Improvement of ANFIS Model for Prediction of Compressive Strength of Manufactured Sand Concrete

Abstract

1. Introduction

2. Research Significance

3. Materials and Methods

3.1. Adaptive Neuro Fuzzy Inference System (ANFIS)

3.2. Teaching-Learning-Based Optimization (TLBO)

3.2.1. Initialization of the Population

3.2.2. Teacher Phase

3.2.3. Learner Phase

3.3. Principal Component Analysis (PCA)

- Preparation and normalization of inputs;

- Calculation of the covariance matrix;

- Calculation of the eigenvalues and eigenvectors;

- Estimation of the proportion of total variance of each principal component;

- Identification of the loading of principal components and contribution of inputs.

3.4. Collection of Data

3.5. Quality Assessment Criteria

4. Results and Discussions

4.1. PCA’s Results

4.2. Optimization Procedure: Determination of Optimal Population Size

4.3. Prediction Capability: Improvement of Single ANFIS

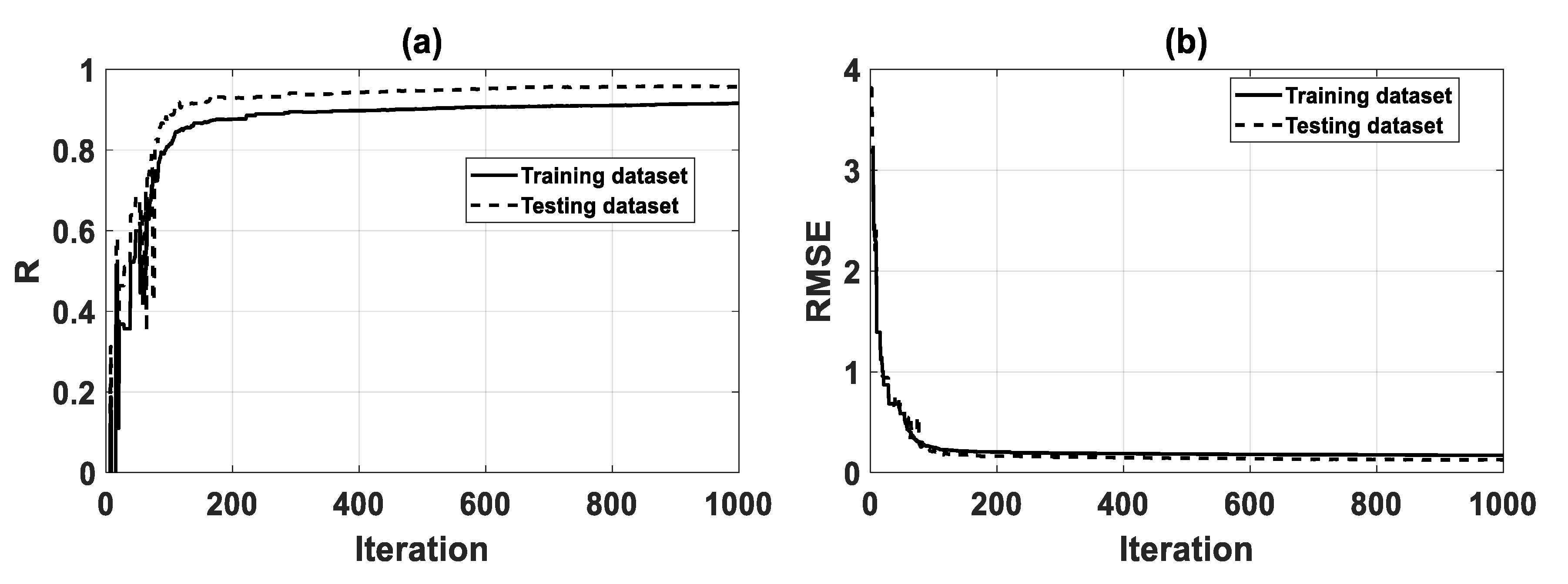

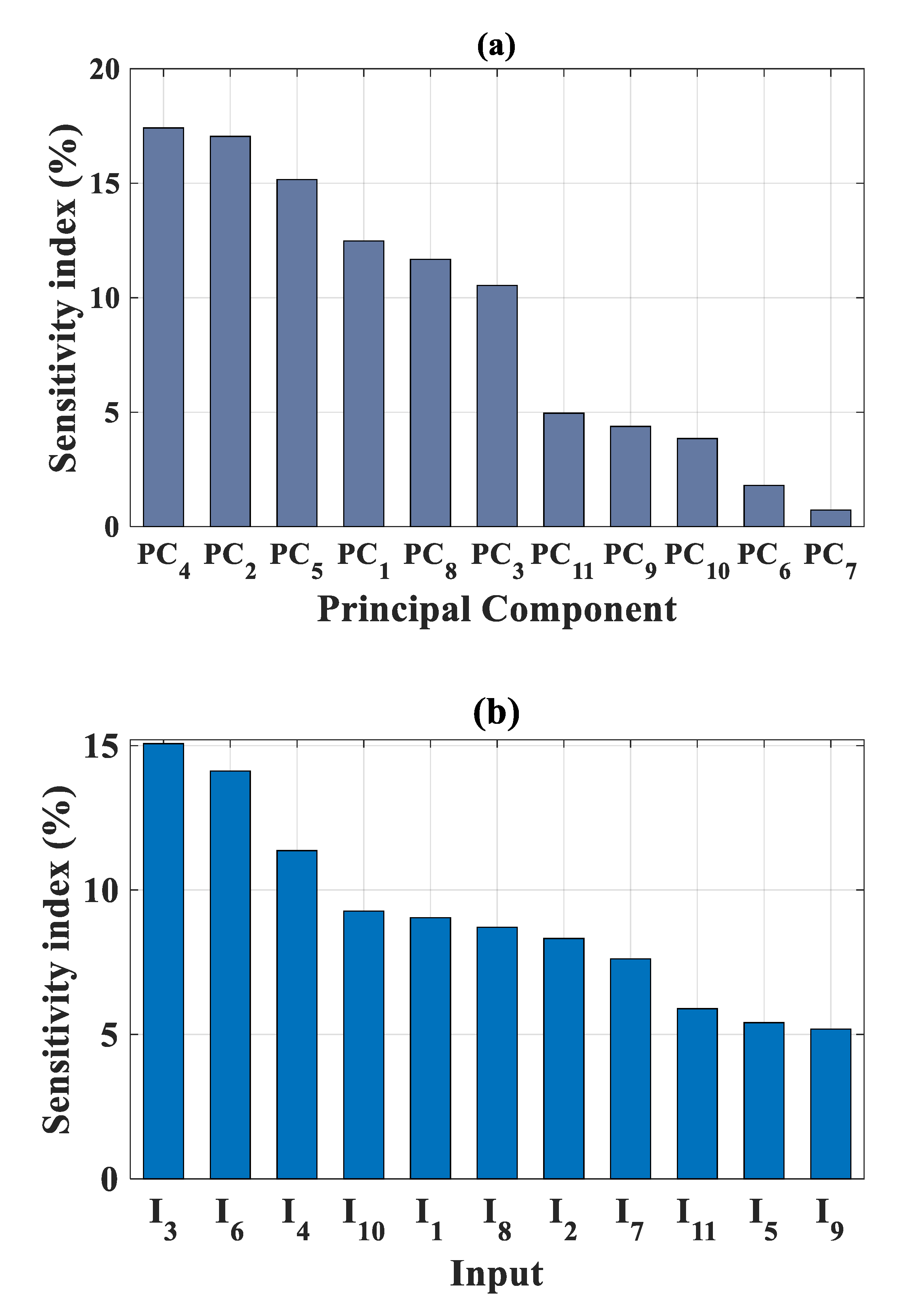

4.4. Sensitivity Analysis

4.5. Comparison with Existing Models in the Literature

5. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations

| Designation | Explanation |

| MSC | Manufactured Sand Concrete |

| ANFIS | Adaptive Neuro Fuzzy Inference System |

| ANN | Artificial Neural Networks |

| SVM | Support Vector Machine |

| FL | Fuzzy Logic |

| TLBO | Teaching-Learning-Based Optimization |

| PCA | Principal Component Analysis |

| PCk (k = 1:11) | Principal components |

| EV | Explained variance |

| CS | Cumulative sum |

| AI | Artificial Intelligence |

| R | Correlation Coefficient |

| RMSE | Root Mean Squared Error |

| MAE | Mean Absolute Error |

| Std | Standard deviation |

| Ii (I = 1:11) | Designation of inputs |

| Y | Designation of target |

References

- Nanthagopalan, P.; Santhanam, M. Fresh and hardened properties of self-compacting concrete produced with manufactured sand. Cem. Concr. Compos. 2011, 33, 353–358. [Google Scholar] [CrossRef]

- Ji, T.; Chen, C.-Y.; Zhuang, Y.-Z.; Chen, J.-F. A mix proportion design method of manufactured sand concrete based on minimum paste theory. Constr. Build. Mater. 2013, 44, 422–426. [Google Scholar] [CrossRef]

- Shen, W.; Yang, Z.; Cao, L.; Cao, L.; Liu, Y.; Yang, H.; Lu, Z.; Bai, J. Characterization of manufactured sand: Particle shape, surface texture and behavior in concrete. Constr. Build. Mater. 2016, 114, 595–601. [Google Scholar] [CrossRef]

- Swamy, R.N. The Alkali-Silica Reaction in Concrete; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Zhao, S.B.; Ding, X.X.; Li, C.Y. Bond-Slip Relation of Plain Steel Bar in Concrete with Machine-Made Sand. Available online: https://www.scientific.net/AMM.238.142 (accessed on 5 July 2019).

- Li, B.; Ke, G.; Zhou, M. Influence of manufactured sand characteristics on strength and abrasion resistance of pavement cement concrete. Constr. Build. Mater. 2011, 25, 3849–3853. [Google Scholar] [CrossRef]

- Gonçalves, J.; Tavares, L.; Filho, R.T.; Fairbairn, E.; Cunha, E. Comparison of natural and manufactured fine aggregates in cement mortars. Cem. Concr. Res. 2007, 37, 924–932. [Google Scholar] [CrossRef]

- Yamei, H.; Lihua, W. Effect of Particle Shape of Limestone Manufactured Sand and Natural Sand on Concrete. Procedia Eng. 2017, 210, 87–92. [Google Scholar] [CrossRef]

- Mundra, S.; Sindhi, P.; Chandwani, V.; Nagar, R.; Agrawal, V. Crushed rock sand—An economical and ecological alternative to natural sand to optimize concrete mix. Perspect. Sci. 2016, 8, 345–347. [Google Scholar] [CrossRef]

- Guan, M.; Liu, W.; Lai, M.; Du, H.; Cui, J.; Gan, Y. Seismic behaviour of innovative composite walls with high-strength manufactured sand concrete. Eng. Struct. 2019, 195, 182–199. [Google Scholar] [CrossRef]

- Guan, M.; Lai, Z.; Xiao, Q.; Du, H.; Zhang, K. Bond behavior of concrete-filled steel tube columns using manufactured sand (MS-CFT). Eng. Struct. 2019, 187, 199–208. [Google Scholar] [CrossRef]

- Li, B.; Wang, J.; Zhou, M. Effect of limestone fines content in manufactured sand on durability of low- and high-strength concretes. Constr. Build. Mater. 2009, 23, 2846–2850. [Google Scholar] [CrossRef]

- Shen, W.; Liu, Y.; Wang, Z.; Cao, L.; Wu, D.; Wang, Y.; Ji, X. Influence of manufactured sand’s characteristics on its concrete performance. Constr. Build. Mater. 2018, 172, 574–583. [Google Scholar] [CrossRef]

- Ding, X.; Li, C.; Xu, Y.; Li, F.; Zhao, S. Experimental study on long-term compressive strength of concrete with manufactured sand. Constr. Build. Mater. 2016, 108, 67–73. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.; Guo, C.; Wu, S.; Gao, X.; Peng, S. The physical and chemical impact of manufactured sand as a partial replacement material in Ultra-High Performance Concrete (UHPC). Cem. Concr. Compos. 2019, 99, 203–213. [Google Scholar] [CrossRef]

- Park, S. Study on the Fluidity and Strength Properties of High Performance Concrete Utilizing Crushed Sand. Int. J. Concr. Struct. Mater. 2012, 6, 231–237. [Google Scholar] [CrossRef]

- Donza, H.; Cabrera, O.; Irassar, E. High-strength concrete with different fine aggregate. Cem. Concr. Res. 2002, 32, 1755–1761. [Google Scholar] [CrossRef]

- Mak, S.L.; Torii, K. Strength development of high strength concretes with and without silica fume under the influence of high hydration temperatures. Cem. Concr. Res. 1995, 25, 1791–1802. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Hatzigeorgiou, G.D.; Karamani, C.; Skentou, A.; Zoumpoulaki, I.; Asteris, P.G. Soft computing-based techniques for concrete beams shear strength. Procedia Struct. Integr. 2019, 17, 924–933. [Google Scholar] [CrossRef]

- Yeh, I.-C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Asteris, P.G.; Ashrafian, A.; Rezaie-Balf, M. Prediction of the compressive strength of self-compacting concrete using surrogate models. 2019, 24, 137–150. Comput. Concr. 2019, 24, 137–150. [Google Scholar]

- Asteris, P.G.; Kolovos, K.G. Self-compacting concrete strength prediction using surrogate models. Neural Comput. Applic. 2019, 31, 409–424. [Google Scholar] [CrossRef]

- Sarir, P.; Chen, J.; Asteris, P.G.; Armaghani, D.J.; Tahir, M.M. Developing GEP tree-based, neuro-swarm, and whale optimization models for evaluation of bearing capacity of concrete-filled steel tube columns. Eng. Comput. 2019, 1–19. [Google Scholar] [CrossRef]

- Apostolopoulou, M.; Armaghani, D.J.; Bakolas, A.; Douvika, M.G.; Moropoulou, A.; Asteris, P.G. Compressive strength of natural hydraulic lime mortars using soft computing techniques. Procedia Struct. Integr. 2019, 17, 914–923. [Google Scholar] [CrossRef]

- Van Dao, D.; Ly, H.-B.; Trinh, S.H.; Le, T.-T.; Pham, B.T. Artificial Intelligence Approaches for Prediction of Compressive Strength of Geopolymer Concrete. Materials 2019, 12, 983. [Google Scholar]

- Dao, D.; Trinh, S.H.; Ly, H.-B.; Pham, B.T. Prediction of Compressive Strength of Geopolymer Concrete Using Entirely Steel Slag Aggregates: Novel Hybrid Artificial Intelligence Approaches. Appl. Sci. 2019, 9, 1113. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Behnood, A. Estimating the optimal mix design of silica fume concrete using biogeography-based programming. Cem. Concr. Compos. 2019, 96, 95–105. [Google Scholar] [CrossRef]

- Bingöl, A.F.; Tortum, A.; Gül, R. Neural networks analysis of compressive strength of lightweight concrete after high temperatures. Mater. Des. (1980–2015) 2013, 52, 258–264. [Google Scholar] [CrossRef]

- Mishra, M.; Bhatia, A.S.; Maity, D. A comparative study of regression, neural network and neuro-fuzzy inference system for determining the compressive strength of brick–mortar masonry by fusing nondestructive testing data. Eng. Comput. 2019, 1–15. [Google Scholar] [CrossRef]

- Bui, D.T.; Abdullahi, M.M.; Ghareh, S.; Moayedi, H.; Nguyen, H. Fine-tuning of neural computing using whale optimization algorithm for predicting compressive strength of concrete. Eng. Comput. 2019, 1–12. [Google Scholar] [CrossRef]

- Behnood, A.; Golafshani, E.M. Predicting the compressive strength of silica fume concrete using hybrid artificial neural network with multi-objective grey wolves. J. Clean. Prod. 2018, 202, 54–64. [Google Scholar] [CrossRef]

- Peng, C.-H.; Yeh, I.-C.; Lien, L.-C. Building strength models for high-performance concrete at different ages using genetic operation trees, nonlinear regression, and neural networks. Eng. Comput. 2010, 26, 61–73. [Google Scholar] [CrossRef]

- Tsai, H.-C.; Lin, Y.-H. Predicting high-strength concrete parameters using weighted genetic programming. Eng. Comput. 2011, 27, 347–355. [Google Scholar] [CrossRef]

- Yeh, I.-C. Optimization of concrete mix proportioning using a flattened simplex–centroid mixture design and neural networks. Eng. Comput. 2008, 25, 179–190. [Google Scholar] [CrossRef]

- Alipour, R.; Toghroli, A.; Mu’Azu, M.; Katebi, J.; Mohammadhassani, M.; Khalafi, S.; Mohamad, E.T.; Wakil, K.; Khorami, M. Computational optimized finite element modelling of mechanical interaction of concrete with fiber reinforced polymer. Comput. Concr. 2019, 23, 061. [Google Scholar]

- Asteris, P.G.; Nikoo, M. Artificial bee colony-based neural network for the prediction of the fundamental period of infilled frame structures. Neural Comput. Appl. 2019, 1–11. [Google Scholar] [CrossRef]

- Jang, J.R. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Nguyen, P.T.; Tuyen, T.T.; Shirzadi, A.; Pham, B.T.; Shahabi, H.; Omidvar, E.; Amini, A.; Entezami, H.; Prakash, I.; Phong, T.V. Development of a Novel Hybrid Intelligence Approach for Landslide Spatial Prediction. Appl. Sci. 2019, 9, 2824. [Google Scholar] [CrossRef]

- Kaloop, M.R.; Kumar, D.; Samui, P.; Gabr, A.R.; Hu, J.W.; Jin, X.; Roy, B. Particle Swarm Optimization Algorithm-Extreme Learning Machine (PSO-ELM) Model for Predicting Resilient Modulus of Stabilized Aggregate Bases. Appl. Sci. 2019, 9, 3221. [Google Scholar] [CrossRef]

- Xu, H.; Zhou, J.; Asteris, P.G.; Armaghani, D.J.; Tahir, M.M. Supervised Machine Learning Techniques to the Prediction of Tunnel Boring Machine Penetration Rate. Appl. Sci. 2019, 9, 3715. [Google Scholar] [CrossRef]

- Le, L.T.; Nguyen, H.; Dou, J.; Zhou, J. A Comparative Study of PSO-ANN, GA-ANN, ICA-ANN, and ABC-ANN in Estimating the Heating Load of Buildings’ Energy Efficiency for Smart City Planning. Appl. Sci. 2019, 9, 2630. [Google Scholar] [CrossRef]

- Pham, B.T.; Son, L.H.; Hoang, T.-A.; Nguyen, D.-M.; Bui, D.T. Prediction of shear strength of soft soil using machine learning methods. Catena 2018, 166, 181–191. [Google Scholar] [CrossRef]

- Jang, J.; Sun, C.; Mizutani, E. Neuro-Fuzzy and Soft Computing-A Computational Approach to Learning and Machine Intelligence [Book Review]. IEEE Trans. Autom. Control. 1997, 42, 1482–1484. [Google Scholar] [CrossRef]

- Esmaeili, M.; Osanloo, M.; Rashidinejad, F.; Aghajani Bazzazi, A.; Taji, M. Multiple regression, ANN and ANFIS models for prediction of backbreak in the open pit blasting. Eng. Comput. 2014, 30, 549–558. [Google Scholar] [CrossRef]

- Pham, B.T.; Nguyen, M.D.; Van Dao, D.; Prakash, I.; Ly, H.B.; Le, T.T.; Ho, L.S.; Nguyen, K.T.; Ngo, T.Q.; Hoang, V.; et al. Development of artificial intelligence models for the prediction of Compression Coefficient of soil: An application of Monte Carlo sensitivity analysis. Sci. Total. Environ. 2019, 679, 172–184. [Google Scholar] [CrossRef] [PubMed]

- Pham, B.T.; Jaafari, A.; Prakash, I.; Singh, S.K.; Quoc, N.K.; Bui, D.T. Hybrid computational intelligence models for groundwater potential mapping. Catena 2019, 182, 104101. [Google Scholar] [CrossRef]

- Karaboga, D.; Kaya, E. Adaptive network based fuzzy inference system (ANFIS) training approaches: A comprehensive survey. Artif. Intell. Rev. 2018, 1–31. [Google Scholar] [CrossRef]

- Le, L.M.; Ly, H.-B.; Pham, B.T.; Le, V.M.; Pham, T.A.; Nguyen, D.-H.; Tran, X.-T.; Le, T.-T. Hybrid Artificial Intelligence Approaches for Predicting Buckling Damage of Steel Columns Under Axial Compression. Materials 2019, 12, 1670. [Google Scholar] [CrossRef]

- Termeh, S.V.R.; Khosravi, K.; Sartaj, M.; Keesstra, S.D.; Tsai, F.T.-C.; Dijksma, R.; Pham, B.T. Optimization of an adaptive neuro-fuzzy inference system for groundwater potential mapping. Hydrogeol. J. 2019, 1–24. [Google Scholar] [CrossRef]

- Takagi, T.; Sugeno, M. Derivation of Fuzzy Control Rules from Human Operator’s Control Actions. IFAC Proc. Vol. 1983, 16, 55–60. [Google Scholar] [CrossRef]

- Takagi, T.; Sugeno, M. Fuzzy Identification of Systems and Its Applications to Modeling and Control. In Readings in Fuzzy Sets for Intelligent Systems; Elsevier BV: Amsterdam, The Netherlands, 1993; pp. 387–403. [Google Scholar]

- Abraham, A. Adaptation of Fuzzy Inference System Using Neural Learning. In Granular Computing; Springer Science and Business Media LLC: Berlin, Germany, 2005; Volume 181, pp. 53–83. [Google Scholar]

- Nguyen, H.-L.; Le, T.-H.; Pham, C.-T.; Le, T.-T.; Ho, L.S.; Le, V.M.; Pham, B.T.; Ly, H.-B. Development of Hybrid Artificial Intelligence Approaches and a Support Vector Machine Algorithm for Predicting the Marshall Parameters of Stone Matrix Asphalt. Appl. Sci. 2019, 9, 3172. [Google Scholar] [CrossRef]

- Aditya, M.; Chandranath, C.; Singh, R.N. Flood Forecasting Using ANN, Neuro-Fuzzy, and Neuro-GA Models. J. Hydrol. Eng. 2009, 14, 647–652. [Google Scholar]

- Nayak, P.C.; Sudheer, K.P.; Rangan, D.M.; Ramasastri, K.S. Short-term flood forecasting with a neurofuzzy model. Water Resour. Res. 2005, 41, 41. [Google Scholar] [CrossRef]

- Bui, K.-T.T.; Bui, D.T.; Zou, J.; Van Doan, C.; Revhaug, I. A novel hybrid artificial intelligent approach based on neural fuzzy inference model and particle swarm optimization for horizontal displacement modeling of hydropower dam. Neural Comput. Appl. 2016, 29, 1495–1506. [Google Scholar] [CrossRef]

- Bui, D.T.; Khosravi, K.; Li, S.; Shahabi, H.; Panahi, M.; Singh, V.P.; Chapi, K.; Shirzadi, A.; Panahi, S.; Chen, W.; et al. New Hybrids of ANFIS with Several Optimization Algorithms for Flood Susceptibility Modeling. Water 2018, 10, 1210. [Google Scholar]

- Chen, M.-Y. A hybrid ANFIS model for business failure prediction utilizing particle swarm optimization and subtractive clustering. Inf. Sci. 2013, 220, 180–195. [Google Scholar] [CrossRef]

- Jaafari, A.; Panahi, M.; Pham, B.T.; Shahabi, H.; Bui, D.T.; Rezaie, F.; Lee, S. Meta optimization of an adaptive neuro-fuzzy inference system with grey wolf optimizer and biogeography-based optimization algorithms for spatial prediction of landslide susceptibility. Catena 2019, 175, 430–445. [Google Scholar] [CrossRef]

- Pham, B.T.; Prakash, I. Spatial Prediction of Rainfall Induced Shallow Landslides Using Adaptive-Network-Based Fuzzy Inference System and Particle Swarm Optimization: A Case Study at the Uttarakhand Area, India. In Advances and Applications in Geospatial Technology and Earth Resources; Springer Science and Business Media LLC: Berlin, Germany, 2017; pp. 224–238. [Google Scholar]

- Ly, H.-B.; Le, L.M.; Duong, H.T.; Nguyen, T.C.; Pham, T.A.; Le, T.-T.; Le, V.M.; Nguyen-Ngoc, L.; Pham, B.T. Hybrid Artificial Intelligence Approaches for Predicting Critical Buckling Load of Structural Members under Compression Considering the Influence of Initial Geometric Imperfections. Appl. Sci. 2019, 9, 2258. [Google Scholar] [CrossRef]

- Cavaleri, L.; Asteris, P.G.; Psyllaki, P.P.; Douvika, M.G.; Skentou, A.D.; Vaxevanidis, N.M. Prediction of Surface Treatment Effects on the Tribological Performance of Tool Steels Using Artificial Neural Networks. Appl. Sci. 2019, 9, 2788. [Google Scholar] [CrossRef]

- Asteris, P.G.; Nozhati, S.; Nikoo, M.; Cavaleri, L.; Nikoo, M. Krill herd algorithm-based neural network in structural seismic reliability evaluation. Mech. Adv. Mater. Struct. 2018, 26, 1146–1153. [Google Scholar] [CrossRef]

- Rao, R.; Savsani, V.; Vakharia, D.; Savsani, V. Teaching–learning-based optimization: A novel method for constrained mechanical design optimization problems. Comput. Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.J.; Vakharia, D.P. Teaching–learning-based optimization: An optimization method for continuous non-linear large scale problems. Inf. Sci. 2012, 183, 1–15. [Google Scholar] [CrossRef]

- Rao, R.V.; Patel, V. An elitist teaching-learning-based optimization algorithm for solving complex constrained optimization problems. Int. J. Ind. Eng. Comput. 2012, 3, 535–560. [Google Scholar] [CrossRef]

- Hassanzadeh, Y.; Jafari-Bavil-Olyaei, A.; Aalami, M.-T.; Kardan, N. Experimental and numerical investigation of bridge pier scour estimation using ANFIS and teaching–learning-based optimization methods. Eng. Comput. 2019, 35, 1103–1120. [Google Scholar] [CrossRef]

- Abhishek, K.; Kumar, V.R.; Datta, S.; Mahapatra, S.S. Application of JAYA algorithm for the optimization of machining performance characteristics during the turning of CFRP (epoxy) composites: Comparison with TLBO, GA, and ICA. Eng. Comput. 2017, 33, 457–475. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Prayogo, D. A novel fuzzy adaptive teaching–learning-based optimization (FATLBO) for solving structural optimization problems. Eng. Comput. 2017, 33, 55–69. [Google Scholar] [CrossRef]

- Bayat, M.; Ghorbanpour, M.; Zare, R.; Jaafari, A.; Pham, B.T. Application of artificial neural networks for predicting tree survival and mortality in the Hyrcanian forest of Iran. Comput. Electron. Agric. 2019, 164, 104929. [Google Scholar] [CrossRef]

- Jolliffe, I.T. Principal Component Analysis; Springer Series in Statistics, 2nd ed.; Springer: New York, NY, USA, 2002; ISBN 978-0-387-95442-4. [Google Scholar]

- Gosav, S.; Praisler, M.; Birsa, M.L. Principal Component Analysis Coupled with Artificial Neural Networks—A Combined Technique Classifying Small Molecular Structures Using a Concatenated Spectral Database. Int. J. Mol. Sci. 2011, 12, 6668–6684. [Google Scholar] [CrossRef]

- Defernez, M.; Kemsley, E.K. Avoiding overfitting in the analysis of high-dimensional data with artificial neural networks (ANNs). Analyst 1999, 124, 1675–1681. [Google Scholar] [CrossRef]

- May, R.; Dandy, G.; Maier, H. Review of Input Variable Selection Methods for Artificial Neural Networks. Artificial Neural Networks—Methodological Advances and Biomedical Applications; IntechOpen Limited: London, UK, 2011. [Google Scholar]

- Feng, S.; Zhou, H.; Dong, H. Using deep neural network with small dataset to predict material defects. Mater. Des. 2019, 162, 300–310. [Google Scholar] [CrossRef]

- Le, T.-T.; Guilleminot, J.; Soize, C. Stochastic continuum modeling of random interphases from atomistic simulations. Application to a polymer nanocomposite. Comput. Methods Appl. Mech. Eng. 2016, 303, 430–449. [Google Scholar] [CrossRef]

- Krzanowski, W.J. Principles of Multivariate Analysis: A User’s Perspective, Revised, Subsequent ed.; Oxford University Press: New York, NY, USA, 2000; ISBN 978-0-19-850708-6. [Google Scholar]

- Ly, H.-B.; Desceliers, C.; Le, L.M.; Le, T.-T.; Pham, B.T.; Nguyen-Ngoc, L.; Doan, V.T.; Le, M. Quantification of Uncertainties on the Critical Buckling Load of Columns under Axial Compression with Uncertain Random Materials. Materials 2019, 12, 1828. [Google Scholar] [CrossRef]

- Noori, R.; Sabahi, M.; Karbassi, A.; Baghvand, A.; Zadeh, H.T.; Karbassi, A. Multivariate statistical analysis of surface water quality based on correlations and variations in the data set. Desalination 2010, 260, 129–136. [Google Scholar] [CrossRef]

- Pham, B.T.; Jaafari, A.; Prakash, I.; Bui, D.T. A novel hybrid intelligent model of support vector machines and the MultiBoost ensemble for landslide susceptibility modeling. Bull. Eng. Geol. Environ. 2019, 78, 2865–2886. [Google Scholar] [CrossRef]

- Ding, X.; Li, C.; Xu, Y.; Li, F.; Zhao, S. Dataset of long-term compressive strength of concrete with manufactured sand. Data Brief. 2016, 6, 959–964. [Google Scholar] [CrossRef]

- Zhao, S.; Ding, X.; Zhao, M.; Li, C.; Pei, S. Experimental study on tensile strength development of concrete with manufactured sand. Constr. Build. Mater. 2017, 138, 247–253. [Google Scholar] [CrossRef]

- Zhao, S.; Hu, F.; Ding, X.; Zhao, M.; Li, C.; Pei, S. Dataset of tensile strength development of concrete with manufactured sand. Data Brief. 2017, 11, 469–472. [Google Scholar] [CrossRef]

- Cavaleri, L.; Chatzarakis, G.E.; Trapani, F.D.; Douvika, M.G.; Roinos, K.; Vaxevanidis, N.M.; Asteris, P.G. Modeling of surface roughness in electro-discharge machining using artificial neural networks. Adv. Mater. Res. 2017, 6, 169. [Google Scholar]

- Chen, H.; Asteris, P.G.; Armaghani, D.J.; Gordan, B.; Pham, B.T. Assessing Dynamic Conditions of the Retaining Wall: Developing Two Hybrid Intelligent Models. Appl. Sci. 2019, 9, 1042. [Google Scholar] [CrossRef]

- Psyllaki, P.; Stamatiou, K.; Iliadis, I.; Mourlas, A.; Asteris, P.; Vaxevanidis, N. Surface treatment of tool steels against galling failure. MATEC Web Conf. 2018, 188, 04024. [Google Scholar] [CrossRef]

- Asteris, P.G.; Plevris, V. Anisotropic masonry failure criterion using artificial neural networks. Neural Comput. Applic. 2017, 28, 2207–2229. [Google Scholar] [CrossRef]

- Khozani, Z.S.; Khosravi, K.; Pham, B.T.; Kløve, B.; Mohtar, W.H.M.W.; Yaseen, Z.M. Determination of compound channel apparent shear stress: Application of novel data mining models. J. Hydroinform. 2019. [Google Scholar] [CrossRef]

- Pham, B.T.; Nguyen, M.D.; Bui, K.-T.T.; Prakash, I.; Chapi, K.; Bui, D.T. A novel artificial intelligence approach based on Multi-layer Perceptron Neural Network and Biogeography-based Optimization for predicting coefficient of consolidation of soil. Catena 2019, 173, 302–311. [Google Scholar] [CrossRef]

- Zhou, J.; Nekouie, A.; Arslan, C.A.; Pham, B.T.; Hasanipanah, M. Novel approach for forecasting the blast-induced AOp using a hybrid fuzzy system and firefly algorithm. Eng. Comput. 2019, 1–10. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Pham, B.T.; Tuyen, T.T.; Hai Yen, H.P.; Prakash, I.; Vu, T.T.; Chapi, K.; Shirzadi, A.; Shahabi, H.; Dou, J.; et al. Development of an Artificial Intelligence Approach for Prediction of Consolidation Coefficient of Soft Soil: A Sensitivity Analysis. Open Constr. Build. Technol. J. 2019, 13. [Google Scholar]

- Ly, H.-B.; Monteiro, E.; Le, T.-T.; Le, V.M.; Dal, M.; Regnier, G.; Pham, B.T. Prediction and Sensitivity Analysis of Bubble Dissolution Time in 3D Selective Laser Sintering Using Ensemble Decision Trees. Materials 2019, 12, 1544. [Google Scholar] [CrossRef]

| Parameter | Compressive Strength of Cement | Tensile Strength of Cement | Curing Age | Dmax of Crushed Stone | Stone Powder Content in Sand | Fineness Modulus of Sand |

| Unit | MPa | MPa | Days | mm | % | [-] |

| Notation | I1 | I2 | I3 | I4 | I5 | I6 |

| Min | 35.50 | 6.90 | 3.00 | 16.00 | 0.00 | 2.20 |

| Average | 47.95 | 8.25 | 80.93 | 28.31 | 7.54 | 3.06 |

| Median | 46.80 | 8.00 | 28.00 | 31.50 | 6.60 | 3.15 |

| Max | 63.40 | 10.20 | 388.00 | 31.50 | 20.00 | 3.50 |

| Std | 4.29 | 0.60 | 102.36 | 3.68 | 4.48 | 0.27 |

| CV (%) | 8.95 | 7.29 | 126.48 | 12.99 | 59.42 | 8.98 |

| Parameter | Water to Binder Ratio | Water to Cement Ratio | Water | Sand Ratio | Slump | Cubic Compressive Strength of Concrete * |

| Unit | [-] | [-] | kg/m3 | % | mm | MPa |

| Notation | I7 | I8 | I9 | I10 | I11 | Y |

| Min | 0.25 | 0.31 | 120.00 | 28.00 | 11.00 | 19.00 |

| Average | 0.43 | 0.46 | 175.49 | 37.23 | 98.34 | 55.80 |

| Median | 0.45 | 0.45 | 180.00 | 36.00 | 70.00 | 56.45 |

| Max | 0.69 | 0.69 | 291.00 | 44.00 | 260.00 | 96.30 |

| Std | 0.09 | 0.07 | 15.16 | 4.00 | 66.64 | 16.70 |

| CV (%) | 20.81 | 14.42 | 8.64 | 10.74 | 67.77 | 29.93 |

| Input | PC1 | PC2 | PC3 | PC4 | PC5 | PC6 | PC7 | PC8 | PC9 | PC10 | PC11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I1 | 14.02 | 5.43 | 17.64 | 0.92 | 12.21 | 0.24 | 0.18 | 2.43 | 2.92 | 8.73 | 35.28 |

| I2 | 11.81 | 4.96 | 26.94 | 0.00 | 5.63 | 1.38 | 0.00 | 0.05 | 2.70 | 12.69 | 33.85 |

| I3 | 3.57 | 1.07 | 3.60 | 40.88 | 36.66 | 0.86 | 0.34 | 10.97 | 1.84 | 0.21 | 0.00 |

| I4 | 18.43 | 1.64 | 0.81 | 1.73 | 5.55 | 2.68 | 1.27 | 61.74 | 2.57 | 0.05 | 3.53 |

| I5 | 10.04 | 0.58 | 3.31 | 10.17 | 2.96 | 57.17 | 6.72 | 0.42 | 5.69 | 2.93 | 0.00 |

| I6 | 0.09 | 1.55 | 10.78 | 42.35 | 33.39 | 3.42 | 4.56 | 0.22 | 2.40 | 1.05 | 0.19 |

| I7 | 18.97 | 10.34 | 4.49 | 0.01 | 1.73 | 0.16 | 0.93 | 0.18 | 11.30 | 31.64 | 20.26 |

| I8 | 6.48 | 31.74 | 0.04 | 0.06 | 0.35 | 0.91 | 1.91 | 0.07 | 15.77 | 37.60 | 5.07 |

| I9 | 9.87 | 1.82 | 15.68 | 0.04 | 0.51 | 0.17 | 57.86 | 12.10 | 0.08 | 1.80 | 0.06 |

| I10 | 1.70 | 34.07 | 2.63 | 0.85 | 0.02 | 0.96 | 0.28 | 2.83 | 51.88 | 3.23 | 1.54 |

| I11 | 5.03 | 6.79 | 14.08 | 3.00 | 0.99 | 32.05 | 25.95 | 9.00 | 2.84 | 0.07 | 0.21 |

| EV | 29.71 | 19.71 | 14.32 | 9.80 | 7.57 | 6.60 | 5.25 | 3.69 | 2.30 | 0.90 | 0.16 |

| CS | 29.71 | 49.42 | 63.73 | 73.54 | 81.10 | 87.70 | 92.95 | 96.64 | 98.94 | 99.84 | 100.00 |

| Criteria | Training Dataset | Testing Dataset |

|---|---|---|

| R | 0.92 | 0.96 |

| RMSE | 6.62 | 4.93 |

| MAE | 4.77 | 4.09 |

| Error mean | −0.08 | 0.26 |

| Error Std | 6.64 | 4.95 |

| Slope | 0.86 | 0.94 |

| Model | Data Used | Designation | R | RMSE | MAE | Error Std | Slope |

|---|---|---|---|---|---|---|---|

| Individual ANFIS | raw | ANFIS/R | 0.86 | 8.58 | 6.24 | 8.63 | 0.78 |

| Individual ANFIS | pre-processed | ANFIS/P | 0.93 | 6.46 | 5.28 | 6.49 | 0.89 |

| Individual ANN | pre-processed | ANN/P | 0.90 | 7.67 | 5.06 | 7.67 | 0.77 |

| ANFIS+TLBO | raw | ANFIS-TLBO/R | 0.88 | 7.65 | 5.02 | 7.59 | 0.76 |

| ANFIS+TLBO | pre-processed | ANFIS-TLBO/P | 0.96 | 4.93 | 4.09 | 4.95 | 0.94 |

| PCs | PC1 | PC2 | PC3 | PC4 | PC5 | PC6 | PC7 | PC8 | PC9 | PC10 | PC11 |

| Sensitivity index (%) | 12.48 | 17.04 | 10.53 | 17.41 | 15.16 | 1.80 | 0.72 | 11.68 | 4.37 | 3.85 | 4.95 |

| Inputs | I1 | I2 | I3 | I4 | I5 | I6 | I7 | I8 | I9 | I10 | I11 |

| Sensitivity index (%) | 9.04 | 8.32 | 15.07 | 11.36 | 5.41 | 14.12 | 7.61 | 8.71 | 5.19 | 9.27 | 5.89 |

| Curing Age | Model | R | RMSE | MAE | Error Std | Slope |

|---|---|---|---|---|---|---|

| 7 days | Ding et al. [14] (Equation (6) in [14] *) | 0.61 | 14.42 | 10.25 | 10.41 | 1.77 |

| Our model | 0.90 | 7.43 | 5.22 | 6.06 | 0.99 | |

| Δ (%) | +29.00 | +48.49 | +49.03 | +41.78 | +76.00 | |

| 28 days | Ding et al. [14] (Equation (5)) | 0.92 | 5.31 | 4.44 | 5.32 | 0.94 |

| Our model | 0.95 | 5.20 | 4.08 | 5.18 | 0.87 | |

| Δ (%) | +3.00 | +2.07 | +8.11 | +2.63 | −7.00 | |

| 56 days | Ding et al. [14] (Equation (6) in [14] *) | 0.91 | 6.36 | 3.90 | 5.38 | 0.68 |

| Our model | 0.87 | 5.94 | 5.43 | 4.46 | 0.83 | |

| Δ (%) | −4.00 | +6.53 | −39.23 | +17.01 | +15.00 | |

| 3–388 days | Ding et al. [14] (Equation (6) in [14] *) | 0.77 | 12.82 | 9.96 | 12.54 | 0.66 |

| Our model | 0.93 | 6.16 | 4.57 | 6.17 | 0.88 | |

| Δ (%) | +16.00 | +51.92 | +54.11 | +50.76 | +22.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ly, H.-B.; Pham, B.T.; Dao, D.V.; Le, V.M.; Le, L.M.; Le, T.-T. Improvement of ANFIS Model for Prediction of Compressive Strength of Manufactured Sand Concrete. Appl. Sci. 2019, 9, 3841. https://doi.org/10.3390/app9183841

Ly H-B, Pham BT, Dao DV, Le VM, Le LM, Le T-T. Improvement of ANFIS Model for Prediction of Compressive Strength of Manufactured Sand Concrete. Applied Sciences. 2019; 9(18):3841. https://doi.org/10.3390/app9183841

Chicago/Turabian StyleLy, Hai-Bang, Binh Thai Pham, Dong Van Dao, Vuong Minh Le, Lu Minh Le, and Tien-Thinh Le. 2019. "Improvement of ANFIS Model for Prediction of Compressive Strength of Manufactured Sand Concrete" Applied Sciences 9, no. 18: 3841. https://doi.org/10.3390/app9183841

APA StyleLy, H.-B., Pham, B. T., Dao, D. V., Le, V. M., Le, L. M., & Le, T.-T. (2019). Improvement of ANFIS Model for Prediction of Compressive Strength of Manufactured Sand Concrete. Applied Sciences, 9(18), 3841. https://doi.org/10.3390/app9183841