Research on an Output Power Model of a Doubly-Fed Variable-Speed Pumped Storage Unit with Switching Process

Abstract

:1. Introduction

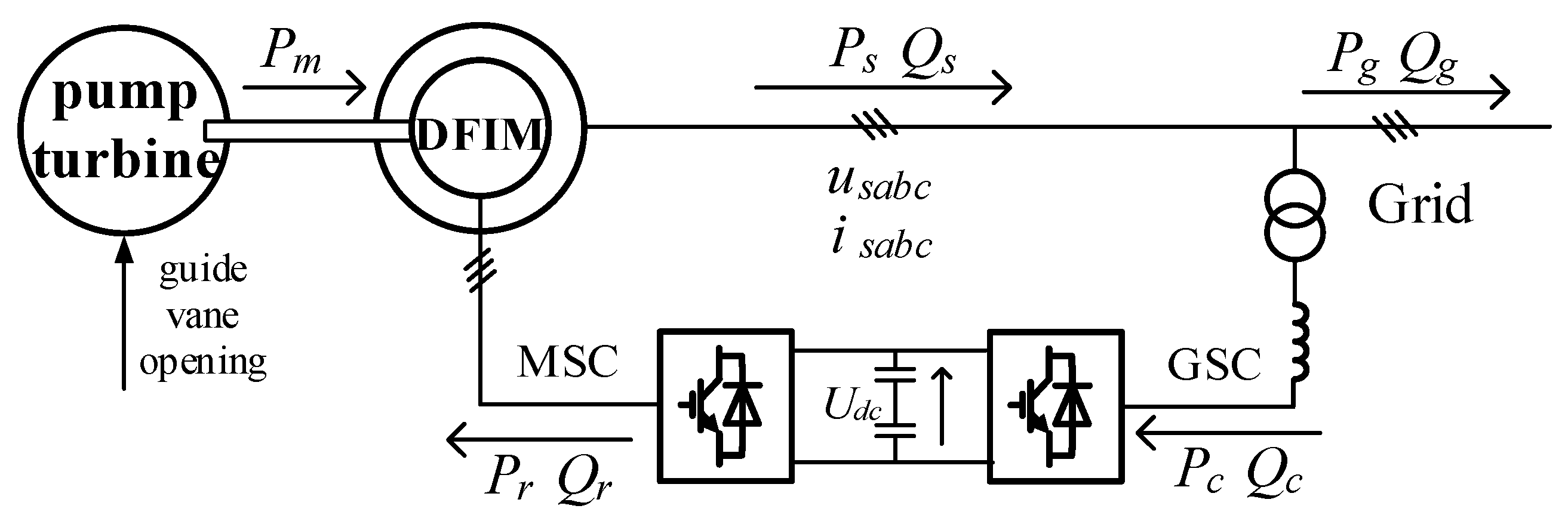

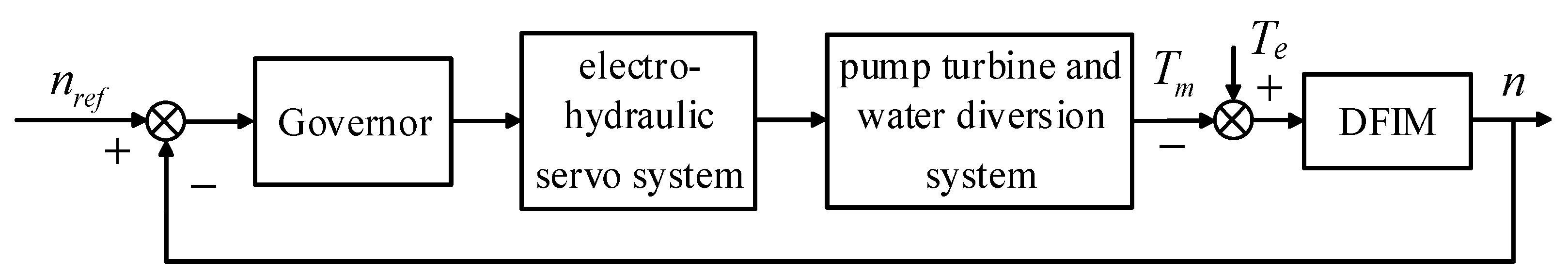

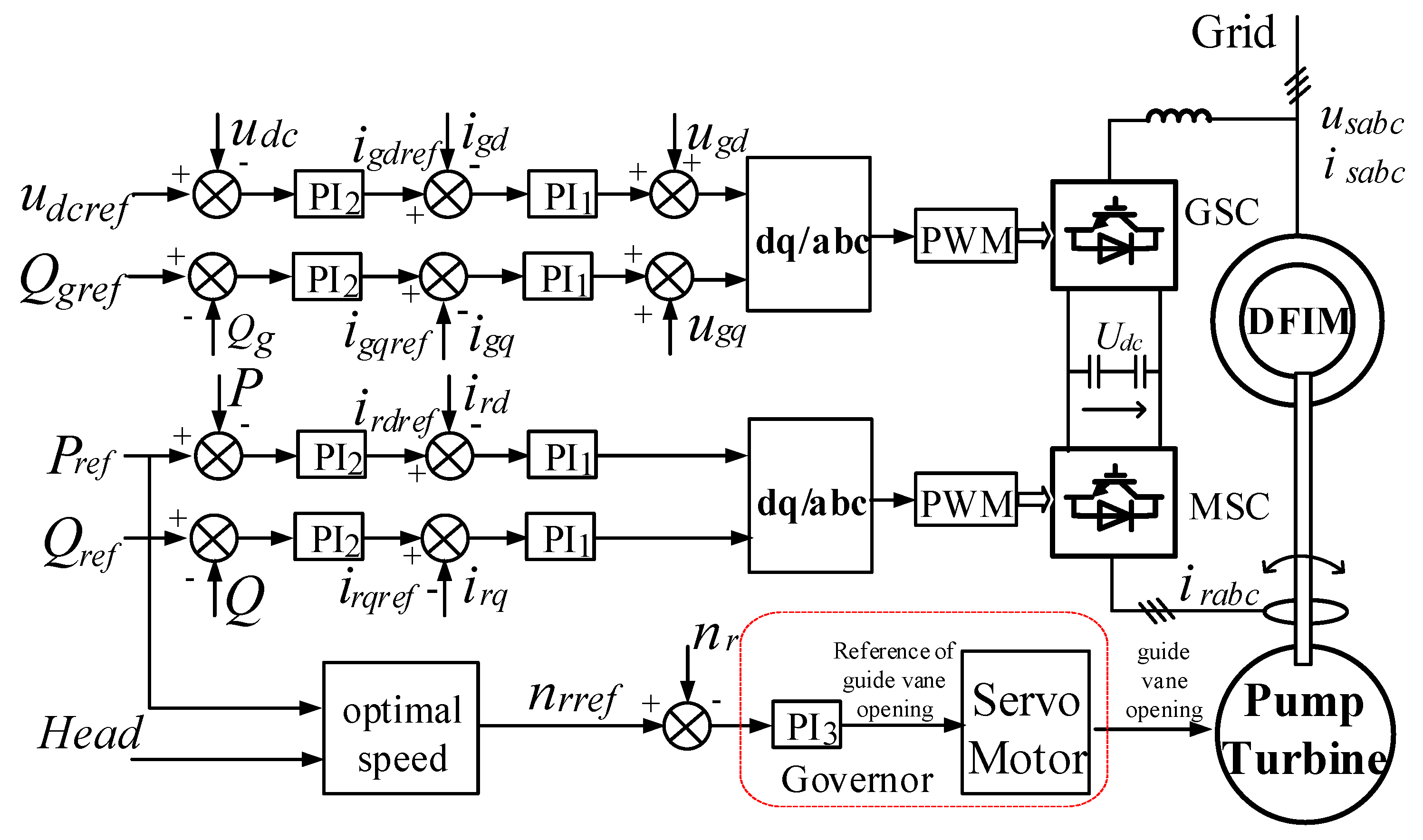

2. The Composition and Mathematical Model of Doubly-Fed Variable-Speed Pumped Storage Units

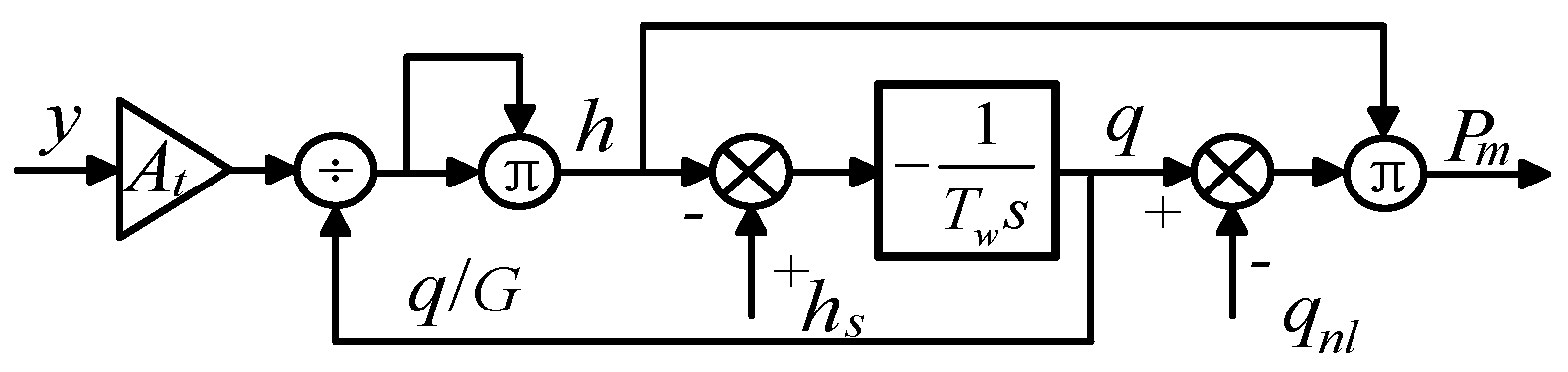

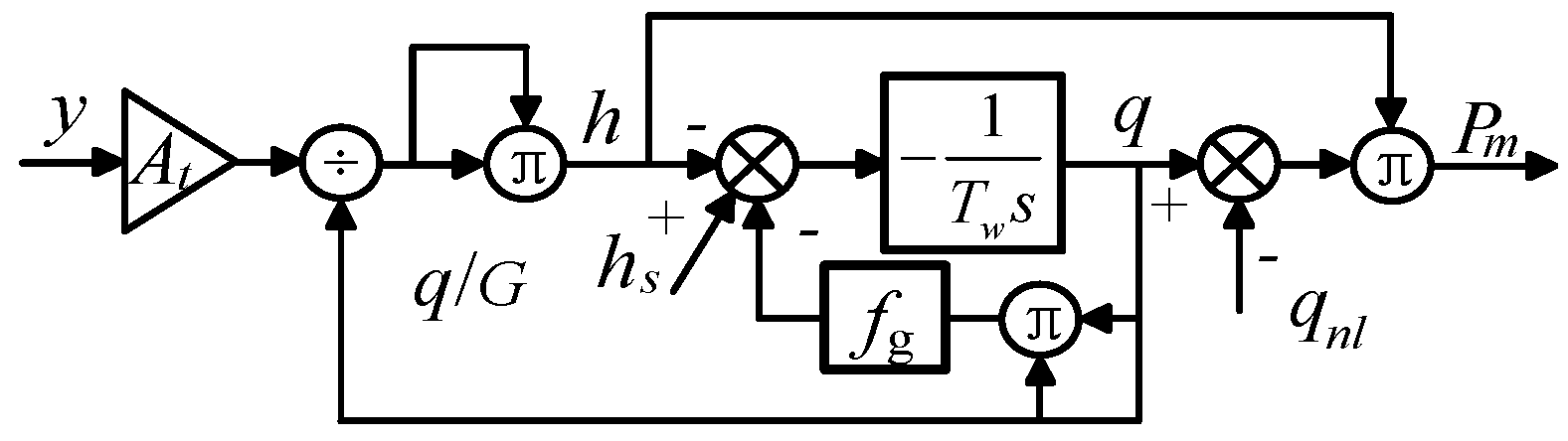

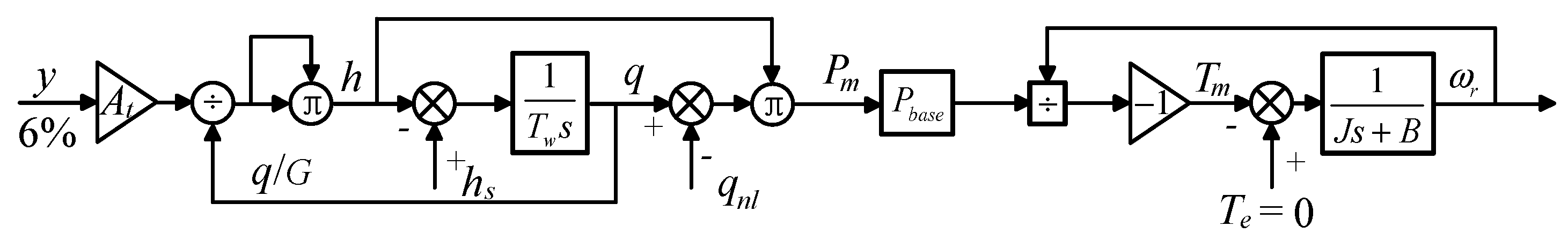

2.1. Mathematical Model of the Reversible Pump-Turbine

2.2. Model of DFIM

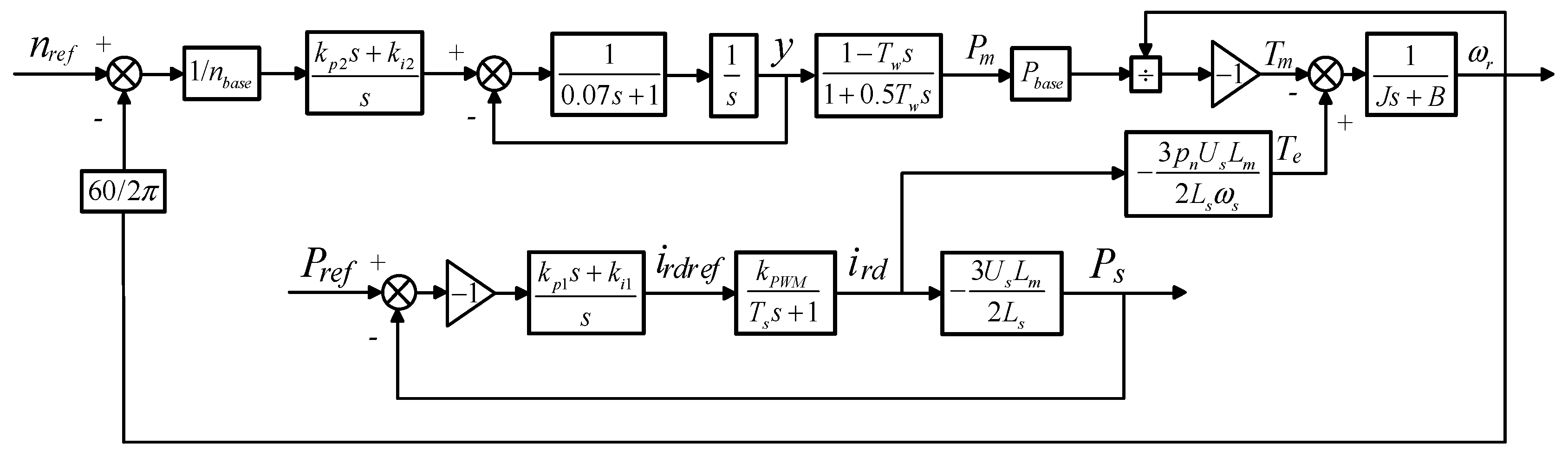

3. Control Method and Control Characteristics of the Switching Process of the DFVSPS Unit

3.1. Generating Mode

3.1.1. Start-Up in Generating Mode

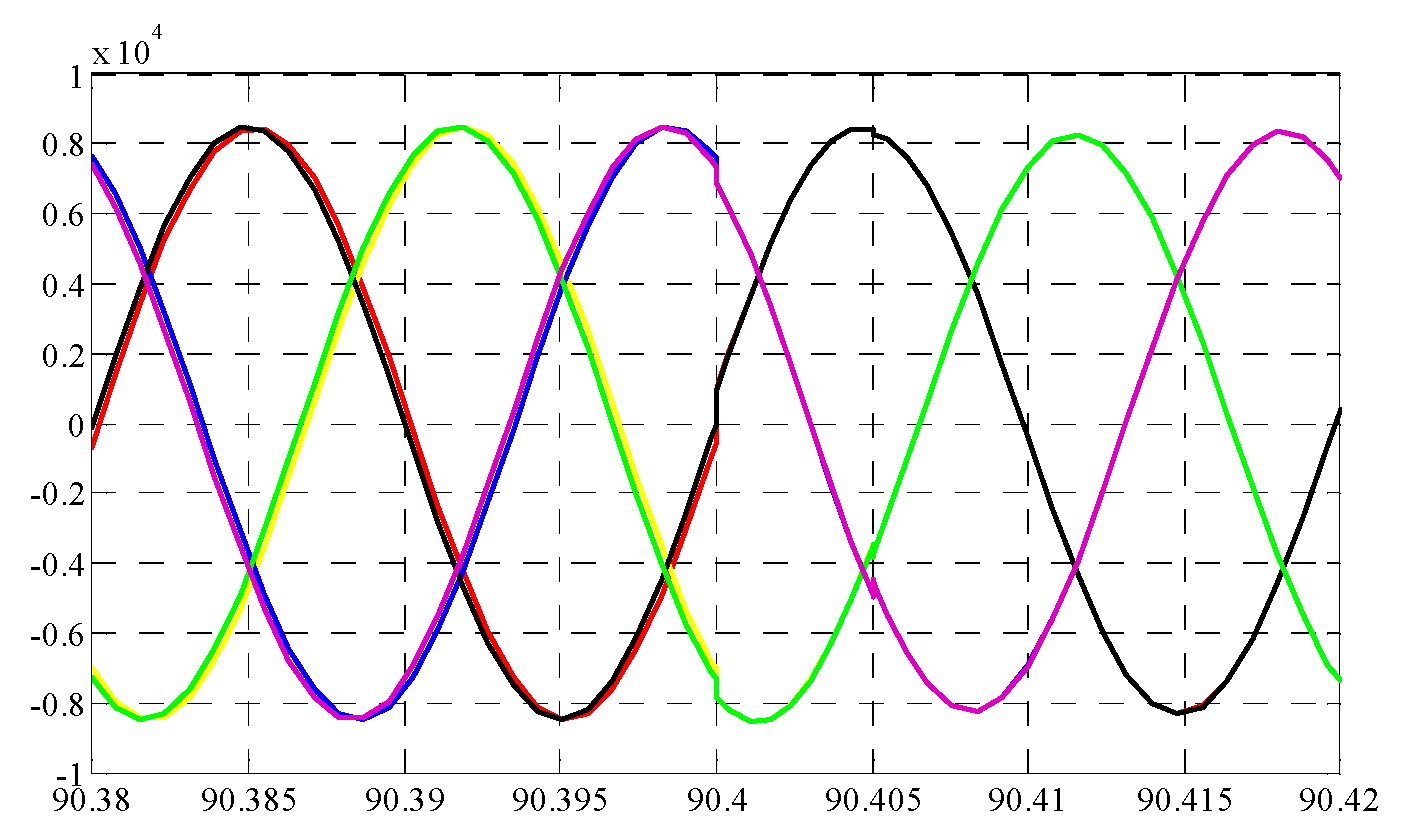

3.1.2. Voltage Regulation and Grid Connection

3.1.3. On-Grid Operation Stage

3.1.4. Orderly Shutdown Stage

3.2. Pump Mode

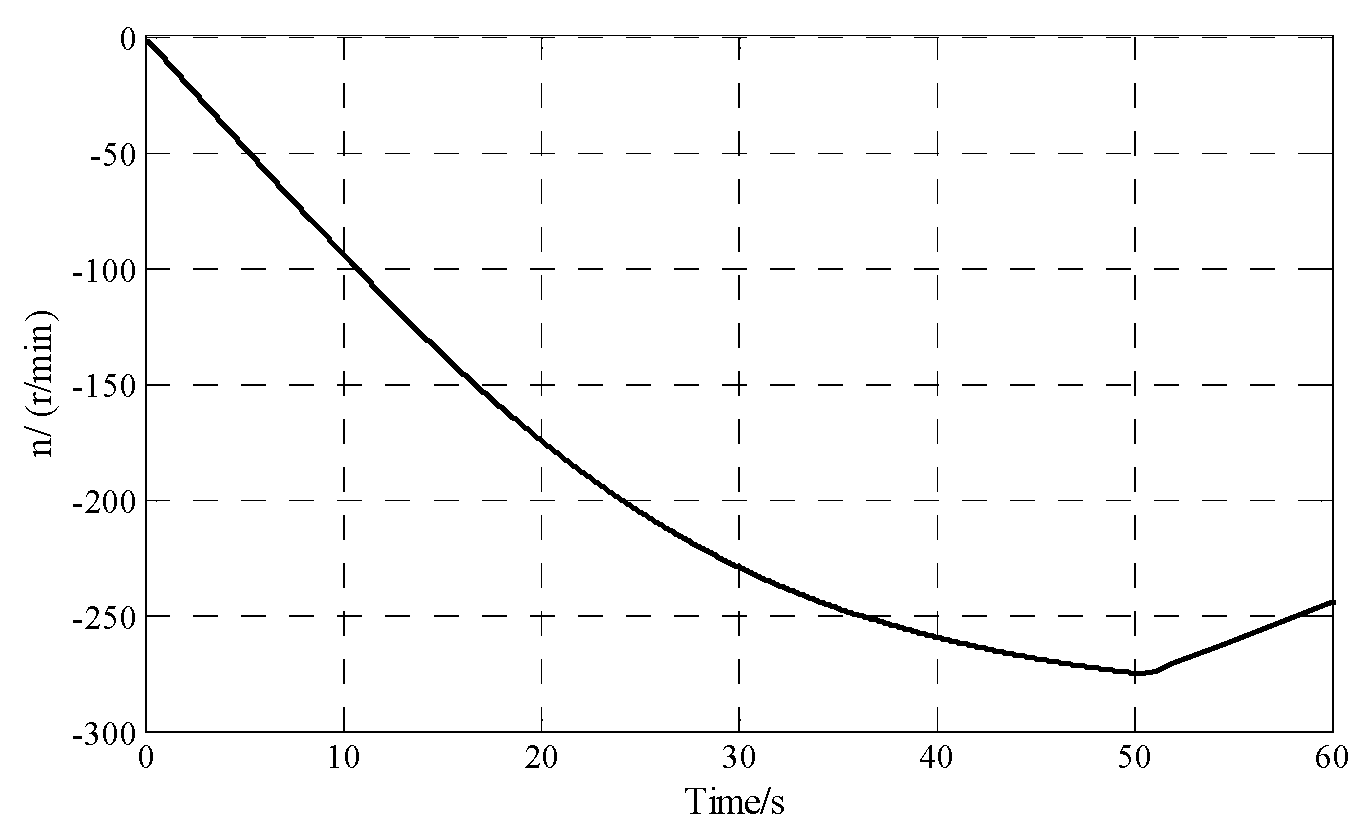

3.2.1. Start-Up in Pump Mode

3.2.2. On-Grid Operation Stage

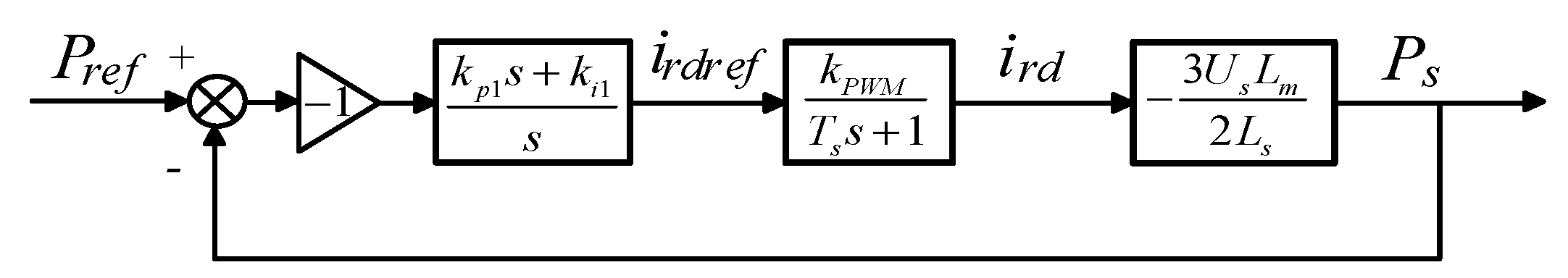

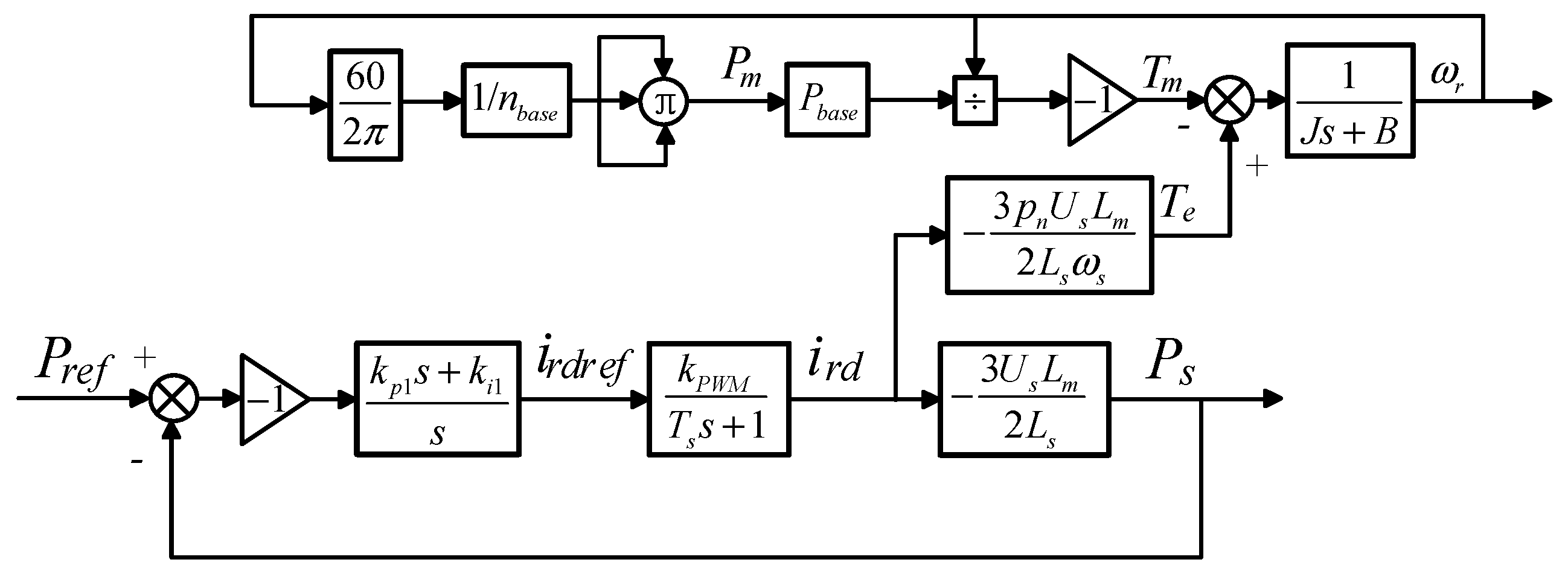

4. Output Power Modelling for the Switching Process of the DFVSPS Unit

4.1. Generating Mode

4.1.1. Start-Up in Generating Mode

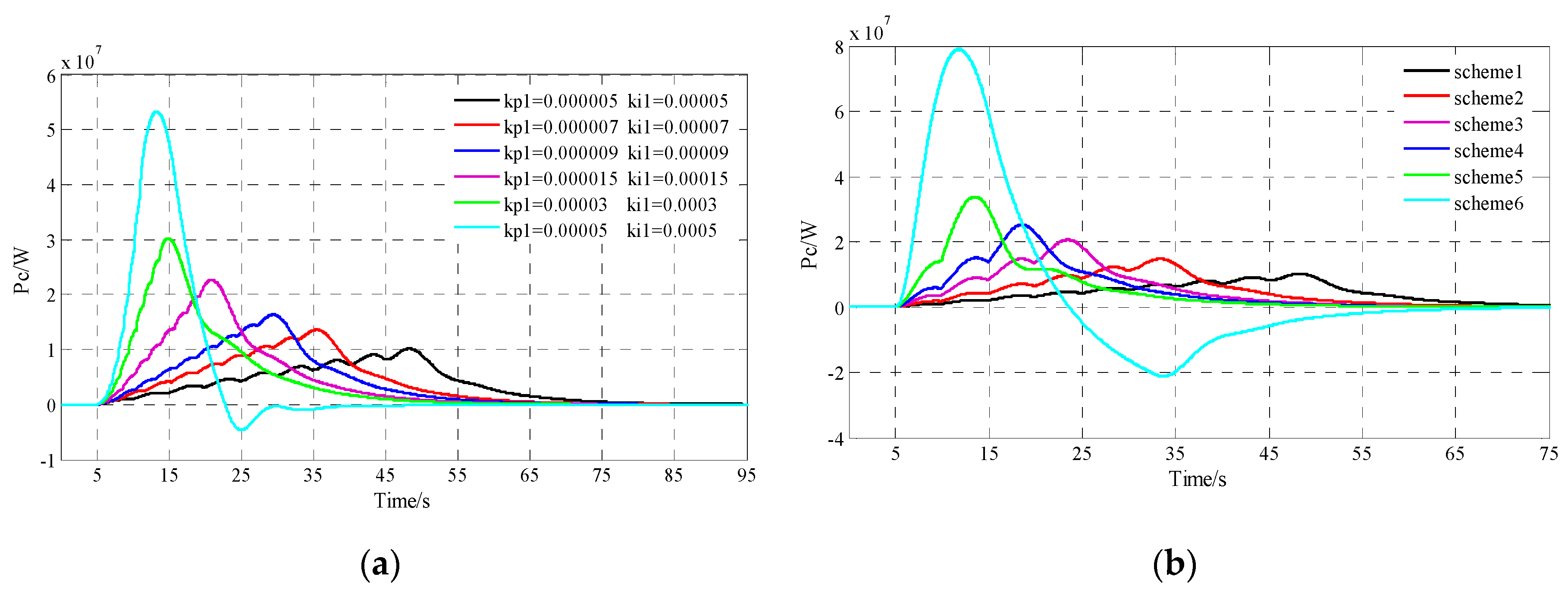

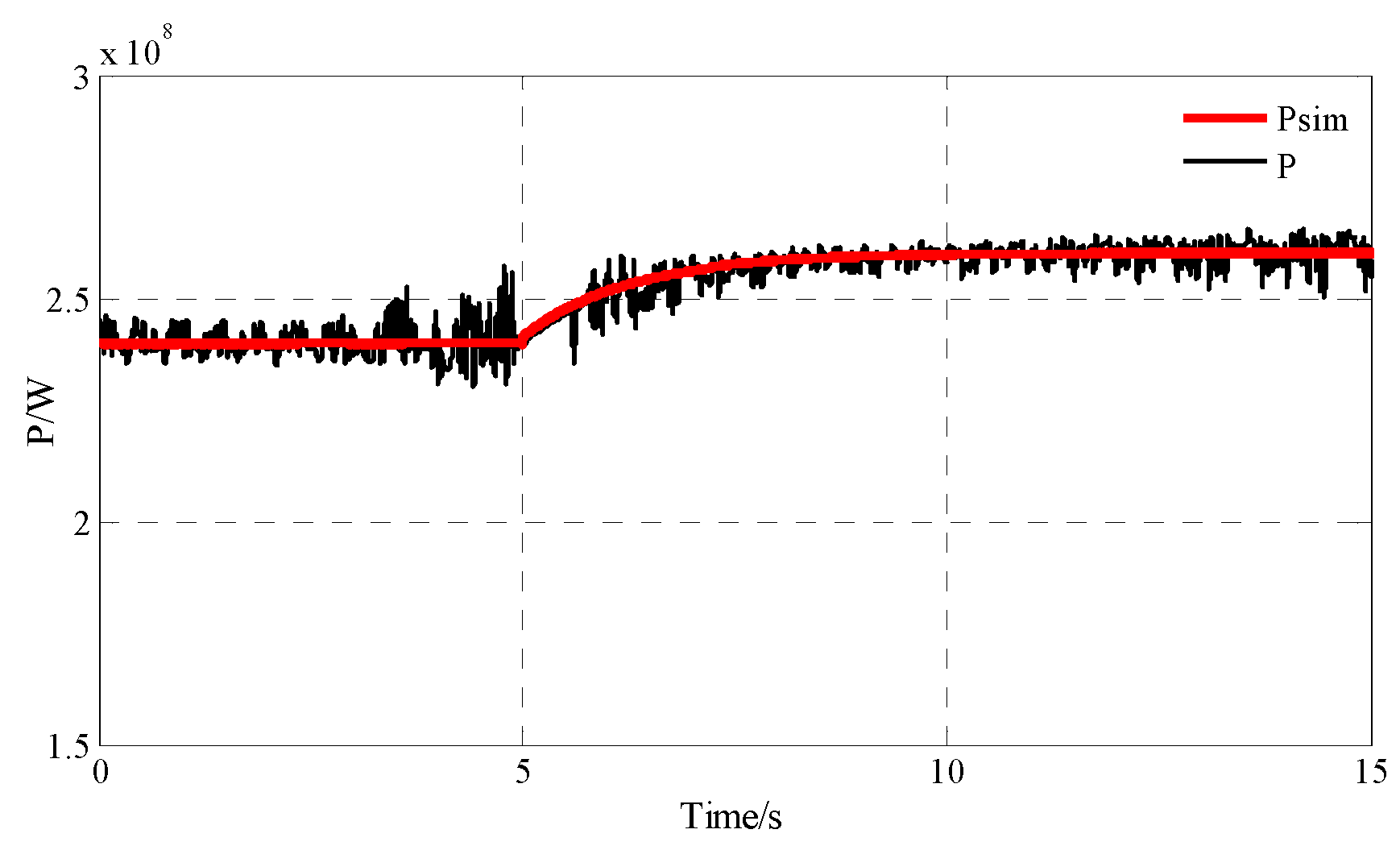

4.1.2. On-Grid Operation Stage

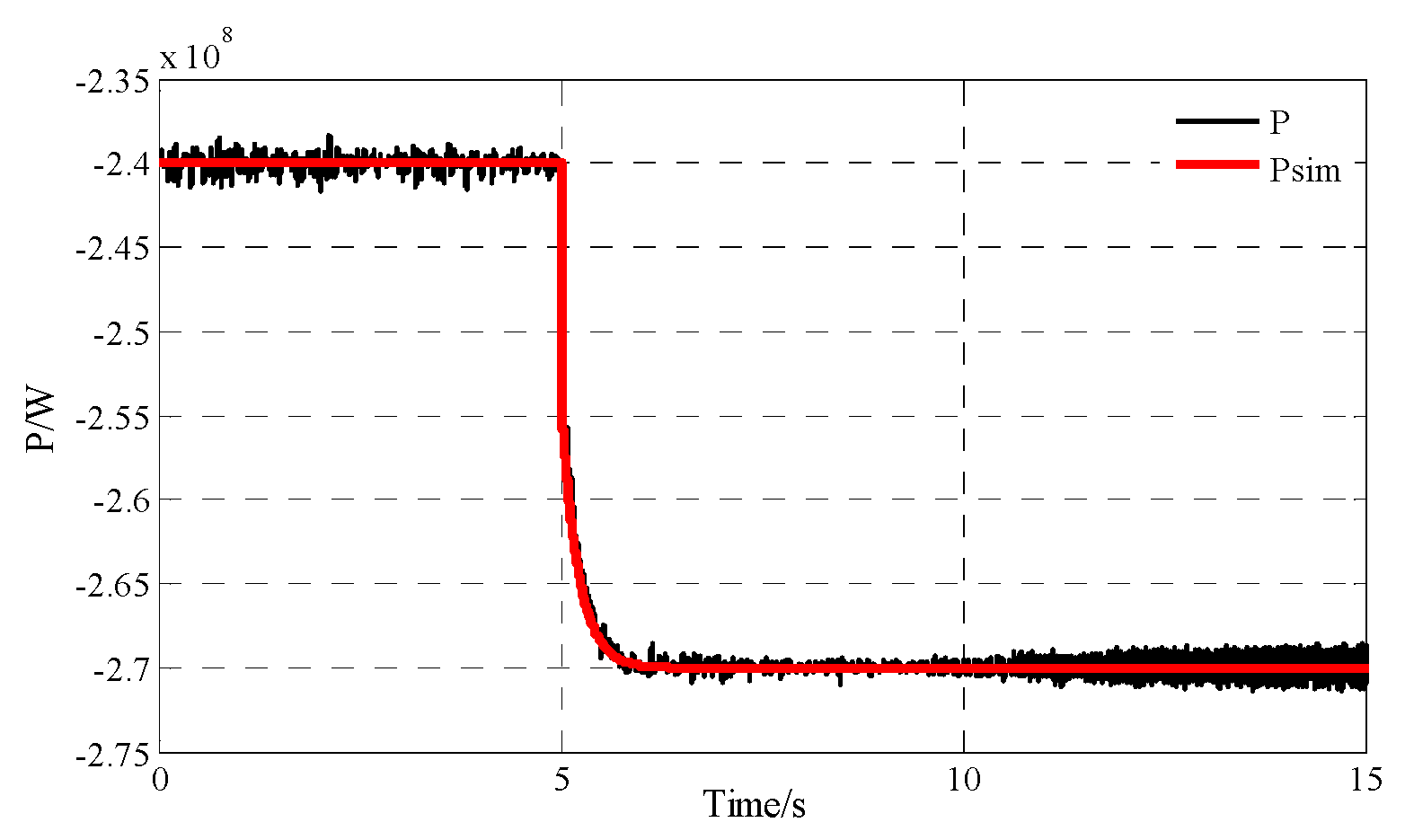

- (1)

- The stator side power control closed loop is an independent control loop, and its control effect is affected by the PI regulator parameters kp1, ki1, PWM converter switching frequency, and electromagnetic parameters of the DFIM, etc.

- (2)

- The speed control closed loop is mainly used to control the guide vane control system of pump turbine. The regulation of the speed closed loop is affected by the stator side power control closed loop, as well as by parameters such as water inertia time constant of pump turbine, pump turbine governor parameters kp2, ki2, and mechanical parameters of DFIM, etc.

4.1.3. Orderly Shutdown Stage

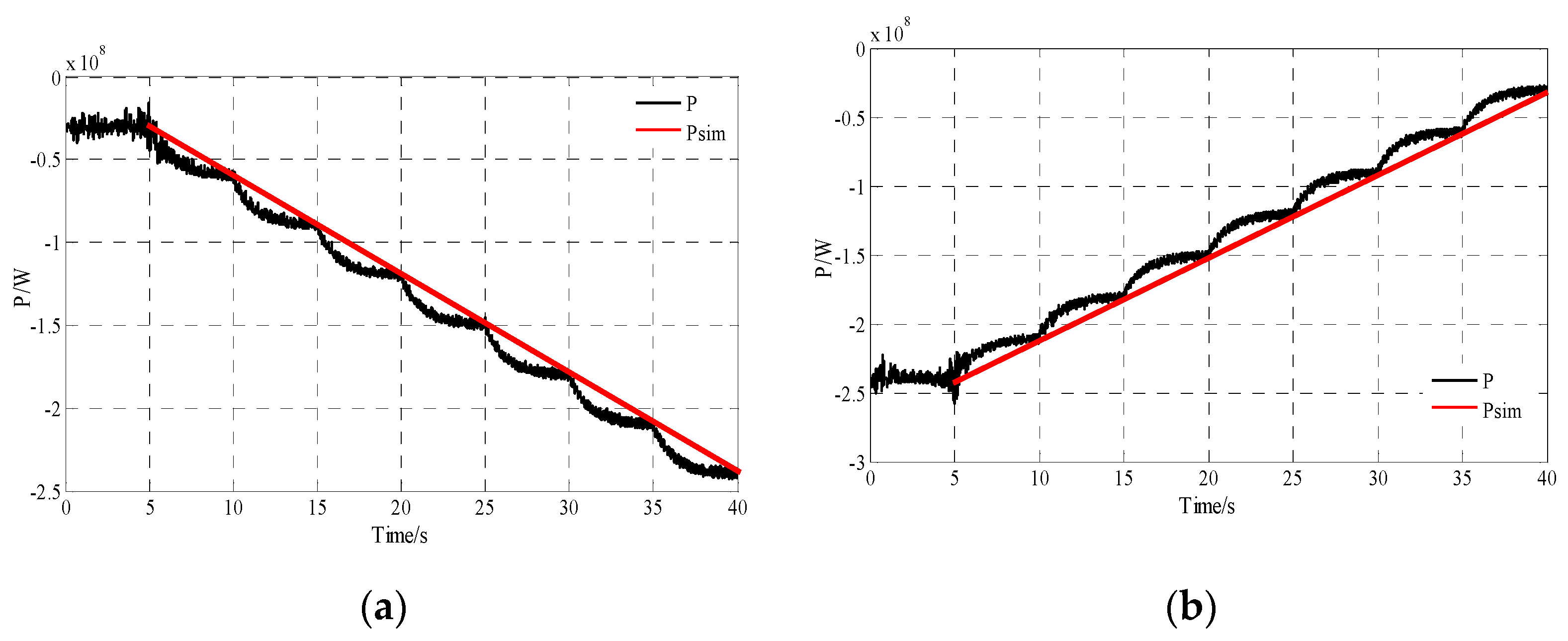

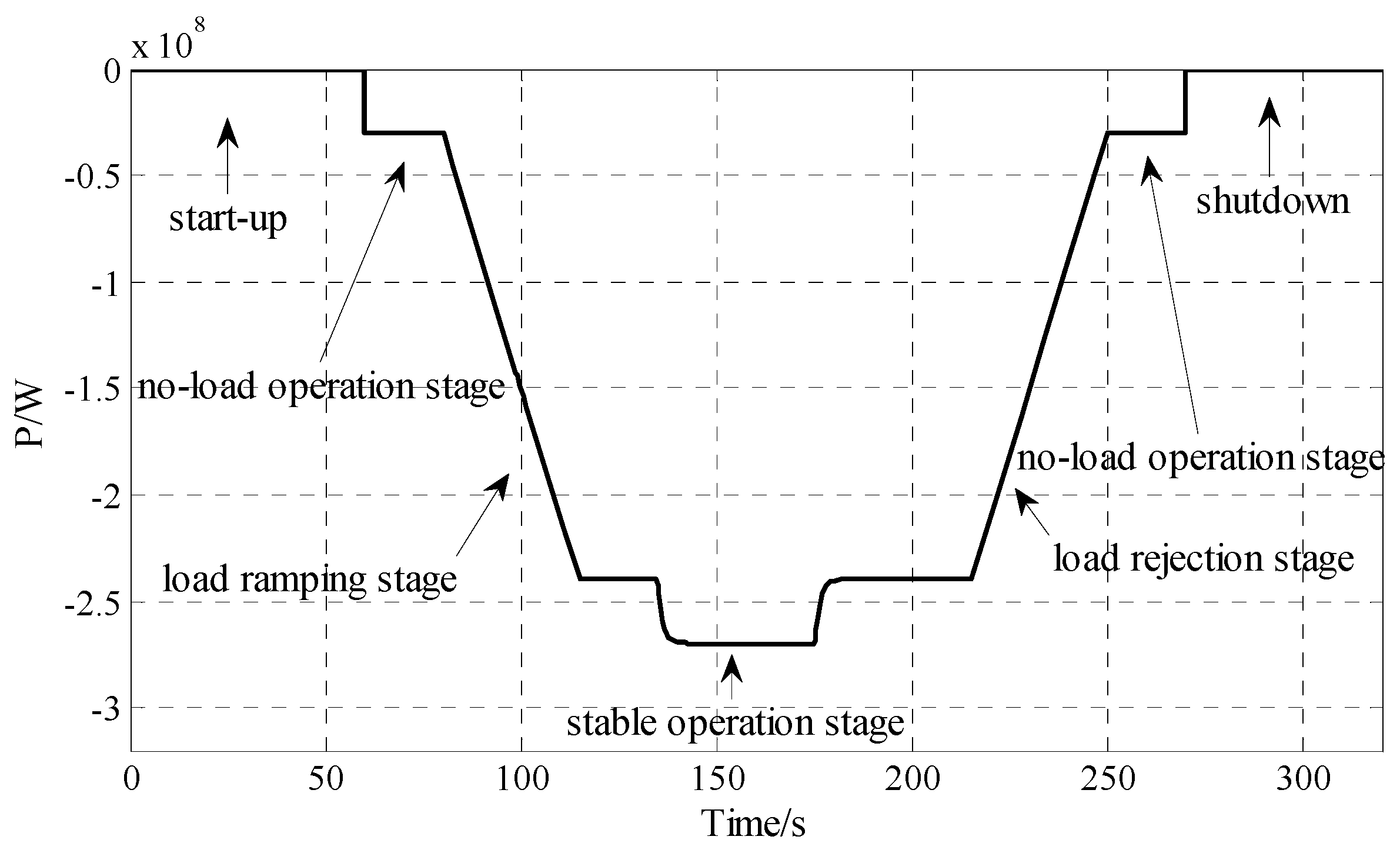

4.2. Pump Mode

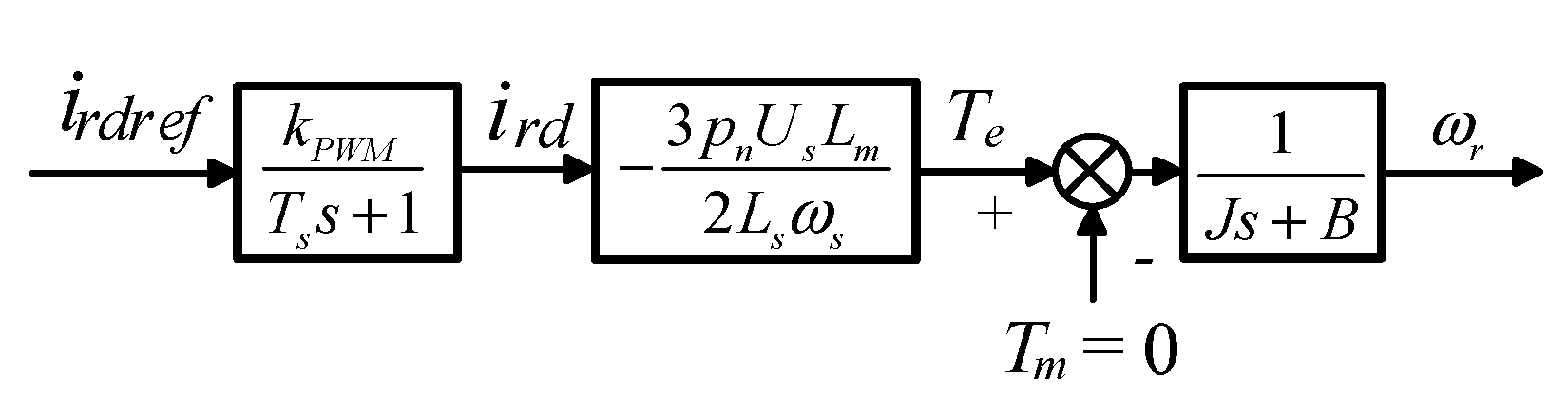

4.2.1. Start-up in Pump Mode

4.2.2. On-Grid Operation Stage

4.2.3. Orderly Shutdown Stage

4.3. Comparison of Simulation Time

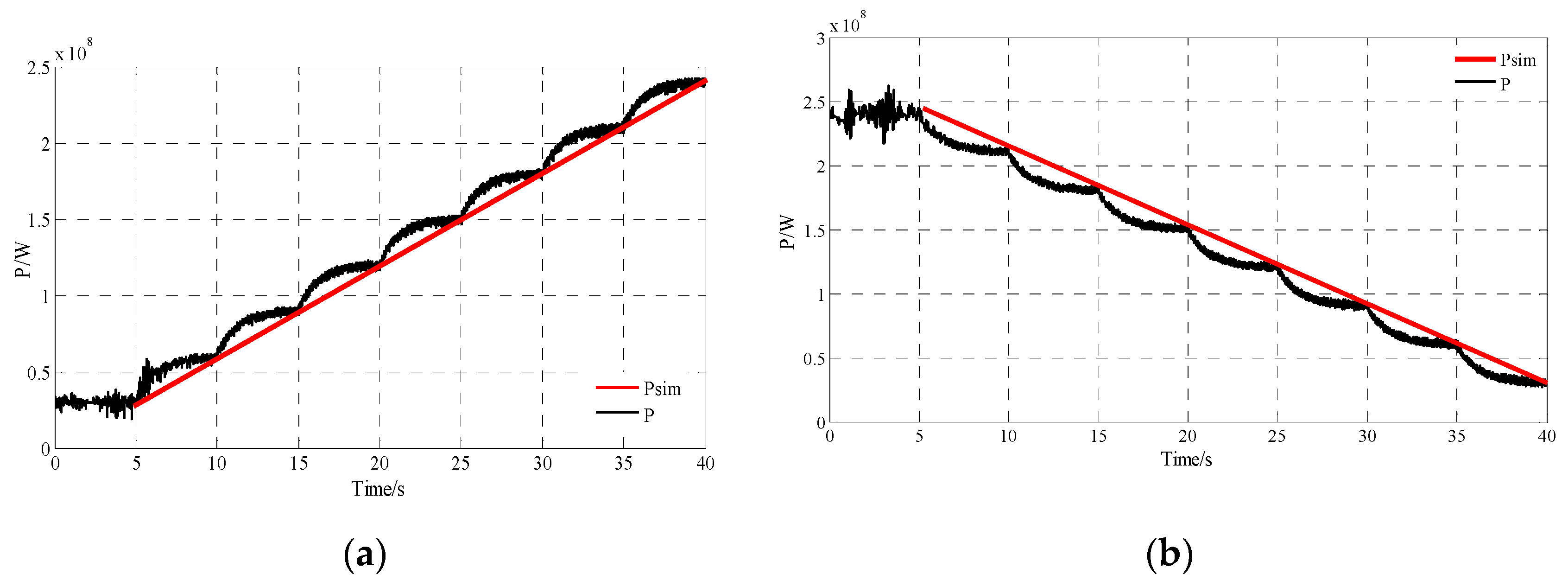

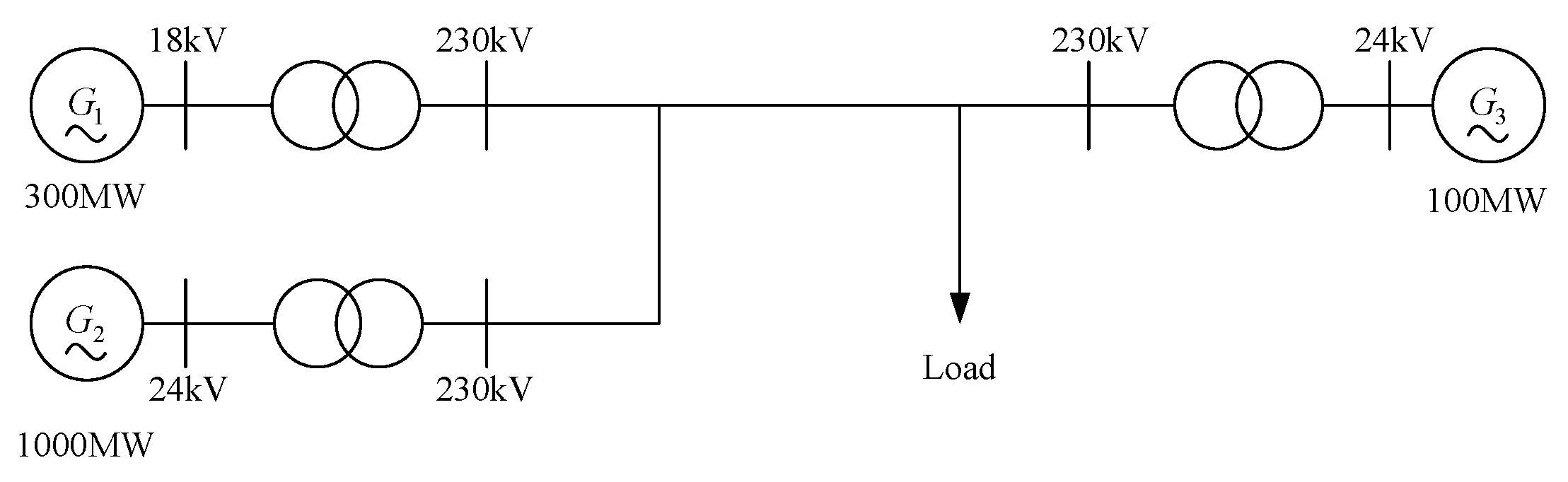

5. Example of Power System Simulation Using the Simplified Model

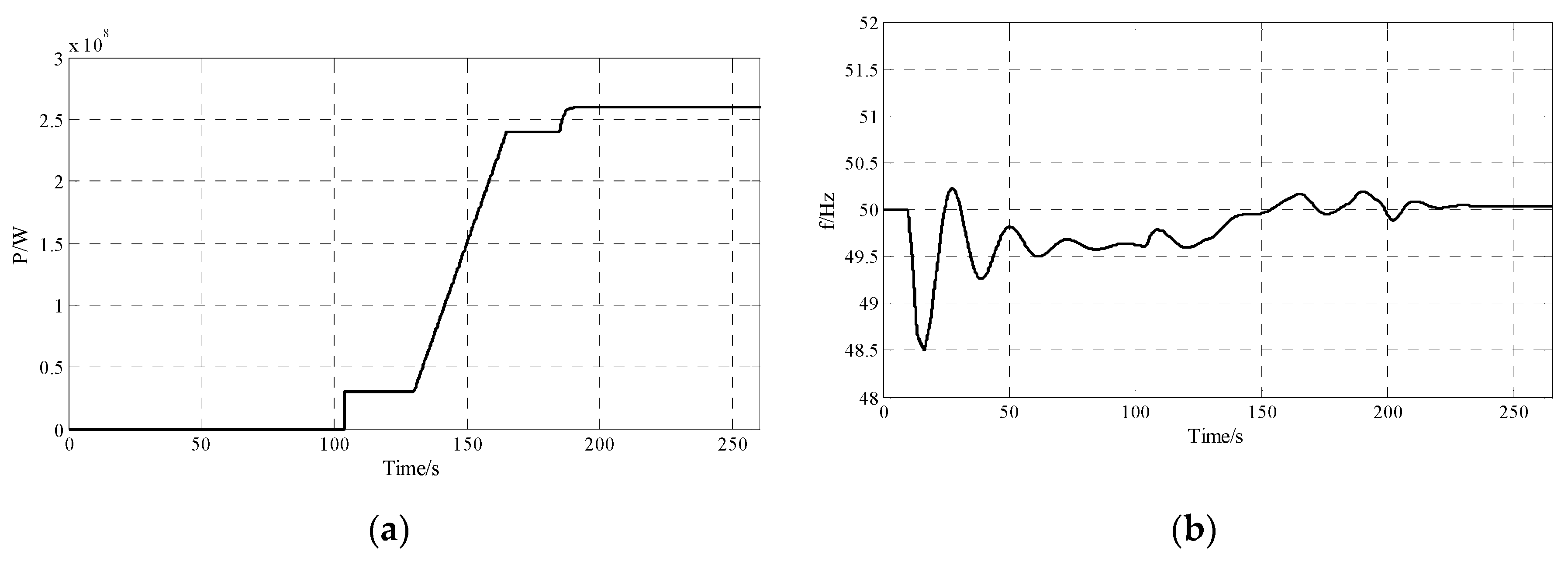

5.1. Generating Mode

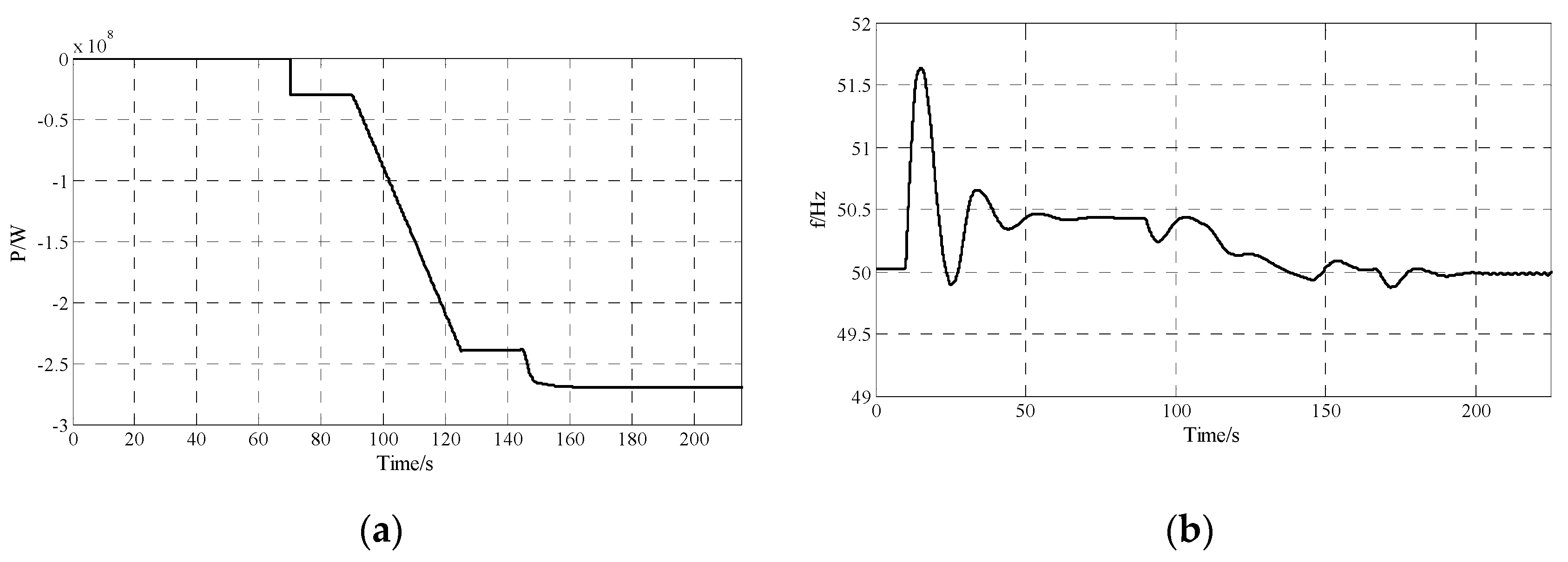

5.2. Pump Mode

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Saiju, R.; Koutnik, J.; Krueger, K. Dynamic analysis of start-up strategies of AC excited Double Fed Induction Machine for pumped storage power plant. In Proceedings of the 2009 13th European Conference on Power Electronics and Applications, Barcelona, Spain, 8–10 September 2009; pp. 1–8. [Google Scholar]

- O’Dwyer, C.; Flynn, D. Using Energy Storage to Manage High Net Load Variability at Sub-Hourly Time-Scales. IEEE Trans. Power Syst. 2015, 30, 2139–2148. [Google Scholar] [CrossRef]

- Castillo, A.; Gayme, D.F. Grid-scale energy storage applications in renewable energy integration: A survey. Energy Convers. Manag. 2014, 87, 885–894. [Google Scholar] [CrossRef]

- Pérez-Díaz, J.I.; Chazarra, M.; García-González, J.; Cavazzini, G.; Stoppato, A. Trends and challenges in the operation of pumped-storage hydropower plants. Renew. Sustain. Energy Rev. 2015, 44, 767–784. [Google Scholar] [CrossRef]

- Vargas-Serrano, A.; Hamann, A.; Hedtke, S.; Franck, C.M.; Hug, G. Economic benefit analysis of retrofitting a fixed-speed pumped storage hydropower plant with an adjustable-speed machine. In Proceedings of the 2017 IEEE Manchester PowerTech, Manchester, UK, 18–22 June 2017. [Google Scholar]

- Sivakumar, N.; Das, D.; Padhy, N.P. Variable speed operation of reversible pump-turbines at Kadamparai pumped storage plant–A case study. Energy Convers. Manag. 2014, 78, 96–104. [Google Scholar] [CrossRef]

- Li, D.; Wang, H.; Li, Z.; Nielsen, T.K.; Goyal, R.; Wei, X.; Qin, D. Transient characteristics during the closure of guide vanes in a pump-turbine in pump mode. Renew. Energy 2018, 118, 973–983. [Google Scholar] [CrossRef]

- Sun, H.; Xiao, R.; Liu, W.; Wang, F. Analysis of S Characteristics and Pressure Pulsations in a Pump-Turbine with Misaligned Guide Vanes. J. Fluids Eng. 2013, 135, 511011. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.X.; Zhu, W.; Wang, Z.; Zhang, J.; Zeng, C.; Yao, Y. Analysis of the internal flow behavior on S-shaped region of a Francis pump turbine on turbine mode. Eng. Comput. 2016, 33, 543–561. [Google Scholar] [CrossRef]

- Liu, J.; Liu, S.; Sun, Y. Three-dimensional flow simulation of transient power interruption process of a prototype pump-turbine at pump mode. J. Mech. Sci. Technol. 2013, 27, 1305–1312. [Google Scholar] [CrossRef]

- Fu, X.; Li, D.; Wang, H.; Zhang, G.; Li, Z.; Wei, X. Analysis of transient flow in a pump-turbine during the load rejection process. J. Mech. Sci. Technol. 2018, 32, 2069–2078. [Google Scholar] [CrossRef]

- Khodayar, M.E.; Abreu, L.; Shahidehpour, M. Transmission-constrained intrahour coordination of wind and pumped-storage hydro units. IET Gener. Transm. Distrib. 2013, 7, 755–765. [Google Scholar] [CrossRef]

- Ma, T.; Yang, H.; Lu, L.; Peng, J. An Optimization Sizing Model for Solar Photovoltaic Power Generation System with Pumped Storage. Energy Procedia 2014, 61, 5–8. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, J.; Kemmetmüller, W.; Kugi, A. Modeling and static optimization of a variable speed pumped storage power plant. Renew. Energy 2017, 111, 38–51. [Google Scholar] [CrossRef]

- Joseph, A.; Desingu, K.; Semwal, R.R.; Chelliah, T.R.; Khare, D. Dynamic Performance of Pumping Mode of 250 MW Variable Speed Hydro-Generating Unit Subjected to Power and Control Circuit Faults. IEEE Trans. Energy Convers. 2017, 33, 430–441. [Google Scholar] [CrossRef]

- Joseph, A.; Chelliah, T.R. A Review of Power Electronic Converters for Variable Speed Pumped Storage Plants: Configurations, Operational Challenges and Future Scopes. IEEE J. Emerg. Sel. Top. Power Electr. 2017, 6, 103–119. [Google Scholar] [CrossRef]

- Zuo, Z.; Fan, H.; Liu, S.; Wu, Y. S-shaped characteristics on the performance curves of pump-turbines in turbine mode–A review. Renew. Sustain. Energy Rev. 2016, 60, 836–851. [Google Scholar] [CrossRef]

- Feltes, J.; Koritarov, V.; Guzowski, L.; Donalek, P.; Grande-Moran, C.; Troullie, C.; Koritarov, V. Modeling Adjustable Speed Pumped Storage Hydro Units Employing Doubly-Fed Induction Machines; Argonne National Lab. (ANL): Argonne, IL, USA, 2013. [Google Scholar]

- Demello, F.P.; Koessler, R.J.; Agee, J.; Anderson, P.M.; Doudna, J.H.; Fish, J.H.; Hamm, P.A.L.; Kundur, P.; Lee, D.C.; Rogers, G.J.; et al. Hydraulic turbine and turbine control models for system dynamic studies. IEEE Trans. Power Syst. 1992, 7, 167–179. [Google Scholar]

- Zuo, Z.; Liu, S. Flow-induced instabilities in pump-turbines in China. Engineering 2017, 3, 504–511. [Google Scholar] [CrossRef]

- Li, D.; Zuo, Z.; Wang, H.; Liu, S.; Wei, X.; Qin, D. Review of positive slopes on pump performance characteristics of pump-turbines. Renew. Sustain. Energy Rev. 2019, 112, 901–916. [Google Scholar] [CrossRef]

- Liang, J.; Harley, R.G. Pumped storage hydro-plant models for system transient and long-term dynamic studies. Power Energy Soc. Gen. Meet. IEEE 2010, 89, 1–8. [Google Scholar]

- Golkhandan, R.K.; Aghaebrahimi, M.R.; Farshad, M. Control strategies for enhancing frequency stability by DFIGs in a power system with high percentage of wind power penetration. Appl. Sci. 2017, 7, 1140. [Google Scholar] [CrossRef]

- Li, B.; Liu, J.; Wang, X.; Zhao, L. Fault Studies and Distance Protection of Transmission Lines Connected to DFIG-Based Wind Farms. Appl. Sci. 2018, 8, 562. [Google Scholar] [CrossRef]

- Cai, G.; Chen, X.; Sun, Z.; Yang, D.; Liu, C.; Li, H. A Coordinated Dual-Channel Wide Area Damping Control Strategy for a Doubly-Fed Induction Generator Used for Suppressing Inter-Area Oscillation. Appl. Sci. 2019, 9, 2353. [Google Scholar] [CrossRef]

- Zeng, W.; Yang, J.; Hu, J. Pumped storage system model and experimental investigations on S-induced issues during transients. Mech. Syst. Signal Process. 2017, 90, 350–364. [Google Scholar] [CrossRef]

- Shen, Y.; Ji, Z.; Pan, T.; Wu, D. A no-load grid-connected strategy based on one-cycle control for doubly-fed wind power system. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 1822–1826. [Google Scholar]

- Kuwabara, T.; Shibuya, A.; Furuta, H.; Furuta, H.; Kita, E.; Mitsuhashi, K. Design and dynamic response characteristics of 400 MW adjustable speed pumped storage unit for Ohkawachi power station. IEEE Trans. Energy Convers. 1996, 11, 376–384. [Google Scholar] [CrossRef]

- Lung, J.K.; Lu, Y.; Hung, W.L.; Kao, W. Modeling and dynamic simulations of doubly fed adjustable-speed pumped storage units. IEEE Trans. Energy Convers. 2007, 22, 250–258. [Google Scholar] [CrossRef]

- Laabidi, M.; Rebhi, B.; Kourda, F.; Elleuch, M.; Ghodbani, L. Braking of induction motor with the technique of discrete frequency control. In Proceedings of the 2010 7th International Multi- Conference on Systems, Signals and Devices, Amman, Jordan, 27–30 June 2010; pp. 1–6. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| rated power | 300 MW | stator resistance Rs | 0.00103 Ω |

| frequency | 50 Hz | rotor resistance Rr | 0.00065 Ω |

| rated voltage | 18 kV | stator inductance Ls | 0.000194 H |

| inertia J | 4,000,000 kg·m2 | rotor inductance Lr | 0.000267 H |

| pole pairs p | 12 | mutual inductance Lr | 0.00567 H |

| kp1 | 0.000005 | 0.000007 | 0.000009 | 0.000015 | 0.00003 | 0.00005 |

|---|---|---|---|---|---|---|

| ki1 | 0.00005 | 0.00007 | 0.00009 | 0.00015 | 0.0003 | 0.0005 |

| response time | 5.0 | 3.5 | 2.8 | 1.8 | 1.1 | 0.75 |

| Generating Mode | Pump Mode | |

|---|---|---|

| Start-up | 2 min | 2 min |

| Load ramping stage | 2 h and 58 min | 2 h and 40 min |

| Stable operation stage | 3 h and 4 min | 2 h and 22 min |

| Load rejection stage | 2 h and 50 min | 2 h and 55 min |

| Shutdown stage | 10 min | 10 min |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, G.; Ren, J. Research on an Output Power Model of a Doubly-Fed Variable-Speed Pumped Storage Unit with Switching Process. Appl. Sci. 2019, 9, 3368. https://doi.org/10.3390/app9163368

Zhao G, Ren J. Research on an Output Power Model of a Doubly-Fed Variable-Speed Pumped Storage Unit with Switching Process. Applied Sciences. 2019; 9(16):3368. https://doi.org/10.3390/app9163368

Chicago/Turabian StyleZhao, Guopeng, and Jiyun Ren. 2019. "Research on an Output Power Model of a Doubly-Fed Variable-Speed Pumped Storage Unit with Switching Process" Applied Sciences 9, no. 16: 3368. https://doi.org/10.3390/app9163368

APA StyleZhao, G., & Ren, J. (2019). Research on an Output Power Model of a Doubly-Fed Variable-Speed Pumped Storage Unit with Switching Process. Applied Sciences, 9(16), 3368. https://doi.org/10.3390/app9163368