Application of an Adaptive “Neuro-Fuzzy” Inference System in Modeling Cutting Temperature during Hard Turning

Abstract

Featured Application

Abstract

1. Introduction

- Reducing the processing time and costs (in relation to finishing grinding).

- It is feasible to handle multiple surfaces in one clamp, which is rarely possible when grinding, avoiding the effects that occur during grinding (the appearance of structural changes due to overheating of the surface layer, residual stresses, and cracks), and improving the exploitation characteristics of the parts.

2. Experimental Setup

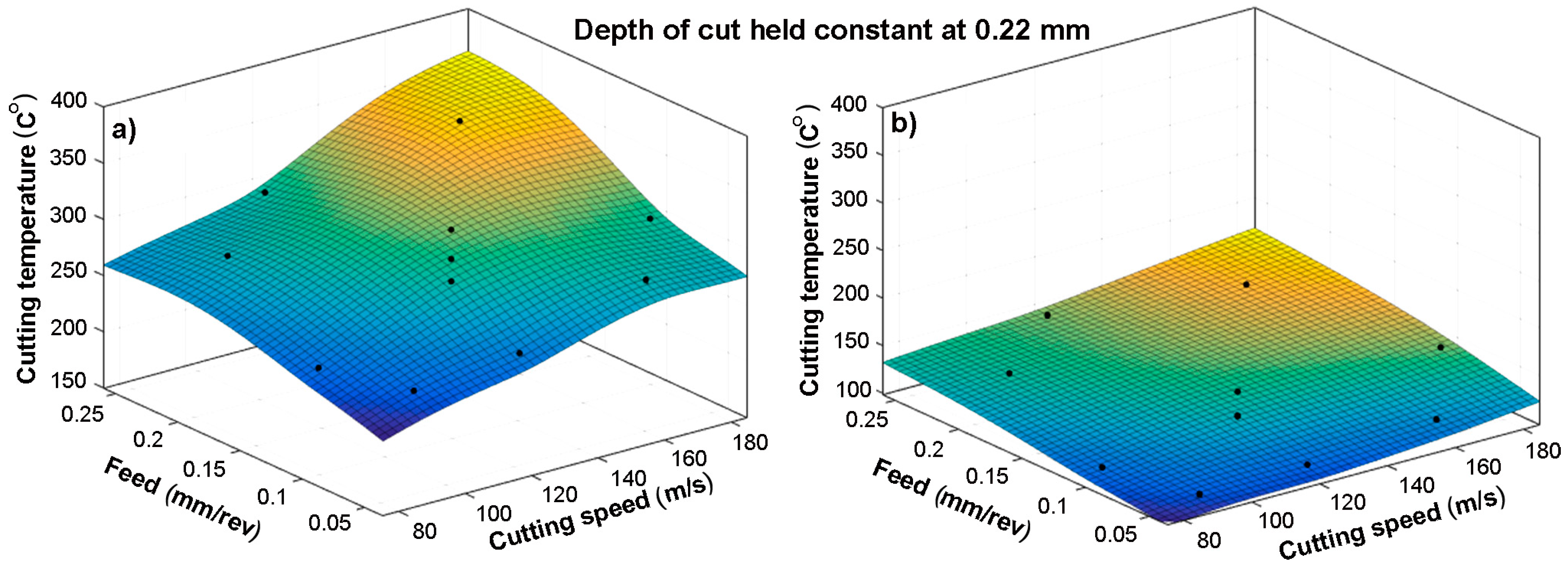

3. Response Surface Methodology

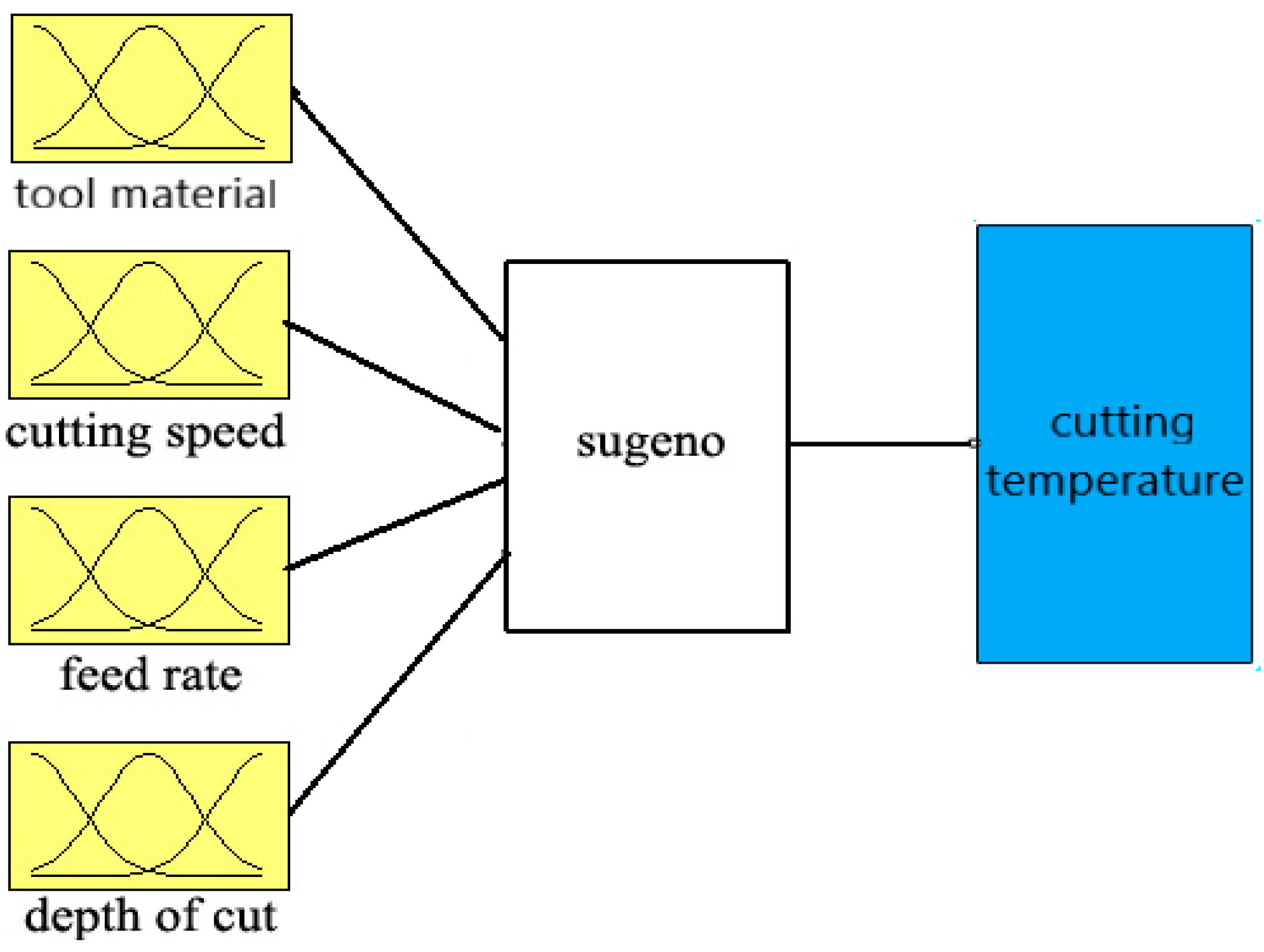

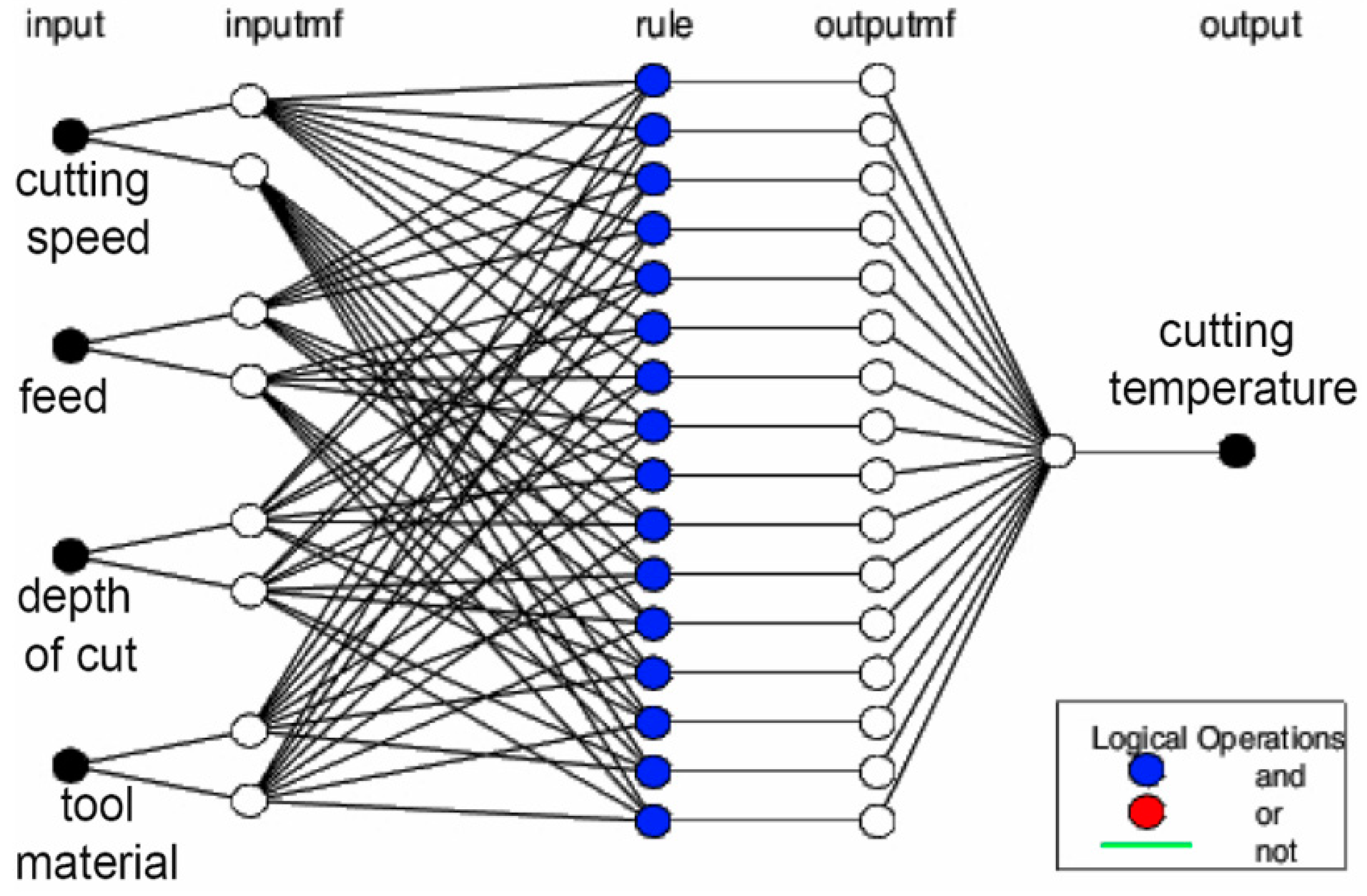

4. Adaptive Neuro-Fuzzy System

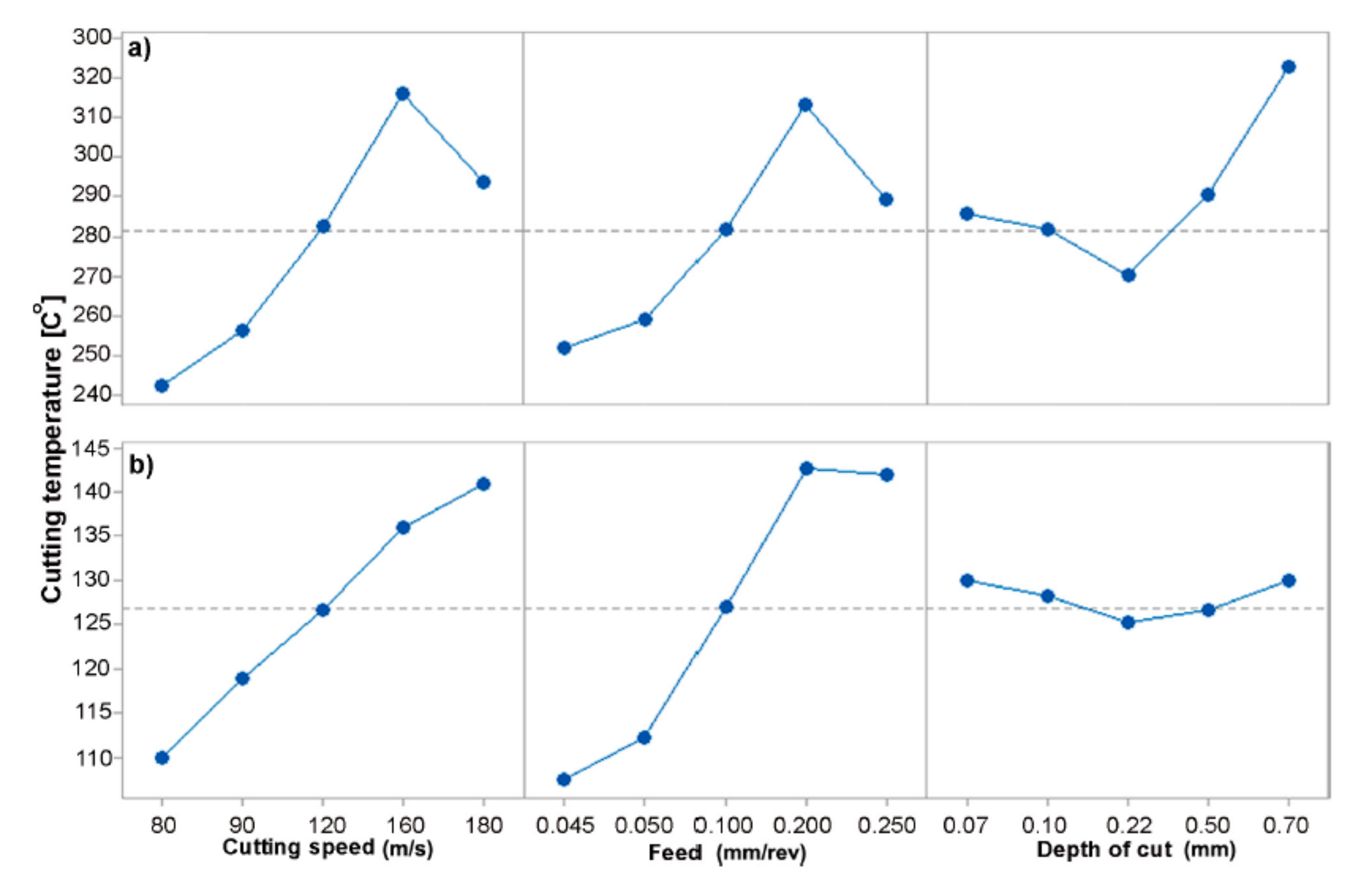

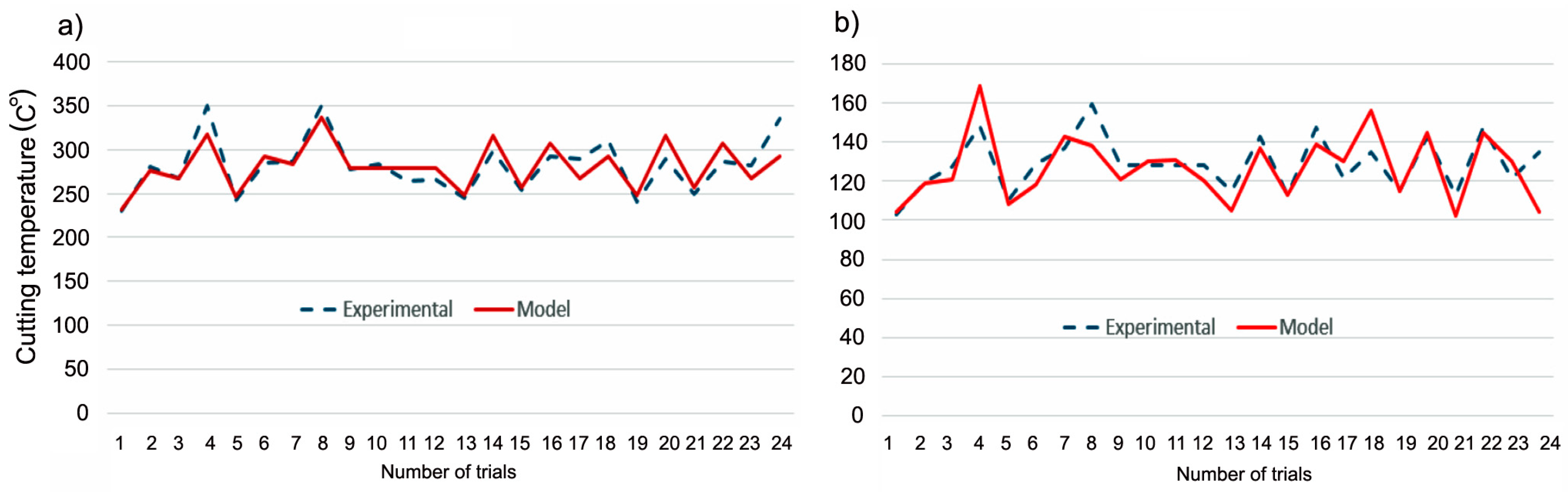

5. Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nieslony, P.; Krolczyk, G.; Wojciechowski, S.; Chudy, R.; Zak, K.; Maruda, R. Surface quality and topographic inspection of variable compliance part after precise turning. Appl. Surf. Sci. 2018, 434, 91–101. [Google Scholar] [CrossRef]

- Armarego, E.; Jawahir, I.; Ostafiev, V.; Venuvinod, P.K. Modeling of Machining Operations; CIRP Working Group Paper; STC-C: Paris, France, 1996. [Google Scholar]

- Mikołajczyk, T.; Nowicki, K.; Kłodowski, A.; Pimenov, D. Neural network approach for automatic image analysis of cutting edge wear. Mech. Syst. Signal Process. 2017, 88, 100–110. [Google Scholar] [CrossRef]

- Sharma, V.S.; Sharma, S.K.; Sharma, A.K. Cutting tool wear estimation for turning. J. Intell. Manuf. 2007, 19, 99–108. [Google Scholar] [CrossRef]

- Kovac, P.; Rodic, D.; Pucovský, V.; Savkovic, B.; Gostimirovic, M. Application of fuzzy logic and regression analysis for modeling surface roughness in face milliing. J. Intell. Manuf. 2012, 24, 755–762. [Google Scholar] [CrossRef]

- Avci, E. Comparison of wavelet families for texture classification by using wavelet packet entropy adaptive network based fuzzy inference system. Appl. Soft Comput. 2008, 8, 225–231. [Google Scholar] [CrossRef]

- Mia, M.; Dhar, N.R. Optimization of surface roughness and cutting temperature in high-pressure coolant-assisted hard turning using Taguchi method. Int. J. Adv. Manuf. Technol. 2017, 88, 739–753. [Google Scholar] [CrossRef]

- Pontes, F.J.; Ferreira, J.R.; Silva, M.B.; Paiva, A.P.; Balestrassi, P.P. Artificial neural networks for machining processes surface roughness modeling. Int. J. Adv. Manuf. Technol. 2009, 49, 879–902. [Google Scholar] [CrossRef]

- Kovač, P.; Rodic, D.; Pucovský, V.; Savkovic, B.; Gostimirović, M. Multi-output fuzzy inference system for modeling cutting temperature and tool life in face milling. J. Mech. Sci. Technol. 2014, 28, 4247–4256. [Google Scholar] [CrossRef]

- Andjelkovic, B.; Djordjevic, B.; Milovančević, M.; Jovanovic, N. Modeling steady-state thermal defectoscopy of steel solids using two side testing. Therm. Sci. 2016, 20, 1333–1343. [Google Scholar] [CrossRef]

- Ay, H.; Yang, W.-J. Heat transfer and life of metal cutting tools in turning. Int. J. Heat Mass Transf. 1998, 41, 613–623. [Google Scholar] [CrossRef]

- Nedić, B.; Eric, M. Cutting temperature measurement and material machinability. Therm. Sci. 2014, 18, 259–268. [Google Scholar] [CrossRef]

- Matras, A.; Zębala, W.; Kowalczyk, R. Precision milling of hardened steel with CBN tools. Key Eng. Mater. 2014, 581, 182–187. [Google Scholar] [CrossRef]

- Jawahir, I.; Balaji, A.; Rouch, K.; Baker, J. Towards integration of hybrid models for optimized machining performance in intelligent manufacturing systems. J. Mater. Process. Technol. 2003, 139, 488–498. [Google Scholar] [CrossRef]

- El-Mounayri, H.; Briceno, J.F.; Gadallah, M.H. A new artificial neural network approach to modeling ball-end milling. Int. J. Adv. Manuf. Technol. 2009, 47, 527–534. [Google Scholar] [CrossRef]

- Kannan, T.D.B.; Kannan, G.R.; Kumar, B.S.; Baskar, N. Application of Artificial Neural Network Modeling for Machining Parameters Optimization in Drilling Operation. Procedia Mater. Sci. 2014, 5, 2242–2249. [Google Scholar] [CrossRef]

- Zuperl, U.; Čuš, F.; Mursec, B.; Ploj, T. A hybrid analytical-neural network approach to the determination of optimal cutting conditions. J. Mater. Process. Technol. 2004, 157–158, 82–90. [Google Scholar] [CrossRef]

- Ambrogio, G.; Filice, L.; Shivpuri, R.; Umbrello, D. Application of NN technique for predicting the in-depth residual stresses during hard machining of AISI 52100 steel. Int. J. Mater. Form. 2008, 1, 39–45. [Google Scholar] [CrossRef]

- Mia, M.; Królczyk, G.; Maruda, R.; Wojciechowski, S. Intelligent Optimization of Hard-Turning Parameters Using Evolutionary Algorithms for Smart Manufacturing. Materials 2019, 12, 879. [Google Scholar] [CrossRef]

- Petković, D.; Madić, M.; Radovanović, M.; Janković, P.; Radenković, G. Modeling of cutting temperature in the biomedical stainless steel turning process. Therm. Sci. 2016, 20, 1345–1354. [Google Scholar] [CrossRef]

- Mikołajczyk, T.; Nowicki, K.; Bustillo, A.; Pimenov, D.Y. Predicting tool life in turning operations using neural networks and image processing. Mech. Syst. Signal Process. 2018, 104, 503–513. [Google Scholar] [CrossRef]

- Prabhu, S.; Ambigai, R.; Vinayagam, B.K. Performance analysis of AlTiN/AlCrN coating on cemented carbide cutting tool using fuzzy logic analysis. Aust. J. Mech. Eng. 2018, 1–12. [Google Scholar] [CrossRef]

- Lo, S.-P. The Application of an ANFIS and Grey System Method in Turning Tool-Failure Detection. Int. J. Adv. Manuf. Technol. 2002, 19, 564–572. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, B. Chatter prediction using merged wavelet denoising and ANFIS. Soft Comput. 2019, 23, 4439–4458. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Haron, C.H.C. Online tool wear prediction system in the turning process using an adaptive neuro-fuzzy inference system. Appl. Soft Comput. 2013, 13, 1960–1968. [Google Scholar] [CrossRef]

- Ho, W.-H.; Tsai, J.-T.; Lin, B.-T.; Chou, J.-H. Adaptive network-based fuzzy inference system for prediction of surface roughness in end milling process using hybrid Taguchi-genetic learning algorithm. Expert Syst. Appl. 2009, 36, 3216–3222. [Google Scholar] [CrossRef]

- Geronimo, T.M.; Cruz, C.E.; de Souza Campos, F.; Aguiar, P.R.; Bianchi, E.C. MLP and ANFIS Applied to the Prediction of Hole Diameters in the Drilling Process. In Artificial Neural Networks—Architectures and Applications; IntechOpen Limited: London, UK, 2013; p. 27. [Google Scholar]

- Huang, Y.; Dawson, T.G. Tool crater wear depth modeling in CBN hard turning. Wear 2005, 258, 1455–1461. [Google Scholar] [CrossRef]

- Kowalczyk, R.; Matras, A.; Zębala, W. Analysis of the surface roughness after the sintered carbides turning with PCD tools. In Proceedings of the Photonics Applications in Astronomy, Communications, Industry, and High-Energy Physics Experiments, Warsaw, Poland, 16 December 2014; p. 929012. [Google Scholar]

- Ueda, T.; Hosokawa, A.; Oda, K.; Yamada, K. Temperature on Flank Face of Cutting Tool in High Speed Milling. CIRP Ann. 2001, 50, 37–40. [Google Scholar] [CrossRef]

- Ueda, T.; Al Huda, M.; Yamada, K.; Nakayama, K.; Kudo, H. Temperature Measurement of CBN Tool in Turning of High Hardness Steel. CIRP Ann. 1999, 48, 63–66. [Google Scholar] [CrossRef]

- Müller-Hummel, P.; Lahres, M. Infrared temperature measurement on diamond-coated tools during machining. Diam. Relat. Mater. 1994, 3, 765–769. [Google Scholar] [CrossRef]

| Machining Parameters | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Cutting speed vc (m/min) | 80 | 90 | 120 | 160 | 180 |

| Feed f (mm/rev) | 0.045 | 0.05 | 0.1 | 0.2 | 0.25 |

| Depth of cut a (mm) | 0.07 | 0.1 | 0.22 | 0.5 | 0.7 |

| C (%) | Si (%) | Mn (%) | Cr (%) | V (%) |

|---|---|---|---|---|

| 0.9 | 0.25 | 2 | 0.35 | 0.1 |

| Inserts | Rake Angle | Back Angle | Inclination Angle | Tool Cutting Edge Angles | Nose Radius | Side Clearance | ||

|---|---|---|---|---|---|---|---|---|

| γ (°) | α (°) | λ (°) | κ (°) | κ1 (°) | r (mm) | (°) | ||

| CBN | CNMA 120404 | −6 | 6 | −6 | 91 | 5 | 0.4 | 0 |

| HM | CNMA 120404 | −6 | 6 | −6 | 91 | 5 | 0.4 | 0 |

| No. | Factor | …Θi Measured | Θi Model | ||||

|---|---|---|---|---|---|---|---|

| v (m/min) | f (mm/rev) | a (mm) | HM Θ (°C) | CBN Θ (°C) | HM Θ (°C) | CBN Θ (°C) | |

| 1. | 90 | 0.05 | 0.10 | 230 | 104 | 232.08 | 102.65 |

| 2. | 160 | 0.05 | 0.10 | 280 | 119 | 275.56 | 119.65 |

| 3. | 90 | 0.20 | 0.10 | 268 | 121 | 267.65 | 127.43 |

| 4. | 160 | 0.20 | 0.10 | 350 | 169 | 317.79 | 148.53 |

| 5. | 90 | 0.05 | 0.50 | 242 | 108 | 246.30 | 110.49 |

| 6. | 160 | 0.05 | 0.50 | 285 | 118 | 292.44 | 128.78 |

| 7. | 90 | 0.20 | 0.50 | 286 | 143 | 284.05 | 137.16 |

| 8. | 160 | 0.20 | 0.50 | 350 | 138 | 337.26 | 159.87 |

| 9. | 120 | 0.10 | 0.22 | 277 | 121 | 279.60 | 128.01 |

| 10. | 120 | 0.10 | 0.22 | 283 | 130 | 279.60 | 128.01 |

| 11. | 120 | 0.10 | 0.22 | 264 | 131 | 279.60 | 128.01 |

| 12. | 120 | 0.10 | 0.22 | 266 | 120 | 279.60 | 128.01 |

| 13. | 80 | 0.10 | 0.22 | 245 | 105 | 247.74 | 114.91 |

| 14. | 180 | 0.10 | 0.22 | 298 | 137 | 315.57 | 142.61 |

| 15. | 120 | 0.045 | 0.22 | 254 | 113 | 257.56 | 113.02 |

| 16. | 120 | 0.25 | 0.22 | 293 | 139 | 307.24 | 147.67 |

| 17. | 120 | 0.10 | 0.07 | 290 | 130 | 268.02 | 121.48 |

| 18. | 120 | 0.10 | 0.70 | 310 | 156 | 291.82 | 134.97 |

| 19. | 80 | 0.10 | 0.22 | 240 | 115 | 247.74 | 114.91 |

| 20. | 180 | 0.10 | 0.22 | 290 | 145 | 315.57 | 142.61 |

| 21. | 120 | 0.045 | 0.22 | 250 | 102 | 257.56 | 113.02 |

| 22. | 120 | 0.25 | 0.22 | 286 | 145 | 307.24 | 147.67 |

| 23. | 120 | 0.10 | 0.07 | 282 | 130 | 268.02 | 121.48 |

| 24. | 120 | 0.10 | 0.70 | 336 | 104 | 291.82 | 134.97 |

| Model Adequacy | HM Θ (°C) | CBN Θ (°C) | |

|---|---|---|---|

| Fa = 4.20467 | Fa = 3.77465 | ||

| Significance | Fro | 679937.42 | 214918.52 |

| Fr1 (v) | 105.27 | 71.11 | |

| Fr2 (f) | 72.60 | 35.71 | |

| Fr3 (a) | 12.62 | 8.24 | |

| Input of ANFIS | Temperature Θ (°C) | |||||||

|---|---|---|---|---|---|---|---|---|

| Tool Material | vc (m/min) | f (mm/rev) | a (mm) | Experimental | ANFIS | |||

| CBN | HM | CBN | HM | CBN | HM | |||

| Training data | ||||||||

| 1. | 19. | 90 | 0.05 | 0.1 | 104 | 165 | 103.9 | 164.6 |

| 2. | 20. | 160 | 0.05 | 0.1 | 119 | 122 | 119.0 | 121.9 |

| 3. | 21. | 90 | 0.2 | 0.1 | 121 | 150 | 121.0 | 149.9 |

| 4. | 22. | 160 | 0.2 | 0.1 | 169 | 200 | 169.0 | 200.0 |

| 5. | 23. | 90 | 0.05 | 0.5 | 108 | 230 | 108.0 | 229.9 |

| 6. | 24. | 160 | 0.05 | 0.5 | 118 | 189 | 118.0 | 188.2 |

| 7. | 25. | 90 | 0.2 | 0.5 | 143 | 245 | 143.0 | 244.9 |

| 8. | 26. | 160 | 0.2 | 0.5 | 138 | 230 | 137.9 | 230.0 |

| 9. | 27. | 120 | 0.1 | 0.22 | 121 | 280 | 127.3 | 280.0 |

| 10. | 28. | 120 | 0.1 | 0.22 | 130 | 183 | 127.3 | 188.2 |

| 11. | 29. | 120 | 0.1 | 0.22 | 131 | 184 | 127.3 | 188.2 |

| 12. | 30. | 120 | 0.1 | 0.22 | 120 | 190 | 127.3 | 188.2 |

| 13. | 31. | 80 | 0.1 | 0.22 | 105 | 196 | 97.0 | 183.3 |

| 14. | 32. | 180 | 0.1 | 0.22 | 137 | 200 | 140.9 | 201.0 |

| 15. | 33. | 120 | 0.045 | 0.22 | 113 | 210 | 113.0 | 208.9 |

| 16. | 34. | 120 | 0.25 | 0.22 | 139 | 160 | 139.0 | 164.6 |

| 17. | 35 | 120 | 0.1 | 0.07 | 130 | 208 | 129.9 | 183.9 |

| 18. | 36. | 120 | 0.1 | 0.7 | 156 | 161 | 130.23 | 161.0 |

| Average error for training data: 2.1% | ||||||||

| Test data | ||||||||

| 37. | 41. | 80 | 0.1 | 0.22 | 115 | 202 | 97.0 | 201.0 |

| 38. | 42. | 180 | 0.1 | 0.22 | 145 | 195 | 140.9 | 183.3 |

| 39. | 43. | 120 | 0.045 | 0.22 | 102 | 165 | 113.0 | 164.6 |

| 40. | 44. | 120 | 0.25 | 0.22 | 145 | 210 | 139.0 | 208.9 |

| Average error for test data: 5.1% | ||||||||

| Validation data | ||||||||

| 45. | 47. | 120 | 0.25 | 0.22 | 145 | 160 | 139.3 | 165.6 |

| 46. | 48. | 120 | 0.1 | 0.07 | 130 | 250 | 127.2 | 229.4 |

| Average error for validation data: 4.5% | ||||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savkovic, B.; Kovac, P.; Dudic, B.; Rodic, D.; Taric, M.; Gregus, M. Application of an Adaptive “Neuro-Fuzzy” Inference System in Modeling Cutting Temperature during Hard Turning. Appl. Sci. 2019, 9, 3739. https://doi.org/10.3390/app9183739

Savkovic B, Kovac P, Dudic B, Rodic D, Taric M, Gregus M. Application of an Adaptive “Neuro-Fuzzy” Inference System in Modeling Cutting Temperature during Hard Turning. Applied Sciences. 2019; 9(18):3739. https://doi.org/10.3390/app9183739

Chicago/Turabian StyleSavkovic, Borislav, Pavel Kovac, Branislav Dudic, Dragan Rodic, Mirfad Taric, and Michal Gregus. 2019. "Application of an Adaptive “Neuro-Fuzzy” Inference System in Modeling Cutting Temperature during Hard Turning" Applied Sciences 9, no. 18: 3739. https://doi.org/10.3390/app9183739

APA StyleSavkovic, B., Kovac, P., Dudic, B., Rodic, D., Taric, M., & Gregus, M. (2019). Application of an Adaptive “Neuro-Fuzzy” Inference System in Modeling Cutting Temperature during Hard Turning. Applied Sciences, 9(18), 3739. https://doi.org/10.3390/app9183739