Noise Sources and Control, and Exposure Groups in Chemical Manufacturing Plants

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Noise and the Manufacturing Sector

Noise Levels in the Manufacturing Sector

3.2. Exposure Groups in Chemical Manufacturing Plants

3.2.1. Occupational Classes in Chemical Manufacturing Plants

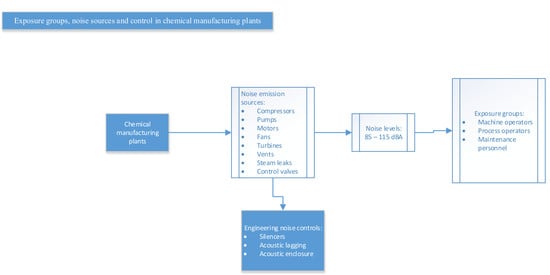

3.2.2. Relationship between Emitted Noise Levels and Exposure Groups

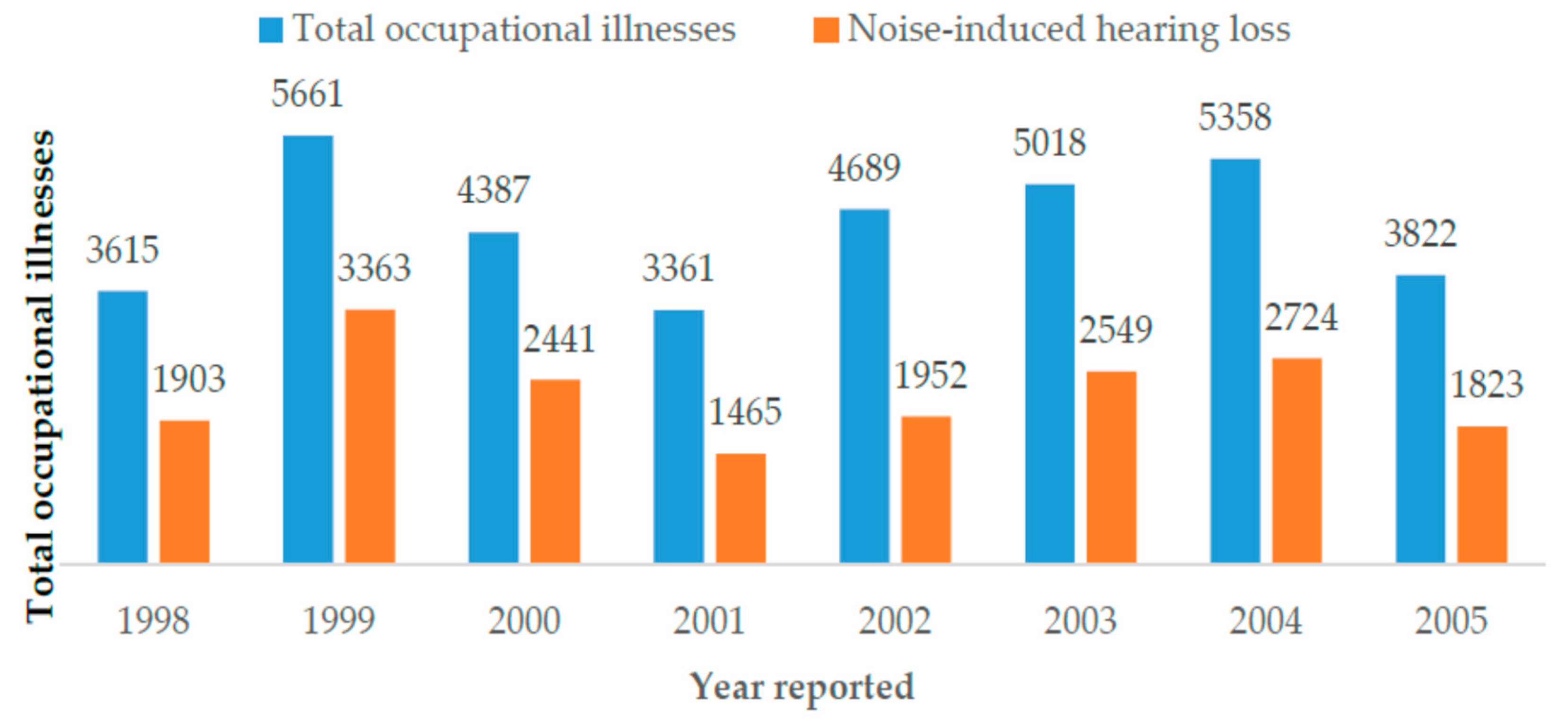

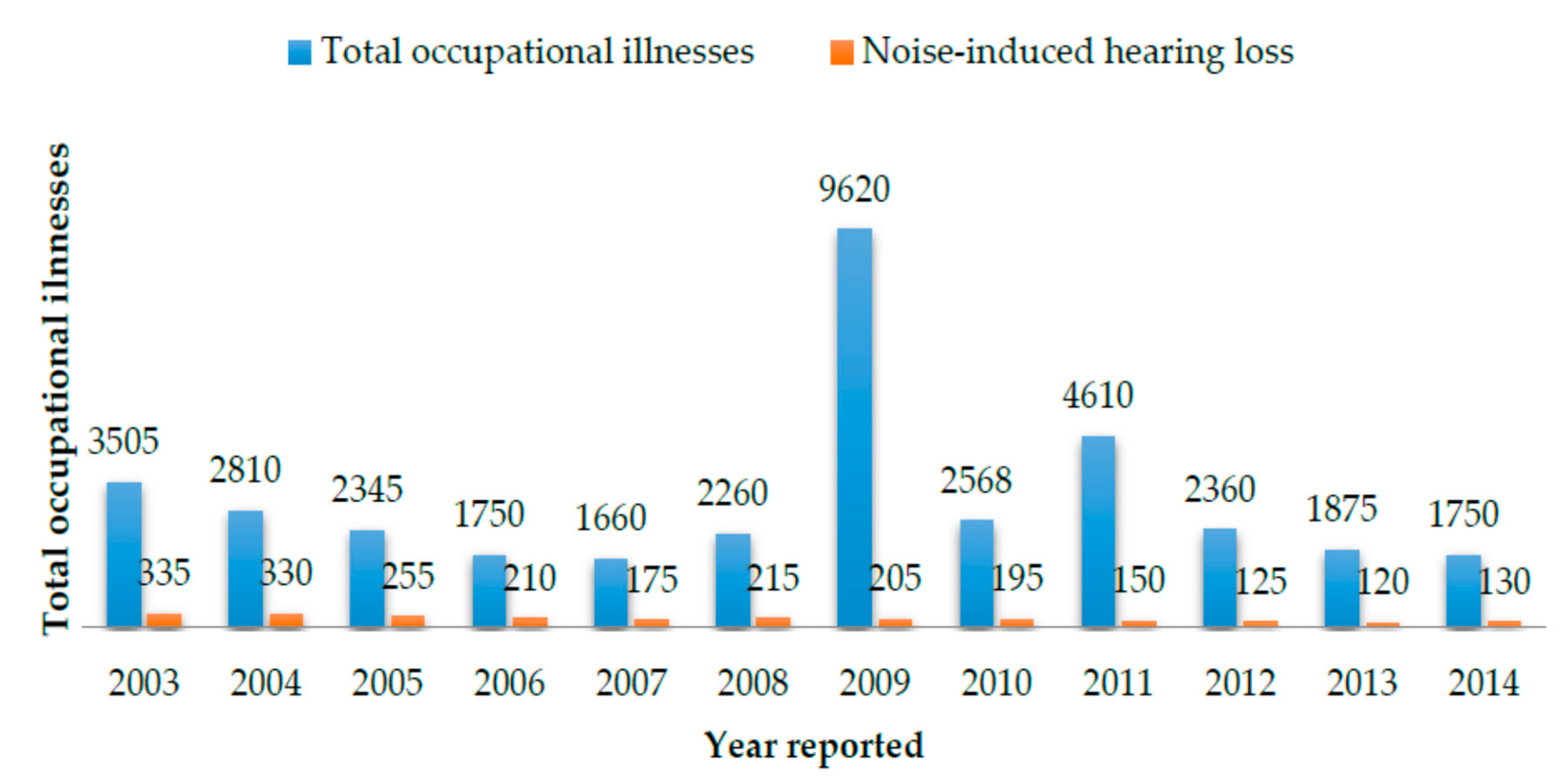

3.2.3. Compensable Claims as Indicator of Noise Exposure

3.3. Noise Control in Chemical Manufacturing Plants

4. Discussion

4.1. Noise in the Manufacturing Sector

4.2. Employment and Noise Exposure in the Manufacturing Sector

4.3. Noise Control for Chemical Manufacturing Plants

4.3.1. Workplace Regulation

Regulatory Control of Plant Equipment

Regulatory Control through Inspection and Enforcement of Noise Regulations

Organisational and Administrative Controls

Hearing Protection Devices

4.3.2. Costs and Benefits of Noise Control and Regulation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Ethical Statement

References

- North American Industry Classification System. Industries at a Glance. Available online: http://www.bls.gov/iag/tgs31-33.htm (accessed on 12 May 2016).

- Fuente, A.; Hickson, L. Noise-induced hearing loss in Asia. Int. J. Audiol. 2011, 50, S3–S10. [Google Scholar] [CrossRef] [PubMed]

- Kidnay, A.J.; Parrish, W. Fundamentals of Natural Gas Processing; CRC Press: Boca Raton, FL, USA, 2006; Volume 200, p. 1. [Google Scholar]

- Austin, G.T. Shreve’s Chemical Process Industries, 5th ed.; McGraw-Hill: New York, NY, USA, 1984; pp. 748–749. [Google Scholar]

- Occupational Safety and Health Administration. Occupational Safety and Health Administration Technical Manual. Noise. Available online: https://www.osha.gov/dts/osta/otm/noise/hcp/index.html (accessed on 12 July 2016).

- South African National Standard. Recommended Practice for the Design of Low-noise Machinery and Equipment; South African National Standard 11690-2; Part 2: Noise Control Strategies; Standards South Africa: Pretoria, South Africa, 1996; pp. 1–23. [Google Scholar]

- Miller, R.K. Noise Control Solutions for Power Plants; The Fairmont Press Inc.: Lilburn, GA, USA, 1984; pp. 23–100. [Google Scholar]

- South African National Standard. Acoustics—Recommended Practice for the Design of Low-noise Machinery and Equipment; South African National Standard 11688-1; Part 1: Planning; Standards South Africa: Pretoria, South Africa, 1995; pp. 4–35. [Google Scholar]

- South African National Standard. Acoustics—Recommended Practice for the Design of Low-noise Machinery; South African National Standard 11688-2; Part 2: Introduction to the Physics of Low-Noise Design; Standards South Africa: Pretoria, South Africa, 1998; pp. 1–41. [Google Scholar]

- Health and Safety Executive. Control of Noise at Work Regulations 2005; Health and Safety Executive: Richmond, UK, 2005. [Google Scholar]

- Occupational Safety and Health Administration. Occupational Noise Exposure 1910.95; Occupational Safety and Health Administration: Washington, DC, USA, 1995.

- Department of Labour. Noise-Induced Hearing Loss Regulations 307. Available online: http://www.labour.gov.za/DOL/downloads/legislation/regulations/occupational-health-and-safety/Regulation%20-%20307%20-%20OHS%20-%20Noise%20Induced%20Hearing%20Loss.pdf (accessed on 21 October 2015).

- Passchier-Vermeer, W.; Passchier, W. Noise exposure and public health. Environ. Health Perspect. 2000, 108, 123–131. [Google Scholar] [PubMed]

- Health and Safety Executive. Non-Auditory Effects of Noise at Work: A Review of the Literature. Available online: www.hse.gov.uk/resarch/crr_pdf/1991/crr91030.pdf (accessed on 12 August 2017).

- Dembe, A.E. The social consequences of occupational injuries and illnesses. Am. J. Ind. Med. 2001, 40, 403–417. [Google Scholar] [CrossRef] [PubMed]

- Health and Safety Executive. Perceptions of the Cost Implications of Health and Safety Failures. Available online: www.hse.gov.uk/research/rrpdf/rr403.pdf (accessed on 6 November 2018).

- National Institute for Occupational Safety and Health. NIOSH Health Hazard. Evaluation Program Noise Measurement Database. Available online: https://www.cdc.gov/niosh/data/datasets/RD-1005-2014-01 (accessed on 22 May 2019).

- United States Environmental Protection Agency. Noise from Industrial Plants; United States Environmental Protection Agency: Washington, DC, USA, 1971; pp. 32–273.

- Gerdart, S. Health and Safety in Today’s Manufacturing Industry; Wilfrid Laurier University: Brantford, ON, Canada, 2013; pp. 177–195. [Google Scholar]

- Schneider, E.; Paoli, P.; Brun, E. Thematic Report: Noise in Figures; European Agency for Safety & Health at Work, Risk Observatory, Luxembourg Office for Official Publication of the European Communities: Bilbao, Spain, 2005; p. 7. [Google Scholar]

- Burgess, W.A. Recognition of Health Hazards in Industry: A Review of Materials and Processes, 2nd ed.; John Wiley & Sons-Interscience: New York, NY, USA, 1995; pp. 279–316. [Google Scholar]

- Mutchler, J.E. Plastics. In In-Plant Practices for Job Related Health Hazards Control; Cralley, L.V., Cralley, L.J., Eds.; Volume 1: Production processes; Wiley-Interscience Publication: Fallbrook, CA, USA, 1989; pp. 571–597. [Google Scholar]

- Cavalcante, F.; Ferrite, S.; Meira, T.C. Exposure to noise in the manufacturing industry in Brazil. Rev. CEFAC J. 2013, 15, 1364–1370. [Google Scholar] [CrossRef]

- Sayler, S.K.; Roberts, B.J.; Manning, M.A.; Sun, K.; Neitzel, R.L. Patterns and trends in OSHA occupational noise exposure measurements from 1979 to 2013. Occup. Environ. Med. 2019, 76, 118–124. [Google Scholar] [CrossRef] [PubMed]

- Institute of Occupational Medicine. Behavioral Studies of People’s Attitudes to Wearing Hearing Protection and How These Might Be Changed (Research Report 028); Health and Safety Executive: Edinburgh, UK, 2002; p. 22. [Google Scholar]

- Bedi, R. Evaluation of occupational environment in two textile plants in Northern India with specific reference to noise. Ind. Health 2006, 44, 112–116. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Awadalkarim, M.A. Noise Induced Hearing Loss at two textile plants in Sudan. Eur. Acad. Res. 2015, 11, 13995–14006. [Google Scholar]

- Ejigu, M.A. Excessive sound noise risk assessment in textile mills of an Ethopian-Kombolcha textile industry share company. Int. J. Res. Ind. Eng. 2019, 8, 105–114. [Google Scholar]

- Moon, Y.H.; Kwon, S.P. Hearing impairment due to noise in the Kyung-In industrial area in Korea. Yonsei Med. J. 1976, 17, 30–38. [Google Scholar] [CrossRef]

- Odusanya, O.O.; Nwawolo, C.C.; Ademuson, E.O.; Akinola, D.O. Disabling hearing loss in two industries in Lagos, Nigeria. Niger. J. Clin. Pract. 2004, 7, 4–7. [Google Scholar]

- Boateng, C.A.; Amedofu, G.K. Industrial noise pollution and its effects on the hearing capabilities of workers: A study from saw mills, printing presses and corn mills. Afr. J. Health Sci. 2004, 11, 55–60. [Google Scholar] [CrossRef]

- Chen, J.D.; Tsai, J.Y. Hearing loss among workers at an oil refinery in Taiwan. Arch. Environ. Health 2003, 58, 55–58. [Google Scholar] [CrossRef]

- Rikhotso, O.; Harmse, J.L.; Engelbrecht, J.C. Evaluation of passive hearing protection device selection outcomes at a chemical manufacturing company. Occup. Health S. Afr. 2018, 24, 2–11. [Google Scholar]

- National Institute for Occupational Safety and Health. Industrial hygiene characterization of urea formaldehyde and polyurethane foam insulation. Available online: https://www.cdc.gov/niosh/docs/83-108/83-108.pdf?id=10.26616/NIOSHPUB83108 (accessed on 15 August 2017).

- Lynch, J.R. Ammonia. In In-Plant Practices for Job Related Health Hazards Control; Cralley, L.V., Cralley, L.J., Eds.; Volume 1: Production processes; Wiley-Interscience Publication: Fallbrook, CA, USA, 1989; p. 73. [Google Scholar]

- Pringle, D.; Warren, E. Aldehydes and alcohols (Oxo reaction). In In-Plant Practices for Job Related Health Hazards Control; Cralley, L.V., Cralley, L.J., Eds.; Volume 1: Production processes; Wiley-Interscience Publication: Fallbrook, CA, USA, 1989; p. 8. [Google Scholar]

- National Institute for Occupational Safety and Health. Evaluation of Neurological Dysfunction among Workers Exposed to Trichloroethylene. Health Hazard. Evaluation Report 2004-0372-3054. Available online: https://www.cdc.gov/niosh/hhe/hhe/report/pdfs/2004-0372-3054.pdf (accessed on 22 May 2019).

- Neghab, M.; Maddahi, M.; Rajaeefard, A.R. Hearing impairment and hypertension associated with long term occupational noise exposure. Iran. Red Crescent Med. J. 2009, 11, 160–165. [Google Scholar]

- Howell, R.W. A seven-year review of measured hearing levels in male manual steelworkers with high initial thresholds. Br. J. Ind. Med. 1978, 35, 27–31. [Google Scholar] [CrossRef][Green Version]

- Mizan, G.; Abrahams, O.; Sekobe, G.; Kgalamano, S.; Ndaba, M.; Manganyi, J.; Renton, K.; Wilson, K.S. Noise induced hearing loss and hearing conservation in 8 primary iron and steel companies in South Africa. Occup. Health S. Afr. 2013, 20, 7–13. [Google Scholar]

- Noweir, M.H.; Bafail, A.O.; Jomoah, I.M. Noise pollution in metalwork and woodwork industries in the Kingdom of Saudi Arabia. Int. J. Occup. Saf. Ergon. 2014, 20, 661–670. [Google Scholar] [CrossRef]

- Guerra, M.R.; Lourenco, P.M.C.; Bustamante-Teixeira, M.T.; Alves, M.J.M. Prevalence of noise-induced hearing loss in metallurgical company. J. Public Health 2005, 59, 238–244. [Google Scholar]

- Singh, L.P.; Bhardwaj, A.; Deepak, K.; Bedi, R. Occupational noise exposure in small scale hand tools manufacturing (forging) industry (SSI) in Northern India. Ind. Health 2009, 47, 423–430. [Google Scholar] [CrossRef]

- Ologe, F.E.; Olajide, T.G.; Nwawolo, C.C.; Oyejola, B.A. Deterioration of noise-induced hearing loss among bottling factory workers. J. Laryngol. Otol. 2008, 122, 786–794. [Google Scholar] [CrossRef]

- National Academy of Engineering. Technology for a Quieter America; The National Academies Press: Washington, DC, USA, 2010; pp. 33–34. [Google Scholar]

- Barber, A. Handbook of Noise and Vibration Control, 6th ed.; Elsevier: Oxford, UK, 1992; pp. 37–45. [Google Scholar]

- De Beer, L. Chemical Processing. Available online: http://www.iloencyclopaedia.org/part-xii-57503/oil-and-natural-gas (accessed on 11 February 2016).

- National Institute for Occupational Safety and Health. Industrial Noise Control Manual (DHEW (NIOSH) Publication No. 79-117); National Institute for Occupational Safety and Health: Cambridge, MA, USA, 1978; pp. 1–295.

- Fagerlund, A.; Karczub, D.G.; Martin, T. Identification and Prediction of Piping System Noise. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.94.9689&rep=rep1&type=pdf (accessed on 14 December 2015).

- Rayner, R. Pump Users Handbook. pp. 1–21. Available online: http://www.sciencedirect.com/science/book/9781856172165 (accessed on 27 November 2015).

- Occupational Hygiene Training Association. Noise—Measurement and Its Effects. Available online: www.ohlearning.com/training/training-materials/w503-noise--measurement-and-its-effects.aspx (accessed on 20 January 2016).

- Gerges, S.N.Y.; Sehrndt, G.A.; Parthey, W. World Health Organization Monograph on Occupational Exposure to Noise: Evaluation, Prevention and Control; World Health Organization: Geneva, Switzerland, 2001; p. 107. [Google Scholar]

- Arca Regler GMBH. Industrial Process Control Valves. Available online: http://www.arca.de/download/2/IndustrielleProzessregelventileengl.pdf (accessed on 14 December 2015).

- Emerson. Control Valve Handbook. Available online: http://www.documentation.emersonprocess.com/groups/public/documents/book/cvh99.pdf (accessed on 14 December 2015).

- Boyce, M.P. Gas Turbine Engineering Handbook. pp. 721–759. Available online: http://www.sciencedirect.com/science/article/pii/B9780750678469500006 (accessed on 26 November 2015).

- Lynch, J.R. Low-density polyethylene. In In-Plant Practices for Job Related Health Hazards Control; Cralley, L.V., Cralley, L.J., Eds.; Volume 1: Production processes; Wiley-Interscience Publication: Fallbrook, CA, USA, 1989; p. 608. [Google Scholar]

- De Beer, L. Oil and Natural Gas. Available online: http://www.iloencyclopaedia.org/part-xii-57503/oil-and-natural-gas (accessed on 11 February 2016).

- United States Department of Energy. Steam Pressure Reduction: Opportunities and Issues. Available online: http://www.nrel.gov/docs/fy06osti/37853.pdf (accessed on 24 December 2015).

- Oil and Gas Producers. Flaring & Venting in the Oil & Gas Exploration & Production Industry. An Overview of Purpose, Quantities, Issues, Practices and Trends; International Association of Oil & Gas Producers: London, UK, 2000. [Google Scholar]

- South African National Standard. The Measurement and Assessment of Occupational Noise for Hearing Conservation Purposes; South African National Standard 10083; Standards South Africa: Pretoria, South Africa, 2013. [Google Scholar]

- Smith, B.J.; Peters, R.J.; Owen, S. Acoustics and Noise Control, 2nd ed.; Pearson Longman: Essex, UK, 1996; pp. 203–206. [Google Scholar]

- Robert, J.; Pathak, B.P. Noise levels: A database of industrial noise level measurements. Online Rev. 1988, 12, 211–217. [Google Scholar] [CrossRef]

- Mining Industry Occupational Safety and Health. Noise Database: Minerals Council South Africa. Available online: www.mosh.co.za/downloads/noise/noise-database (accessed on 22 May 2019).

- International Labour Organization. International Standard Classification of Occupations. p. 318. Available online: http://www.ilo.org/wcmsp5/groups/public/dgreports/dcomm/publ/documents/publication/wcms_172572.pdf (accessed on 18 February 2016).

- Department of Higher Education and Training. OFO Register. Available online: https://webapps.dhet.gov.za/OFORegister/Home/About (accessed on 11 May 2019).

- International Organization for Standardization. Acoustics—Determination of Occupational Noise Exposure—Engineering Method; ISO 9612:2009(E); International Organization for Standardization: Geneva, Switzerland, 2009; p. 1. [Google Scholar]

- National Institute for Occupational Safety and Health. NIOSH Health Hazard Evaluation Report; Kelly, J., Ed.; NIOSH Health Hazard Evaluation Report: HETA 91-305-2267; National Institute for Occupational Safety and Health: Cincinnati, OH, USA. Available online: https://www.cdc.gov/niosh/hhe/reports/pdfs/1991-0305-2267.pdf (accessed on 6 August 2019).

- National Institute for Occupational Safety and Health. Thomson Consumer Electronics; Tubbs, R.L., Ed.; NIOSH Health Hazard Evaluation Report: HETA-91-0021-2144; National Institute for Occupational Safety and Health: Cincinnati, OH, USA. Available online: https://wwwcdc.gov/niosh/hhe/reports/pdfs/1991-0021-2144.pdf?id=10.26616/NIOSHHETA910212144 (accessed on 6 August 2019).

- National Institute for Occupational Safety and Health. Evaluating Worker Exposure to Noise at a Manufacturer of Industrial Centrifugal Equipment; Tubbs, R.L., Ed.; NIOSH Health Hazard Evaluation Report: HETA 95-0167-2539; National Institute for Occupational Safety and Health: Cincinnati, OH, USA. Available online: https://www.cdc.gov/niosh/hhe/reports/pdfs/1995-0167-2539.pdf (accessed on 6 August 2019).

- Kock, S.; Andersen, T.; Kolstad, H.A.; Kofoed-Nielsen, B.; Wiesler, F.; Bonde, J.P. Surveillance of noise exposure in the Danish workplace: A baseline survey. Occup. Environ. Med. 2004, 61, 838–843. [Google Scholar] [CrossRef]

- Nodoushan, R.J.; Esmaielpour, M.R.M.; Ravandi, M.R.G.; Mehrparvar, A.H.; Gholamezadeh, R. Field validation of a standard hearing loss prediction model in an Iranian textile industry. Int. J. Occup. Hyg. 2008, 9, 163–170. [Google Scholar]

- National Institute for Occupational Safety and Health. Evaluation of Exposures in a Steel Coil Pickling Plant; Li, J.F., de Prio, M.A., Eds.; NIOSH Health Hazard Evaluation Report: HHE Report No. 2017-0022-3311; National Institute for Occupational Safety and Health: Cincinnati, OH, USA. Available online: https://www.cdc.gov/niosh/hhe/reports/pdfs/2017-0022-3311.pdf (accessed on 6 August 2019).

- Prabu, M.; Gokulram, M.; Magibalan, S.; Senthilkumar, P.; Boopathi, R. Noise reducing in glass manufacturing industry. J. Eng. Res. 2018, 18, 33–41. [Google Scholar]

- Concawe. An assessment of occupational exposure to noise in western european oil refineries. Available online: https://www.concawe.eu/wp-content/uploads/2017/01/rpt_90-53ocr-2004-01701-01-e.pdf (accessed on 15 August 2017).

- Bureau of Labor Statistics, Department of Labor. Employer-Reported Workplace Injuries and Illnesses. Available online: http://www.bls.gov/iif/oshwc/osh/os/osnr0021.pdf (accessed on 12 May 2016).

- Health and Safety Executive. Noise-Induced Hearing Loss in Great Britain. Available online: http://www.hse.gov.uk/Statistics/causdis/deafness/index.htm (accessed on 3 May 2016).

- Department of Labour. Annual Report of the Compensation Fund. Available online: http://www.labour.gov.za/doc/downloads/annual-reports/compensation-for-occupational-injuries-and-diseases/2002/part2.pdf (accessed on 19 April 2017).

- Department of Labour. Annual Report of the Compensation Fund 2005; Compensation Commissioner, Department of Labour: Pretoria, South Africa, 2005; p. 25.

- Fritschi, L.; Lewkowski, K.; Heyworth, J.; Li, A.I.; McCausland, K.; Williams, W. National prevalence of occupational noise exposure. Occup. Environ. Med. 2017, 74, A1–A166. [Google Scholar] [CrossRef]

- International Organization for Standardization. Acoustics—Acoustic Insulation for Pipes, Valves and Flanges; ISO 15665:2003(E); International Organization for Standardization: Geneva, Switzerland, 2003; pp. 1–35. [Google Scholar]

- Advanced Noise Solutions. Industrial Noise Reduction. Available online: https://www.advanced-noise-solutions.co.uk/industrial-noise-reduction.html (accessed on 21 May 2019).

- Health and Safety Executive. Sound Solutions Case Studies. Available online: http://www.hse.gov.uk/NOISE/casestudies/soundsolutions/index.html (accessed on 15 August 2017).

- Cumming, J.R., Jr.; Golden, B.G. Silencer Application Handbook, 1993th ed.; Universal Silencer: Stoughton, WI, USA, 1993; pp. 61–141. [Google Scholar]

- International Organization for Standardization. Acoustics—Guidelines for Noise Control by Silencers; ISO 14163:1998(E); International Organization for Standardization: Geneva, Switzerland, 1998; pp. 1–41. [Google Scholar]

- International Organization for Standardization. Acoustics—Guidelines for Noise Control by Enclosures and Cabins; ISO 15667:2000(E); International Organization for Standardization: Geneva, Switzerland, 2000. [Google Scholar]

- National Institute for Occupational Safety and Health. Compendium of Materials for Noise Control; Publication No. HEW (NIOSH) 75-165); National Institute for Occupational Safety and Health: Cincinnati, OH, USA, 1975; pp. 28–56.

- Cralley, L.V.; Cralley, L.J. In-Plant Practices for Job Related Health Hazards Control; John Wiley & Sons: New York, NY, USA, 1989; Volume 1, pp. 1–3. [Google Scholar]

- Inceusa. Noise Control Engineering Journal. 2019. Available online: https://www.inceusa.org/publications/noise-control-engineering-journal/ (accessed on 22 May 2019).

- National Institute for Occupational Safety and Health. Noise Statistics. Available online: http://www.cdc.gov/niosh/topics/noise/stats/html (accessed on 15 May 2017).

- Office for National Statistics. Employment by Industry. Available online: http://www.ons.gov.uk/employmentlabourmarket/peopleinwork/employmentandemployeetypes/datasets/employmentbyindustryempl3 (accessed on 15 May 2017).

- Statistics South Africa. Quarterly Labour Force Survey; Quarter 4: 2016; Publication No. P0211; Statistics: Pretoria, South Africa, 2016; p. 2.

- Nandi, S.S.; Dhatrak, S.V. Occupational noise-induced hearing loss in India. Ind. J. Occup. Environ. Med. 2008, 12, 53–56. [Google Scholar] [CrossRef]

- Health and Safety Executive. Topic Inspection Pack Noise; Health and Safety Executive: London, UK, 2008. [Google Scholar]

- Tak, S.; Davis, R.R.; Calvert, G.M. Exposure to hazardous workplace noise and use of hearing protection devices among US workers—NHANES, 1999–2004. Am. J. Ind. Med. 2009, 52, 358–371. [Google Scholar] [CrossRef]

- National Institute for Occupational Safety and Health. Burden, Need and Impact. Available online: https://www.cdc.gov/niosh/programs/manuf/burden.html (accessed on 3 April 2019).

- Masterson, E.A.; Bushnell, P.T.; Themann, C.L.; Morata, T.C. Hearing impairment among noise-exposed workers—United States, 2003–2012. Morb. Mortal. Wkly. Rep. 2016, 2016, 389–394. [Google Scholar] [CrossRef]

- Tao, L.; Zeng, L.; Wu, K.; Zhang, H.; Wu, J.; Zhao, Y.; Li, N.; Zhao, Y. Comparison of four task-based measurement indices with full-shift dosimetry in a complicated noise environment. Int. J. Ind. Ergon. 2016, 53, 149–156. [Google Scholar] [CrossRef]

- Virji, M.A.; Woskie, S.R.; Waters, M.; Brueck, S.; Stancescu, D.; Gore, R.; Estill, C.; Princes, M. Agreement between task-based estimates of the full-shift noise exposure and the full-shift noise dosimetry. Ann. Occup. Hyg. 2009, 53, 201–214. [Google Scholar]

- Neitzel, R.L.; Andersson, M.; Andersson, E. Comparison of multiple measures of noise exposure in paper mills. Ann. Occup. Hyg. 2016, 60, 581–596. [Google Scholar] [CrossRef]

- Shackleton, S.; Piney, M.D. A comparison of two methods of measuring personal noise exposure. Ann. Occup. Hyg. 1984, 28, 373–390. [Google Scholar]

- National Institute for Occupational Safety and Health. Occupationally-Induced Hearing Loss. Employers and Employees in Manufacturing Need Your Help. Available online: https://www.cdc.gov.niosh/docs/2010-136/pdfs/2010-136.pdf (accessed on 16 August 2017).

- Park, S.K.; Elmarsafawy, S.; Mukherjee, B.; Spiro, A.; Vokonas, P.S.; Nie, H.; Weisskopf, M.G.; Schwartz, J.; Hu, H. Cumulative lead exposure and age-related hearing loss: The VA normative aging study. Hear. Res. 2010, 269, 48–55. [Google Scholar] [CrossRef]

- Baumann, H.D.; Coney, W.B. Noise of gas flows. In Noise and Vibration Control Engineering. Principles and Applications, 2nd ed.; Ver, I.L., Beranek, L.L., Eds.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2006; pp. 611–658. [Google Scholar]

- National Institute for Occupational Safety and Health. Criteria for a Recommended Standard, Revised Criteria. 1998. Available online: http://www.cdc.gov/niosh/docs/98-126/pdfs/98-126.pdf (accessed on 2 July 2013).

- Hager, L.D. Hearing Conservation: The Standards. Available online: http://www.audiologyonline.com/articles/hearing-conservation-the-standards-1228 (accessed on 14 July 2014).

- Morata, T.C.; Meinke, D. Uncovering effective strategies for hearing loss prevention. Acoust. Aust. 2016, 44, 67–75. [Google Scholar] [CrossRef]

- Veebeek, J.H.; Kateman, E.; Morata, T.C.; Dreschler, W.A.; Mischke, C. Interventions to prevent occupational noise-induced hearing loss: A cochrane systemic review. Int. J. Audiol. 2014, 53, S84–S96. [Google Scholar] [CrossRef]

- Thunder, T.D. Hearing Conservation in the United States: A Historical Perspective. Available online: http://www.audiologyonline.com/articles/hearing-conservation-in-us-historical-1263 (accessed on 14 July 2016).

- International Organization for Standardization. Acoustics—Noise Control Design Procedures for Open Plant; ISO 15664: 2001(E); International Organization for Standardization: Geneva, Switzerland, 2001; pp. 1–21. [Google Scholar]

- Danish Standards. Acoustics—Declaration and Verification of Noise Emission Values of Machinery and Equipment; DS/EN ISO 4871; Danish Standards: Copenhagen, Denmark, 2009. [Google Scholar]

- International Electrotechnical Commission. Acoustics—Determination of Sound Pressure Levels of Multisource Industrial Plants for Evaluation of Sound Pressure Levels in the Environment—Engineering Method; IEC 8297; IHS Markit: Eaglewood, IL, USA, 1994. [Google Scholar]

- International Electrotechnical Commission. Industrial-Process Control Valves: Noise Considerations—Control Valve Aerodynamic Noise Prediction Method; IEC 60534-8-3; IHS Markit: Eaglewood, IL, USA, 2010. [Google Scholar]

- International Electrotechnical Commission. Industrial-Process Control Valves: Noise Considerations—Section 4: Prediction of Noise Generated by Hydrodynamic Flow; IEC 60534-8-4; IHS Markit: Eaglewood, IL, USA, 2015. [Google Scholar]

- EEMUA. Noise Procedure Specification. The Engineering Equipment and Materials Users Association; EEMUA 140; IHS Markit: Eaglewood, IL, USA, 2014. [Google Scholar]

- International Organization for Standardization. Determination of Sound Insulation Performance of Enclosures. Measurements in Situ (for Acceptance and Verification Purposes); ISO 11546-2; International Organization for Standardization: Geneva, Switzerland, 1995. [Google Scholar]

- Thiede, I.; Thiede, M. Quantifying the costs and benefits of occupational health and safety at a Bangladesh shipbuilding company. Int. J. Occup. Environ. Health 2015, 21, 127–136. [Google Scholar] [CrossRef]

- Silverstein, M. Getting home safe and sound: The Occupational Safety and Health Administration at 38. Am. J. Public Health 2008, 98, 416–423. [Google Scholar] [CrossRef]

- Viscusi, W.K. The impact of occupational safety and health regulation. Bell J. Econ. 1979, 10, 117–140. [Google Scholar] [CrossRef]

- Howard, J.; Hearl, F. Occupational safety and health in the United States of America: Now and the future. Ind. Health 2012, 50, 80–83. [Google Scholar] [CrossRef]

- Smith, R.S. The Occupational Safety and Health Act: Its Goals and Its Achievements. Evaluative Studies Series; Contract No.: VT-103-200; American Enterprise Institute for Public Policy Research: Washington, DC, USA, 1976; p. 67. [Google Scholar]

- Bruce, R.D.; Bommer, A.S.; Moritz, C.T.; Moritz, C.T. Noise, Vibration, and Ultrasound. In The Occupational Environment—Its Evaluation and Control; DiNardi, S.R., Ed.; American Industrial Hygiene Association Press: Fairfax, VA, USA, 1997; p. 445. [Google Scholar]

- Beamer, B.; McCleery, T.; Hayden, C. Buy quiet initiative in the United States of America. Acoust. Aust. 2016, 44, 51–54. [Google Scholar] [CrossRef]

- International Labour Organisation. Report III (Part 1B), Labour Inspection, International Labour Conference; 95th Session; International Labour Office: Geneva, Switzerland, 2006; p. 7. [Google Scholar]

- International Labour Organization. A Guide to Selected Labour Inspection Systems (with Special Reference to Occupational Safety and Health). Available online: http:/www.ilo.org/wcmsp5/groups/public/---ed_dialogue/---lab_admin/documents/publication/wcms_160576.pdf (accessed on 10 June 2017).

- International Labour Organization. Labour Inspection Sanctions: Law and Practice of National Labour Inspection Systems. Available online: http://www.ilo.org//wcmsp5/groups/public/---ed_dialogue/---lab_admin/documents/publication/wcms_213143.pdf (accessed on 10 June 2017).

- Occupational Safety and Health Administration. Industry Profile for OSHA Standard 19100095. Available online: https://www.osha.gov/pls/imis/industryprofile.standard?P_esize=&p_state=Federal&p_type=2&p_standard=1910.95 (accessed on 16 August 2017).

- Department of Labour. Annual Report of the Compensation Fund 2016; Compensation Commissioner, Department of Labour: Pretoria, South Africa, 2016.

- Smith, R.S. The impact of OSHA inspections on manufacturing injury rates. J. Hum. Resour. 1979, 14, 145–170. [Google Scholar] [CrossRef]

- Viscusi, W.K. The impact of occupational safety and health regulation, 1973–1983. RAND J. Econ. 1986, 17, 570–580. [Google Scholar] [CrossRef]

- Gray, W.B.; Mendeloff, J.M. The declining effects of OSHA inspections on manufacturing injuries, 1979–1998. Ind. Labor. Relat. Rev. 2005, 58, 571–587. [Google Scholar] [CrossRef]

- Gray, W.B.; Jones, C.A. Are OSHA health inspections effective? A longitudinal study in the manufacturing sector. Rev. Econ. Stat. 1991, 73, 504–508. [Google Scholar] [CrossRef]

- Hahn, R.W.; Hird, J.A. The costs and benefits of regulation: Review and synthesis. Yale J. Regul. 1991, 8, 233–278. [Google Scholar]

- Bauer, E.R.; Babich, D.R. Administrative Controls for Reducing Worker Noise Exposures. Available online: https://www.cdc.gov/niosh/mining/UseFiles/works/pdfs/acfrw.pdf (accessed on 14 August 2019).

- European Agency for Safety and Health at Work. Reducing the Risks from Occupational Noise. Available online: https://osha.europa.eu/en/tools-and-publications/publications/report-reducing (accessed on 23 April 2017).

- Health and Safety Laboratory. Real World Use and Performance of Hearing Protection. Available online: http://www.hse.gov.uk/research/rrpdf/rr720.pdf (accessed on 20 June 2018).

- Franks, J.R.; Stephenson, M.R.; Merry, C.J. Preventing Occupational Hearing Loss—A Practical Guide; National Institute for Occupational Safety and Health: Cincinnati, OH, USA, 1996.

- Wood, E.W.; Barnes, J.D. Prediction of machinery noise. In Noise and Vibration Control Engineering. Principles and Applications, 2nd ed.; Ver, I.L., Beranek, L.L., Eds.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2006; pp. 659–660. [Google Scholar]

- James, H.S. Estimating OSHA compliance costs. Policy Sci. 1998, 31, 321–341. [Google Scholar] [CrossRef]

- Health and Safety Executive. Final Regulatory Impact Assessment of the Control of Noise at Work Regulations. 2005. Available online: http://www.hse.gov.uk/noise.pdf (accessed on 12 October 2018).

- Health and Safety Executive. The Costs and Benefits of the Noise at Work Regulations. 1989. Available online: www.hse.gov.uk/research/crr_pdf/1996/crr96116.pdf (accessed on 12 October 2018).

- Moorhouse, A.T. A procedure for quantifying the benefit and cost effectiveness of noise control methods. Build. Acoust. 1994, 1, 151–157. [Google Scholar] [CrossRef]

- European Foundation for the Improvement of Living and Working Conditions. The Costs and Benefits of Occupational Safety and Health. Available online: https://www.osh.org.il/UpLoadsFiles/00.cost%20and%20%20benefit%20of%20occupational%20accidents.pdf (accessed on 26 November 2018).

- Health and Safety Executive. Costs of Compliance with Health and Safety Regulations in SME’s. Available online: www.hse.gov.uk/research/eepdf/rr174.pdf (accessed on 6 November 2018).

- Rzepecki, J. Cost and benefits of implementing an occupational safety and health management system (OSH MS) in enterprises in Poland. Int. J. Occup. Environ. Health 2012, 18, 181–193. [Google Scholar] [CrossRef][Green Version]

- Riano-Casallas, M.I.; Tompa, E. Cost-benefit analysis of investment in occupational health and safety in Colombian companies. Am. J. Ind. Med. 2018, 61, 893–900. [Google Scholar] [CrossRef]

- Murphy, E.; King, E.A. Environmental Noise Pollution: Noise Mapping, Public Health, and Policy; Elsevier Inc.: Burlington, NJ, USA, 2014; p. 239. [Google Scholar]

- Yokoyama, K.; Iijima, S.; Ito, H.; Kan, M. The socio-economic impact of occupational diseases and injuries. Ind. Health 2013, 51, 459–461. [Google Scholar]

| Country | Industry | Average Noise Level in dBA 1 | References |

|---|---|---|---|

| Food manufacturing | |||

| US | Food manufacturing | 90–92 | OSHA, 1979–2006 [5] |

| US EPA, 1971 [18] | |||

| UK | Food processing | 88–94 | Institute of Occupational Medicine, 2002 [25] |

| Textile plants | |||

| US | Textile product mills | 89–95 | OSHA, 1979–2006 [5] |

| US EPA, 1971 [18] | |||

| India | Textile plants | 80–102 | Bedi, 2006 [26] |

| Sudan | Textiles: | Ahmed and Awadalkarim, 2015 [27] | |

| Weaving | 88–86 | ||

| Preparing | 63–93 | ||

| Ethiopia | Textiles: | Ejigu, 2019 [28] | |

| Spinning mill | 86–115 | ||

| Weaving mill | 92–101 | ||

| UK | Textiles: | Institute of Occupational Medicine, 2002 [25] | |

| Twisting area | 88–92 | ||

| Winding area | 82–85 | ||

| South Korea | Textile plant | 81–110 | Moon and Kwon, 1976 [29] |

| US | Apparel manufacturing | 81 | OSHA, 1979–2006 [5] |

| US EPA, 1971 [18] | |||

| Nigeria | Textile industry | 97–105 | Odusanya, Nwawolo, Ademuson and Akinola 2004 [30] |

| US | Leather and allied product manufacturing | 90 | OSHA, 1979–2006 [5] |

| US EPA, 1971 [18] | |||

| Wood industry | |||

| US | Wood product manufacturing | 92–94 | OSHA, 1979–2006 [5] |

| US EPA, 1971 [18] | |||

| South Korea | Wood industry | 71–100 | Moon and Kwon, 1976 [29] |

| US | Paper manufacturing | 90–92 | OSHA, 1979–2006 [5] |

| US EPA, 1971 [18] | |||

| Printing and publishing industry | |||

| US | Printing and publishing | 82–93 | OSHA, 1979–2006 [5] |

| US EPA, 1971 [18] | |||

| Ghana | Printing company | 79–90 | Boateng and Amedofu, 2004 [31] |

| Petroleum and related industries | |||

| US | Petroleum and coal products manufacturing | 87–92 | OSHA, 1979–2006 [5] |

| US EPA, 1971 [18] | |||

| US | Refinery units: | Burgess, 1995 [21] | |

| Hydrocracker plant | 93–100 | ||

| Fluid cracker | 89–115 | ||

| Hydrofluoric alkylation unit | 89–100 | ||

| Catalytic hydrocracking | 90–100 | ||

| Crude distillation | 85–111 | ||

| Taiwan | Oil refinery | 73–89 | Chen and Tsai, 2003 [32] |

| Chemical manufacturing | |||

| SA | Chemical manufacturing company | 85-95 | Rikhotso, Harmse and Engelbrecht, 2018 [33] |

| US | Urea formaldehyde and polyurethane foam insulation: | NIOSH, 1983 [34] | |

| Manufacturer A | 83–94 | ||

| Manufacturer B | 81–86 | ||

| US | Chemical manufacturing | 85–92 | OSHA, 1979–2006 [5] US EPA, 1971 [18] Lynch, 1989 [35] Pringle and Warren, 1989 [36] |

| South Korea | Chemical industry | 91–100 | Moon and Kwon, 1976 [29] |

| US | Polyethylene battery separator manufacturing: | NIOSH, 2004 [37] | |

| regrind | 95–97 | ||

| Extruder lines | 82–94 | ||

| Iran | Petrochemical industry | 88–93 | Neghab, Maddahi & Rafeefard, 2009 [38] |

| US | Plastics and rubber products manufacturing | 86–92 | OSHA, 1979–2006 [5] US EPA, 1971 [18] Mutchler, 1989 [22] |

| US | Nonmetallic mineral product manufacturing | 88–94 | OSHA, 1979–2006 [5] US EPA, 1971 [18] |

| Steel industry | |||

| US | Primary metal manufacturing | 91–92 | OSHA, 1979–2006 [5] US EPA, 1971 [18] |

| UK | Steel industry | 90–100 | Howell, 1978 [39] |

| SA | Iron and steel companies | 78–106 | Mizan, Abrahams, Sekobe, Kgalamano et al. 2013 [40] |

| US | Fabricated metal product manufacturing | 90–92 | OSHA, 1979–2006 [5] US EPA, 1971 [18] |

| Saudi Arabia | Beverage cans manufacturing | 92–98 | Noweir, Bafail & Jomoah, 2014 [41] |

| Steel reinforcement forming for concrete | 91–95 | ||

| Steel sheets forming and processing | 87–91 | ||

| Brazil | Metallurgical company | 83-102 | Guerra, Lourenco, Bustamante-Teixeira & Alves 2005 [42] |

| Machinery manufacturing | |||

| US | Machinery manufacturing | 86–93 | OSHA, 1979–2006 [5] US EPA, 1971 [18] |

| India | Small scale hand tools manufacturing industry | 81-110 | Singh, Bhardwaj, Deepark & Bedi, 2009 [43] |

| US | Computer and electronic product manufacturing | 85–91 | OSHA, 1979–2006 [5] US EPA, 1971 [18] |

| US | Electrical equipment, appliance, and component manufacturing | 87–90 | OSHA, 1979–2006 [5] |

| Saudi Arabia | Industrial and household appliance manufacturing | 85–86 | Noweir, Bafail & Jomoah, 2014 [41] |

| US | Transportation equipment manufacturing | 88–92 | OSHA, 1979–2006 [5] US EPA, 1971 [18] |

| US | Furniture and related product manufacturing | 88–93 | OSHA, 1979–2006 [5] US EPA, 1971 [18] |

| Bottling and tobacco industry | |||

| US | Beverage and tobacco product manufacturing | 86–96 | OSHA, 1979–2006 [5] US EPA, 1971 [18] |

| Nigeria | Bottling industry | 95–103 | Odusanya, Nwawolo, Ademuson & Akinola 2004 [30] |

| Nigeria | Bottling factory | 92–99 | Ologe, Olajde, Nwawolo & Oyejola, 2008 [44] |

| Miscellaneous manufacturing | |||

| US | Miscellaneous manufacturing | 87–91 | OSHA, 1979–2006 [5] |

| US EPA, 1971 [18] | |||

| Country | Permissible Exposure Level/Noise Rating Limit in dBA (8-h Average) | Exchange Rate in dB | dBA Level for HCP Institution | dBA Level for Engineering Controls |

|---|---|---|---|---|

| SA | 85 | 3 | 85 | 85 |

| UK | 80 (lower exposure action value) 85 (Upper exposure action value) 87 (exposure value with HPD use) 140 1 (Peak noise level) | 3 | 80 | 87 |

| US | 90 | 5 | 85 | 90 |

| Process Equipment | Process Application: Noise Generation Mechanism | Specific Process Equipment Examples | Emitted Noise Level (Range) in dBA | Source or Record Type | References |

|---|---|---|---|---|---|

| Duct and pipe flow | Process product flow: High velocity flow, flow resistance, flow turbulence [9,48]. | Duct and pipe flow | 100 | Conference paper | Fagerlund, Karczub & Martin, 2005 [49] |

| Flow machines/pumps and hydraulic systems (Positive displacement and reciprocating pumps) | Pressurisation and movement of gases and fluids within pipelines: Tooth meshing, friction, inertia, rolling, cooling fan, air intake [7,9,22,47,48,50,51]. | Screw type Vane type Axial piston type Gear (aluminium) type Vane (mobile) type Gear (machine stock) type | 71–78 75–82 76–86 78–88 84–92 96–104 | Handbooks | Miller, 1984 [7] |

| Burgess, 1995 [21] | |||||

| Lynch, 1989 [35] | |||||

| Free jets | Release of gas through nozzles. Mixing layer of the turbulence due to gas stream speed: High velocity air and steam jets [7,9,48] | Free jets (1 m from blowoff nozzle) | 105 | Handbook | Gerges, Sehrndt & Parthey, 2001 [52] |

| Valves and piping (Globe and rotary valves) | Direct control or manipulation of the process through positioning of valve plug or disc from the actuator: Cavitation, turbulence, shock and pulsation [7,53,54]. | De-areator valve Pressurised pipes and valves Turbine admission valve | 95–100 90–100 100 | Handbooks | Miller, 1984 [7] |

| Emerson, 2005 [54] | |||||

| Fans and blowers (Axial and centrifugal fans) | Movement of high quantities of air through use of power-driven rotating impellers: Fan, speed changer, fan motor, fan shroud [7,48,51] | Forced draft fan | 100 | Handbook and regulatory database | Miller, 1984 [7] |

| Induced draft fan | 90–100 | US EPA, 1971 [18] | |||

| Compressors and turbines | Compressors (pressure generation) and Turbines (power generation): discharge piping and expansion joint, antisurge bypass, intake piping and suction drum, air intake, discharge to air, timing gears, speed changers [7,48,51,55,56,57]. | Air compressor Steam turbine generator Turbine admission valve Turbine drive Turbine generator brush gear Compressor platforms | 95–100 90–95 100 95–100 95–100 90 | Handbook and regulatory database | Miller, 1984 [7] |

| US EPA, 1971 [18] | |||||

| Steam leaks | Indication of process leaks on corroded pipelines, joints, process valves: High velocity air and steam process leaks [7,48,58]. | Steam leaks (within 25 feet radius) | 100 | Handbook | Miller, 1984 [7] |

| Vents | Intentional and controlled gas or liquid release into atmosphere during emergencies, shut down activities and absence of storage facilities: High velocity air and steam vents [7,48,59]. | Vents (within 10 feet of vent outlet) | 140–160 | Handbook | Miller, 1984 [7] |

| Motors | Power source for driving fans, pumps, generators by converting electric power to mechanical power: Cooling air fan, mechanical and electrical motor noise [7,48,51]. | Motors | 90 | Handbook | Miller, 1984 [7] |

| Country | Work Activity Observed | Job Category | Area Noise Level Range (in dBA) | Daily Noise Exposure Range (in dBA) | Evaluation Criteria | Reference |

|---|---|---|---|---|---|---|

| UK | Compressed gas supply depot | Workers | 85–94 | 80–90 | Exchange rate: 3 dB, criterion level: 85 dBA, 87 dBA | Institute of Occupational Medicine, 2002 [25] |

| Paper coating (laminating) | 81–88 | 84–88 | ||||

| Ship building (blacksmith shop) | 90–10 | 90–95 | ||||

| Light engineering (fabrication) | 84–105 | 85–93 | ||||

| Food processing | 87–94 | 89–92 | ||||

| Coal fired power station | 93–102 | 85–102 | ||||

| Bottling | 84–92 | 84–97 | ||||

| Textiles (twisting and winding) | 88–92 | 85–94 | ||||

| Ferrous foundry | 81–112 | 86–108 | ||||

| Ship building (heavy fabrication) | 83–106 | 88–99 | ||||

| US | Stator manufacturing | Process operators Machine tapping operators | - | 84–88 | Exchange rate: 3 dB, criterion level: 85 dBA | NIOSH, 1991 [67] |

| 78–82 | ||||||

| US | Television manufacturing company: | Operators | 83–88 | Exchange rate: 3 dB, criterion level: 85 dBA | NIOSH, 1991 [68] | |

| Metal stabilizing lehr | 81–88 | |||||

| Frit dispensing department | 86 | |||||

| Thump and flush department | 88 | |||||

| US | Industrial centrifugal manufacturing | Balance machine | - | 85 ** | NIOSH (Exchange rate: 3 dB, criterion level: 85 dBA) | NIOSH, 1995 [69] |

| 88 | ||||||

| Basket floor operator | - | 89 ** | ||||

| 93 | ||||||

| Boring mill (main bay) operator | - | 83 ** | ||||

| 85 | ||||||

| Crating operator | - | 81 ** | OSHA (Exchange rate: 5 dB, criterion level: 90 dBA) | |||

| 87 | ||||||

| Fitting floor operator | - | 84 ** | ||||

| 87 | ||||||

| Welding operator | - | 87 ** | ||||

| 91 | ||||||

| Denmark | Various Danish manufacturing industries: | - | Exchange rate: 3 dB, criterion level: 85 dBA, 87 dBA | Kock, Andersen, Kolstad, Kofoed-Nielsen, Wiesler and Bonde, 2004 [70] | ||

| Manufacturer of machinery | 81–84 | |||||

| Manufacturer of furniture | - | 82–84 | ||||

| Manufacturer of basic metals | - | 84–87 | ||||

| Manufacturer of wood | - | 84–86 | ||||

| Manufacturer of minerals | Workers | - | 84–86 | |||

| Manufacturer of food | - | 84–86 | ||||

| Manufacturer of fabrication metals | - | 84–86 | ||||

| Manufacturer of motor vehicles | - | 83–86 | ||||

| Publishing and printing | - | 82–84 | ||||

| Iran | Textile industry | Spinning operator | - | 93 | Exchange rate: 3 dB, criterion level: 85 dBA, 87 dBA | Nodoushan, Esmaielpour, Ravandi, Mehrparvar and Gholamezadeh, 2008 [71] |

| Baling operator | - | 98 | ||||

| Carding operator | - | 91 | ||||

| Combing operator | - | 86 | ||||

| US | Steel coil manufacturing plant: | 76–93 | 84 ** | NIOSH (Exchange rate: 3 dB, criterion level: 85 dBA) | NIOSH, 2017 [72] | |

| Exit labourer 1 | 91 | |||||

| Pickling and crane cab | 50–86 | 70 ** | OSHA (Exchange rate: 5 dB, criterion level: 90dBA) | |||

| Exit labourer 2 | 84 | |||||

| India | Glass manufacturing | Coater-1 | - | 92 (83) * | Exchange rate: 3 dB, criterion level: 85 dBA, 87 dBA | Prabu, Gokulram, Magibalam, Senthilkumar and Boopathi, 2018 [73] |

| Offline-2 | - | 91 (85) * | ||||

| Cold end-2 | - | 89 (84) * | ||||

| Offline-4 | - | 96 (84) * | ||||

| US | Urea formaldehyde and Polyurethane foam insulation | Part-time drum washer | 83–94 | 84–92 ^ | OSHA (Exchange rate: 5 dB, criterion level: 90 dBA) | NIOSH, 1983 [34] |

| Part-time drum washer | 88–97 # | |||||

| Electric-powered screwdriver operator | 93–96 ^ | |||||

| Foaming agent drum filling operator | 95–99 # | |||||

| Europe | European petroleum refineries | Crude distillation operators | - | 85–95 ^ 80–95 # | Exchange rate: 3 dB, criterion level: 85 dBA and 90 dBA | Concawe, 1990 [74] |

| Vacuum distillation operators | - | 80–95 ^ 85–95 # | ||||

| Isomerisation operators | - | 85–95 ^ - | ||||

| Catalytic cracker operators | - | 85–95 ^ 85–95 # | ||||

| Catalytic reformer operators | - | 80–95 ^ 85–95 # | ||||

| Hydrotreater operators | - | 80–95 ^ 95 # | ||||

| Sulphur plant operators | - | 80–95 ^ 80–95 # | ||||

| Alkylation plant operators | - | 90–95 ^ - | ||||

| Utilities operators | - | 80–95 ^ 80–95 # |

| Noise Source | Noise Control Solution and Typical Noise Reduction | Case History | Noise Control Solution | Noise Reduction Achieved | Author |

|---|---|---|---|---|---|

| Duct and pipe flow | Lagging or acoustical insulation: One-inch thick pipe insulation or double thickness of pipe wall insulation: 20 dB to 40 dB with no acoustical leaks [51,80]. | Steam line regulators generating 97 dBA | Modification of the main valve plug with throttling vanes with a reduction in pressure from 555 to 100 pascal in a 2 inch steam line | Pipeline noise reduced to 85 dBA | NIOSH, 1978 [48] |

| Flow machines (pumps), compressors and turbines | Acoustic enclosure: 5 dB to 10 dB noise reduction for sound insulating wrapping [6]. | Industrial mixer hydraulic pump emitting 97 dBA | Low-cost engineering modifications | Noise reduced to 80 dBA | Advanced Noise Solutions, 2003–2019 [81] |

| Screw compressor emitting 100 dBA with tonal content | Reactive silencers fitted into either side of pipe intake | 20 dB overall noise reduction | HSE, 2017 [82] | ||

| Acoustic enclosure: 10 dB to 25 dB noise reduction for single shell enclosures with sound absorbing lining. | Steam generator feed pumps emitting high tonal noise at 100–105 dBA, causing noise at the turbine hall to be 92–98 dBA | 4 inch acoustical glass fibre insulating enclosure lined with perforated sheet steel on the inside installed on each feed pump | Turbine hall noise reduction to 88–89 dBA | NIOSH, 1978 [48] | |

| Noise reduction of more than 25 dB for double shell enclosures with sound absorbing lining [83,84]. | |||||

| Free jets and vents | Silencer: 10 dB to 20 dB noise reduction [6,83,84]. | Ordinary jet noise exceeding 95 dBA | Proper routing of the airstream and installing a silencer | 20 dB noise reduction | Mutchler, 1989 [22] |

| Compressors | Design stage (rotor blade alteration or adjustment control through design): increase in number of rotor blades from 20 to 80 results in 10 dB noise reduction [18,85]. | Motor generator emitting 94 dBA | ½ inch thick glass fibre lined with plywood acoustic enclosure | 10 dB noise reduction | NIOSH, 1978 [48] |

| Gas turbines | Intake and exhaust silencer: a noise insertion loss of 20 to 49 dB in low frequency range and a 40 to 60 dB noise insertion loss at 40 to 60 dB [18,83,84]. | Reciprocating air compressors generating 88 dBA | Intake silencers fitted at each compressor | 17 dB overall noise reduction | HSE, 2017 [82] |

| Machinery noise | Acoustic barriers with absorbent linings: 5 dB–10 dB noise reduction in low frequencies | Gearbox of a 9000 steam turbine emitting 120 dBA inside engine room | Acoustic enclosure using acoustic panels with high transmission properties and a silencer installed at propeller shaft | Noise reduction unknown, noise confined within the acoustic enclosure with a decrease in adjacent areas | NIOSH, 1978 [48] |

| 20 dB noise reduction in high frequencies [85,86]. | |||||

| Fans (blowers) | Fan blade design, enclosure and silencers: locating the fan cut-off at optimum clearance in relation to tips of the impeller results in 12 dB noise reduction [18,85]. | High pressure, low-volume centrifugal fan unit emitting 95 dBA | 50 mm thick acoustical panel enclosure | 20 dB noise reduction | HSE, 2017 [82] |

| Rotary blowers emitting high noise levels due to unit rotational speed | Hybrid active silencer with absorptive packing for both low and high frequency noise attenuation | 42 dB noise reduction | HSE, 2017 [82] |

| Standard | Scope | Stage of Usefulness/Consideration | Responsibility | |||

|---|---|---|---|---|---|---|

| Design | Replacement | Retrofitting | Supplier | Employer | ||

| South African National Standard 11688-1. Part 1 [8] | Defines and is intended to provide basic noise control concepts for machinery and equipment during the entire production chain with the aim to assist designers of the final machinery and equipment. | ✓ | ✓ | ✓ | ✓ | ✓ |

| South African National Standard 11690-2. Part 2 [6] | Defines workplace technical aspects relating to noise control. | - | - | - | - | ✓ |

| South African National Standard 11688-2. Part 2 [9] | Defines and is intended for use by machinery and equipment designers and users. Also intended for use by regulators, supervisors or inspectors with the objective of noise reduction in existing plants. | ✓ | ✓ | ✓ | ✓ | ✓ |

| International Organisation for Standardisation. ISO 14163:1998(E) [84] | Defines practical silencer selection for use in gaseous media. | - | ✓ | ✓ | ✓ | ✓ |

| International Organisation for Standardisation. ISO 15667:2000(E) [85] | Defines the acoustical performance and performance criteria of enclosures and cabins. Also defines the agreements of the acoustical and operational requirements between the supplier, manufacturer and end user. | ✓ | ✓ | ✓ | ✓ | ✓ |

| International Organisation for Standardisation. ISO 15664: 2001(E) [109] | Defines noise control design procedures for new plants, plant modifications or during extensions. | ✓ | - | ✓ | ✓ | ✓ |

| International Organisation for Standardisation. ISO 15665:2003(E) [80] | Defines a standardised methodology for the measurement of acoustic performance of Class A, B and C pipe insulation. | ✓ | - | ✓ | ✓ | ✓ |

| International Organisation for Standardisation. ISO 4871 [110] | Provides information on machinery and equipment required declaration of noise emission values and provides a methodology for declared noise emission value verification. | ✓ | ✓ | ✓ | ✓ | ✓ |

| International Electrotechnical Commission. ISO 8297 [111] | Defines an engineering method for determining sound power levels in large industrial plants containing multiple noise sources | - | - | - | - | ✓ |

| International Electrotechnical Commission 60534-8-3. Part 8-3 [112] | Addresses valve and connected piping’s noise generated through aerodynamic processes | ✓ | ✓ | ✓ | ✓ | ✓ |

| International Electro Commission 60534-8-4. Part 8-4 [113] | Predicts control valve noise generated noise levels during liquid flow and the resultant noise levels downstream of the valve; and outside the piping. | ✓ | ✓ | - | - | ✓ |

| EEMUA 140 [114] | Indicates the method for specifying maximum acceptable noise levels and describes acceptable test methods for determining equipment noise emission | ✓ | ✓ | ✓ | ✓ | ✓ |

| International Organisation for Standardisation. ISO 11546-2 [115] | Specifies in situ methods to the determination of the sound insulation performance of machine enclosures. | ✓ | ✓ | ✓ | ✓ | ✓ |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rikhotso, O.; Harmse, J.L.; Engelbrecht, J.C. Noise Sources and Control, and Exposure Groups in Chemical Manufacturing Plants. Appl. Sci. 2019, 9, 3523. https://doi.org/10.3390/app9173523

Rikhotso O, Harmse JL, Engelbrecht JC. Noise Sources and Control, and Exposure Groups in Chemical Manufacturing Plants. Applied Sciences. 2019; 9(17):3523. https://doi.org/10.3390/app9173523

Chicago/Turabian StyleRikhotso, Oscar, Johannes Leon Harmse, and Jacobus Christoffel Engelbrecht. 2019. "Noise Sources and Control, and Exposure Groups in Chemical Manufacturing Plants" Applied Sciences 9, no. 17: 3523. https://doi.org/10.3390/app9173523

APA StyleRikhotso, O., Harmse, J. L., & Engelbrecht, J. C. (2019). Noise Sources and Control, and Exposure Groups in Chemical Manufacturing Plants. Applied Sciences, 9(17), 3523. https://doi.org/10.3390/app9173523