Abstract

This study presents a method that is based on the three-stage network Data Envelopment Analysis (DEA) to evaluate the sustainability of packaging systems for a product. This method facilitates the selection of better product packaging alternatives from an environmentally friendly point of view and it comprises the following four steps: (i) the definition of packaging sustainability indicator (PSI) based on environmental efficiency and impact indicator of three-stage in packaging life cycle, (ii) modeling a three-stage Network DEA model for a packaging system, (iii) computing PSI based on the DEA model, and (iv) result analysis. An empirical test has been progressed to prove the feasibility of the proposed method by selecting the three types of milk packaging systems. The results indicated that the PSI value of PrePack is the maximum and the Tetra Pak minimum. According to these results, the study provides an environmentally friendly evaluation method for product packaging systems, which is more intuitive than Life Cycle Assessment (LCA).

1. Introduction

The packages, one of the significant elements in the development of economic and social, provide great convenience to consumers. At the same time, packaging wastes have a significant impact on the natural environment. The quantity of packages continues to surge, and the problems of excessive resource consumption and mounting environmental pollution have become increasingly acute. Therefore, how to choose a more environmentally friendly and sustainable packaging system for the goods has become an unshakable responsibility for packaging designers. The development of practical packaging system environmental impact assessment technology is very urgent.

Packaging is a system for preserving the safety and quality of commercial products throughout the distribution chain to the consumer. The packaging system is a multi-level, multi-stage, multi-objective integrated system. There are interactions impacts and mutual coupling relationships between stages or departments on the sustainability evaluation for a packaging system. These potential impacts cannot be ignored for the evaluation of packaging systems. The sustainability evaluation methods of packaging system can be classified into the qualitative and quantitative method. The former mainly uses includes questionnaire or interview inquiry [1,2], and the latter mainly includes Life Cycle Assessment (LCA) or Analytic Hierarchy Process (AHP) [3]. LCA is playing an important role in quantitative assessing the environmental performance of the product packaging system [4,5,6,7,8]. Riccardo Accorsi et al. [4] used the LCA methodology to determine the environmental impacts categories on the bottled EVOO life cycle, and focused attention on packaging decisions. Yahya Saleh [5] used life cycle assessment (LCA) methodology to assess and compare the potential environmental impacts of some packaging materials used in beverage packages, such as glass, aluminum (Al), and polyethylene terephthalate (PET). Zhang Hai et al. [6] used the LCA methodology to compare the environmental life cycle impacts on three packaging films incorporating different active agents, such as silver nanoparticles, titanium dioxide nanoparticles, and a mixture of both. Zhang Hai et al. [7] conducted an LCA of the overall environmental performance of the food and packaging system and considered the effect of food loss reduction by using active packaging. Another study by Jay Singh et al. [8] discussed the environmental performance of transport packaging of liquid milk by the LCA method and compared the impact of different packaging systems. Although LCA quantifies the environmental efficiency of packaging systems in a more or less credible way, and the improved method of LCA is ongoing, it does not directly give a definite answer as to whether a packaging system is sustainable [9]. The other two obvious limitations of LCA methodology are that the accuracy of the evaluation results highly depended on the completeness of the data sets, and assumed that each stage of the packaging system is independent.

Data envelopment analysis (DEA) is a non-parametric technique for measuring the performance of decision-making units (DMUs) that use multiple inputs to produce multiple outputs. The principle is to evaluate the PSI of multiple packaging systems by approaching and fitting method (near the envelope surface). DMU is considered to be efficient when no other DMUs can produce more outputs with less or equal amounts of inputs. The underlying mathematical model is linear programming to determine the relative efficiencies of a set of functionally similar DMUs. Charnes et al. [10] originally proposed the first DEA model, known as the Charnes, Cooper and Rhoades (CCR) model. Ma Fei et al. [11] applied a Super-SBM DEA considering the undesirable outputs to measure the integrated transport efficiency (ITE) of 31 provinces in China during the period of 2009–2016. Fu Hai-ling et al. [12] studied the scale and efficiency of cassava planting using the output-oriented DEA model. However, conventional DEA deals with one-stage production processes, where the internal structure of the DMUs is not taken into account and each DMU as a “black box” by considering only the inputs consumed and outputs produced [13]. The Network DEA (NDEA) paradigm refers to multi-stage processes, where the underlying structure, which indicates the flow of the intermediate measures among the stages, plays a key role in the efficiency assessment [14,15,16].

The network DEA method is widely used in various fields. Ding man et al. [17] studied the efficiency of China’s listed commercial banks based on a three-stage process where the number of workers, operating expenses, and fixed assets are used to generate deposits and deposit taking of interbank in the first stage, and then the investment securities, loans, and due from banks are produced in the second stage by using the intermediate premiums as a resource. Those second stage outputs are then used as third stage input resources to output the net profit and normal loan rate. Wang Song ji et al. [18] measured the efficiency of supporting agriculture of China’s Rural Credit Cooperatives based on a two-stage process. In their paper, the first stage is called the operating activities process, which uses inputs of the number of workers and total assets to produce outputs of the balance of loans relating to agricultural supporting. Those first stage outputs are then used as second stage input resources to output the added value of primary industry and township enterprises, and rural per capita net income. Yang Guo-liang et al. [19] applied the two-stage Network DEA to 64 Chinese research universities and their evolution over the period of 2010–2013. However, An Qing-xian et al. [20] indicated that resource sharing exists, not only among multiple entities, but also among various stages of a single network structure system. They integrate cooperative game theory with network data envelopment analysis (DEA) to explore the payoff allocation problem in a three-stage system. Li Feng et al. [21] improved the two-stage network DEA methodology to determine the relative efficiency while taking the internal structure and possible allocated costs into account. Recently, some further studies of DEA method have begun to involve sustainability. The same two-stage process has been applied in environmental sustainability evaluation contexts (Reza Kiani Mavi [22]; Chen Lei [23]; Alireza Tajbakhsh [24]; and, many others). More detailed reviews of DEA method applying in sustainability can be seen in Haibo Zhou et al. [25].

Packaging systems have multi-stage characteristics throughout the overall life cycle, so that the conventional DEA has poor applicability to the packaging system. In this paper, first, the overall packaging system life cycle has been divided into three stages. Subsequently, a three-stage NDEA model is constructed to compute the PSI. The PSIs have been used to evaluate the environmentally friendly of the packaging system in its overall life cycle, and the ideal results are obtained. Finally, we use the PSI to make an empirical study on the environmental performance of three types of milk packaging system and obtain satisfactory results.

2. Terminology

2.1. Packaging Sustainability Indicator (PSI)

In fact, PSI includes three aspects: social sustainability, economic sustainability, as well as environmental sustainability. The impact of social and economic sustainability is an important part of the PSI, but it is difficult to quantify the social sustainability index and some economic sustainability index of packaging system directly. Accordingly, in this study, we do not consider the social and economic sustainability implications, just verifying the feasibility of the three-stage Network DEA model by evaluating environmental sustainability, and future research will increase the impact of social and economic sustainability.

In terms of environmental sustainability, PSI represents the level of resource consumption and environmental emissions throughout the packaging life cycle, which measures how well three-stage inputs (consumption of resource and energy as well as environmental emissions) and outputs (recycling rate, etc.). In our study, PSI will be defined as the sum of environmental efficiency weighted for each stage in the packaging life cycle, (stage p = 1, 2, 3).

2.2. Environmental Efficiency

In our study, environmental efficiency, which is a key measure to compare the environmental performance in a single-stage, demonstrates the level of multiple resources and energy consumption and environmental emissions at each stage of the packaging system to reflect the environmental score. Ep is denoted as environmental efficiency in stage p, where p = 1, 2, 3.

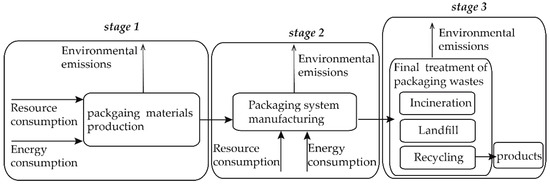

2.3. Impact Weight

The environmental impacts of packaging system were divided into two parts, one of which is the consumption of resources and energy and the other is the environmental discharge during the entire life process. The impact weight refers to the ratio of single-stage environmental impact to the overall life cycle environmental impact. In this paper, the production of packaging materials, the manufacturing of the packaging system, and the final treatment of packaging wastes after consumption are considered. In the final stage, the three treatments, landfill, incineration, and recycling, are also taken into account. Weights of post-consumption materials (used packages) for recycling and reusing are also included in this stage, as outlined in Figure 1.

Figure 1.

The system boundary of three-stage for packaging system.

Here, wp (stage p = 1, 2, 3) represents the impact weight of each stage and computed by the ratio of the input and unintended output (environmental emissions) in each stage to the total value of the entire system, including the input and unintended output (environmental emissions).

3. Modeling

3.1. Nomenclatures

We use the following notation to describe the three-stage Network DEA model. Suppose that there are n DMUs denoted by DMUj (j = 1, …, k, …, n; DMUk is denoted as the kth unit to be evaluated, k ϵ j), and that for each DMUj:

In the stage 1, there are i1 (i1 = 1, …, m1) relevant resource consumes as inputs, denoted by = (, , …, )T, product d1 (d1 = 1, …, D1) desirable outputs as intermediate variable, denoted by = (, , …, )T and ( = 1, …, ) environmental emission as undesirable outputs, denoted by = (, , …, )T.

In the stage 2, the desirable outputs from stage 1 are applied into the stage 2 sub-DMU as internal inputs, with i2 (i2 = 1, …, m2) external inputs = (, , …, )T to obtain d2 (d2 = 1, …, D2) desirable outputs, denoted by = (, , …, )T and ( = 1, …, ) undesirable outputs, denoted by = (, , …, )T.

In the stage 3, the desirable outputs from stage 2 were served as internal input resources in the stage 3 sub-DMU to obtain ( = 1, …, ) undesirable outputs, denoted by = (, , …, )T, and r (r = 1, …, s) desirable outputs denoted by = (, , …, )T, which go back to the circulation of the packaging system.

3.2. Three-Stage Network DEA Model

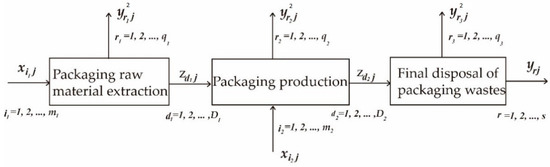

In this section, the dual-role factors of the resource consumption and environmental emissions in packaging systems are incorporated into the additive network DEA model proposed by I.M. Premachandra and Joe Zhu. (2016) [26]. Consider the structure illustrated in Figure 2.

Figure 2.

The three-stage Network data envelopment analysis (DEA) model for the evaluation packaging systems.

The above Figure 2 illustrates a three-stage network process situation of the packaging system, where each DMU is composed of three sub-DMUs in cascades, and the undesirable environmental emissions from three sub-DMUs are converted into inputs as the resources consumption in another form. According to the characteristics of the packaging system, the external resources inputs are added in stage 2 sub-DMU. Subsequently, we build the output-oriented additive three-stage Network DEA model (multiplier model) that aims to maximize the level of PSI given the current level of resource consumes.

3.3. Additive Three-Stage Network DEA Model

In this section, we will discuss the environmental efficiency of the sub-DMUs in the three stages. Thus, we propose to combine the three stages in a weighted sum of efficiency scores of stages 1, 2, and 3 as the PSI of the three stages under a constant return to the scale (CRS), which can be written as follows:

Main function: (computing the maximum PSI)

where, w1, w2, and w3 denote the impact weights of sub-DMUs in the first, second, and third stages, respectively, such that w1 + w2 + w1 = 1. E1, E2, and E3 denote the environmental efficiency of the sub-DMUs in stages 1, 2, and 3, respectively.

Environmental efficiency: (Ep in stage 1, 2, 3)

Here, relevant enterprises or departments should pay for environmental emissions in the overall life cycle of the packaging system. Since the subsequent treatment of environmental emissions has little impact on the packaging system, it is not included within the system boundaries of the packaging system. Thus, all environmental emissions of DMUk being assessed are converted into input metrics as the consumption in another form of stage 1 sub-DMU.

As above, all environmental emissions of DMUk being assessed are converted into input indexes as the consumption in another form of stage 2 sub-DMU. The process output indexes of stage 1 sub-DMU are also used as internal input indexes for stage 2 sub-DMU and are recorded as intermediate variables.

Similarly, all environmental emissions of DMUk being assessed are converted into input indexes as the consumption in another form of stage 3 sub-DMU, and the process output indexes of stage 2 sub-DMU are also used as internal input indexes for stage 3 sub-DMU, which are recorded as intermediate variables.

Where:

In the above model, (i1 = 1, …, m1), (i2 = 1, …, m2) ≥ 0: are unknown relative weights attached to external inputs , , respectively.

( = 1, …, ), ( = 1, …, ), ( = 1, …, ) ≥ 0: are unknown relative weights attached to undesirable outputs , , , respectively.

(d1 = 1, …, D1), (d2 = 1, …, D2) ≥ 0: are unknown relative weights attached to intermediate variables , , respectively.

(r = 1, …, s) ≥ 0: are unknown relative weights attached to desirable outputs .

Impact weight: (wp in stage 1, 2, 3).

We use w1, w2, and w3 to represent the relative importance or contribution of the efficiency of each stage to the overall sustainability of the given DMU in the whole process.

w1: The ratio of the sum of resource consumption and environmental emissions in stage 1 sub-DMU to the sum of the total inputs of the three stages (including all the resource consumption, environmental emissions, and intermediate variables) is denoted as the impact weight of stage 1 sub-DMU.

where TI represents the total amounts of input resources consumed by the whole packaging systems, which can be denoted by

w2: That the ratio of the sum of resource consumption, environmental emissions, and intermediate variables (from stage 1 sub-DMU to stage 2 sub-DMU) in stage 2 sub-DMU to the sum of the total inputs of the three stages (including all the resource consumption, environmental emissions, and intermediate variables) is denoted as the impact weight of stage 2 sub-DMU.

w3: That the ratio of the sum of all inputs (including all the resource consumption, environmental emissions, and the intermediate variables from stage 2 sub-DMU) in stage 3 sub-DMU to the sum of the total inputs of the three stages (including all the resource consumption, environmental emissions, and intermediate variables) is denoted as the impact weight of stage 3 sub-DMU.

Substituting Equations (2)–(4) of Ep and Equations (5)–(7) of wp into Equation (1) for simplification to obtain fractional model (9) of PSI. Equation (10) is all the restrictions to compute the PSI, also is the restrictions to compute Ep of each stage (p = 1, 2, 3), as follows:

Boundary constraints in Equations (9) and (10):

The above model is a nonlinear program, and we need to transform it into a standard linear program by applying the Charnes–Cooper transformation, let

The above fractional model (9) and (10) can be transformed into the following linear model (12) and (13) based on Equation (11), the result is as follows:

By simplifying Equation (11), we can get:

Boundary constraints in Equation (12) and (13):

By simplifying Equation (6) based on Equation (11), we can also get the new TI (TIn):

Once we obtain an optimal solution to linear model (12) and (13), the PSI for the three-stage network processes can be calculated accordingly. However, because of the linear systems Equations (12) and (13) has multiple unknown variables, so the linear model may have multiple optimal solutions, the respective Ep of the sub-DMUs may not be unique. Therefore, we can choose a set of multipliers based on three sub-DMUs that produce the highest first or second or third stage Ep while maintaining the PSI of the whole network processes. In addition, minimizing the efficiency gap between the three sub-DMUs in the three stages is also a standard strategy for choosing multipliers [27].

There is the environmental efficiency in stage 1, 2, and 3, respectively (Ep in stage 1, 2, 3): simplify by the Charnes–Cooper transformation, we also can get Equations (13) and (15) in Stage 1 sub-DMU:

As above, we also can get Equations (13) and (16) in Stage 2 sub-DMU:

Similarly, we can get Equations (13) and (17) in Stage 3 sub-DMU:

The common constraint condition of all the environmental efficiency (Ep in stage 1, 2, 3):

3.4. Solving the Model

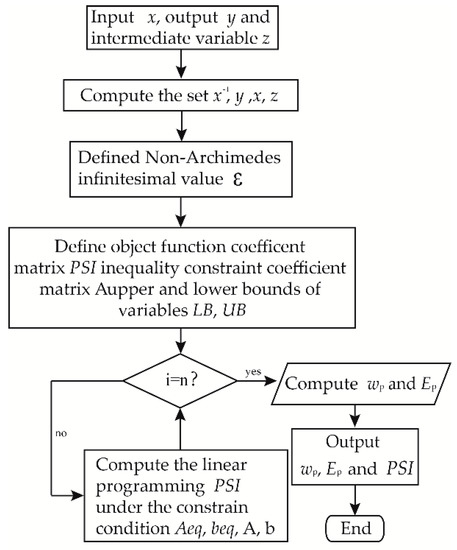

The above the three-stage Network DEA model (multiplier model) was solved using Matlab programming and implemented in MATLAB R2015b (free trial version). The programming flow chart is shown in Figure 3.

Figure 3.

The programing flows chart of three-stage network DEA (NDEA) model in MATLAB R2015b.

In Figure 3, input x is including resource consumes (, ) and the environmental emission (, , and ); output y is including the desirable outputs of the packaging system ; intermediate variable z is including the desirable outputs of stage 1 and stage 2 and , which also be served as the internal inputs of stage 2 and stage 3, respectively.

We can give the ranking of all the packaging systems based on the result of additive three-stage Network DEA. The higher the PSI value, the more sustainability of the packaging system. The wp can give us the information as to how much contribution does each sub-DMU make for the PSI, which can help the managers making the measures and suggestions specifically and accurately to improve the PSI of packaging system. The result analysis of the three-stage Network DEA model is as follows:

If PSI = 1, then the evaluated unit “k” (DMUk) is sustainability efficiency DMU; If PSI < 1, then the evaluated unit “k” (DMUk) is sustainability inefficiency DMU, and PSI = w1∙E1+ w2∙E2 + w3∙E3, only if Ep is effective (Ep = 1, stage p = 1, 2, 3) in each stage lead to the PSI being effective in the whole packaging system (Impact weights: w1 + w2 + w3 = 1).

4. Empirical Tests

In this section, we perform empirical tests to demonstrate the applications of our model. In order to test the feasibility of the proposed model, the three-stage Network DEA model is employed to evaluate the relative-to-best environmental efficiency of five alternatives milk packaging system. In the section that follows, we will demonstrate the applications of our analytical model in evaluating the SPI for packaging systems.

4.1. Materials

In these empirical tests, assumed that there is 1000 L milk that needs packaging, and the DMUs are as follows (see Figure 4):

Figure 4.

The pictures of three types of packaging system come from China. (a) Composite box, (b) PrePack, (c) Tetra Pak.

Figure 4a shows the picture of the real products of composite box. The packaging materials of composite box is consisted of cardboard made in China, low density polyethylene (LDPE made in China), and auxiliary materials, and the structure is three-layers composite structure (print layer/cardboard/LDPE). Packaging 1000 L of milk needs 4000 stand-up composite box of 250 mL each. The primary data was based on the study carried out by Chinese researcher Qin et al. [28] and the CLCD-China-ECER 0.8 database. All the above these data represent average cardboard and LDPE industry information.

Figure 4b shows the picture of the real products of PrePack. The packaging materials of PrePack are made by LDPE film co-extrusion (made in China), and the structure is a three-layers composite structure. Packaging 1000 L of milk needs 5000 pouched PrePack of 200 mL each. The weight of the PrePack was measured and found 3.55 g and required 17.75 kg of polyethylene packaging in total. The primary data of PrePack was based on the study that was carried out by Chinese researcher Xie et al. [29] and Xie et al. [30]. These data represent average LDPE film industry information.

Figure 4c shows the picture of the real products of Tetra Pak. The packaging materials of Tetra Pak is consisted of cardboard (made in China), LDPE (made in China) and aluminum laminate (Al made in China). The structure is a six-layers composite structure (PE/cardboard-PE-Al-PE/PE). Packaging 1000 L of milk needs 1000 stand-up Tetra Pak, 1000 mL each. The weight of the Tetra Pak was measured and found to be 28.56. The 1000 L of milk required 28.56 kg of cardboard -PE-Al laminate and cardboard-PE-Al laminate was made from 21.93 kg cardboard, 5.29 kg polyethylene, and 1.34 kg aluminum foil. The primary data of Tetra Pak was also based on the study carried out by Chinese researcher Xie et al. [29] and Xie et al. [30]. All the above these data represent the average industry level. The detailed information of three types of packaging systems are shown in Table 1.

Table 1.

The basic information about decision-making units (DMUs).

In this section, we constructed two virtual DMUs using the cubic-Hermite interpolation function. The purposes are dual. On the one hand, when the number of DMUs is insufficient, adding virtual units can improve the accuracy of the model calculation and reduce errors. On the other hand, the evaluation results of virtual DMUs can provide directions for how to improve the inefficient DMU. The reason for choosing the cubic-Hermite interpolation function method is that it not only satisfies the same function value of the interpolation polynomial as the original function value, but also satisfies the derivative value at the node which is equal to the derivative value of the original function. The function of cubic-Hermite interpolation for n nodes (x1, x2, …, xn) is as follows [31]:

where k and j are the two nodes.

4.2. Input Data

The indexes of input and output of each stage as follows are selected based on the related study in the LCA method [28,29,30,32].

External input:

In the first stage, crude oil consumption is denoted as (j = 1, 2, 3, 4, 5), natural gas consumption is denoted as (j = 1, 2, 3, 4, 5);

In the second stage (external input), coal consumption is denoted as (j = 1, 2, 3, 4, 5), the electricity consumption of packaging technology equipment (die cutting and blow molding) is denoted as (j = 1, 2, 3, 4, 5); the origin data of each index are shown in Table 2:

Table 2.

The indexes and origin data of external input.

4.3. Output Data

Undesired output (environmental emissions):

- In first phase, CO2 emissions is denoted as (j = 1, 2, 3, 4, 5);

- In second phase, CO2 emissions is denoted as (j = 1, 2, 3, 4, 5);

- In third phase, CO2 emissions is denoted as (j = 1, 2, 3, 4, 5);

Desired output: In third phase, recycled materials is denoted as (j = 1, 2, 3, 4, 5); the origin data of each index are shown in Table 3:

Table 3.

The indexes and origin data of desired output and undesired output.

4.4. Intermediate Variable

The intermediate variable: the intermediate variable from the first stage to the second stage is the packaging materials output, denoted as (j = 1, 2, 3, 4, 5), and the intermediate variable from the second stage to the third stage is the package quantity, denoted as (j = 1, 2, 3, 4, 5); the origin data of each index are shown in Table 4:

Table 4.

The indexes and origin data of intermediate variable.

4.5. Data Collection and Computation

In this section, the proposed methodology is applied to evaluate the environmental sustainability of milk packages, the data of which has been collected from the published article and CLCD-China-ECER 0.8 database. The data used for packaging sustainability indicator model based on the three-stage Network DEA method are given in Table 5.

Table 5.

The original data of five types of DMUs in the three-stage Network DEA model.

This research uses MATLAB R2015b (free trial version) to program. The computed results are shown in Table 6 and Table 7.

Table 6.

The results of impact weight (wp) about five types of DMUs.

Table 7.

The results of packaging sustainability indicator (PSI) and Ep about five types of DMUs.

5. Result and Discussion

Table 6 shows the results of impact weight (wp) about five types of DMUs. The value of wp indicates the contribution level of Ep for PSI. In Table 6, the contribution level of Ep for PSI will increase with the wp increase.

Table 7 shows the results of packaging sustainability indicator and environmental efficiency of five packaging systems in the three-stage Network DEA model. The packaging sustainability indicator of PrePack (DMU1) is the largest, up to 1, while the Tetra Pak (DMU5) come second after PrePack (DMU1), whereas the Composite box (DMU3) is found to have the lowest PSI, just 0.66. When compared with LCA method, the evaluation results of the three-stage Network DEA model and the ranking are consistent [28,29].

For plastic packaging, the fossil fuels category presents the largest contribution by the raw material from crude oil. Approximately 99% of the plastics produced today are petroleum-based, and the packaging industry alone consumes over 38% of these plastics [33]. However, PrePack has less demand for resources and energy. The production technology of PrePack is simple by three-layer low-density polyethylene coextrusion. Therefore, PrePack is the more sustainable one compared to other packaging systems. As we all know, there needs a fixed cost for a series of packaging production equipment to normal work.

For Tetra Pak, the application widely and large batch production made lower resource consumption of unit package relative to other packaging systems. For the Composite box (DMU3), it is usually on a small scale, resulting in a higher resource consumption per unit package relative to other packaging systems. Tetra Pak and composite box are multi-layer (PE/cardboard-PE-Al-PE/PE and PA/cardboard/PE) composite materials and complexity production technology, but the recycle rate of Tetra Pak is up to 47%, causing the environmental burden to be reduced in packaging wastes treatment.

In terms of environmental efficiency, E3 of the Composite box (DMU3) equals 0.0816 in the stage of packaging wastes treatment. E2 of Tetra Pak (DMU5) equals 0.4097 in packaging system manufacturing, less than 1(inefficient). We can base on interpolation DMU4 to improve the inefficient DMU3, by adding the recycling rate of DMU3 and reducing CO2 emission, while based on interpolation DMU4 to improve the Tetra Pak (DMU5), by reducing the weight of single layer and the number of layers. They imply that the main sources of inefficiency are excessive resource consumption, CO2 emissions in the stage of packaging wastes treatment, and the rate of recycling and reusing shortfalls in the packaging system. An effective packaging waste management system is needed, since this waste not only uses up valuable resources but it also increases environmental pollution. As shown in Table 3, the weight of packaging wastes treatment is the largest in the three stages of the packaging systems.

Secondly, most manufacturers are quite capable of fulfilling engineering specifications to achieve satisfactory levels of packaging materials production and packaging system manufacturing at the first stage and second stage. However, many of them are less capable of utilizing the combinations of packaging recycling and cyclic utilization to reduce environmental impacts with good practical performances at the third stage (final treatment: recycling). Accordingly, the waste recycling managing level of government should be raised to a larger extent. Inside the government, the responsibilities of various departments should be defined. It is better to set an effective recycling facility in public. Outside the government, the policy makers should set up a series of incentives, listen to the advice from citizens and enterprises frequently, and finally achieve the information exchanging between the government and the public. It means that environmental sustainability plays a significant role in packaging system evaluation.

From the above, when compared with LCA method, the evaluation results and the ranking of three-stage Network DEA model are consistent. However, the three-stage Network DEA method proposed by us considers the interaction and coupling between sub-DMU. The proposed model does not have strict requirements on data volume, and the evaluation results are very intuitive. What is more, we can get the information about which sub-DMU needs improvement clearly.

6. Conclusions

In this paper, PSI, a new indicator of packaging sustainability, is proposed to evaluate the environmental friendliness of the product packaging system. It normalizes the environmental efficiency of three stages into an index that made the evaluation result more intuitive to display the sustainability level of the packaging system. A three-stage Network DEA model was employed to assess the greenness level of the whole life cycle of packaging. The results of the empirical tests of three milk packaging show the feasibility of this method. In addition, the interpolation method is used to increase the data set of virtual DMU, which enhances the processing ability of the network DEA model under the condition of the insufficient data set.

Future work integrating more attributes and indicators will be explored to increase the scope of greenness capturing within the green packaging assessment process as well as expanding the applicability and accuracy of the proposed approach.

7. Patents

A multi-stage network data envelopment analysis model for evaluating packaging sustainability indicator, The Intellectual Property Office of the People’s Republic of China, applicant: Hunan University of Technology, application number: 201811240051.6.

Supplementary Materials

The following are available online at http://www.mdpi.com/2076-3417/9/2/246/s1.

Author Contributions

The study model was conceived of and established by Y.X. and Y.G. Y.G., S.Z. and H.B. contributed significantly to the data collection and analysis. Y.G. and Z.L. integrated and organized the results. The authors contributed equally to writing the paper and through reading. The authors have read and approved the manuscript.

Funding

This research was funded by Green Packaging and Security Special Research Fund of China Packaging Federation grant number [2016ZBLY06].

Acknowledgments

The financial support by Green Packaging and Security Special Research Fund of China Packaging Federation (2016ZBLY06) is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| DEA | Data Envelopment Analysis; |

| PSI | Packaging Sustainability Indicator; |

| LCA | Life Cycle Assessment; |

| AHP | Analytic Hierarchy Process; |

| Al | aluminum laminate; |

| PET | polyethylene terephthalate; |

| DMUs | decision-making units; |

| CCR | Charnes, Cooper and Rhoades; |

| NDEA | Network DEA; |

| Ep | environmental efficiency (stage p = 1, 2, 3); |

| wp | impact weight (stage p = 1, 2, 3); |

| CRS | constant return to the scale; |

| TI | the total amounts of input resources consumed by the whole packaging systems; |

| LDPE | low density polyethylene; |

| PE | polyethylene; |

| the nomenclature of three-stage Network DEA model are listed in Section 3 in detail. | |

References

- Orzan, G.; Cruceru, A.F.; Bălăceanu, C.T. Consumers’ Behavior Concerning Sustainable Packaging: An Exploratory Study on Romanian Consumers. Sustainability 2018, 10, 1787. [Google Scholar] [CrossRef]

- Hao, Y.; Liu, H.; Chen, H.J.; Sha, Y.H. What affect consumers’ willingness to pay for green packaging? Evidence from China. Resour. Conserv. Recycl. 2019, 141, 21–29. [Google Scholar] [CrossRef]

- Yang, J.; Li, H.L.; School, B. Evaluation of Green Degree for Packaging Industry in China Based on Fuzzy Analytic Hierarchy Process. Ecol. Econ. 2018, 34, 78–82. [Google Scholar]

- Accorsi, R.; Versari, L.; Manzini, R. Glass vs. Plastic: Life Cycle Assessment of Extra-Virgin Olive Oil Bottles across Global Supply Chains. Sustainability 2015, 7, 2818–2840. [Google Scholar] [CrossRef]

- Saleh, Y. Comparative life cycle assessment of beverages packages in Palestine. J. Clean. Prod. 2016, 131, 28–42. [Google Scholar] [CrossRef]

- Zhang, H.; Hortal, M.; School, B. Selection of nanomaterial-based active agents for packaging application: Using life cycle assessment (LCA) as a tool. Packag. Technol. Sci. 2016, 30, 575–586. [Google Scholar] [CrossRef]

- Zhang, H.; Hortal, M.; Dobon, A. The effect of active packaging on minimizing food losses: Life cycle assessment (LCA) of essential oil component-enabled packaging for fresh beef. Packag. Technol. Sci. 2015, 28, 761–774. [Google Scholar] [CrossRef]

- Singh, J.; Krasowski, A.; Singh, S.P. Life cycle inventory of HDPE bottle-based liquid milk packaging systems. Packag. Technol. Sci. 2011, 24, 49–60. [Google Scholar] [CrossRef]

- Wever, R.; Vogtländer, J. Eco-efficient value creation: An alternative perspective on packaging and sustainability. Packag. Technol. Sci. 2013, 26, 229–248. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision-making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Ma, F.; Wang, W.L.; Sun, Q.P.; Liu, F. Integrated Transport Efficiency and Its Spatial Convergence in China’s Provinces: A Super-SBM DEA Model Considering Undesirable Outputs. Appl. Sci. 2018, 8, 1698. [Google Scholar] [CrossRef]

- Fu, H.L.; Qu, Y.; Pan, Y. Efficiency of Cassava Production in China: Empirical Analysis of Field Surveys from Six Provinces. Appl. Sci. 2018, 8, 1356. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S. Network DEA. Socio-Econ. Plan. Sci. 2000, 34, 35–49. [Google Scholar] [CrossRef]

- Saen, R.F. Developing a new data envelopment analysis methodology for supplier selection in the presence of both undesirable outputs and imprecise data. Int. J. Adv. Manuf. Technol. 2010, 51, 1243–1250. [Google Scholar] [CrossRef]

- Tone, K.; Tsutsui, M. Network DEA: A slacks-based measure approach. Eur. J. Oper. Res. 2009, 197, 243–252. [Google Scholar] [CrossRef]

- Lewis, H.F.; Sexton, T.R. Network DEA: Efficiency analysis of organizations with complex internal structure. Comput. Oper. Res. 2004, 31, 1365–1410. [Google Scholar] [CrossRef]

- Wang, S.J.; Li, Y.; Tuo, M.Y. The Evaluation of Rural Credit Cooperatives’ Agricultural Efficiency Under the Background of Reform for 40 Years—Based on the Calculation and Analysis of the Network DEA Method. J. Financ. Dev. Res. 2018, 12, 69–76. (In Chinese) [Google Scholar] [CrossRef]

- Ding, M.; Ma, C.Q.; Zhou, Z.B.; Liu, D.B. Research on the Efficiency of China’s Listed Commercial Banks Based on a Three-stage Additive DEA Model. Syst. Eng. 2013, 31, 19–26. (In Chinese) [Google Scholar]

- Yang, G.L.; Fukuyama, H.; Song, Y.Y. Measuring the inefficiency of Chinese research universities based on a two-stage network DEA model. J. Informetr. 2018, 12, 10–30. [Google Scholar] [CrossRef]

- An, Q.X.; Wen, Y.; Ding, T.; Li, Y.L. Resource sharing and payoff allocation in a three-stage system: Integrating network DEA with the Shapley value method. Omega 2018. [Google Scholar] [CrossRef]

- Li, F.; Zhu, Q.Y.; Chen, Z. Allocating a fixed cost across the decision-making units with two-stage network structures. Omega 2018, 83, 139–154. [Google Scholar] [CrossRef]

- Mavi, K.M.; Saen, R.F.; Goh, M. Joint analysis of eco-efficiency and eco-innovation with common weights in two-stage network DEA: A big data approach. Technol. Forecast. Soc. 2018. [Google Scholar] [CrossRef]

- Chen, L.; Lai, F.J.; Wang, Y.M.; Huang, Y. A two-stage network data envelopment analysis approach for measuring and decomposing environmental efficiency. Comput. Ind. Eng. 2018, 119, 388–403. [Google Scholar] [CrossRef]

- Alireza, T.; Elkafi, H. Evaluating sustainability performance in fossil-fuel power plants using a two-stage data envelopment analysis. Energy Econ. 2018, 74, 154–178. [Google Scholar] [CrossRef]

- Zhou, H.B.; Yang, Y.; Chen, Y.; Zhu, J. Data envelopment analysis application in sustainability: The origins, development and future directions. Eur. J. Oper. Res. 2017, 264, 1–16. [Google Scholar] [CrossRef]

- Premachandra, I.M.; Zhu, J.; Watson, J. Chapter 7 “Mutual Fund Industry Performance: A Network Data Envelopment Analysis Approach”. In Data Envelopment Analysis (International Series in Operations Research & Management Science); Price, C., Zhu, J., Eds.; Springer Science + Business Media: New York, NY, USA, 2016; Volume 2016, pp. 165–228. ISBN 978-1-4899-7684-0. [Google Scholar]

- Wu, J.; Zhu, Q.Y.; Ji, X.; Chu, J.F. Two-stage network processes with shared resources and resources recovered from undesirable outputs. Eur. J. Oper. Res. 2016, 251, 182–197. [Google Scholar] [CrossRef]

- Qin, F.X. Research of LCA in milk production. Dairy Sci. Technol. 2006, 29, 224–226. (In Chinese) [Google Scholar] [CrossRef]

- Xie, M.H.; Li, L.; Qiao, Q.; Sun, Q.H. A comparative study on milk packaging using life cycle assessment: From PA-PE-Al laminate and polyethylene in China. J. Clean. Prod. 2011, 19, 2100–2106. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, K.L.; Tan, H.H. LCA of Canned Potato Chip Packaging. Packag. J. 2015, 7, 1–6. (In Chinese) [Google Scholar] [CrossRef]

- Chand, A.K.B.; Viswanathan, P. A constructive approach to cubic Hermite Fractal Interpolation Function and its constrained aspects. Bit 2013, 53, 841–865. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, J.; Rao, P.V.M. Environmental Impact Assessment Framework for Product Packaging. Manag. Environ. Qual. 2017, 29, 499–515. [Google Scholar] [CrossRef]

- Rabnawaz, M.; Wyman, I. A roadmap towards green packaging: The current status and future outlook for polyesters in the packaging industry. Green Chem. 2017, 19, 4737–4753. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).