A Novel Bidirectional Wireless Power Transfer System for Mobile Power Application

Abstract

:Featured Application

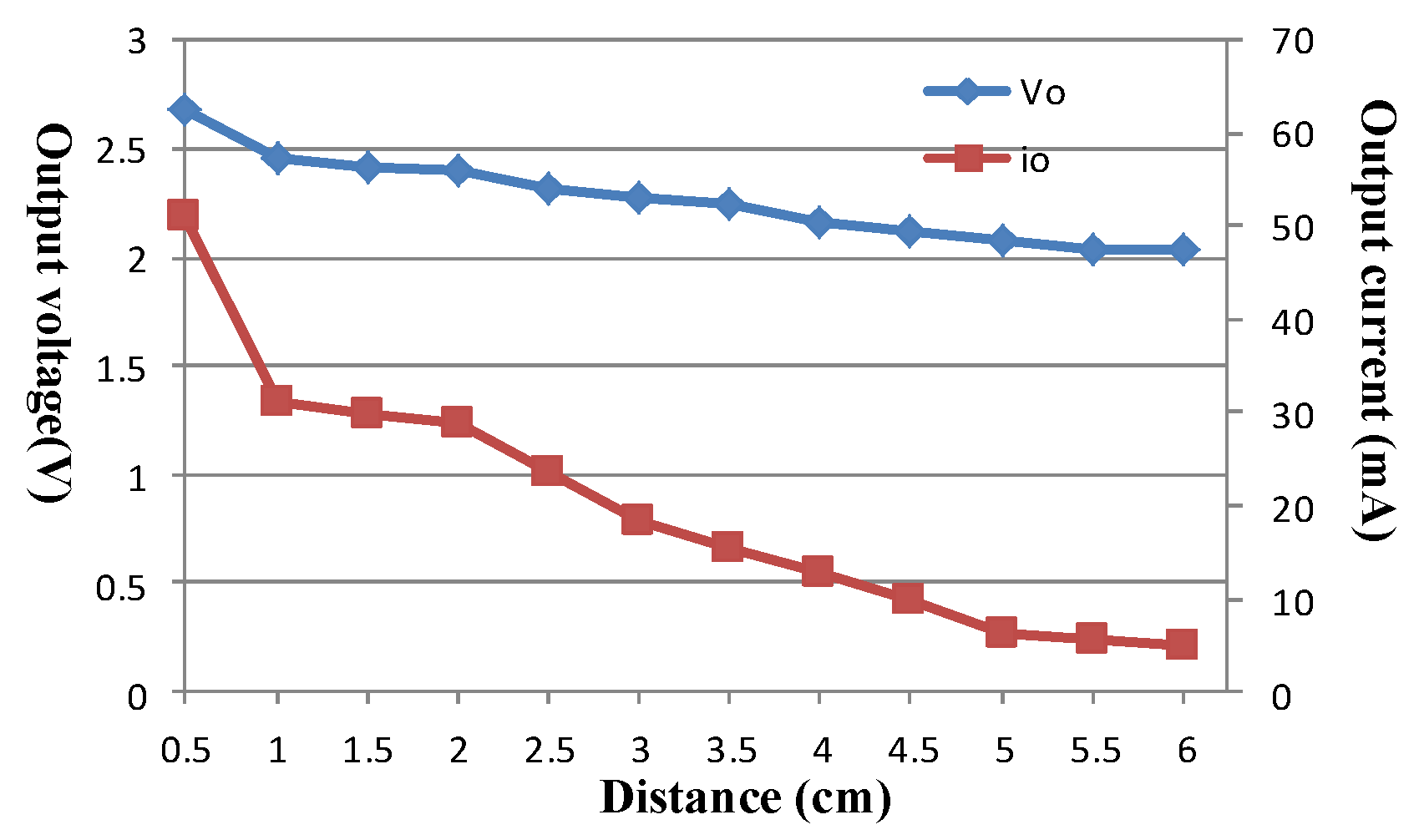

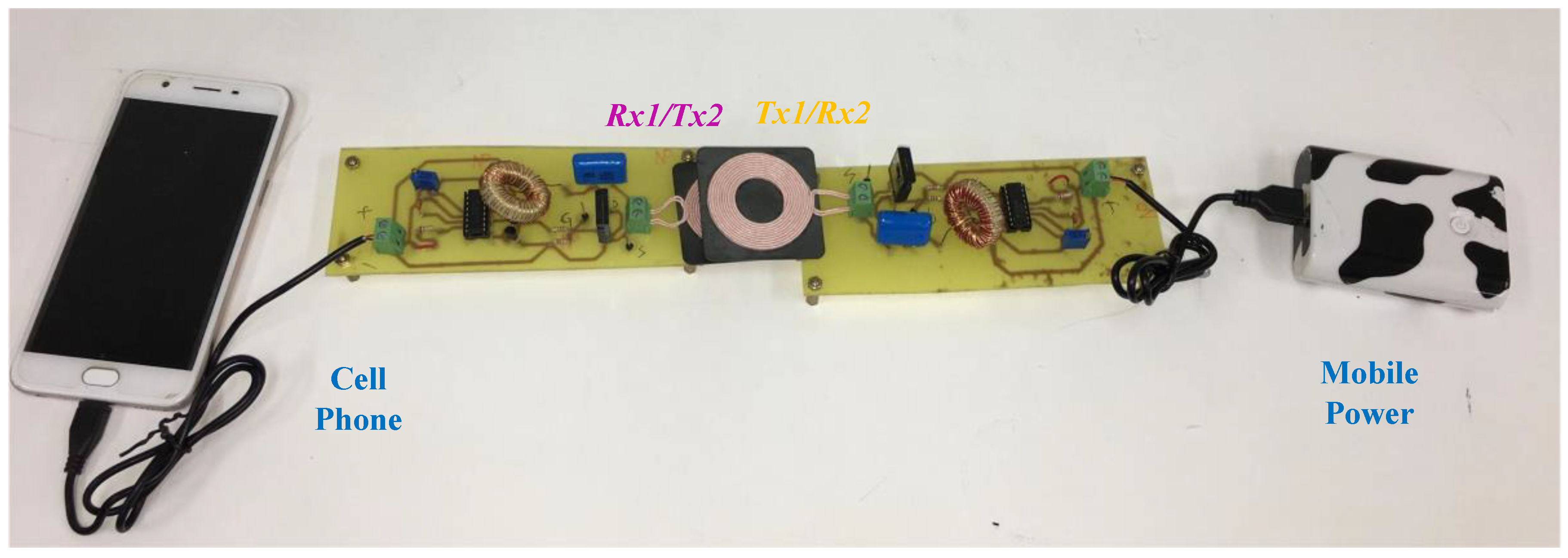

Abstract

1. Introduction

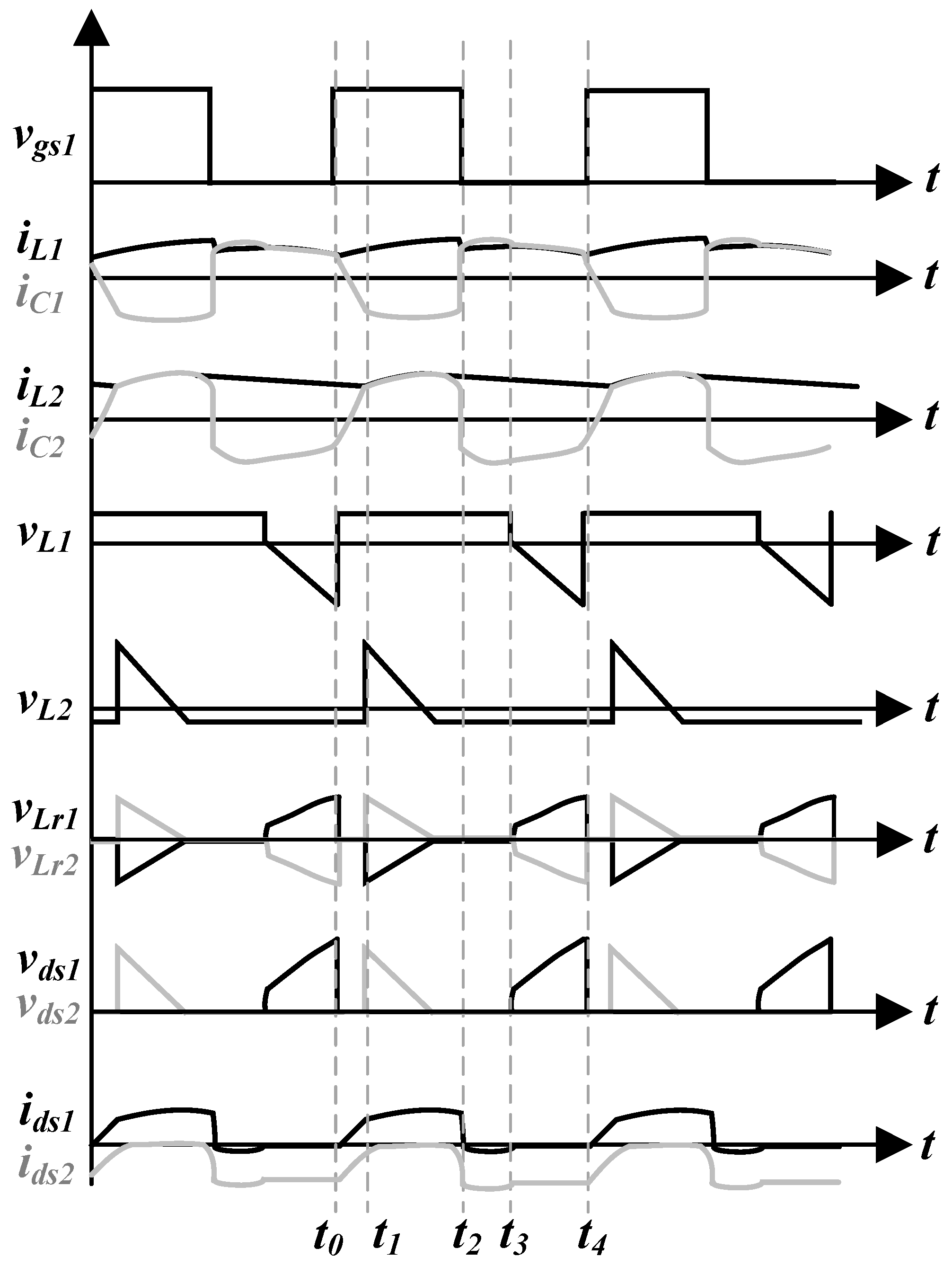

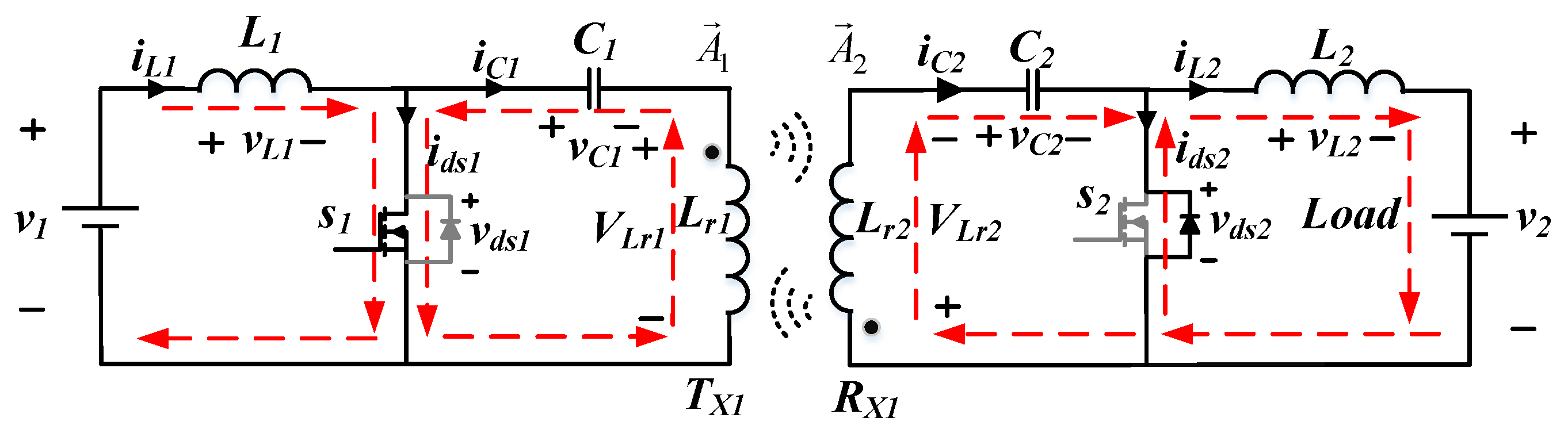

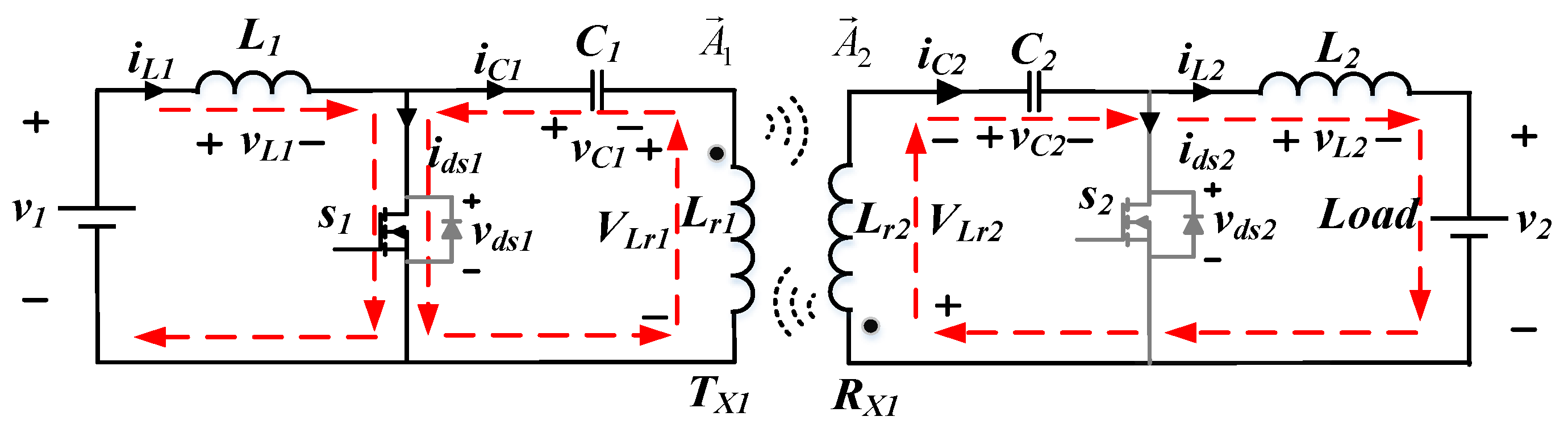

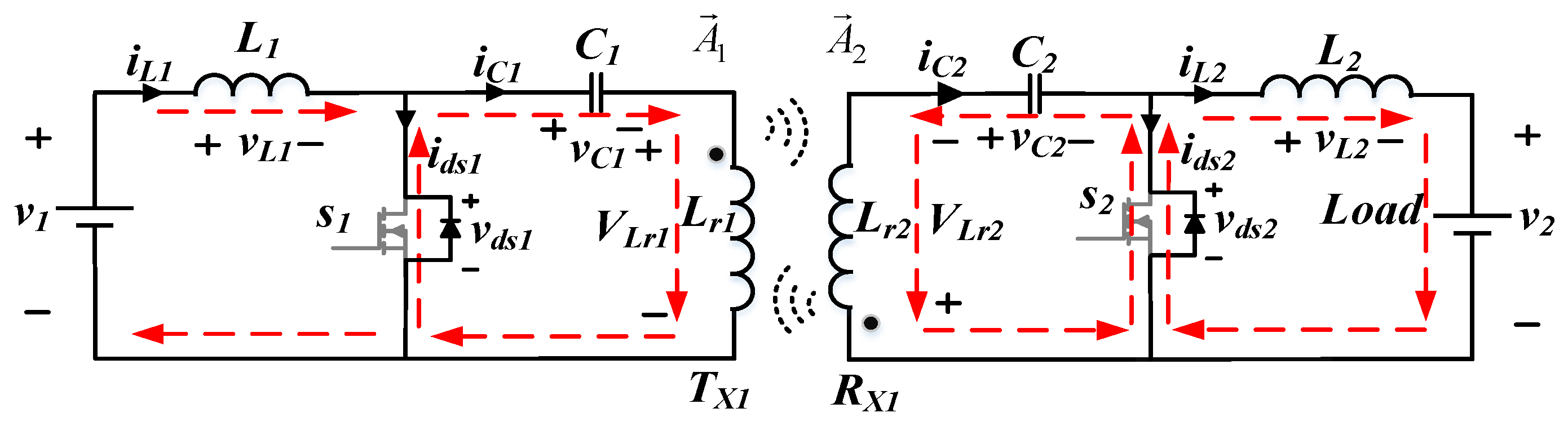

2. Analysis of Proposed Circuit Topology

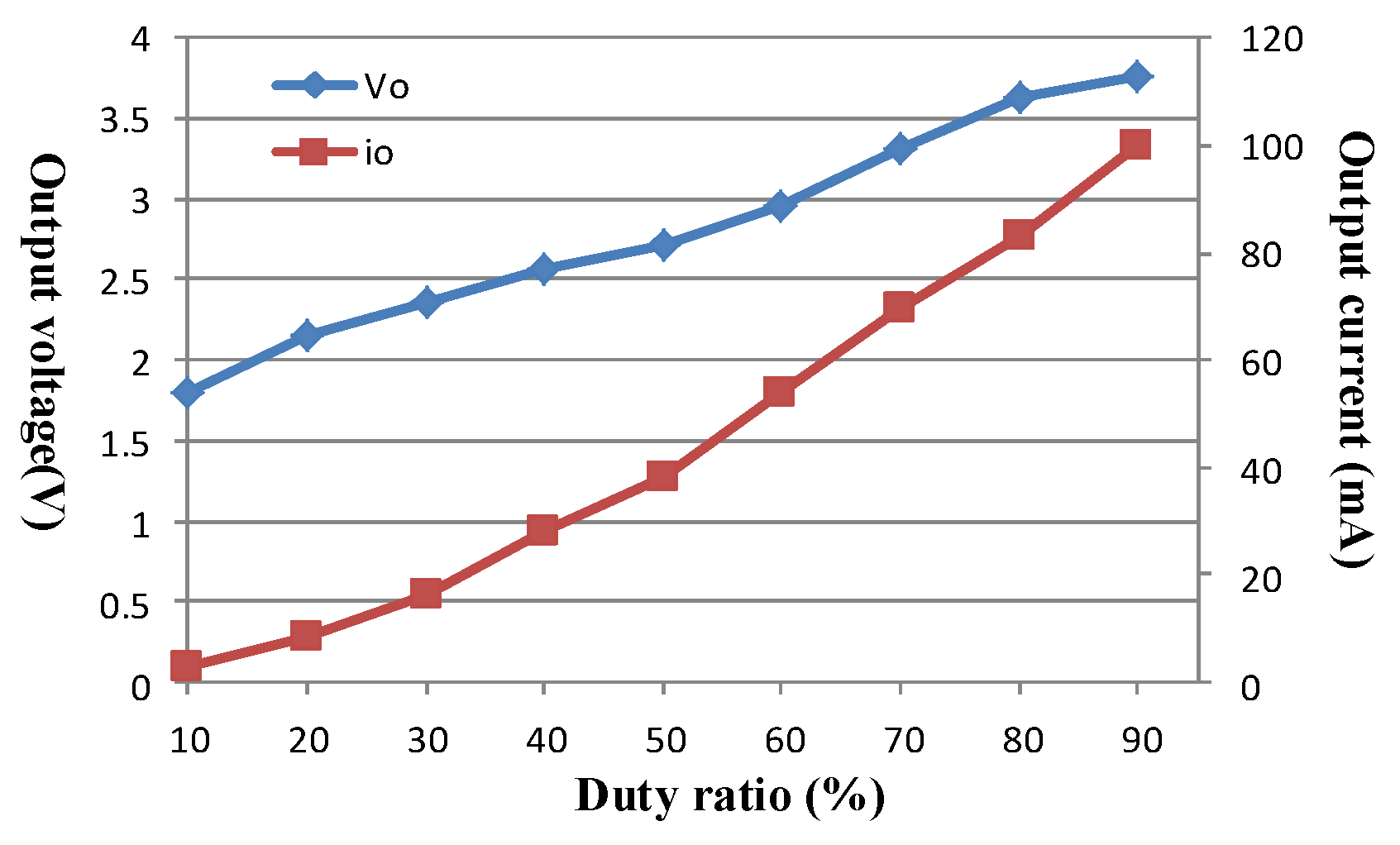

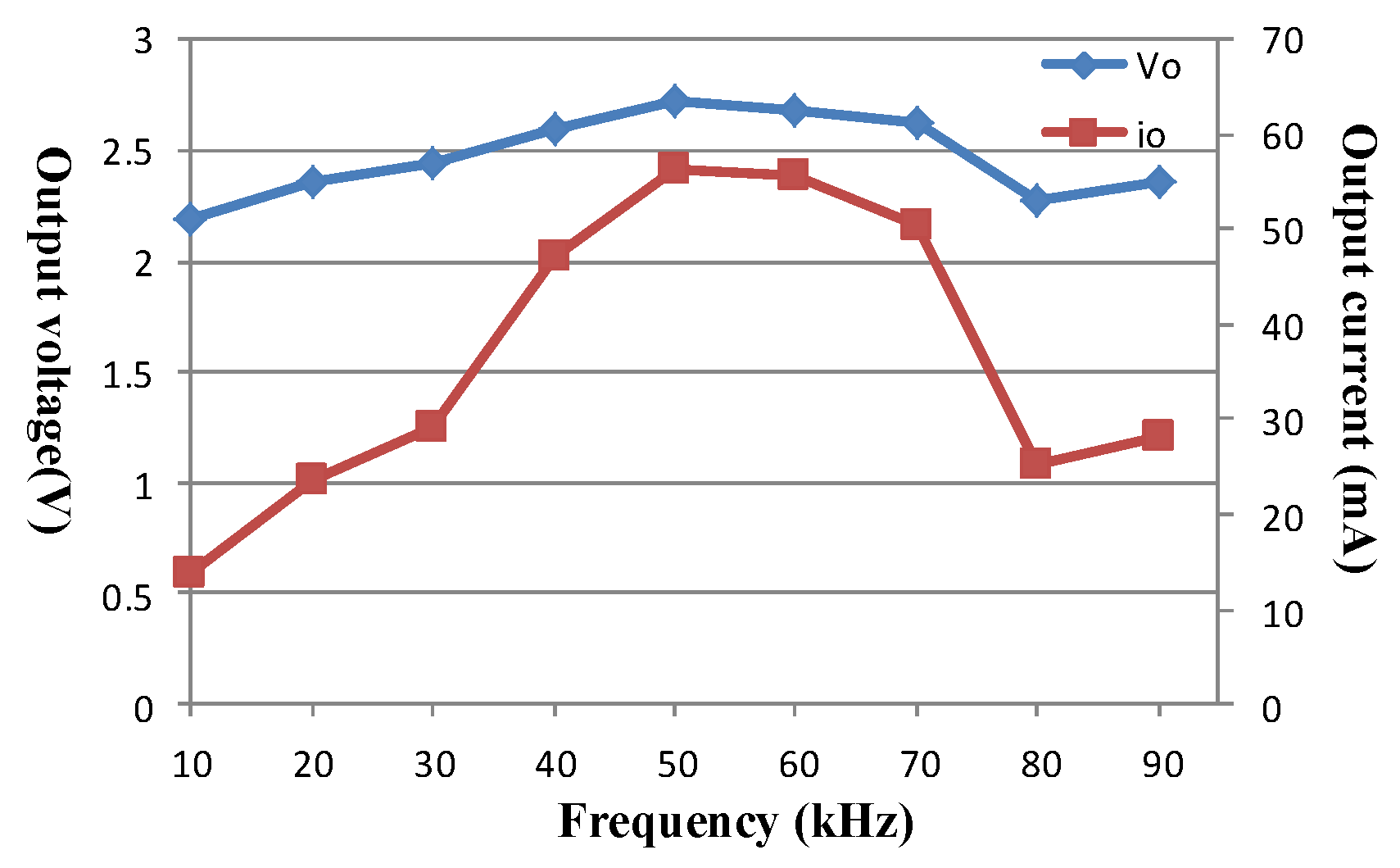

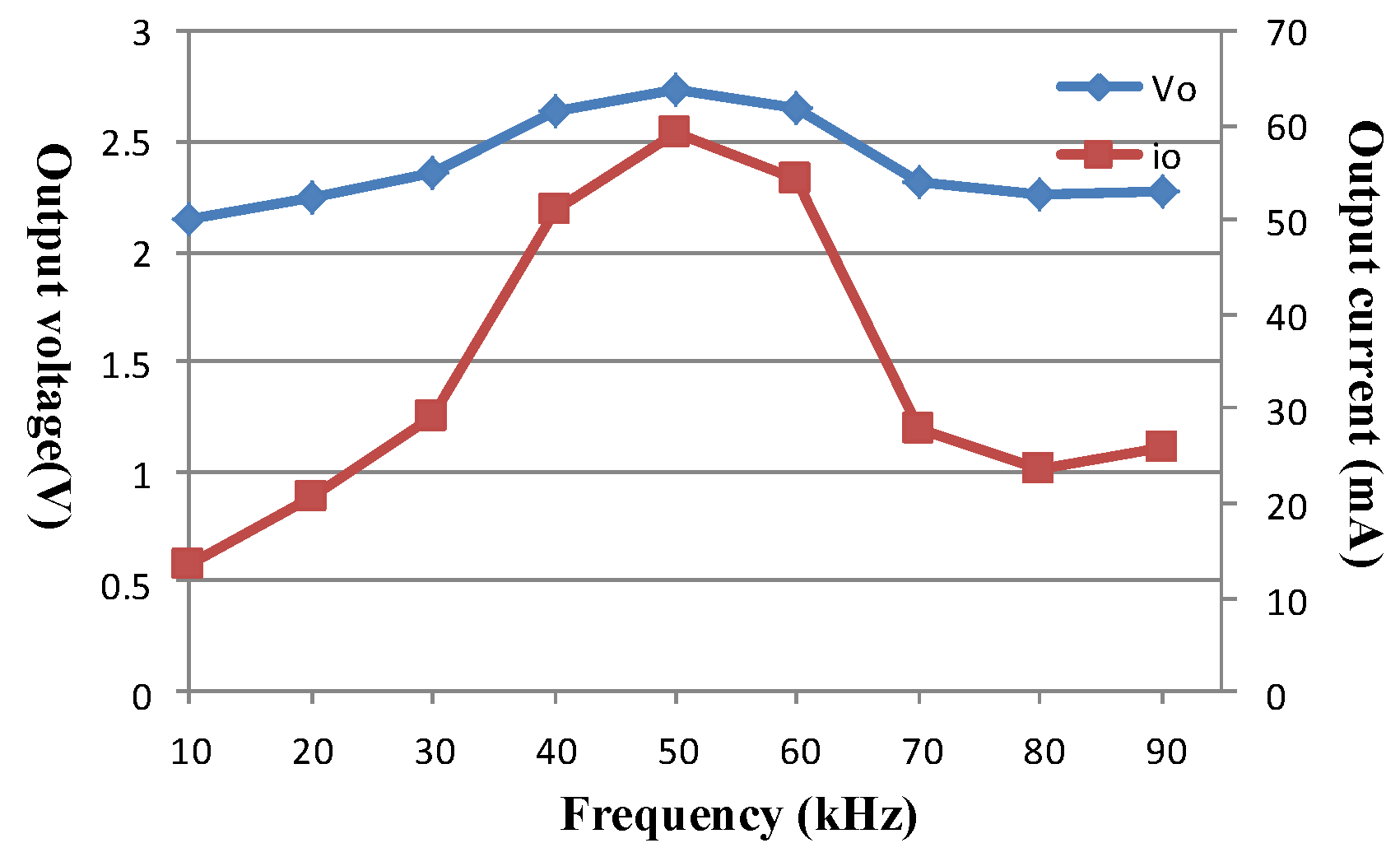

3. Simulation and Experimental Results

4. System Analysis and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| EV | Electric vehicle |

| WPT | Wireless power transfer |

| Tx | Transmitter |

| Rx | Receiver |

| M | Mutual inductance |

| , | Magnetic vector potential |

| Permeability of vacuum | |

| L1, L2 | Boost inductor |

| C1, C2, Cr1, Cr2 | Resonant capacitor |

| Lr1, Lr2 | Resonant coupled inductor |

| S1, S2 | Active switch |

| Vgsx | Gate signal of active switch x, x = 1, 2 |

| V1, V2 | Voltage sources of primary and secondary side |

| D1, D2 | Switching duty ratios of switch 1 and switch 2 |

References

- Nutwong, S.; Sangswang, A.; Naetiladdanon, S. An Inverter Topology for Wireless Power Transfer System with Multiple Transmitter Coils. Appl. Sci. 2019, 9, 1551. [Google Scholar] [CrossRef]

- Tao, X.; Rong, C.; Lu, C.; Huang, X.; Zeng, Y.; Hu, Z.; Liu, M. A Novel Approach to Reach Impedance Matching in Wireless Power Transfer Systems. Appl. Sci. 2019, 9, 976. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, C.; Jiang, J.; Song, K.; Wei, G. A 3-kW Wireless Power Transfer System for Sightseeing Car Supercapacitor Charge. IEEE Trans. Power Electron. 2017, 32, 3301–3316. [Google Scholar] [CrossRef]

- Li, Y.; Grabham, N.; Torah, R.; Tudor, J.; Beeby, S. Textile-Based Flexible Coils for Wireless Inductive Power Transmission. Appl. Sci. 2018, 8, 912. [Google Scholar] [CrossRef]

- Matsumoto, H.; Neba, Y.; Ishizaka, K.; Itoh, R. Comparison of characteristics on planar contactless power transfer systems. IEEE Trans. Power Electron. 2012, 27, 2980–2993. [Google Scholar] [CrossRef]

- Xie, K.; Huang, A.; Chen, L.; Guo, S.; Zhang, H. Half-Cycle Resonance Tracking for Inductively Coupled Wireless Power Transmission System. IEEE Trans. Power Electron. 2018, 33, 2668–2679. [Google Scholar] [CrossRef]

- Ahn, D.; Hong, S. A transmitter or a receiver consisting of two strongly coupled resonators for enhanced resonant coupling in wireless power transfer. IEEE Trans. Ind. Electron. 2014, 61, 1193–1203. [Google Scholar] [CrossRef]

- Zhong, W.X.; Liu, X.; Hui, S.Y.R. A novel single-layer winding array and receiver coil structure for contactless battery charging systems with free-positioning and localized charging features. IEEE Trans. Ind. Electron. 2011, 58, 4136–4144. [Google Scholar] [CrossRef]

- Lee, J.; Han, B. A Bidirectional Wireless Power Transfer EV Charger Using Self-Resonant PWM. IEEE Trans. Power Electron. 2015, 30, 1784–1787. [Google Scholar] [CrossRef]

- Yan, X.; Li, J.; Zhang, B.; Jia, Z.; Tian, Y.; Zeng, H.; Lv, Z. Virtual Synchronous Motor Based-Control of a Three-Phase Electric Vehicle Off-Board Charger for Providing Fast-Charging Service. Appl. Sci. 2018, 8, 856. [Google Scholar] [CrossRef]

- Khan, S.U.; Mehmood, K.K.; Haider, Z.M.; Bukhari, S.B.A.; Lee, S.-J.; Rafique, M.K.; Kim, C.-H. Energy Management Scheme for an EV Smart Charger V2G/G2V Application with an EV Power Allocation Technique and Voltage Regulation. Appl. Sci. 2018, 8, 648. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, Y.; Madawala, U.K.; Thrimawithana, D.J.; Ma, H. A New Controller for Bidirectional Wireless Power Transfer Systems. IEEE Trans. Power Electron. 2018, 33, 9076–9087. [Google Scholar] [CrossRef]

- Abdulaal, A.; Cintuglu, M.H.; Asfour, S.; Mohammed, O.A. Solving the Multivariant EV Routing Problem Incorporating V2G and G2V Options. IEEE Trans. Transp. Electrif. 2017, 3, 238–248. [Google Scholar] [CrossRef]

- Hu, K.; Yi, P.; Liaw, C. An EV SRM Drive Powered by Battery/Supercapacitor With G2V and V2H/V2G Capabilities. IEEE Trans. Ind. Electron. 2015, 62, 4714–4727. [Google Scholar] [CrossRef]

- Kerviel, A.; Pesyridis, A.; Mohammed, A.; Chalet, D. An Evaluation of Turbocharging and Supercharging Options for High-Efficiency Fuel Cell Electric Vehicles. Appl. Sci. 2018, 8, 2474. [Google Scholar] [CrossRef]

- Kuroda, K.; Omori, H.; Kimura, N.; Morizane, T.; Fukuda, K.; Michikoshi, H.; Mekhilef, S.; Nakaoka, M. A wireless V2H apparatus with a new SiC-MOSFET and unique bidirectional controlled single-ended converter. In Proceedings of the 2017 IEEE 3rd International Future Energy Electronics Conference and ECCE Asia (IFEEC 2017–ECCE Asia), Kaohsiung, Taiwan, 3–7 June 2017; pp. 298–303. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Deng, J.; Nguyen, T.D.; Mi, C.C. A double-sided LCC compensation network and its tuning method for wireless power transfer. IEEE Trans. Veh. Technol. 2015, 64, 2261–2273. [Google Scholar] [CrossRef]

- Berger, A.; Agostinelli, M.; Vesti, S.; Oliver, A. A wireless charging system applying phase-shift and amplitude control to maximize efficiency and extracted power. IEEE Trans. Power Electron. 2015, 30, 6338–6348. [Google Scholar] [CrossRef]

- Liao, Y.; Hsu, C. A Novel AC/DC Bridgeless and Contactless Electrical Energy Transmission System for Multi-Load Applications. IEEE Trans. Ind. Appl. 2016, 52, 1148–1156. [Google Scholar] [CrossRef]

- Diekhans, T.; De, R.W. A dual-side controlled inductive power transfer system optimized for large coupling factor variations and partial Load. IEEE Trans. Power Electron. 2015, 30, 6320–6328. [Google Scholar] [CrossRef]

| Parameters | Primary Side Circuit | Secondary Side Circuit |

|---|---|---|

| Inductor | L1 = 1 mH | L2 = 1 mH |

| Resonant tank | C1 = 660 nF, Lr1 = 15.3 uH | C2 = 660 nF, Lr2 = 15.3 uH |

| Transmitter/Receiver | 20 turns, width of winding = 2.7 mm, with two layers | 20 turns, width of winding = 2.7 mm, with two layers |

| LED Load to Emulate portable device | Forward voltage 3.5 V | |

| Switching frequency | Approximately 50 kHz | |

| MOSFET | IRF 540 | |

| Transistor | 2222A NPN, 2907A PNP | |

| PWM IC | Low Voltage PWM Controller (LT1619 or MAX1967) | |

| Coil of Transmitter/Receiver Length 50 mm width 50mm High 5.4 mm |  | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, Y.-H.; Lin, Y. A Novel Bidirectional Wireless Power Transfer System for Mobile Power Application. Appl. Sci. 2019, 9, 3769. https://doi.org/10.3390/app9183769

Liao Y-H, Lin Y. A Novel Bidirectional Wireless Power Transfer System for Mobile Power Application. Applied Sciences. 2019; 9(18):3769. https://doi.org/10.3390/app9183769

Chicago/Turabian StyleLiao, Yi-Hung, and Yue Lin. 2019. "A Novel Bidirectional Wireless Power Transfer System for Mobile Power Application" Applied Sciences 9, no. 18: 3769. https://doi.org/10.3390/app9183769

APA StyleLiao, Y.-H., & Lin, Y. (2019). A Novel Bidirectional Wireless Power Transfer System for Mobile Power Application. Applied Sciences, 9(18), 3769. https://doi.org/10.3390/app9183769