Abstract

Laser-induced periodic surface structures have been extensively studied for various materials because of their promising applications. For these applications, uniform rippled structures with well-defined large areas are required. However, the efficient fabrication of uniform rippled structures is a challenge. Morphologies of rippled structures of multiple-shot-ablated regions considerably affect the processing efficiency of uniform rippled structures because incubation effects are crucial. In this study, the effects of a pulse number and irradiation modes on surface morphologies of rippled structures on the titanium surface are experimentally studied. The experimental results indicate the following: (1) Samples first irradiated using several shots and then using remaining shots by designing laser pulse irradiation modes exhibit improved surface morphologies, such as larger ablation areas and finer rippled structures. (2) When the pulse number in the first series is less than that in the second series, the rippled structures are characterized using larger areas and periods. (3) The ablated areas with rippled structures increase with the increasing number of pulses. (4) The periods of ripples reduce with the increasing number of pulses. Therefore, according to different requirements, uniform rippled structures can be efficiently fabricated and adjusted using the designed laser pulse modes and pulse number.

1. Introduction

Laser-induced periodic surface structures (LIPSS, which is referred to as ripples) have been extensively studied for various materials, including metals [1,2,3,4,5,6,7], semiconductors [8,9], and dielectrics [10,11], because of their promising applications in colorization [12], solar cells [13], surface wetting [14], and cell growth of implants [15]. For the aforementioned applications, uniform rippled structures with a well-defined large area are required. However, the efficient fabrication of uniform rippled structures with large areas is a challenge, and this limits its industrial applications. Compared with other physical and chemical methods for the fabrication of uniform rippled structures with large areas [16], directly inducing rippled structures by using a femtosecond laser is a relatively controllable approach. Ripples with periods close to the central wavelength of incident lasers are considered typical ripples, which are caused by the interference between incident laser waves and surface-scattered waves [17,18]. Ripples with periods significantly smaller than the incident laser wavelengths are termed subwavelength ripples. Some explanations of formation mechanisms of subwavelength ripples have been proposed, including self-organization [19,20], second harmonic generation [21], Coulomb explosion [22], and interaction between the incident laser and surface plasmon [11,23,24]. Furthermore, processing parameters considerably affect the formation and morphology of ripples, such as pulse durations [25,26], polarization [27], pulse fluence [28], incidence angle [29], pulse number [30,31], central wavelength [32], pulse delay [33], and processing environments [34,35,36]. For the fabrication of uniform rippled structures with a large area, the scanning speed and the scanning interval are crucial for the surface morphologies of ripple structures [16]. In addition, the morphologies of ripple structures of multiple-shot-ablated regions considerably affect the processing efficiency and precision of uniform rippled structures with large areas because incubation effects are crucial during multiple-shot ablation [37]. For metals, the incubation effect is attributed to the accumulation of laser-induced chemicals, structural changes in the material, and/or plastic deformation of the surface [37]. Such defects, which are generated by the first impinging pulses, facilitate the absorption of the subsequent laser pulses, thus enhancing the elimination of ablation and materials [37]. Therefore, during multiple-shot ablation, it is essential to study the effects of the pulse number and irradiation modes on the surface morphologies of rippled structures with the consideration of the incubation effect.

In this study, the effects of the pulse number and irradiation modes on surface morphologies of rippled structures, including ablation areas and periods of subwavelength ripples, on the titanium surface are experimentally examined during the multishot femtosecond induced ripples. The evolution of ablation craters and subwavelength ripples with the increasing pulse number is investigated. The interference between a surface plasmon field and laser field plays an important role for the formation of subwavelength ripples. For investigating incubation effects during a multishot regime, different laser pulse irradiation modes are designed. The samples which are first irradiated using several shots and then irradiated using the remaining shots have larger ablation areas and finer rippled structures. Therefore, according to different requirements of rippled structure areas and periods, the uniform rippled structures with a large area can be efficiently fabricated and adjusted using the designed laser pulse modes and pulse number.

2. Materials and Methods

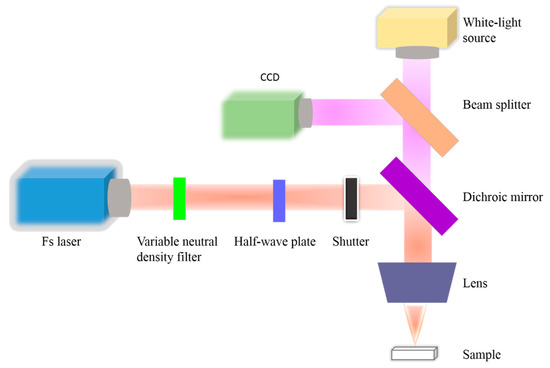

Figure 1 shows the experimental setup. The femtosecond laser pulse used in these experiments is generated using a commercial regenerative Ti-sapphire laser system (Spectra-Physics Spitfire Ace).

Figure 1.

Schematic diagram of experimental setup.

The femtosecond laser pulse is with a central wavelength of 800 nm, pulse width of 50 fs, and repetition rate of 100 Hz. A variable neutral density filter is used to control the laser fluence incident on the sample surface. The polarization direction of incident laser pulses can be adjusted by a half-wave plate. A mechanical shutter is used to control the pulse number. The femtosecond laser travels through a dichroic mirror and lens with an achromatic doublet (f = 100 mm) to focus on the sample surface. To monitor laser processing, a charge-coupled device camera is used for the imaging of the titanium sample surface (10 mm × 10 mm × 0.5 mm, Kejing Hefei). The surface morphologies of the titanium sample after femtosecond laser irradiation are characterized through scanning electron microscopy (SEM) (FEI XL30 S-FEG, FEI, Hillsboro, OR, USA). The beam radius is determined in a set of laser ablation experiments by systematical variation of the laser pulse energy. In that way, a beam radius of w0 (1/e2) ∼ 40 μm is determined in the processing plane. The ablation threshold is then determined accordingly, which is about 0.16 J/cm2. All experiments are conducted at the same laser fluence, and the incident laser fluence is fixed at 0.20 J/cm2. The experiments are performed in air at room temperature.

3. Results and Discussion

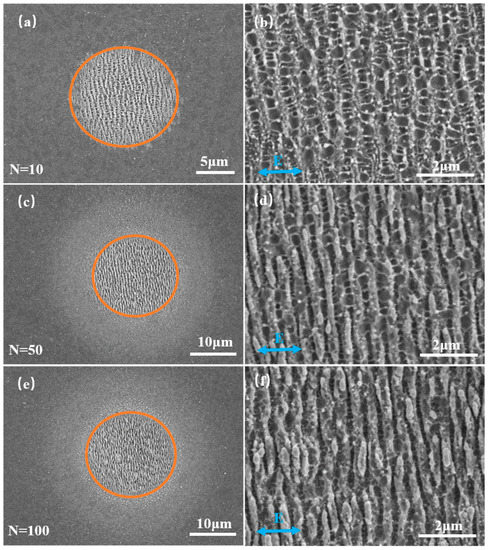

The effects of the pulse number on ablation shapes and subwavelength ripples on the titanium surface are experimentally investigated in this study. Figure 2 shows SEM images of ablation shapes and subwavelength ripples on titanium obtained at different femtosecond pulses. In these experiments, the selected number of pulses (N) is 10, 50, and 100. The repetition rate and incident laser fluence are 100 Hz and0.20 J/cm2, respectively. The orange circular regions in Figure 2a,c,e represent regions with surface periodic structures, and the diameter of a region with ripple structures is represented by D. The diameters of rippled regions are approximately 14.0, 18.1, and 18.6 μm after 10, 50, and 100 shots, respectively. These diameters increased by 29.3% and 32.9% for 50 and 100 shots, respectively, compared with that for 10 shots. The change in the rippled region from 10 shots to 50 shots is considerably larger than that from 50 to 100 shots, which is attributed to incubation.

Figure 2.

SEM images of ablation shapes and subwavelength ripples on titanium obtained at different femtosecond pulses: (a,b) N = 10, (c,d) N = 50, and (e,f) N = 100.

The periods of ripples formed on the titanium surface are affected by the pulse number. The morphologies of rippled structures are shown in Figure 2b,d,f after 10, 50, and 100 shots, respectively. The period of ripple structures is represented by λ. The periods of ripples with an orientation perpendicular to laser polarization are approximately 620, 550, and 480 nm for 10, 50, and 100 shots, respectively. The interference between the surface plasmon field and laser field are crucial in forming subwavelength ripples, based on the study in [11]. At the interface between a metal with permittivity εM and air with permittivity εA, if the value of the real component of the complex dielectric function is less than −1, surface plasmons can be resonantly excited by the coupling between the surface electrons of the dielectric and the incident field, which is characterized by surface electromagnetic waves (also named the surface plasmon field). For metals, the excitation conditions of surface plasma field are always satisfied after the incident femtosecond laser irradiation. Because of the interference between the absorbed laser field and surface plasmon field, coupling field intensity is enhanced in some areas and reduced in other areas. The absorbed laser beam profile is reshaped by the presence of surface plasmons, which displays periodic patterns. Then energy with spatially periodic patterns leads to the periodic patterns of the free electron temperature distribution and lattice temperature distribution. Under the interactions of laser and materials, sub-wavelength ripples are formed in some areas. During the formation of subwavelength ripples, the absorbed energies are gradually absorbed. The cumulative absorbed energy is attributed to differences of subwavelength ripples and ablation areas on titanium obtained at different femtosecond pulses.

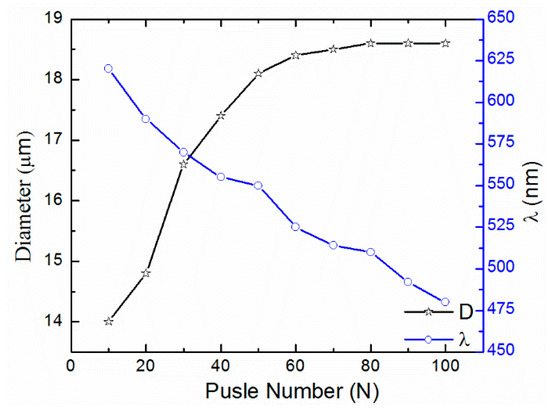

To investigate the evolution of ablation craters and subwavelength ripples with the increasing pulse number, the corresponding experiments are performed. Figure 3 presents dimensions and periods of multiple-shot ablated regions with subwavelength ripples as a function of the pulse number. Figure 3 shows that the ablated areas with ripple structures increase with the increasing number of pulses. The diameters of ablated areas significantly change from 14.0 μm to 18.1 μm during the first 50 pulses, which further indicates the incubation behavior of the femtosecond pulse laser ablation of metals. When the pulse number increased from 60 to 100, the diameters of ablated areas are the same, varying from 18.4 μm to 18.6 μm.

Figure 3.

Dimensions and periods of multiple-shot ablated regions with subwavelength ripples as a function of pulse number. The laser pulse energy is 0.20 J/cm2 in all cases.

The pulse number has considerable effects on the periods of subwavelength ripples (Figure 3). The periods of ripple structures reduce with the increasing number of pulses. For 10 and 30 shots, the periods of ripples are approximately 620 and 570 nm, respectively, which is within the range of 0.7 λin < λ < λin. The ripples with periods in the range of 0.6 λin < λ < 0.7 λin are formed when the pulse number increases from 40 shots to 100 shots. The aforementioned experimental results are consistent with those of previous studies and literature [38]. The femtosecond laser-induced ripple evolution is observed from shot to shot in a multishot regime. When the incident laser fluence is slightly higher than the ablation threshold, several main stages of ripple dynamic evolution, including primary ripples or random nanoroughness (N = 10–30) and secondary ripples (N > 30), are observed. This phenomenon is termed the blue shift of ripple periods, which is attributed to the shift of the dispersion curve of surface plasmon-polariton (SPP) dispersion generated by the scattering of SPPs [39].

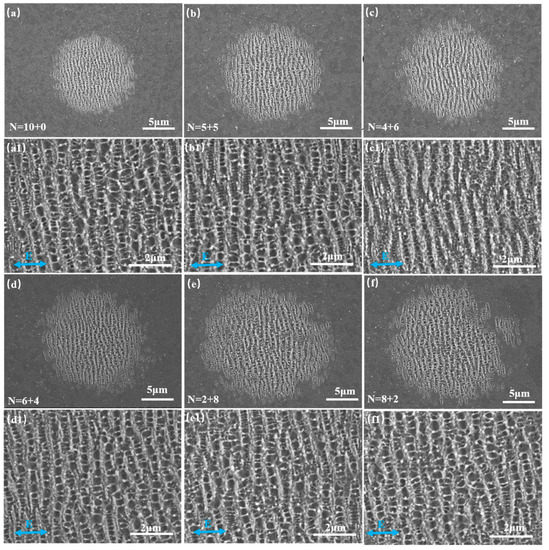

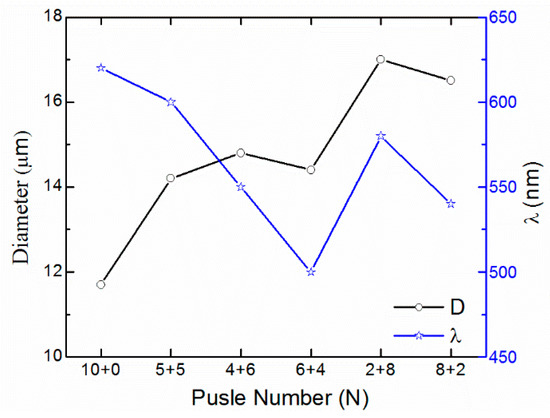

To study incubation effects during a multishot regime, the effects of the femtosecond laser pulse irradiation modes on ablation morphology and those of subwavelength ripples on titanium are experimentally studied. The formation of rippled structures by two consecutive series of pulses is observed. First, the sample is exposed to a series of pulses comprising several pulses. The second series of pulses comprising remaining pulses is used to irradiate the same place of the sample surface. All experiments are performed under the same number of total pulses. The aforementioned process is termed laser pulse irradiation modes. For example, in our experiments, the total number of laser pulses, which is denoted by N, is fixed at 10. Figure 4a,a1 shows that the femtosecond laser pulse irradiation mode N = 10 + 0 refers to the samples irradiated using 10 consecutive shots. The femtosecond laser pulse irradiation mode N = 5 + 5 refers to the samples irradiated using the first five shots and remaining five shots at the same place. Figure 4 and Figure 5 indicate that laser pulse irradiation modes considerably affect ablation morphology and subwavelength ripples on the metal titanium. The respective ablation diameter (D) and the periodicity (λ) of the ripples obtained at those modes:

Figure 4.

SEM images of ablation morphology and subwavelength ripples on titanium at different femtosecond laser pulse irradiation modes: (a,a1) N = 10 + 0, (b,b1) N = 5 + 5, (c,c1) N = 4 + 6, (d,d1) N = 6 + 4, (e,e1) N = 2 + 8, and (f,f1) N = 8 + 2. (a1–f1) show the magnification of the ripple structures in the central region in (a–f), respectively. The total pulse number is 10 in all cases. The laser pulse energy is fixed at 0.20 J/cm2 in all cases.

Figure 5.

Dimensions and periods of a multiple-shot ablated region with subwavelength ripples at different femtosecond pulse irradiation modes.

- N = 10 + 0 (D ≈ 11.7 µm, λ ≈ 620 nm)

- N = 5 + 5 (D ≈ 14.2 µm, λ ≈ 600 nm)

- N = 4 + 6 (D ≈ 14.8 µm, λ ≈ 550 nm)

- N = 6 + 4 (D ≈ 14.4 µm, λ ≈ 500 nm)

- N = 2 + 8 (D ≈ 17.0 µm, λ ≈ 580 nm)

- N = 8 + 2 (D ≈ 16.5 µm, λ ≈ 540 nm)

Comparing the femtosecond laser pulse irradiation modes N = 10 + 0 and other modes, superior surface morphologies characterized by larger ablation areas and finer rippled structures, can be obtained at the modes of N = 5 + 5, N = 4 + 6, N = 6 + 4, N = 2 + 8, and N = 8 + 2. Hence, the experimental results indicate that samples first irradiated using several shots and then the remainder shots have superior surface morphologies, including larger ablation areas and finer rippled structures, because of different incubation coefficients. An incubation coefficient is used to describe the dependence of multi-shot ablation threshold Φth,N of metals on the number N of impinging pulses and the threshold fluence with a single pulse Φth,1 [40,41]. Incubation is absent for S = 1 and the ablation threshold stays constant irrespective of the number of pulses. As far as the damage accumulation mechanism reduces the ablation threshold, the incubation coefficient gets lower [37,42,43]. For the laser pulse irradiation modes N = 10 + 0, N = 5 + 5, N = 4 + 6, N = 6 + 4, N = 2 + 8, and N = 8 + 2, two consecutive series of pulses are different. Hence, the incubation coefficients are also different and the incubation effects are different. By comparing the femtosecond laser pulse irradiation modes N = 4 + 6 and N = 6 + 4, we can easily find that rippled structures on titanium are characterized by larger areas and periods when the pulse number in the first series is less than that in the second series. The similar experimental phenomena have been observed for the situation of N = 2 + 8 and N = 8 + 2. Therefore, according to different requirements of rippled structure areas and periods, uniform rippled structures with large areas can be efficiently fabricated. Moreover, uniform rippled structures with large areas can be adjusted by designing laser pulse modes. For example, to obtain improved uniform rippled structures with large areas, two-step scanning methods can be used (those irradiated using two consecutive series of pulses). Furthermore, fabrication efficiency and feature size of rippled structures can be considered to select the pulse number of two series.

4. Conclusions

Ripples have been extensively studied for various materials because of their promising applications. For all of the aforementioned applications, uniform rippled structures with well-defined large areas are required. However, the efficient fabrication of uniform rippled structures with a large area is a challenge, which limits its industrial applications. Not only scanning speed and intervals but also pulse number and irradiation modes are crucial for surface morphologies of uniform rippled structures with a large area. In multishot femtosecond induced ripples, the incubation effects are crucial for the formation of surface rippled structures. Therefore, in this study, the effects of the pulse number and irradiation modes on the surface morphologies of rippled structures, including ablation areas and periods of subwavelength ripples, are studied on the metal titanium surface. The experimental results indicate the following: (1) An increase in ablated areas with ripple structures is observed with the increasing number of pulses. The diameters of ablated areas significantly vary from 14.0 μm to 18.1 μm during the first 50 pulses. When the pulse number increases from 60 to 100, the diameters of the ablated areas are approximately the same, which varies from 18.4 μm to 18.6 μm. (2) The periods of ripple structures reduce with an increase in the number of pulses. The interference between the surface plasmon field and laser field plays an important role for the formation of subwavelength ripples. (3) Samples first irradiated using several shots and then the remaining shots have larger ablation areas and finer rippled structures because of different incubation effects. (4) When the pulse number in the first series is less than that in the second series, rippled structures on titanium are characterized by larger areas and periods. Therefore, uniform rippled structures with large areas can be modified by designing the laser pulse modes and pulse number.

Author Contributions

Y.Y., D.L. and W.H. designed the experiments, performed the SEM characterization and analyzed the data. Y.Y. wrote the manuscript. D.L. and K.Z. edited the manuscript. J.C. supervised the work.

Funding

This research was financially supported by National Key R&D Program of China (Grant No. 2018YFB1107401), National Natural Science Foundation of China (NSFC) (Grant Nos. 51805014 and 51705328), Beijing Natural Science Foundation (Grant Nos. 3174045 and 3194045), open project of Beijing Engineering Research Center of Laser Technology (Grant No. BG0046-2018-03), and Shanghai Sailing Program (Grant No. 17YF1408500).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, X.; Li, C.; Ma, C.; Feng, J.; Hong, W.; Zhang, Z. Formation of laser induced periodic structures on stainless steel using multi-burst picosecond pulses. Opt. Express 2018, 26, 6325–6330. [Google Scholar] [CrossRef] [PubMed]

- Fraggelakis, F.; Mincuzzi, G.; Lopez, J.; Manek-Hönninger, I.; Kling, R. Texturing metal surface with MHz ultra-short laser pulses. Opt. Express 2017, 25, 18131–18139. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Wang, A.; Li, B.; Cui, T.; Lu, Y. Electrons dynamics control by shaping femtosecond laser pulses in micro/nanofabrication: Modeling, method, measurement and application. Light Sci. Appl. 2018, 7, 17134. [Google Scholar]

- Höhm, S.; Rosenfeld, A.; Krüger, J.; Bonse, J. Laser-induced periodic surface structures on titanium upon single- and two-color femtosecond double-pulse irradiation. Opt. Express 2015, 23, 25959–25971. [Google Scholar] [CrossRef] [PubMed]

- Bonse, J.; Höhm, S.; Rosenfeld, A.; Krüger, J. Sub-100-nm laser-induced periodic surface structures upon irradiation of titanium by Ti:sapphire femtosecond laser pulses in air. Appl. Phys. A 2013, 110, 547–551. [Google Scholar] [CrossRef]

- Bonse, J.; Koter, R.; Hartelt, M.; Spaltmann, D.; Pentzien, S.; Höhm, S.; Rosenfeld, A.; Krüger, J. Tribological performance of femtosecond laser-induced periodic surface structures on titanium and a high toughness bearing steel. Appl. Surf. Sci. 2015, 336, 21–27. [Google Scholar] [CrossRef]

- Bonse, J.; Höhm, S.; Koter, R.; Hartelt, M.; Spaltmann, D.; Pentzien, S.; Rosenfeld, A.; Krüger, J. Tribological performance of sub-100-nm femtosecond laser-induced periodic surface structures on titanium. Appl. Surf. Sci. 2016, 374, 190–196. [Google Scholar] [CrossRef]

- Liu, X.; Yu, L.; Chen, Q.; Sun, H. Mask-free construction of three-dimensional silicon structures by dry etching assisted gray-scale femtosecond laser direct writing. Appl. Phys. Lett. 2017, 110, 091602. [Google Scholar] [CrossRef]

- Kuladeep, R.; Sahoo, C.; Narayana Rao, D. Direct writing of continuous and discontinuous sub-wavelength periodic surface structures on single-crystalline silicon using femtosecond laser. Appl. Phys. Lett. 2014, 104, 222103. [Google Scholar] [CrossRef]

- Chen, Y.; Salter, P.; Knauer, S.; Weng, L.; Frangeskou, A. Laser writing of coherent colour centres in diamond. Nat. Photon. 2016, 11, 77–80. [Google Scholar] [CrossRef]

- Yuan, Y.; Jiang, L.; Li, X.; Wang, C.; Xiao, H.; Lu, Y.; Tsai, H. Formation mechanisms of sub-wavelength ripples during femtosecond laser pulse train processing of dielectrics. J. Phys. D: Appl. Phys. 2012, 45, 175301. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, C.; Liu, H.; Dai, Q.; Wu, L.; Lan, S.; Gopal, A.V.; Trofimov, V.A.; Lysak, T.M. Selective appearance of several laser-induced periodic surface structure patterns on a metal surface using structural colors produced by femtosecond laser pulses. Appl. Surf. Sci. 2012, 258, 7625–7632. [Google Scholar] [CrossRef]

- Yuan, H.; Yost, V.; Page, M.; Stradins, P.; Meier, D.; Branz, H. Efficient black silicon solar cell with a density-graded nanoporous surface: Optical properties, performance limitations, and design rules. Appl. Phys. Lett. 2009, 95, 123501. [Google Scholar] [CrossRef]

- Raimbault, O.; Benayoun, S.; Anselme, K.; Mauclair, C.; Bourgade, T.; Kietzig, A.; Girard-Lauriault, P.; Valette, S.; Donnet, C. The effects of femtosecond laser-textured Ti-6Al-4V on wettability and cell response. Mater. Sci. Eng. C 2016, 69, 311–320. [Google Scholar] [CrossRef]

- Cunha, A.; Elie, A.; Plawinski, L.; Serro, A.P.; Botelho do Rego, A.M.; Almeida, A.M.; Urdaci, C.; Durrieu, M.; Vilar, R. Femtosecond laser surface texturing of titanium as a method to reduce the adhesion of staphylococcus Aureus and biofilm formation. Appl. Surf. Sci. 2016, 360, 485–493. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, F.; Cheng, Y.; Xu, N.; Xu, Z. Large area uniform nanostructures fabricated by direct femtosecond laser ablation. Opt. Express 2008, 16, 19354–19365. [Google Scholar] [CrossRef]

- Sipe, J.E.; Young, J.F.; Preston, J.S.; van Driel, H.M. Laser-induced periodic surface structute. I. Theory, Phys. Rev. B 1983, 27, 1141–1154. [Google Scholar] [CrossRef]

- Young, J.F.; Preston, J.S.; van Driel, H.M.; Sipe, J.E. Laser-induced periodic surface structure. II. Experiments on Ge, Si, Al, and brass. Phys. Rev. B 1983, 27, 1152–1172. [Google Scholar] [CrossRef]

- Yang, W.; Bricchi, E.; Kazansky, P.G.; Bovatsek, J.; Arai, A.Y. Self-assembled periodic sub-wavelength structures by femtosecond laser direct writing. Opt. Express 2006, 14, 10117. [Google Scholar] [CrossRef]

- Costache, F.; Henyk, M.; Reif, J. Modification of dielectric surfaces with ultra-short laser pulses. Appl. Surf. Sci. 2002, 186, 352–357. [Google Scholar] [CrossRef]

- Le Harzic, R.; DÖrr, D.; Sauer, D.; Stracke, F.; Zimmermann, H. Generation of high spatial frequency ripples on silicon under ultrashort laser pulses irradiation. Appl. Phys. Lett. 2011, 98, 211905. [Google Scholar] [CrossRef]

- Dong, Y.; Molian, P. Coulomb explosion-induced formation of highly oriented nanoparticles on thin films of 3C–SiC by the femtosecond pulsed laser. Appl. Phys. Lett. 2003, 84, 10. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, F.; Cheng, Y.; Xu, N.; Xu, Z. Origin of laser-induced near-subwavelength ripples: Interference between surface plasmons and incident laser. ACS Nano 2009, 3, 4062–4070. [Google Scholar] [CrossRef]

- Wang, J.; Guo, C. Formation of extraordinarily uniform periodic structures on metals induced by femtosecond laser pulses. J. Appl. Phys. 2006, 100, 023511. [Google Scholar] [CrossRef]

- Forster, M.; Kautek, W.; Faure, N.; Audouard, E.; Stoian, R. Periodic nanoscale structures on polyimide surfaces generated by temporally tailored femtosecond laser pulses. Phys. Chem. Chem. Phys. 2011, 13, 4155–4158. [Google Scholar] [CrossRef]

- Hsu, E.M.; Crawford, T.H.; Tiedje, H.F.; Haugen, H.K. Periodic surface structures on gallium phosphide after irradiation with 150 fs–7 ns laser pulses at 800 nm. Appl. Phys. Lett. 2007, 91, 111102. [Google Scholar] [CrossRef]

- Han, W.; Jiang, L.; Li, X.; Liu, P.; Xu, L.; Lu, Y. Continuous modulations of femtosecond laser induced periodic surface structures and scanned line-widths on silicon by polarization changes. Opt. Express 2013, 21, 15505–15513. [Google Scholar] [CrossRef]

- Liang, F.; Vallée, R.; Chin, S.L. Pulse fluence dependent nanograting inscription on the surface of fused silica. Appl. Phys. Lett. 2012, 100, 251105. [Google Scholar] [CrossRef]

- Hwang, T.; Guo, C. Angular effects of nanostructure-covered femtosecond laser induced periodic surface structures on metals. J. Appl. Phys. 2010, 108, 073523. [Google Scholar] [CrossRef]

- Lou, K.; Qian, J.; Shen, D.; Wang, H.; Ding, T.; Wang, G.; Dai, Y.; Zhao, Q. Recording, erasing, and rewriting of ripples on metal surfaces by ultrashort laser pulses. Opt. Lett. 2018, 43, 1778–1781. [Google Scholar] [CrossRef]

- Bonse, J.; Krüger, J. Pulse number dependence of laser-induced periodic surface structures for femtosecond laser irradiation of silicon. J. Appl. Phys. 2010, 108, 034903. [Google Scholar] [CrossRef]

- Yuan, Y.; Jiang, L.; Li, X.; Wang, C.; Lu, Y. Adjustment of ablation shapes and subwavelength ripples based on electron dynamics control by designing femtosecond laser pulse trains. J. Appl. Phys. 2012, 112, 103103. [Google Scholar] [CrossRef]

- Yuan, Y.; Jiang, L.; Li, X.; Wang, C.; Yuan, L.; Qu, L.; Lu, Y. Adjustments of dielectrics craters and their surfaces by ultrafast laser pulse train based on localized electron dynamics control. Appl. Opt. 2013, 52, 4035–4041. [Google Scholar] [CrossRef]

- Shen, M.Y.; Carey, J.E.; Crouch, C.H.; Kandyla, M.; Stone, H.A.; Mazur, E. High-density regular arrays of nanometer-scale rods formed on silicon surfaces via femtosecond laser irradiation in water. Nano Lett. 2008, 8, 2087–2091. [Google Scholar] [CrossRef]

- Ulmeanu, M.; Jipa, F.; Radu, C.; Enculescu, M.; Zamfirescu, M. Large scale microstructuring on silicon surface in air and liquid by femtosecond laser pulses. Appl. Surf. Sci. 2012, 258, 9314–9317. [Google Scholar] [CrossRef]

- Deng, G.L.; Feng, G.Y.; Liu, K.; Zhou, S. Temperature dependence of laser-induced micro/nanostructures for femtosecond laser irradiation of silicon. Appl. Opt. 2014, 53, 3004–3009. [Google Scholar] [CrossRef]

- Mannion, P.T.; Magee, J.; Coyne, E.; O’Connor, G.M.; Glynn, T.J. The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl. Surf. Sci. 2004, 233, 275–287. [Google Scholar] [CrossRef]

- Ionin, A.A.; Kudryashov, S.I.; Makarov, S.V.; Rudenko, A.A.; Seleznev, L.V.; Sinitsyn, D.V.; Emel’yanov, V.I. Nonlinear optical dynamics during femtosecond laser nanostructuring of a silicon surface. Laser Phys. Lett. 2015, 12, 025902. [Google Scholar] [CrossRef]

- Raether, H. Surface Plasmons on Smooth Surfaces. In Surface Plasmons on Smooth and Rough Surfaces and on Gratings; Springer tracts in modern physics 111; Springer: Berlin, Germany, 1988. [Google Scholar]

- Račiukaitis, G.; Brikas, M.; Gečys, P.; Voisiat, B.; Gedvilas, M. Use of high repetition rate and high power lasers in microfabrication: How to keep the efficiency high? J. Laser Micro Nanoen. 2009, 4, 186–191. [Google Scholar] [CrossRef]

- Jee, Y.; Becker, M.F.; Walser, R.M. Laser-induced damage on single-crystal metal surfaces. J. Opt. Soc. Am. B 1988, 5, 648–659. [Google Scholar] [CrossRef]

- Gómez, D.; Goenaga, I. On the incubation effect on two thermoplastics when irradiated with ultrashort laser pulses: Broadening effects when machining microchannels. Appl. Surf. Sci. 2006, 253, 2230–2236. [Google Scholar] [CrossRef]

- Ni, X.; Wang, C.; Yang, L.; Li, J.; Chai, L.; Jia, W.; Zhang, R.; Zhang, Z. Parametric study on femtosecond laser pulse ablation of Au films. Appl. Surf. Sci. 2006, 253, 1616–1619. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).