Abstract

In this research, the moisture susceptibility of a nanoclay-modified asphalt concrete (AC) mixture containing plastic film (in flakes) collected as urban waste was evaluated with specimens subjected to the tecnico accelerated ageing (TEAGE) procedure. The TEAGE procedure attempts to simulate—in a laboratory setting—the effect of field ageing by applying watering/drying cycles and ultraviolet radiation. For comparison purposes, three AC mixtures were considered, one for control, without plastic and nanoclay, a mixture with only plastic, and a mixture with both plastic and nanoclay. Furthermore, only half of the specimens were subjected to the ageing procedure. The plastic was added to the mixture using the dry process, and the nanoclay was blended with the bitumen before mixture preparation. The moisture susceptibility was evaluated, using a total of 48 Marshall specimens, by the indirect tensile strength ratio (ITSR). From the results of this study, the nanoclay-modified AC mixture containing plastic film presented slightly higher indirect tensile strength (ITS) values, lower moisture susceptibility, and enhanced ageing resistance. These slight improvements can be justified by the reduced air voids content of the samples and consequently they must be seen as conservative. Nevertheless, the modification of AC mixtures with flakes of plastic and nanoclay can be a viable solution for the recycling of plastic film collected as urban waste, being an eco-friendly alternative to disposal in landfills.

1. Introduction

Plastics cover a wide range of synthetic polymers, being used for the production of a very wide range of products that are extensively used in our everyday life. They are applied in many industry sectors, such as building and construction, electronics, automotive, agriculture, health, packaging, and energy [1], making the world plastic production increase year by year at a rate of about 4%, reaching almost 350 million tonnes in 2017 (65 million tonnes in Europe) [2]. After use, 42% of post-consumer waste plastics are incinerated and 27% are lost in landfills [1]. Only the remaining share (31%) is recycled. Packaging is the most demanded sector with 40% of all plastic production, 63% of all plastic waste, and 83% of all plastic that is recycled [3]. In terms of polymer, roughly 50% of plastic packaging waste from households is plastic film, mainly in the form of low-density polyethylene (LDPE) [3,4]. Plastic film includes all flexible packaging, such as grocery bags, food storage bags, product wraps, cling wrap, etc. They are mostly single-use plastic products.

Despite the benefits of plastics, the way some plastic products are produced, used, and discarded poses some problems. Most of them come from fossil sources being non-biodegradable, which leads to high contamination with ecological and health implications [5]. To minimize these problems, recycling rate targets have been imposed [6] and a transition to a circular economy has been fostered [7,8]. In a circular economy, plastic waste is considered as a resource capable of substituting virgin material.

As an alternative to virgin polymers, plastic waste has been used as additives to modify bitumen with the purpose of enhancing asphalt concrete (AC) mixtures with economic and environmental benefits [9,10]. The modification can be done either by mixing the additive previously with bitumen (wet process) [11] or by adding the additive directly to aggregates during the blending process (dry process) [9,12,13]. The dry process is simpler and more economical than the wet one [9], being considered by many researchers to be the best one [14,15]. The addition of waste thermoplastic polymers has been widely studied, e.g., polyethylene (PE) [15,16], polypropylene (PP) [11], polystyrene (PS) [17], polymerizing vinyl chloride (PVC) [10], polyethylene terephthalate (PET) [18], as well as combined polymers [9]. Regarding plastic film waste, studies have been conducted using plastic film from the agricultural sector [12,19] or focusing on specific plastic sources, like bags [20]. There appears to be a gap in the literature regarding the incorporation of plastic film waste (in flakes) collected as urban waste in AC mixtures, which represent a huge percentage of plastic packaging waste.

AC mixtures are subjected to traffic loads as well as climatic loads over their lifetime. In contrast to traffic loads, which have been investigated in several studies, the effect of climatic conditions (moisture, oxygen, heat, cold, ultraviolet (UV) light, freeze–thaw cycles, etc.) during prolonged periods is not well established, mainly when the AC mixtures have additives incorporated, even though they contribute considerably to the degradation of the pavement structures. Moisture susceptibility, defined as the loss of mechanical characteristics of materials resulting from the presence of water in AC mixtures, is commonly evaluated using the indirect tensile strength ratio (ITSR). This susceptibility is a complex process that depends on several factors, such as aggregate mineral composition, bitumen grade, bitumen-aggregate adhesion, and air voids (not only the content but also their distribution and connectivity) as well as the interaction between them [21,22,23,24,25]. In general, plastic waste additives increase moisture resistance of AC mixtures [16]. But, regrettably, this is not always the case [9]. The incorporation of additives might increase AC mixtures behaviour complexity. Diab, et al. [26] studied the moisture resistance (using ITSR) of polymer-modified AC mixtures (six different polymeric products were tested). They found that polymeric products, not only the type but also the content, have different moisture resistance. AC mixtures are subjected to environmental conditions as they age and consequently their properties evolve over time due to interaction of these factors. Age hardening and moisture damage have been pointed to as the primary factors affecting the durability of AC mixtures [27]. Nevertheless, even if there are more studies on moisture susceptibility, there are also studies considering moisture and ageing simultaneously [26,28,29,30], highlighting the importance to consider both.

The AC mixture ageing is generally divided into two phases; the phase of mixing, laying, and compaction, where the short-term ageing occurs; and, the pavement service life phase, where the long-term ageing occurs. To simulate ageing in the laboratory, the methods more frequently used are those described by the AASHTO standard practice R30-02 [31]. This standard proposes a method—the long-term oven ageing (LTOA)—to simulate the long-term ageing of the compacted asphalt mixture to an equivalent of 7–10 years of field service. On one hand, the LTOA method has several advantages, such as, it uses simple equipment and it is easy to implement and reproduce (consists of placing the compacted test specimens in a conditioning oven for 120 ± 0.5 h at a temperature of 85 ± 3 °C). On the other hand, it presents a few drawbacks, particularly, by not simulating most of the actions present during field ageing (e.g., solar radiation, moisture, and freeze-thaw), the field-ageing equivalency is difficult and not consensual. Smith Braden and Howard Isaac [32] matched the damage caused by laboratory conditioning protocols to the damage produced by exposure to non–load-associated environmental factors for up to 5 years in the southeast United States, concluding that the 7–10 years of field service simulation claimed by the AASHTO R30-02 are not realistic. It depends greatly on climate [29] and the procedure described in AASHTO R30-02 does not consider the moisture and UV radiation. Several authors are highlighting the importance of solar radiation, particularly the UV, in the ageing process [33,34,35]. As the UV rays possess high energy, they promote photodegradation mechanisms, for instance, they are able to break C=C bonds, and accelerate the degradation of polymers such as the styrene-butadiene-styrene (SBS) [36]. Thus, UV is an important action to reproduce when evaluating the ageing of a mixture to be applied in wearing course (surface layers) and when new additives/modifiers are involved. In order to account for these aspects, Crucho, Picado-Santos, Neves, Capitão, and Al-Qadi [29] developed a new accelerated ageing method for compacted bituminous mixtures, called tecnico accelerated ageing (TEAGE). It simulates the ageing of asphalt mixtures under specific environmental conditions by applying watering/drying cycles and UV radiation in equivalent levels to those observed in the field during a certain time. Those authors [29] compared the effect of TEAGE and R30-02 long-term ageing methods on an AC 14 gap-graded mixture by using stiffness, fatigue resistance, and indirect tensile strength (ITS) results. Compared to the R30-02 long-term ageing method, the ITS values of TEAGE aged specimens were higher, stiffness values were lower, as well as fatigue resistance values. However, the results are not comparable since the section of TEAGE aged specimens is not homogeneous, due to a differential ageing level in specimen depth (e.g., the top surface, with direct exposure to UV radiation suffered a higher ageing severity than the bottom surface). To consider that heterogeneity, the authors recovered the bitumen and carried out tests over it, whose results were used to predict stiffness through the depth of the specimen, concluding that the TEAGE method addresses in a more consistent way the ageing mechanisms that could be seen in the field.

The ageing effect has been addressed in several studies, e.g., [37,38,39,40]. Islam, et al. [41] studied, for the first time, ageing (long-term and short-term) effects using ITS tests, and found that for long-term oven-aged specimens, ITS increases with ageing, while for short-term oven-aged loose samples, ITS increases with the conditioning period until reaching a peak and then decreases.

On these grounds and taking into account that there is a need to use new materials to obtain both sustainable and high-performance pavements (to support an increase of traffic intensity, the presence of large and heavier trucks, and all the climatic agents), nanomaterials have attracted increasing attention in bitumen modification. They tend to improve AC mixture performance [42,43,44,45,46]. Regarding moisture, nanomaterials can work as antistrip additives, improving aggregates coating, and reducing thus moisture susceptibility [47,48,49,50,51]. Nanoclay has been used successfully [43], besides other properties, to improve moisture resistance as well as ageing resistance [50,52].

There are in the literature, studies encompassing moisture, ageing, polymers, and nanomaterials [26,50,52]. However, to date, few or no studies consider moisture, ageing, nanomaterials, and plastic waste simultaneously, i.e., a set of issues that can interact between themselves and may change AC mixture behaviour. This work attempted to contribute to that gap in literature by evaluating the moisture susceptibility of a nanoclay modified-AC mixture with flakes of plastic film collected as urban waste with and without ageing. The moisture susceptibility is evaluated by the ITSR value and the TEAGE method was used to simulate long-term ageing in a laboratory. For a better interpretation of the results, two additional AC mixtures are tested in parallel for comparison purposes, via a control AC mixture and a mixture with only plastic flakes. In addition, aged and unaged specimens are considered.

2. Materials and Methods

The materials and methods used in this study were selected to assess the moisture susceptibility and the ageing effect on nanoclay-modified AC mixtures containing flakes of plastic film collected as urban waste.

2.1. Materials

An asphalt mixture with a maximum aggregate size of 14 mm was selected (AC 14), which is used in surface layers. The materials used for the production of the AC mixtures are those described below.

2.1.1. Aggregates and Bitumen

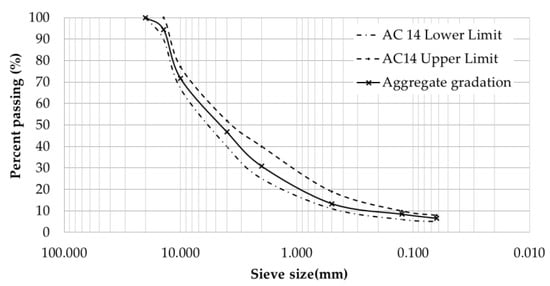

The AC mixtures were produced with two types of aggregates (gneiss and limestone) and a conventional 35/50 paving grade bitumen supplied by Cepsa Portugal (located in Matosinhos, Portugal). For the mixture of aggregates the following aggregate fractions were selected: fraction 0/4 of crushed gneiss; fraction 4/8 of crushed gneiss; fraction 6/14 of crushed gneiss; and, limestone filler. The gradation limits used for the AC 14 mixture are the ones defined in the Portuguese road administration specifications [53]. Figure 1 presents the aggregate gradation as well as the gradation limits.

Figure 1.

Aggregate gradation of the asphalt concrete with an aggregate size of 14 mm (AC 14) mixture.

2.1.2. Plastic

The flakes of plastic film collected as urban waste came from an LDPE plastic recycling plant (Ambiente-Recuperação de Materiais Plásticos, S.A., located in Leiria, Portugal). The recycling process starts by packing film waste collection (municipal waste) which is then pressed into bales that are transported to the plant. There, the bales are broken, and the following steps are conducted to produce LDPE pellets: sorting (hand picking), grading (size reduction, film is cut into flakes), washing, drying, and extrusion (flakes are melted and extruded into pellets). This study uses flakes (Figure 2), collected after the drying process, instead of plastic pellets, reducing thus the recycling costs and easing the plastic addition during the AC mixture blending (dry process).

Figure 2.

Flakes of plastic film collected as urban waste.

The quantity of flakes to add was defined using Marshall test results and volumetric properties [54]. Fonseca, Almeida, Capitão, Bandeira, and Rodrigues [54] tested an AC mixture with the same grading considering 0%, 2%, 4%, 6%, and 8% of flakes of plastic film, by weight of bitumen. The mixture with 6% presented better results (higher stability and lower flow) and consequently that was the percentage considered.

2.1.3. Nanoclay

The nanoclay is a hydrophilic bentonite (H2Al2O6Si) with beige colour, a molecular mass of 180.1 g/mol, a density of 2,400 kg/m3, and pH in the range of 6.0 to 9.0. The nanometric dimension of the nanoclay is the thickness of its silicate layers of about 1 to 2 nm. In literature, nanoclay content range from 1% to 30% by weight of bitumen [43], being the mean value about 3.7%. This study considers 4.0% to be ideal, as in previous studies [42,50]. The blending procedure of nanoclay with the bitumen is detailed in [42]. Briefly, the procedure involved the use of a mechanical stirring effect to achieve an adequate dispersion of the nanoparticles into the bitumen.

2.2. Methods

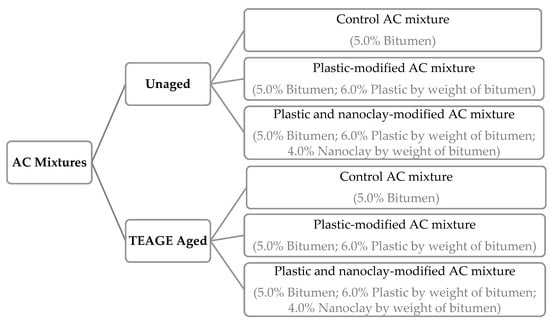

For comparison purposes, three AC mixtures were produced: (1) a control one, without plastic and nanoclay; (2) a mixture containing only flakes of plastic film; and, (3) a mixture with both flakes of plastic film and nanoclay. The AC mixture design, in Portugal, is based on the Marshall method. However, as this study deals with a typical AC surface mixture whose binder content is well-established, the Marshall method was not specifically carried out once this was done before for the same materials. The binder content considered in this study was thus 5.0% by the weight of the mixture [54,55,56].

The moisture susceptibility of the compacted AC mixtures was evaluated using the indirect tensile strength ratio (ITSR) considering unaged and aged conditions (TEAGE procedure). Therefore, for each one of the three AC mixtures tested, 16 (2 ageing conditions × 2 ITSR conditions × 4 specimens) cylindrical specimens (63.5 mm height and 101.5 mm diameter) were produced and tested, which gives a total of 48 specimens. All the AC mixtures were produced in the laboratory at a target temperature of 165 °C accordingly the EN12697-35 [55], and the specimens were prepared by impact compactor by applying 75 blows on each side [56].

The bulk density of each specimen and the maximum density of each mixture were determined following the EN12697-6 [57] and the EN12697-5 [58], respectively. Figure 3 summarizes the tested AC mixtures.

Figure 3.

Tested asphalt concrete (AC) mixtures.

2.2.1. Ageing Conditioning

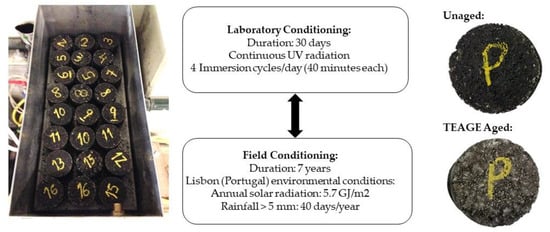

The TEAGE method was used to simulate in the laboratory the ageing of the asphalt mixtures [29]. Taking into account the historical climate data, TEAGE was tuned to simulate the effects of UV radiation and precipitation that the pavement in service will undergo in the Lisbon region (Portugal) during seven years. According to the Köppen–Geiger climate classification, Lisbon has a temperate dry hot-summer climate (classification Csa) with no freeze–thaw cycles. Thus, the UV radiation and the moisture damage will be important mechanism regarding the ageing of the asphalt pavement. Due to solar radiation, Lisbon receives an average annual energy of 5.7 GJ/m2. Regarding precipitation, Lisbon has in average 40 days per year with rainfall higher than 5 mm. This amount of daily precipitation, 5 mm, is considered to be sufficient to cause a water flow in the pavement surface. The TEAGE prototype uses UV lamps to apply an equivalent level of energy and uses a combination of watering/drying cycles to simulate the effect of precipitation. The duration and details of the ageing conditioning are presented in Figure 4. From Figure 4, the effect of UV radiation on the colouration of the AC mixture specimens is visible.

Figure 4.

Tecnico accelerated ageing (TEAGE) simulation.

2.2.2. Moisture Sensitivity

Indirect tensile strength (ITS) tests were used to evaluate the moisture sensitivity by calculating the indirect tensile strength ratio ITSR as described in the EN 12697-12 [59]. The test temperature was 25 °C which is the recommended standard temperature in the EN 12697-12 [41]. ITSR is the ratio between the ITS of conditioned (wet) specimens, by immersion in water at 40 °C for approximately 72 h, and the ITS of unconditioned (dry) specimens. The ITS results are the average of four individual specimens per group. The wet set of specimens was previously subjected to vacuum with an absolute pressure of 6.7 kPa for a period of 30 min.

The ITS is defined as the maximum tensile stress calculated as a function of the peak load and the dimensions of the specimen [60], Equation (1):

where ITS is the indirect tensile strength in GPa, P is the peak load in kN, D and H are the diameter and the height of the specimen in mm, respectively.

3. Results and Discussion

3.1. Volumetric Characterisation

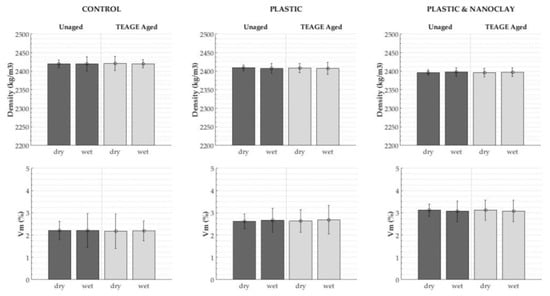

The volumetric characterization is supported by the analysis of the air voids content of each specimen which was determined according to EN 12697-8 [61]. Figure 5 presents average bulk density values and air voids content (Vm) values for each AC mixture and set of specimens (dry/wet and unaged/aged). The vertical error bar represents the standard deviation of four specimens.

Figure 5.

Bulk density and air voids content results for each AC mixture and set of specimens (dry/wet and unaged/aged).

From Figure 5, it is possible to observe the following:

- For each AC mixture, all sets have similar volumetric properties.

- The air voids contents of the tested AC mixtures are relatively low, which can be justified by the impact energy compaction used (75 blows) and by the fact that it is a dense-graded AC mixture.

- There was a decrease in the bulk density, and consequently an increase in air voids content, with the addition of plastic, as would be expected, since the plastic was used in replacement of bitumen, which is a denser material than the plastic.

- The specimens with plastic and nanoclay present higher air voids content. This can be partially explained by the increase of bitumen viscosity caused by the nanoclay.

3.2. Moisture Sensitivity and Ageing Effect

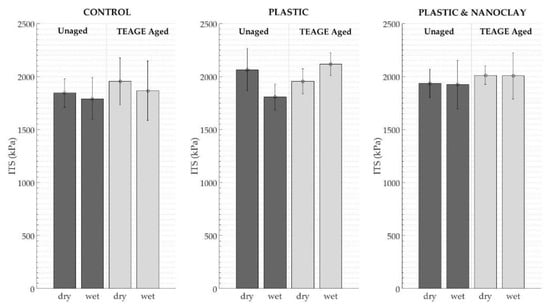

The ITSR of AC mixtures is an indicator of their resistance to moisture susceptibility. However, before presenting ITSR results, average ITS values for each case (AC mixture, dry vs wet, and unaged vs TEAGE aged) are presented in Table 1, depicted in Figure 6 and then discussed.

Table 1.

Indirect tensile strength (ITS) values.

Figure 6.

Indirect tensile strength (ITS) results.

From Figure 6, it is possible to observe the following:

- All the AC mixtures showed high ITS values even in wet specimens. It can be justified by the reduced air voids content of the samples that minimizes the moisture damage of the mixture [23], and by the bitumen grade used (low penetration grade) [21].

- Notwithstanding the slightly higher air voids content, both modified AC mixtures presented an increase in the conventional ITS (unaged and dry conditions). Compared with the ITS of the control AC mixture, the plastic modified AC mixture presented an increase of 12%, and the plastic and nanoclay-modified AC mixture presented an increase of 5%.

- In general, ITS values of wet specimens (where moisture damage is present) are lower than the dry ones (no moisture damage).

- Ageing tends to increase ITS values as bitumen became stiffener during the ageing process [29,50]. The exception, on average, was the dry set of specimens of the plastic modified-AC mixture, which is more a verification of the fact for this set of tests than a documented trend, once the variability of the samples could induce some “not normal” results as can be understood by the interval of results found in Figure 6.

- The outcome of the ageing effect in the plastic modified-AC mixture is not obvious. The TEAGE aged dry specimens presented lower values (5%) than the unaged ones, and the TEAGE aged wet specimens presented higher values (8%) than the TEAGE aged dry ones.

- Nanoclay addition improved the resistance of plastic modified-AC mixture to moisture damage. The ITS values were similar in dry and wet specimens. The ageing effect on the plastic and nanoclay-modified AC mixture was less pronounced than in the other specimens.

A two-way analysis of variance (ANOVA) with interaction on the obtained ITS values was conducted. The response variable was ITS (dry and wet) and the influence factors were AC mixture and ageing. The ANOVA results are shown in Table 2. From the ‘‘p-value” column, which presents the statistical significance level of the two-way ANOVA. It is observed that the p-values of the influence of ageing, AC mixture, and ageing-AC mixture interaction (AB) are higher than the threshold value of 0.05. Therefore, those factors do not have a significant effect on results. Only for wet specimens, the ageing effect was pronounced (p-value equal to 0.075).

Table 2.

Two-way ANOVA with interaction results.

After carrying out a one-way ANOVA to evaluate only the ageing effect (Table 3), it is observed that it was only significant for the plastic-modified mixture (p-value equal to 0.008).

Table 3.

One-way ANOVA (p-values).

Therefore and as already mentioned, the effect of ageing in the plastic modified-AC mixture is not obvious. On the one hand, for wet specimens, the ITS has a statically significant increase, on the other, for dry specimens, the ITS has a non-statically significant decrease. The unaged dry specimens results are in line with a previous study [54] that evaluated the moisture susceptibility effect on AC mixtures containing flakes of plastic film collected as urban waste without ageing. Exposure to moisture reduced ITS values by 10% as in this research (12%). The effect of ageing on the plastic-modified materials are not well established yet. Al-Hadidy [41] studied the effect of two ageing levels (1: 100 °C for 48 h and 2: 100 °C for 96 h) on ITS results of AC mixtures containing PP polymers (wet process) and compared the results with the ones from a control mixture. ITS values increased with ageing. However, those variations depended on the ageing level. For the 96 h-ageing level, the increase was less pronounced for the AC mixtures containing PP polymers. In the Al-Hadidy study, only the temperature effect was evaluated and for a short period of time. In the TEAGE ageing procedure, the specimens (both the dry and the wet ones) are subjected to temperature, watering/drying cycles, and UV radiation during 30 days, which may have a particular role in deteriorating the material (especially plastic film) that thermal ageing may not reproduce accurately.

Concerning the isolated effect of nanoclay modification, López-Montero, Crucho, Picado-Santos, and Miró [50] assessed the effect of nanoclay on ageing and moisture damage of a gap-graded AC 14 mixture using the ITS test, and compared the results with the ones from a non-modified mixture. They found a significant increase in ITS values with nanoclay modification and with ageing in both dry and wet conditions. Similar results were reported in [52].

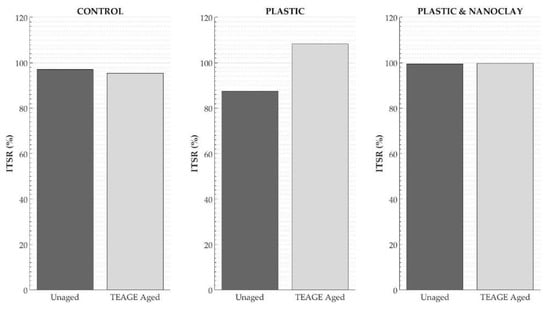

Figure 7 presents ITSR values that represent the ratio between the ITS of wet specimens and the ITS of dry specimens presented in Figure 6.

Figure 7.

Indirect tensile strength ratio (ITSR) values.

All ITSR values are considered to be good, they are all above 85% whatever the AC mixture, indicating greater resistance to moisture damage. Once again, it can be explained by the air voids content values as well as by good affinity between the aggregates and the bitumen. The ageing considerably increased (21%) the moisture resistance of plastic modified-AC mixture. For the other two mixtures, the ITSR was near 100% and consequently the water did not deteriorate nor improve them and the ageing effect was minimal.

Diab, Enieb, and Singh [26] studied, among others, the influence of ageing (oven ageing during 16 h) on the ITSR of polymer-modified AC mixtures (six different polymeric products were tested). They found that polymeric products have different moisture susceptibility and that oven ageing can have different effects. In some modifications ITSR values increase while in others they decrease. These results suggest that the behaviour of plastic-modified AC mixtures might be complex and in some cases the expected trends could be not valid to reach bold conclusions.

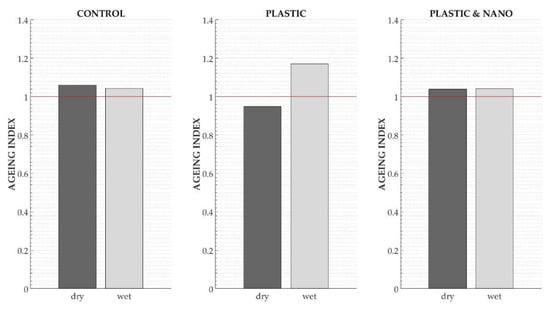

In order to differently appreciate the effect of ageing on ITS values by separating dry and wet samples, an ageing index was calculated. This index is the quotient between the ITS of aged specimens and the ITS of unaged specimens [50]. Figure 8 shows the results.

Figure 8.

Values of ageing index for the tested mixtures and dry/wet specimens.

There was almost no difference for the control and plastic and nanoclay-modified AC mixtures. That was not the case for the plastic-modified mixture and as aforementioned this could be due to some variability of the samples, especially for the results of the dry set of samples, once the wet group showed the same trend than the others AC mixtures, namely having an ageing index greater than one. Some further testing framework will be needed, namely analysing more samples in the same context, different compositions with plastic, and different percentages of plastic content, but also appreciate the effect through the use of performance tests such the ones allowing comparison for fatigue and permanent deformation contexts, where the effect of ageing could be better separated.

4. Conclusions

The main objective of this study was to investigate the moisture susceptibility (by ITSR values) and the ageing effect (TEAGE procedure) of nanoclay-modified AC mixtures containing flakes of plastic film collected as urban waste. Three AC mixtures were produced: (1) a control one, without plastic and nanoclay; (2) a mixture containing only flakes of plastic film; and, (3) a mixture with both flakes of plastic film and nanoclay. In addition, aged and unaged specimens were considered.

After testing the AC mixtures and comparing the results, the following conclusions can be drawn:

- In general, the conditioning for moisture sensitivity caused a decrease in the ITS of the AC mixtures, and the ageing conditioning caused an increase in the ITS of the AC mixtures.

- The use of plastic to modify the AC mixture caused an increase of the ITS values in both ages (unaged and aged) and moisture conditioning (dry and wet), except in the case of the aged dry group where the ITS values were similar. However, the trends observed regarding moisture susceptibility and effect of ageing were not clear.

- The plastic and nanoclay-modified AC mixture presented higher ITS values, lower moisture susceptibility, and enhanced ageing resistance. Regarding moisture susceptibility, the mixture presented similar ITS values for the dry and wet specimens, and consequently high ITSR values, indicating that the moisture conditioning had no effect on the properties of the mixture. Regarding ageing, if compared with the control mixture, the plastic and nanoclay-modified AC mixture presented slightly lower ageing index. The improvements obtained can be considered as relatively small, although, it worth mention that the plastic and nanoclay-modified AC mixture had an air void content higher than the control AC mixture, thus theoretically more vulnerable to moisture and ageing effect. Thus, the results obtained from the side of the modified AC mixture must be considered as conservative.

- The reduced air voids content of the AC mixtures tested certainly influenced the results. Lower compaction energy would have led to a higher air voids content and consequently, the moisture susceptibility, as well as the ageing effect, would be higher.

Therefore, the modification of AC mixtures with flakes of plastic and nanoclay hydrophilic bentonite might be a viable solution for the recycling of plastic film collected as urban waste. From the environmental point of view, it is an eco-friendly alternative to plastic waste disposal in landfills.

Regarding economic aspects, nanoclay modification is an expensive way to improve AC mixture performance. In fact, the construction cost can increase up to five times in relation to a conventional AC mixture [42]. Furthermore, in spite of plastic film and nanoclay together do not constitute today an industrial alternative to other types of modified mixtures in order to increase performance, this paper underlines that it is a trend with potential. Nanoclay plus plastic film could improve the performance and reduce the environmental burden, using an attractive mixture, even on the life-cycle cost point of view, especially if all the environmental costs are considered.

Although the reported results give a good indication of the potential of the modifications in evaluation, future research is recommended to see what happens in an AC mixture with a higher air voids content as well as to enhance the effect of ageing and moisture on plastic-modified AC mixtures.

Author Contributions

Conceptualization, A.A., J.C., C.A. and L.P.S.; methodology, A.A., J.C., C.A. and L.P.S.; validation, A.A., J.C., C.A. and L.P.S.; investigation, A.A., J.C. and C.A.; resources, A.A., J.C. and C.A.; writing—original draft preparation, A.A. and C.A.; writing—review and editing, A.A., J.C. and L.P.S.; supervision, L.P.S.; project administration, L.P.S.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- PlasticsEurope. Plastics—The Facts 2018—An Analysis of European Plastics Production, Demand and Waste Data; Association of Plastics Manufactures: Brussels, Belgium, 2018. [Google Scholar]

- Statista. Global Plastic Production from 1950 to 2017. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 6 September 2019).

- Mepex Consult AS. Basic Facts Report on Design for Plastic Packaging Recyclability; Mepex Consult AS: Asker, Norway, 2017. [Google Scholar]

- Horodytska, O.; Valdés, F.J.; Fullana, A. Plastic flexible films waste management—A state of art review. Waste Manag. 2018, 77, 413–425. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Plastic Waste: Ecological and Human Health Impacts; Science Communication Unit, the University of the West of England (UWE), Ed.; European Commission’s Directorate-General Environment: Bristol, UK, 2011; (In-depth Reports). [Google Scholar]

- European Commission. Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the Implementation of EU Waste Legislation, Including the Early Warning Report for Member States at Risk of Missing the 2020 Preparation for Re-Use/Recycling Arget on Municipal Waste COM(2018) 656 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—A European Strategy for Plastics in a Circular Economy—COM/2018/028 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Crippa, M.; De Wilde, B.; Koopmans, R.; Leyssens, J.; Muncke, J.; Ritschkoff, A.-C.; Van Doorsselaer, K.; Velis, C.; Wagner, M.A. A Circular Economy for Plastics—Insights from Research and Innovation to Inform Policy and Funding Decisions; Directorate-General for Research and Innovation European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Movilla-Quesada, D.; Raposeiras, A.C.; Silva-Klein, L.T.; Lastra-González, P.; Castro-Fresno, D. Use of plastic scrap in asphalt mixtures added by dry method as a partial substitute for bitumen. Waste Manag. 2019, 87, 751–760. [Google Scholar] [CrossRef] [PubMed]

- Ziari, H.; Nasiri, E.; Amini, A.; Ferdosian, O. The effect of EAF dust and waste PVC on moisture sensitivity, rutting resistance, and fatigue performance of asphalt binders and mixtures. Constr. Build. Mater. 2019, 203, 188–200. [Google Scholar] [CrossRef]

- Karmakar, S.; Majhi, D.; Roy, T.K.; Chanda, D. Moisture Damage Analysis of Bituminous Mix by Durability Index Utilizing Waste Plastic Cup. J. Mater. Civ. Eng. 2018, 30, 04018216. [Google Scholar] [CrossRef]

- Martin-Alfonso, J.E.; Cuadri, A.A.; Torres, J.; Hidalgo, M.E.; Partal, P. Use of plastic wastes from greenhouse in asphalt mixes manufactured by dry process. Road Mater. Pavement Des. 2019. [Google Scholar] [CrossRef]

- Sarang, G.; Lekha, B.M.; Krishna, G.; Ravi Shankar, A.U. Comparison of Stone Matrix Asphalt mixtures with polymer-modified bitumen and shredded waste plastics. Road Mater. Pavement Des. 2016, 17, 933–945. [Google Scholar] [CrossRef]

- Sarang, G. Replacement of stabilizers by recycling plastic in asphalt concrete. In Use of Recycled Plastics in Eco-efficient Concrete; Pacheco-Torgal, F., Khatib, J., Colangelo, F., Tuladhar, R., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 307–325. [Google Scholar]

- Mishra, B.; Gupta, M.K. Use of plastic waste in bituminous mixes by wet and dry methods. Inst. Civ. Eng. Munic. Eng. 2018, 0, 1–11. [Google Scholar] [CrossRef]

- Giri, J.P.; Panda, M.; Sahoo, U.C. Use of waste polyethylene for modification of bituminous paving mixes containing recycled concrete aggregates. Road Mater. Pavement Des. 2018, 1–21. [Google Scholar] [CrossRef]

- Vila-Cortavitarte, M.; Lastra-González, P.; Calzada-Pérez, M.Á.; Indacoechea-Vega, I. Analysis of the influence of using recycled polystyrene as a substitute for bitumen in the behaviour of asphalt concrete mixtures. J. Clean Prod. 2018, 170, 1279–1287. [Google Scholar] [CrossRef]

- Leng, Z.; Sreeram, A.; Padhan, R.K.; Tan, Z. Value-added application of waste PET based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (RAP). J. Clean. Prod. 2018, 196, 615–625. [Google Scholar] [CrossRef]

- Jeong, K.-D.; Lee, S.-J.; Kim, K.W. Laboratory evaluation of flexible pavement materials containing waste polyethylene (WPE) film. Constr. Build. Mater. 2011, 25, 1890–1894. [Google Scholar] [CrossRef]

- Nouali, M.; Derriche, Z.; Ghorbel, E.; Chuanqiang, L. Plastic bag waste modified bitumen a possible solution to the Algerian road pavements. Road Mater. Pavement Des. 2019, 1–13. [Google Scholar] [CrossRef]

- Zhang, J.; Apeagyei, A.K.; Airey, G.D.; Grenfell, J.R.A. Influence of aggregate mineralogical composition on water resistance of aggregate–bitumen adhesion. Int. J. Adhes. Adhes. 2015, 62, 45–54. [Google Scholar] [CrossRef]

- Do, T.C.; Tran, V.P.; Le, V.P.; Lee, H.J.; Kim, W.J. Mechanical characteristics of tensile strength ratio method compared to other parameters used for moisture susceptibility evaluation of asphalt mixtures. J. Traffic Transp. Eng. 2019. [Google Scholar] [CrossRef]

- Terrel, R.L.; AI-Swailmi, S. Water Sensitivity of Asphalt—Aggregate Mixes: Test Selection; Strategic Highway Research Program, National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Masad, E.; Castelblanco, A.; Birgisson, B. Effects of Air Void Size Distribution, Pore Pressure, and Bond Energy on Moisture Damage. J. Test. Eval. 2006, 34, 15–23. [Google Scholar]

- Arambula, E.; Masad, E.; Martin, A.E. Influence of Air Void Distribution on the Moisture Susceptibility of Asphalt Mixes. J. Mater. Civ. Eng. 2007, 19, 655–664. [Google Scholar] [CrossRef]

- Diab, A.; Enieb, M.; Singh, D. Influence of aging on properties of polymer-modified asphalt. Constr. Build. Mater. 2019, 196, 54–65. [Google Scholar] [CrossRef]

- Airey, G.D.; Choi, Y.-K. State of the Art Report on Moisture Sensitivity Test Methods for Bituminous Pavement Materials. Road Mater. Pavement Des. 2002, 3, 355–372. [Google Scholar] [CrossRef]

- Teh, S.Y.; Hamzah, M.O. Asphalt mixture workability and effects of long-term conditioning methods on moisture damage susceptibility and performance of warm mix asphalt. Constr. Build. Mater. 2019, 207, 316–328. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S.; Al-Qadi, I.L. Tecnico accelerated ageing (TEAGE)—A new laboratory approach for bituminous mixture ageing simulation. Int. J. Pavement Eng. 2018, 1–13. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I. Effect of laboratory aging on moisture susceptibility and resilient modulus of asphalt concrete mixes containing PE and PP polymers. Karbala Int. J. Mod. Sci. 2018, 4, 377–381. [Google Scholar] [CrossRef]

- AASHTO. Standard Practice for Mixture Conditioning of Hot Mix Asphalt (HMA)—AASHTO Designation: R 30-02; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015. [Google Scholar]

- Smith Braden, T.; Howard Isaac, L. Comparing Laboratory Conditioning Protocols to Longer-Term Aging of Asphalt Mixtures in the Southeast United States. J. Mater. Civ. Eng. 2019, 31, 04018346. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.; Yu, J.; Shi, C.; Zhang, D. Influence of surface modification on physical and ultraviolet aging resistance of bitumen containing inorganic nanoparticles. Constr. Build. Mater. 2015, 98, 735–740. [Google Scholar] [CrossRef]

- Yi, M.W.; Wang, J.C.; Feng, X.D. Effect of Ultraviolet Light Aging on Fatigue Properties of Asphalt. Key Eng. Mater. 2014, 599, 125–129. [Google Scholar] [CrossRef]

- Feng, Z.-G.; Bian, H.-J.; Li, X.-J.; Yu, J.-Y. FTIR analysis of UV aging on bitumen and its fractions. Mater. Struct. 2016, 49, 1381–1389. [Google Scholar] [CrossRef]

- De Sá Araujo, M.d.F.A.; Lins, V.d.F.C.; Pasa, V.M.D.; Leite, L.F.M. Weathering aging of modified asphalt binders. Fuel Process. Technol. 2013, 115, 19–25. [Google Scholar] [CrossRef]

- Islam, M.R.; Tarefder, R.A. Study of Asphalt Aging Through Beam Fatigue Test. Transp. Res. Rec. 2015, 2505, 115–120. [Google Scholar] [CrossRef]

- Yin, F.; Arámbula-Mercado, E.; Epps Martin, A.; Newcomb, D.; Tran, N. Long-term ageing of asphalt mixtures. Road Mater. Pavement Des. 2017, 18, 2–27. [Google Scholar] [CrossRef]

- Airey, G.D. State of the Art Report on Ageing Test Methods for Bituminous Pavement Materials. Int. J. Pavement Eng. 2003, 4, 165–176. [Google Scholar] [CrossRef]

- Izadi, A.; Motamedi, M.; Alimi, R.; Nafar, M. Effect of aging conditions on the fatigue behavior of hot and warm mix asphalt. Constr. Build. Mater. 2018, 188, 119–129. [Google Scholar] [CrossRef]

- Islam, M.R.; Hossain, M.I.; Tarefder, R.A. A study of asphalt aging using Indirect Tensile Strength test. Constr. Build. Mater. 2015, 95, 218–223. [Google Scholar] [CrossRef]

- Crucho, J.M.L.; Neves, J.M.C.d.; Capitão, S.D.; Picado-Santos, L.G.d. Mechanical performance of asphalt concrete modified with nanoparticles: Nanosilica, zero-valent iron and nanoclay. Constr. Build. Mater. 2018, 181, 309–318. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Farinha, J.P.S. An overview of the use of nanoclay modified bitumen in asphalt mixtures for enhanced flexible pavement performances. Road Mater. Pavement Des. 2019, 20, 671–701. [Google Scholar] [CrossRef]

- Fang, C.; Yu, R.; Liu, S.; Li, Y. Nanomaterials Applied in Asphalt Modification: A Review. J. Mater. Sci. Technol. 2013, 29, 589–594. [Google Scholar] [CrossRef]

- Li, R.; Xiao, F.; Amirkhanian, S.; You, Z.; Huang, J. Developments of nano materials and technologies on asphalt materials—A review. Constr. Build. Mater. 2017, 143, 633–648. [Google Scholar] [CrossRef]

- Saltan, M.; Terzi, S.; Karahancer, S. Performance analysis of nano modified bitumen and hot mix asphalt. Constr. Build. Mater. 2018, 173, 228–237. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Moghadas Nejad, F.; Oveisi, K. Investigating the effects of using nanomaterials on moisture damage of HMA. Road Mater. Pavement Des. 2015, 16, 536–552. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Moghadas Nejad, F. Use of aggregate nanocoating to decrease moisture damage of hot mix asphalt. Road Mater. Pavement Des. 2016, 17, 32–51. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Nejad, F.M.; Oveisi, K. Estimating the moisture damage of asphalt mixture modified with nano zinc oxide. Mater. Struct. 2016, 49, 1165–1174. [Google Scholar] [CrossRef]

- López-Montero, T.; Crucho, J.; Picado-Santos, L.; Miró, R. Effect of nanomaterials on ageing and moisture damage using the indirect tensile strength test. Constr. Build. Mater. 2018, 168, 31–40. [Google Scholar] [CrossRef]

- Sezavar, R.; Shafabakhsh, G.; Mirabdolazimi, S.M. New model of moisture susceptibility of nano silica-modified asphalt concrete using GMDH algorithm. Constr. Build. Mater. 2019, 211, 528–538. [Google Scholar] [CrossRef]

- Crucho, J.M.L.; Neves, J.M.C.d.; Capitão, S.D.; Picado-Santos, L.G.d. Evaluation of the durability of asphalt concrete modified with nanomaterials using the TEAGE aging method. Constr. Build. Mater. 2019, 214, 178–186. [Google Scholar] [CrossRef]

- IP. Paving Materials Specifications; Infraestruturas de Portugal: Lisbon, Portugal, 2014. (In Portuguese) [Google Scholar]

- Fonseca, M.; Almeida, A.; Capitão, S.; Bandeira, R.; Rodrigues, C. Avaliação do Uso de Plástico Recuperado de Resíduos Sólidos Urbanos Como Agente Modificador de Misturas Betuminosas. In Proceedings of the 9th Congresso Rodoviário Português (9th Portuguese Road Congress), Lisbon, Portugal, 28–30 May 2019. (In Portuguese). [Google Scholar]

- CEN. EN12697-35. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 35: Laboratory Mixing; CEN: Brussels, Belgium, 2004. [Google Scholar]

- CEN. EN12697-30. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 30: Specimen Prepared by Impact Compactor; CEN: Brussels, Belgium, 2012. [Google Scholar]

- CEN. EN12697-6. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 6: Determination of Bulk Density of Bituminous Specimens; CEN: Brussels, Belgium, 2012. [Google Scholar]

- CEN. EN12697-5. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 5: Determination of the Maximum Density; CEN: Brussels, Belgium, 2018. [Google Scholar]

- CEN. EN12697-12. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 12: Determination of the Water Sensitivity of Bituminous Specimens; CEN: Brussels, Belgium, 2018. [Google Scholar]

- CEN. EN12697-23. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens; CEN: Brussels, Belgium, 2017. [Google Scholar]

- CEN. EN12697-8. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 8: Determination of Void Characteristics of Bituminous Specimens; CEN: Brussels, Belgium, 2012. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).