An EKF-Based Method and Experimental Study for Small Leakage Detection and Location in Natural Gas Pipelines

Abstract

1. Introduction

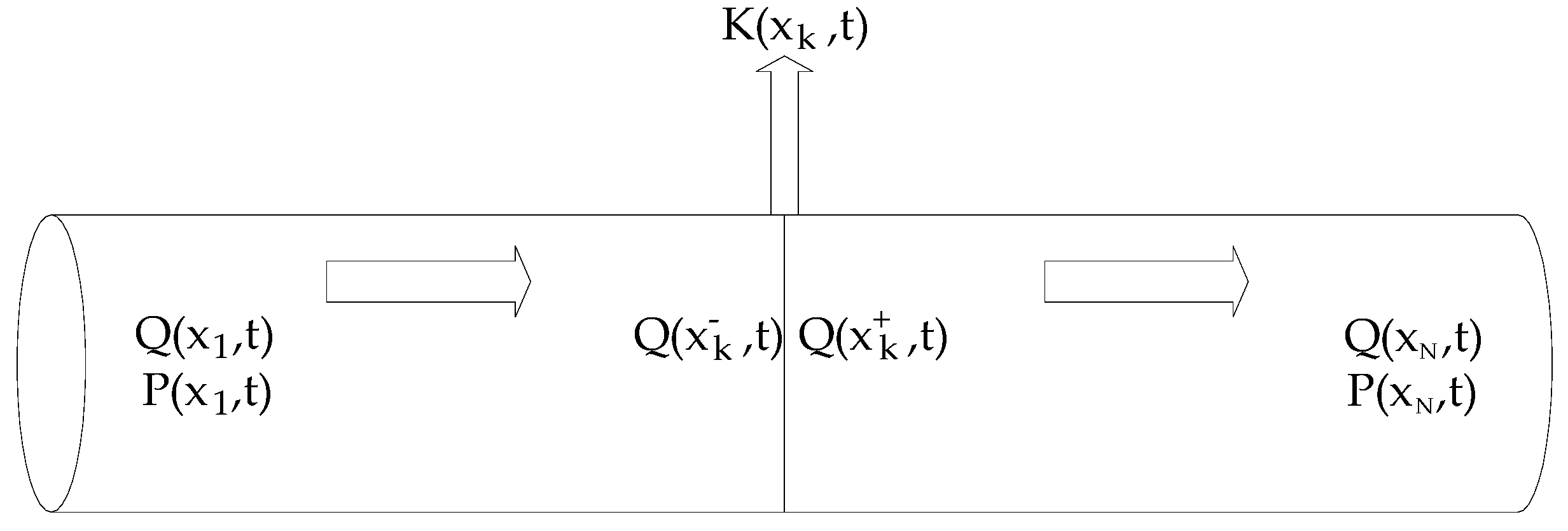

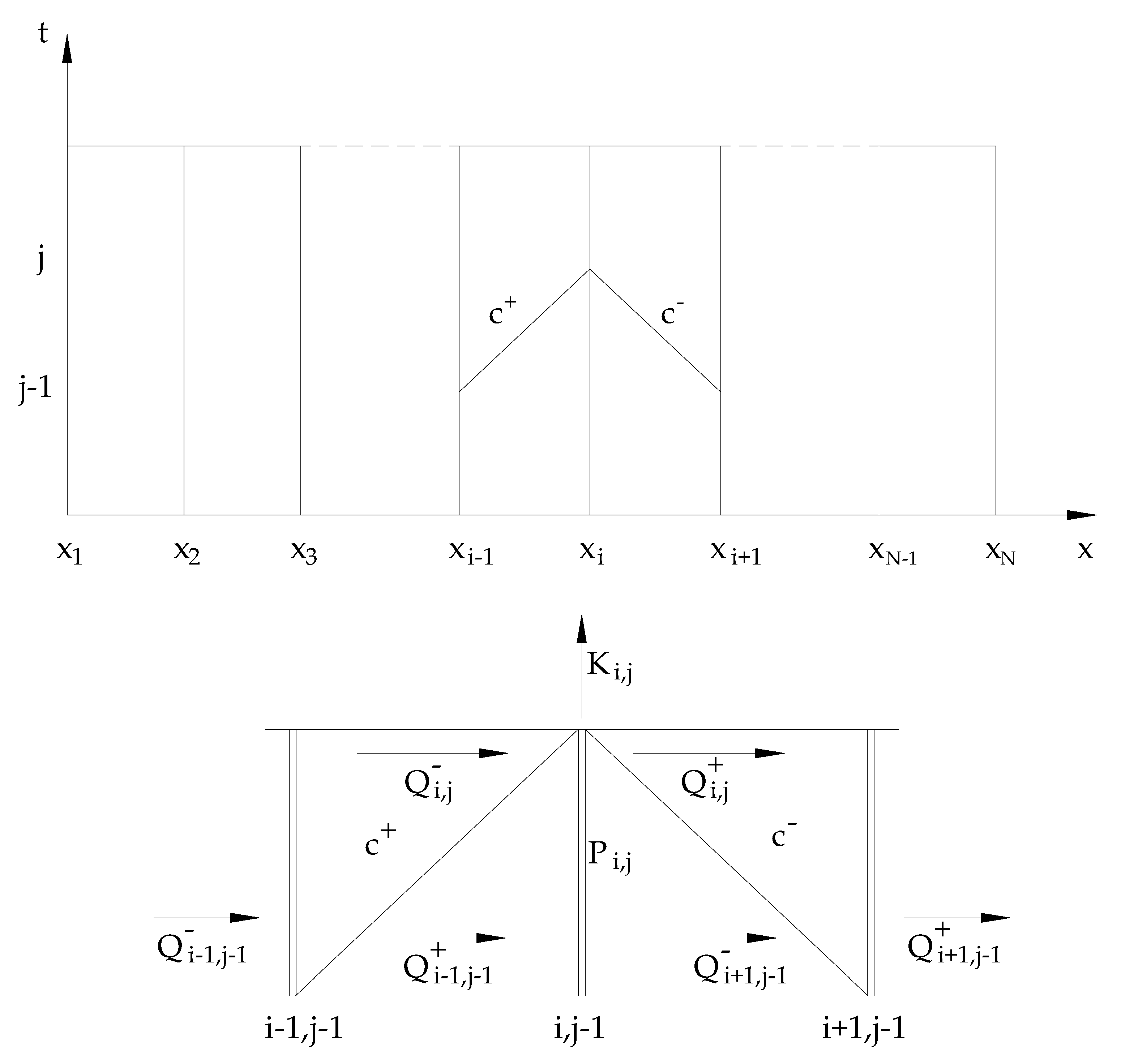

2. The Pipeline Transient Flow Model Containing the Virtual Multi-Point Leakages

3. State Estimation by EKF

- With the initial value , linearize the Equations near and obtain the transfer matrix ;

- Solve the nonlinear Equations (5)–(7), as , and can be computed and obtained: ; ;

- Use the following formula to compute the Kalman gain: ;

- Obtain the optimal estimate by measuring the valueobtain the optimal estimated variance matrix at time jobtain the optimal estimate by measuring the valueand obtain the optimal estimated variance matrix at time

- Go back to step 2 and calculate the optimal estimate of the moment . From the above computation, we can obtain the optimal estimation of the state vector .

4. Calculating the Actual Leakage Rate and Location

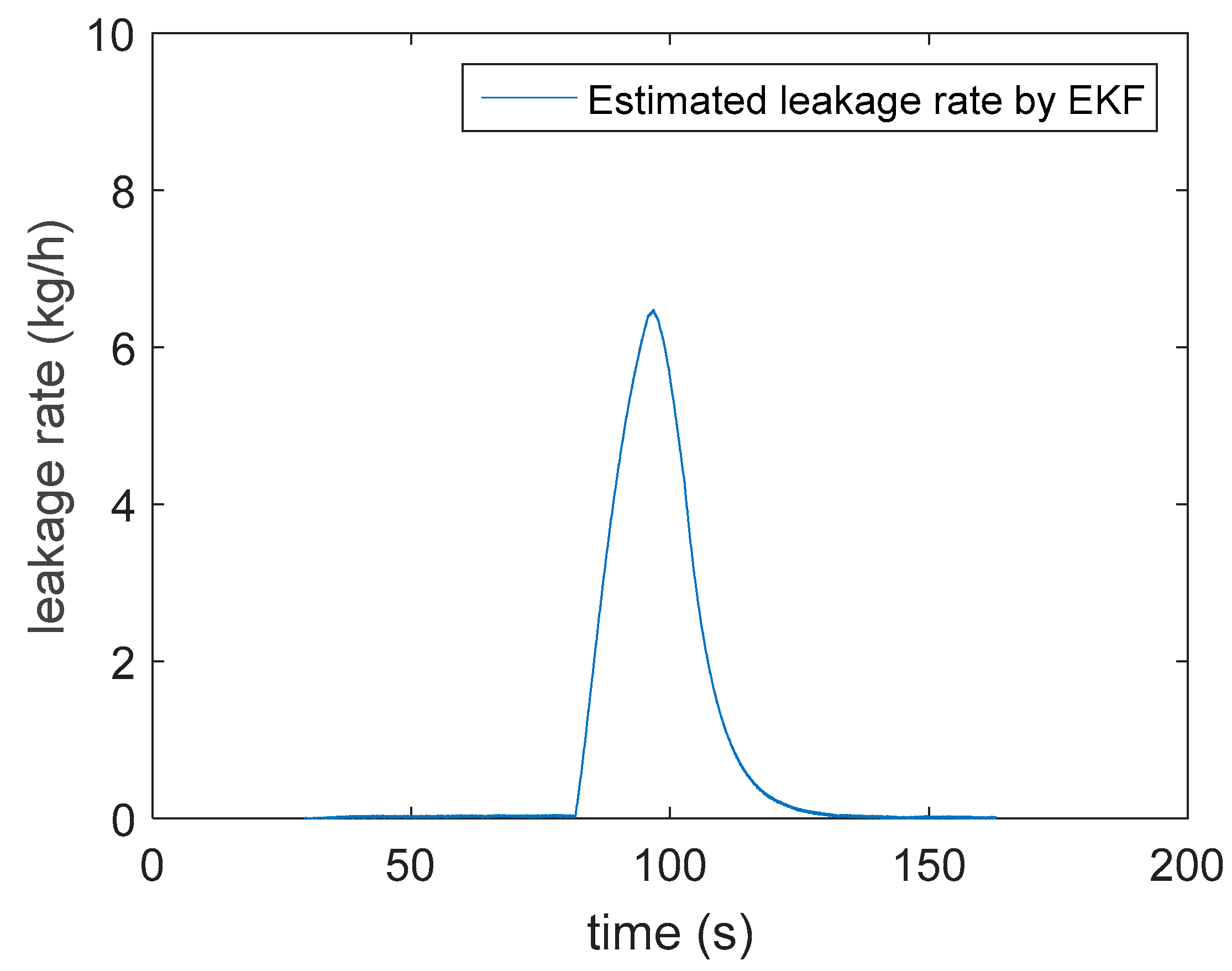

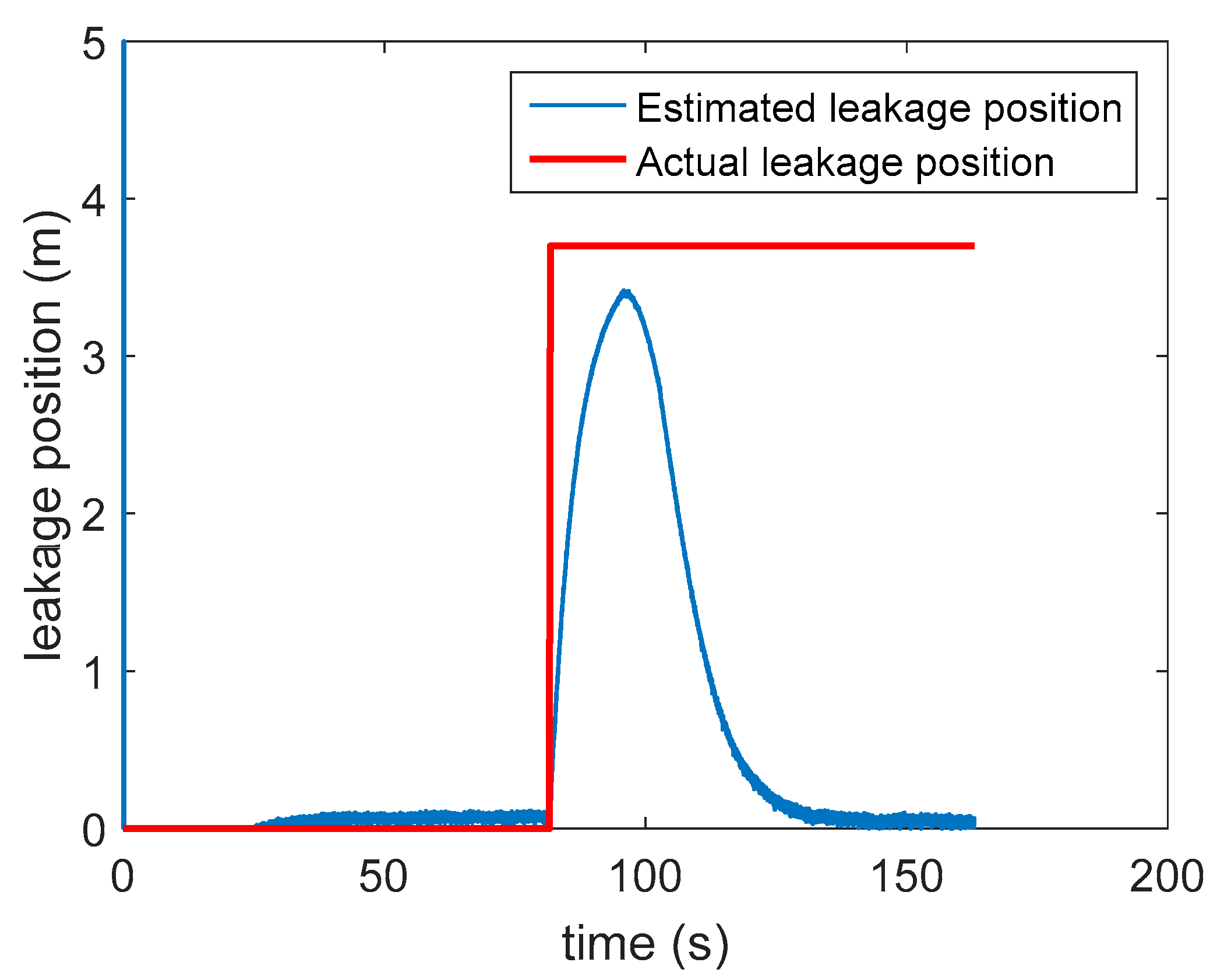

5. A Simulation Example

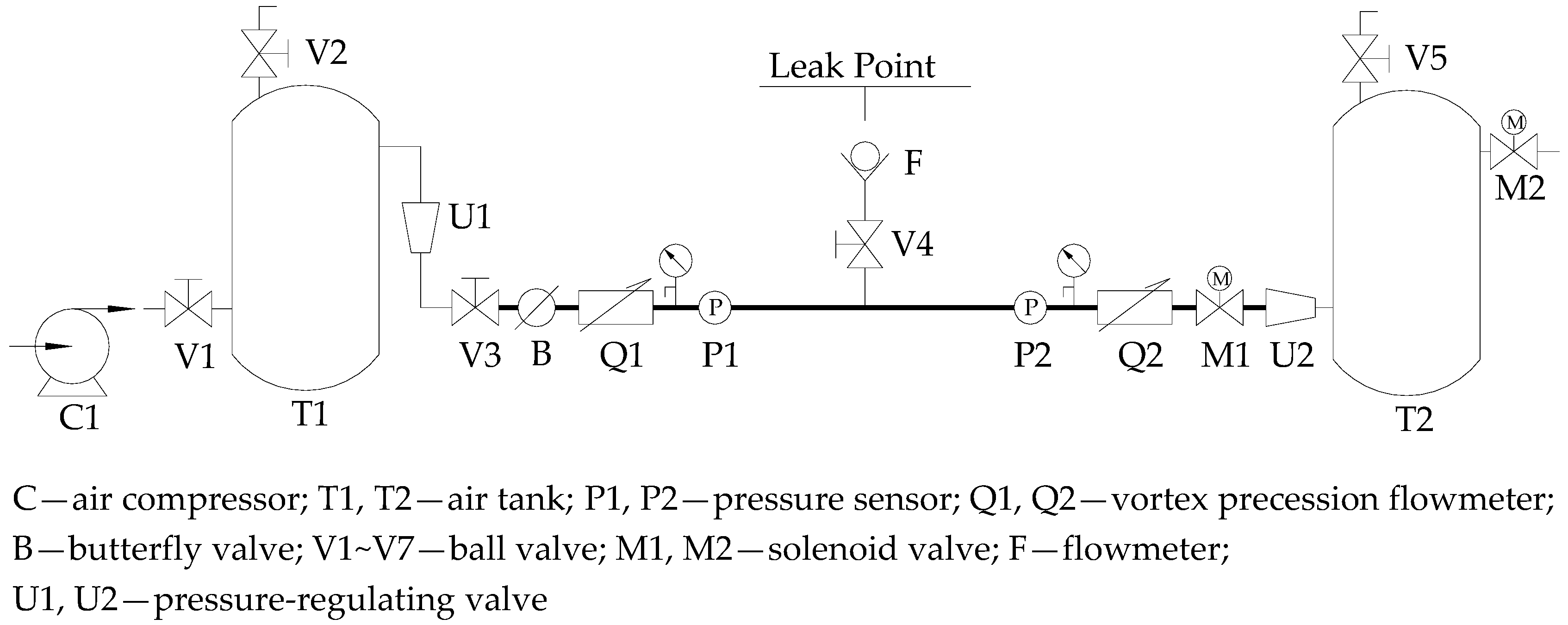

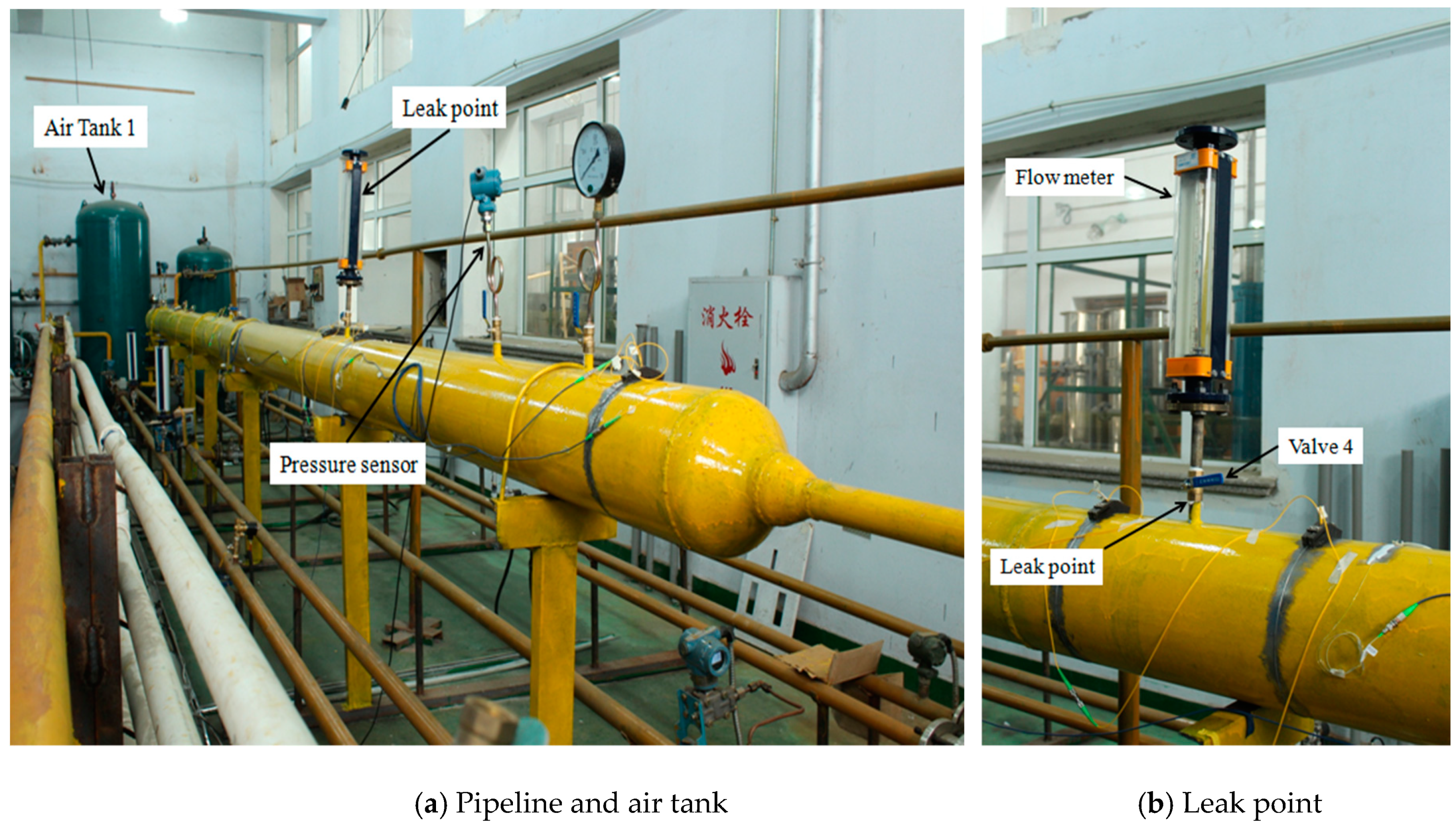

6. A Physical Experiment Case Study

- In order to simulate the actual natural gas pipelines, an air compressor is used to pressurize tank T1.

- Once a stable pressure is achieved, the valve M1 is opened to form the flow from T1 to T2.

- Adjusting the pressure of the gas storage tank and the opening of the butterfly valve B to maintain starting and ending pressures in the pipeline to be 800 and 750 kPa, respectively. At this point, the flow rate at the beginning of the pipeline is 132 kg/h and all the sensors begin to collect data.

- After 80 s, the ball valve V4 is open to a certain degree to allow a leak at leak point 1.

7. Conclusion and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Montiel, H.; Vilchez, J.; Casal, J.; Arnaldos, J. Mathematical modelling of accidental gas releases. J. Hazard. Mater. 1998, 59, 211–233. [Google Scholar] [CrossRef]

- Kostowski, W.J.; Skorek, J. Real gas flow simulation in damaged distribution pipelines. Energy 2012, 45, 481–488. [Google Scholar] [CrossRef]

- Bariha, N.; Mishra, I.M.; Srivastava, V.C. Hazard analysis of failure of natural gas and petroleum gas pipelines. J. Loss Prev. Process Ind. 2016, 40, 217–226. [Google Scholar] [CrossRef]

- Damavandi, M.Y.; Kiaei, I.; Sheikh-El-Eslami, M.K.; Seifi, H.; Sheikh-El-Eslami, M.K. New approach to gas network modeling in unit commitment. Energy 2011, 36, 6243–6250. [Google Scholar] [CrossRef]

- Fu, Z.M.; Huang, J.Y.; Fu, M. Quantitative analysis of thermal radiation damaging effects caused by liquid or gaseous hydrocarbon fires. China Saf. Sci. J. 2008, 18, 29–36. [Google Scholar]

- Szente, V.; Vad, J.A. Semi-empirical model for characterisation of flow coefficient for pneumatic solenoid valves. Periodica Polytech. Mech. Eng. 2004, 47, 131–142. [Google Scholar]

- Demissie, A.; Zhu, W.; Belachew, C.T. A multi-objective optimization model for gas pipeline operations. Comput. Chem. Eng. 2017, 100, 94–103. [Google Scholar] [CrossRef]

- Zeng, X.; Dong, F.-F.; Xie, X.-D.; Du, G.-F. A new analytical method of strain and deformation of pipeline under fault movement. Int. J. Press. Vessels Pip. 2019, 172, 199–211. [Google Scholar] [CrossRef]

- Zhu, J.; Ho, S.C.M.; Patil, D.; Wang, N.; Hirsch, R.; Song, G. Underwater pipeline impact localization using piezoceramic transducers. Smart Mater. Struct. 2017, 26, 107002. [Google Scholar] [CrossRef]

- Jiang, T.; Ren, L.; Jia, Z.; Li, D.; Li, H. Application of FBG Based Sensor in Pipeline Safety Monitoring. Appl. Sci. 2017, 7, 540–551. [Google Scholar] [CrossRef]

- Siswantoro, N.; Doğan, A.; Priyanta, D.; Zaman, M.B.; Semin, S. Possibility of Piezoelectric Sensor to Monitor Onshore Pipeline in Real Time Monitoring. Int. J. Mar. Eng. Innov. Res. 2019, 3, 199–211. [Google Scholar] [CrossRef]

- Von Fischer, J.C.; Cooley, D.; Chamberlain, S.; Gaylord, A.; Griebenow, C.J.; Hamburg, S.P.; Salo, J.; Schumacher, R.; Theobald, D.; Ham, J. Rapid, vehicle-based identification of location and magnitude of urban natural gas pipeline leaks. Environ. Sci. Technol. 2017, 51, 4091–4099. [Google Scholar] [CrossRef] [PubMed]

- Pham, H.Q.; Tran, B.V.; Doan, D.T.; Le, V.S.; Pham, Q.N.; Kim, K.; Kim, C.; Terki, F.; Tran, Q.H. Highly Sensitive Planar Hall Magnetoresistive Sensor for Magnetic Flux Leakage Pipeline Inspection. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Chen, Q.; Shen, G.; Jiang, J.; Diao, X.; Wang, Z.; Ni, L.; Dou, Z. Effect of rubber washers on leak location for assembled pressurized liquid pipeline based on negative pressure wave method. Process Saf. Environ. Prot. 2018, 119, 181–190. [Google Scholar] [CrossRef]

- Ge, C.; Wang, G.; Ye, H. Analysis of the smallest detectable leakage flow rate of negative pressure wave-based leak detection systems for liquid pipelines. Comput. Chem. Eng. 2008, 32, 1669–1680. [Google Scholar] [CrossRef]

- Silva, R.A.; Buiatti, C.M.; Cruz, S.L.; Pereira, J.A.F.R. Pressure wave behavior and leak detection in pipelines. Comput. Chem. Eng. 1996, 20, 491–496. [Google Scholar] [CrossRef]

- Yashiro, S.; Okabe, T.; Takeda, N. Damage identification in a holed CFRP laminate using a chirped fiber Bragg grating sensor. Compos. Sci. Technol. 2007, 67, 286–295. [Google Scholar] [CrossRef]

- Tsuda, H.; Lee, J.-R.; Guan, Y. Fatigue crack propagation monitoring of stainless steel using fiber Bragg grating ultrasound sensors. Smart Mater. Struct. 2006, 15, 1429. [Google Scholar] [CrossRef]

- Ali, S.; Bin Qaisar, S.; Saeed, H.; Khan, M.F.; Naeem, M.; Anpalagan, A. Network Challenges for Cyber Physical Systems with Tiny Wireless Devices: A Case Study on Reliable Pipeline Condition Monitoring. Sensors 2015, 15, 7172–7205. [Google Scholar] [CrossRef]

- Huo, L.; Li, C.; Jiang, T.; Li, H.-N. Feasibility Study of Steel Bar Corrosion Monitoring Using a Piezoceramic Transducer Enabled Time Reversal Method. Appl. Sci. 2018, 8, 2304–2317. [Google Scholar] [CrossRef]

- Soojin, C.; Yun, C.; Lynch, J.P.; Zimmerman, A.T. Smart Wireless Sensor Technology for Structural Health Monitoring of Civil Structures. Steel Struct. 2008, 8, 267–275. [Google Scholar]

- Soojin, C.; Lynch, J.P.; Lee, J.J. Development of an Automated Wireless Tension Force Estimation System for Cable-stayed Bridges. J. Intell. Mater. Syst. Struct. 2009, 21, 361–376. [Google Scholar]

- Jang, S.; Jo, H.; Cho, S.; Mechitov, K.; Rice, J.A.; Sim, S.-H.; Jung, H.-J.; Yun, C.-B.; Spencer, B.F.J.; Agha, G. Structural health monitoring of a cable-stayed bridge using smart sensor technology: Deployment and evaluation. Smart Struct. Syst. 2010, 6, 439–459. [Google Scholar] [CrossRef]

- Song, G.; Wang, C.; Wang, B. Structural Health Monitoring (SHM) of Civil Structures. Appl. Sci. 2018, 7, 789–791. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, L.; Liu, L.; Huo, L. Prestress Monitoring of a Steel Strand in an Anchorage Connection Using Piezoceramic Transducers and Time Reversal Method. Sensors 2018, 18, 4018–4037. [Google Scholar] [CrossRef] [PubMed]

- Mitra, M.; Gopalakrishnan, S. Guided wave based structural health monitoring: A review. Smart Mater. Struct. 2016, 25, 053001. [Google Scholar] [CrossRef]

- Kong, Q.; Robert, R.H.; Silva, P.; Mo, Y.L. Cyclic Crack Monitoring of a Reinforced Concrete Column under Simulated Pseudo-Dynamic Loading Using Piezoceramic-Based Smart Aggregates. Appl. Sci. 2016, 6, 341–354. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, X.; Hao, H.; Ou, J. Guided wave propagation and spectral element method for debonding damage assessment in RC structures. J. Sound Vib. 2009, 324, 751–772. [Google Scholar] [CrossRef]

- Lu, G.; Li, Y.; Wang, T.; Xiao, H.; Xiao, H. A multi-delay-and-sum imaging algorithm for damage detection using piezoceramic transducers. J. Intell. Mater. Syst. Struct. 2017, 28, 1150–1159. [Google Scholar] [CrossRef]

- Yang, J.; Choi, J.; Hwang, S.; An, Y.-K.; Sohn, H. A reference-free micro defect visualization using pulse laser scanning thermography and image processing. Meas. Sci. Technol. 2016, 27, 085601–085610. [Google Scholar] [CrossRef]

- Hou, J.; Wang, P.; Jing, T.; Jankowski, Ł. Experimental Study for Damage Identification of Storage Tanks by Adding Virtual Masses. Sensors 2019, 19, 220–236. [Google Scholar] [CrossRef] [PubMed]

- Kim, N.; Jang, K.; An, Y.-K. Self-Sensing Nonlinear Ultrasonic Fatigue Crack Detection under Temperature Variation. Sensors 2018, 18, 2527–2541. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Liu, H.; Annamdas, V.G.M.; Soh, C.K. Monitoring damage propagation using PZT impedance transducers. Smart Mater. Struct. 2009, 18, 045003. [Google Scholar] [CrossRef]

- John, S.; Sirohi, J.; Wang, G.; Wereley, N.M. Comparison of piezoelectric, magnetostrictive, and electrostrictive hybrid hydraulic actuators. J. Intell. Mater. Syst. Struct. 2007, 18, 1035–1048. [Google Scholar] [CrossRef]

- An, Y.-K.; Shen, Z.; Wu, Z. Stripe-PZT Sensor-Based Baseline-Free Crack Diagnosis in a Structure with a Welded Stiffener. Sensors 2016, 16, 1511–1529. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Ho, S.C.M.; Huo, L.; Song, G. A novel fractal contact-electromechanical impedance model for quantitative monitoring of bolted joint looseness. IEEE Access 2018, 6, 40212–40220. [Google Scholar] [CrossRef]

- Kong, Q.; Fan, S.; Bai, X.; Mo, Y.L.; Song, G. A novel embeddable spherical smart aggregate for structural health monitoring: Part I. Fabrication and electrical characterization. Smart Mater. Struct. 2017, 26, 095050. [Google Scholar] [CrossRef]

- Kong, Q.; Fan, S.; Mo, Y.L.; Song, G. A novel embeddable spherical smart aggregate for structural health monitoring: Part II. Numerical and experimental verifications. Smart Mater. Struct. 2017, 26, 095051. [Google Scholar] [CrossRef]

- Dumoulin, C.; Deraemaeker, A. Real-time fast ultrasonic monitoring of concrete cracking using embedded piezoelectric transducers. Smart Mater. Struct. 2017, 26, 104006. [Google Scholar] [CrossRef]

- Ghimire, M.; Wang, C.; Dixon, K.; Serrato, M. In situ monitoring of prestressed concrete using embedded fiber loop ringdown strain sensor. Measurement 2018, 124, 224–232. [Google Scholar] [CrossRef]

- Tejedor, J.; Macias-Guarasa, J.; Martins, H.F.; Piote, D.; Pastor-Graells, J.; Martin-Lopez, S.; Corredera, P.; Gonzalez-Herraez, M. A Novel Fiber Optic Based Surveillance System for Prevention of Pipeline Integrity Threats. Sensors 2017, 17, 355–373. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.; Ho, S.C.M.; Song, G.; Cai, C.S. Scour Monitoring System Using Fiber Bragg Grating Sensors and Water-Swellable Polymers. J. Bridg. Eng. 2017, 22, 04017029–04017039. [Google Scholar] [CrossRef]

- Meng, L.; Wang, L.; Hou, Y. Development of Large-Strain Macrobend Optical-Fiber Sensor with Helical-Bending Structure for Pavement Monitoring Application. J. Aerosp. Eng. 2019, 32, 04019021–04019030. [Google Scholar] [CrossRef]

- Zhang, G.; Zhu, J.; Song, Y.; Peng, C.; Song, G. A Time Reversal Based Pipeline Leakage Localization Method with the Adjustable Resolution. IEEE Access 2018, 6, 26993–27000. [Google Scholar] [CrossRef]

- Chen, B.; Hei, C.; Luo, M.; Ho, M.S.C.; Song, G.; Chuang, H. Pipeline two-dimensional impact location determination using time of arrival with instant phase (TOAIP) with piezoceramic transducer array. Smart Mater. Struct. 2018, 27, 105003. [Google Scholar] [CrossRef]

- Du, G.; Kong, Q.; Zhou, H.; Gu, H. Multiple Cracks Detection in Pipeline Using Damage Index Matrix Based on Piezoceramic Transducer-Enabled Stress Wave Propagation. Sensors 2017, 17, 1812–1822. [Google Scholar] [CrossRef] [PubMed]

- Ren, L.; Jiang, T.; Jia, Z.-G.; Li, D.-S.; Yuan, C.-L.; Li, H.-N. Pipeline corrosion and leakage monitoring based on the distributed optical fiber sensing technology. Measurement 2018, 122, 57–65. [Google Scholar] [CrossRef]

- Zhao, X.; Li, W.; Zhou, L.; Song, G.; Ba, Q.; Ho, S.C.M.; Ou, J. Application of support vector machine for pattern classification of active thermometry based pipeline scour monitoring. Struct. Control Health Monit. 2015, 22, 903–918. [Google Scholar] [CrossRef]

- Jia, Z.; Ren, L.; Li, H.; Wu, W.; Jiang, T. Performance Study of FBG Hoop Strain Sensor for Pipeline Leak Detection and Localization. J. Aerosp. Eng. 2018, 31, 04018050–04018059. [Google Scholar] [CrossRef]

- Hou, Q.; Jiao, W.; Ren, L.; Cao, H.; Song, G. Experimental study of leakage detection of natural gas pipeline using FBG based strain sensor and least square support vector machine. J. Loss Prev. Process. Ind. 2014, 32, 144–151. [Google Scholar] [CrossRef]

- Zhu, J.; Ren, L.; Ho, S.C.M.; Jia, Z.; Song, G. Gas pipeline leakage detection based on PZT sensors. Smart Mater. Struct. 2017, 26, 025022. [Google Scholar] [CrossRef]

- Jia, Z.G.; Ren, L.; Li, H.N.; Ho, S.; Song, G. Experimental study of pipeline leak detection based on hoop strain measurement. Struct. Control Health Monit. 2015, 22, 799–812. [Google Scholar] [CrossRef]

- Ren, L.; Jia, Z.-G.; Li, H.-N.; Song, G. Design and experimental study on FBG hoop-strain sensor in pipeline monitoring. Opt. Fiber Technol. 2014, 20, 15–23. [Google Scholar] [CrossRef]

- Hou, Q.; Ren, L.; Jiao, W.; Zou, P.; Song, G. An Improved Negative Pressure Wave Method for Natural Gas Pipeline Leak Location Using FBG Based Strain Sensor and Wavelet Transform. Math. Probl. Eng. 2013, 2013, 1–8. [Google Scholar] [CrossRef]

- Wang, F.; Huo, L.; Song, G. A piezoelectric active sensing method for quantitative monitoring of bolt loosening using energy dissipation caused by tangential damping based on the fractal contact theory. Smart Mater. Struct. 2017, 27, 015023. [Google Scholar] [CrossRef]

- Huynh, T.-C.; Dang, N.-L.; Kim, J.-T. Preload Monitoring in Bolted Connection Using Piezoelectric-Based Smart Interface. Sensors 2018, 18, 2766–2785. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.; Wang, T.; Yang, D.; Liu, S.; Shao, J.; Li, Y. A Smart Washer for Bolt Looseness Monitoring Based on Piezoelectric Active Sensing Method. Appl. Sci. 2016, 6, 320–329. [Google Scholar] [CrossRef]

- Du, G.F.; Kong, Q.Z.; Wu, F.H.; Ruan, J.; Song, G. An experimental feasibility study of pipeline corrosion pit detection using a piezoceramic time reversal mirror. Smart Mater. Struct. 2016, 25, 037002. [Google Scholar] [CrossRef]

- Peng, J.; Hu, S.; Zhang, J.; Cai, C.; Li, L.-Y. Influence of cracks on chloride diffusivity in concrete: A five-phase mesoscale model approach. Constr. Build. Mater. 2019, 197, 587–596. [Google Scholar] [CrossRef]

- Li, X.; Bai, Y.; Su, C.; Li, M. Effect of interaction between corrosion defects on failure pressure of thin wall steel pipeline. Int. J. Press. Vessels Pip. 2016, 138, 8–18. [Google Scholar] [CrossRef]

- Khante, S.N.; Jain, N. Erosion Identification and Assessment of a Steel Pipeline Using EMI Technique; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2018; pp. 347–355. [Google Scholar]

- Du, G.; Kong, Q.; Lai, T.; Song, G. Feasibility Study on Crack Detection of Pipelines Using Piezoceramic Transducers. Int. J. Distrib. Sens. Netw. 2013. [Google Scholar] [CrossRef]

- Camerini, C.; Rebello, J.M.A.; Braga, L.; Santos, R.; Chady, T.; Psuj, G.; Pereira, G. In-Line Inspection Tool with Eddy Current Instrumentation for Fatigue Crack Detection. Sensors 2018, 18, 2161–2172. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Luo, M.; Liu, Q.; Du, G.; Song, G. PZT transducer array enabled pipeline defect locating based on time-reversal method and matching pursuit de-noising. Smart Mater. Struct. 2019, 28. [Google Scholar] [CrossRef]

- Evgeniou, T.; Pontil, M.; Poggio, T. Regularization Networks and Support Vector Machines. Adv. Comput. Math. 2000, 13, 1–50. [Google Scholar] [CrossRef]

- Geiger, G.; Bollermann, B.; Tetzner, R. Leak monitoring of an ethylene gas pipeline. In Proceedings of the PSIG Annual Meeting, Palm Springs, CA, USA, 20–22 October 2004. [Google Scholar]

- Julier, S.J.; Uhlmann, J.K. New extension of the Kalman filter to nonlinear systems. In Proceedings of the AeroSense ’97, Orlando, FL, USA, 20–25 April 1997; pp. 182–193. [Google Scholar]

- Xie, L.; Zhou, Z.; Zhao, L.; Wan, C.; Tang, H.; Xue, S. Parameter Identification for Structural Health Monitoring with Extended Kalman Filter Considering Integration and Noise Effect. Appl. Sci. 2018, 8, 2480–2498. [Google Scholar] [CrossRef]

- Hao, Y.; Xu, A.; Sui, X.; Wang, Y. A Modified Extended Kalman Filter for a Two-Antenna GPS/INS Vehicular Navigation System. Sensors 2018, 18, 3809–3830. [Google Scholar] [CrossRef] [PubMed]

- Pointon, H.A.G.; McLoughlin, B.J.; Matthews, C.; Bezombes, F.A. Towards a Model Based Sensor Measurement Variance Input for Extended Kalman Filter State Estimation. Drones 2019, 3, 19–37. [Google Scholar] [CrossRef]

- Ko, N.Y.; Youn, W.; Choi, I.H.; Song, G.; Kim, T.S. Features of Invariant Extended Kalman Filter Applied to Unmanned Aerial Vehicle Navigation. Sensors 2018, 18, 2855–2880. [Google Scholar] [CrossRef] [PubMed]

- Verde, C. Leakage location in pipelines by minimal order nonlinear observer. In Proceedings of the 2001 American Control Conference (Cat. No.01CH37148), Arlington, VA, USA, 25–27 June 2001; pp. 1733–1738. [Google Scholar]

- Xiao, M.L.; Zhang, Y.B. An adaptive three-stage extended Kalman filter for Nonlinear discrete-time system in presence of unknown inputs. ISA Trans. 2018, 75, 101–117. [Google Scholar] [CrossRef] [PubMed]

- Benkherouf, A. Leak detection and location in gas pipelines. Control Theory Appl. 1998, 135, 142–148. [Google Scholar] [CrossRef]

- Gomm, J. Adaptive neural network approach to on-line learning for process fault diagnosis. Trans. Inst. Meas. Control. 1998, 20, 144–152. [Google Scholar] [CrossRef]

- Cui, W. Kalman Filter Based Fault Detection and Diagnosis. Master’s Thesis, Flinders University, College of Science and Engineering, Bedford Park, Australia, 2018. [Google Scholar]

- Nguyen, L.H.; Goulet, J.-A. Anomaly detection with the Switching Kalman Filter for structural health monitoring. Struct. Control Health Monit. 2018, 25, e2136. [Google Scholar] [CrossRef]

- Sergey, A.B.; Oleg, F.L. Waves Attenuation and the Pressure Surge Method Performance. In Proceedings of the PSIG Annual Meeting, Calgary, AB, Canada, 23–26 October 2007. [Google Scholar]

- Ge, C.; Ye, H.; Wang, G.; Yang, H. A fast leak locating method based on wavelet transform. Tsinghua Sci. Technol. 2009, 14, 551–555. [Google Scholar] [CrossRef]

- Zhang, L.-B.; Qin, X.-Y.; Wang, Z.-H.; Liang, W. Designing a reliable leak detection system for West Products Pipeline. J. Loss Prev. Process Ind. 2009, 22, 981–989. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Q.; Zhu, W. An EKF-Based Method and Experimental Study for Small Leakage Detection and Location in Natural Gas Pipelines. Appl. Sci. 2019, 9, 3193. https://doi.org/10.3390/app9153193

Hou Q, Zhu W. An EKF-Based Method and Experimental Study for Small Leakage Detection and Location in Natural Gas Pipelines. Applied Sciences. 2019; 9(15):3193. https://doi.org/10.3390/app9153193

Chicago/Turabian StyleHou, Qingmin, and Weihang Zhu. 2019. "An EKF-Based Method and Experimental Study for Small Leakage Detection and Location in Natural Gas Pipelines" Applied Sciences 9, no. 15: 3193. https://doi.org/10.3390/app9153193

APA StyleHou, Q., & Zhu, W. (2019). An EKF-Based Method and Experimental Study for Small Leakage Detection and Location in Natural Gas Pipelines. Applied Sciences, 9(15), 3193. https://doi.org/10.3390/app9153193