Field Optimization and Electrostatic Stress Reduction of Proposed Conductor Scheme for Pliable Gas-Insulated Transmission Lines

Abstract

:Featured Application

Abstract

1. Introduction

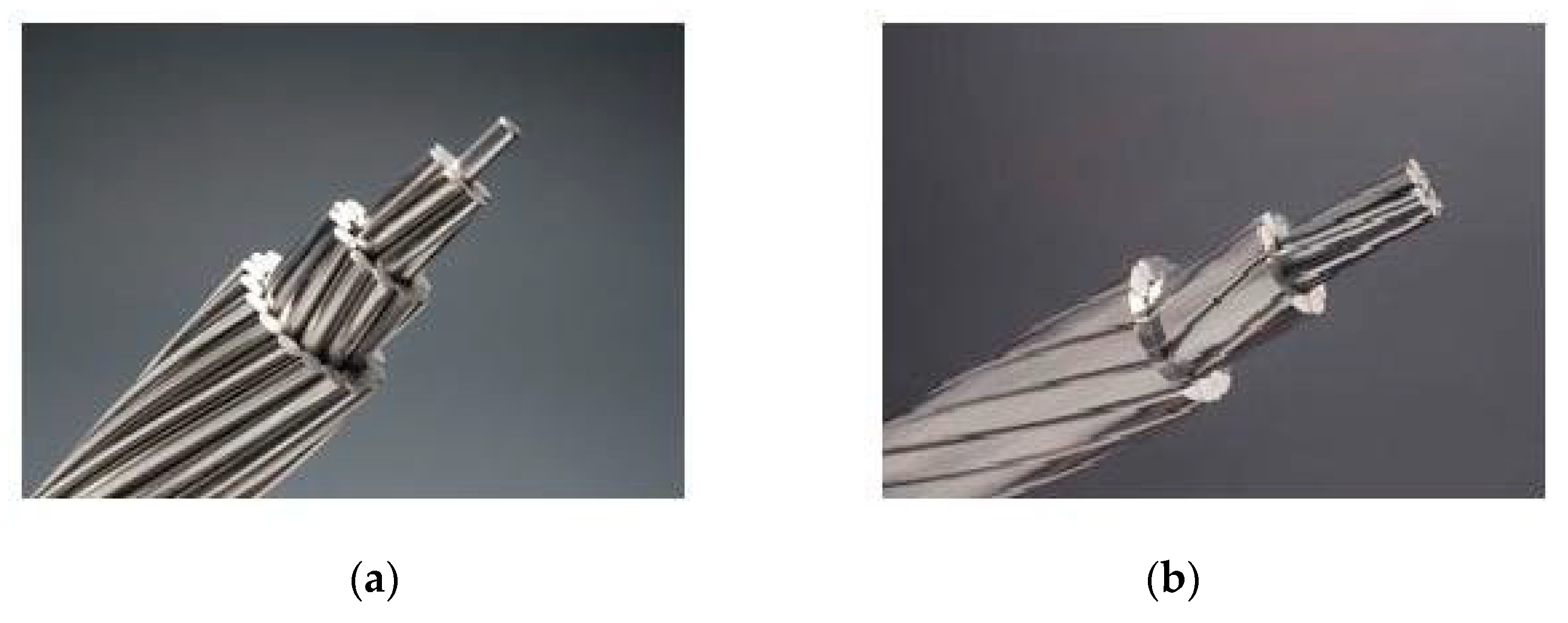

2. Stranded Conductor Geometric Variants

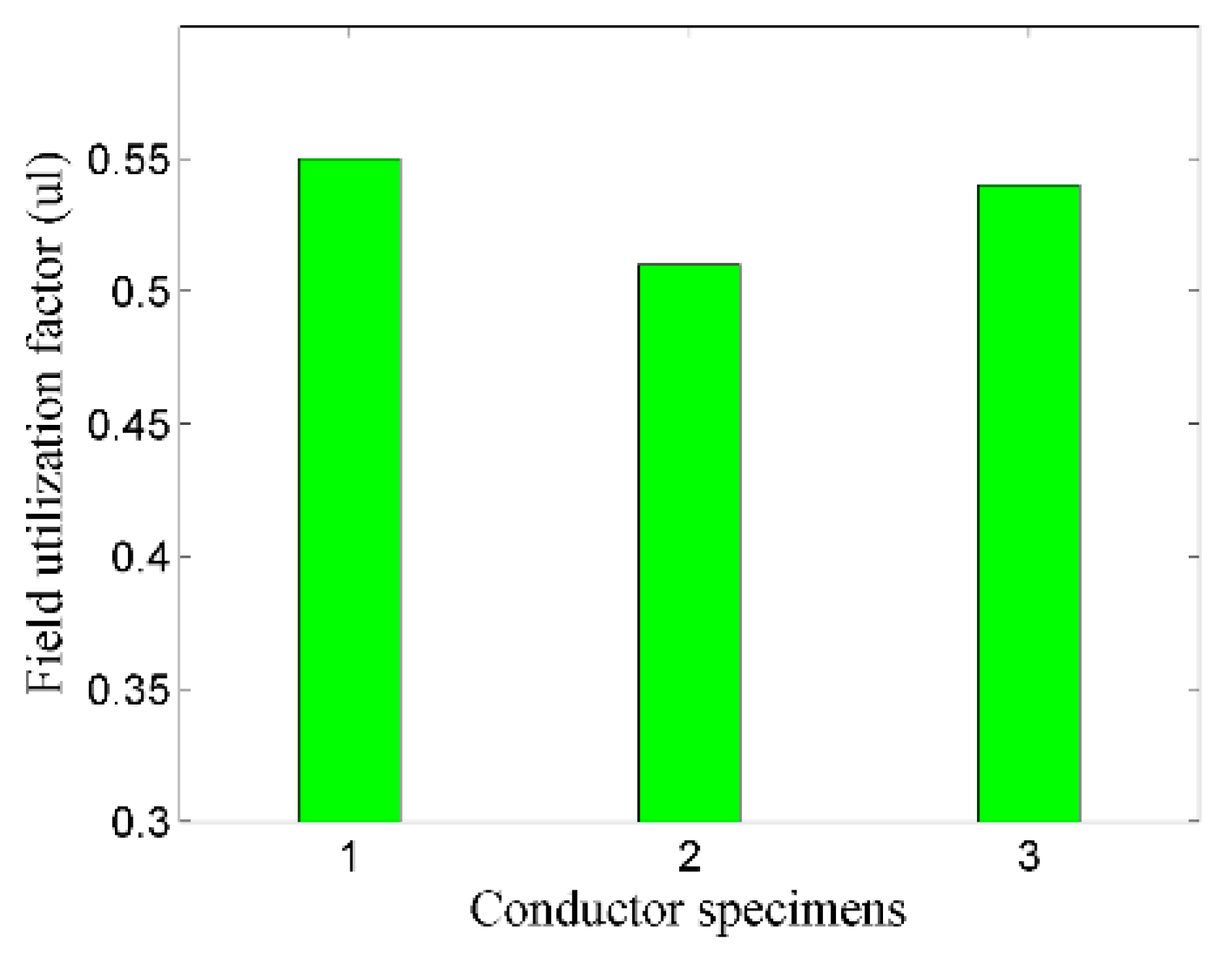

Electric Field Dispersal Regarding Strand Geometry

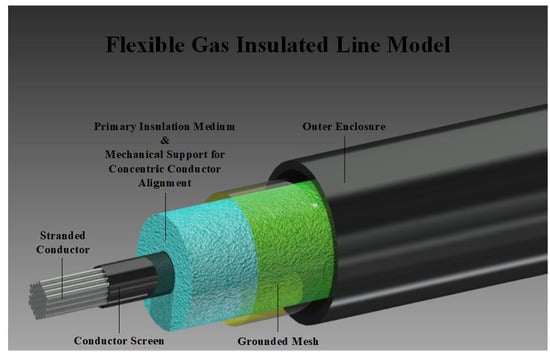

3. Design and Analysis

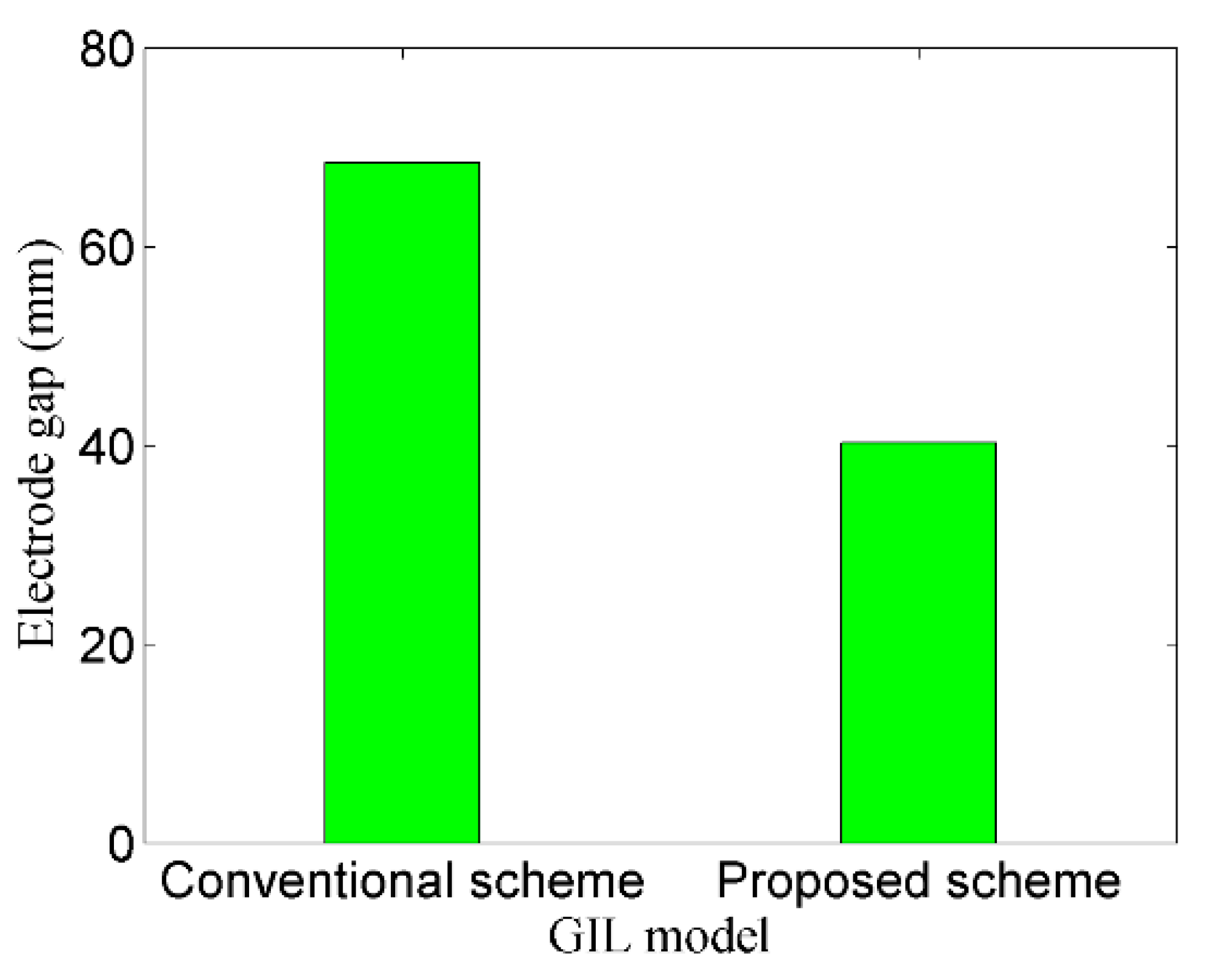

3.1. Dimensional Optimization of FGIL Enclosure Apropos of Stranded Conductor

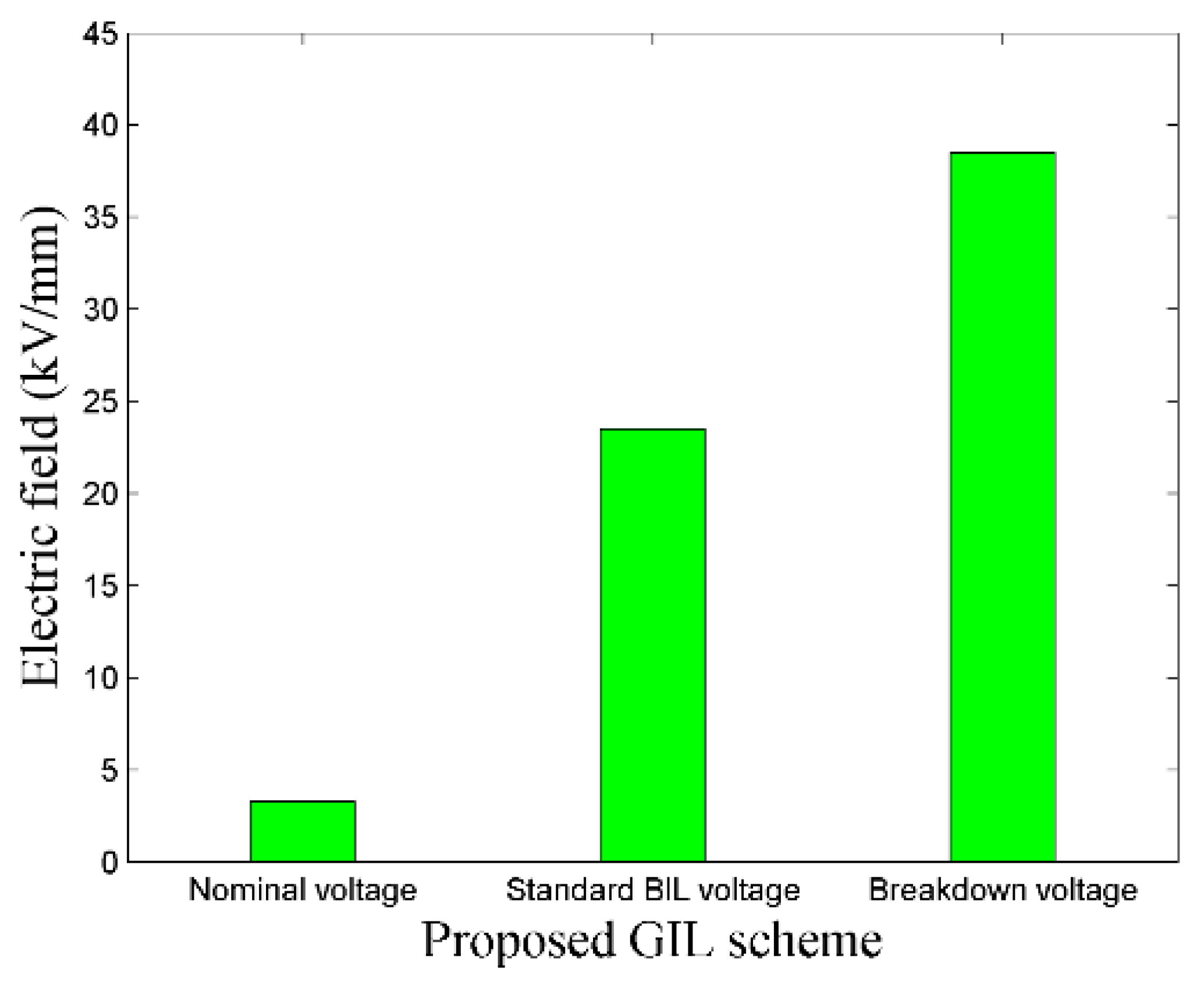

3.2. Electrostatic Field Optimization of the FGIL

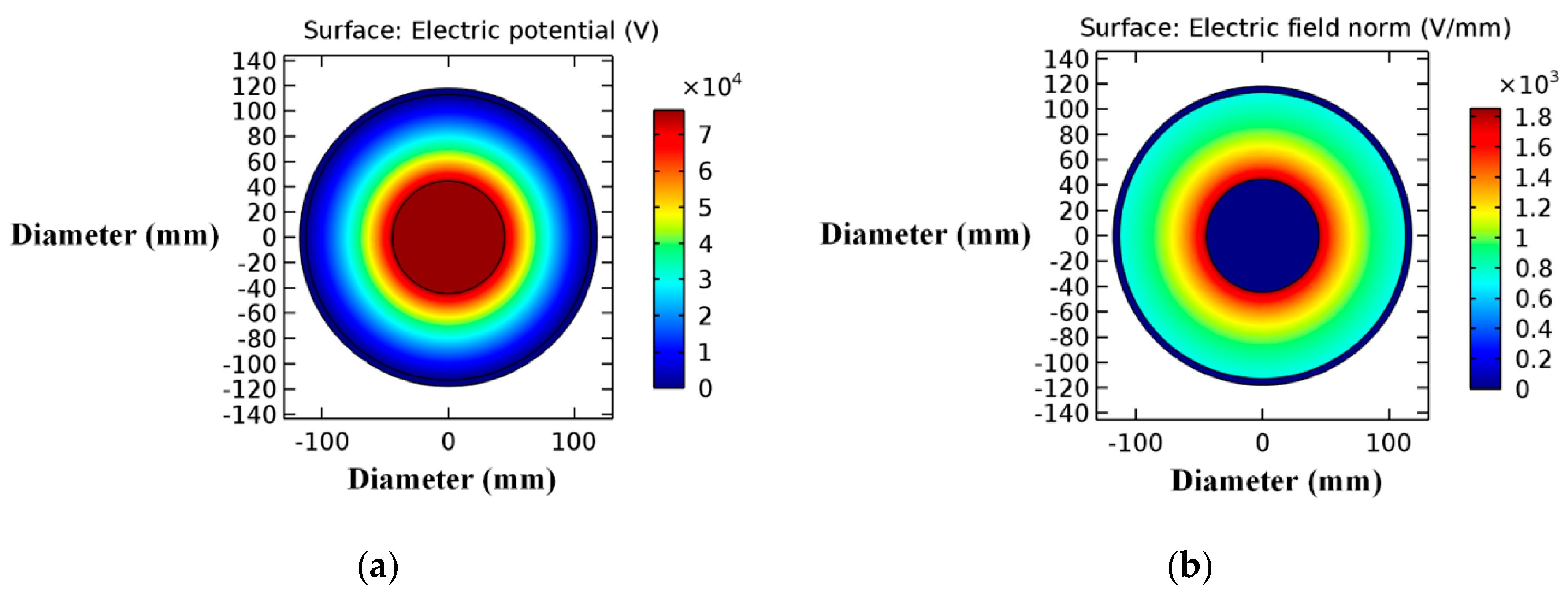

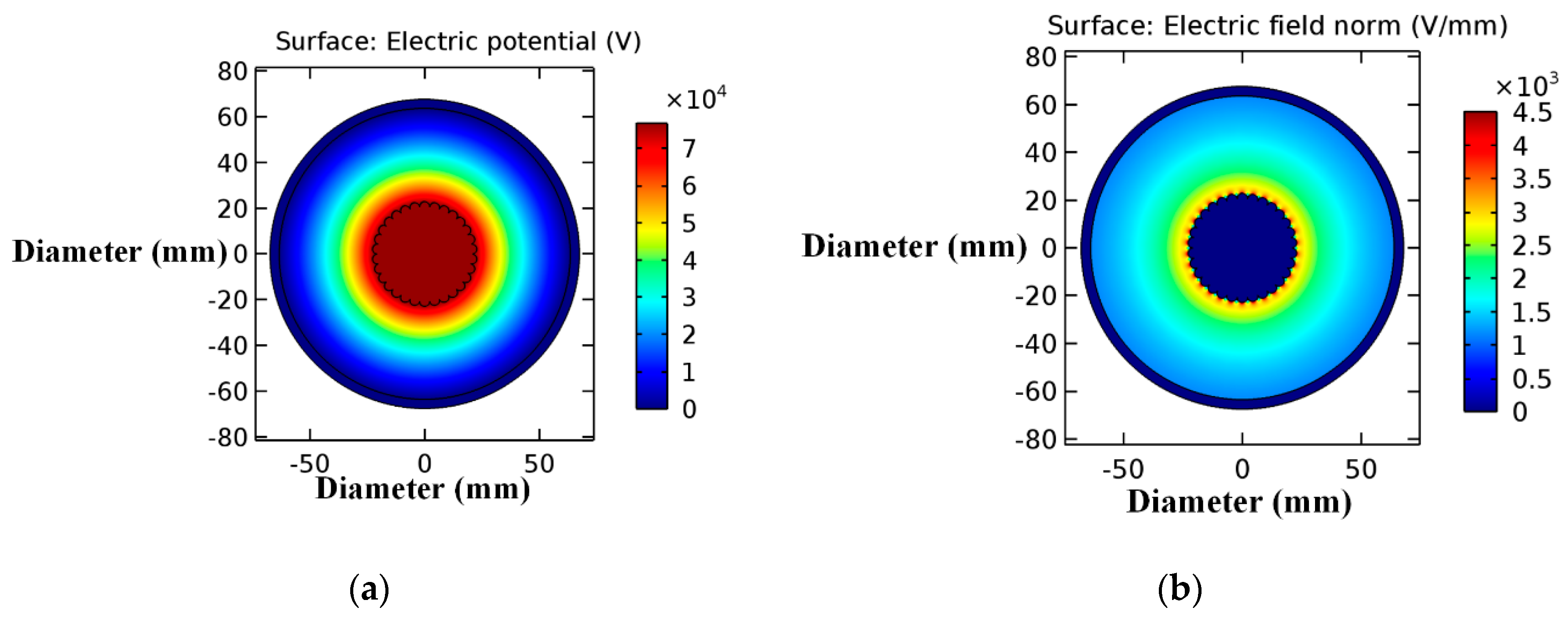

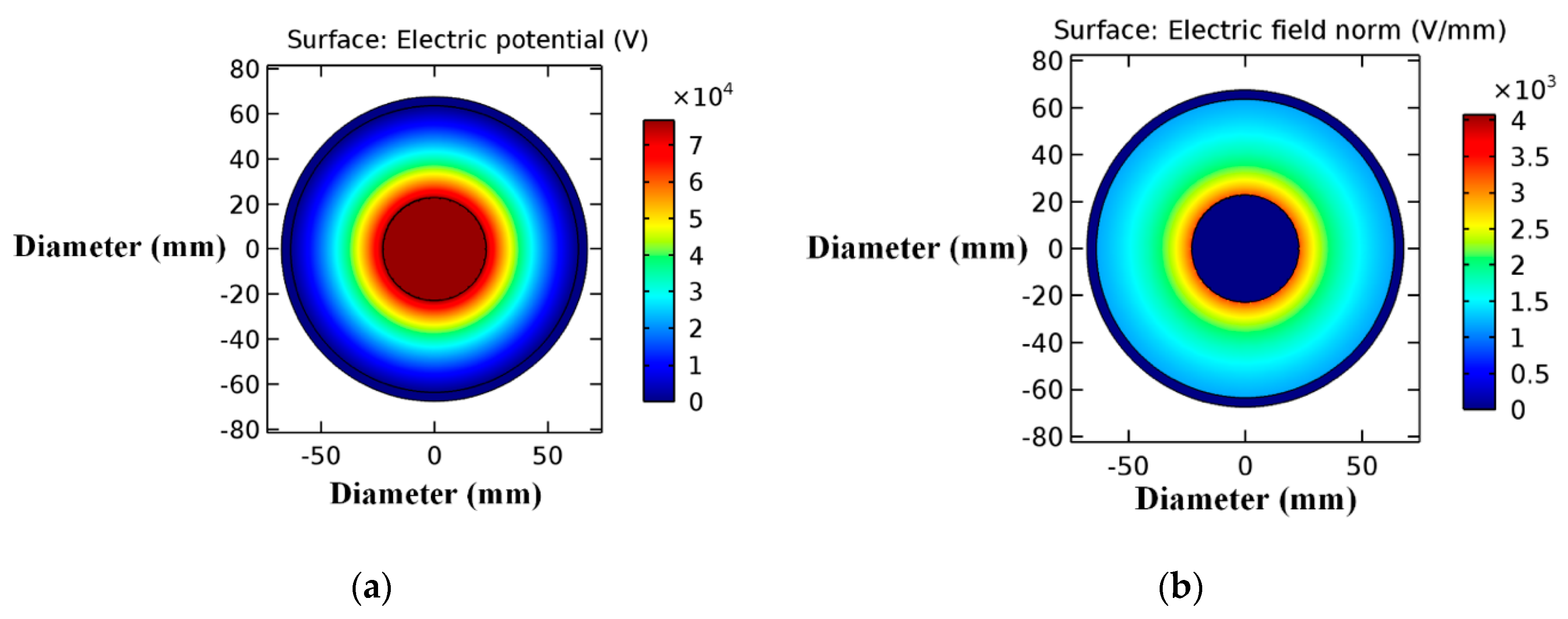

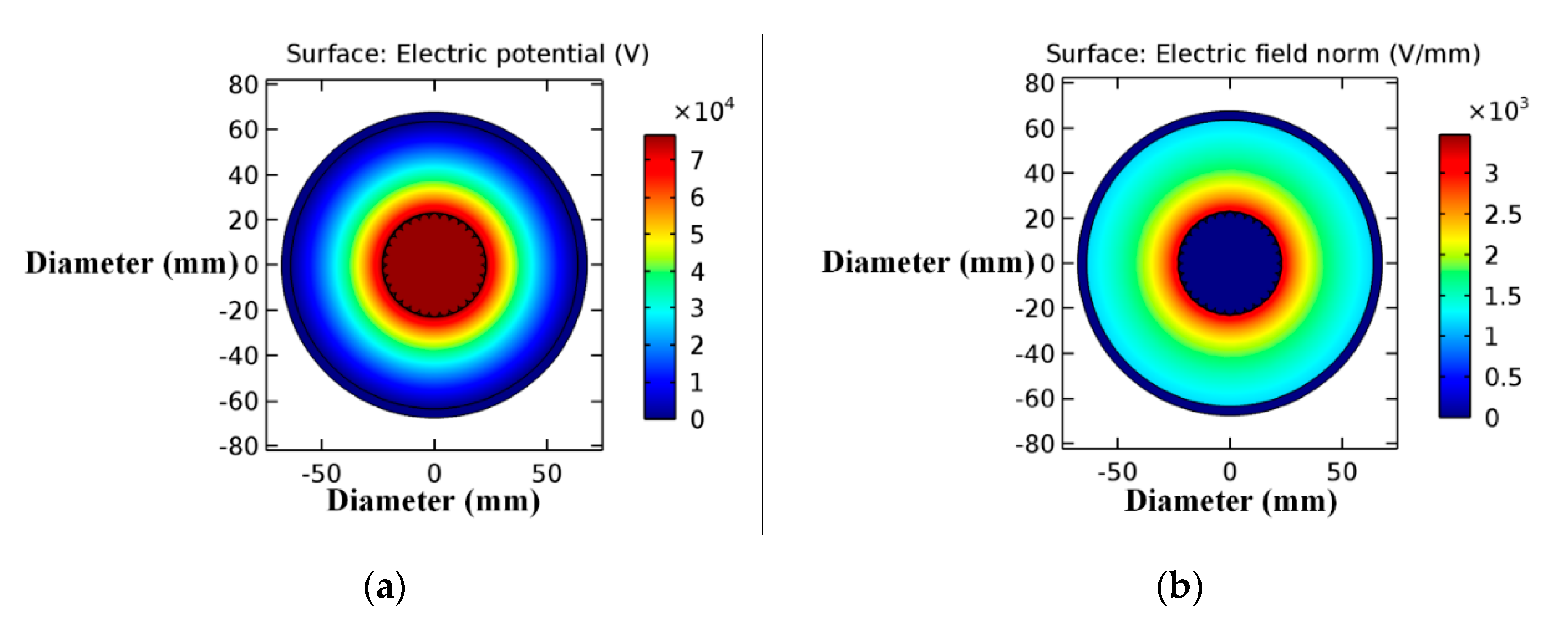

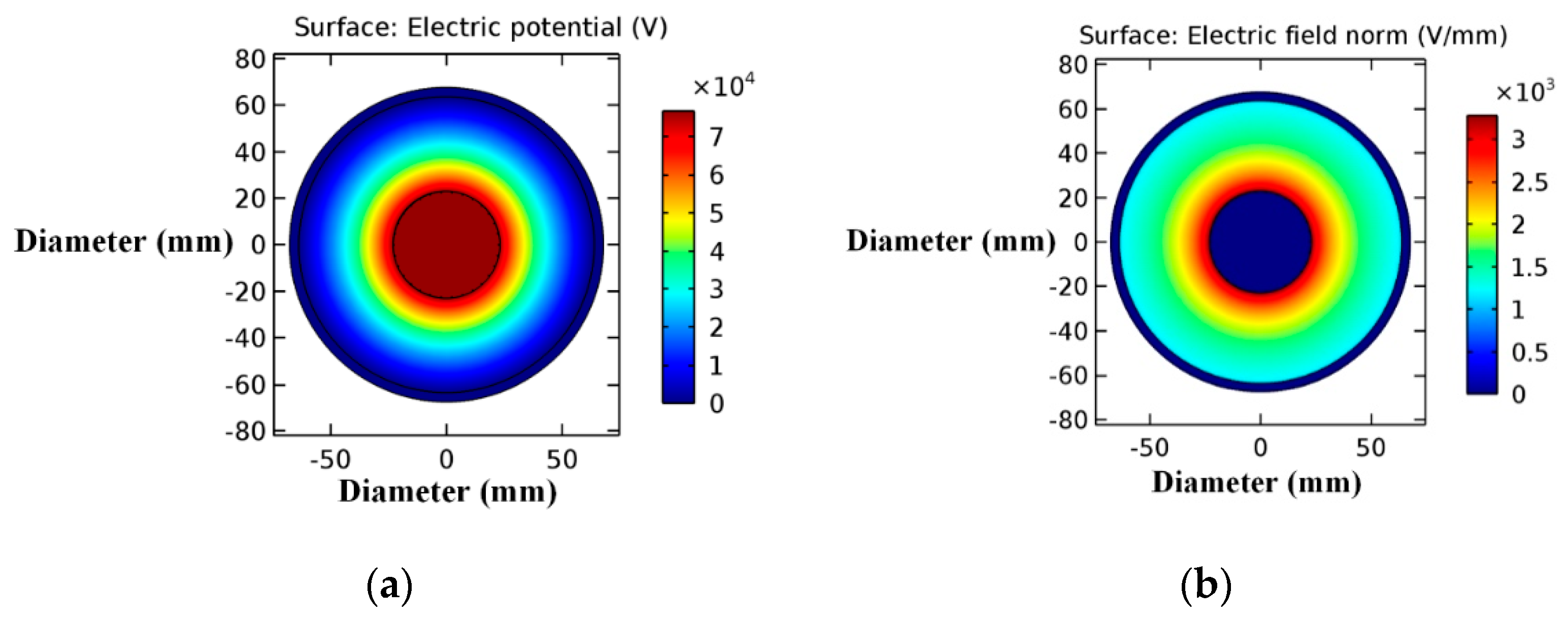

3.2.1. Electrostatic Field Dispersion Apropos of Conventional and Stranded Conductors

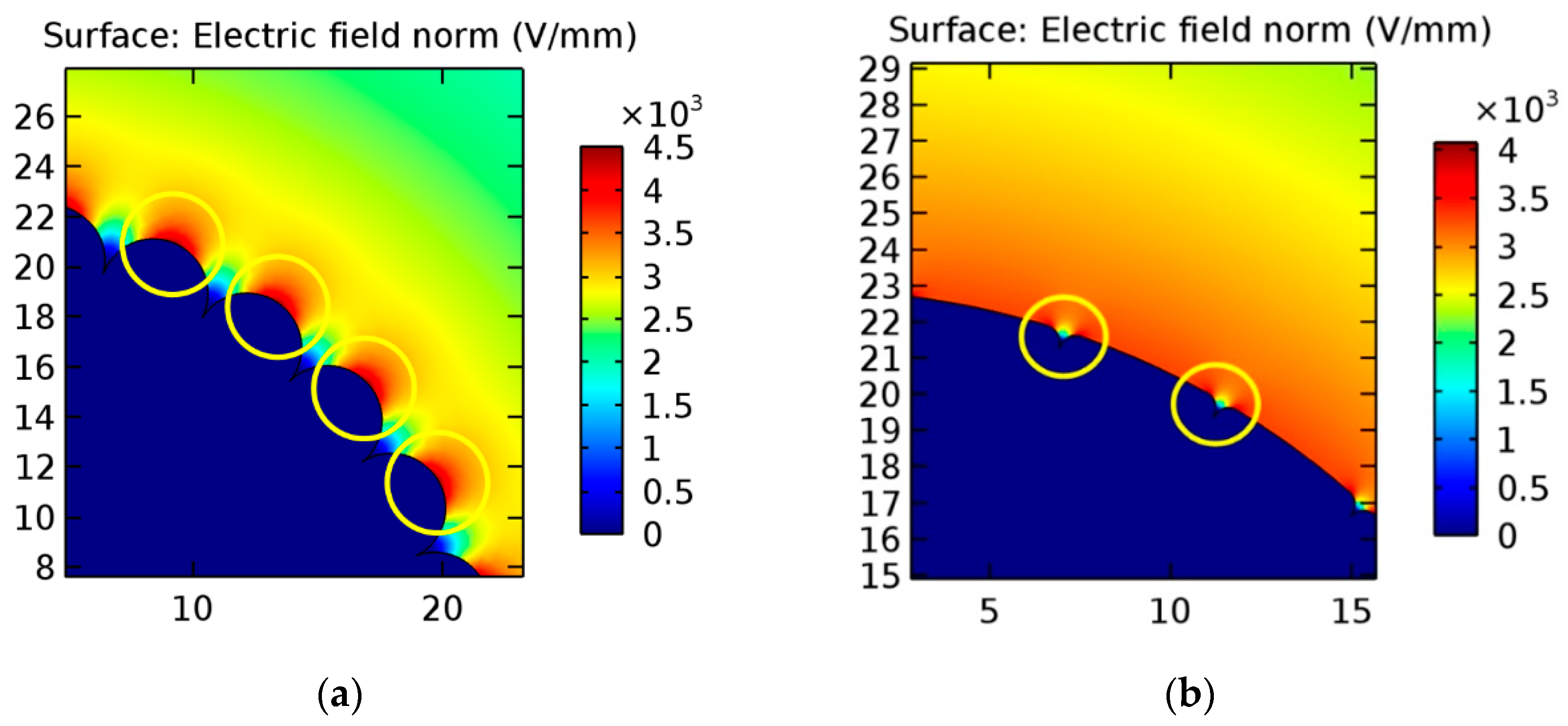

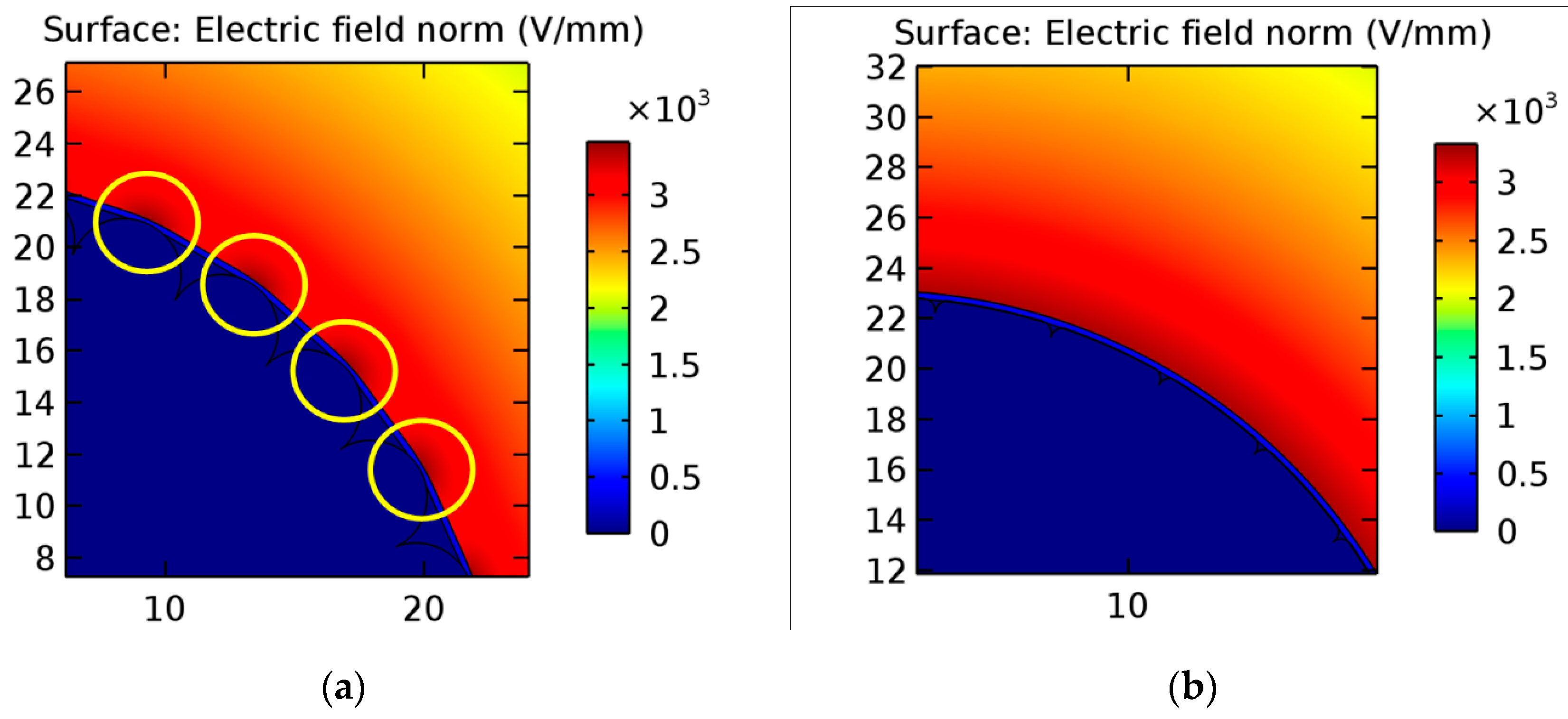

3.2.2. Contour Irregularity Suppression of Stranded Conductor

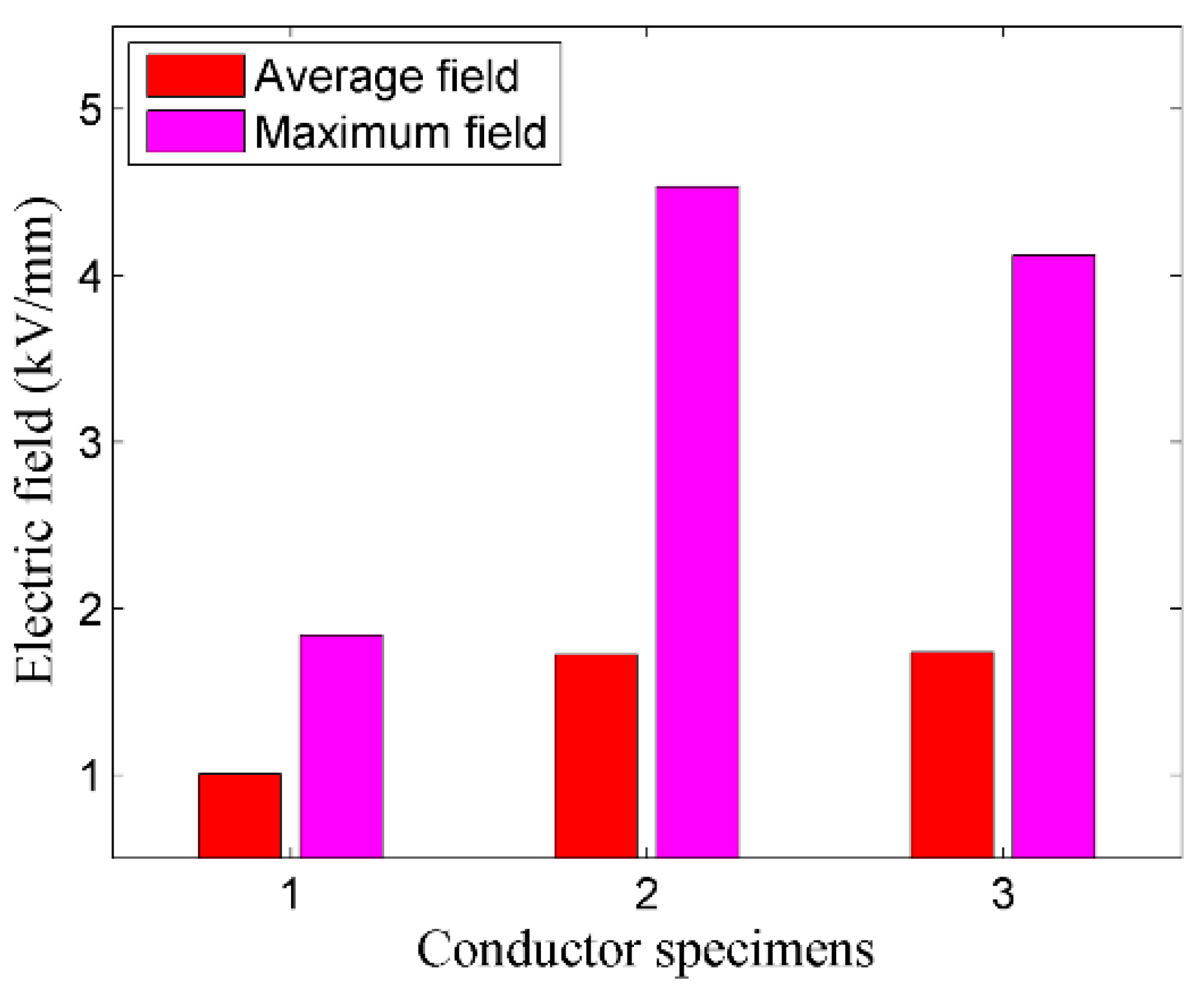

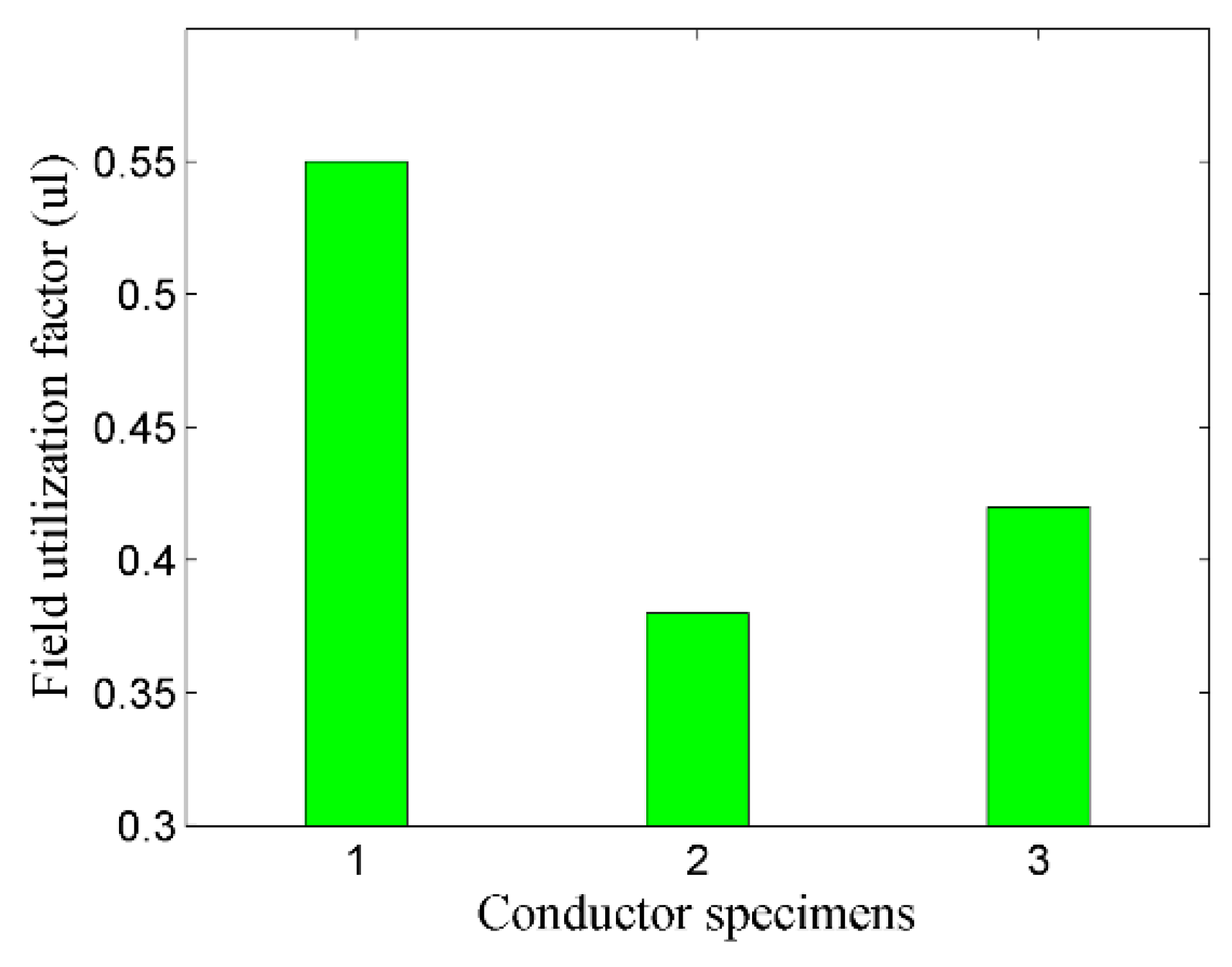

3.2.3. Electrostatic Field Dispersion Apropos of Film-Coated Stranded Conductors

3.3. Dielectric Appraisal of FGIL Apropos of the Stranded Conductor

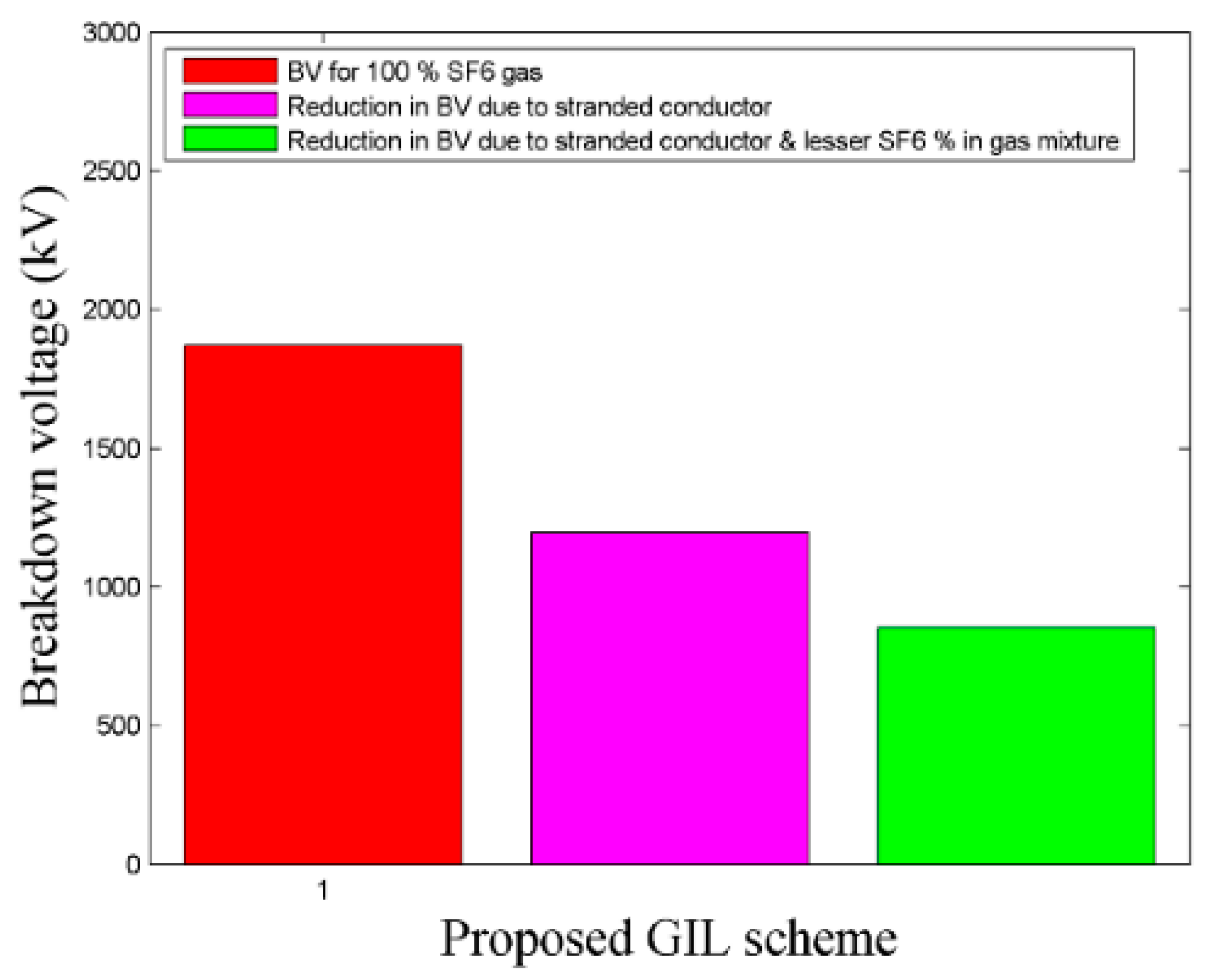

3.3.1. Breakdown Voltage of the Proposed Configuration Regarding Streamer Breakdown Theory

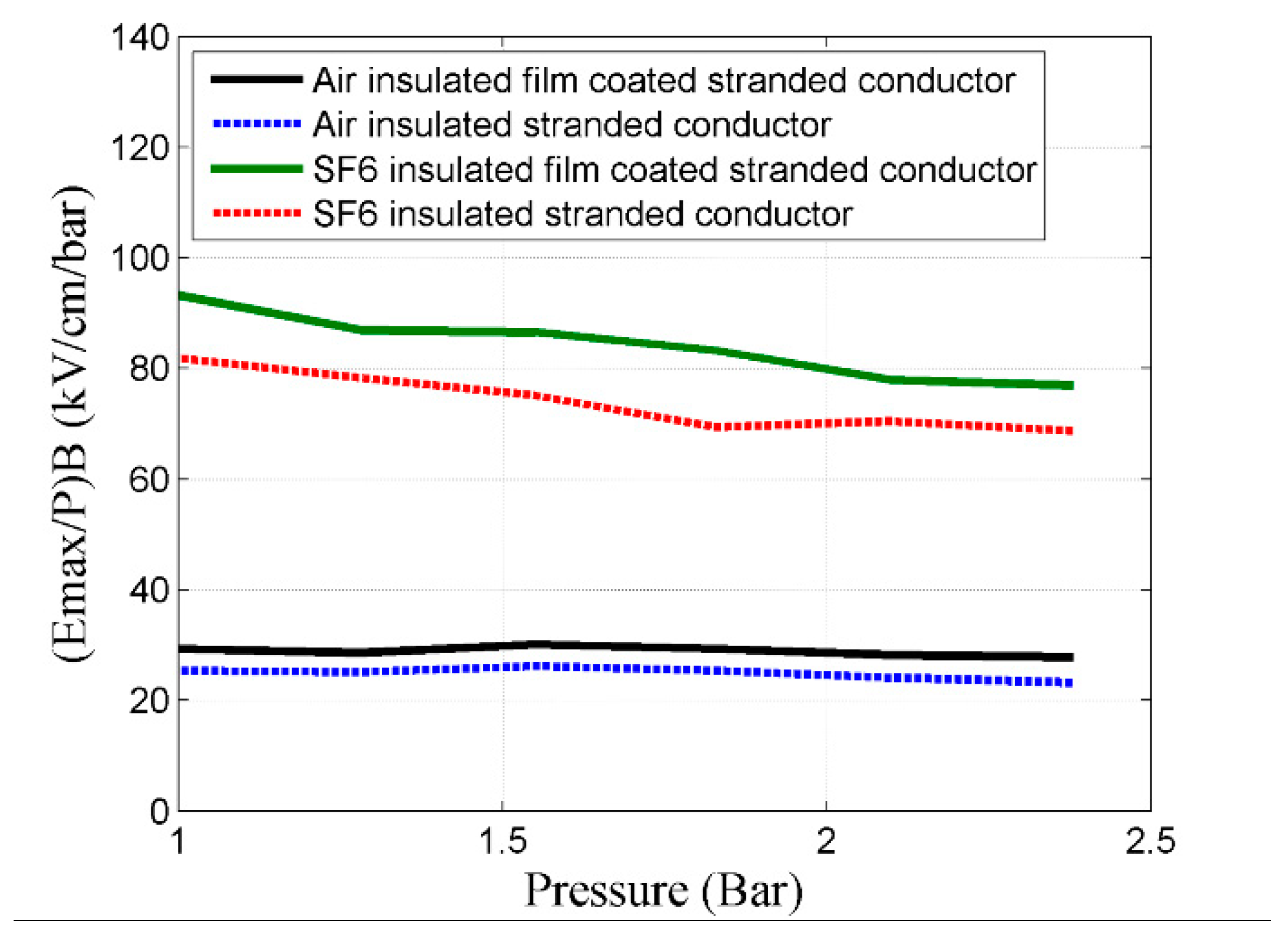

3.3.2. Breakdown Field Strength of the Proposed Configuration Regarding Critical Field Intensity Theory

3.4. Field Stress Distribution in Bended Segment of FGIL

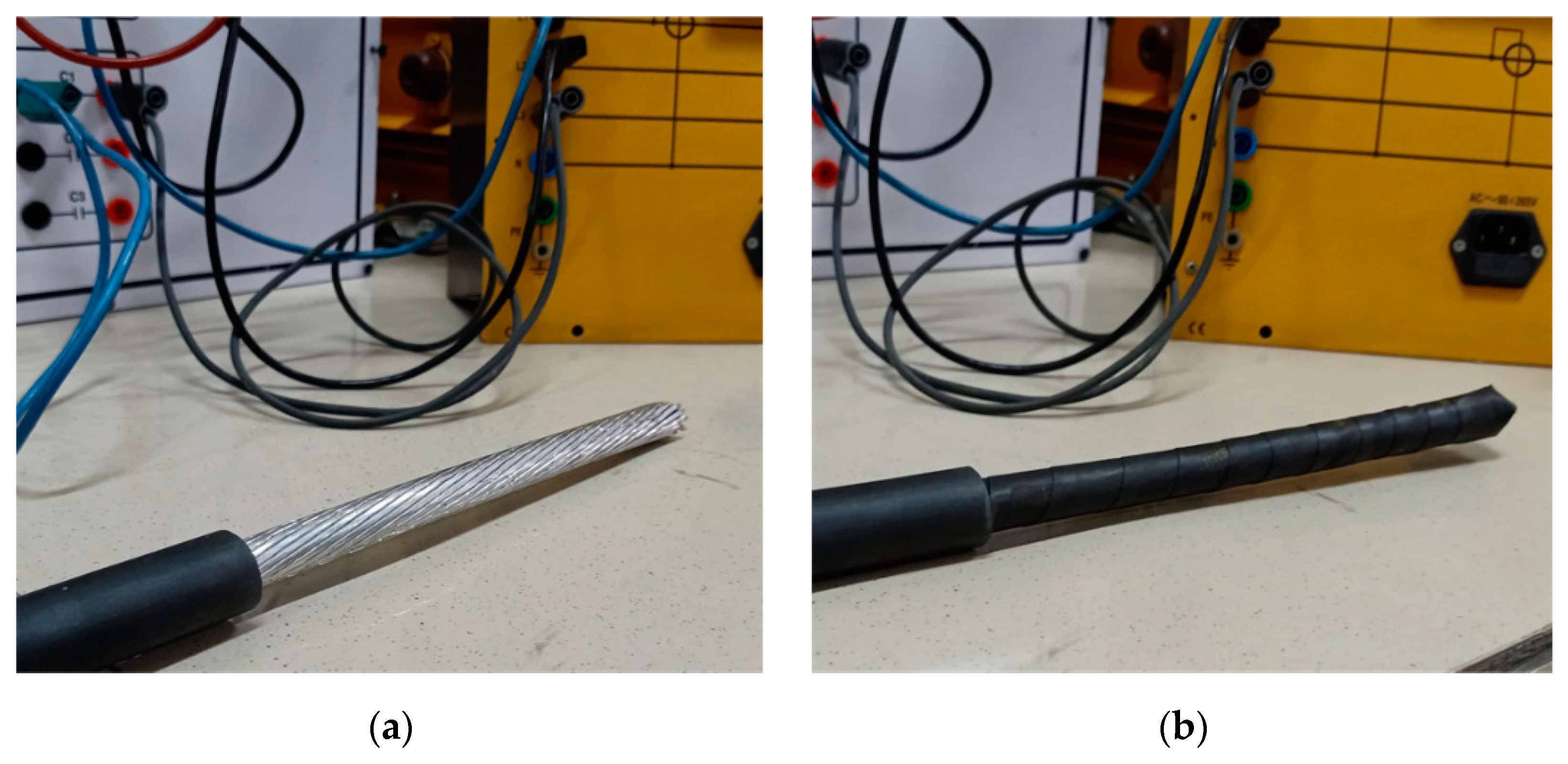

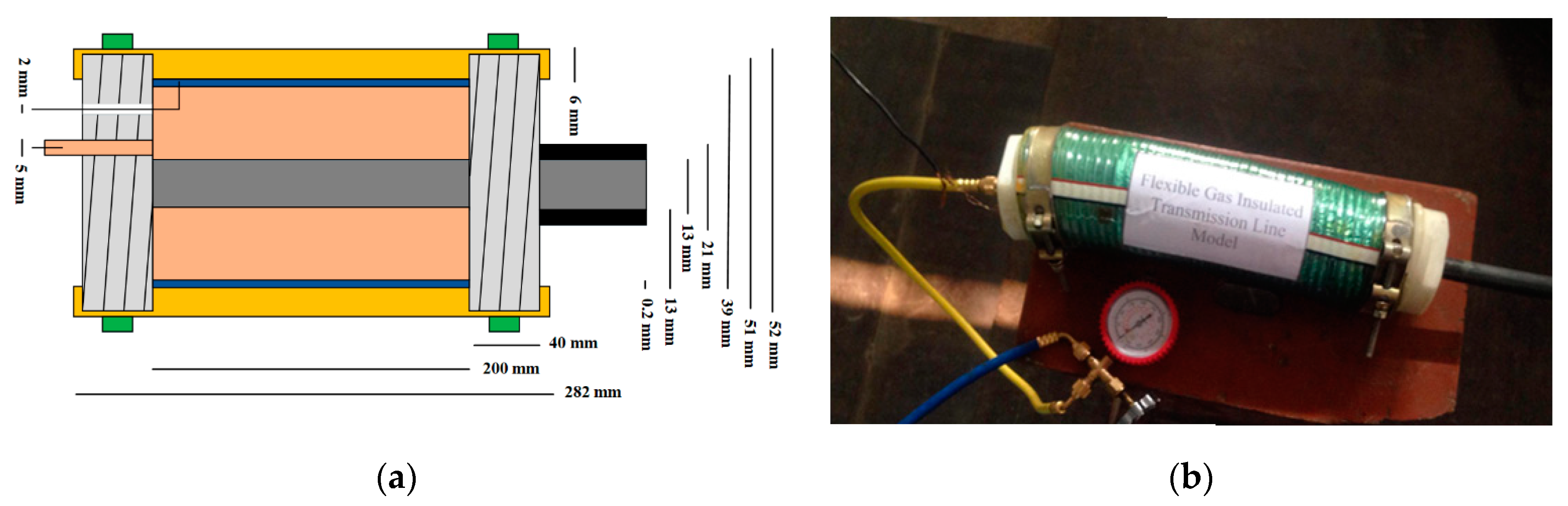

4. Fabrication of the Scaled FGIL Model

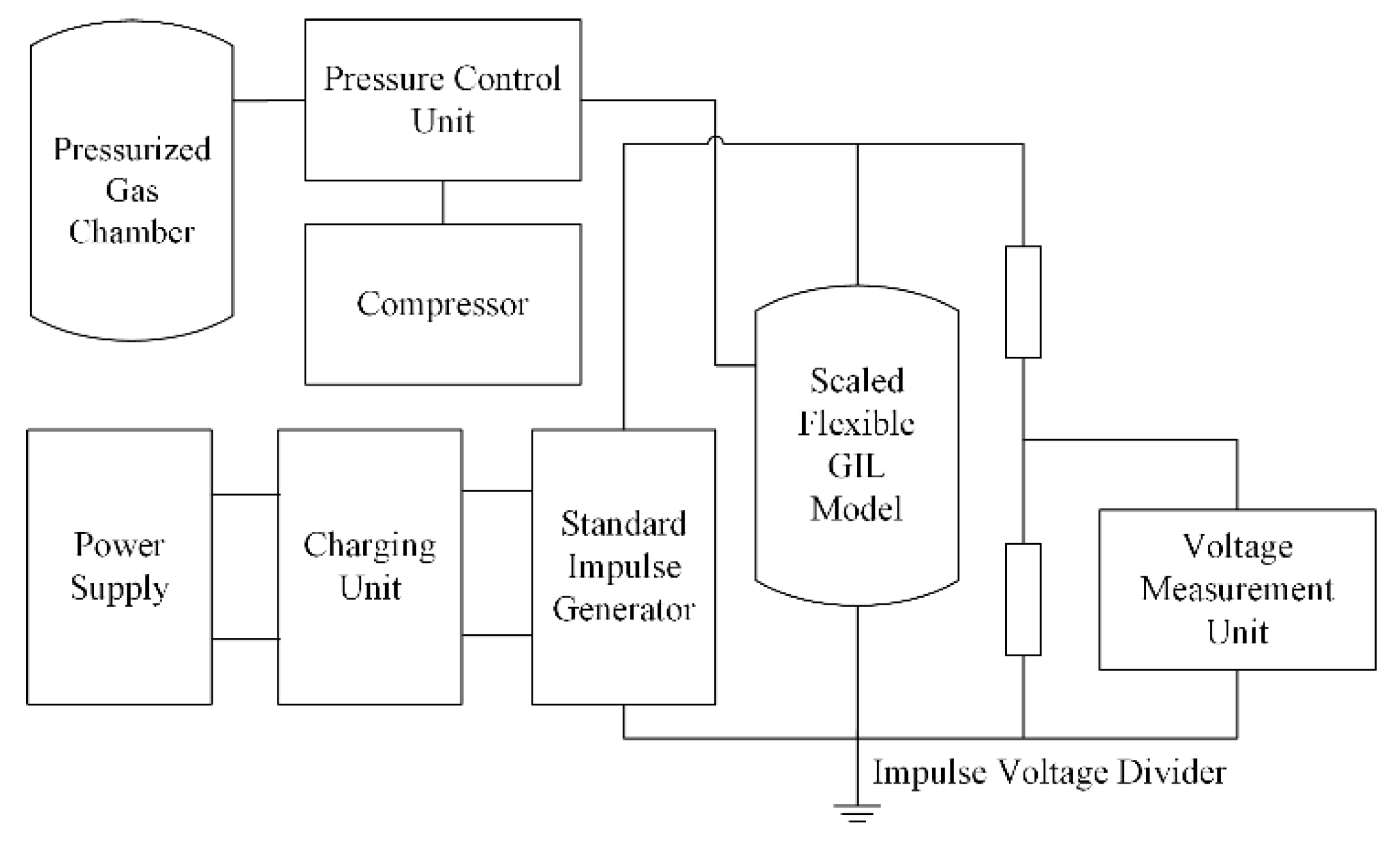

5. Experimental Setup Development

5.1. Dielectric Breakdown Analysis of the Fabricated FGIL Models

5.1.1. Power Frequency Discharge Test

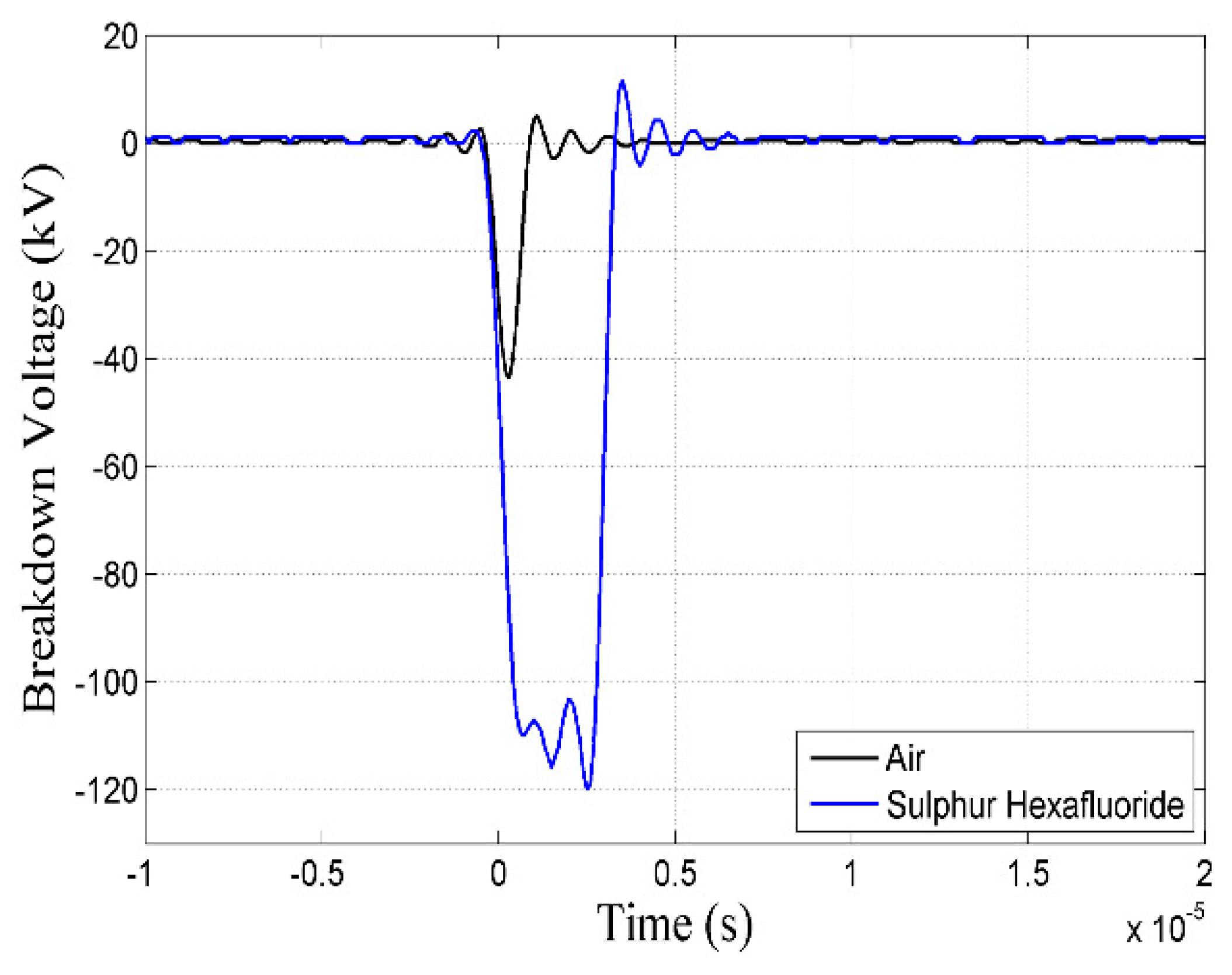

5.1.2. Lightning Impulse Discharge Test

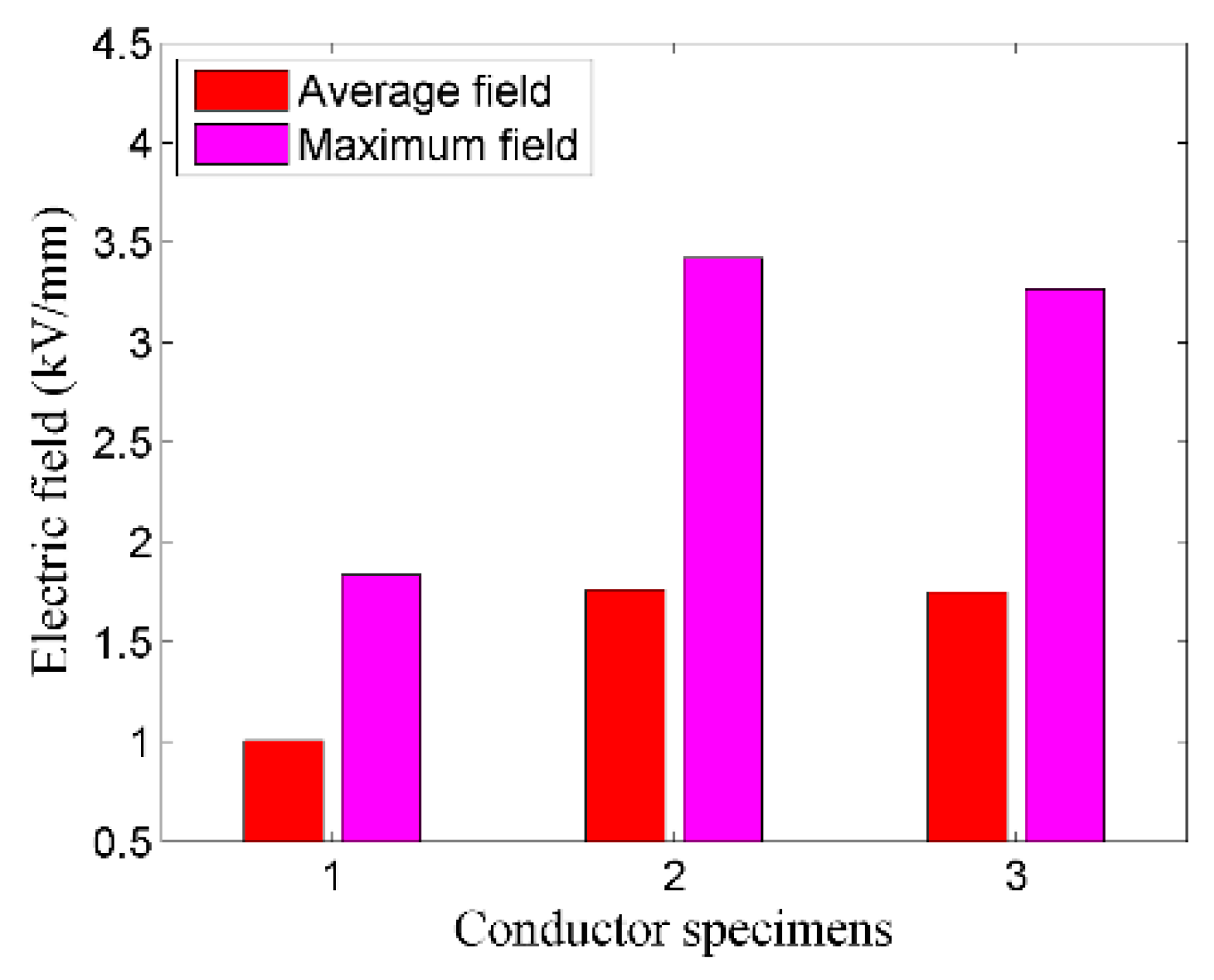

5.2. Critical Field and Breakdown Field Analysis of Fabricated FGIL Models

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mohammadi, F.; Zheng, C. Stability Analysis of Electric Power System. In Proceedings of the 4th National Conference on Technology in Electrical and Computer Engineering, Tehran, Iran, 19 February 2018. [Google Scholar]

- Adedeji, K.; Ponnle, A.; Abe, B.; Jimoh, A. Effect of increasing energy demand on the corrosion rate of buried pipelines in the vicinity of high voltage overhead transmission lines. In Proceedings of the 2015 Intl Aegean Conference on Electrical Machines & Power Electronics (ACEMP), 2015 Intl Conference on Optimization of Electrical & Electronic Equipment (OPTIM) & 2015 Intl Symposium on Advanced Electromechanical Motion Systems (ELECTROMOTION), Side, Turkey, 2–4 September 2015; pp. 299–303. [Google Scholar]

- Sardaro, R.; Bozzo, F.; Fucilli, V. High-voltage overhead transmission lines and farmland value: Evidences from the real estate market in Apulia, southern Italy. Energy Policy 2018, 119, 449–457. [Google Scholar] [CrossRef]

- Wiedemann, P.M.; Boerner, F.; Claus, F. How far is how far enough? Safety perception and acceptance of extra-high-voltage power lines in Germany. J. Risk Res. 2018, 21, 463–479. [Google Scholar] [CrossRef]

- Fan, F.; Wu, G.; Wang, M.; Cao, Q.; Yang, S. Robot Delay-Tolerant Sensor Network for Overhead Transmission Line Monitoring. Appl. Sci. 2018, 8, 847. [Google Scholar] [CrossRef]

- Gautam, B.R.; Li, F.; Ru, G. Assessment of urban roof top solar photovoltaic potential to solve power shortage problem in Nepal. Energy Build. 2015, 86, 735–744. [Google Scholar] [CrossRef]

- Hajeforosh, S.; Pooranian, Z.; Shabani, A.; Conti, M. Evaluating the high frequency behavior of the modified grounding scheme in wind farms. Appl. Sci. 2017, 7, 1323. [Google Scholar] [CrossRef]

- Mohammadi, F.; Zheng, C.; Su, R. Fault Diagnosis in Smart Grid Based on Data-Driven Computational Methods. In Proceedings of the 5th International Conference on Applied Research in Electrical, Mechanical, and Mechatronics Engineering, Tehran, Iran, 28 February 2019. [Google Scholar]

- Xu, K.; Zhang, X.; Chen, Z.; Wu, W.; Li, T. Risk assessment for wildfire occurrence in high-voltage power line corridors by using remote-sensing techniques: A case study in Hubei Province, China. Int. J. Remote Sens. 2016, 37, 4818–4837. [Google Scholar] [CrossRef]

- Benato, R.; Sessa, S.D.; Guizzo, L.; Rebolini, M. Saving environmental impact of electrical energy transmission by employing existing/planned transport corridors. In Proceedings of the 2017 IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Milan, Italy, 6–9 June 2017; pp. 1–6. [Google Scholar]

- Benato, R.; Sessa, S.D.; Guizzo, L.; Rebolini, M. Synergy of the future: High voltage insulated power cables and railway-highway structures. IET Gener. Transm. Distrib. 2017, 11, 2712–2720. [Google Scholar] [CrossRef]

- Lauria, D.; Quaia, S. Technical comparison between a gas-insulated line and a traditional three-bundled OHL for a 400 kV, 200 km connection. In Proceedings of the 2015 International Conference on Clean Electrical Power (ICCEP), Taormina, Italy, 16–18 June 2015; pp. 597–601. [Google Scholar]

- Kukharchuk, I.; Kazakov, A.; Trufanova, N. Investigation of heating of 150 kV underground cable line for various conditions of laying. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tomsk, Russia, 4–6 December 2017; p. 022041. [Google Scholar]

- Salata, F.; Nardecchia, F.; de Lieto Vollaro, A.; Gugliermetti, F. Underground electric cables a correct evaluation of the soil thermal resistance. Appl. Therm. Eng. 2015, 78, 268–277. [Google Scholar] [CrossRef]

- Magier, T.; Tenzer, M.; Koch, H. Direct Current Gas-Insulated Transmission Lines. IEEE Trans. Power Deliv. 2018, 33, 440–446. [Google Scholar] [CrossRef]

- Magier, T.; Dehler, A.; Koch, H. AC Compact High Power Gas-Insulated Transmission Lines. In Proceedings of the 2018 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), Denver, CO, USA, 16–19 April 2018; pp. 1–5. [Google Scholar]

- Koch, H.; Goll, F.; Magier, T.; Juhre, K. Technical aspects of gas insulated transmission lines and application of new insulating gases. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1448–1453. [Google Scholar] [CrossRef]

- Widger, P.; Haddad, A. Evaluation of SF6 leakage from gas insulated equipment on electricity networks in Great Britain. Energies 2018, 11, 2037. [Google Scholar] [CrossRef]

- Brinkley, C.; Leach, A. Energy next door: A meta-analysis of energy infrastructure impact on housing value. Energy Res. Soc. Sci. 2019, 50, 51–65. [Google Scholar] [CrossRef]

- Mueller, C.E.; Keil, S.I.; Bauer, C. Effects of spatial proximity to proposed high-voltage transmission lines: Evidence from a natural experiment in Lower Saxony. Energy Policy 2017, 111, 137–147. [Google Scholar] [CrossRef]

- Crespi, C.M.; Vergara, X.P.; Hooper, C.; Oksuzyan, S.; Wu, S.; Cockburn, M.; Kheifets, L. Childhood leukaemia and distance from power lines in California: A population-based case-control study. Br. J. Cancer 2016, 115, 122. [Google Scholar] [CrossRef] [PubMed]

- Shabangu, T.; Shrivastava, P.; Abe, B.; Adedeji, K.; Olubambi, P. Influence of AC interference on the cathodic protection potentials of pipelines: Towards a comprehensive picture. In Proceedings of the 2017 IEEE AFRICON, Cape Town, South Africa, 18–20 September 2017; pp. 597–602. [Google Scholar]

- Zarchi, D.A.; Vahidi, B. Optimal placement of underground cables to maximise total ampacity considering cable lifetime. IET Gener. Transm. Distrib. 2016, 10, 263–269. [Google Scholar] [CrossRef]

- Koch, H. Gas. Insulated Transmission Lines (GIL); John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- McDonald, J.D. Electric Power Substations Engineering; CRC press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Zhou, T. Study on Mechanical Properties of Transmission Pipe Materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Sanya, China, 10–11 November 2018; p. 012090. [Google Scholar]

- Tenzer, M.; Koch, H.; Imamovic, D. Underground transmission lines for high power AC and DC transmission. In Proceedings of the 2016 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), Dallas, TX, USA, 3–5 May 2016; pp. 1–4. [Google Scholar]

- Chakir, A.; Koch, H. Corrosion protection for gas-insulated transmission lines. In Proceedings of the IEEE Power Engineering Society Summer Meeting, Chicago, IL, USA, 21–25 July 2002; pp. 220–224. [Google Scholar]

- Chakir, A.; Koch, H. Seismic calculations of directly buried gas-insulated transmission lines (GIL). In Proceedings of the IEEE/PES Transmission and Distribution Conference and Exhibition, Yokohama, Japan, 6–10 October 2002; pp. 1026–1029. [Google Scholar]

- Imamovic, D.; Tenzer, M.; Koch, H.; Lutz, B. High power underground transmission lines. In Proceedings of the 9th International Conference on Insulated Power Cables, Paris, France, 21–25 June 2015. [Google Scholar]

- Alvi, M.J.; Izhar, T.; Qaiser, A.A.; Afzaal, M.U.; Anjum, A.; Safdar, A. Pliability Assay of Conventional Gas Insulated Transmission Line and Flexible Gas Insulated Transmission Line Regarding Horizontal Directional Drilling Based Underground Cable Laying for Metropolitan Areas. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–5. [Google Scholar]

- Liang, X.; Shen, Y.; Liu, Y.; Wang, J.; Gao, Y.; Li, S.; Wang, M.; Gao, S. Investigations on the basic electrical properties of Polyurethane foam material. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 863–866. [Google Scholar]

- Zhu, Y.; He, L.; Zhou, S.; Zhang, D.; Fang, J. Insulation performance of rigid polyurethane foam and its application in station post insulator. In Proceedings of the 2018 12th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Xi’an, China, 20–24 May 2018; pp. 970–973. [Google Scholar]

- Alvi, M.; Izhar, T.; Qaiser, A. Proposed scheme of pliable gas insulated transmission line and its comparative appraisal regarding electrostatic and dielectric aspects. Electronics 2018, 7, 328. [Google Scholar] [CrossRef]

- Guo, J.; Chen, H. Research on Horizontal Directional Drilling Locatingtechnology Based on Seismic Interference. In Proceedings of the 2019 Symposium on Piezoelectrcity, Acoustic Waves and Device Applications (SPAWDA), Harbin, China, 11–14 January 2019; pp. 1–4. [Google Scholar]

- Wang, Y.; Wen, G.; Chen, H. Horizontal directional drilling-length detection technology while drilling based on bi-electro-magnetic sensing. Sensors 2017, 17, 967. [Google Scholar] [CrossRef]

- Bascom, E.C.R.; Rezutko, J. Novel installation of a 138kv pipe-type cable system under water using horizontal directional drilling. In Proceedings of the 2014 IEEE PES T&D Conference and Exposition, Chicago, IL, USA, 14–17 April 2014; pp. 1–5. [Google Scholar]

- Paun, A.; Frigura-Iliasa, F.M.; Frigura-Iliasa, M.; Andea, P.; Vatau, D. A FEW ASPECTS CONCERNING THE INFLUENCE OF THE ELECTRODES ON THE SF^ sub 6^ INSULATION DIELECTRIC BEHAVIOR. Int. Multidiscip. Sci. Geoconf. Sgem Surv. Geol. Min. Ecol. Manag. 2018, 18, 9–16. [Google Scholar]

- Yang, X.; Zhao, X.; Hu, J.; He, J. Grading electric field in high voltage insulation using composite materials. IEEE Electr. Insul. Mag. 2018, 34, 15–25. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, X.; Li, Q.; Hu, J.; He, J. Nonlinear effective permittivity of field grading composite dielectrics. J. Phys. D Appl. Phys. 2018, 51, 075304. [Google Scholar] [CrossRef]

- Chen, L.; Griffiths, H.; Haddad, A.; Kamarudin, M. Breakdown of cf 3 i gas and its mixtures under lightning impulse in coaxial-GIL geometry. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1959–1967. [Google Scholar] [CrossRef]

- Chen, L.; Widger, P.; Kamarudin, M.S.; Griffiths, H.; Haddad, A. CF3I gas mixtures: Breakdown characteristics and potential for electrical insulation. IEEE Trans. Power Deliv. 2016, 32, 1089–1097. [Google Scholar] [CrossRef]

- Gao, C.; Yu, Y.; Wang, Z.; Wang, W.; Zheng, L.; Du, J. Study on the Relationship between Electrical Tree Development and Partial Discharge of XLPE Cables. J. Nanomater. 2019, 2019. [Google Scholar] [CrossRef]

- Illias, H.A.; Tunio, M.A.; Bakar, A.H.A.; Mokhlis, H.; Chen, G. Partial discharge phenomena within an artificial void in cable insulation geometry: Experimental validation and simulation. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 451–459. [Google Scholar] [CrossRef]

- Refaat, S.S.; Shams, M.A. A review of partial discharge detection, diagnosis techniques in high voltage power cables. In Proceedings of the 2018 IEEE 12th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG 2018), Qatar, Doha, 10–12 April 2018; pp. 1–5. [Google Scholar]

- Danikas, M.; Papadopoulos, D.; Morsalin, S. Propagation of Electrical Trees under the Influence of Mechanical Stresses: A Short Review. Eng. Technol. Appl. Sci. Res. 2019, 9, 3750–3756. [Google Scholar]

- Goetz, T.; Linde, T.; Simka, P.; Speck, J.; Backhaus, K.; Gabler, T.; Riechert, U.; Grossmann, S. Surface discharges on dielectric coated electrodes in gas-insulated systems under DC voltage stress. In Proceedings of the VDE High Voltage Technology 2018, ETG-Symposium, Berlin, Germany, 12–14 November 2018; pp. 1–6. [Google Scholar]

- Romero, A.; Rácz, L.; Mátrai, A.; Bokor, T.; Cselkó, R. A review of sulfur-hexafluoride reduction by dielectric coatings and alternative gases. In Proceedings of the 2017 6th International Youth Conference on Energy (IYCE), Budapest, Hungary, 21–24 June 2017; pp. 1–5. [Google Scholar]

- Wang, R.; Cui, C.; Zhang, C.; Ren, C.; Chen, G.; Shao, T. Deposition of SiO x film on electrode surface by DBD to improve the lift-off voltage of metal particles. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1285–1292. [Google Scholar] [CrossRef]

- Kumar, G.A.; Ram, S.T. Investigation of Dielectric Coating on Particle Movement in Single Phase Gas Insulated Bus Duct Under Sf 6/Co 2 Gas Mixture. In Proceedings of the 2018 International Conference on Emerging Trends and Innovations In Engineering And Technological Research (ICETIETR), Arakkunnam, Kerala, 11–13 July 2018; pp. 1–6. [Google Scholar]

- Sun, Z.; Fan, W.; Liu, Z.; Bai, Y.; Geng, Y.; Wang, J. Improvement of dielectric performance of solid/gas composite insulation with YSZ/ZTA coatings. Sci. Rep. 2019, 9, 3888. [Google Scholar] [CrossRef] [PubMed]

- Van Der Born, D.; Morshuis, P.; Smit, J.; Girodet, A. The influence of thin dielectric coatings on LI and AC breakdown strength in SF6 and dry air. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 287–290. [Google Scholar]

- Hama, H.; Okabe, S. Factors dominating dielectric performance of real-size gas insulated system and their measures by dielectric coatings in SF 6 and potential gases. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1737–1748. [Google Scholar] [CrossRef]

- Krivda, A.; Straumann, U.; Martinon, M.; Logakis, E.; Tsang, F.; Narendran, M. Electrical and chemical characterization of thin epoxy layers for high voltage applications. In Proceedings of the 2014 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Des Moines, IA, USA, 19–22 October 2014; pp. 816–819. [Google Scholar]

- Arnold, P.; Hering, M.; Tenbohlen, S.; Köhler, W.; Riechert, U.; Straumann, U. Discharge phenomena at partially damaged dielectric electrode coatings in SF6-insulated systems at AC and DC stress. In Proceedings of the 20th Internaional Conference on Gas Discharges and Their Application, Orléans, France, 6–11 July 2014. [Google Scholar]

- Gremaud, R.; Doiron, C.; Baur, M.; Simka, P.; Teppati, V.; Hering, M.; Speck, J.; Grossmann, S.; Källstrand, B.; Johansson, K. Solid-gas insulation in HVDC gas-insulated system: Measurement modeling and experimental validation for reliable operation. In Proceedings of the Cigré Session 46, Paris, France, 21–26 August 2016; p. D1_101. [Google Scholar]

- Conductor Strand Types. Available online: www.anixter.com (accessed on 1 April 2019).

- Malik, N.H.; Al-Arainy, A.; Qureshi, M.I. Electrical Insulation in Power Systems; Marcel Dekker: New York, NY, USA, 1998. [Google Scholar]

- Koch, H.J. Super Session ‘Vision 2020’IEEE General Meeting 2008 Application of long high capacity gas insulated lines in structures. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting-Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2018; pp. 1–5. [Google Scholar]

- Benato, R.; Di Mario, C.; Koch, H. High-capability applications of long gas-insulated lines in structures. IEEE Trans. Power Deliv. 2007, 22, 619–626. [Google Scholar] [CrossRef]

- Kopsidas, K.; Rowland, S.M.; Boumecid, B. A holistic method for conductor ampacity and sag computation on an OHL structure. IEEE Trans. Power Deliv. 2012, 27, 1047–1054. [Google Scholar] [CrossRef]

- Alawar, A.; Bosze, E.J.; Nutt, S.R. A composite core conductor for low sag at high temperatures. IEEE Trans. Power Deliv. 2005, 20, 2193–2199. [Google Scholar] [CrossRef]

- Christen, T.; Donzel, L.; Greuter, F. Nonlinear resistive electric field grading part 1: Theory and simulation. IEEE Electr. Insul. Mag. 2010, 26, 47–59. [Google Scholar] [CrossRef]

- Donzel, L.; Greuter, F.; Christen, T. Nonlinear resistive electric field grading Part 2: Materials and applications. IEEE Electr. Insul. Mag. 2011, 27, 18–29. [Google Scholar] [CrossRef]

- Gao, L.; Yang, X.; Hu, J.; He, J. ZnO microvaristors doped polymer composites with electrical field dependent nonlinear conductive and dielectric characteristics. Mater. Lett. 2016, 171, 1–4. [Google Scholar] [CrossRef]

- Boucher, S.; Chambard, R.; Hassanzadeh, M.; Castellon, J.; Metz, R. Study of the influence of nonlinear parameters on the efficiency of a resistive field grading tube for cable termination. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2413–2420. [Google Scholar] [CrossRef]

- Pradhan, M.; Greijer, H.; Eriksson, G.; Unge, M. Functional behaviors of electric field grading composite materials. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 768–778. [Google Scholar] [CrossRef]

- Power Cables. Available online: www.zmscable.com (accessed on 1 April 2019).

- Li, X.; Zhao, H.; Jia, S.; Murphy, A.B. Study of the dielectric breakdown properties of hot SF6–CF4 mixtures at 0.01–1.6 MPa. J. Appl. Phys. 2013, 114, 053302. [Google Scholar] [CrossRef]

- IEC Standard, I. 60060-1: High Voltage Test Techniques—Part 1: General Definitions and Test Requirements; International Electrotechnical Commission: Geneva, Switzerland, September 2010. [Google Scholar]

| Sr. No. | Conductor Type | Strand Geometry |

|---|---|---|

| 1. | Concentric strand | Circular |

| 2. | Compact strand | Circular |

| 3. | Compact strand | Trapezoidal |

| Specimen No. | Category | Material | Structure | Strand Geometry | Profile | Diameter (mm) |

|---|---|---|---|---|---|---|

| 1. | Conventional | Aluminum | Hollow | Smooth | 89 | |

| 2. | Proposed | Aluminum | Stranded | Circular | Irregular | 44.79 |

| 3. | Proposed | Aluminum | Stranded | Trapezoidal | Irregular | 44.70 |

| Specimen No. | Category | Material | Structure | Strand Geometry | Diameter (mm) | Film Material | Film Thickness (mm) |

|---|---|---|---|---|---|---|---|

| 1. | Conventional | Aluminum | Hollow | 89 | |||

| 2. | Proposed | Aluminum | Stranded | Circular | 44.79 | SiC-impregnated polyester tape | 0.2 |

| 3. | Proposed | Aluminum | Stranded | Trapezoidal | 44.70 | SiC-impregnated polyester tape | 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alvi, M.J.; Izhar, T.; Qaiser, A.A.; Kharal, H.S.; Safdar, A. Field Optimization and Electrostatic Stress Reduction of Proposed Conductor Scheme for Pliable Gas-Insulated Transmission Lines. Appl. Sci. 2019, 9, 2988. https://doi.org/10.3390/app9152988

Alvi MJ, Izhar T, Qaiser AA, Kharal HS, Safdar A. Field Optimization and Electrostatic Stress Reduction of Proposed Conductor Scheme for Pliable Gas-Insulated Transmission Lines. Applied Sciences. 2019; 9(15):2988. https://doi.org/10.3390/app9152988

Chicago/Turabian StyleAlvi, Muhammad Junaid, Tahir Izhar, Asif Ali Qaiser, Hafiz Shafqat Kharal, and Adnan Safdar. 2019. "Field Optimization and Electrostatic Stress Reduction of Proposed Conductor Scheme for Pliable Gas-Insulated Transmission Lines" Applied Sciences 9, no. 15: 2988. https://doi.org/10.3390/app9152988

APA StyleAlvi, M. J., Izhar, T., Qaiser, A. A., Kharal, H. S., & Safdar, A. (2019). Field Optimization and Electrostatic Stress Reduction of Proposed Conductor Scheme for Pliable Gas-Insulated Transmission Lines. Applied Sciences, 9(15), 2988. https://doi.org/10.3390/app9152988