Development of a Novel Shaft Dryer for Coal-Based Green Needle Coke Drying Process

Abstract

Featured Application

Abstract

1. Introduction

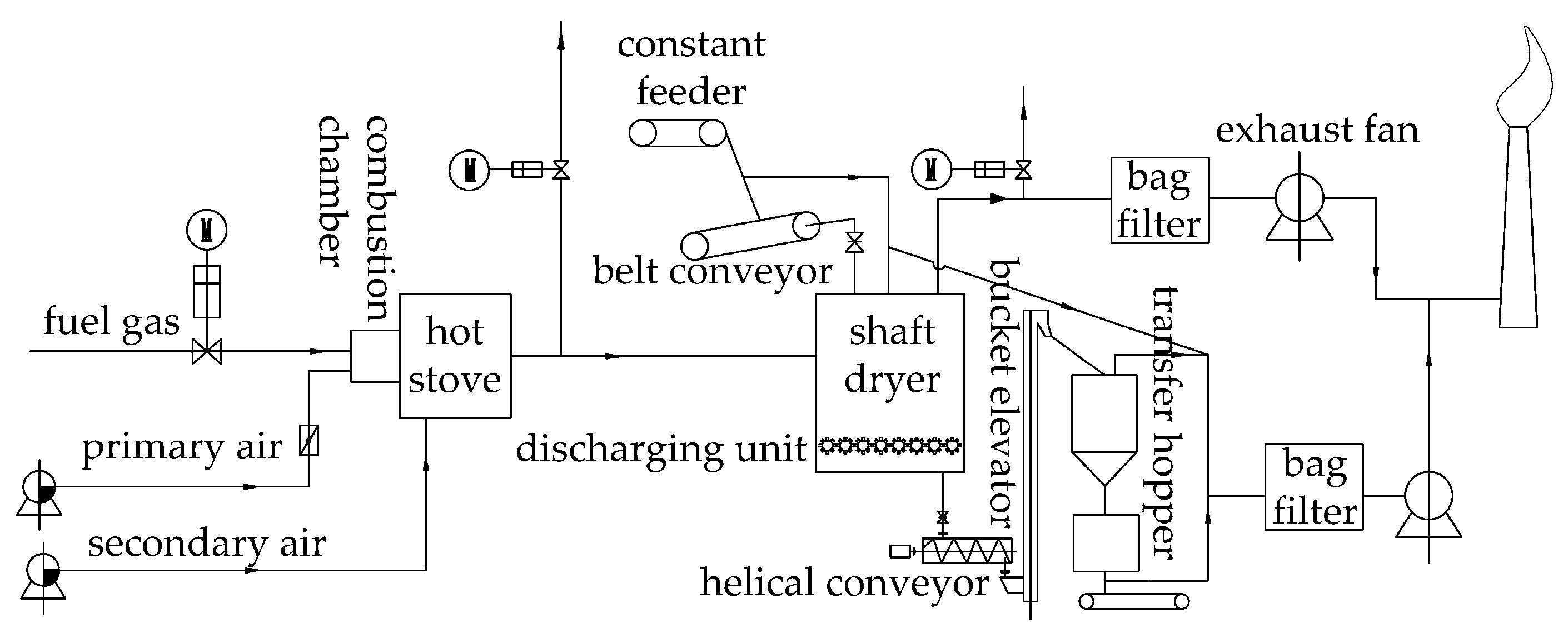

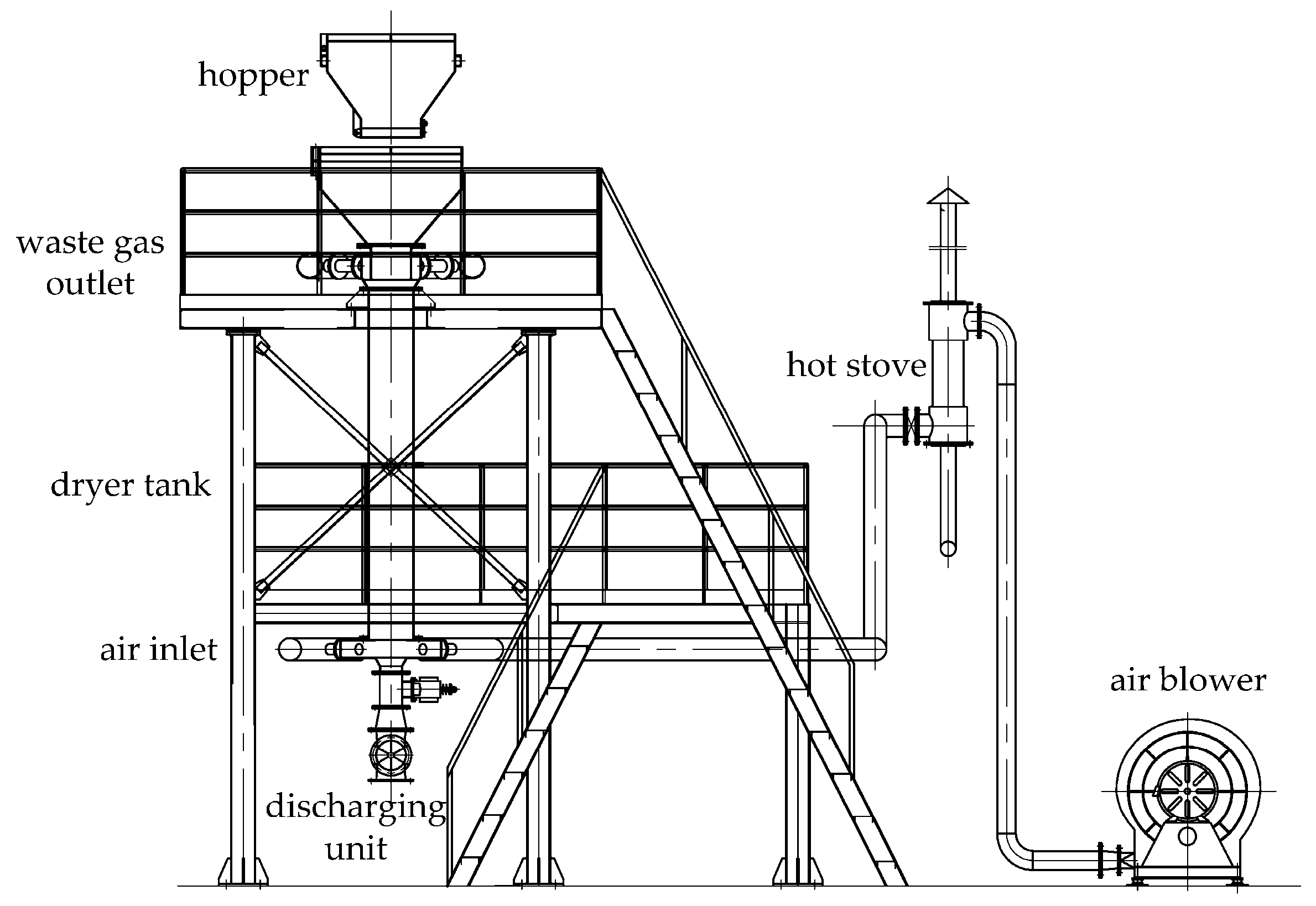

2. Design of the Novel Drying System and Shaft Dryer

- It has a simple structure and no mechanical transmission unit, making it easy to maintain, with low noise while operating and low failure rates.

- It is a wholly-sealed system, and thus the energy efficiency can be as high as 65%–75% with no leak of environmental pollutants.

- It can be built by using less metal, less land area, lower capital investment cost, compared with other drying methods.

- It uses medium-temperature gas as the heat source, which will not cause the over-burnt quality of green cokes.

- It does not need liner inside the shaft dryer, ensuring that final green cokes have good quality.

- It has a low breakage rate of green coke because of the low-speed flow of green coke inside the shaft dryer, which further reduces the amount of dust and the cost of environmental assets.

- It can easily adjust the residence time and the resultant moisture content of green cokes.

- It has less strict requirement on the particle size of green cokes because of the use of gravity discharging and related units.

3. Materials and Experimental Methods

3.1. Materials

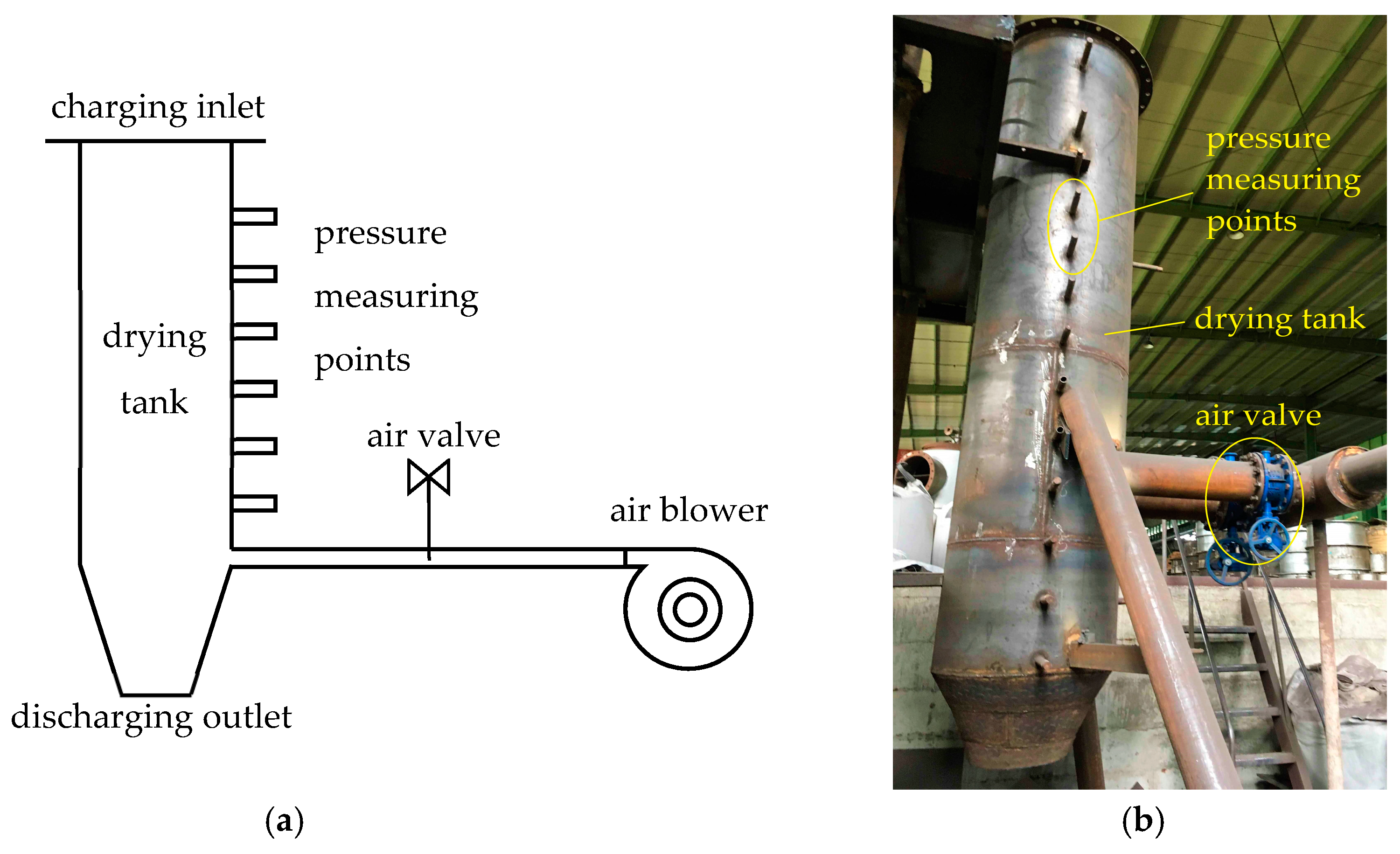

3.2. Experimental Methods

3.2.1. Method to Determine the Initial Moisture Content

3.2.2. Method to Determine the Vertex Angle of Pile of Green Cokes

3.2.3. Method to Determine the Pressure Drop Characteristics

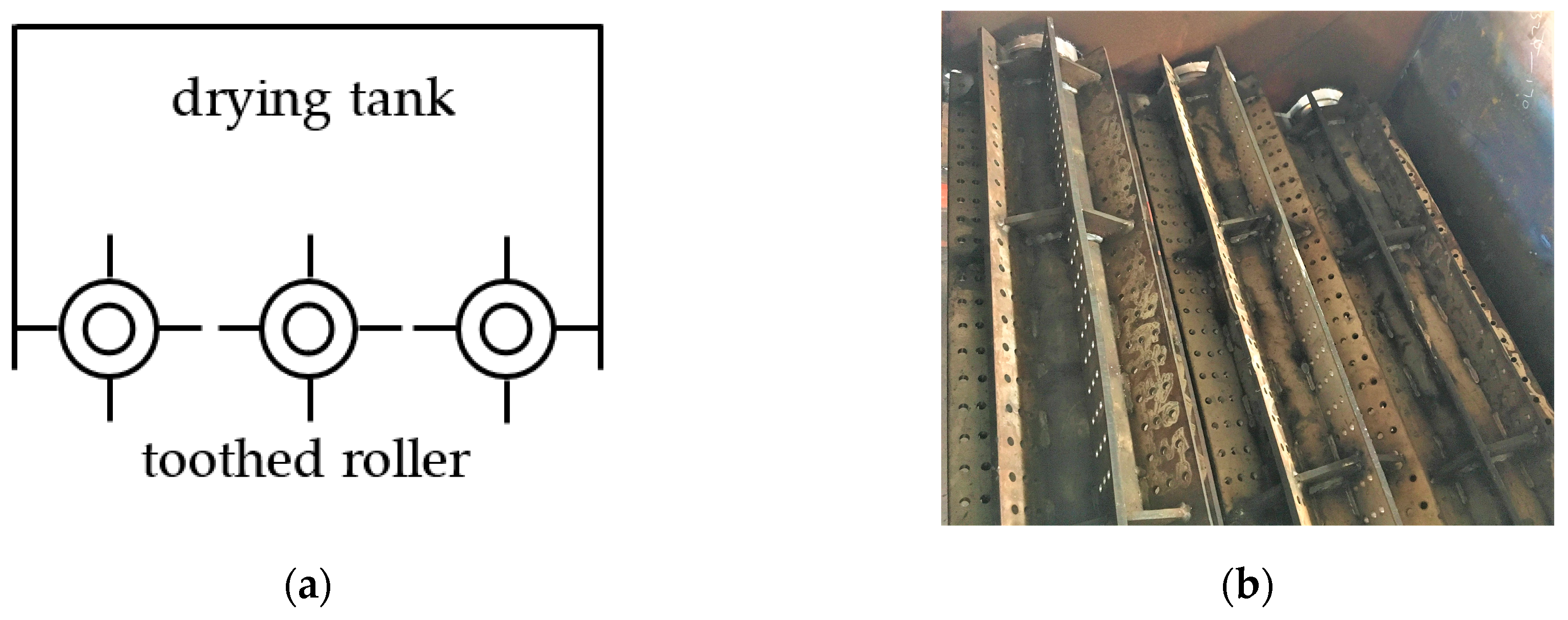

3.2.4. Method to Determine the Discharge Characteristics of the Toothed Roller

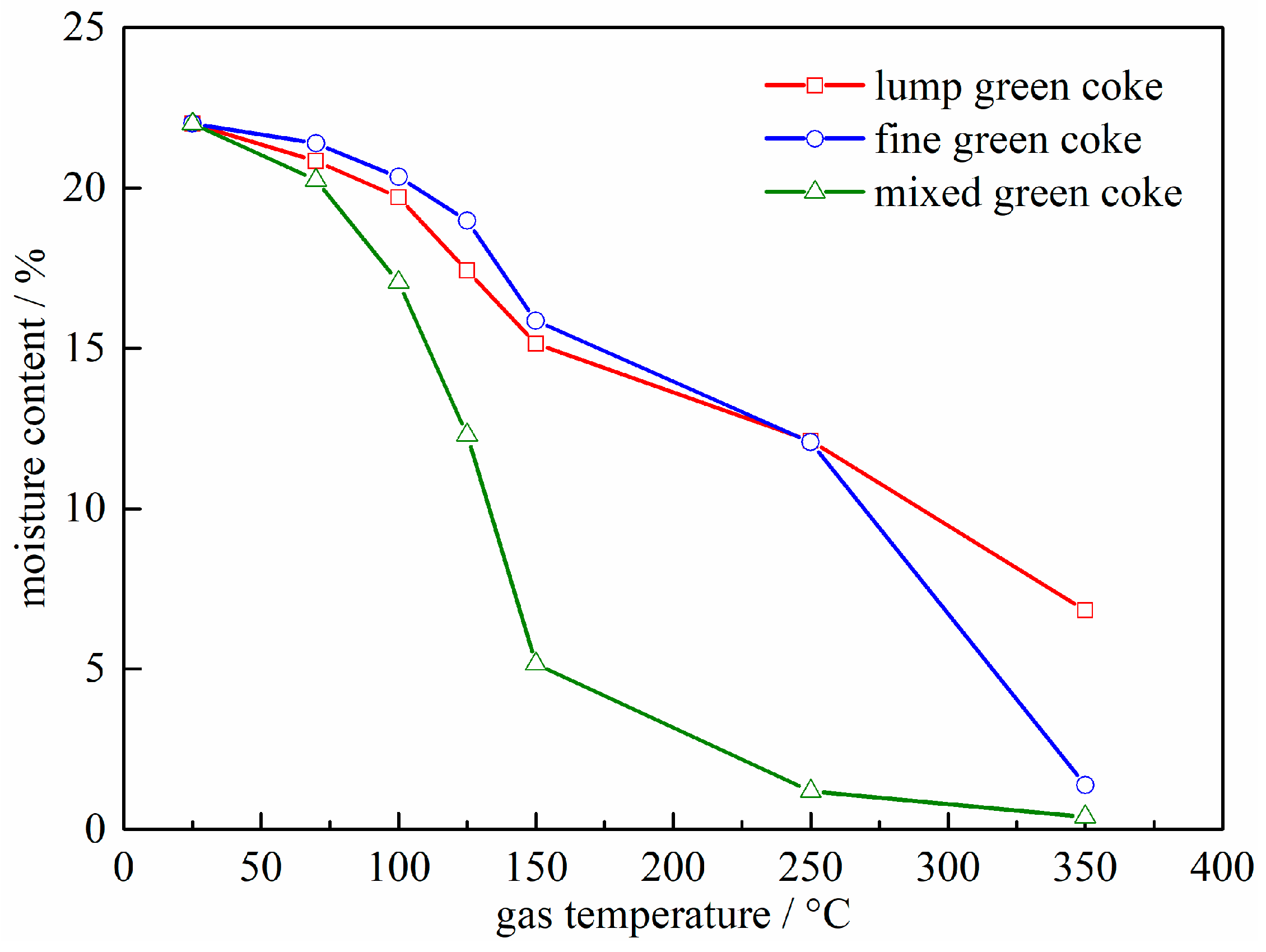

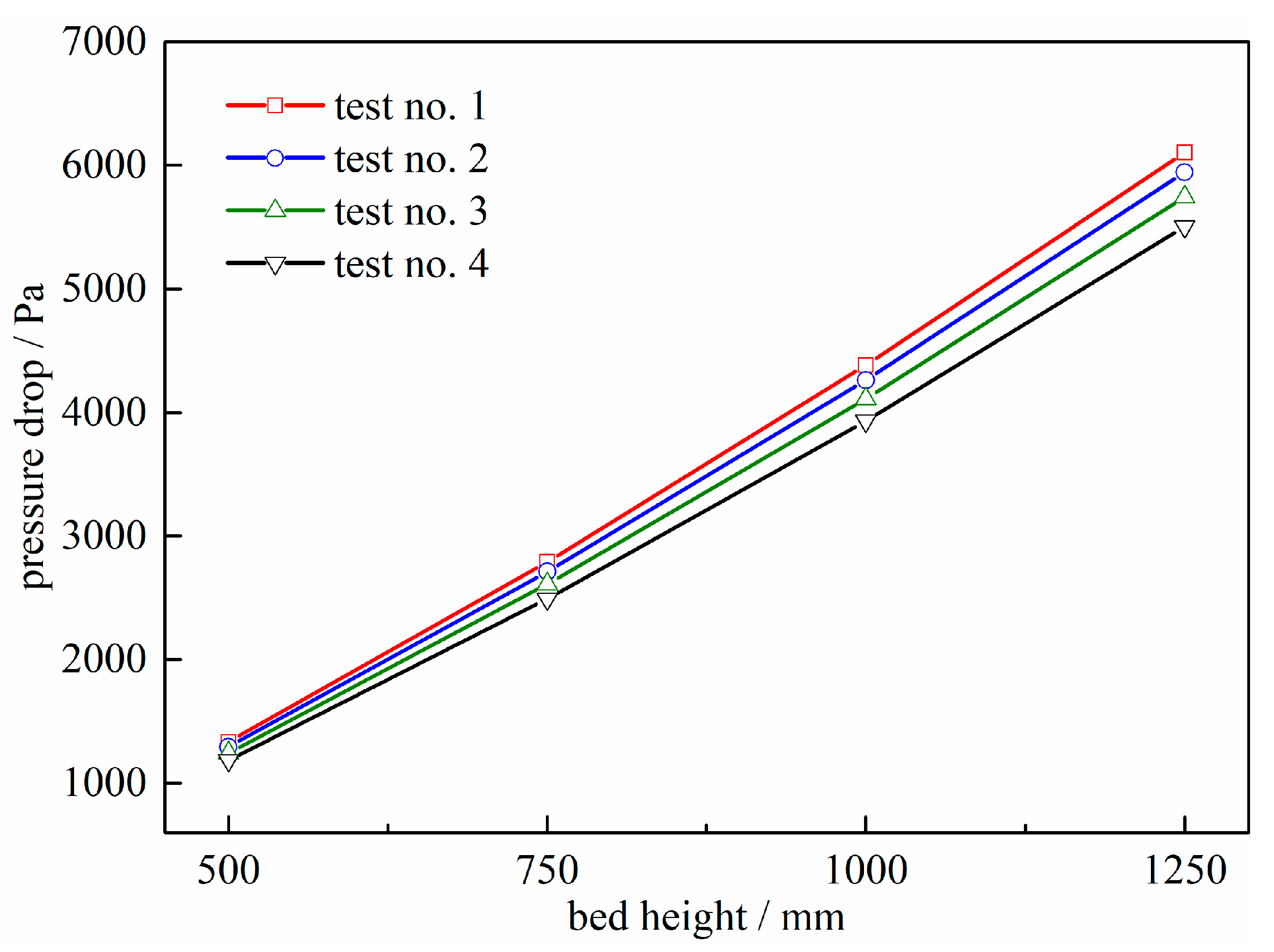

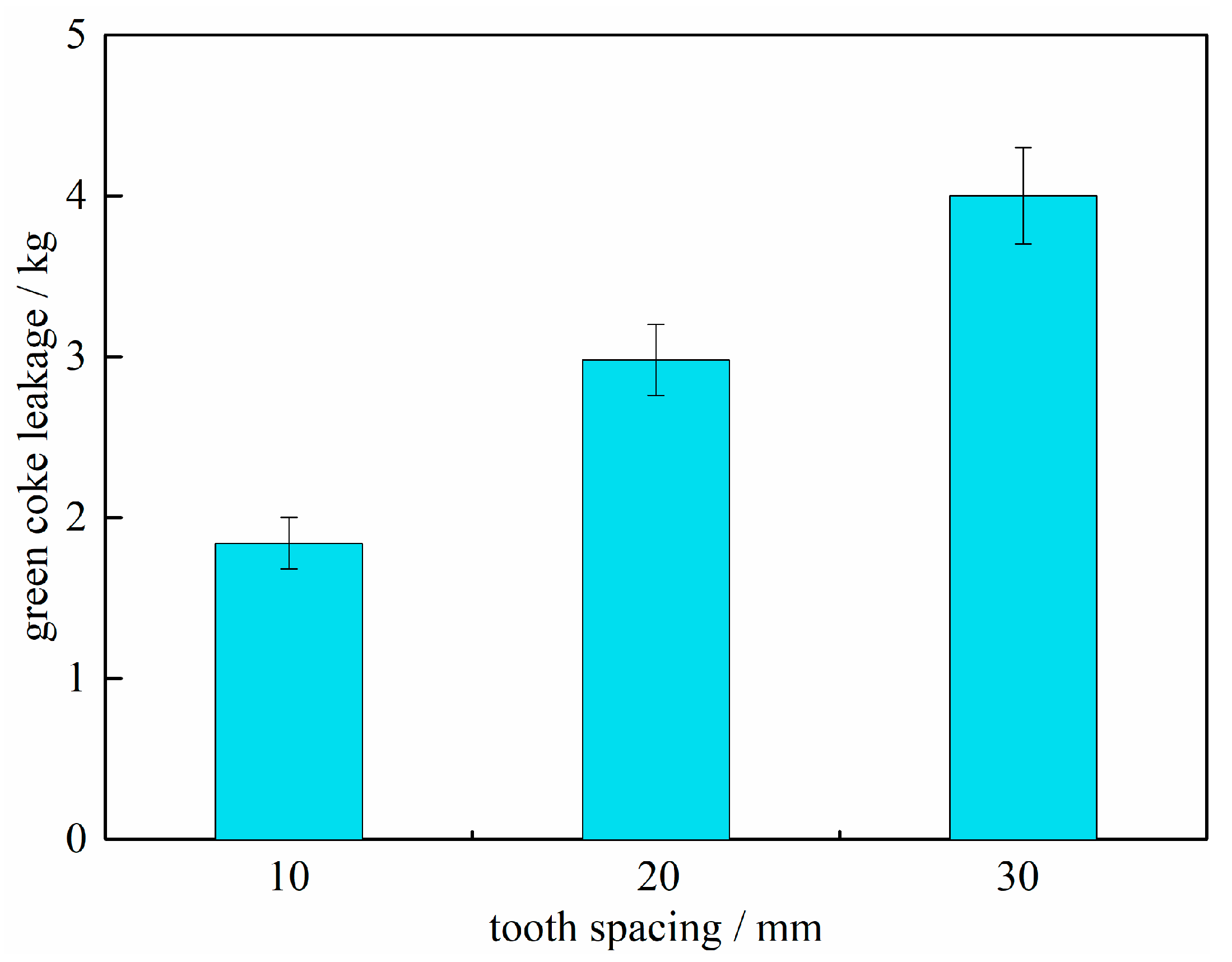

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Halim, H.P.; Im, J.S.; Lee, C.W. Preparation of needle coke from petroleum by-products. Carbon Lett. 2013, 14, 152–161. [Google Scholar] [CrossRef]

- Wang, R.; Lu, G.; Qiao, W.; Yu, J. Catalytic graphitization of coal-based carbon materials with light rare earth elements. Langmuir 2016, 32, 8583–8592. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Zhang, Y.; Lv, J.; Yang, H.; Wu, J. Energy-cyber-physical system enabled management for energy-intensive manufacturing industries. J. Clean. Prod. 2019, 226, 892–903. [Google Scholar] [CrossRef]

- Wang, J.; Gu, F.; Liu, Y.; Fan, Y.; Guo, J. Bidirectional interactions between trading behaviors and carbon prices in European Union emission trading scheme. J. Clean. Prod. 2019, 224, 435–443. [Google Scholar] [CrossRef]

- Guo, J.; Su, B.; Yang, G.; Feng, L.; Liu, Y.; Gu, F. How Do Verified Emissions Announcements Affect the Comoves between Trading Behaviors and Carbon Prices? Evidence from EU ETS. Sustainability 2018, 10, 3255. [Google Scholar] [CrossRef]

- Lv, J.; Gu, F.; Zhang, W.; Guo, J. Life cycle assessment and life cycle costing of sanitary ware manufacturing: A case study in China. J. Clean. Prod. 2019, 238, 117938. [Google Scholar] [CrossRef]

- Li, X.; Sun, W.; Zhao, L.; Cai, J. Emission characterization of particulate matter in the ironmaking process. Environ. Technol. 2019, 40, 282–292. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, W.; Li, X.; Ye, Z.; Huang, J.; Zhang, G.; Cai, J. Assessment of particulate emissions from a sinter plant in steelmaking works in China. Environ. Monit. Assess. 2017, 189, 368. [Google Scholar] [CrossRef]

- Xu, X.; Li, K.; Jia, H.; Yu, X.; Deng, J.; Mu, Y. Data-driven dynamic modeling of coupled thermal and electric outputs of microturbines. IEEE Trans. Smart Grid 2016, 9, 1387–1396. [Google Scholar] [CrossRef]

- Sun, W.; Wang, Y.; Zhang, F.; Zhao, Y. Dynamic allocation of surplus byproduct gas in steel plant by dynamic programming with reduced state space algorithm. Eng. Optim. 2018, 50, 1578–1592. [Google Scholar] [CrossRef]

- Sun, W.; Xu, X.; Lv, Z.; Mao, H.; Wu, J. Environmental impact assessment of wastewater discharge with multi-pollutants from iron and steel industry. J. Environ. Manag. 2019, 245, 210–215. [Google Scholar] [CrossRef]

- Li, X.; Sun, W.; Zhao, L.; Cai, J. Material metabolism and environmental emissions of BF-BOF and EAF steel production routes. Miner. Process. Extr. Metall. Rev. 2018, 39, 50–58. [Google Scholar] [CrossRef]

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, C.; Xu, Y.; Hu, C.; Zhao, X. Preparation and Characterization of Coal Pitch-Based Needle Coke (Part I): The Effects of Aromatic Index (fa) in Refined Coal Pitch. Energy Fuels 2019, 33, 3456–3464. [Google Scholar] [CrossRef]

- Kondrasheva, N.K.; Rudko, V.A.; Nazarenko, M.Y.; Povarov, V.G.; Derkunskii, I.; Konoplin, R.; Gabdulkhakov, R. Influence of parameters of delayed coking process and subsequent calcination on properties and morphology petroleum needle coke from decant oil mixture of west Siberian oil. Energy Fuels 2019, 33, 6373–6379. [Google Scholar] [CrossRef]

- Hardin, E.E.; Ellis, P.J.; Beilharz, C.L.; McCoy, L. A Comprehensive Review of the Effects of Calcination at Various Temperatures on Coke Structure and Properties Part II. In Essential Readings in Light Metals; Springer Science and Business Media LLC: Cham, Switzerland, 2016; Volume 4, pp. 73–83. [Google Scholar]

- Wang, Y.H.; Zhao, L.; Sun, W.Q.; Ye, Z.; Cai, J.J. Characteristics of particulate matter emissions from the coking process. Environ. Sci. 2018, 39, 5359–5364. [Google Scholar]

- Zhang, W.; Gu, F.; Guo, J. Can smart factories bring environmental benefits to their products? A case study of household refrigerators. J. Ind. Ecol. 2019. [Google Scholar] [CrossRef]

- Sun, W.; Xu, X.; Wu, J. Chlorine corrosion of blast furnace gas pipelines: Analysis from thermal perspective. J. Min. Met. Sect. B Met. 2019, 55, 197–208. [Google Scholar] [CrossRef]

- Liu, C.; Sang, S.; Zhang, K.; Song, F.; Wang, H.; Fan, X. Effects of temperature and pressure on pore morphology of different rank coals: Implications for CO2 geological storage. J. CO2 Util. 2019, 34, 343–352. [Google Scholar] [CrossRef]

- Zhang, W.; Guo, J.; Gu, F.; Gu, X. Coupling life cycle assessment and life cycle costing as an evaluation tool for developing product service system of high energy-consuming equipment. J. Clean. Prod. 2018, 183, 1043–1053. [Google Scholar] [CrossRef]

- Alonso, E.; Gallo, A.; Roldán, M.; Pérez-Rábago, C.; Fuentealba, E. Use of rotary kilns for solar thermal applications: Review of developed studies and analysis of their potential. Sol. Energy 2017, 144, 90–104. [Google Scholar] [CrossRef]

- Hernández, D.; Quinteros-Lama, H.; Tenreiro, C.; Gabriel, D. Assessing Concentration Changes of Odorant Compounds in the Thermal-Mechanical Drying Phase of Sediment-Like Wastes from Olive Oil Extraction. Appl. Sci. 2019, 9, 519. [Google Scholar] [CrossRef]

- Eremin, A.Y.; Stakheev, S.G.; Zagainov, N.V. Drying of coking batch by means of secondary energy resources. Coke Chem. 2017, 60, 185–188. [Google Scholar] [CrossRef]

- Yannick, E.R.; Abraham, T.F.; Marcel, E.; Alexis, K. Experimental Study of the Drying Kinetics of Mango (mangifera indica L.) during Airflow Drying Licking Countercurrent. Am. J. Food Sci. Technol. 2019, 7, 127–132. [Google Scholar] [CrossRef][Green Version]

- Si, C.; Wu, J.; Wang, Y.; Zhang, Y.; Shang, X. Drying of Low-Rank Coals: A Review of Fluidized Bed Technologies. Dry. Technol. 2015, 33, 277–287. [Google Scholar] [CrossRef]

- Liu, C.-H.; Zhang, L.-B.; Srinivasakannan, C.; Peng, J.-H.; Liu, B.-G.; Xia, H.-Y. Dielectric Properties and Optimization of Parameters for Microwave Drying of Petroleum Coke Using Response Surface Methodology. Dry. Technol. 2014, 32, 328–338. [Google Scholar] [CrossRef]

- Pang, M.; Peng, Y.; Zhou, P.; Du, Y. Thermodynamic modeling of the Hf-N system. J. Min. Met. Sect. B Met. 2018, 54, 111–118. [Google Scholar] [CrossRef]

- Lecompte, S.; Ntavou, E.; Tchanche, B.; Kosmadakis, G.; Pillai, A.; Manolakos, D.; De Paepe, M. Review of Experimental Research on Supercritical and Transcritical Thermodynamic Cycles Designed for Heat Recovery Application. Appl. Sci. 2019, 9, 2571. [Google Scholar] [CrossRef]

- Saucedo-Zendejo, F.; Reséndiz-Flores, E. Transient heat transfer and solidification modelling in direct-chill casting using a generalized finite differences method. J. Min. Met. Sect. B Met. 2019, 55, 47–54. [Google Scholar] [CrossRef]

- Sun, W.Q.; Yue, X.Y.; Wang, Y.H.; Cai, J.J. Energy and exergy recovery from exhaust hot water using ORC (organic Rankine cycle) and a retrofitted configuration. J. Cent. South Univ. 2018, 25, 1464–1474. [Google Scholar] [CrossRef]

- Sun, W.; Zhou, Y.; Lv, J.; Wu, J. Assessment of multi-air emissions: Case of particulate matter (dust), SO2, NOx, CO2 from iron and steel industry of China. J. Clean. Prod. 2019, 232, 350–358. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, F.; Zhu, Y.; Gong, B. Method of Desulfurization Process Selection Based on Improved Fuzzy Comprehensive Evaluation: A Case Study of Papermaking Desulfurization in China. Processes 2019, 7, 446. [Google Scholar] [CrossRef]

- Liu, J.; Yu, Q.; Zuo, Z.; Yang, F.; Han, Z.; Qin, Q. Reactivity and performance of dry granulation blast furnace slag cement. Cem. Concr. Compos. 2019, 95, 19–24. [Google Scholar] [CrossRef]

- Matiukhin, V.; Yaroshenko, Y.; Bulatov, K. On Modernization of Air Supply Systems for Improvement of Gas Distribution in Shaft Furnaces. Solid State Phenom. 2018, 284, 1390–1397. [Google Scholar] [CrossRef]

- Ozgen, F.; Celik, N. Evaluation of design parameters on drying of kiwi fruit. Appl. Sci. 2019, 9, 10. [Google Scholar] [CrossRef]

- Al-Kassir, A.; Coelho, P.; Garcia-Sanz-Calcedo, J.; Moral, F.J.; Al-Karany, R.K.; Yusaf, T. An Experimental Technology of Drying and Clean Combustion of Biomass Residues. Appl. Sci. 2018, 8, 905. [Google Scholar] [CrossRef]

- Prabakar, D.; Manimudi, V.T.; Mathimani, T.; Kumar, G.; Rene, E.R.; Pugazhendhi, A. Pretreatment technologies for industrial effluents: Critical review on bioenergy production and environmental concerns. J. Environ. Manag. 2018, 218, 165–180. [Google Scholar] [CrossRef]

- De Castro, J.A.; De Oliveira, E.M.; De Campos, M.F.; Takano, C.; Yagi, J.-I. Analyzing cleaner alternatives of solid and gaseous fuels for iron ore sintering in compacts machines. J. Clean. Prod. 2018, 198, 654–661. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, F.; Dai, F.; Gu, X.; Yue, F.; Bao, B. Decision framework for feasibility analysis of introducing the steam turbine unit to recover industrial waste heat based on economic and environmental assessments. J. Clean. Prod. 2016, 137, 1491–1502. [Google Scholar] [CrossRef]

- Prasai, T.P.; Walsh, K.B.; Midmore, D.J.; Jones, B.E.; Bhattarai, S.P. Manure from biochar, bentonite and zeolite feed supplemented poultry: Moisture retention and granulation properties. J. Environ. Manag. 2018, 216, 82–88. [Google Scholar] [CrossRef]

- Shiau, J.-S.; Ko, Y.-C.; Ho, C.-K.; Hung, M.-T. Results of tuyere coke sampling with regard to application of appropriate coke strength after reaction (CSR) for a blast furnace. J. Min. Met. Sect. B: Met. 2017, 53, 131–138. [Google Scholar] [CrossRef]

- Ali, S.S.; Basu, A.; Alfadul, S.M.; Asif, M. Nanopowder Fluidization Using the Combined Assisted Fluidization Techniques of Particle Mixing and Flow Pulsation. Appl. Sci. 2019, 9, 572. [Google Scholar] [CrossRef]

- Gu, F.; Guo, J.; Hall, P.; Gu, X. An integrated architecture for implementing extended producer responsibility in the context of Industry 4.0. Int. J. Prod. Res. 2019, 57, 1458–1477. [Google Scholar] [CrossRef]

| Method | Advantage | Disadvantage | Operation and Maintenance | Quality of Green Coke | Energy Efficiency (%) | Productivity | Capital Investment Cost |

|---|---|---|---|---|---|---|---|

| standing dehydration tank | simper tank structure; low energy consumption; high safety | uneven drying effect; low drying efficiency; unstable moisture content; large area occupied; high capital investment cost | easy | unstable moisture content | - | medium | high |

| rotary dryer | good drying effect; wide applicability; easy to achieve mechanization and automation; good uniformity of green coke; simple operation | multiple transmission components of the dryer, which need continual running repairs; large device, large area occupied, high capital investment cost; serious burning loss of green coke | difficult | easily polluted and over-burnt | 50–60 | high | high |

| tubular drier | sound safety; light abrasion of green coke | crushing is needed to meet the requirement on green coke particle size; poor drying effect; high failure rate of the dryer | difficult | serious breakage | 30–40 | low | medium |

| airflow dryer | short drying time; good drying effect; big drying capacity; simple dryer structure, small area occupied; easy for manufacture; low capital investment cost | high energy consumption; poor safety; serious dryer wear, short service life; refractory waste gas; crushing is needed to meet the requirement on green coke particle size | moderate | serious breakage | 60–75 | high | low |

| fluidized-bed dryer | big drying capacity; simple dryer structure | wall accretion and bed blocking easily occur; serious dust entrainment in waste gas; uneven drying of green coke; crushing is needed to meet the requirement on green coke particle size | easy | serious breakage | 50–60 | high | medium |

| microwave dryer | good drying effect | underdeveloped technology; high electricity consumption; safety concerns | easy | good | 25–35 | low | high |

| Test No. | Percentage of Size (0, 10) mm (%) | Percentage of Size [10, 30) mm (%) | Percentage of Size [30, 50) mm (%) | Percentage of Size [50, 70] mm (%) | Median Size (mm) |

|---|---|---|---|---|---|

| 1 | 37 | 26 | 12 | 25 | 26.85 |

| 2 | 32 | 25 | 17 | 26 | 29.00 |

| 3 | 33 | 23 | 11 | 33 | 30.45 |

| 4 | 32 | 20 | 13 | 35 | 31.80 |

| No. | Vertical Height (mm) | Hypotenuse (mm) | Vertex Angle (°) |

|---|---|---|---|

| 1 | 314 | 556 | 112 |

| 2 | 283 | 477 | 108 |

| 3 | 287 | 495 | 110 |

| 4 | 283 | 470 | 106 |

| 5 | 284 | 495 | 110 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, G.; Zhang, X.; Cai, J.; Sun, W.; Zhang, K.; Zhang, S. Development of a Novel Shaft Dryer for Coal-Based Green Needle Coke Drying Process. Appl. Sci. 2019, 9, 3301. https://doi.org/10.3390/app9163301

Xie G, Zhang X, Cai J, Sun W, Zhang K, Zhang S. Development of a Novel Shaft Dryer for Coal-Based Green Needle Coke Drying Process. Applied Sciences. 2019; 9(16):3301. https://doi.org/10.3390/app9163301

Chicago/Turabian StyleXie, Guowei, Xinxin Zhang, Jiuju Cai, Wenqiang Sun, Ketao Zhang, and Shiyu Zhang. 2019. "Development of a Novel Shaft Dryer for Coal-Based Green Needle Coke Drying Process" Applied Sciences 9, no. 16: 3301. https://doi.org/10.3390/app9163301

APA StyleXie, G., Zhang, X., Cai, J., Sun, W., Zhang, K., & Zhang, S. (2019). Development of a Novel Shaft Dryer for Coal-Based Green Needle Coke Drying Process. Applied Sciences, 9(16), 3301. https://doi.org/10.3390/app9163301