A Comparative Study of Regression Model and the Adaptive Neuro-Fuzzy Conjecture Systems for Predicting Energy Consumption for Jaw Crusher

Abstract

:1. Introduction

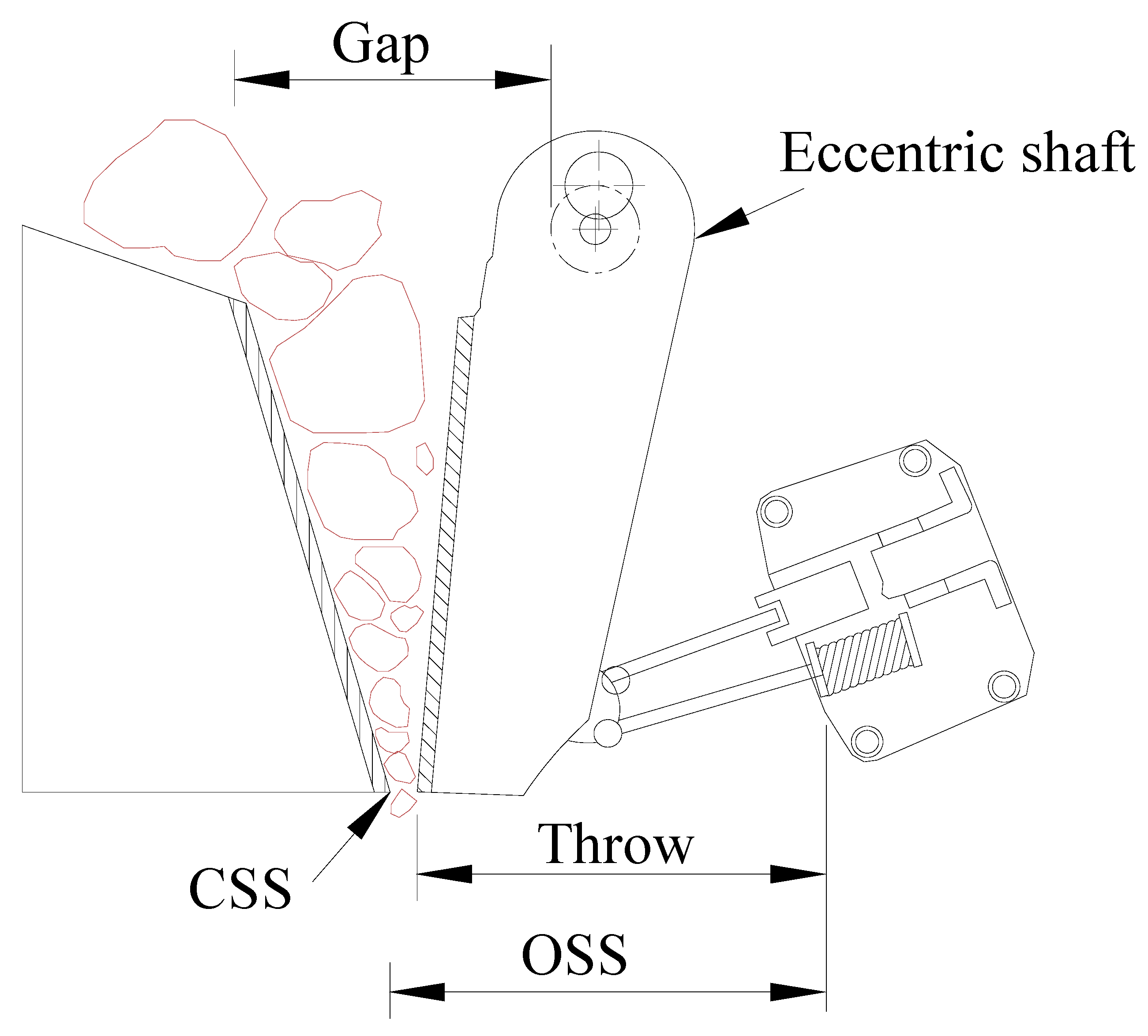

2. Materials and Methods

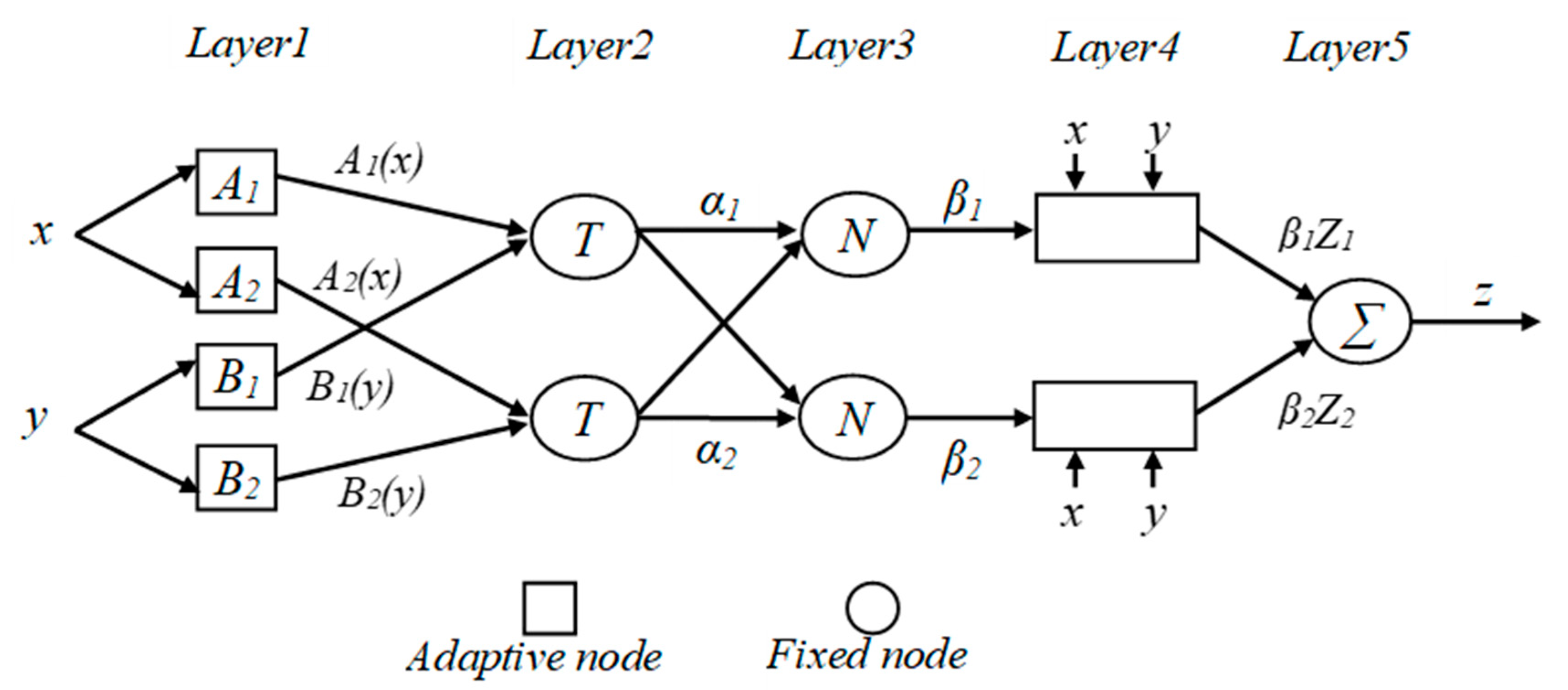

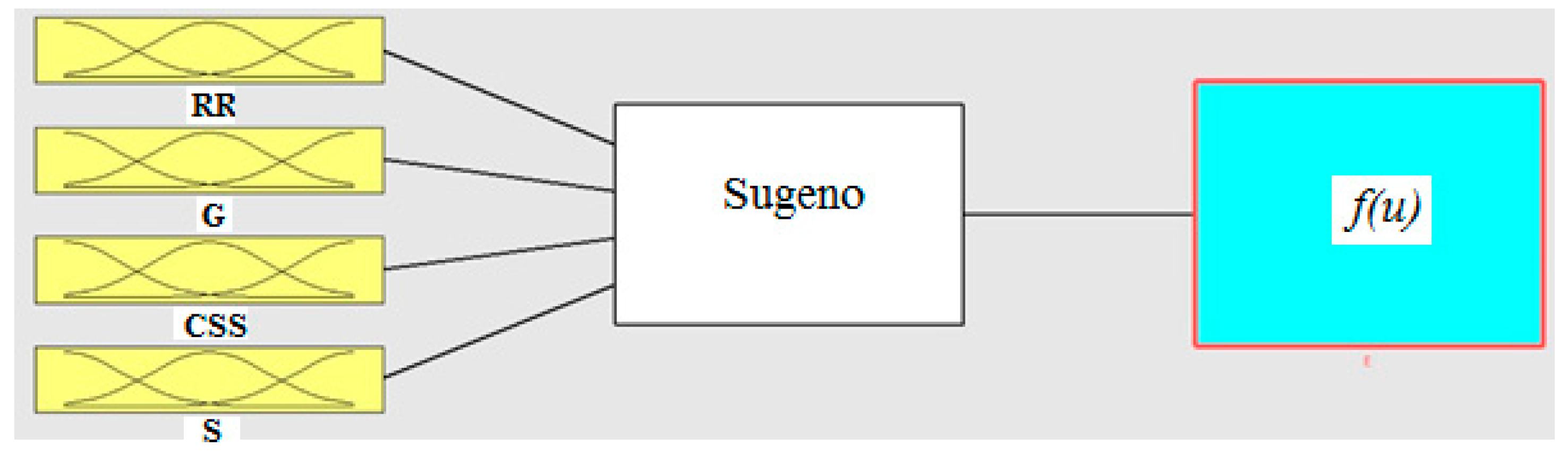

2.1. ANFIS Modeling

2.2. Multiple Regression Model

3. Results and Discussion

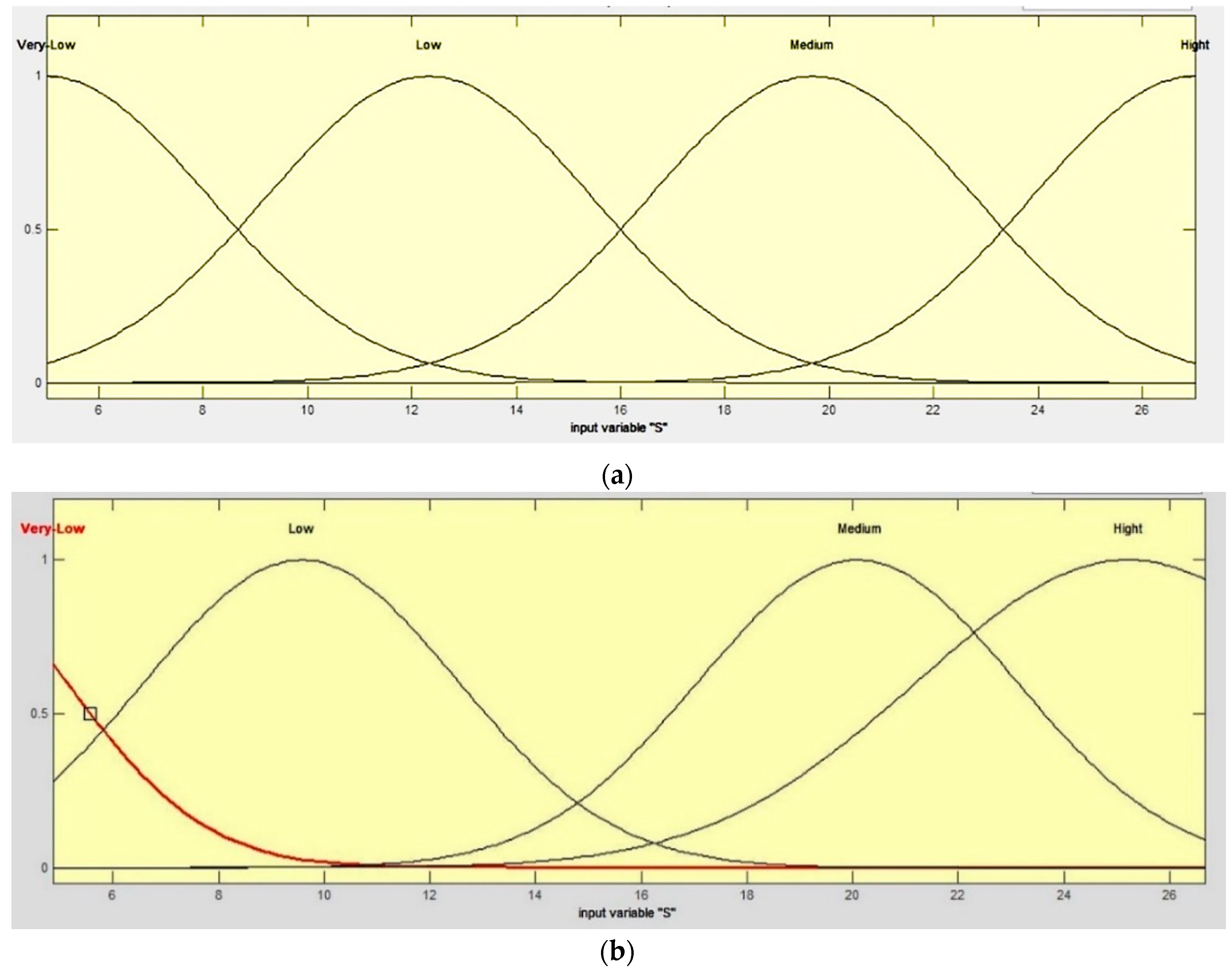

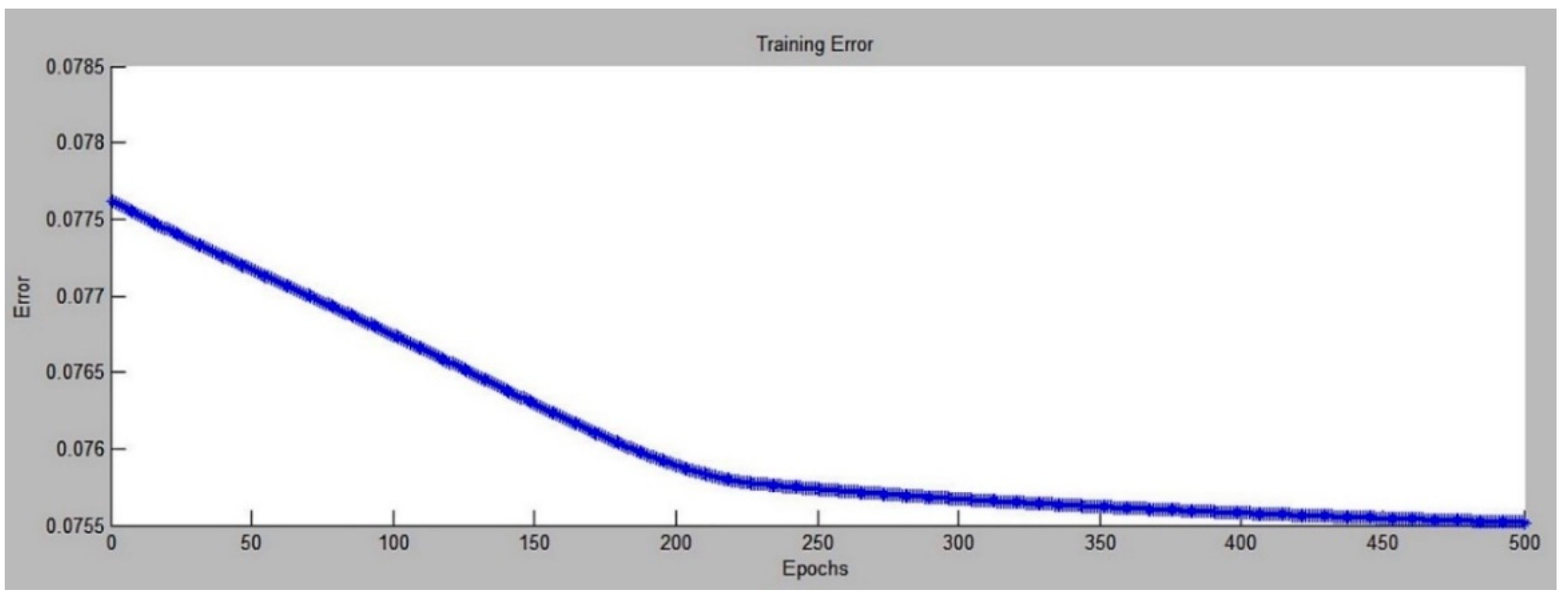

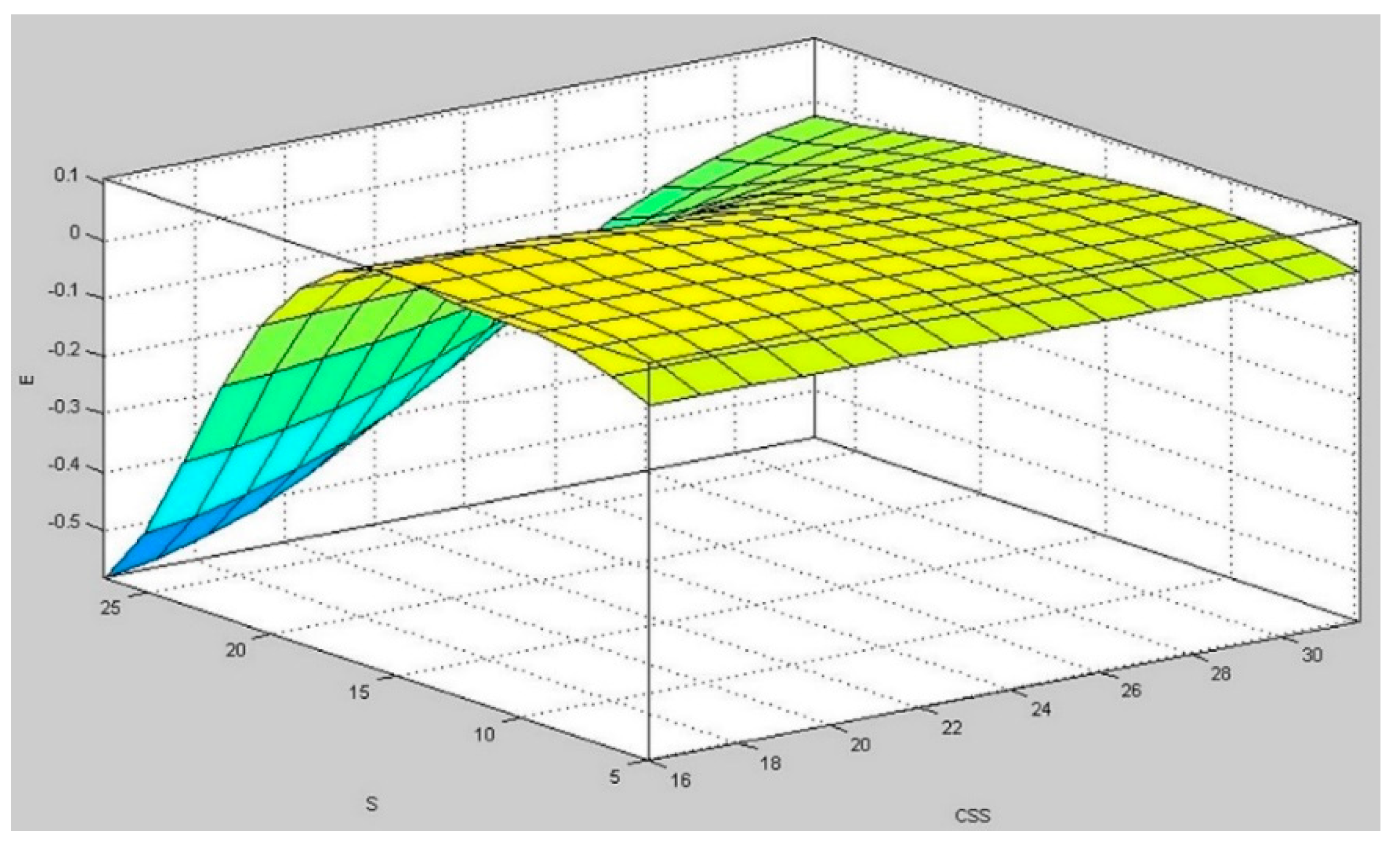

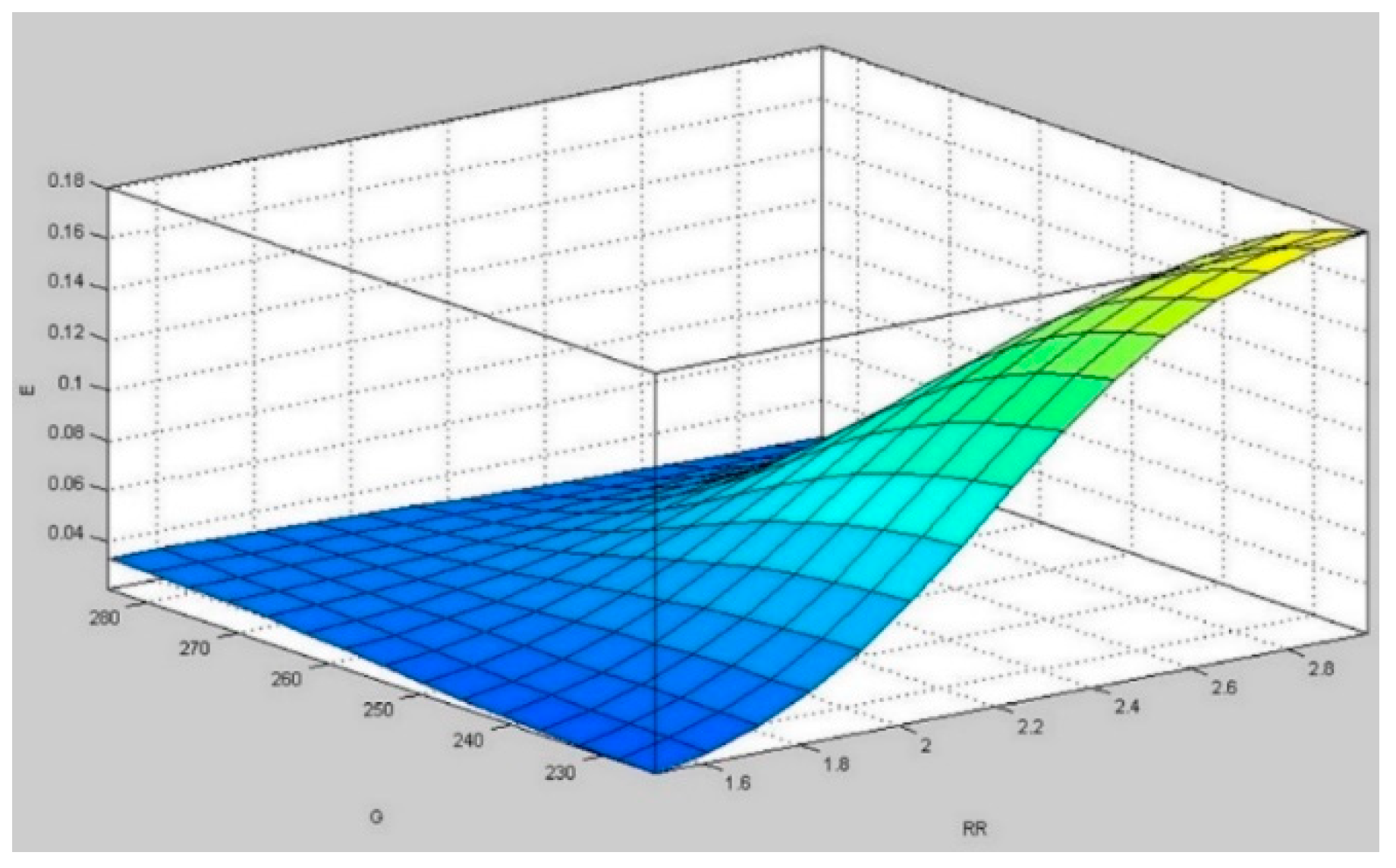

3.1. ANFIS Model

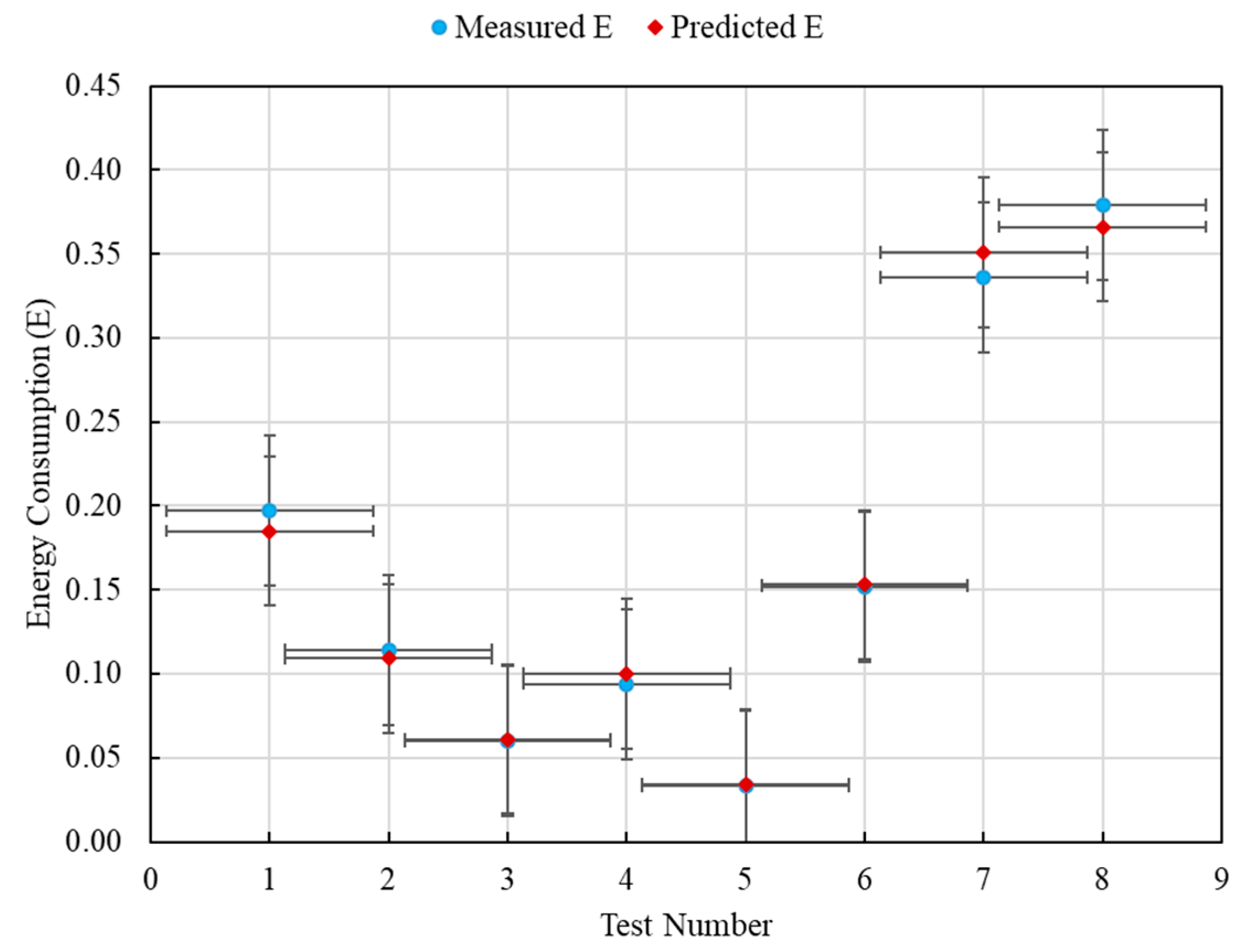

3.2. ANFIS Model Verification

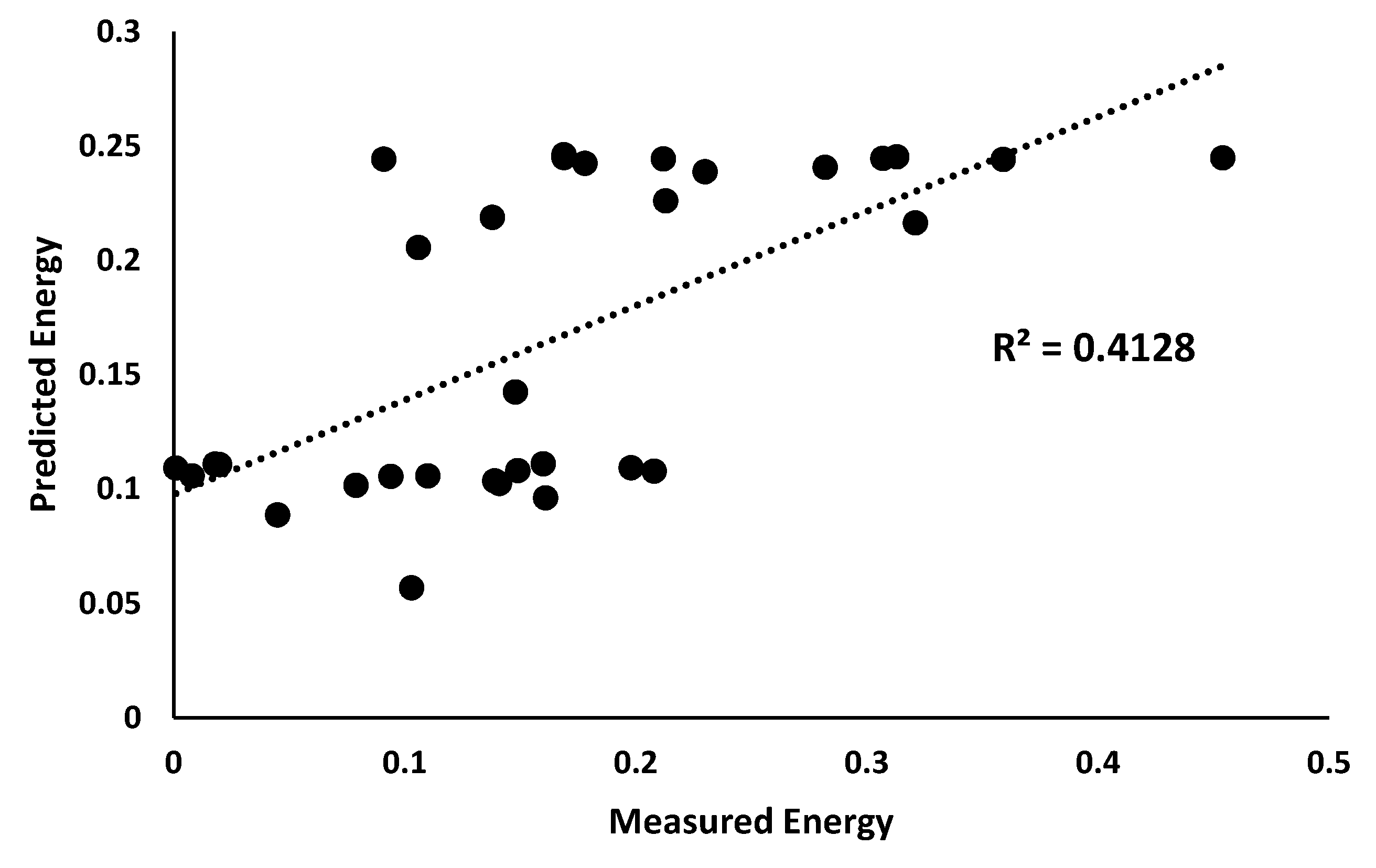

3.3. Working with the Regression Model

4. Conclusions

Conflicts of Interest

References

- Ashby, M.F.; Shercliff, H.; Cebon, D. Materials: Engineering, Science, Processing and Design; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- King, R.P. Modeling and Simulation of Mineral Processing Systems; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Indraratna, B.; Sun, Y.; Nimbalkar, S. Laboratory assessment of the role of particle size distribution on the deformation and degradation of ballast under cyclic loading. J. Geotech. Geoenviron. Eng. 2016, 142, 04016016. [Google Scholar] [CrossRef]

- Mwangi, P.N.u.; Muvengei, O.M.; Mbuya, T.O. Review of Discrete Element Modelling in Optimisation of Energy Consumption of a Single-Toggle Jaw Crusher. In Proceedings of the Sustainable Research and Innovation Conference, Juja, Kenya, 2–4 May 2018; pp. 51–259. Available online: http://sri.jkuat.ac.ke/ojs/index.php/proceedings/article/view/684 (accessed on 18 September 2019).

- Ulsen, C.; Tseng, E.; Angulo, S.C.; Landmann, M.; Contessotto, R.; Balbo, J.T.; Kahn, H. Concrete aggregates properties crushed by jaw and impact secondary crushing. J. Mater. Res. Technol. 2019, 8, 494–502. [Google Scholar] [CrossRef]

- Weiss, N. SME Mining Engineering Handbook, 3rd ed.; American Institute of Mining, Metallurgical and Petroleum Engineering Inc.: Littleton, CO, USA, 2002. [Google Scholar]

- Revuelta, M.B. Mineral Processing. In Mineral Resources; Springer: Berlin, Germany, 2018; pp. 423–530. [Google Scholar]

- Sarkar, S.; Kumar, R.; Murthy, V. Experimental and Numerical Simulation of Crack Propagation in Sandstone by Semi Circular Bend Test. Geotech. Geol. Eng. 2019, 37, 1–13. [Google Scholar] [CrossRef]

- Donovan, J.G. Fracture Toughness Based Models for the Prediction of Power Consumption, Product Size, and Capacity of Jaw Crushers; Virginia Tech: Blacksburg, VA, USA, 2003. [Google Scholar]

- Eloranta, J. The efficiency of blasting versus crushing and grinding. In Proceedings of the 23rd Conference of Explosives and Blasting Technique, Las Vegas, NV, USA, 2–6 February 1997. [Google Scholar]

- Bearman, R.; Barley, R.; Hitchcock, A. Prediction of power consumption and product size in cone crushing. Miner. Eng. 1991, 4, 1243–1256. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, Z.; Wang, H.; Li, G.; Sepehrnoori, K.; Wu, X.; Hong, C. Experimental study on the rock-breaking characteristics of abrasive liquid nitrogen jet for hot dry rock. J. Pet. Sci. Eng. 2019. [CrossRef]

- Bearman, R.T. Jaw and Impact Crushers. In SME Mineral Processing and Extractive Metallurgy Handbook; Society for Mining, Metallurgy, and Exploration, Inc.: Englewood, CO, USA, 2019; p. 367. [Google Scholar]

- Hofler, A.A. Fundamental Breakage Studies of Mineral Particles with an Ultrafast Load Cell Device. Ph.D. Thesis, University of Utah, Salt Lake City, UT, USA, 1992. [Google Scholar]

- Napier-Munn, T.J. Mineral Comminution Circuits: Their Operation and Optimization. Julius Kruttschnitt Mineral Research Centre: Indooroopilly, Australia, 1996. [Google Scholar]

- Svensson, A.; Steer, J. New cone crusher technology and developments in comminution circuits. Miner. Eng. 1990, 3, 83–103. [Google Scholar] [CrossRef]

- DeDiemar, R. New concepts in Jaw Crusher technology. Miner. Eng. 1990, 3, 67–74. [Google Scholar] [CrossRef]

- Legendre, D. Numerical and Experimental Optimization Analysis of a Jaw Crusher and a Bubble Column Reactor; Åbo Akademi University: Turku, Finland, 2019. [Google Scholar]

- Larison, B.W. Aggregate Production Modeling Using Neural Networks and Belief Networks. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 1999. [Google Scholar]

- Shi, J.J. Mathematical Models for Maximizing Aggregate Plant Production. J. Constr. Eng. Manag. 1999, 125, 53–60. [Google Scholar] [CrossRef]

- Halabian, A.M.; Shamsabadi, P.J. Numerical modeling of the RAP construction process and its effects on RAP behavior. Int. J. Geomech. 2014, 15, 04014085. [Google Scholar] [CrossRef]

- Sivacoumar, R.; Raj, S.M.; Chinnadurai, S.J.; Jayabalou, R. Modeling of fugitive dust emission and control measures in stone crushing industry. J. Environ. Monit. 2009, 11, 987–997. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Martin, U.; Rapp, S. Discrete element modeling of the single-particle crushing test for ballast stones. Comput. Geotech. 2017, 88, 61–73. [Google Scholar] [CrossRef]

- Karaboga, D.; Kaya, E. Adaptive network based fuzzy inference system (ANFIS) training approaches: A comprehensive survey. Artif. Intell. Rev. 2018, 1–31. [Google Scholar] [CrossRef]

- Kasabov, N.K. Foundations of Neural Networks, Fuzzy Systems, and Knowledge Engineering; Auckland University of Technology: Auckland, New Zealand, 1996. [Google Scholar]

- Fullér, R. Fuzzy systems. In Introduction to Neuro-Fuzzy Systems; Springer: Berlin, Germany, 2000; pp. 1–131. [Google Scholar]

- Maher, I.; Eltaib, M.; Sarhan, A.A.; El-Zahry, R. Cutting force-based adaptive neuro-fuzzy approach for accurate surface roughness prediction in end milling operation for intelligent machining. Int. J. Adv. Manuf. Technol. 2015, 76, 1459–1467. [Google Scholar] [CrossRef]

- Belegundu, A.D.; Chandrupatla, T.R. Optimization Concepts and Applications in Engineering; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Weigend, A.S. Time Series Prediction: Forecasting the Future and Understanding the Past; Routledge: London, UK, 2018. [Google Scholar]

- Cox, D.R. Analysis of Binary Data; Routledge: London, UK, 2018. [Google Scholar]

| No. | Reduction Ratios | Gape (mm) | CSS (mm) | Strength | Power Consumption kWh/t |

|---|---|---|---|---|---|

| 1 | 1.5 | 284 | 31.75 | 5.697 | 0.103 |

| 2 | 7.798 | 0.161 | |||

| 3 | 18.576 | 0.02 | |||

| 4 | 9.899 | 0.094 | |||

| 5 | 22.493 | 0.018 | |||

| 6 | 12.931 | 0.001 | |||

| 7 | 9.994 | 0.008 | |||

| 8 | 26.662 | 0.16 | |||

| 9 | 9.211 | 0.139 | |||

| 10 | 7.067 | 0.045 | |||

| 11 | 8.893 | 0.141 | |||

| 12 | 12.96 | 0.198 | |||

| 13 | 11.293 | 0.208 | |||

| 14 | 11.461 | 0.149 | |||

| 15 | 10.008 | 0.11 | |||

| 16 | 8.71 | 0.079 | |||

| 17 | 2.97 | 224 | 16 | 6.097 | 0.106 |

| 18 | 7.205 | 0.213 | |||

| 19 | 9.098 | 0.23 | |||

| 20 | 11.99 | 0.359 | |||

| 21 | 12.598 | 0.307 | |||

| 22 | 6.567 | 0.321 | |||

| 23 | 6.696 | 0.138 | |||

| 24 | 12.129 | 0.091 | |||

| 25 | 10.558 | 0.178 | |||

| 26 | 18.164 | 0.169 | |||

| 27 | 13.233 | 0.169 | |||

| 28 | 13.902 | 0.313 | |||

| 29 | 12.874 | 0.454 | |||

| 30 | 12.269 | 0.212 | |||

| 31 | 9.72 | 0.282 | |||

| 32 | 4.863 | 0.148 |

| Test No. | Parameters | Power Consumption kWh/t | Error (%) | ||||

|---|---|---|---|---|---|---|---|

| RR | Gape (mm) | CSS (mm) | S (MPa) | Measured E | Predicted E | ||

| 1 | 1.5 | 284 | 31.75 | 21.666 | 0.197 | 0.185 | 6.09 |

| 2 | 8.33 | 0.114 | 0.109 | 4.39 | |||

| 3 | 6.286 | 0.06 | 0.061 | 1.67 | |||

| 4 | 8.069 | 0.094 | 0.1 | 6.38 | |||

| 5 | 2.97 | 224 | 16 | 4.897 | 0.033 | 0.034 | 3.03 |

| 6 | 8.071 | 0.152 | 0.153 | 0.66 | |||

| 7 | 8.635 | 0.336 | 0.351 | 4.46 | |||

| 8 | 11.021 | 0.379 | 0.366 | 3.43 | |||

| Average Error | 3.76 | ||||||

| R2 | 0.9947 | ||||||

| Regression Statistics | Coefficient | ||

|---|---|---|---|

| Root Mean Squared Error | 0.086 | Intercept | b0 = −79.4983 |

| R2 | 0.413 | reduction ratios | b1 = −14.417, b2 = 0.30816 |

| Adjusted R2 | 0.35 | Gape | b3 = 0.7962, b4 = 0.9599 |

| p-value | 0.00169 | Css | b5 = −3.0399, b6 = 0.961 |

| Strength | b7 = 70.200, b8 = −4.117 | ||

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abuhasel, K.A. A Comparative Study of Regression Model and the Adaptive Neuro-Fuzzy Conjecture Systems for Predicting Energy Consumption for Jaw Crusher. Appl. Sci. 2019, 9, 3916. https://doi.org/10.3390/app9183916

Abuhasel KA. A Comparative Study of Regression Model and the Adaptive Neuro-Fuzzy Conjecture Systems for Predicting Energy Consumption for Jaw Crusher. Applied Sciences. 2019; 9(18):3916. https://doi.org/10.3390/app9183916

Chicago/Turabian StyleAbuhasel, Khaled Ali. 2019. "A Comparative Study of Regression Model and the Adaptive Neuro-Fuzzy Conjecture Systems for Predicting Energy Consumption for Jaw Crusher" Applied Sciences 9, no. 18: 3916. https://doi.org/10.3390/app9183916

APA StyleAbuhasel, K. A. (2019). A Comparative Study of Regression Model and the Adaptive Neuro-Fuzzy Conjecture Systems for Predicting Energy Consumption for Jaw Crusher. Applied Sciences, 9(18), 3916. https://doi.org/10.3390/app9183916