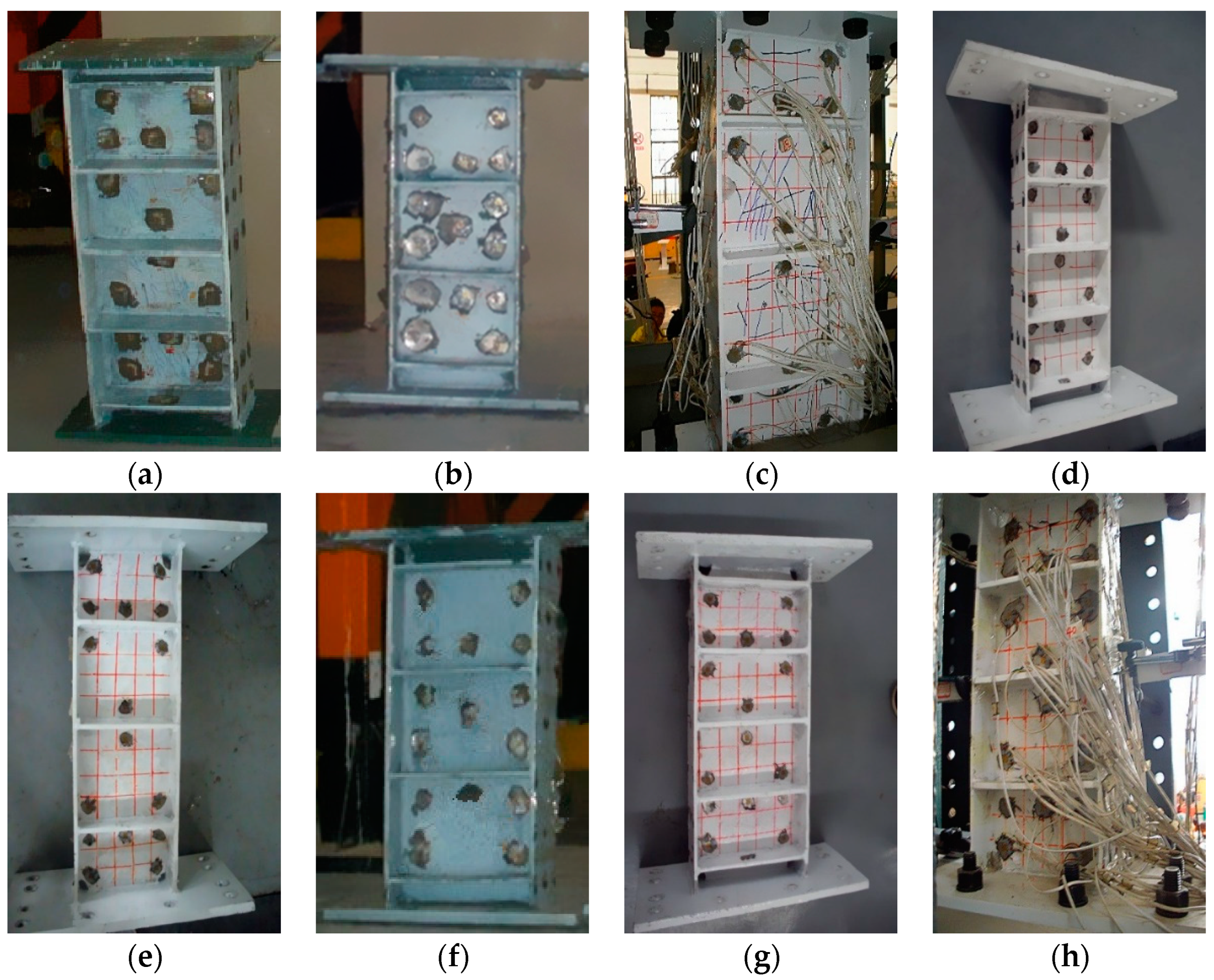

2.1. Specimen Design

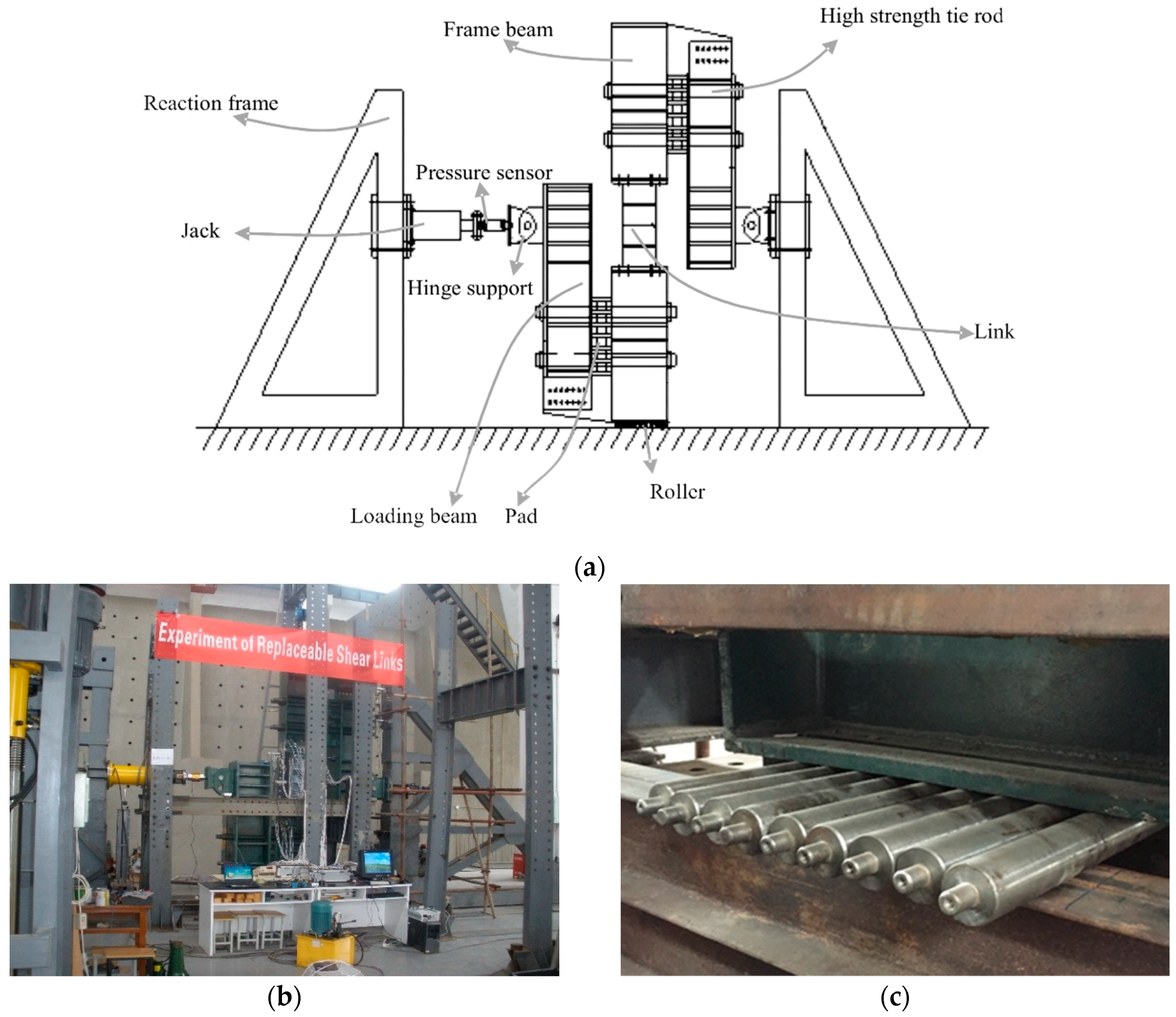

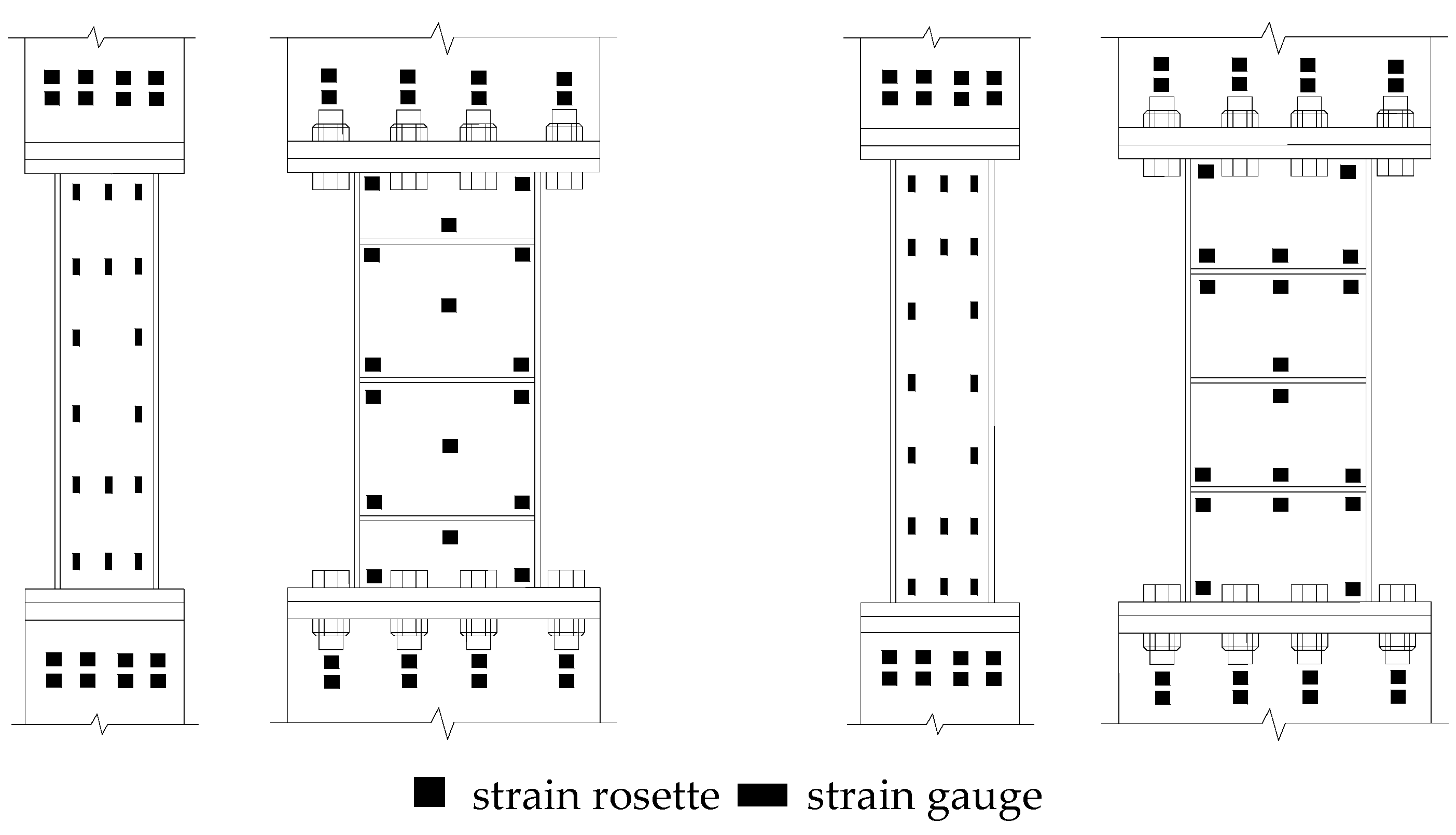

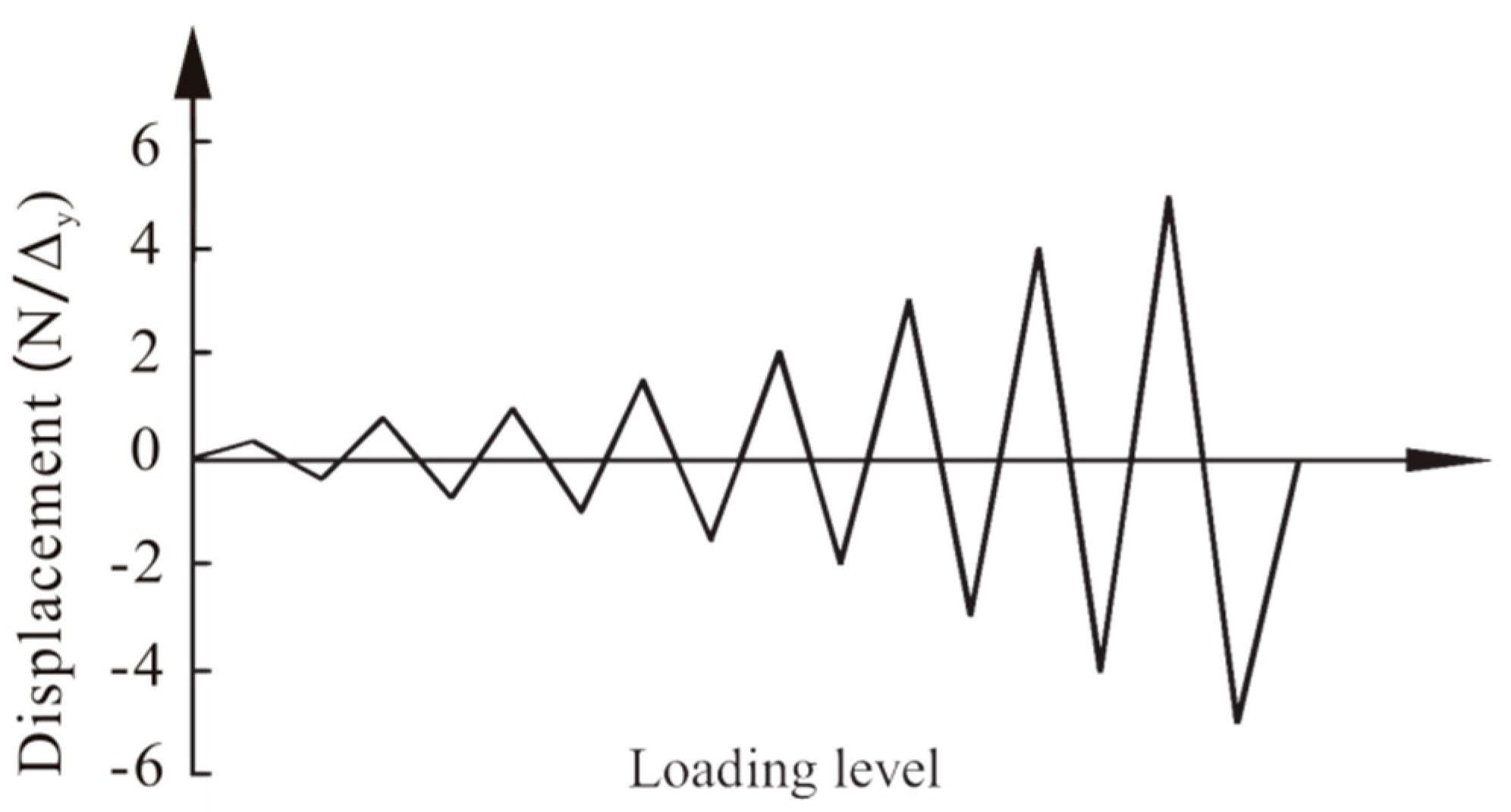

2.2. Test Setup, Instrumentation, and Loading Protocol

3. Experimental Results and Discussion

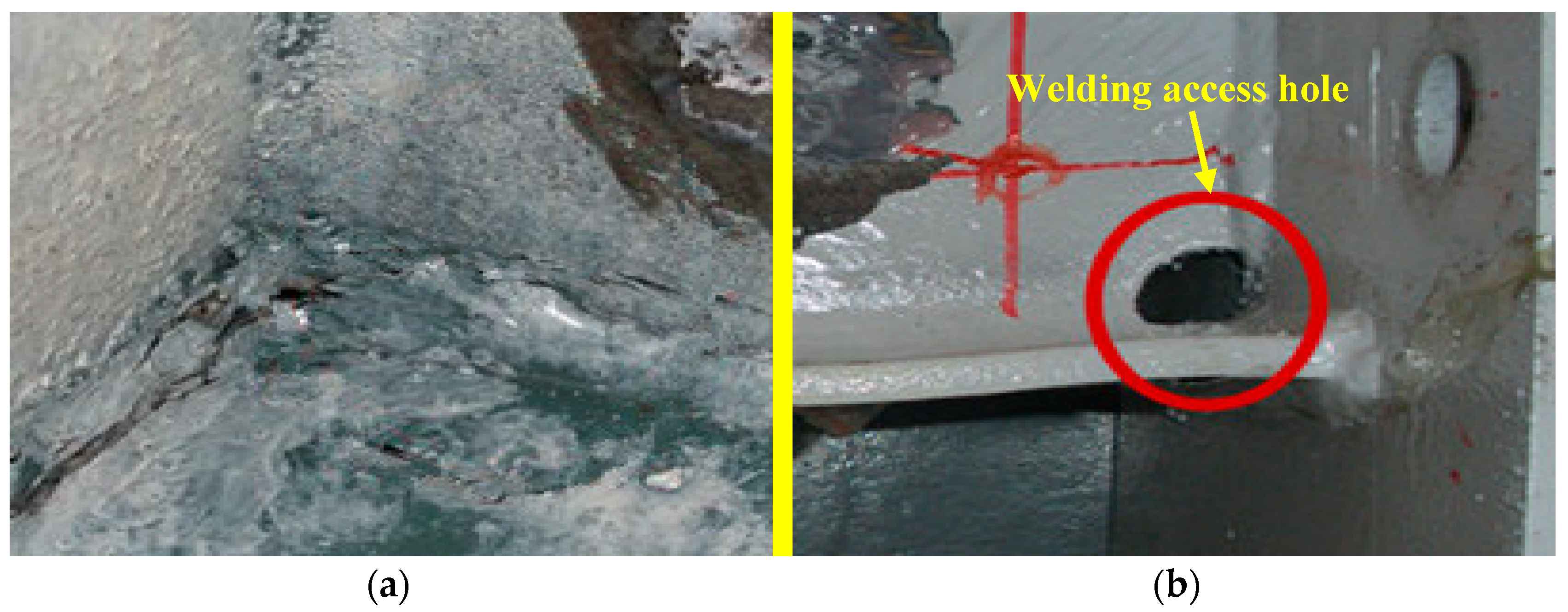

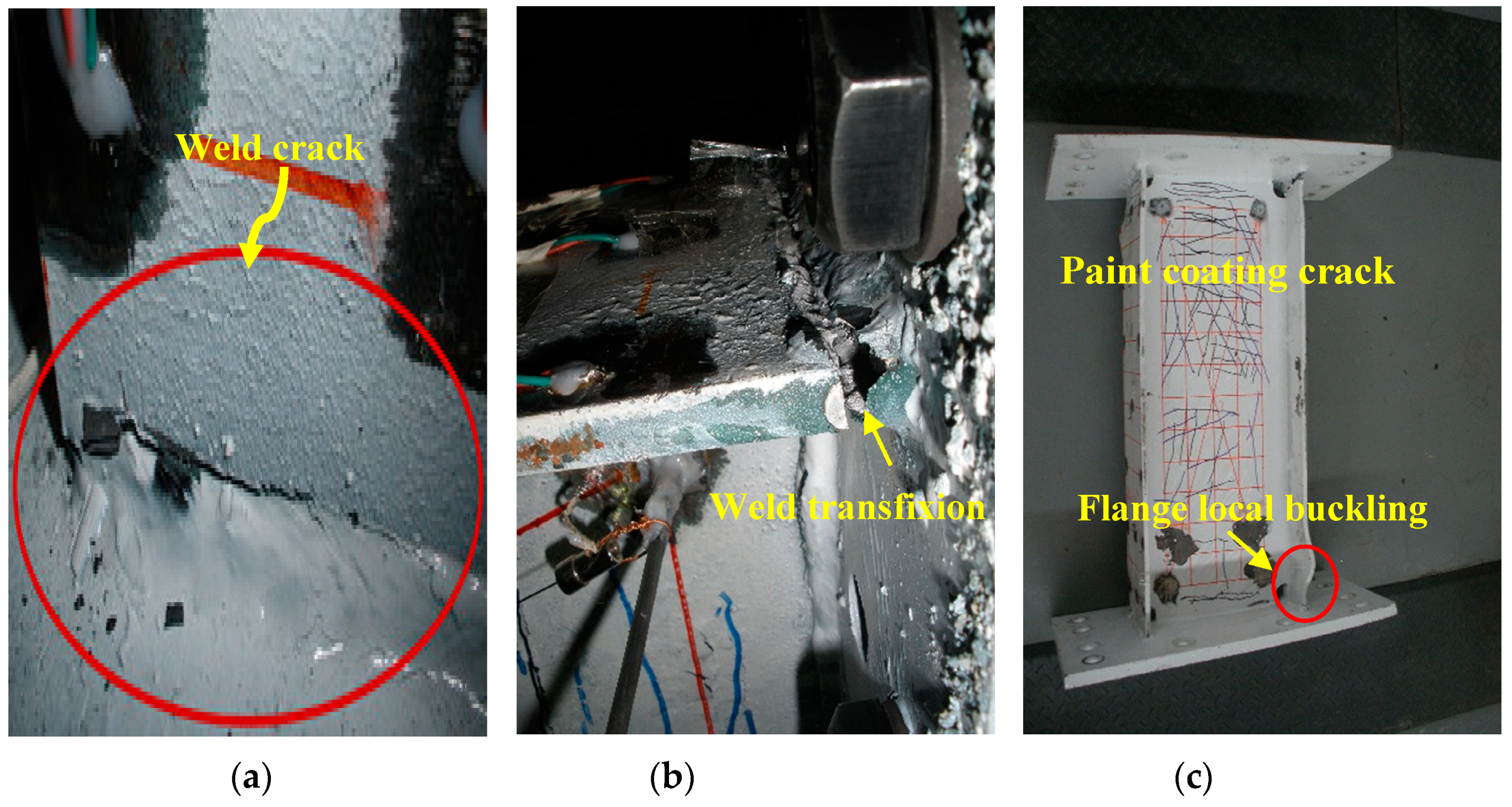

3.1. Damage Processes and Failure Mode

3.2. Stress Distribution and Damage Analysis

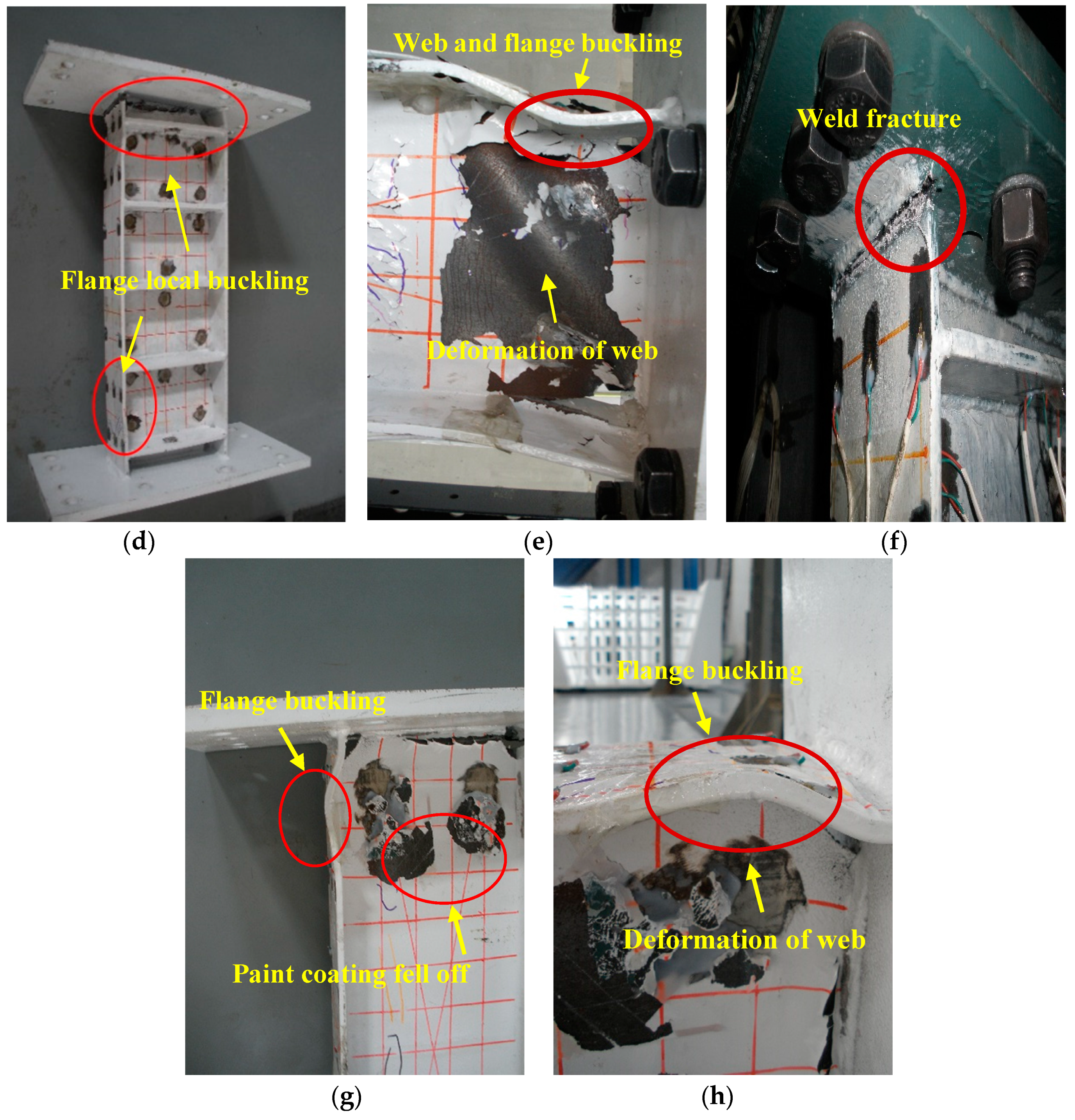

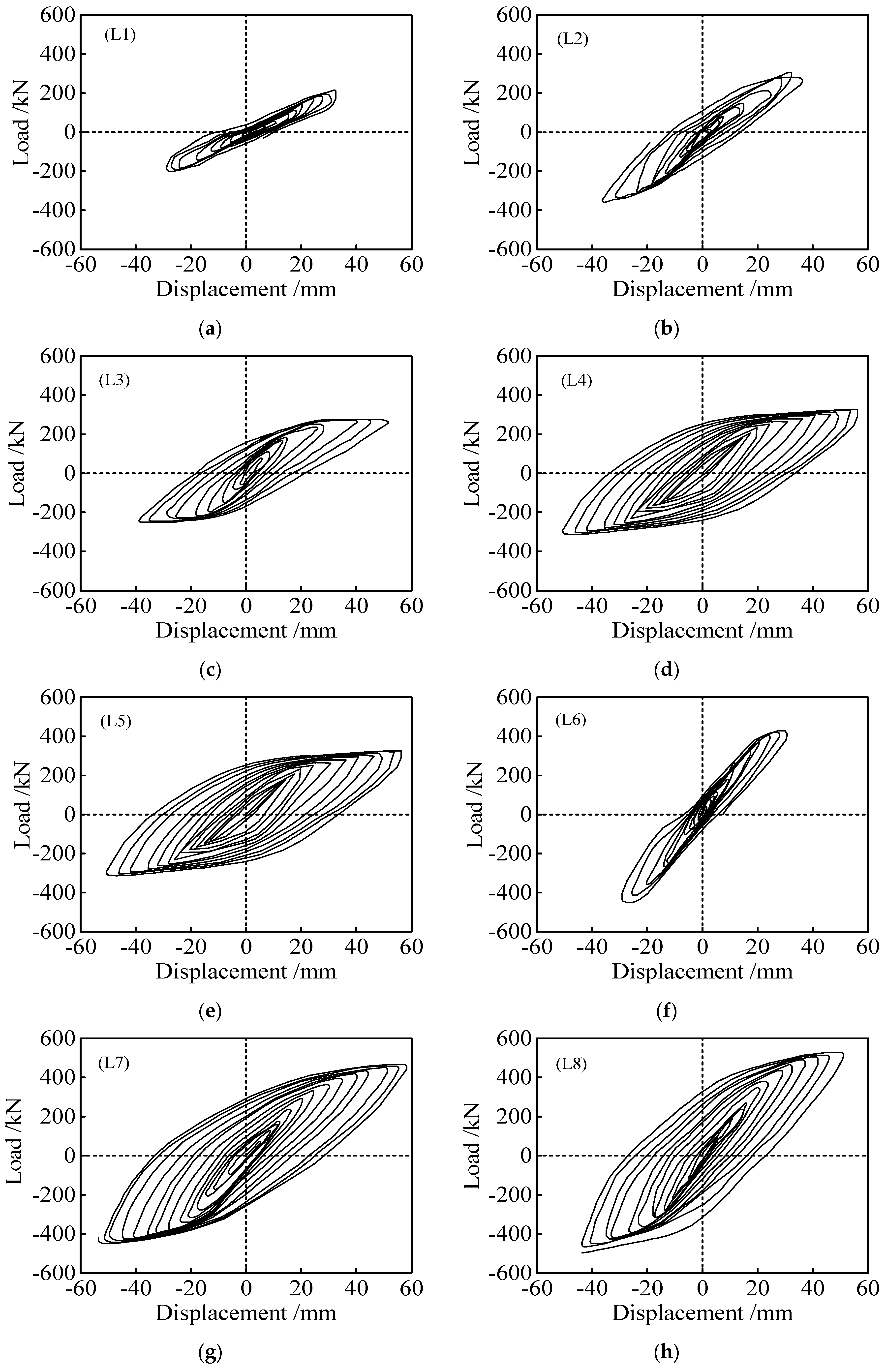

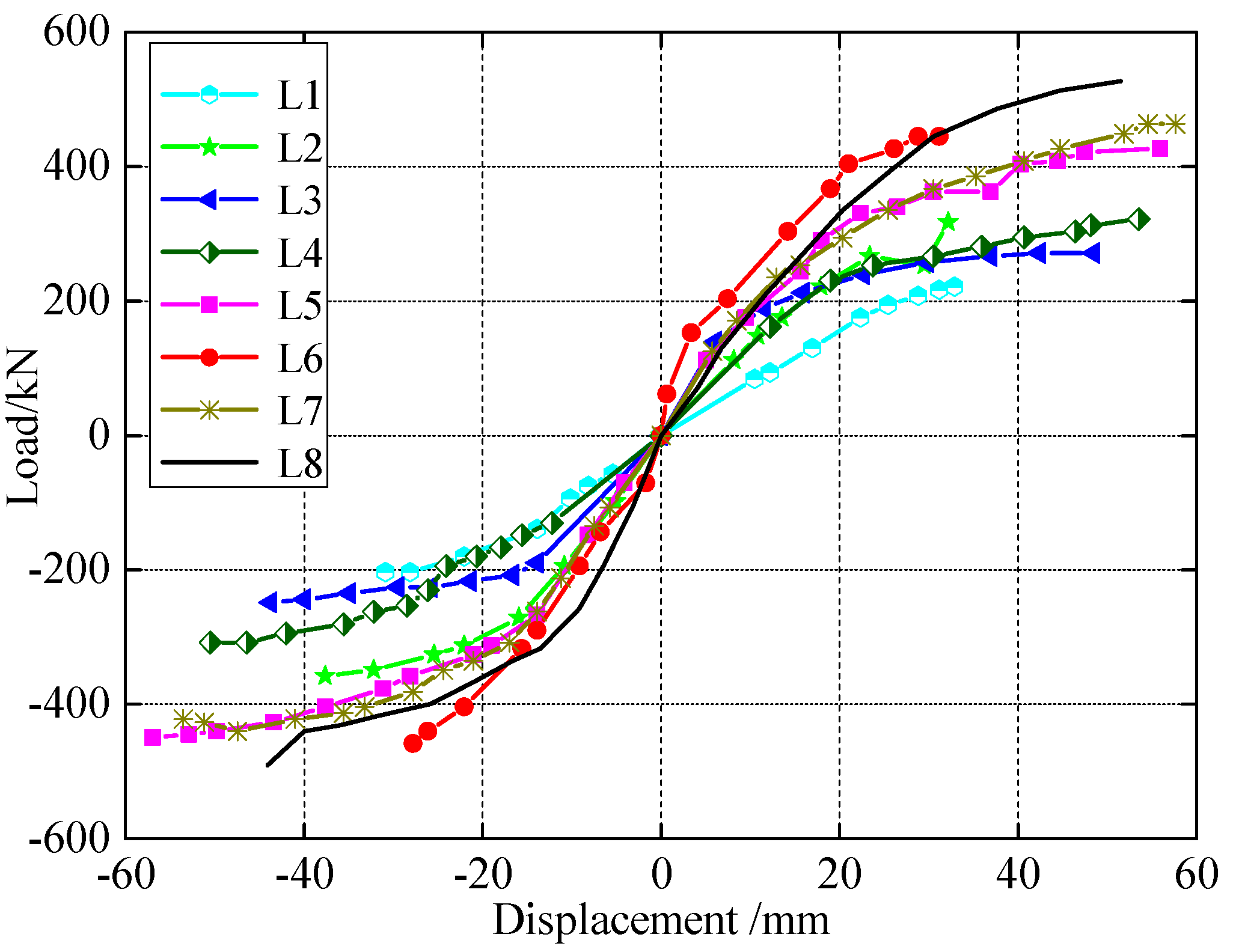

3.3. Hysteresis Curves

3.4. Energy Dissipation Behavior

3.5. Skeleton Curves

3.6. Plastic Rotation Angle

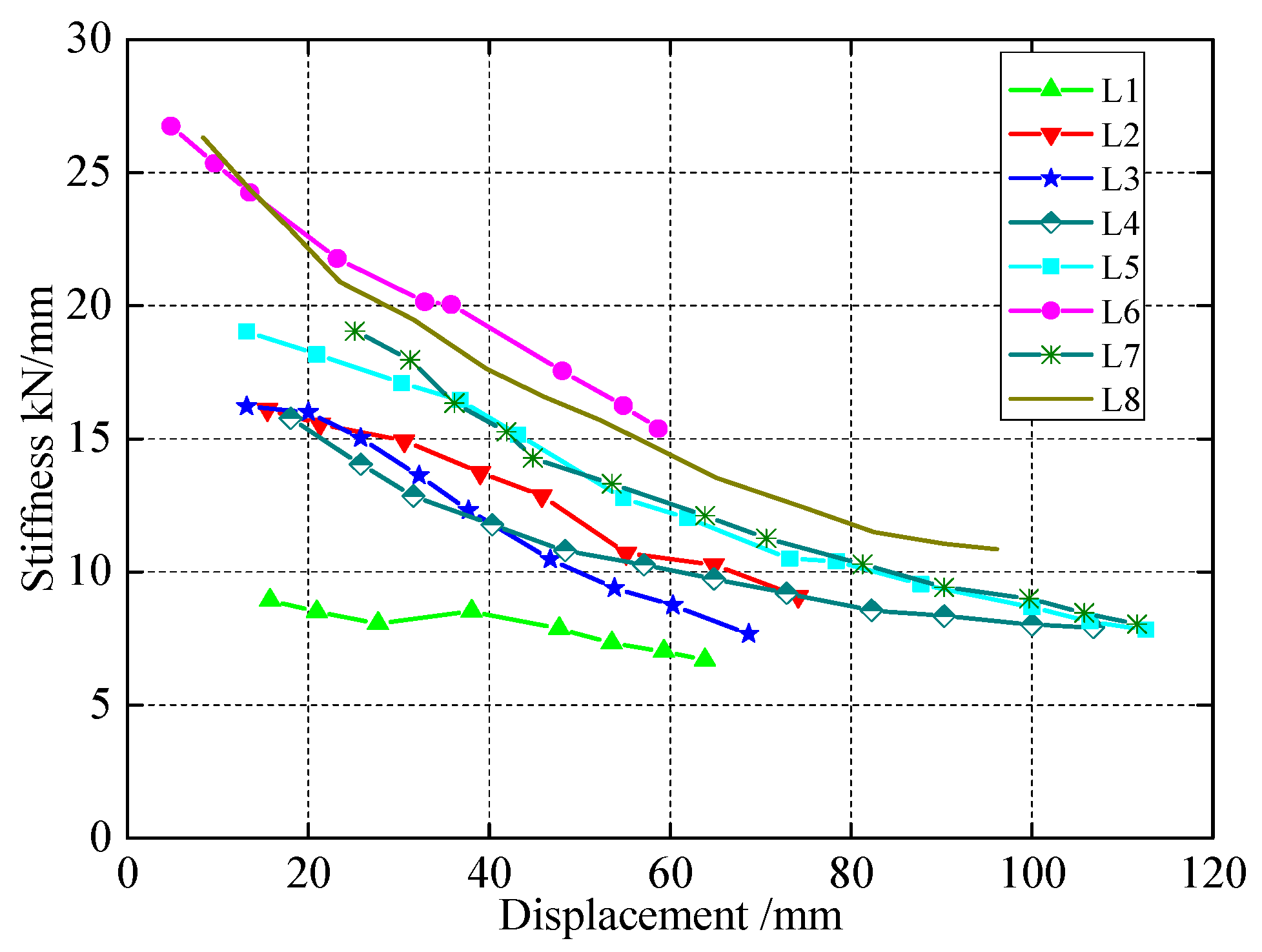

3.7. Stiffness Degradation

3.8. Discussion on Real-Time Damage Monitoring

4. Conclusions

- (1)

- The failure mode of specimens without welding access holes was brittle failure of the link flange-to-end plate weld that cracked, which was caused by the distribution of complex residual stress at the welds of the end plate. Owing to the welding access hole adopted in links, stress distribution of the web was more uniform, and the failure modes of specimens were ductile failure.

- (2)

- Stress distribution of the web was more uniform for links with the welding access hole than for links without the welding access hole, and the effect of the stiffener of specimens after shear yielding was not obvious. Link damage is caused by the incessant interactive actions of the plastic development and deformation, and it is possible to focus the structure’s inelasticity on the link.

- (3)

- The hysteresis curves of the replaceable links with welding access holes were stable and the inelastic deformation of the structure could be concentrated in the links. The link was treated using welding access holes that had a prominent effect on the improvement of seismic behavior.

- (4)

- The energy dissipation capacity of the specimen was mainly dependent on the arrangement of stiffeners and the welding access holes. When the dimensions and lengths of the specimens were the same, the energy dissipation capacity of the specimen with relatively closer stiffener spacing was better. The energy dissipation capacity of the specimen with welding access holes was better than that of specimens without welding access holes, where welding access holes relieved stress distribution.

- (5)

- Welding access holes effectively enhanced the plastic deformation capacity of the links, where the minimum plastic rotation angle of the specimen was 0.10rad and the maximum was 0.16rad. As the section dimension and length of the link were the same, the stiffener spacing had the same remarkable effect on the plastic deformation capacity of the link.

- (6)

- The stiffener spacing, the welding access holes, and the length ratio ζ had a remarkable effect on the bearing capacity of the links. The bearing capacity of the specimen with welding access holes was better than the other specimens. The smaller the length ratio ζ, the larger the bearing capacity would be. The length ratio ζ had a great influence on the initial stiffness of the link.

- (7)

- The stiffness degradation of the link was mainly dependent on the length ratio ζ. As the length and the stiffener spacing were the same, the smaller the length ratio ζ of the specimen, the more obvious the stiffness degradation.

- (8)

- In our future work, we will explore the use of PZT patches and the active sensing method to quickly evaluate structural integrity by detecting cracks and bolt loosening after a seismic event.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fujimoto, M.; Aoyagi, T.; Ukai, K.; Wada, A.; Saito, K. Structural characteristics of eccentric k-braced frames. Trans. Archit. Inst. Jpn. 1972, 195, 39–49. [Google Scholar] [CrossRef]

- Tanabashi, R.; Naneta, K.; Ishida, T. On the rigidity and ductility of steel bracing assemblage. In Proceedings of the 5th World Conference on Earthquake Engineering, Rome, Italy, 25–29 June 1973; IAEE: Rome, Italy, 1974; pp. 834–840. [Google Scholar]

- Roeder, C.W.; Popov, E.P. Inelastic behavior of eccentrically braced steel frames under cyclic loadings. Akusherstvo I Ginekologiia 1953, 2, 67–69. [Google Scholar]

- Teal, R. Practical Design of Eccentric Braced Frames to Resist Seismic Forces; Structural Steel Research Council: Lafayette, CA, USA, 1979. [Google Scholar]

- Libby, J.R. Eccentrically braced frame construction—A case study. Eng. J. 1981, 18, 149–153. [Google Scholar]

- Merovich, A.T.; Nicoletti, J.P.; Hartle, E. Eccentric bracing in tall buildings. ASCE J. Struct. Div. 1982, 108, 3059–3075. [Google Scholar]

- Miller, D.K. Lessons learned from the Northridge earthquake. Eng. Struct. 1998, 20, 249–260. [Google Scholar] [CrossRef]

- Krawinkler, H. Shear in beam–column joints in seismic design of steel frames. AISC Eng. J. 1978, 3, 82–91. [Google Scholar]

- Popov, E.P. Panel zone flexibility in seismic moment joints. J. Constr. Steel Res. 1987, 8, 91–118. [Google Scholar] [CrossRef]

- Naeim, F. The Seismic Design Handbook; Van Nostrand Reinhold: New York, NY, USA, 1989. [Google Scholar]

- Maleki, S.; Tabbakhha, M. Numerical study of Slotted-Web–Reduced-Flange moment connection. J. Constr. Steel Res. 2012, 69, 1–7. [Google Scholar] [CrossRef]

- Rao, D.V.; Kumar, S.R. RHS beam-to-column connection with web opening—Parametric study and design guidelines. J. Constr. Steel Res. 2006, 62, 747–756. [Google Scholar]

- Malley, J.O.; Popov, E.P. Shear links in eccentrically braced frames. J. Struct. Eng. 1984, 110, 2275–2295. [Google Scholar] [CrossRef]

- Kasai, K.; Popov, E.P. Cyclic web buckling control for shear link beams. ASCE J. Struct. Eng. 1986, 112, 505–523. [Google Scholar] [CrossRef]

- Hamed, K.; Ghanbari, G.T.; Mohammad, H. Numerical study on steel shear walls with sinusoidal corrugated plates. Lat. Am. J. Solids Struct. 2016, 13, 2802–2814. [Google Scholar]

- Kazuhiko, K.; Popov, E.P. General behavior of WF steel shear link beams. J. Struct. Eng. 1986, 112, 362–382. [Google Scholar]

- Popov, E.P.; Engelhardt, M.D. Seismic eccentrically braced frames. J. Constr. Steel Res. 2010, 2, 53–74. [Google Scholar] [CrossRef]

- Okazaki, T.; Arce, G.; Ryu, H.C. Experimental study of local buckling, over strength, and fracture of links in eccentrically braced frames. J. Struct. Eng. 2005, 131, 1526–1535. [Google Scholar] [CrossRef]

- Lv, X.L.; Chen, Y.; Jiang, H.J. Experimental study on seismic behavior of “Fuse” of replaceable coupling beam. J. Tongji Univ. 2013, 41, 1318–1325, 1332. [Google Scholar]

- Ji, X.D.; Wang, Y.D.; Ma, Q.F.; Qian, J.R. Cyclic behavior of replaceable steel coupling beams. J. Struct. Eng. 2016, 104, 1–8. [Google Scholar]

- Yin, Z.Z.; Ren, Y.G.; Chen, W.; Liang, Y.X. The seismic performance analysis of replaceable independent links. J. Eng. Mech. 2016, 33, 207–213. [Google Scholar]

- Popov, E.P. Recent research on eccentrically braced frames. Eng. Struct. J. 1983, 5, 3–9. [Google Scholar] [CrossRef]

- Hjelmstad, K.D.; Popov, E.P. Cyclic behavior and design of link beams. J. Struct. Eng. 1983, 109, 2387–2403. [Google Scholar] [CrossRef]

- Popov, E.P.; Tsai, K.C.; Engelhard, M.D. Advances in design of eccentrically braced frames. J. Earthq. Spectra 1987, 3, 43–55. [Google Scholar] [CrossRef]

- Okazaki, T.; Engelhardt, M.D. Cyclic loading behavior of EBF links constructed of ASTM A992 steel. J. Constr. Steel Res. 2007, 63, 751–765. [Google Scholar] [CrossRef]

- Bouwkamp, J.; Vetr, M.G.; Ghamari, A. An analytical model for inelastic cyclic response of eccentrically braced frame with vertical shear link (v-ebf). Case Stud. Struct. Eng. 2016, 6, 31–44. [Google Scholar] [CrossRef]

- Ricles, J.M.; Popov, E.P. Composite action in eccentrically braced frames. J. Struct. Eng. 1989, 115, 2046–2066. [Google Scholar] [CrossRef]

- Ricles, J.M.; Popov, E.P. Inelastic Link Element for EBF Seismic Analysis. J. Struct. Eng. 1994, 120, 441–463. [Google Scholar]

- Uang, C.M.; Seible, F.; McDaniel, C.; Chou, C.C. Performance evaluation of shear links and orthotropic bridge deck panels for the new san francisco–oakland bay bridge. Earthq. Eng. Struct. Dyn. 2010, 34, 393–408. [Google Scholar] [CrossRef]

- Okazaki, T.; Engelhardt, M.D.; Drolias, A.; Schell, E.; Hong, J.K.; Uang, C.M. Experimental investigation of link-to-column connections in eccentrically braced frames. J. Constr. Steel Res. 2009, 65, 1401–1412. [Google Scholar] [CrossRef]

- Wang, B.S.; Sherif, E. Experimental and analytical investigation of tubular links for eccentrically braced frames. Eng. Struct. 2007, 29, 1929–1938. [Google Scholar]

- Lian, M.; Su, M. Seismic performance of high-strength steel fabricated eccentrically braced frame with vertical shear link. J. Constr. Steel Res. 2017, 137, 262–285. [Google Scholar] [CrossRef]

- Gates, W.E.; Morden, M. Professional structural engineering experience related to welded steel moment frames following the Northridge earthquake. Struct. Des. Tall Build. 1996, 5, 29–44. [Google Scholar] [CrossRef]

- Sabol, P. Seismic-resistant steel moment connections: Developments since the 1994 northridge earthquake. Prog. Struc. Eng. Mater. 2010, 1, 68–77. [Google Scholar]

- Xu, W.F.; Yang, X.; Wang, F.L.; Chi, B. Experimental and numerical study on the seismic performance of prefabricated reinforced masonry shear walls. Appl. Sci. 2018, 8, 1856. [Google Scholar] [CrossRef]

- Yang, W.W.; Bao, C.; Ma, X.T.; Zhang, S.R. Study on structural robustness of isolated structure based on seismic response. Appl. Sci. 2018, 8, 1686. [Google Scholar] [CrossRef]

- Mansour, N.; Christopoulos, C.; Tremblay, R. Experimental validation of replaceable shear links for eccentrically braced steel frames. J. Struct. Eng. 2011, 137, 1141–1152. [Google Scholar] [CrossRef]

- Showkati, H.; Ghazijahani, T.G.; Noori, A. Experiments on elastically braced castellated beams. J. Constr. Steel Res. 2012, 77, 163–172. [Google Scholar] [CrossRef]

- Kulak, G.L.; Green, D.L. Design of connectors in web-flange beam or girder splices. Eng. J. 1990, 27, 41–48. [Google Scholar]

- Suo, Y.Q.; Yang, W.W.; Chen, P. Study on hysteresis model of welding material in unstiffened welded joints of steel tubular truss structure. Appl. Sci. 2018, 8, 1701. [Google Scholar] [CrossRef]

- American Institute of Steel Construction. Steel Construction Manual, 13th ed.; AISC 325-05; American Institute of Steel Construction Inc.: Chicago, IL, USA, 2005. [Google Scholar]

- American Institute of Steel Construction. Seismic Provisions for Structural Steel Buildings; AISC 341-10; American Institute of Steel Construction Inc.: Chicago, IL, USA, 2005. [Google Scholar]

- Wang, T.; Song, G.; Liu, S.; Li, Y.; Xiao, H. Review of bolted connection monitoring. Int. J. Distrib. Sens. Netw. 2013, 9, 871213. [Google Scholar] [CrossRef]

- Kulak, G.L.; Fisher, J.W.; Struik, J.H.A. Guide to Design Criteria for Bolted and Riveted Joints, 2nd ed.; Wiley: New York, NY, USA, 1987. [Google Scholar]

- American Institute of Steel Construction. Specification for Structural Steel Buildings; AISC 360-10; American Institute of Steel Construction Inc.: Chicago, IL, USA, 2005. [Google Scholar]

- Chinese National Standard. Design of Steel Structures; GB 50017-2003; China Ministry of Construction: Beijing, China, 2003. [Google Scholar]

- Balageas, D.; Fritzen, C.P.; Güemes, A. Structural Health Monitoring; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Song, G.; Wang, C.; Wang, B. Structural health monitoring (SHM) of civil structures. Appl. Sci. 2017, 7, 789. [Google Scholar] [CrossRef]

- Sun, M.; Staszewski, W.J.; Swamy, R.N. Smart sensing technologies for structural health monitoring of civil engineering structures. Adv. Civ. Eng. 2010, 2010, 724962. [Google Scholar] [CrossRef]

- Li, D.; Ho, S.C.M.; Song, G.; Ren, L.; Li, H. A review of damage detection methods for wind turbine blades. Smart Mater. Struct. 2015, 24, 033001. [Google Scholar] [CrossRef]

- Brownjohn, J. Structural health monitoring of civil infrastructure. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 589–622. [Google Scholar] [CrossRef] [PubMed]

- Lehmhus, D.; Busse, M. Structural health monitoring (SHM). In Material-Integrated Intelligent Systems: Technology and Applications; Wiley: New York, NY, USA, 2018; pp. 529–570. [Google Scholar]

- Du, G.; Kong, Q.; Zhou, H.; Gu, H. Multiple cracks detection in pipeline using damage index matrix based on piezoceramic transducer-enabled stress wave propagation. Sensors 2017, 17, 1812. [Google Scholar] [CrossRef] [PubMed]

- Kong, Q.; Robert, R.H.; Silva, P.; Mo, Y.L. Cyclic crack monitoring of a reinforced concrete column under simulated pseudo-dynamic loading using piezoceramic-based smart aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef]

- Xu, J.; Wang, C.; Li, H.; Zhang, C.; Hao, J.; Fan, S. Health Monitoring of Bolted Spherical Joint Connection Based on Active Sensing Technique Using Piezoceramic Transducers. Sensors 2018, 18, 1727. [Google Scholar] [CrossRef] [PubMed]

- Feng, Q.; Kong, Q.; Huo, L.; Song, G. Crack detection and leakage monitoring on reinforced concrete pipe. Smart Mater. Struct. 2015, 24, 115020. [Google Scholar] [CrossRef]

- Qin, F.; Kong, Q.; Li, M.; Mo, Y.L.; Song, G.; Fan, F. Bond slip detection of steel plate and concrete beams using smart aggregates. Smart Mater. Struct. 2015, 24, 115039. [Google Scholar] [CrossRef]

- Yang, Y.; Divsholi, B.S.; Soh, C.K. A reusable PZT transducer for monitoring initial hydration and structural health of concrete. Sensors 2010, 10, 5193–5208. [Google Scholar] [CrossRef]

- Agrawal, B.N.; Elshafei, M.A.; Song, G. Adaptive antenna shape control using piezoelectric actuators. Acta Astronaut. 1997, 40, 821–826. [Google Scholar] [CrossRef]

- Song, G.; Qiao, P.; Sethi, V.; Prasad, A. Active vibration control of a smart pultruded fiber-reinforced polymer I-beam. Smart Mater. Struct. 2004, 13, 819. [Google Scholar] [CrossRef]

- Sethi, V.; Song, G. Multimodal vibration control of a flexible structure using piezoceramic sensor and actuator. J. Int. Mater. Syst. Struct. 2008, 19, 573–582. [Google Scholar] [CrossRef]

- Park, J.M.; Kong, J.W.; Kim, D.S.; Yoon, D.J. Nondestructive damage detection and interfacial evaluation of single-fibers/epoxy composites using PZT, PVDF and P (VDF-TrFE) copolymer sensors. Compos. Sci. Technol. 2005, 65, 241–256. [Google Scholar] [CrossRef]

- Hirsch, S.; Doerner, S.; Schimpf, S.; Lucklum, R.; Hauptmann, P.; Schmidt, B. A new device with PZT ultrasonic transducers in MEMS technology. J. Phys. Conf. Ser. 2006, 34, 475. [Google Scholar] [CrossRef]

- Siu, S.; Ji, Q.; Wu, W. Stress wave communication in concrete: I. Characterization of a smart aggregate based concrete channel. Smart Mater. Struct. 2014, 23, 125030. [Google Scholar] [CrossRef]

- Ji, Q.; Ho, M.; Zheng, R.; Ding, Z. An exploratory study of stress wave communication in concrete structures. Smart Struct. Syst. 2015, 15, 135–150. [Google Scholar] [CrossRef]

- Xu, Y.; Luo, M.; Hei, C. Quantitative evaluation of compactness of concrete-filled fiber-reinforced polymer tubes using piezoceramic transducers and time difference of arrival. Smart Mater. Struct. 2018, 27, 035023. [Google Scholar] [CrossRef]

- Providakis, C.P.; Stefanaki, K.D.; Voutetaki, M.E.; Tsompanakis, Y.; Stavroulaki, M. Damage detection in concrete structures using a simultaneously activated multi-mode PZT active sensing system: Numerical modelling. Struct. Infrastruct. Eng. 2014, 10, 1451–1468. [Google Scholar] [CrossRef]

- Jiang, T.; Kong, Q.; Wang, W.; Huo, L. Monitoring of grouting compactness in a post-tensioning tendon duct using piezoceramic transducers. Sensors 2016, 16, 1343. [Google Scholar] [CrossRef]

- Luo, M.; Li, W.; Hei, C. Concrete infill monitoring in concrete-filled FRP tubes using a PZT-based ultrasonic time-of-flight method. Sensors 2016, 16, 2083. [Google Scholar] [CrossRef]

- Huo, L.; Wang, F.; Li, H.; Song, G. A fractal contact theory based model for bolted connection looseness monitoring using piezoceramic transducers. Smart Mater. Struct. 2017, 26, 104010. [Google Scholar] [CrossRef]

- Zeng, L.; Parvasi, S.M.; Kong, Q.; Huo, L.; Li, M.; Song, G. Bond slip detection of concrete-encased composite structure using shear wave based active sensing approach. Smart Mater. Struct. 2015, 24, 125026. [Google Scholar] [CrossRef]

- Yin, H.; Wang, T.; Yang, D.; Liu, S.; Shao, J.; Li, Y. A smart washer for bolt looseness monitoring based on piezoelectric active sensing method. Appl. Sci. 2016, 6, 320. [Google Scholar] [CrossRef]

- Yan, S.; Ma, H.; Li, P.; Song, G.; Wu, J. Development and application of a structural health monitoring system based on wireless smart aggregates. Sensors 2017, 17, 1641. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, Y.; Huang, Y.; Jiang, J.; Ho, S.C. A feasibility study on timber moisture monitoring using piezoceramic transducer-enabled active sensing. Sensors 2018, 18, 3100. [Google Scholar] [CrossRef] [PubMed]

- Song, G.; Gu, H.; Mo, Y.L.; Hsu, T.T.C.; Dhonde, H. Concrete structural health monitoring using embedded piezoceramic transducers. Smart Mater. Struct. 2007, 16, 959. [Google Scholar] [CrossRef]

- Laskar, A.; Gu, H.; Mo, Y.L.; Song, G. Progressive collapse of a two-story reinforced concrete frame with embedded smart aggregates. Smart Mater. Struct. 2009, 18, 075001. [Google Scholar] [CrossRef]

| Number | Section Dimension/mm | Length /mm | Number of Stiffeners | Stiffener Spacing | Length Ratio ζ |

|---|---|---|---|---|---|

| L1 | H350 × 175 × 7 × 11 | 900 | 5 | 200 | 1.43 |

| L2 | H250 × 125 × 6 × 9 | 800 | 4 | 200 | 1.84 |

| L3 | H250 × 125 × 6 × 9 | 700 | 3 | 200 | 1.61 |

| L4 | H250 × 125 × 6 × 9 | 700 | 5 | 150 | 1.61 |

| L5 | H350 × 175 × 7 × 11 | 700 | 3 | 200 | 1.11 |

| L6 | H350 × 175 × 7 × 11 | 700 | 4 | 200 | 1.11 |

| L7 | H350 × 175 × 7 × 11 | 700 | 5 | 150 | 1.11 |

| L8 | H350 × 175 × 7 × 11 | 600 | 3 | 150 | 0.95 |

| Type | Yield Strength /MPa | Ultimate Strength /MPa | /105 MPa | Elongation δ/% |

|---|---|---|---|---|

| Web | 271.00 | 430.00 | 1.93 | 30.66 |

| Flange | 261.13 | 436.25 | 2.00 | 24.96 |

| Displacement of Link at Damage Occurrence (mm) | Failure Mode | ||||

|---|---|---|---|---|---|

| Number | Paint Coating Bulging | Web Buckling | Flange Buckling | Flange-to-end Plate Weld Fracture | |

| L1 | 17 | 33 | Brittle fracture of welds | ||

| L2 | 19 | 36 | Brittle fracture of welds | ||

| L3 | 20 | 31 | 42 | 52 | Flexure yield |

| L4 | 21 | 32 | 44 | 55 | Flexure yield |

| L5 | 25 | 40 | 52 | 57 | Shear yield of web |

| L6 | 18 | 30 | Brittle fracture of welds | ||

| L7 | 26 | 41 | 54 | 57 | Shear yield of web |

| L8 | 24 | 35 | 47 | 51 | Shear yield of web |

| Number | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 |

|---|---|---|---|---|---|---|---|---|

| E | 0.91 | 1.00 | 1.59 | 1.98 | 1.57 | 0.78 | 1.68 | 1.66 |

| Number | Initial Stiffness KN/mm | Yield Load /kN | Yield Displacement /mm | Peak Load /kN | Limit Displacement /mm | Plastic Rotation Angle /rad |

|---|---|---|---|---|---|---|

| L1 | 9.0 | 93.3 | 12.4 | 218.8 | 32.8 | 0.07 |

| L2 | 16.1 | 155.3 | 10.8 | 314.4 | 32.2 | 0.08 |

| L3 | 16.2 | 190.0 | 14.0 | 276.0 | 35.5 | 0.10 |

| L4 | 15.9 | 192.3 | 15.6 | 319.4 | 53.7 | 0.15 |

| L5 | 19.0 | 286.8 | 17.9 | 420.0 | 47.5 | 0.14 |

| L6 | 26.7 | 288.5 | 13.4 | 441.2 | 31.3 | 0.09 |

| L7 | 19.1 | 288.4 | 19.2 | 462.6 | 57.7 | 0.16 |

| L8 | 26.4 | 194.4 | 11.1 | 515.0 | 45.3 | 0.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Z.; Feng, D.; Yang, W. Damage Analyses of Replaceable Links in Eccentrically Braced Frame (EBF) Subject to Cyclic Loading. Appl. Sci. 2019, 9, 332. https://doi.org/10.3390/app9020332

Yin Z, Feng D, Yang W. Damage Analyses of Replaceable Links in Eccentrically Braced Frame (EBF) Subject to Cyclic Loading. Applied Sciences. 2019; 9(2):332. https://doi.org/10.3390/app9020332

Chicago/Turabian StyleYin, Zhanzhong, Dazhe Feng, and Wenwei Yang. 2019. "Damage Analyses of Replaceable Links in Eccentrically Braced Frame (EBF) Subject to Cyclic Loading" Applied Sciences 9, no. 2: 332. https://doi.org/10.3390/app9020332

APA StyleYin, Z., Feng, D., & Yang, W. (2019). Damage Analyses of Replaceable Links in Eccentrically Braced Frame (EBF) Subject to Cyclic Loading. Applied Sciences, 9(2), 332. https://doi.org/10.3390/app9020332