Impact of Wind on the Movement of the Load Carried by Rotary Crane

Abstract

1. Introduction

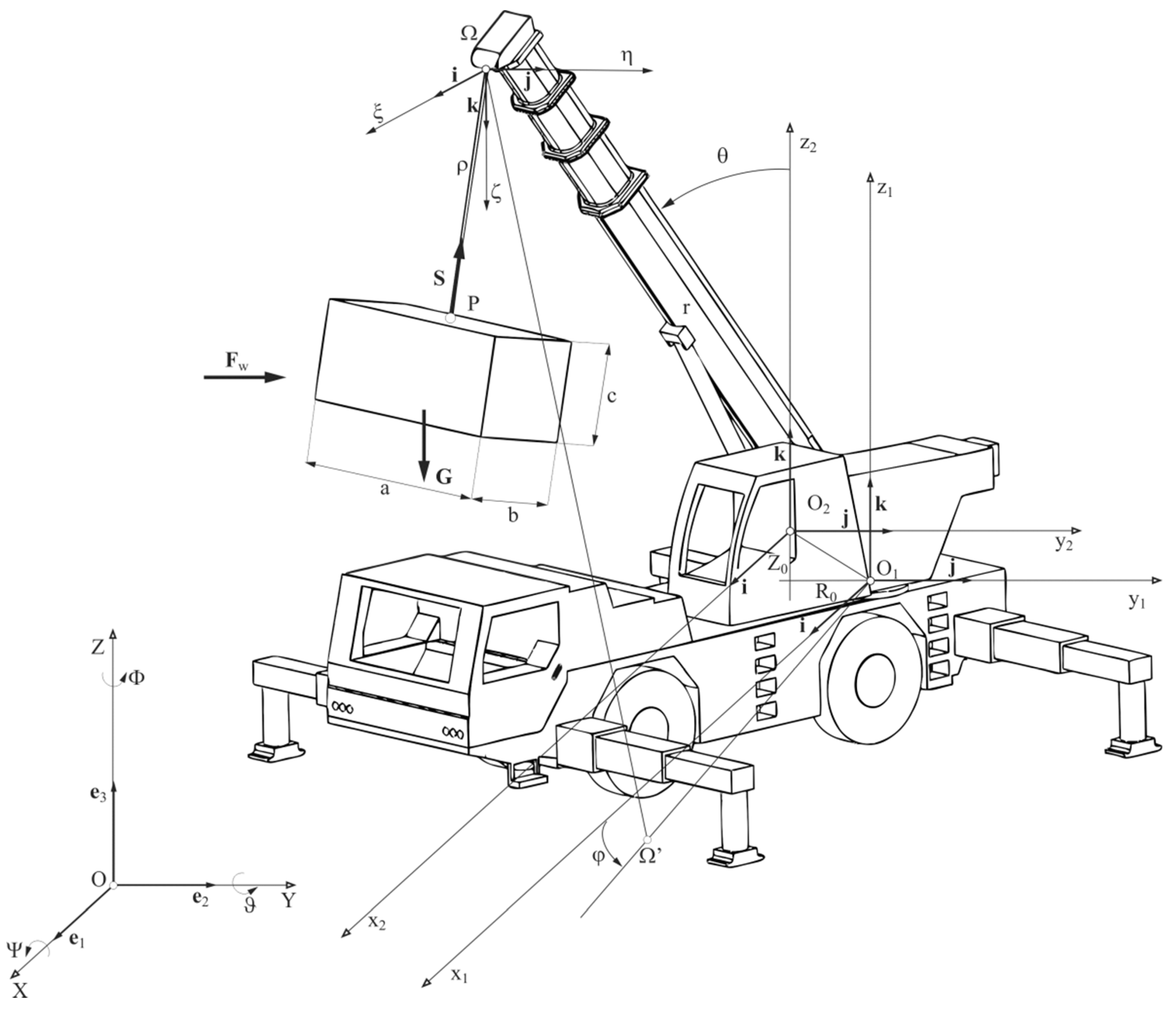

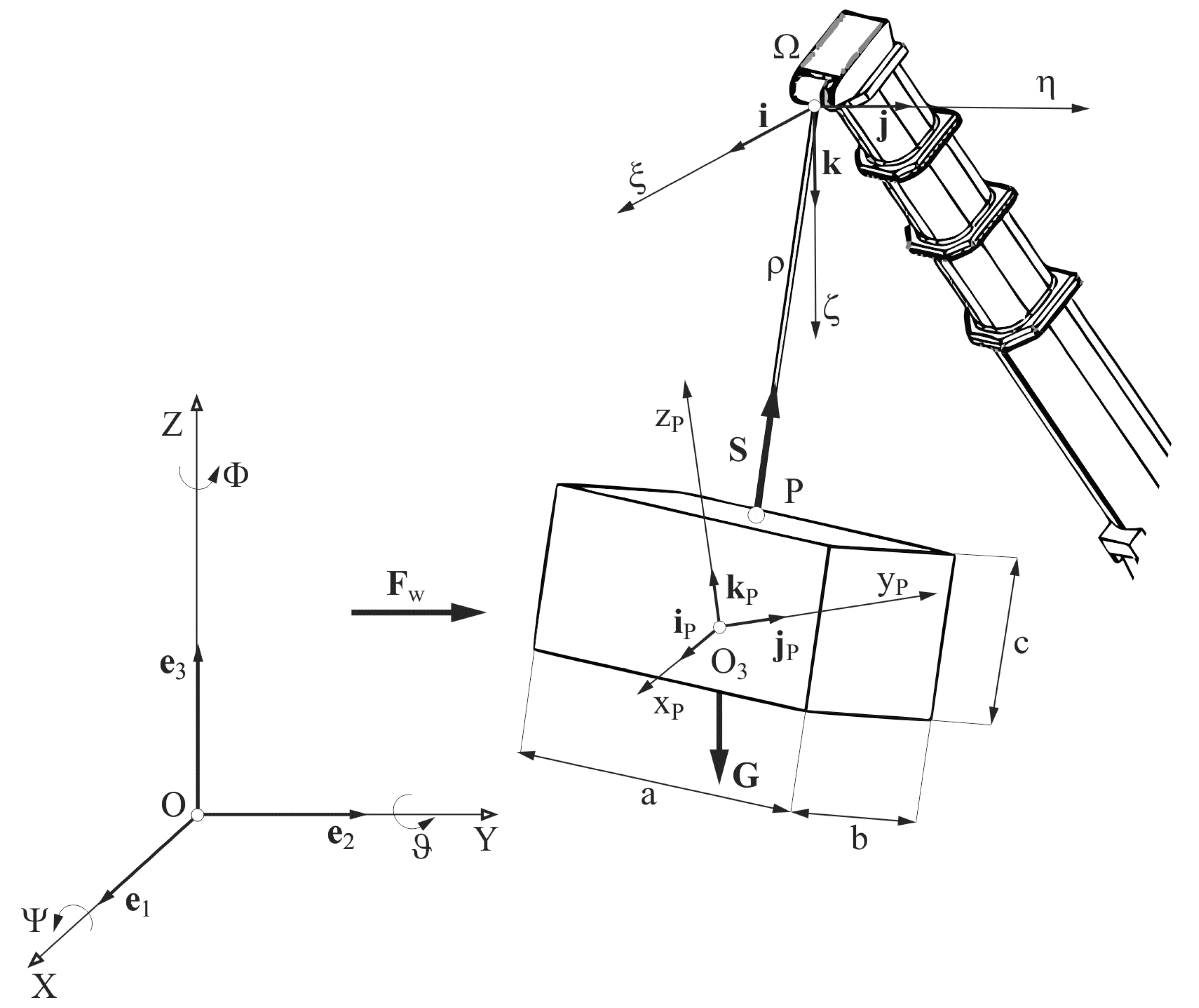

2. Model of the Studied System

3. Equations of Motion for the Studied System

3.1. Equations of Motion of the Main System

3.2. Initial Problem of Load Motion

3.3. Variability of the Area on Which Wind Power Has Influence

4. Results and Discussion

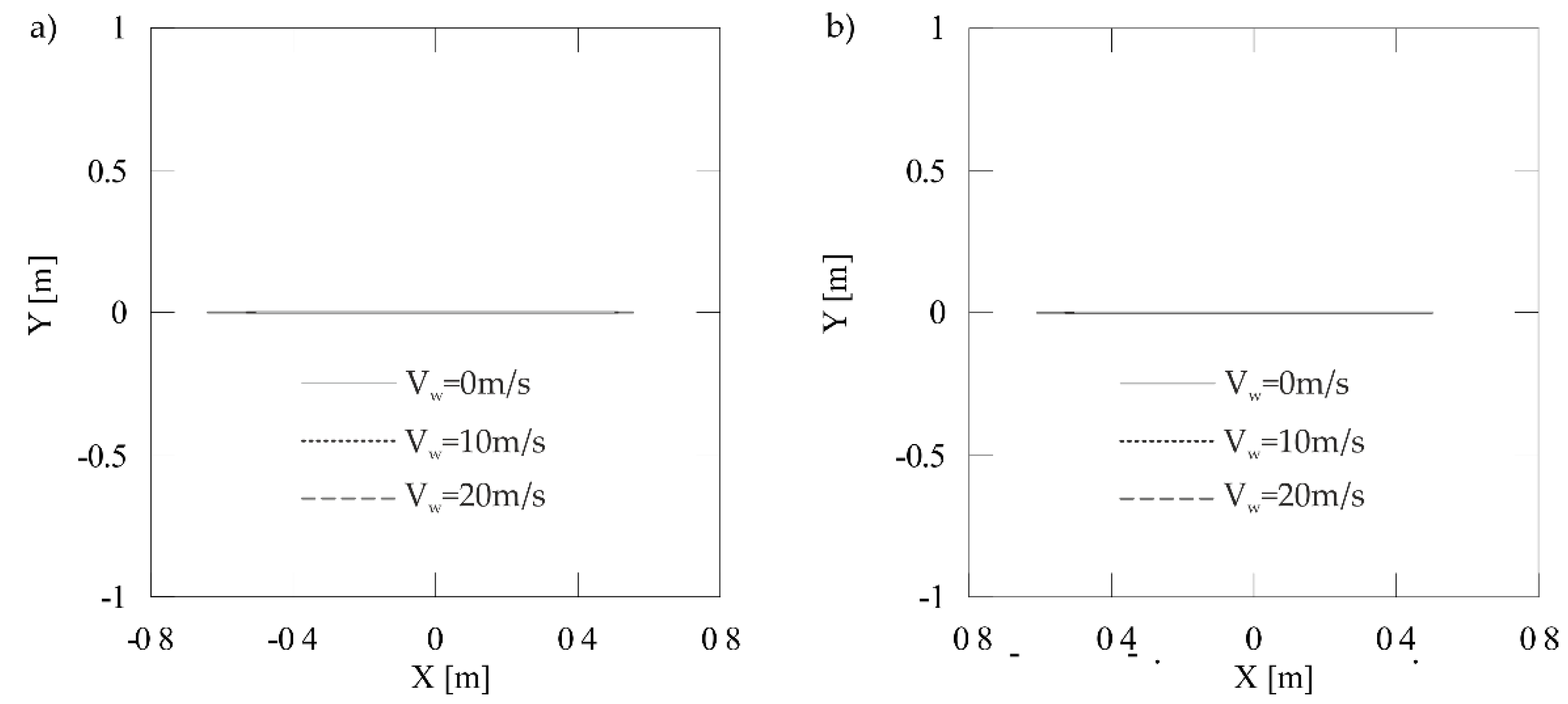

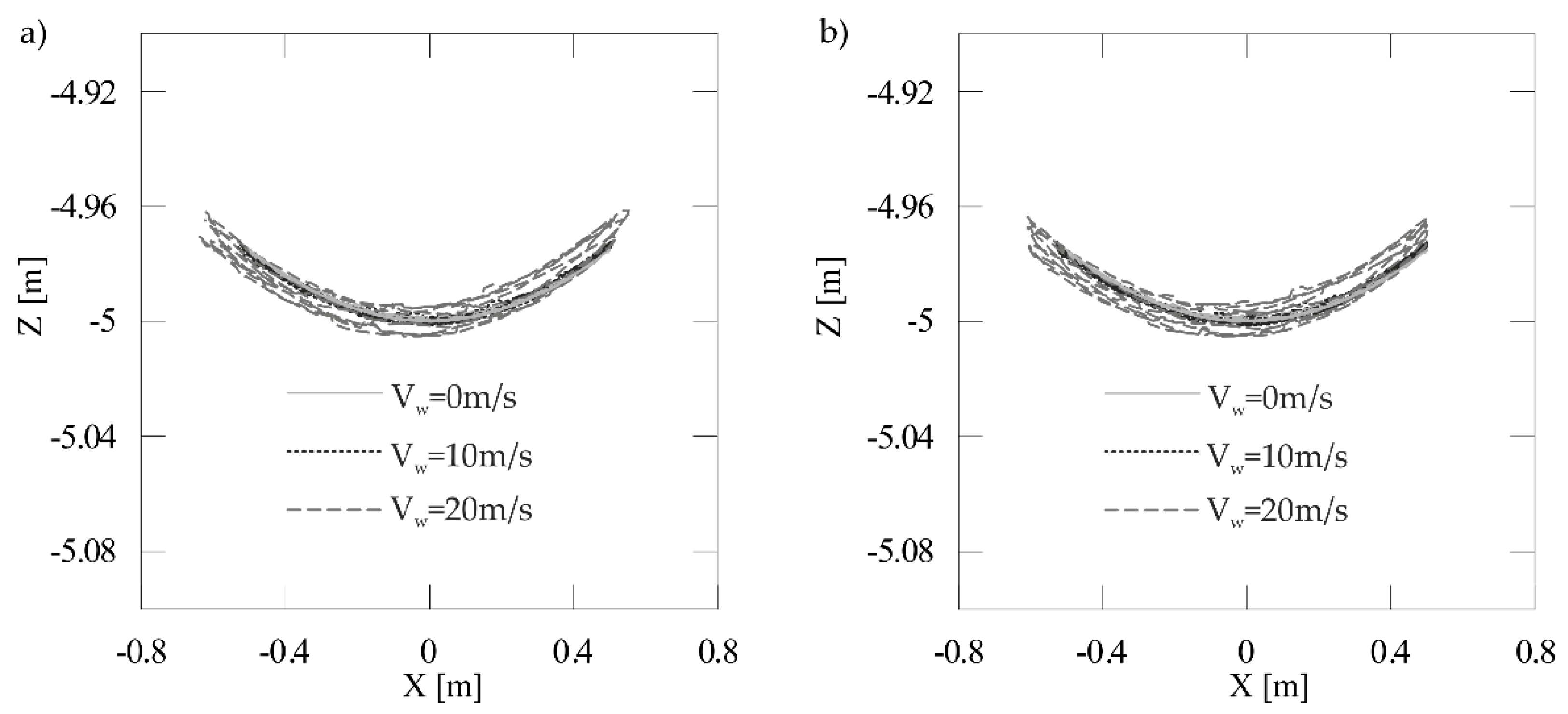

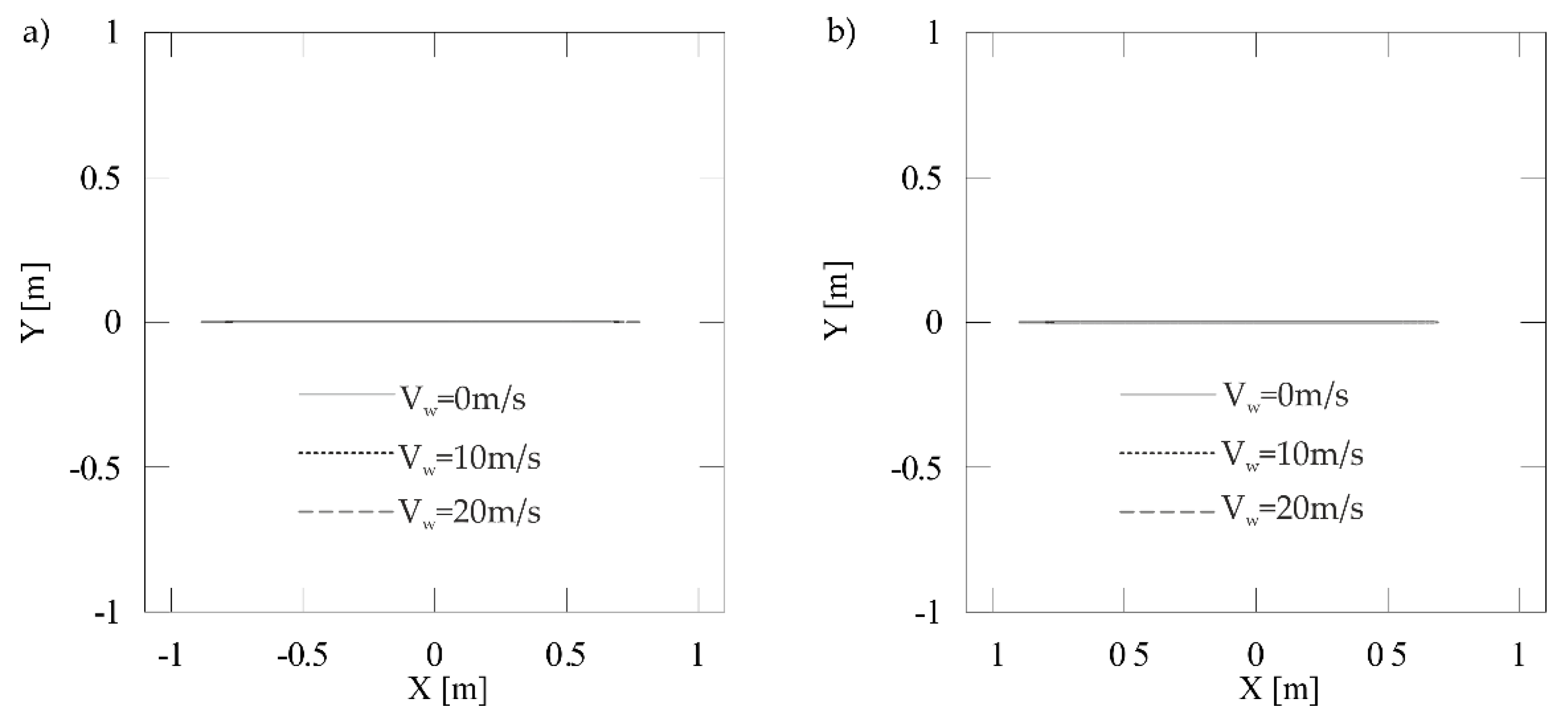

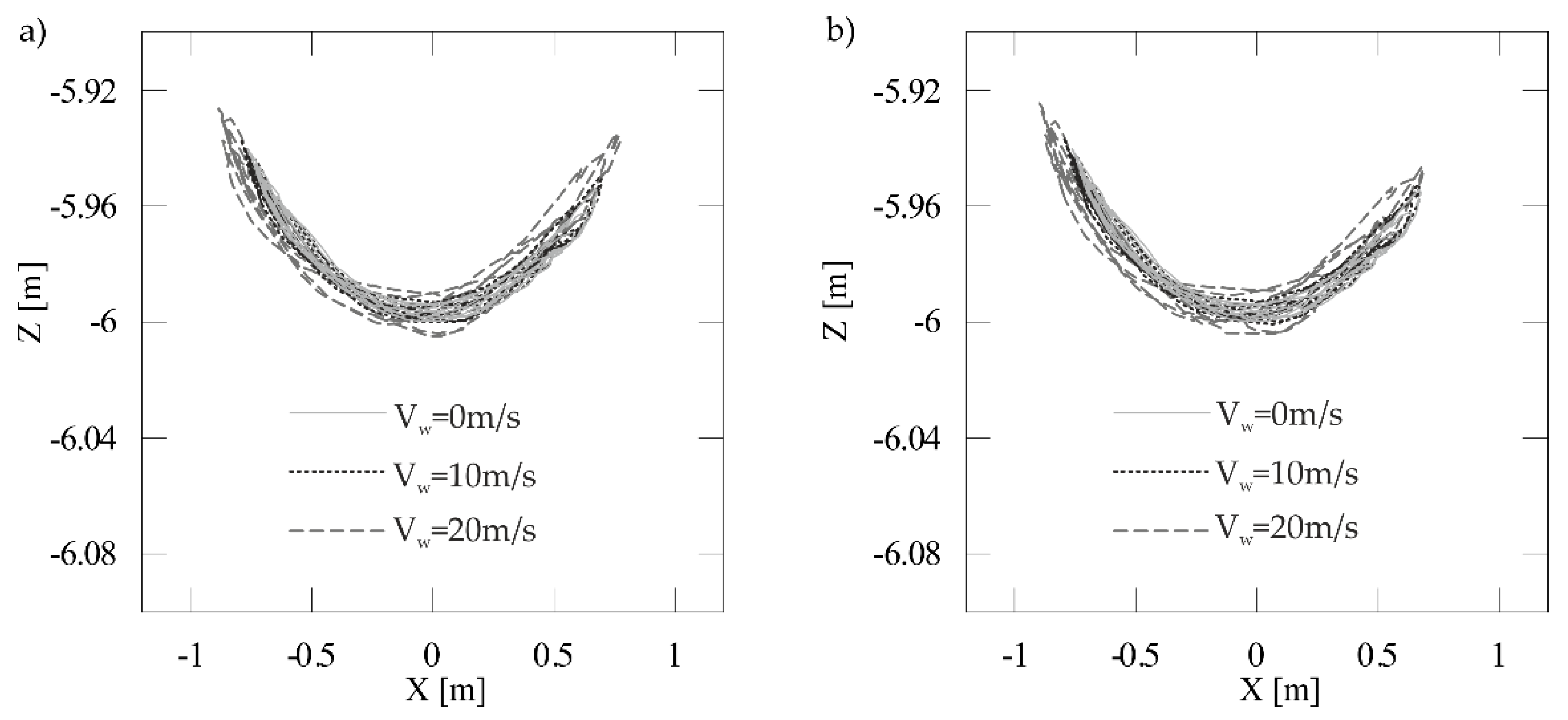

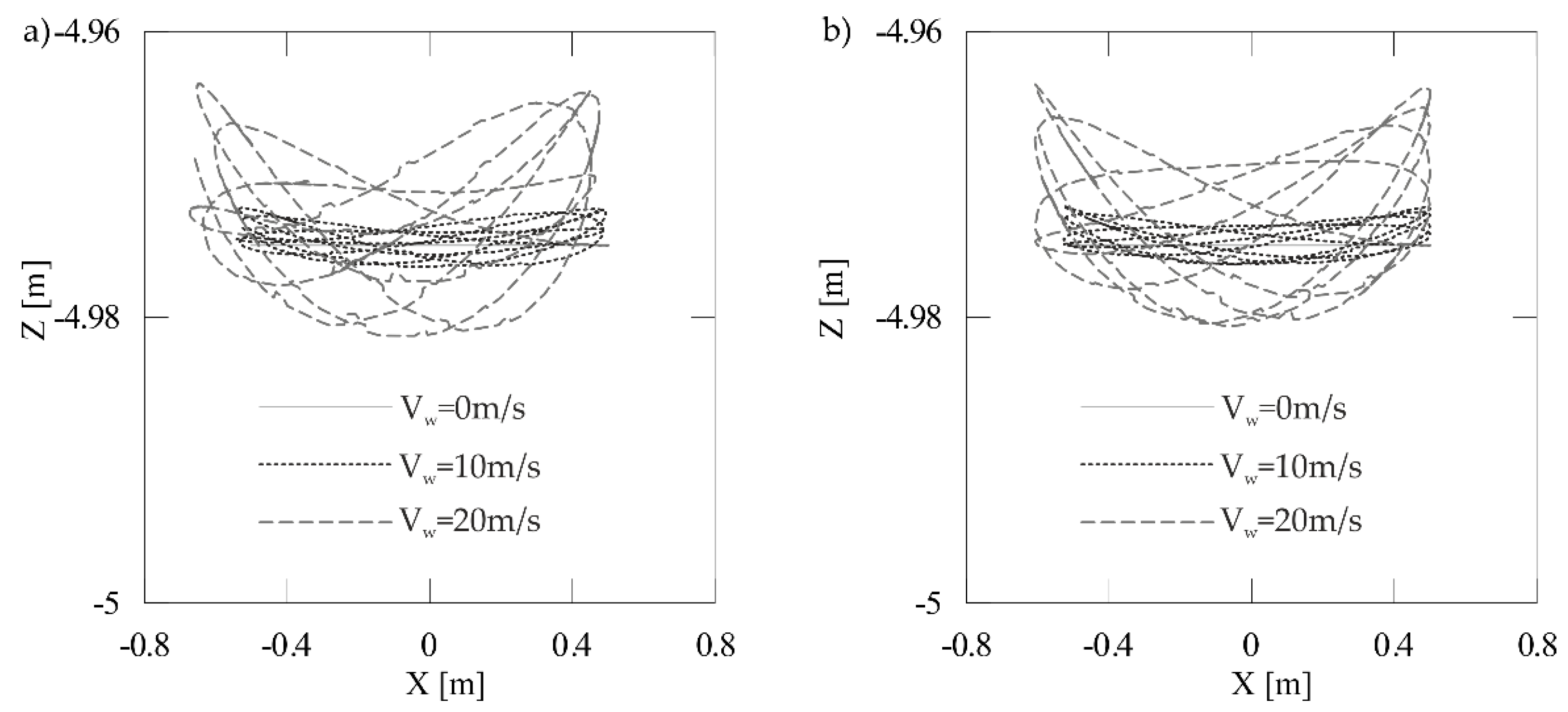

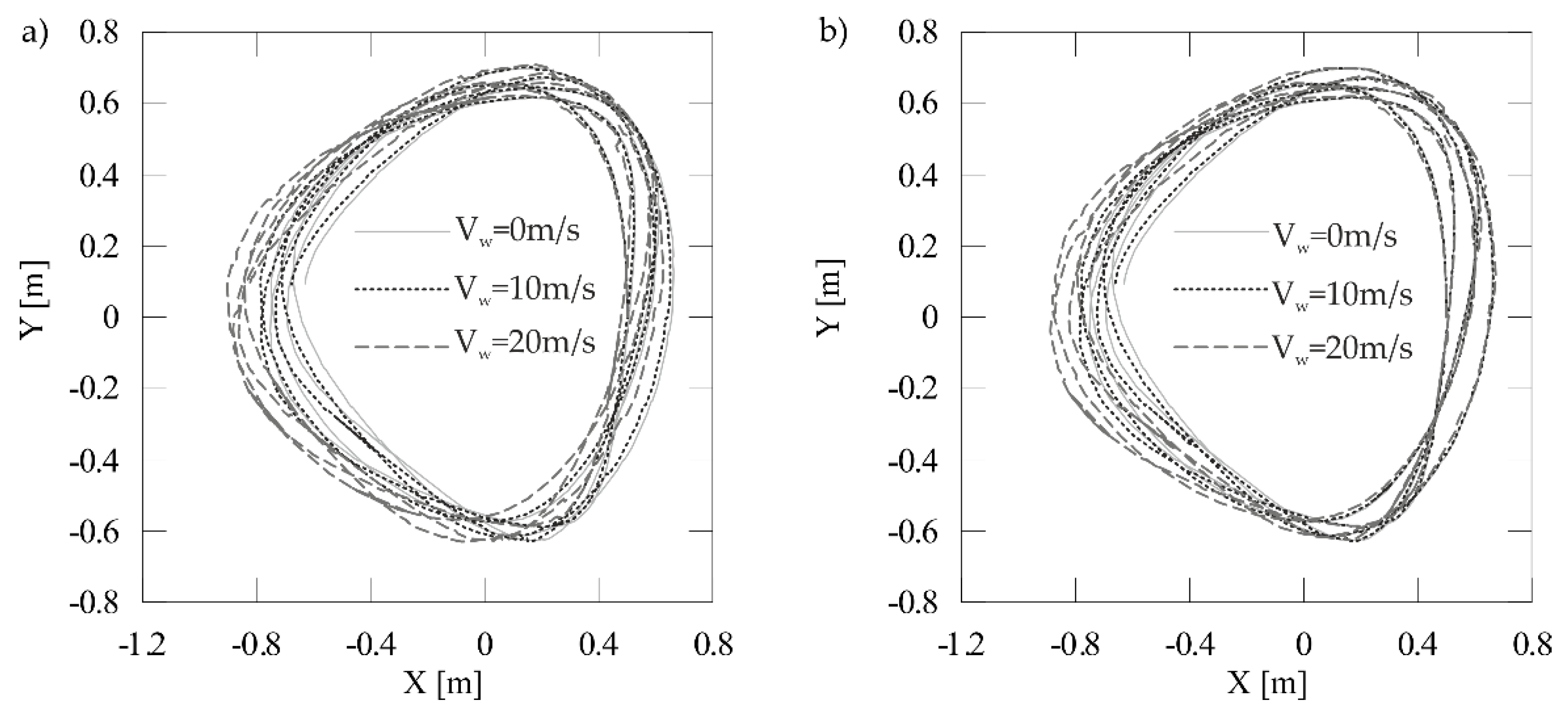

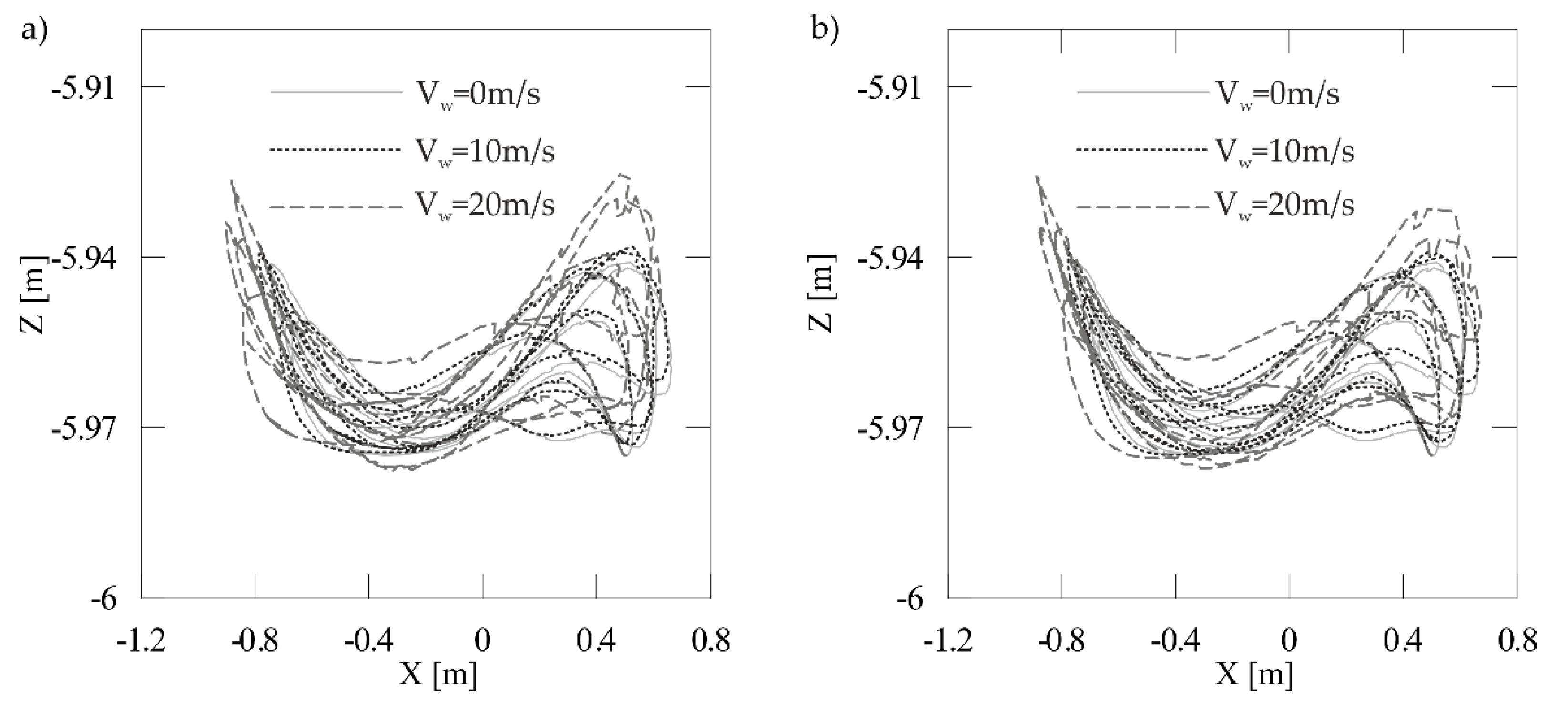

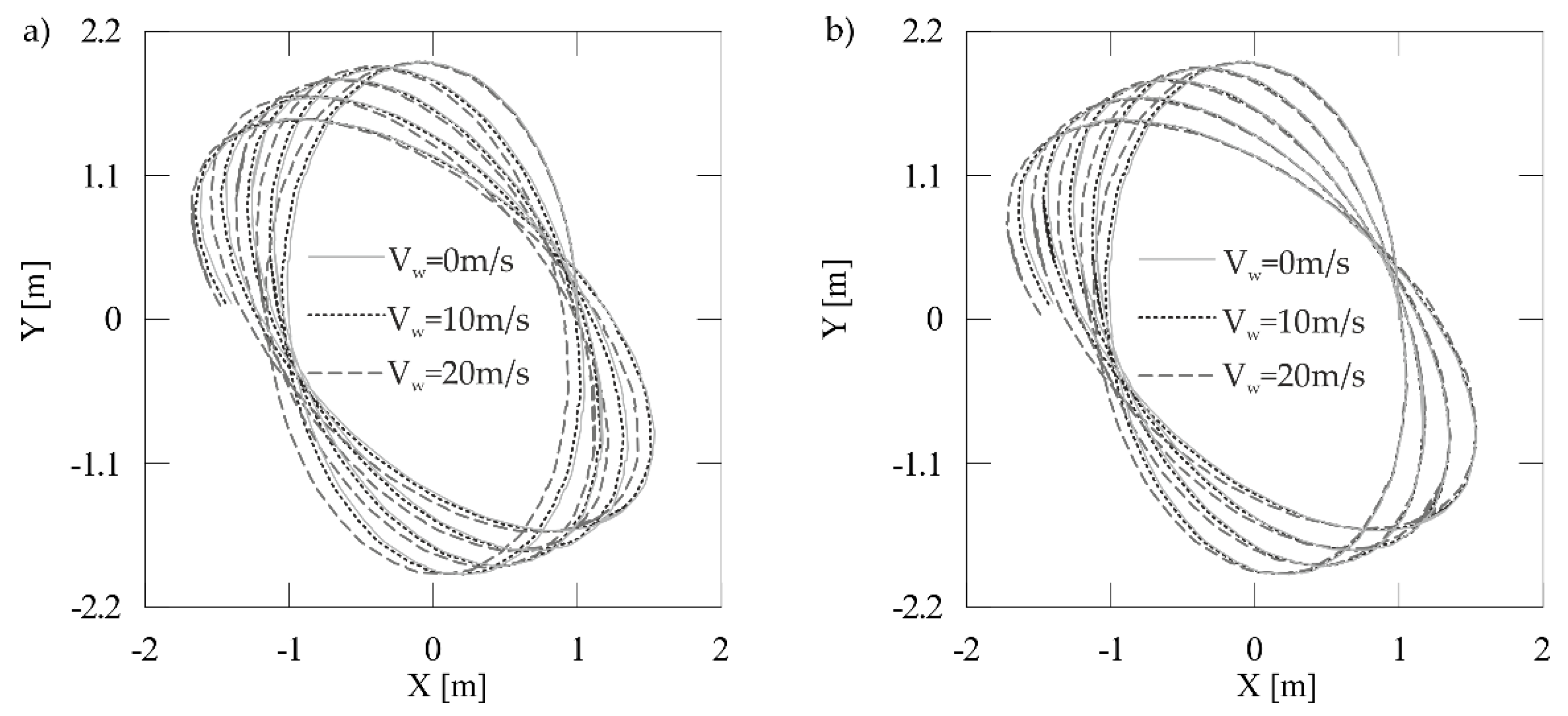

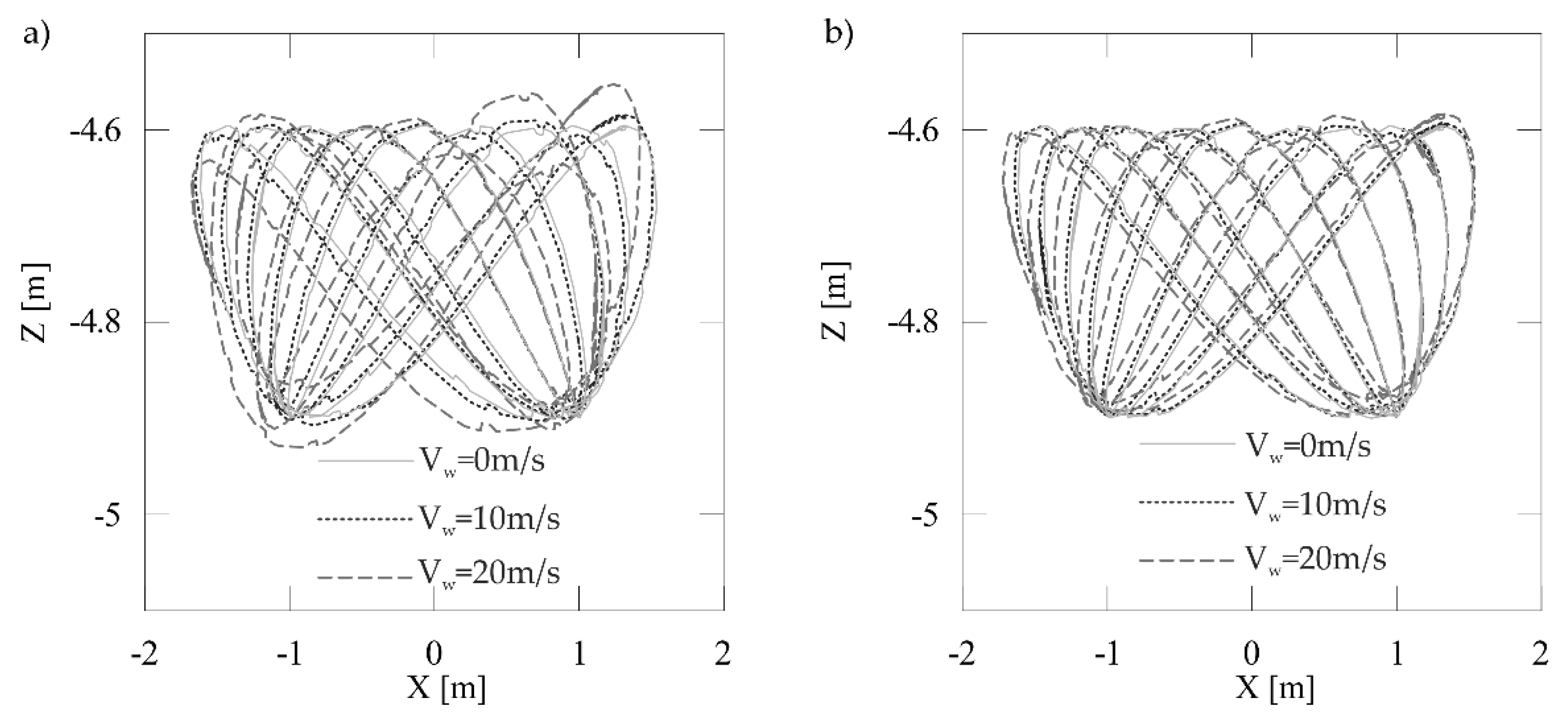

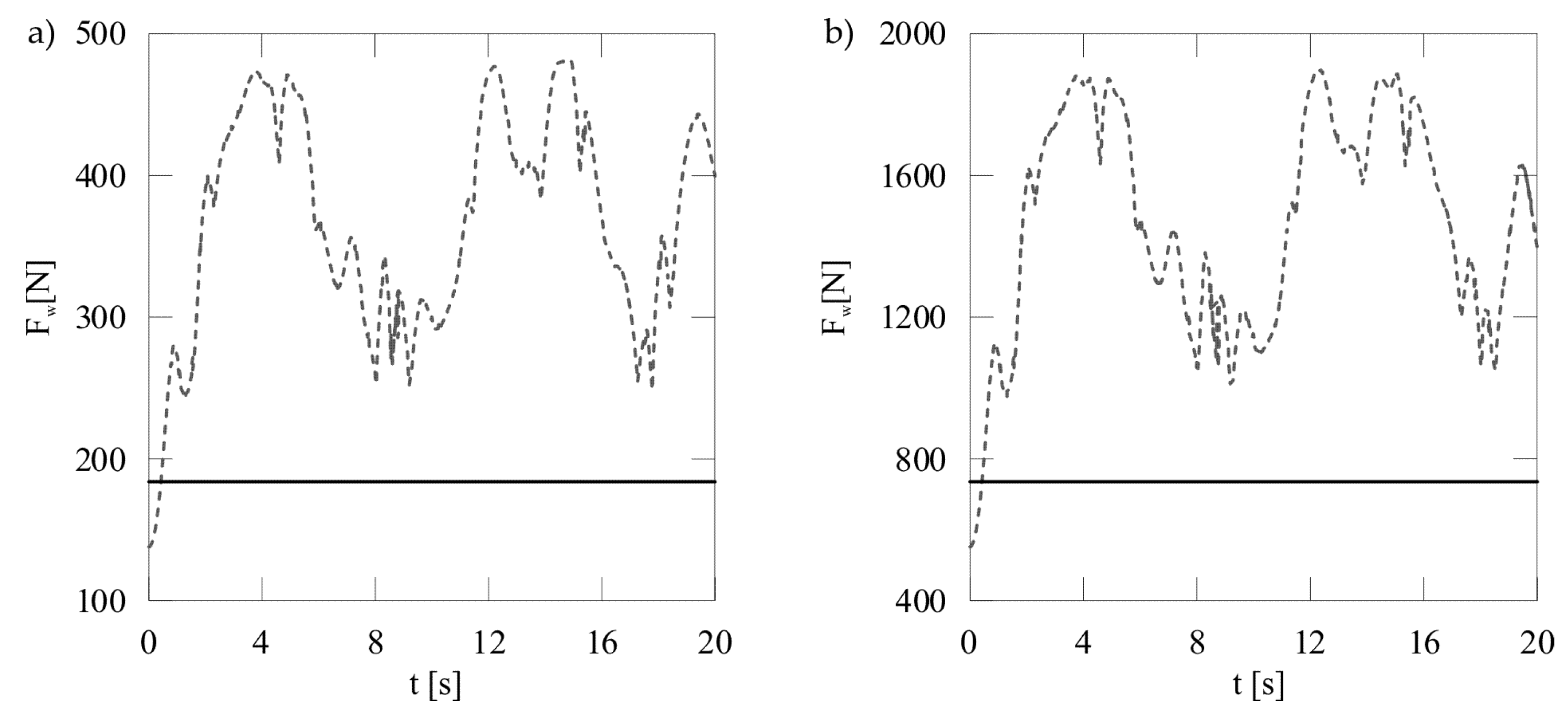

4.1. Movement of the Load as a Mathematical Pendulum

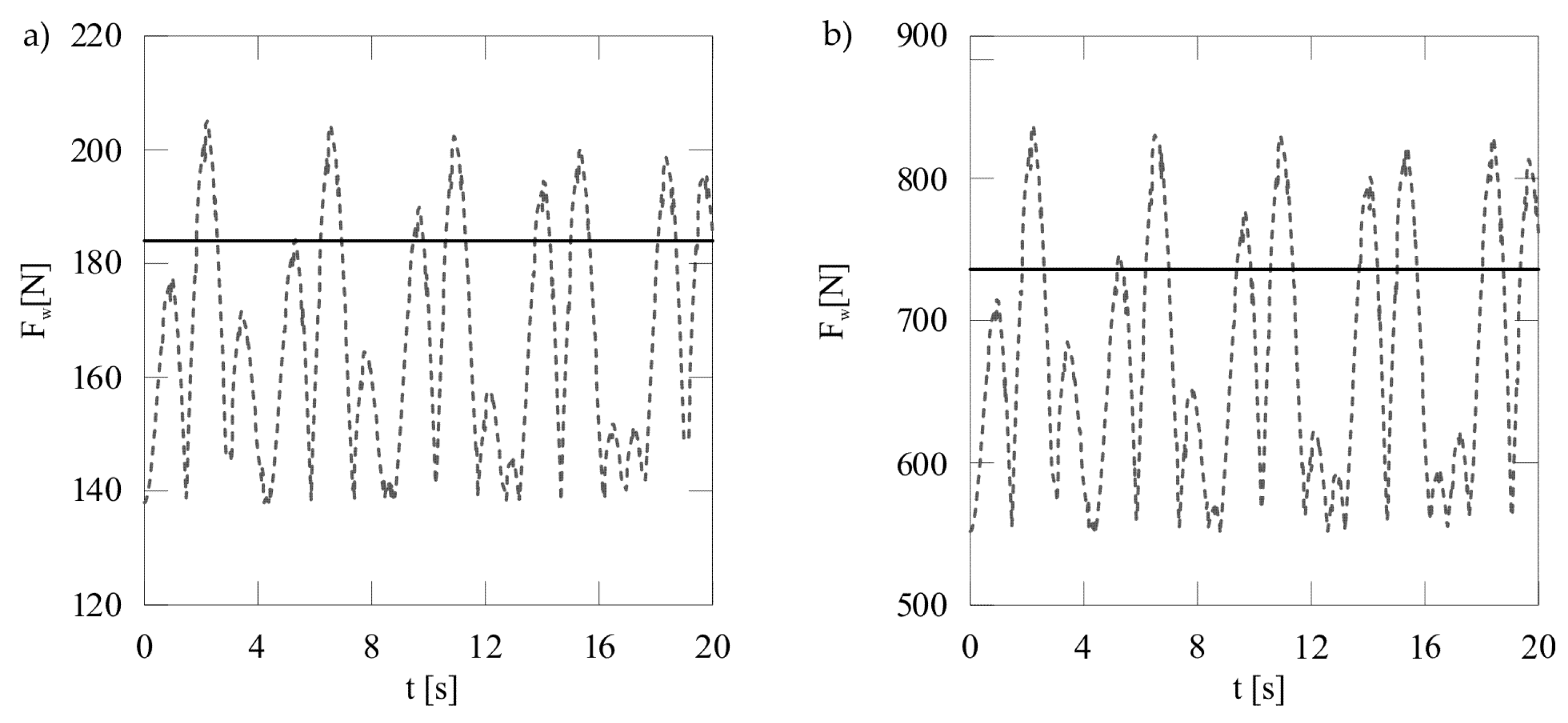

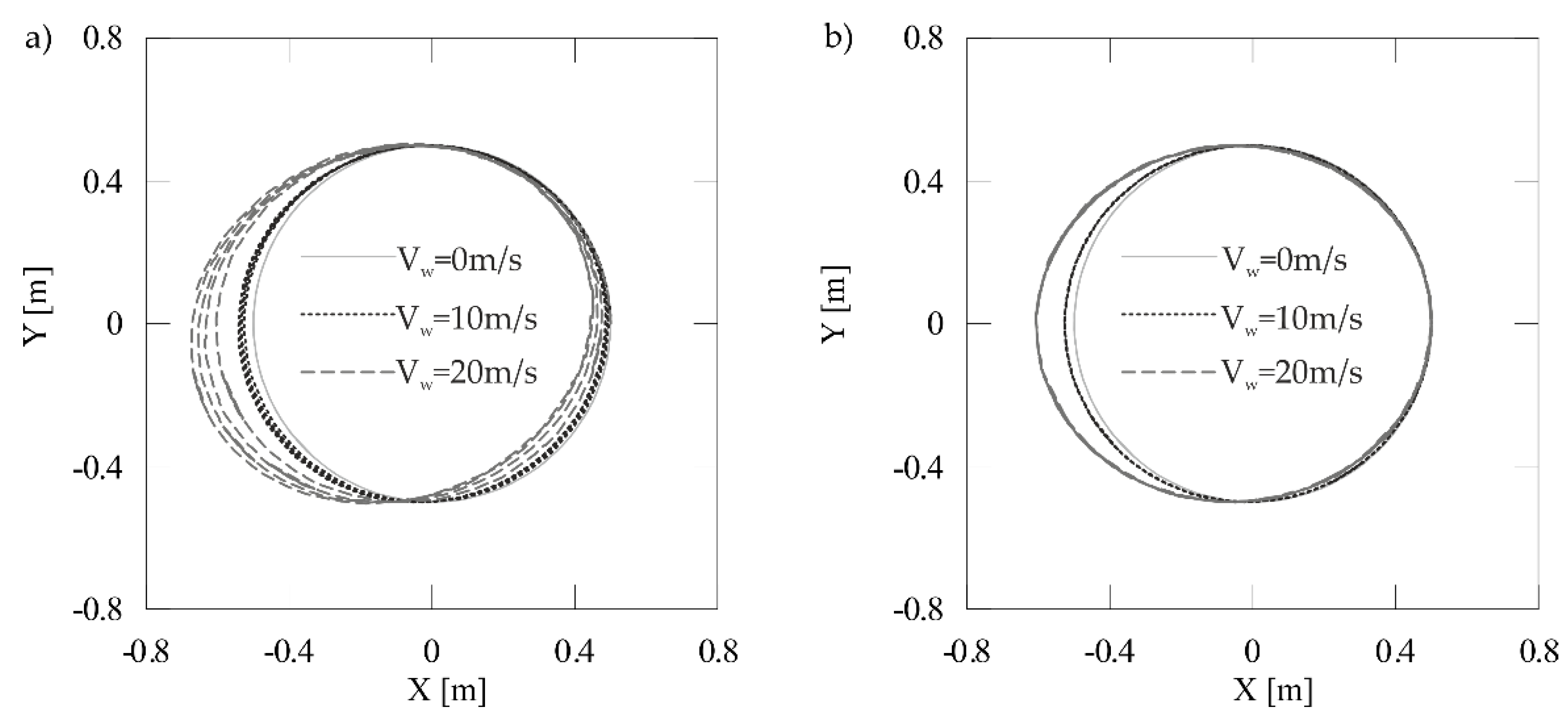

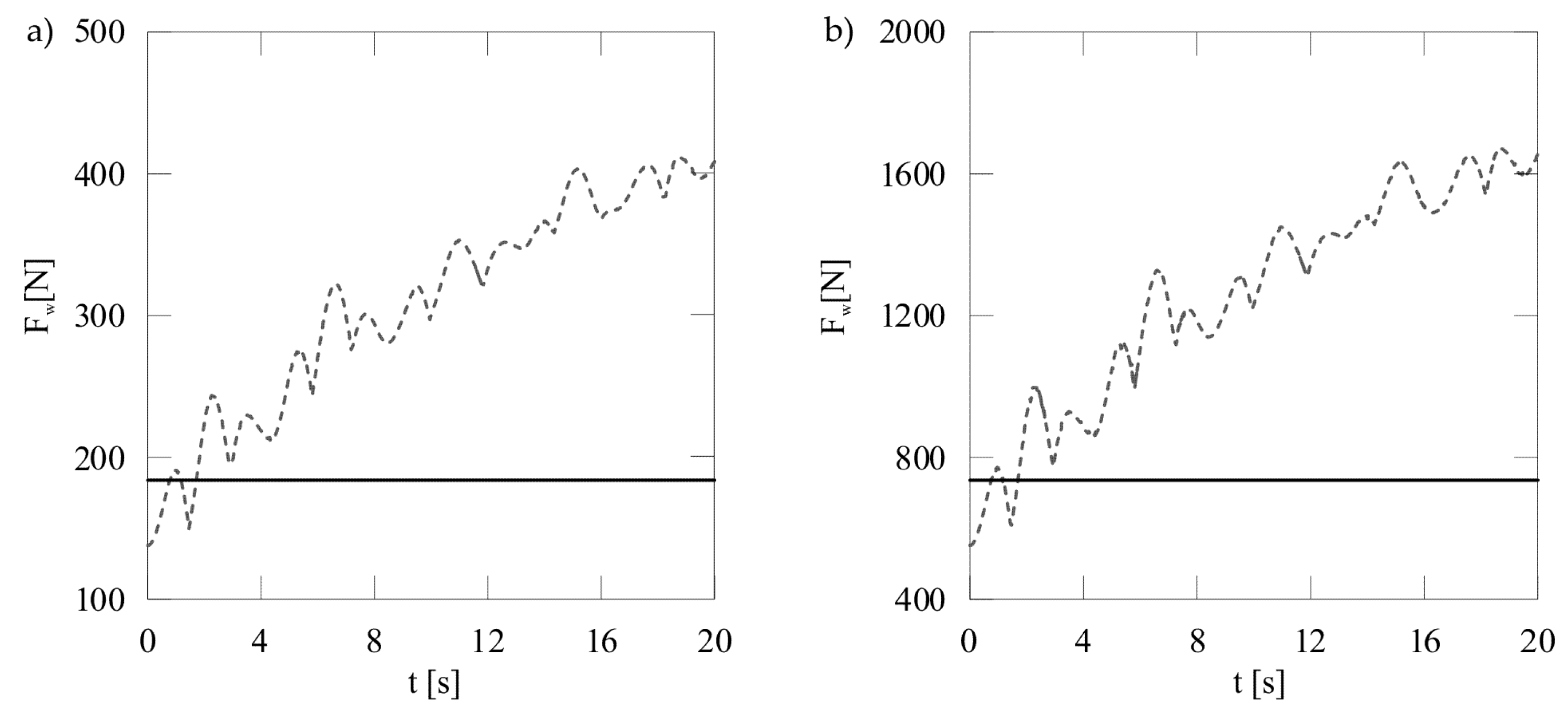

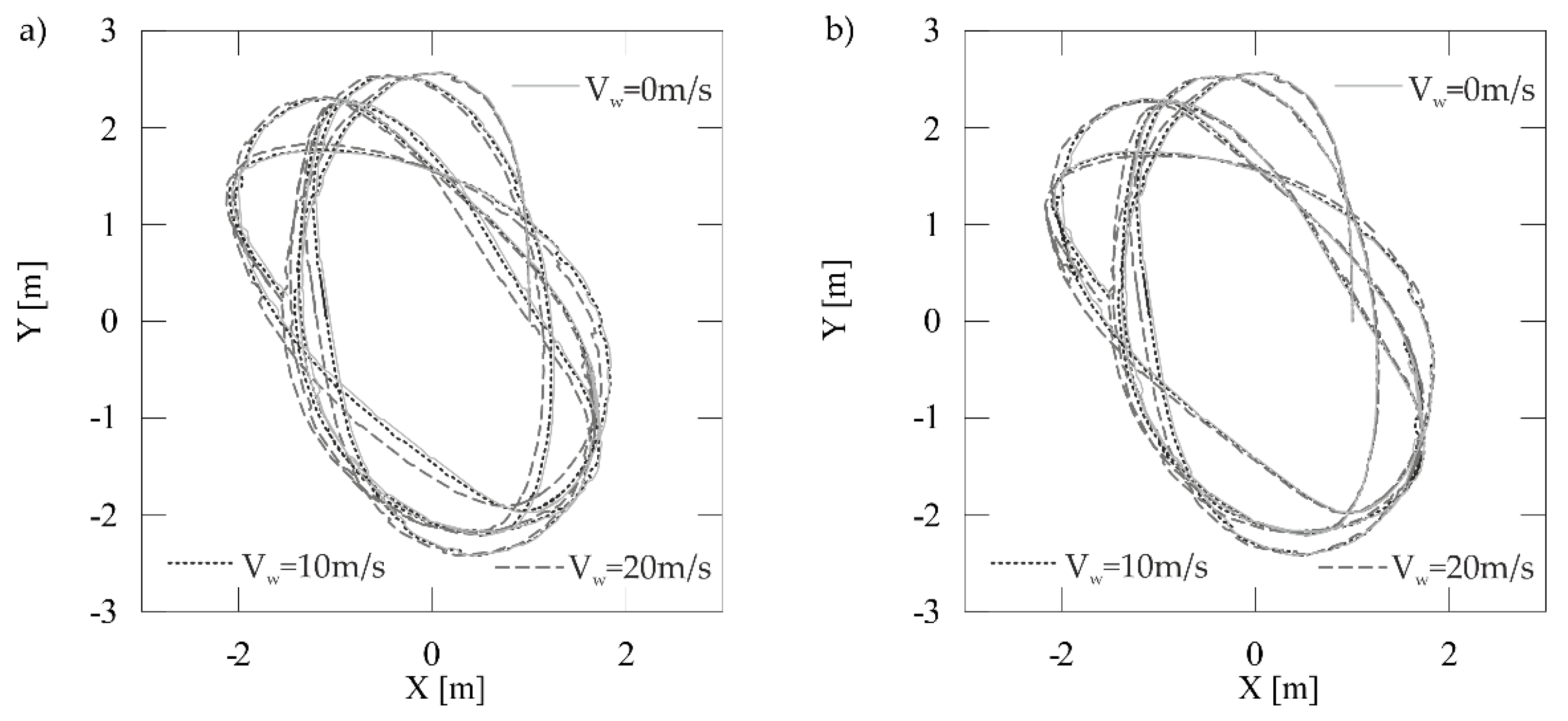

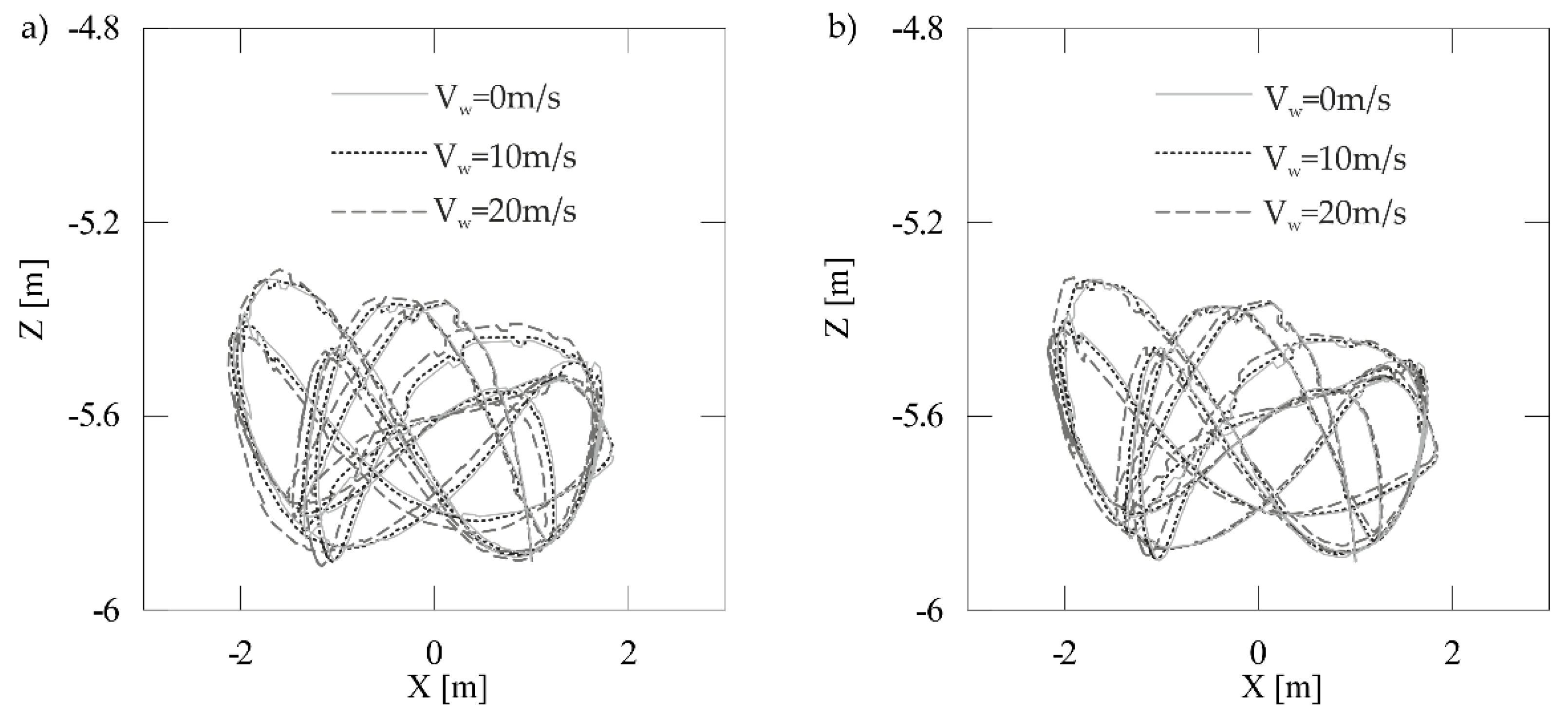

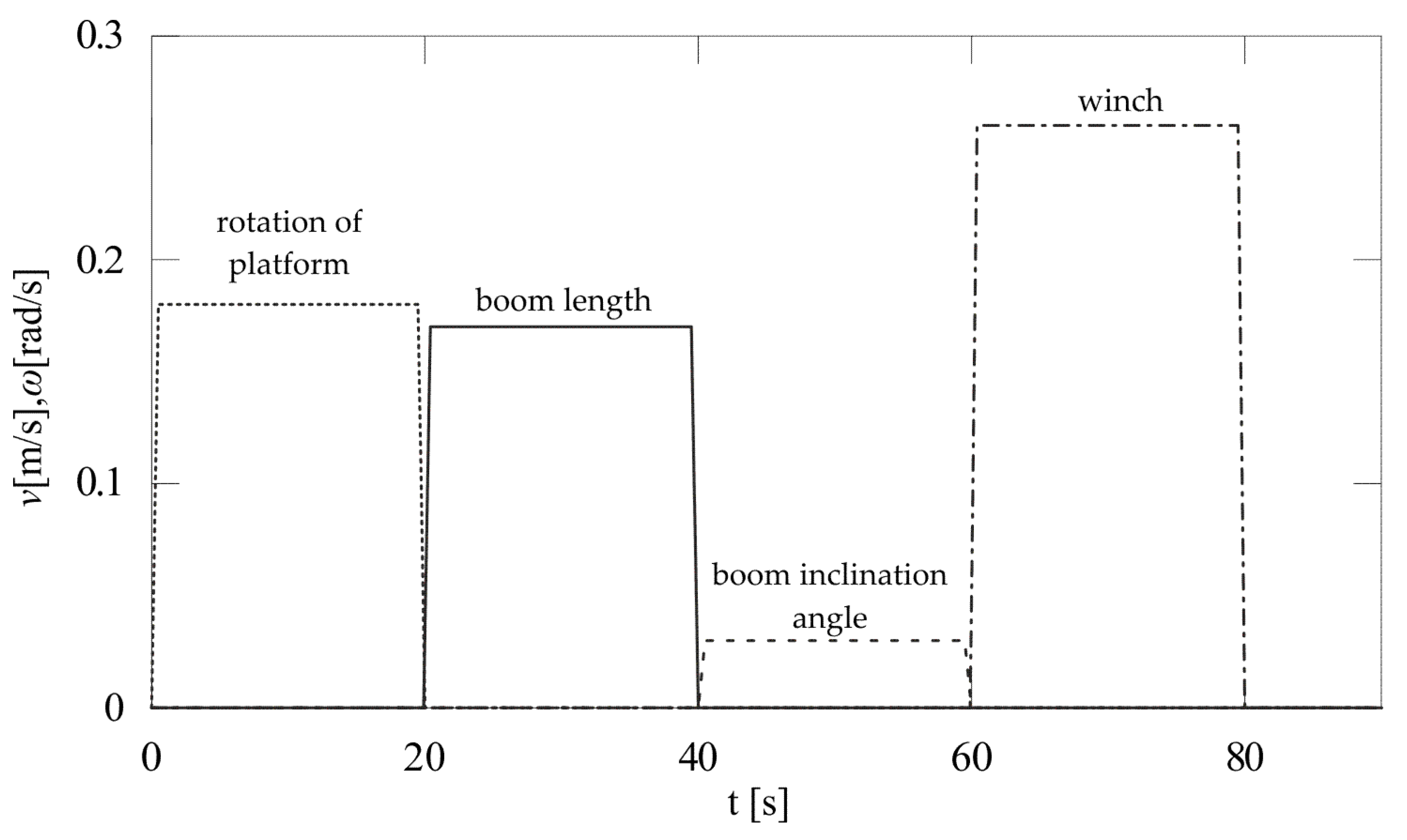

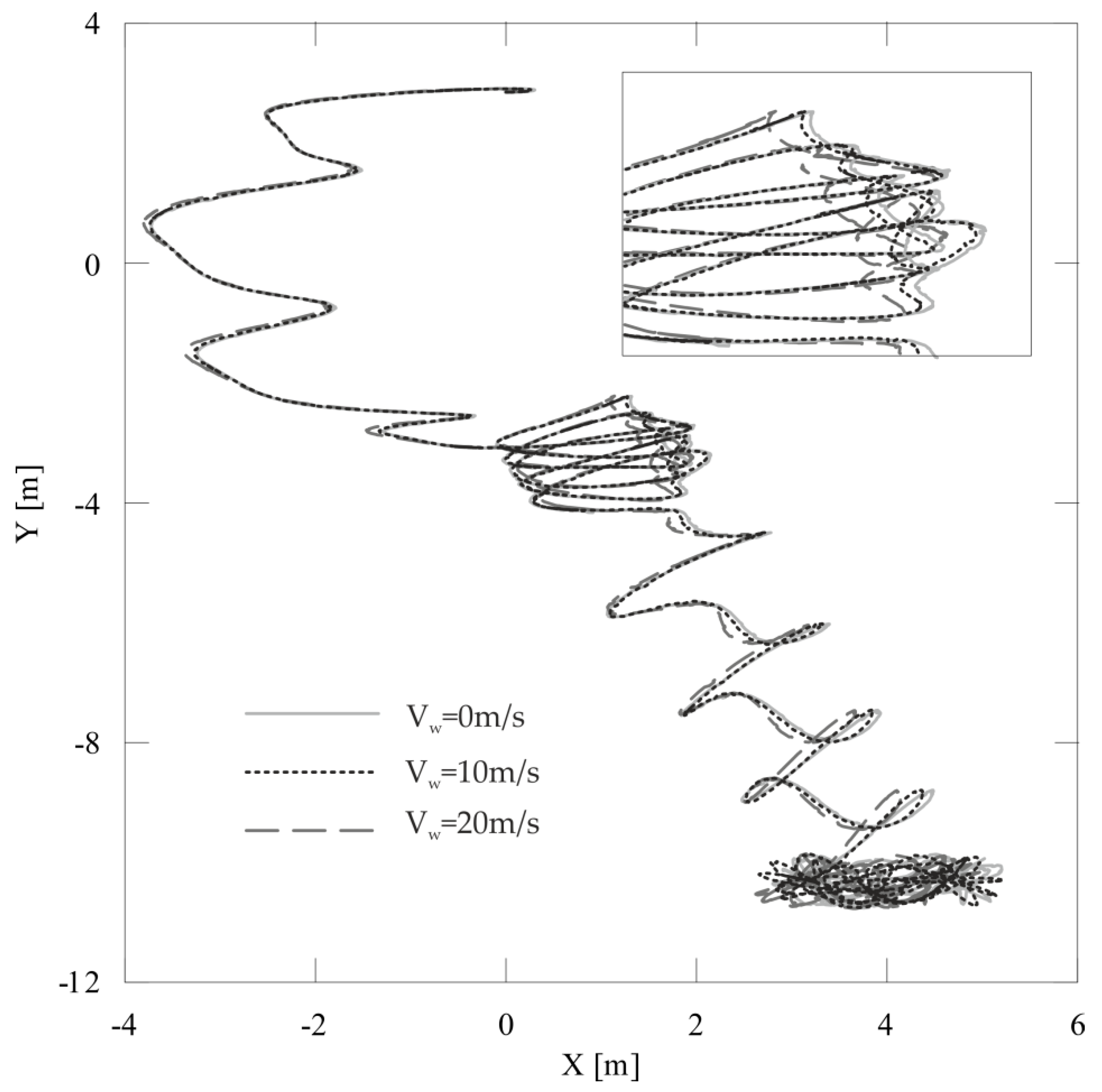

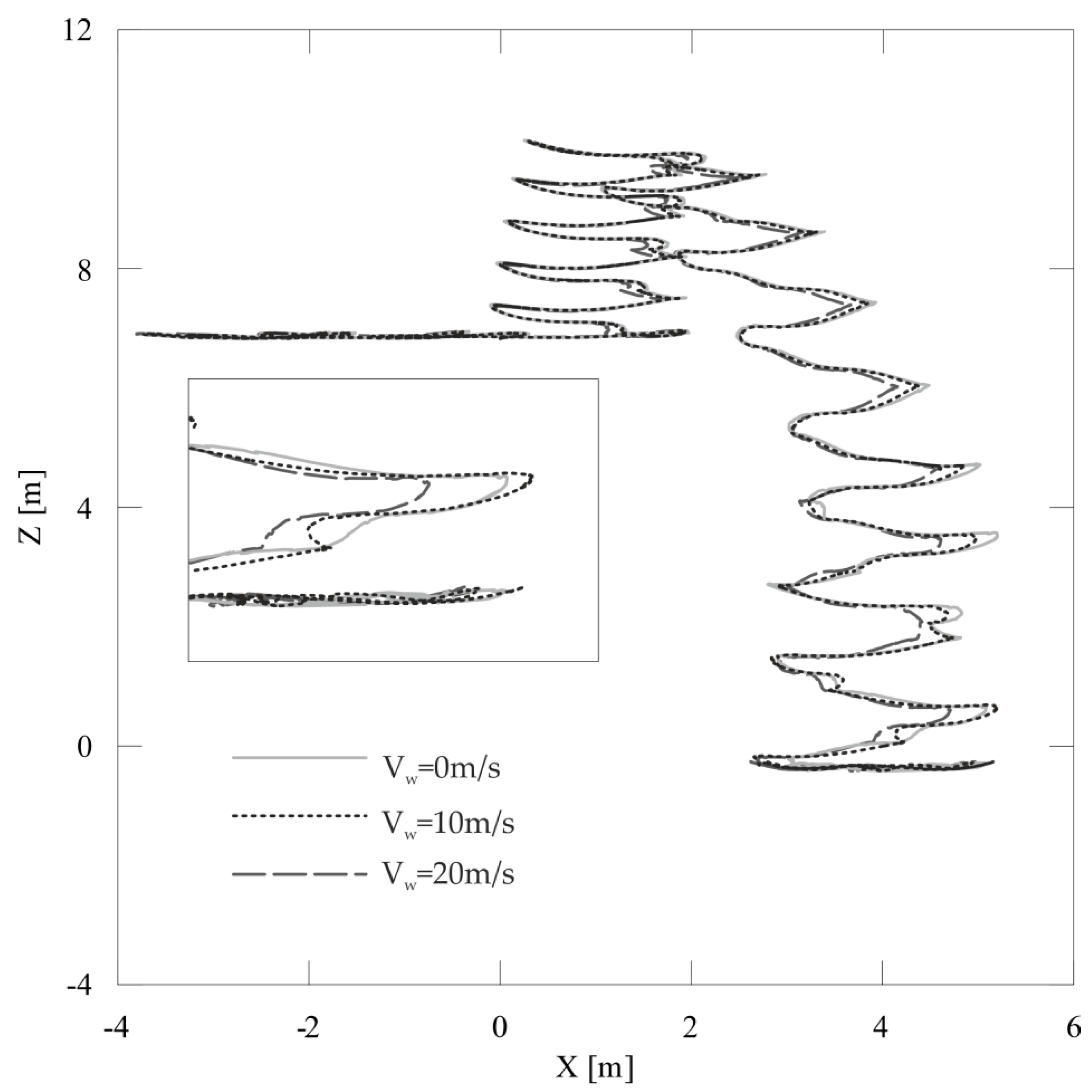

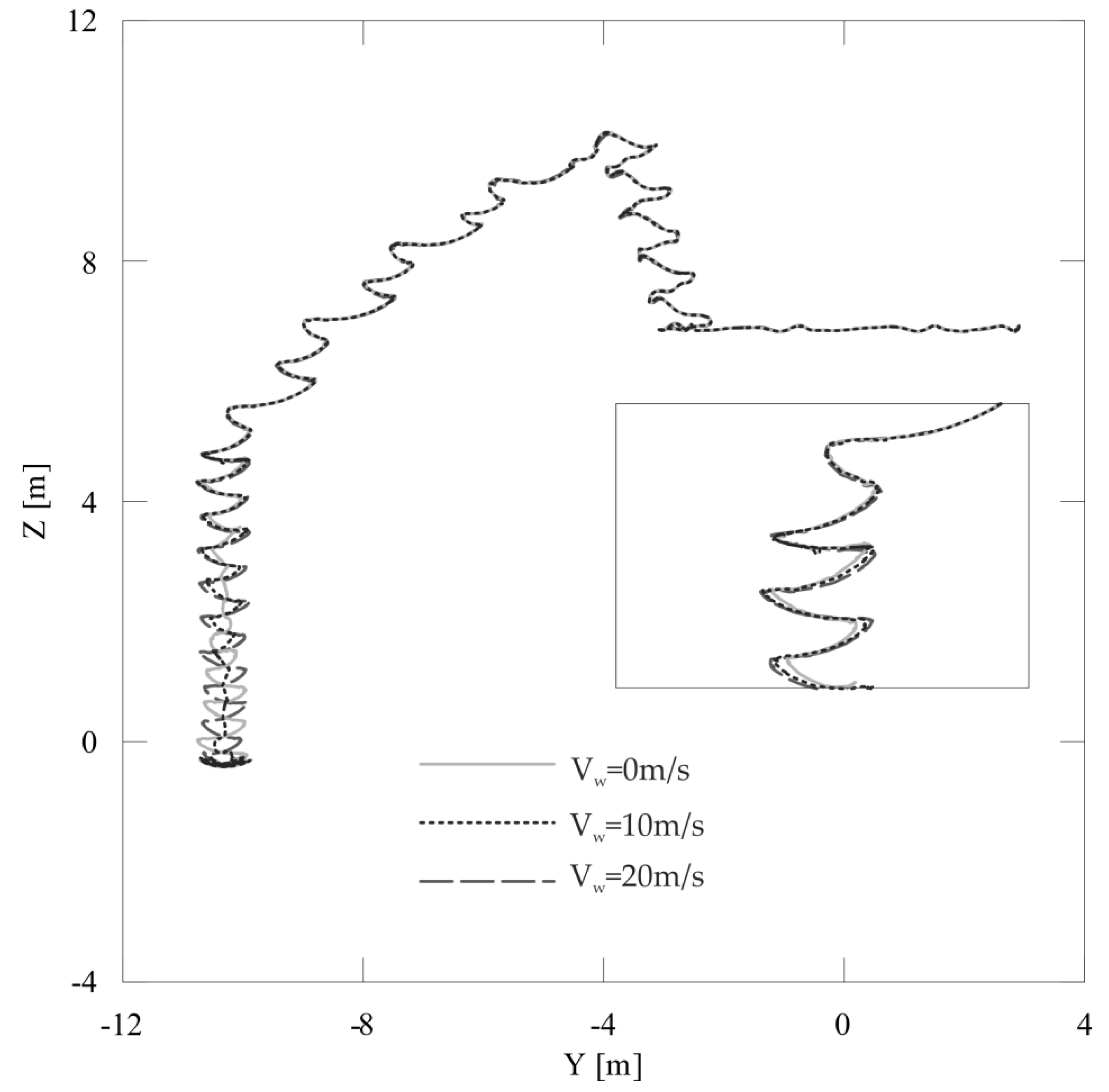

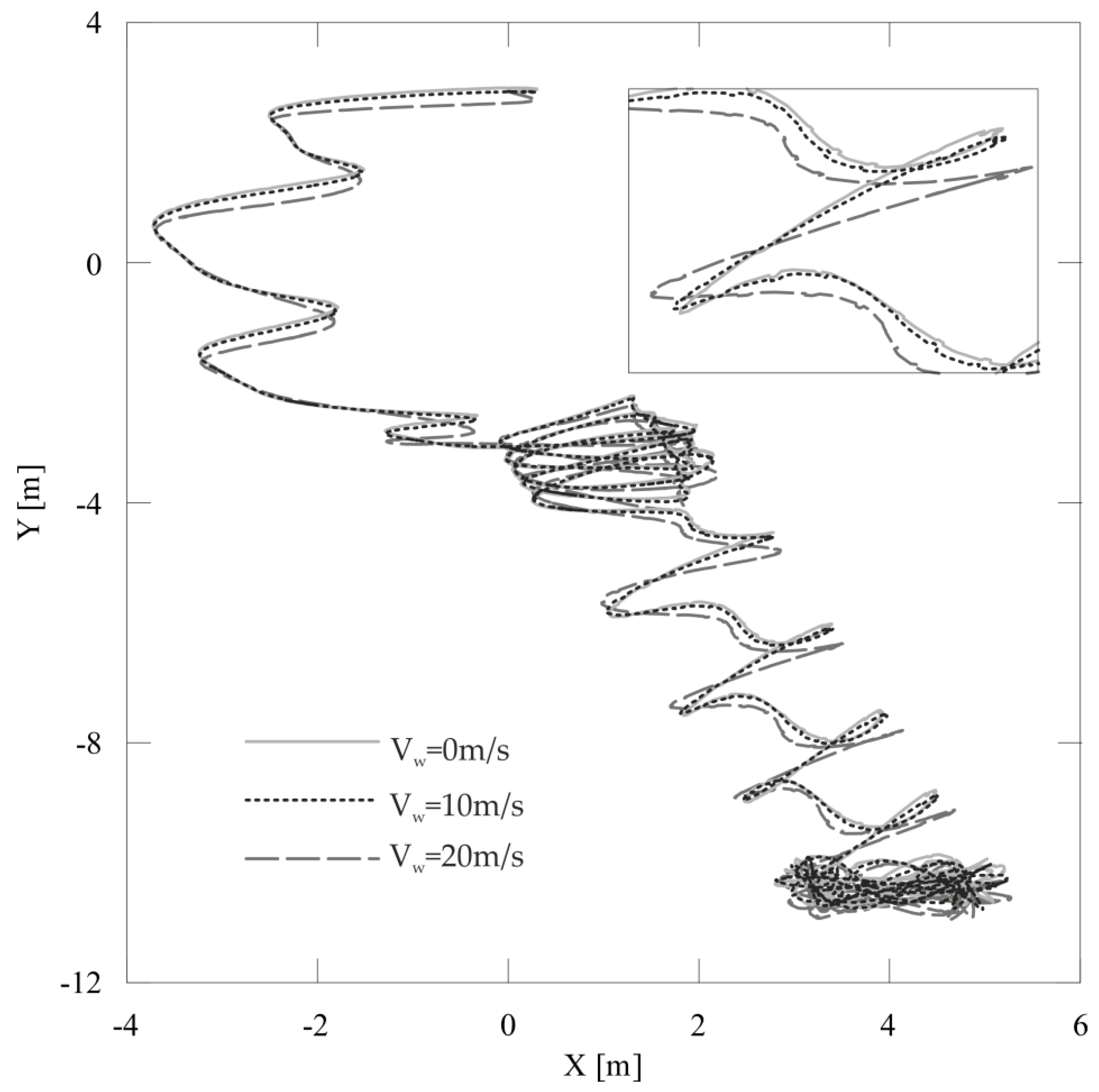

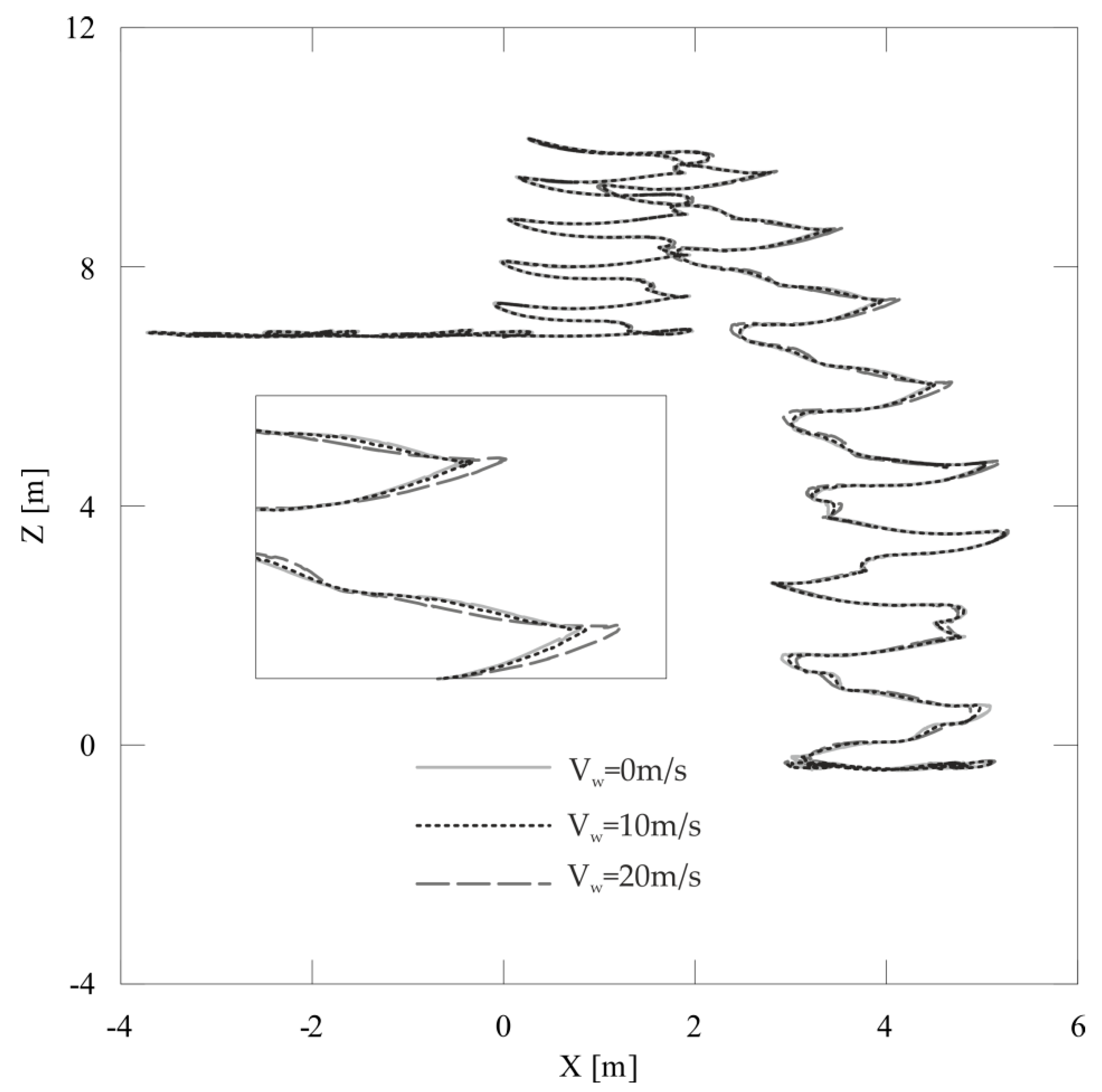

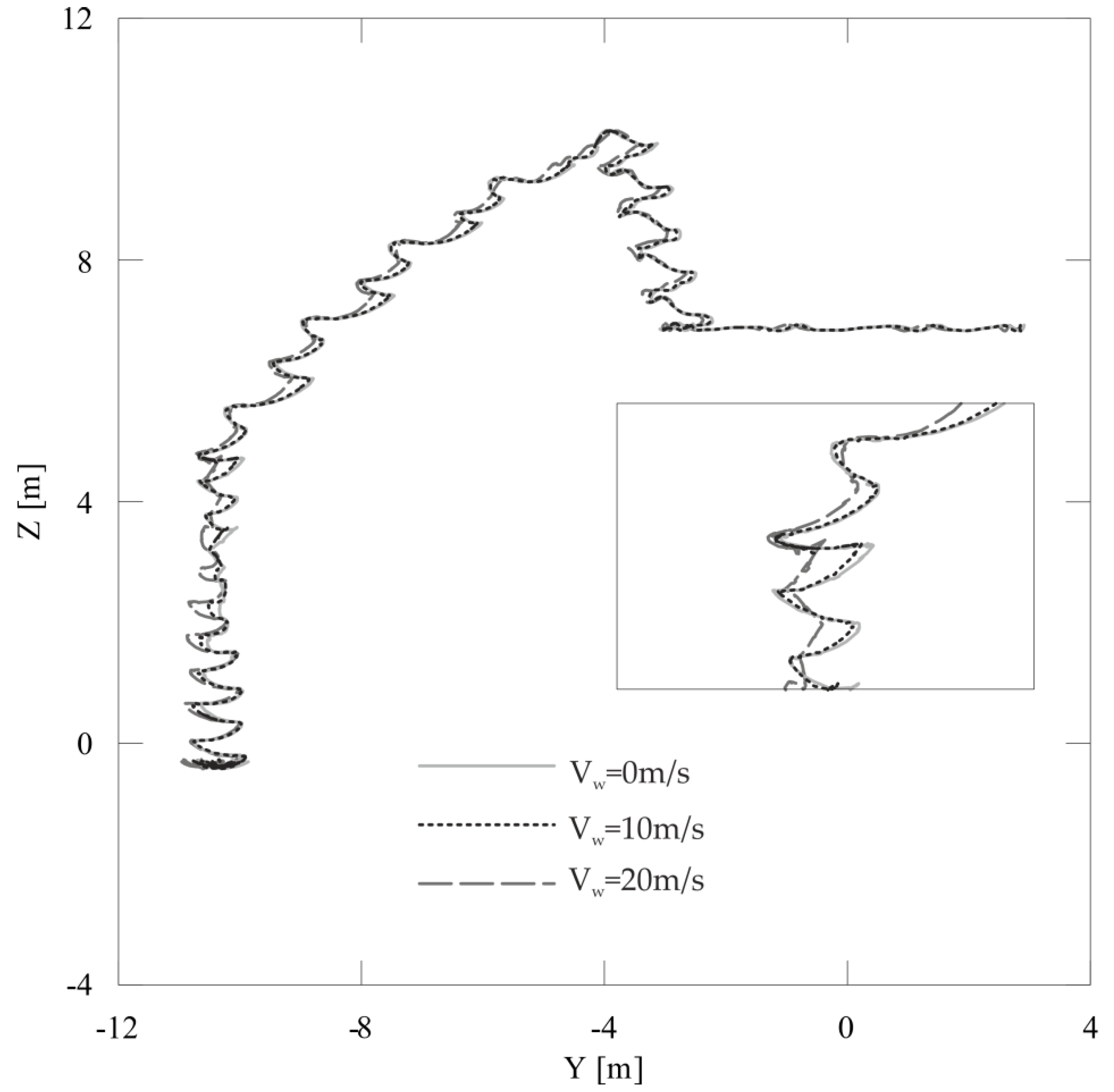

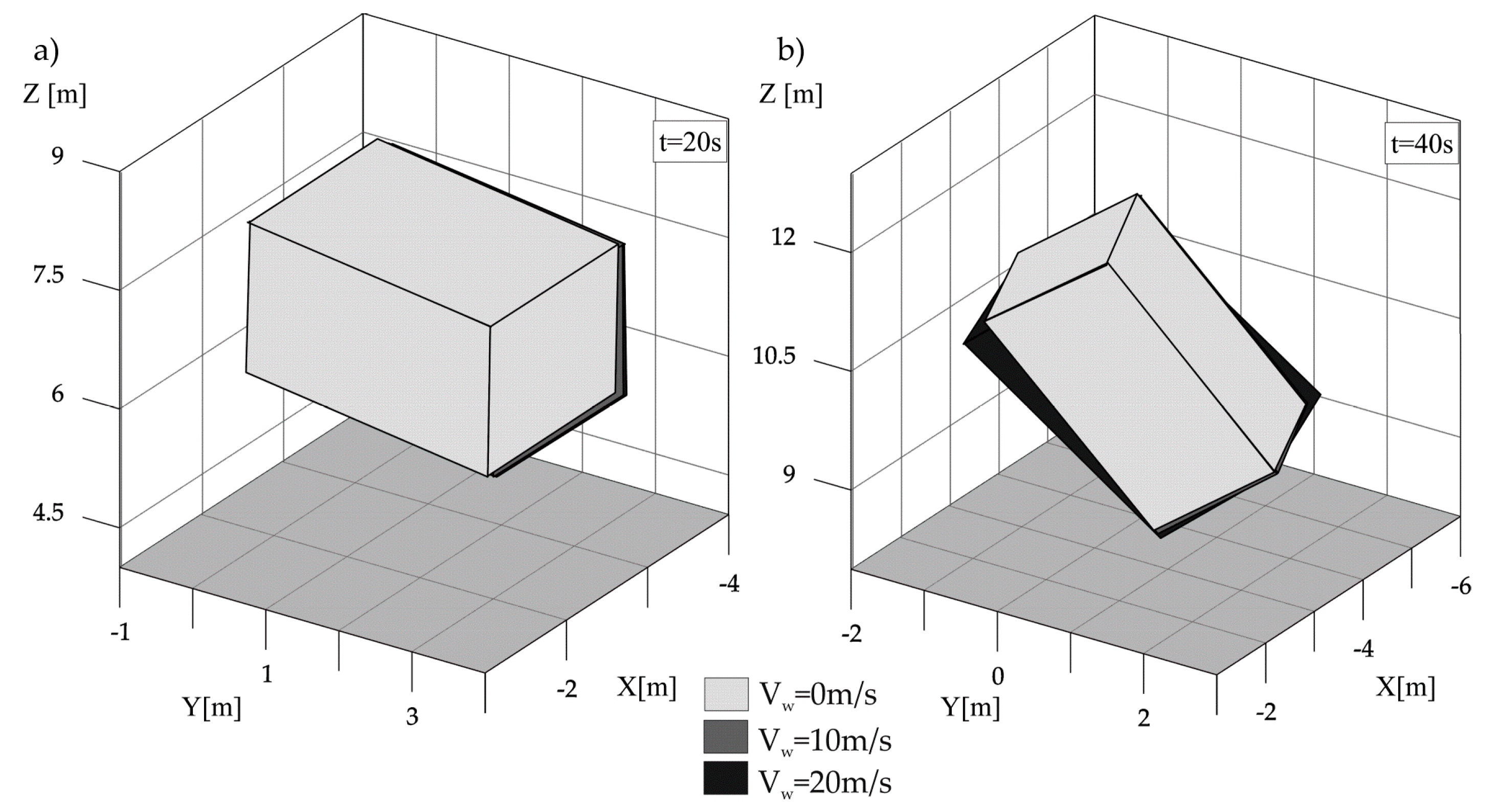

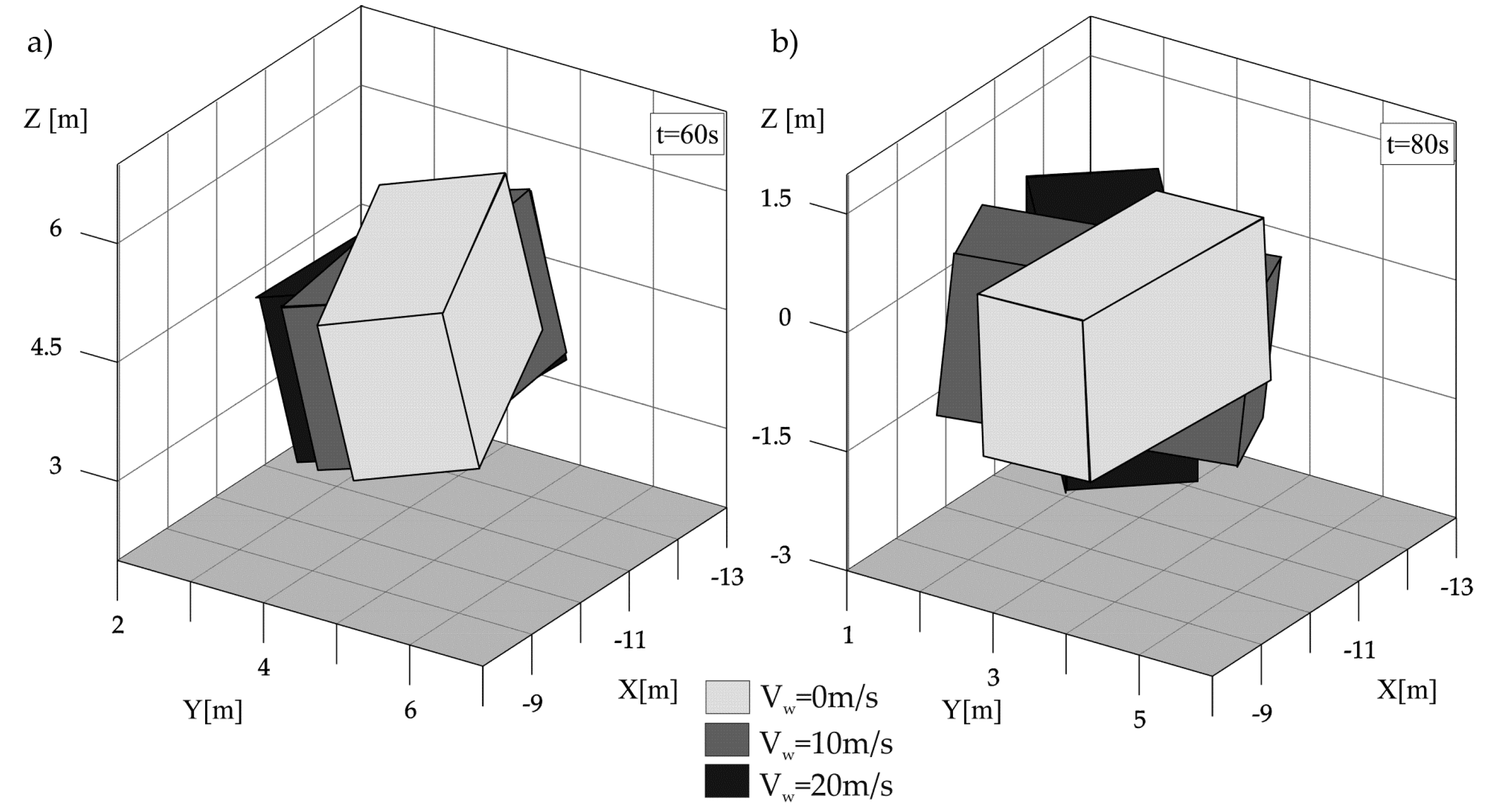

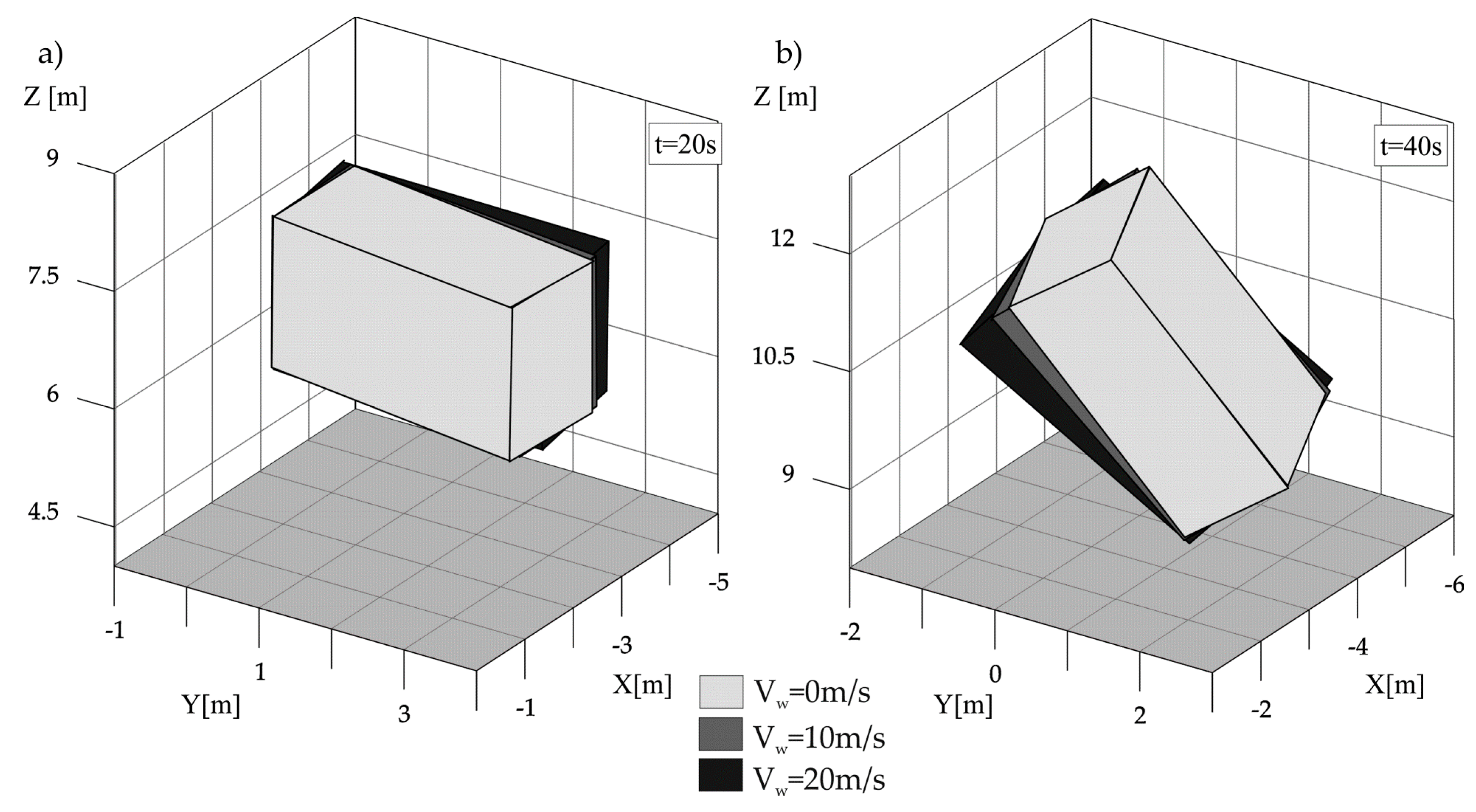

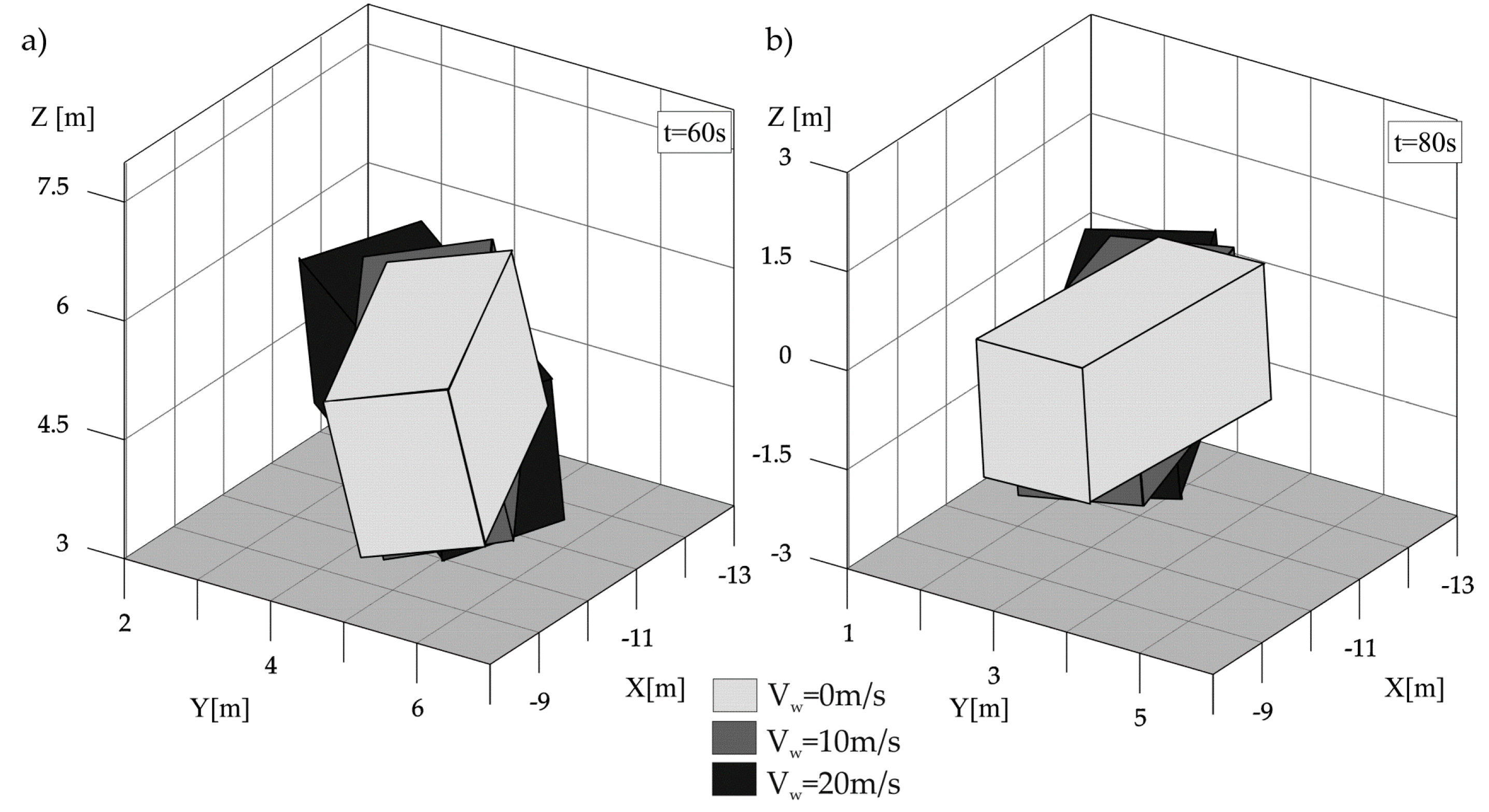

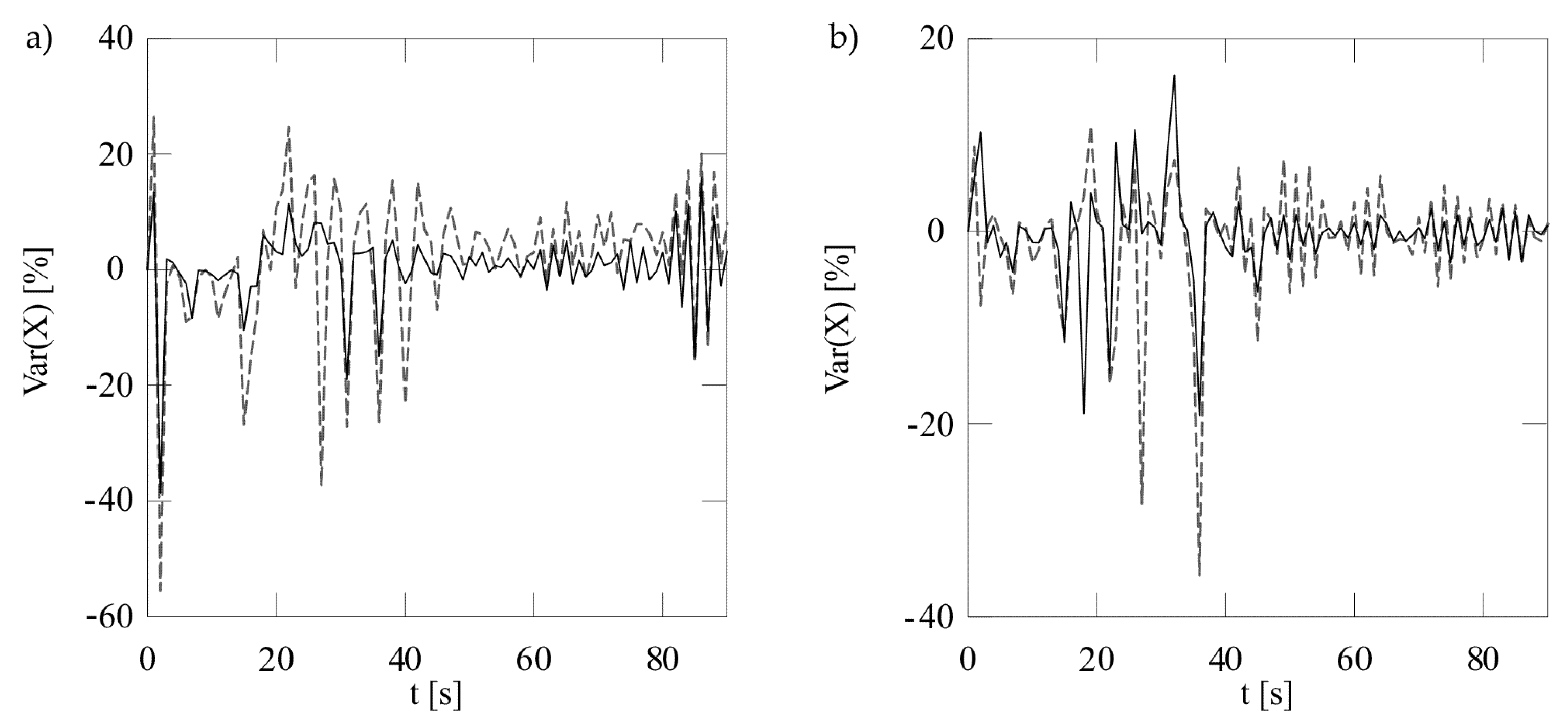

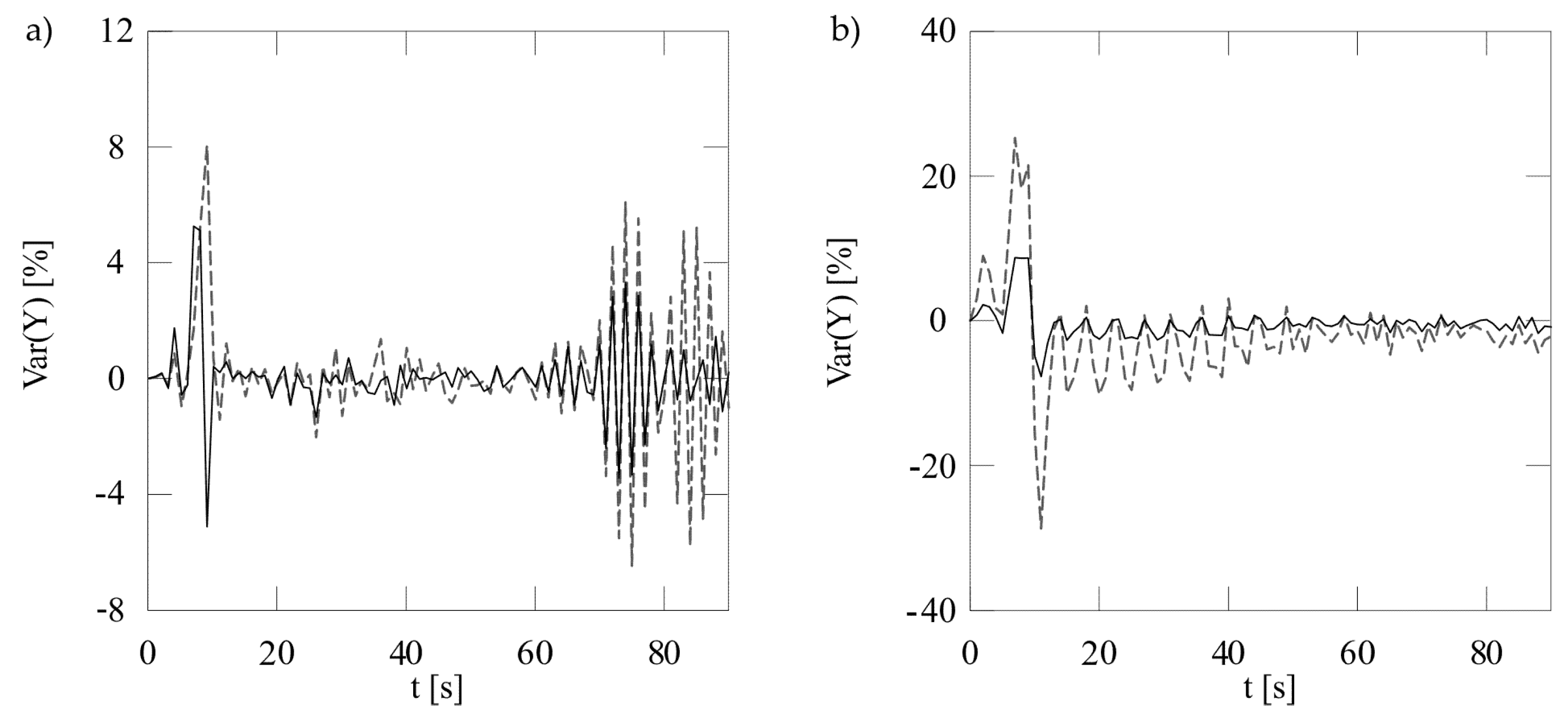

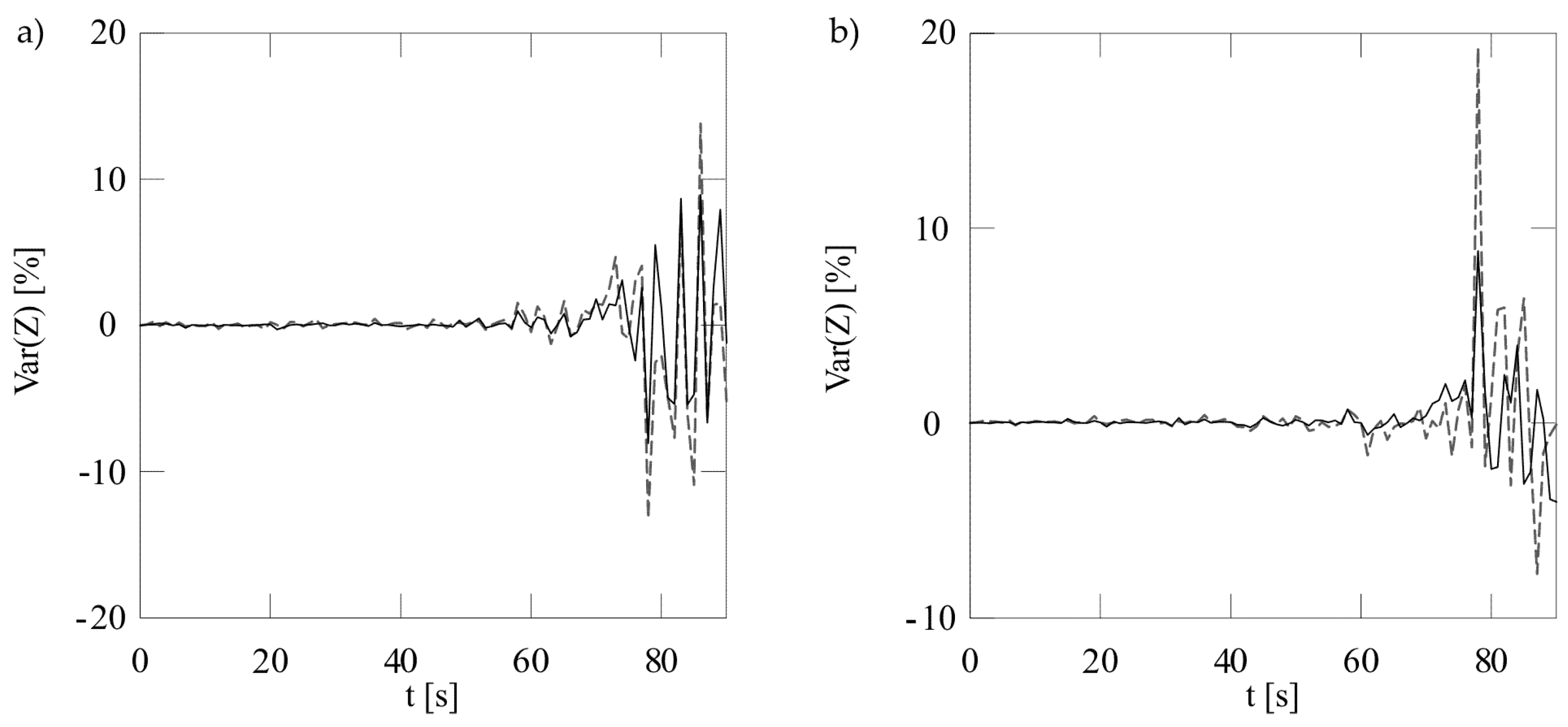

4.2. The Movement of the Load during the Working Cycle of the Truck-Crane

- the control of the crane’s platform rotation together with the telescopic boom—the motion starts at 0 s and lasts for 20 s, the maximum velocity in this motion is equal to 0.18 rad/s

- the control of the working-stroke of the hydraulic actuator system responsible for the change of the total length of the boom—the motion starts at 20 s and lasts for 20 s, the maximum velocity is equal to 0.18 m/s

- the control of the power stroke of the hydraulic actuator of boom change—the forcing lasts for 20 s and starts at 40 s, the maximum velocity is equal to 0.036 rad/s

- the control of winch operation—a 20 s cable extension begins at 60 s, the maximum velocity of cable extension is 0.27 m/s

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Posiadała, B. Influence of crane support system on motion of the lifted load. Mech. Mach. Theory 1997, 32, 9–20. [Google Scholar] [CrossRef]

- Mijailović, R. Modelling the dynamic behavior of the truck-crane. Transport 2011, 26, 410–417. [Google Scholar] [CrossRef]

- Posiadala, B.; Warys, P.; Cekus, D.; Tomala, M. The Dynamics Of The Forest Crane During The Load Carrying. Int. J. Struct. Stab. Dyn. 2013, 13. [Google Scholar] [CrossRef]

- Kacalak, W.; Budniak, Z.; Majewski, M. Stability Assessment as a Criterion of Stabilization of the Movement Trajectory of Mobile Crane Working Elements. Int. J. Appl. Mech. Eng. 2018, 23, 65–77. [Google Scholar] [CrossRef]

- Romanello, G. Stability analysis of mobile cranes and determination of outriggers loading. J. Eng. Des. Technol. 2018, 16, 938–958. [Google Scholar] [CrossRef]

- Kłosiński, J.; Janusz, J. Control of Operational Motions of a Mobile Crane under a Threat of Loss of Stability. SSP 2008, 144, 77–82. [Google Scholar] [CrossRef]

- Wu, J.; Guzzomi, A.L.; Hodkiewicz, M. Static stability analysis of non-slewing articulated mobile cranes. Aust. J. Mech. Eng. 2014, 12, 60–76. [Google Scholar] [CrossRef]

- Sochacki, W. The dynamic stability of a laboratory model of a truck crane. Thin-Walled Struct. 2007, 45, 927–930. [Google Scholar] [CrossRef]

- Tran, Q.H.; Huh, J.; Nguyen, V.B.; Kang, C.; Ahn, J.H.; Park, I.J. Sensitivity analysis for ship-to-shore container crane design. Appl. Sci. 2018, 8, 1667. [Google Scholar] [CrossRef]

- Arena, A.; Casalotti, A.; Lacarbonara, W.; Cartmell, M.P. Dynamics of container cranes: Three-dimensional modeling, full-scale experiments, and identification. Int. J. Mech. Sci. 2015, 93, 8–21. [Google Scholar] [CrossRef]

- Lee, S.-J.; Kang, J.-H. Wind load on a container crane located in atmospheric boundary layers. J. Wind Eng. Ind. Aerodyn. 2008, 96, 193–208. [Google Scholar] [CrossRef]

- Cekus, D.; Gnatowska, R.; Kwiatoń, P. Influence of wind on the movement of the load. J. Phys. Conf. Ser. 2018, 1101, 012005. [Google Scholar] [CrossRef]

- Miadlicki, K.; Pajor, M.; Sakow, M. Loader crane working area monitoring system based on LIDAR scanner. In Advances in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018; pp. 465–474. [Google Scholar]

- Taghaddos, H.; Hermann, U.; Abbasi, A. Automated Crane Planning and Optimization for modular construction. Autom. Constr. 2018, 95, 219–232. [Google Scholar] [CrossRef]

- Pan, Z.; Guo, H.; Li, Y. Automated Method for Optimizing Feasible Locations of Mobile Cranes Based on 3D Visualization. Procedia Eng. 2017, 196, 36–44. [Google Scholar] [CrossRef]

- Cekus, D.; Kwiatoń, P. Analysis of the motion of the load carried by a laboratory mobile crane. In Proceedings of the 24th International Conference Engineering Mechanics 2018, Svratka, Czech Republic, 14–17 May 2018; pp. 137–140. [Google Scholar]

- Trabka, A. Influence of flexibilities of cranes structural components on load trajectory. J. Mech. Sci. Technol. 2016, 30, 1–14. [Google Scholar] [CrossRef]

- Fujioka, D.; Rauch, A.; Singhose, W. Tip-Over Stability Analysis of Mobile Boom Cranes with Double-Pendulum Payloads. In Proceedings of the American Control Conference 2009, St. Louis, MO, USA, 10–12 June 2009; pp. 3136–3141. [Google Scholar]

- Al-Humaidi, H.M.; Hadipriono Tan, F. Mobile crane safe operation approach to prevent electrocution using fuzzy-set logic models. Adv. Eng. Softw. 2009, 40, 686–696. [Google Scholar] [CrossRef]

- Posiadała, B.; Skalmierski, B.; Tomski, L. Motion of the lifted load brought by a kinematic forcing of the crane telescopic boom. Mech. Mach. Theory 1990, 25, 547–556. [Google Scholar] [CrossRef]

- Jaskot, A.; Posiadała, B.; Śpiewak, S. Dynamics modelling of the four-wheeled mobile platform. Mech. Res. Commun. 2017, 83, 58–64. [Google Scholar] [CrossRef]

- Baker, C.J. Ground vehicles in high cross winds part II: Unsteady aerodynamic forces. J. Fluids Struct. 1991, 5, 91–111. [Google Scholar] [CrossRef]

- Liao, C.; Shi, K.; Zhao, X. Predicting the Extreme Loads in Power Production of Large Wind Turbines Using an Improved PSO Algorithm. Appl. Sci. 2019, 9, 521. [Google Scholar] [CrossRef]

- Ahmed, W.K. Advantages and Disadvantages of Using MATLAB/ode45 for Solving Differential Equations in Engineering Applications. Int. J. Eng. 2013, 7, 25–31. [Google Scholar]

- Cekus, D.; Posiadała, B.; Warys, P. Integration of modeling in Solidworks and Matlab/Simulink environments. Arch. Mech. Eng. 2014, 61, 57–74. [Google Scholar] [CrossRef]

- Weerasuriya, A.U.; Tse, K.T.; Zhang, X.; Kwok, K.C.S. Equivalent wind incidence angle method: A new technique to integrate the effects of twisted wind flows to AVA. Build. Environ. 2018, 139, 46–57. [Google Scholar] [CrossRef]

- Hazewinkel, M. Encyclopaedia of Mathematics, 1st ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1995. [Google Scholar]

| Load Mass | Cable Length | Load Dimensions | Aerodynamic Resistance Coefficient | Wind Velocity |

|---|---|---|---|---|

| 7000 kg | 5 m | a = 3.5 m | 1.05 | 0 m/s |

| b = 1.5 m | 10 m/s | |||

| c = 2.0 m | 20 m/s |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cekus, D.; Gnatowska, R.; Kwiatoń, P. Impact of Wind on the Movement of the Load Carried by Rotary Crane. Appl. Sci. 2019, 9, 3842. https://doi.org/10.3390/app9183842

Cekus D, Gnatowska R, Kwiatoń P. Impact of Wind on the Movement of the Load Carried by Rotary Crane. Applied Sciences. 2019; 9(18):3842. https://doi.org/10.3390/app9183842

Chicago/Turabian StyleCekus, Dawid, Renata Gnatowska, and Paweł Kwiatoń. 2019. "Impact of Wind on the Movement of the Load Carried by Rotary Crane" Applied Sciences 9, no. 18: 3842. https://doi.org/10.3390/app9183842

APA StyleCekus, D., Gnatowska, R., & Kwiatoń, P. (2019). Impact of Wind on the Movement of the Load Carried by Rotary Crane. Applied Sciences, 9(18), 3842. https://doi.org/10.3390/app9183842